Christie HD14K-J, HD16K-J, HD20K-J, WU20K-J User Manual

J Series

2.0, 2.4, and 3.0kW

User Manual

020-100707-01

J Series

2.0, 2.4, and 3.0kW

User Manual

020-100707-01

NOTICES

COPYRIGHT AND TRADEMARKS

© 2011 Christie Digital Systems USA, Inc. - All rights reserved.

All brand names and product names are trademarks, registered trademarks or trade names of their respective holders.

REGULATORY

The product has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference when the product is operated in a commercial environment. The

product generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of the product in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at the users own expense.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

㧊 ₆₆⓪ 㠛ⶊ㣿 (A ) 㦒⪲ 㩚㧦䕢㩗䞿❇⪳㦚 䞲 ₆₆㧊㡺┞ 䕦ⰺ㧦 ⡦⓪ ㌂㣿㧦⓪ 㧊㩦㦚 㭒㦮䞮㔲₆ ⧒Ⳇ , Ṗ㩫 㣎㦮 㰖㡃㠦㍲ ㌂㣿䞮⓪ ộ㦚

⳿㩗㦒⪲ 䞿┞┺ .

GENERAL

Every effort has been made to ensure accuracy, however in some cases changes in the products or availability could occur which may not be

reflected in this document. Christie reserves the right to make changes to specifications at any time without notice. Performance specifications

are typical, but may vary depending on conditions beyond Christie's control such as maintenance of the product in proper working conditions.

Performance specifications are based on information available at the time of printing. Christie makes no warranty of any kind with regard to this

material, including, but not limited to, implied warranties of fitness for a particular purpose. Christie will not be liable for errors contained herein

or for incidental or consequential damages in connection with the performance or use of this material.

The product is designed and manufactured with high-quality materials and components that can be recycled and reused. This symbol

means that electrical and electronic equipment, at their end-of-life, should be disposed of separately from regular waste. Please dispose of

the product appropriately and according to local regulations. In the European Union, there are separate collection systems for used

electrical and electronic products. Please help us to conserve the environment we live in!

Canadian manufacturing facility is ISO 9001 and 14001 certified.

GENERAL WARRANTY STATEMENTS

For complete information about Christie limited warranty, please contact your Christie dealer. In addition to the other limitations that may be

specified in Christie limited warranty, the warranty does not cover:

a. Damage occurring during shipment, in either direction.

b. Projector lamps (See Christie separate lamp program policy).

c. Damage caused by use of a projector lamp beyond the recommended lamp life, or use of a lamp supplied by a supplier other than Christie.

d. Problems caused by combination of the product with non-Christie equipment, such as distribution systems, cameras, video tape recorders,

etc., or use of the product with any non-Christie interface device.

e. Damage caused by misuse, improper power source, accident, fire, flood, lightening, earthquake or other natural disaster.

f. Damage caused by improper installation/alignment, or by product modification, if by other than a Christie authorized repair service

provider.

g. For LCD projectors, the warranty period specified applies only where the LCD projector is in “normal use.” “Normal use” means the LCD

projector is not used more than 8 hours a day, 5 days a week. For any LCD projector where “normal use” is exceeded, warranty coverage

under this warranty terminates after 6000 hours of operation.

h. Failure due to normal wear and tear.

PREVENTATIVE MAINTENANCE

Preventative maintenance is an important part of the continued and proper operation of your product. Please see the Maintenance section for

specific maintenance items as they relate to your product. Failure to perform maintenance as required, and in accordance with the maintenance

schedule specified by Christie, will void the warranty.

Table of Contents

1: Introduction

1.1 Labels and Marking .....................................................................................................................1-1

1.2 Purchase Record and Service Contacts .......................................................................................1-2

1.3 Projector Overview......................................................................................................................1-3

1.3.1 How the Projector Works ....................................................................................................1-3

1.3.2 User Interface Overview......................................................................................................1-3

1.3.3 List of Components..............................................................................................................1-3

1.3.4 Key Features ........................................................................................................................1-4

1.4 Safety Warnings and Guidelines .................................................................................................1-5

1.4.1 General Precautions .............................................................................................................1-5

1.4.2 AC /Power Precautions........................................................................................................1-6

1.4.3 Lamp Precautions ................................................................................................................1-6

2: Installation and Setup

2.1 Projector Quick Setup and Installation........................................................................................2-1

2.2 Detailed Setup and Installation....................................................................................................2-7

2.2.1 About the projector .............................................................................................................. 2-7

2.2.2 Installation Considerations ..................................................................................................2-10

2.2.3 Hoisting Procedure ..............................................................................................................2-12

2.2.4 Stacking Procedure ..............................................................................................................2-13

2.2.5 Alignment Procedure ........................................................................................................... 2-16

2.3 Types of Installations...................................................................................................................2-18

2.3.1 Projector Position and Mounting ......................................................................................... 2-21

2.3.2 Mounting..............................................................................................................................2-25

2.3.3 Adjusting Projector Height/Tilt ...........................................................................................2-26

2.3.4 Basic Optical Alignment......................................................................................................2-26

2.3.5 Advanced Optical Alignment ..............................................................................................2-27

2.3.6 Powering Down ...................................................................................................................2-29

2.3.7 Connecting Communications...............................................................................................2-30

2.3.8 Projector Communications ................................................................................................2-35

2.4 Connecting Sources .....................................................................................................................2-36

3: Operation

3.1 Operating the Projector................................................................................................................3-1

3.1.1 Remote Keypad Commands ................................................................................................3-4

3.2 Navigating the Menus..................................................................................................................3-8

3.3 Using Inputs and Channels ..........................................................................................................3-12

3.4 Channel Setup Menu ...................................................................................................................3-14

3.5 Adjusting the Image.....................................................................................................................3-17

3.6 Size and Position Menu ...............................................................................................................3-18

3.7 Image Settings Menu ...................................................................................................................3-23

3.8 Configuration - Adjusting System Parameters and Advanced Controls ....................................3-31

3.9 Lamp Menu..................................................................................................................................3-50

3.10 Input Switching & PIP Menu ....................................................................................................3-52

3.11 Status .........................................................................................................................................3-54

J Series 2.0, 2.4, and 3.0kW User Manual i

020-100707-01 Rev. 1 (10-2011)

Table of Contents

3.12 Using Multiple Projectors......................................................................................................... 3-54

3.13 Remote Control of the Projector............................................................................................... 3-57

3.14 Alarms ...................................................................................................................................... 3-58

4: Web User Interface

4.1 Logging On ................................................................................................................................. 4-1

4.2 Navigating the Web User Interface............................................................................................. 4-2

4.2.1 Help Text............................................................................................................................. 4-2

4.3 Basic Operation........................................................................................................................... 4-3

4.3.1 Main Tabbed Page - General .............................................................................................. 4-3

4.3.2 Main Tabbed Page - Status ................................................................................................. 4-3

4.3.3 Main Tabbed Page - Lens ................................................................................................... 4-4

4.3.4 Tools Tabbed Page - Virtual OSD ...................................................................................... 4-4

4.3.5 Admin Tabbed Page - System............................................................................................. 4-6

4.3.6 Admin Tabbed Page- Users ................................................................................................ 4-8

4.3.7 Advanced Tabbed Page - RTE............................................................................................ 4-9

4.3.8 About Tabbed Page............................................................................................................. 4-13

5: Maintenance

5.1 Projector Location....................................................................................................................... 5-1

5.1.1 Lamp and Filter Replacement ............................................................................................. 5-1

5.2 Replacing the Projection Lens .................................................................................................... 5-6

5.3 Cleaning the Lens ....................................................................................................................... 5-8

5.4 Liquid Coolant Maintenance....................................................................................................... 5-8

5.4.1 Liquid Cooler (P/N: 003-100668-XX)................................................................................ 5-8

5.5 Power Cord and Attachments ..................................................................................................... 5-10

5.6 Ventilation................................................................................................................................... 5-11

5.7 Replacing Keypad Batteries........................................................................................................ 5-11

5.8 Servicing Requirements.............................................................................................................. 5-11

6: Troubleshooting

6.1 Power .......................................................................................................................................... 6-1

6.1.1 Projector Does Not Power ON............................................................................................ 6-1

6.2 Lamp ........................................................................................................................................... 6-1

6.2.1 Lamp Does Not Ignite......................................................................................................... 6-1

6.2.2 Lamp Suddenly Turns OFF................................................................................................. 6-2

6.2.3 Flicker, Shadows Or Dimness............................................................................................. 6-2

6.3 LCD............................................................................................................................................. 6-2

6.3.1 Blank Screen, No Menu Displaying ................................................................................... 6-2

6.4 Remote Keypad........................................................................................................................... 6-2

6.4.1 Remote Keypad Does Not Seem to Work .......................................................................... 6-2

6.5 OSD............................................................................................................................................. 6-3

6.5.1 The OSD Menu does not display ........................................................................................ 6-3

6.6 Ethernet....................................................................................................................................... 6-3

6.6.1 Trouble Establishing Communication with Projector......................................................... 6-3

ii J Series 2.0, 2.4, and 3.0kW User Manual

020-100707-01 Rev. 1 (10-2011)

Table of Contents

6.7 Displays .......................................................................................................................................6-3

6.7.1 The projector is on but there is no display...........................................................................6-3

6.7.2 Severe Motion Artifacts.......................................................................................................6-3

6.7.3 Image Appears ‘Squeezed’ or Vertically Stretched into Center of Screen..........................6-4

6.7.4 The Display is Jittery or Unstable........................................................................................6-4

6.7.5 The Display is Faint.............................................................................................................6-4

6.7.6 The Upper Portion of the Display is Waving, Tearing or Jittering......................................6-4

6.7.7 Portions of the Display are Cut Off or Warped to the Opposite edge .................................6-4

6.7.8 Display Appears Compressed (Vertically Stretched) ..........................................................6-4

6.7.9 Data is Cropped from Edges................................................................................................6-4

6.7.10 Display Quality Appears to Drift from Good to Bad, Bad to Good .................................6-4

6.7.11 Display has Suddenly Frozen ............................................................................................6-5

6.7.12 Colors in the Display are Inaccurate..................................................................................6-5

6.7.13 Display is Not Rectangular ................................................................................................6-5

6.7.14 Display is “Noisy” .............................................................................................................6-5

6.8 Web Interface ..............................................................................................................................6-6

6.8.1 After upgrading the projector software, the Web pages do not display correctly ...............6-6

6.8.2 A backup or Interrogator file cannot be saved.....................................................................6-6

7: Specifications

7.1 Image Performance......................................................................................................................7-1

7.1.1 Pixel Format ........................................................................................................................7-1

7.1.2 Nominal Brightness (ANSI Lumens) .................................................................................7-1

7.1.3 Contrast................................................................................................................................7-1

7.1.4 Luminance Uniformity ........................................................................................................7-1

7.1.5 Color Uniformity .................................................................................................................7-1

7.1.6 Gamma.................................................................................................................................7-2

7.1.7 Grayscale/Color Resolution.................................................................................................7-2

7.1.8 Color Temperature...............................................................................................................7-2

7.1.9 Convergence ........................................................................................................................7-2

7.1.10 Blemishes...........................................................................................................................7-3

7.1.11 Pixel Defects ......................................................................................................................7-3

7.2 Feature Set ...................................................................................................................................7-3

7.2.1 Airflow ................................................................................................................................7-3

7.2.2 Air Filters (Optional) ...........................................................................................................7-3

7.2.3 Dust Sealing.........................................................................................................................7-3

7.2.4 ILS (Intelligent Lens System)..............................................................................................7-3

7.2.5 Projection Lens Compatibility .............................................................................................7-4

7.2.6 Automatic Fans ....................................................................................................................7-4

7.2.7 Constant Lamp Output Management...................................................................................7-4

7.2.8 Shutter .................................................................................................................................7-5

7.2.9 Lamps...................................................................................................................................7-5

7.2.10 Status LED.........................................................................................................................7-5

7.2.11 Electronics/SW .................................................................................................................7-5

7.3 Image Processor Performance .....................................................................................................7-6

7.4 Input (Source Signal) Compatibility ...........................................................................................7-6

J Series 2.0, 2.4, and 3.0kW User Manual iii

020-100707-01 Rev. 1 (10-2011)

Table of Contents

7.4.1 Analog (Only) Input............................................................................................................ 7-6

7.4.2 Twin HDMI Input ............................................................................................................... 7-6

7.4.3 Dual Link DVI Input........................................................................................................... 7-7

7.4.4 Video Decoder Input........................................................................................................... 7-7

7.4.5 Dual 3G/HD/SD - SDI Input............................................................................................... 7-7

7.5 Control Signal Compatibility ..................................................................................................... 7-7

7.5.1 Projector Control................................................................................................................. 7-7

7.5.2 Control Receiver ................................................................................................................. 7-7

7.5.3 RS-232 ................................................................................................................................ 7-8

7.5.4 RS-422 ................................................................................................................................ 7-8

7.5.5 Ethernet ............................................................................................................................... 7-8

7.5.6 USB 2.0 Device Port .......................................................................................................... 7-8

7.5.7 GPIO ................................................................................................................................... 7-8

7.5.8 DMX512 Interface .............................................................................................................. 7-8

7.5.9 Built-In Keypad and Display .............................................................................................. 7-8

7.5.10 Convenience Light ............................................................................................................ 7-8

7.5.11 MMC Slot ......................................................................................................................... 7-8

7.6 Power Requirements ................................................................................................................... 7-9

7.6.1 Lamp Specification ............................................................................................................. 7-9

7.7 Physical Specifications ............................................................................................................... 7-9

7.7.1 Size...................................................................................................................................... 7-9

7.7.2 Adjustment .......................................................................................................................... 7-10

7.7.3 Weight................................................................................................................................. 7-10

7.8 Reliability and Serviceability...................................................................................................... 7-10

7.8.1 Reliability............................................................................................................................ 7-10

7.8.2 Serviceability ...................................................................................................................... 7-10

7.9 Environment................................................................................................................................ 7-10

7.9.1 Temperature/Humidity/Altitude.......................................................................................... 7-10

7.10 Accessories and Service Components ...................................................................................... 7-11

7.11 Regulatory................................................................................................................................. 7-11

A: Menu Tree

A.1 J Series Menu Tree..................................................................................................................... A-1

B: GPIO

B.1 GPIO Port................................................................................................................................... B-1

C: DMX / ArtNet

C.1 DMX and Real Time Events ...................................................................................................... C-1

C.1.1 DMX Channel Setup .......................................................................................................... C-2

iv J Series 2.0, 2.4, and 3.0kW User Manual

020-100707-01 Rev. 1 (10-2011)

1 Introduction

Every effort has been made to ensure the information in this document is accurate and reliable; however,

due to constant research the information in this document is subject to change without notice.

USERS/OPERATORS: This manual is intended for trained users operating professional high-brightness

projection systems. Such users may also be trained to replace the lamp and air filter, but cannot install the

projector or perform any service functions on the J Series projector.

SERVICE: Only Christie accredited technicians knowledgeable about all potential hazards associated

with high voltage, ultraviolet exposure and high temperatures generated by the lamp and associated

circuits are authorized to 1) assemble/install the projector and 2) perform service functions inside the

projector.

This manual contains the following sections:

• Section 1 Introduction

• Section 2 Installation and Setup

• Section 3 Operation

• Section 4 Web User Interface

• Section 5 Maintenance

• Section 6 Troubleshooting

• Section 7 Specifications

• Appendix A: Menu Tree

• Appendix B: GPIO

• Appendix C: DMX / ArtNet

1.1 Labels and Marking

Observe and follow any warnings and instructions marked on the projector.

Indicates a hazardous situation which, if not avoided, will result in death or serious

injury. This signal word is to be limited to the most extreme situations.

Indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a hazardous situation which, if not avoided, could result in minor or moderate

injury. It may also be used without the safety alert symbol as an alternative to

“NOTICE”.

J Series 2.0, 2.4, and 3.0kW User Manual 1-1

020-100707-01 Rev. 1 (10-2011)

Section 1: Introduction

1.2 Purchase Record and Service Contacts

Whether the projector is under warranty or the warranty has expired, Christies highly trained and extensive

factory and dealer service network is always available to quickly diagnose and correct projector malfunctions.

Complete service manuals and updates are available for all projectors. Should a problem be encountered with

any part of the projector, contact your dealer. In most cases, servicing is performed on site. If you have

purchased the projector, fill out the information below and keep with your records.

Table 1.1

Dealer:

Dealer or Christie Sales/Service Contact Phone Number:

Projector Serial Number*:

Purchase Date:

Installation Date:

* The serial number can be found on the license label located on the back of the projector.

Table 1.2 Ethernet Settings

Default Gateway:

DNS Server:

Projector DLP Address:

Projector Mgmt IP Address:

Subnet Mask:

1-2 J Series 2.0, 2.4, and 3.0kW User Manual

020-100707-01 Rev. 1 (10-2011)

1.3 Projector Overview

The J Series is a family of high resolution video/graphics 3 chip 1080p HD, SXGA+ and WUXGA projectors,

see Table 1.3 J Series Projectors. These projectors are based on DLP® technology provided by Texas

Instruments.

1.3.1 How the Projector Works

The projector accepts data/graphics and video input signals for projection onto front or rear screens. Light is

generated by a xenon lamp, then modulated by three Digital Micro-mirror Device (DMD) panels that provide

digitized red, green or blue color information. Light from the “ON” pixels of each panel is reflected, converged

and then projected to the screen through a single front lens, where all pixels are perfectly superimposed as a

sharp full-color image.

1.3.2 User Interface Overview

The projector can be controlled via a menu system displayed on the image. The menu system can be controlled

by an IR remote, wired remote or through the built-in keypad. The LCD screen and built-in keypad allow

functions to be controlled without the need of an OSD display, and provide a quickly accessible interface to

view error reporting. The functions on the OSD can also be controlled using the Christie Serial Protocol, via a

serial or Ethernet connection to the projector. The Web interface provides access to the menu system as a

Virtual OSD (On-screen display) and to features that maintain the projector software and settings.

Section 1: Introduction

1.3.3 List of Components

Ensure the following components were received with the projector:

Projector with Built-In Keypad (LCD status display)

IR remote keypad (includes two, 1.5V AA batteries and an XLR to mini-stereo cable conversion to wired)

Line cord

Lens Mount Security Screw (M6x10mm long, Qty. 2)

Lens Mount Security Screw Driver (5mm Hex, Qty. 1)

Warranty Card

Web Registration Form

J Series 2.0, 2.4, and 3.0kW User Manual 1-3

020-100707-01 Rev. 1 (10-2011)

Section 1: Introduction

1.3.4 Key Features

• Up to 22,000 lumens

• HD (1080p), SXGA+ or WUXGA resolution

• Xenon lamp with 1900W, 2400W or 3000W options

• 10-bit image processor electronics with modular design

• Active fan control for minimum noise level

• User interchangeable projection lenses with no-tool mounting

• LiteLOC for constant brightness maintenance

• Intelligent Lens System (ILS)

• Motorized lens mount for all models

• Auto-setup feature

• Integrated ChristieNET

• Networking ability through RS-232 and RS-422 connectors

• Status LED display on built-in keypad for easy projector status monitoring

• Control with remote keypad, wired remote, or built-in keypad

• Four input slots for Optional Input Modules

Refer to Section 7 Specifications for a complete list of technical specifications.

Table 1.3 J Series Projectors

Model Name Part Number

Roadster S+14K-J 132-010113-XX

Roadster HD14K-J 132-011114-XX

Roadster S+18K-J 132-013116-XX

Roadster HD16K-J 132-014117-XX

Roadster S+22K-J 132-016119-XX

Roadster HD20K-J 132-017110-XX

Roadster WU20K-J 132-018111-XX

1-4 J Series 2.0, 2.4, and 3.0kW User Manual

020-100707-01 Rev. 1 (10-2011)

1.4 Safety Warnings and Guidelines

1.4.1 General Precautions

HIGH BRIGHTNESS. Never look directly into the projector lens. The extreme high

brightness can cause permanent eye damage.

Always power down the projector and disconnect all power sources before servicing

or cleaning.

Section 1: Introduction

FIRE HAZARD. Keep hands, clothes and all combustible material away from the

concentrated light beam of the projector. Position all cables where they cannot

contact hot surfaces or be pulled or tripped over.

All installation and maintenance procedures must be performed by a Christie

accredited service technician.

Projector must be operated in an environment that meets operating specifications, as

listed in Section 7 Specifications.

The American Conference of Governmental Industrial Hygienists (ACGIH) recommends

occupational UV exposure for an 8-hour day to be less than 0.1 microwatts per square

centimeters of effective UV radiation. An evaluation of your workplace is advised to

assure employees are not exposed to cumulative radiation levels exceeding the

government guidelines for your area. Be aware that some medications are known to

increase sensitivity to UV radiation.

J Series 2.0, 2.4, and 3.0kW User Manual 1-5

020-100707-01 Rev. 1 (10-2011)

Section 1: Introduction

1.4.2 AC /Power Precautions

Use only the AC power cord supplied. Do not attempt operation if the AC supply and

cord are not within the specified voltage and power range. Refer to the license label

on the back of the projector or

The projector is equipped with a 3-wire plug with a grounding pin. This is a safety

feature. If you are unable to insert the plug into the outlet, contact an electrician to

have the outlet replaced.

plug.

Do not allow anything to rest on the power cord. Locate the power cord where

persons walking on it or objects rolling over it cannot damage the cord.

1.4.3 Lamp Precautions

Never attempt to access the lamp while the lamp is ON. After turning the lamp OFF, it

is crucial that you wait at least 5 minutes before handling the lamp. This provides

sufficient time for the lamp cooling fans to properly cool the lamp. For all other

precautions critical for safe removal and replacement of the lamp, refer to 5.1.1 Lamp

and Filter Replacement

Section 7 Specifications for rated voltage and power.

NEVER defeat the safety purpose of the grounding-type

.

1-6 J Series 2.0, 2.4, and 3.0kW User Manual

020-100707-01 Rev. 1 (10-2011)

2 Installation and Setup

This section explains how to install, connect and optimize the projector for delivery of superior image

quality. Illustrations are graphical representations only and are provided to enhance the understanding of

the written material.

2.1 Projector Quick Setup and Installation

The following instructions are for those preferring a quick setup. Refer to the remaining subsections for

detailed setup instructions.

Always power down the projector and disconnect all power sources before servicing or

cleaning.

Refer to Safety Warnings and Guidelines in Section 5 Maintenance.

STEP 1 - Installing a Projection Lens

The projection lens, shipped separately from the projector, must be installed prior to setting up the projector.

Remove the lens plug from the lens opening in the projector before installing the lens.

Retain the lens plug for projector transportation to protect the optical components

from dust and debris.

IMPORTANT! The lens seals the projector, preventing contaminants from entering the interior of the

projector. Never operate a projector without a lens.

LENS INSTALLATION

IMPORTANT! Remove the rear lens cap from the lens. Keep the front lens cap on the lens to protect it

during installation.

1. Rotate the lens clamp clockwise to the OPEN position, see Figure 2-1.

FIGURE 2-1

J Series 2.0, 2.4, and 3.0kW User Manual 2-1

020-100707-01 Rev. 1 (10-2011)

Section 2: Installation and Setup

2. Align the lens interface plate with the lens mount. Align the lens electrical connector with the mating

connector on the lens mount. Fully insert the assembly straight into the lens mount opening without

turning. Press using your hand as shown in Figure 2-2.

lens is not inserted at an angle, as this can cause damage.

NOTE: When installing the lens, ensure that the

FIGURE 2-2

3. While holding the lens flat against the lens mount, rotate the lens clamp clockwise to lock the lens

assembly in place. See Figure 2-3.

FIGURE 2-3

4. Remove the front lens cap.

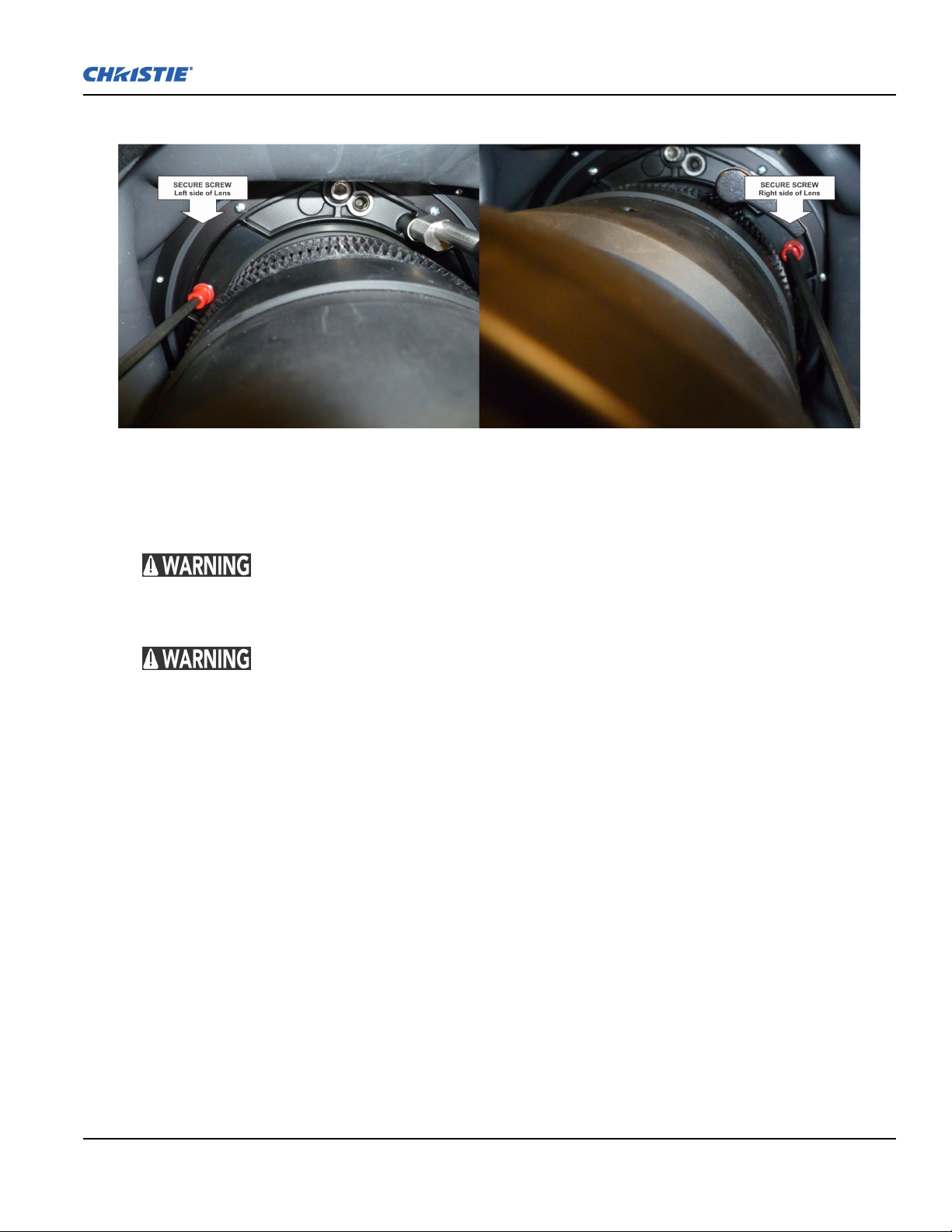

5. For added stability such as motion applications, fasten the security screws provided with the lens mount.

Refer to Figure 2-4.

2-2 J Series 2.0, 2.4, and 3.0kW User Manual

020-100707-01 Rev. 1 (10-2011)

Section 2: Installation and Setup

FIGURE 2-4

6. Use a 5mm hex driver to fasten the red security screws provided with the lens mount (Figure 2-4), or hand

tighten the lens retaining screws attached to the lens. NOTES: 1) Recommended for heaviest lenses such

as 0.73:1 and 1.2:1. 2) The red security screws MUST be installed when hoisting the projector overhead,

or installing the projector in an overhead position.

Use of the lens red security screws or the lens retaining screws is required if the

projector is hoisted or installed in an overhead position.

STEP 2 - Positioning the Projector

2 people are required to safely lift and install the projector.

Place the projector on a sturdy, level surface and position it so that it is perpendicular to the screen at a suitable

distance. With the projector positioned perpendicular to the screen, the image will appear rectangular instead

of keystoned. To level the projector, adjust the height of the feet.

For more detailed instructions on positioning the projector refer to 2.3.1 Projector Position and Mounting later

in this section.

STEP 3 - Connecting a Source

Located at the back of the projector is the input panel where all source connections are made. Each input is

clearly labeled for easy identification. Depending on the type of option card installed, connect your source

using the appropriate cable(s), as follows:

• Analog Input Card, connect 3-, 4-, or 5-wire RGB source to Red/Pr, Green/Y, Blue/Pb, H/C and V using 3,

4 or 5 BNC connectors as required.

• Dual 3G/SD/HD - SDI Input Card, connect SDI (Serial Digital Interface) cable to one of the two inputs, 1-

IN or 2-IN. Both standard-definition (SD) and high-definition (HD) 3GHz signals are accepted and

automatically recognized on either input.

• Dual Link DVI Input Card, connect a single or dual link DVI video signal to the DVI-I connector, an

analog video signal to the DVI-I connector or an analog video signal to the VGA connector. The DVI signal

may contain HDCP (High-Bandwidth Digital Content Protection).

• Twin HDMI Input Card, connect HDMI (High-Definition Multimedia Interface) cable to one of the two

inputs, 1-IN or 2-IN.

J Series 2.0, 2.4, and 3.0kW User Manual 2-3

020-100707-01 Rev. 1 (10-2011)

Section 2: Installation and Setup

• Video Decoder Input Card, depending on the source you can apply the following;

• Composite video source to 1-CVBS, using a BNC Cable

input is selected as CVBS.

• Component input grouping is selected in the projector menu, see Section 3.8 Configuration - Adjusting

System Parameters and Advanced Controls.

• A component signal on Inputs 4(Pr), 5(Y), 6(Pb) using BNC Connectors.

input, YPbPr.

• S-Video to one of the two, 2-SVID or 3-SVID using S-Video cable.

• S-Video using two BNC cables, with Luma (Y) connected to 4 (Sy) and Chroma (C) connected to 6 (Sc).

NOTE: Must be grouped as 1 S-Video + 1 CVBS.

• DMX512 Interface Card, has two 5pin XLR connectors - 1 (input) male and 1 (output) female. If there is

active communications on the DMX512 Interface card the power LED will blink between low intensity and

high intensity.

Refer to Section 2.4 Connecting Sources for more details.

STEP 4 - Connecting the Line Cord

IMPORTANT! Use the line cord provided with the projector. NOTE: Voltage and current requirements are

listed on the license label, located at the back of the projector.

To prevent the line cord from inadvertent disconnection, perform one of the following steps:

NOTE: Same signal can be used on 4, 5 or 6 when

NOTE: Grouped as a component

For 1900W and 2400W Models

1. Connect the line cord of the projector to the AC receptacle at the AC inlet of the projector, then push the

wire clip over the plug to retain it, as shown in Figure 2-5.

FIGURE 2-5

2-4 J Series 2.0, 2.4, and 3.0kW User Manual

020-100707-01 Rev. 1 (10-2011)

Section 2: Installation and Setup

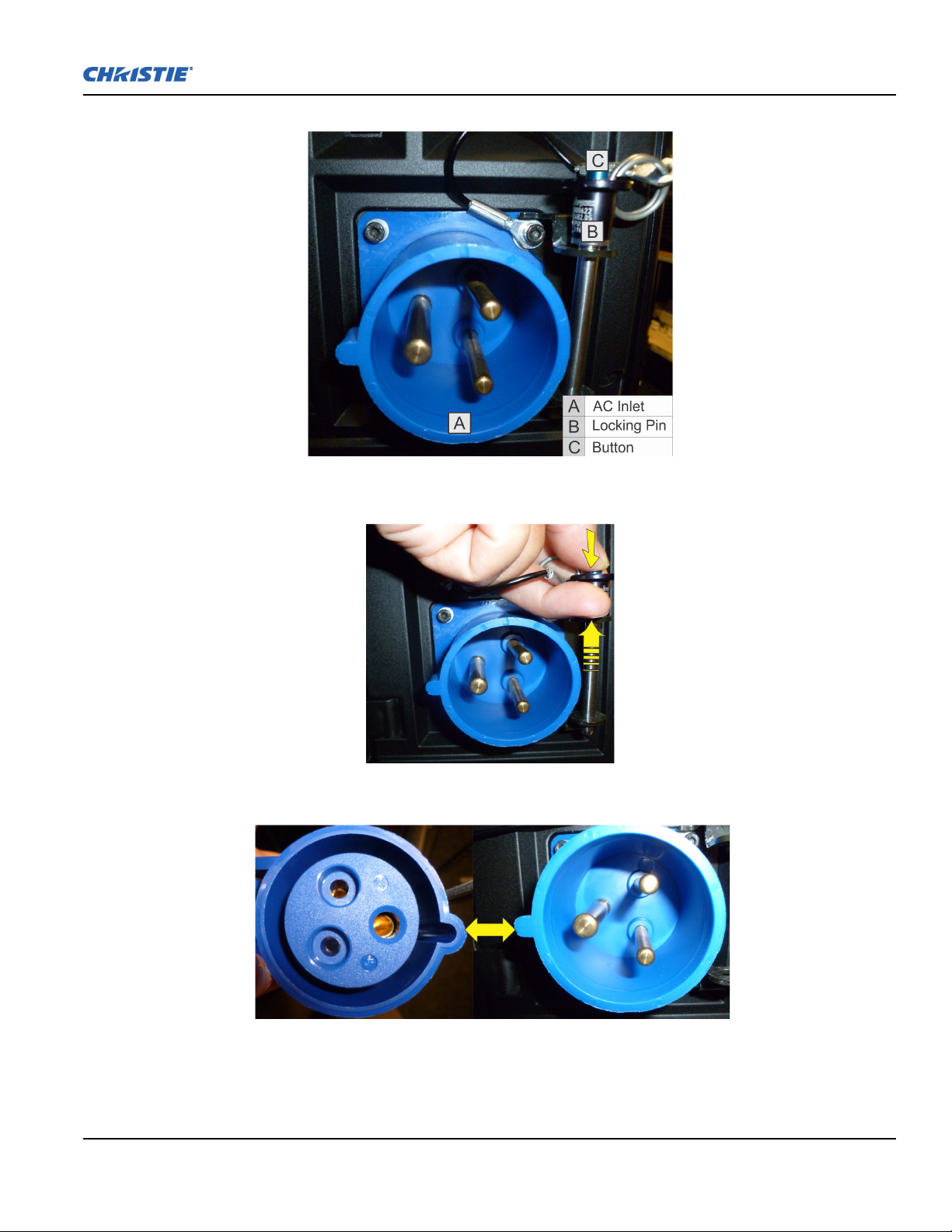

For 3000W Model

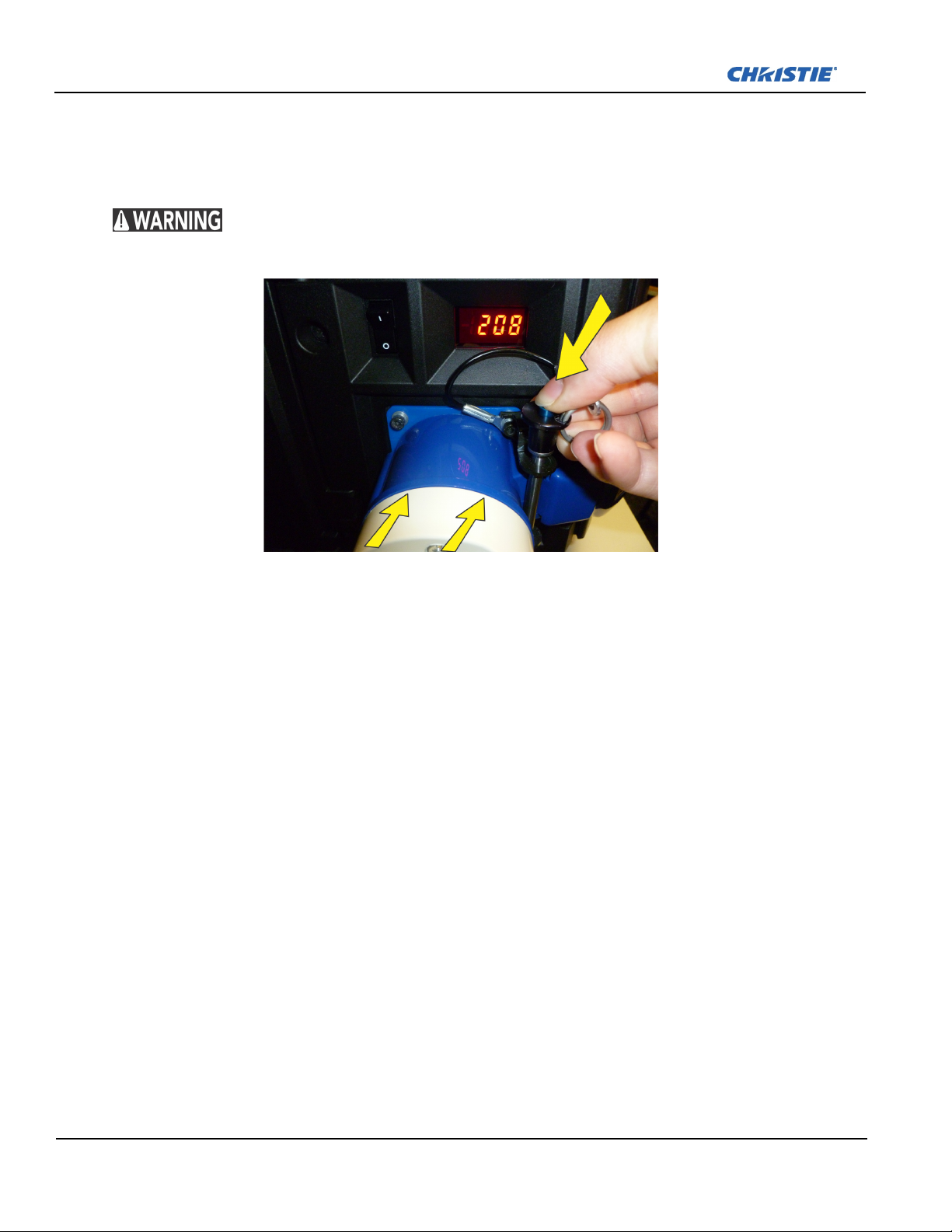

1. Remove the locking pin from the bracket surrounding the AC receptacle at the AC inlet of the projector by

pressing down on the button on the end of the locking pin, and then pull upwards on the pin to remove it,

as shown in Figure 2-6.

FIGURE 2-6

2. Open the cap on the AC plug and line up the slot on the plug with the pin on the receptacle. See Figure 2-7.

FIGURE 2-7

J Series 2.0, 2.4, and 3.0kW User Manual 2-5

020-100707-01 Rev. 1 (10-2011)

Section 2: Installation and Setup

3. Insert the plug fully on to the receptacle. When fully inserted, the cap on the AC plug will rest against the

side of the projector (Figure 2-8).

4. Reinsert the locking pin into the bracket surrounding the AC receptacle by pressing down on the button on

the end of the locking pin and insert the pin into the bracket, as shown in Figure 2-8.

Do not attempt operation if the AC supply and cord is not within the specified ratings.

On power down, wait 5 minutes for the fans to turn OFF before unplugging the

projector. Always switch off the projector before unplugging the AC line cord.

FIGURE 2-8

STEP 5 - Power up

After the AC Power has been switched on, the LCD display above the keypad indicates “Please wait” and the 4

LED status indicators at the rear of the projector will be solid amber.

The projector has reached standby and is ready for use when:

• The LCD displays “Standby mode”

• The Status LED is solid amber

• The Lamp LED is off

To turn on the projector, do one of the following:

• Press and hold the power button on either the built-in keypad or the remote control

• Press the power button twice (quickly) on either the built-in keypad or the remote control

Thereafter; the lamp and fans will power on and a green LED will start scrolling back and forth indicating that

the projector is in warm up mode.

The projector is on and ready to display video when the lamp LED and the status LED are both solid green.

NOTE: See Section 3 Operation for a full description of the status indicators.

NOTE: If the projector has a stepper motor lens mount installed and the inserted lens has never been

calibrated, there will be a short period where the projector calibrates all of the lens motors (zoom, focus,

horizontal, and vertical) by moving them through their full range of motion.

2-6 J Series 2.0, 2.4, and 3.0kW User Manual

020-100707-01 Rev. 1 (10-2011)

STEP 6 - Selecting a Source

Press one of the input keys on the remote or built-in keypad to select and display the image for the source you

connected in Step 3.

STEP 7- Adjusting Image

Adjust the image settings, such as Brightness, Contrast, Gamma, Focus, Zoom, etc. using the direct keys on the

remote or built in keypad.

NOTE: Refer to Section 3 Operation for more details.

2.2 Detailed Setup and Installation

Always power down the projector and disconnect all power sources before servicing

or cleaning.

Section 2: Installation and Setup

Refer to Safety Warnings and Guidelines in

2.2.1 About the projector

Section 5 Maintenance.

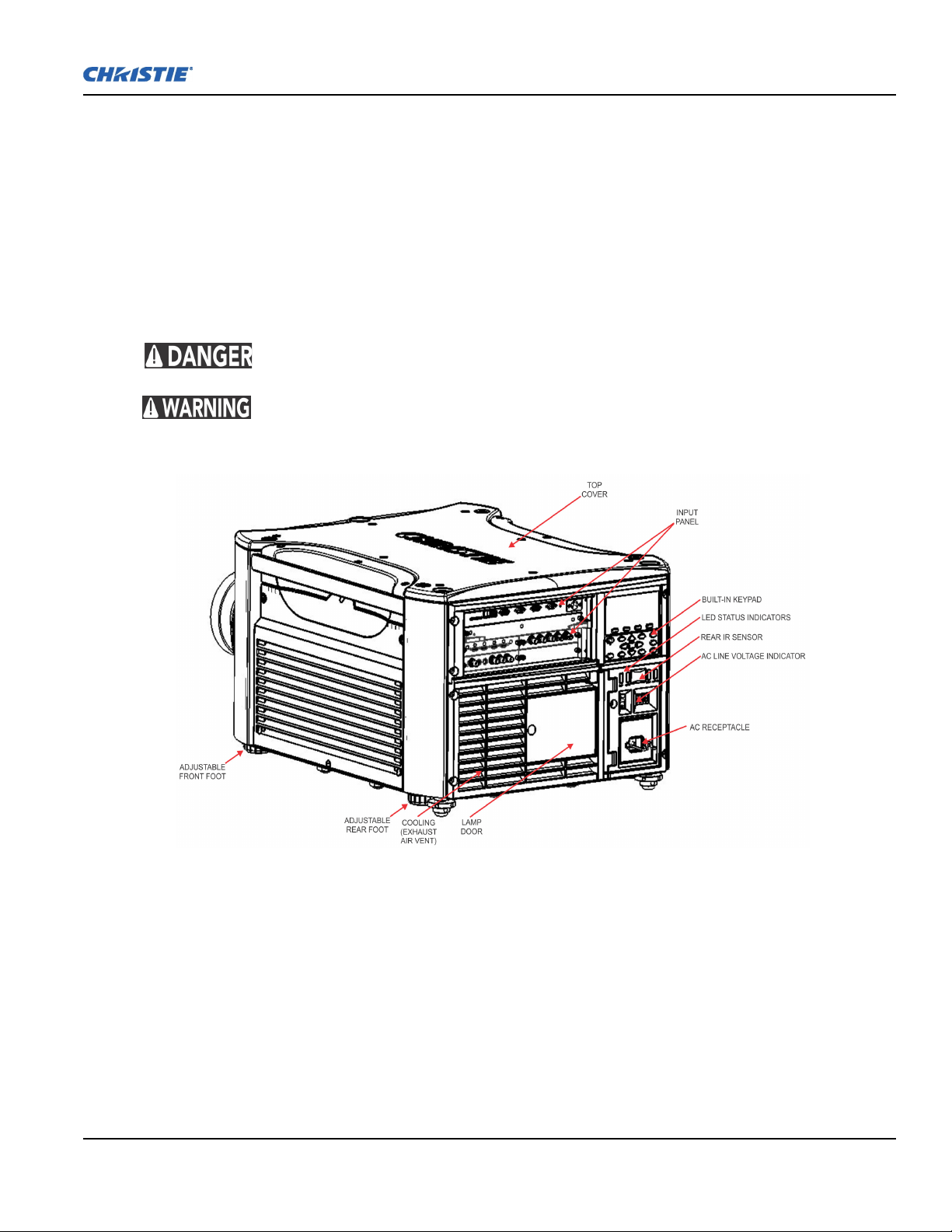

FIGURE 2-9 REAR ORIENTATION

J Series 2.0, 2.4, and 3.0kW User Manual 2-7

020-100707-01 Rev. 1 (10-2011)

Section 2: Installation and Setup

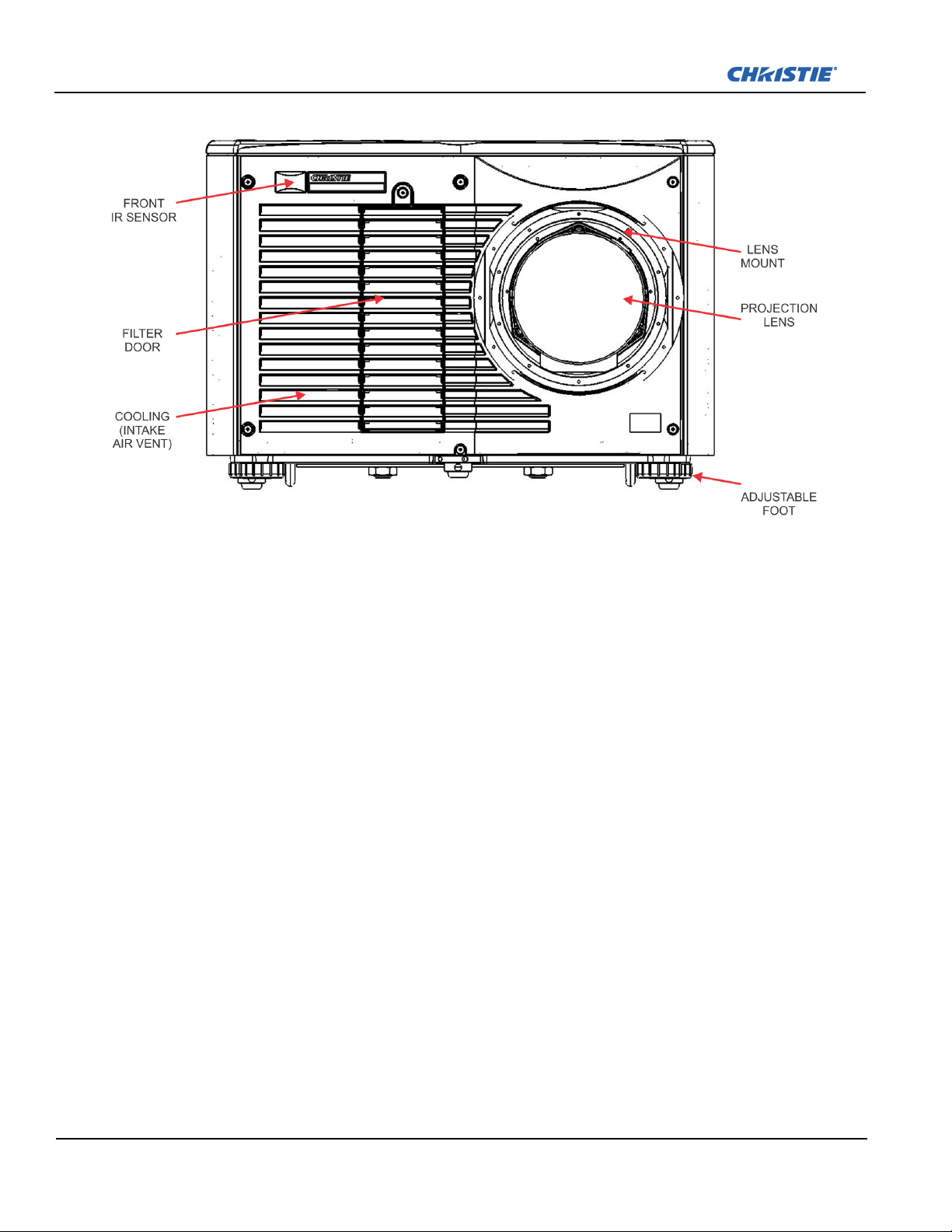

FIGURE 2-10 FRONT ORIENTATION

Built-in Keypad

The built-in keypad is located at the rear of the projector. Use it similarly to the IR remote to control the

projector. An LCD display is located above the keypad for displaying projector status.

AC Receptacle

The AC receptacle is located at the back of the projector. Use this receptacle to plug in an appropriately rated

line cord.

NOTE: The power switch is located above the AC receptacle. Refer to Section 7 Specifications for

details.

AC Line Voltage Indicator

The AC Line Voltage Indicator displays the AC line voltage.

Adjustable Feet

Located on the underside of the projector are four adjustable feet. Raise or lower these feet when positioning

the projector to ensure it is level on all sides so the displayed image will appear rectangular without any

keystone.

Refer to 2.3.3 Adjusting Projector Height/Tilt for instructions on how to adjust the feet.

Input Panel

All source connections are made to the input panel located at the back of the projector. Any of the available

optional input cards can be installed in the 4 option card slots. The slots are labeled 1 through 4. All option

cards have LEDs to indicate their status.

2-8 J Series 2.0, 2.4, and 3.0kW User Manual

020-100707-01 Rev. 1 (10-2011)

Section 2: Installation and Setup

Cooling and Air Vents

Adequate airflow through the projector will prevent it from overheating. Keep all projector vents unobstructed

and ensure adequate airflow around the projector. See Figure 2-11.

Allow at least 1 meter or more of

space between the projector and a

wall or other structure and place it

on a platform that does not extend

past the exhaust vents.

FIGURE 2-11

Lamp Door

The lamp door is located at the rear of the projector, to provide easy access to the lamp module for

replacement. Refer to Section 5.1.1 Lamp and Filter Replacement. The lamp door is fitted with a safety

interlock which switches the lamp off when the door is opened.

Front & Rear IR Sensors

The two IR sensors located on the projector receive transmissions from the IR remote from up to 100 feet

away. It is important to keep the transmission path to these sensors unobstructed for uninterrupted

communications with the projector. The rear IR sensor is located at the back of the projector between the status

LEDs and the front IR sensor is located next to the projector front nameplate.

Projection Lenses, Lens Mount and Other Features

The projector includes a motorized lens mount that allows automated lens control and adjustment: vertical and

horizontal offsets, zoom, and focus. The lens mount can be fitted with any one of the available optional lenses

– see Section 7 Specifications.

J Series 2.0, 2.4, and 3.0kW User Manual 2-9

020-100707-01 Rev. 1 (10-2011)

Section 2: Installation and Setup

• Zoom and Focus – There are two internal lens motors that allow for quick motorized adjustment of zoom

and focus. Adjust zoom to fit the displayed image on the screen and adjust focus to improve the clarity of the

image.

NOTES: 1) The projection lens is shipped separately from the projector. 2) Use the lens cap when

transporting the lens to avoid scratching and damaging the lens, which could affect your displayed image.

Motorized lenses should not be adjusted by hand without first setting them for manual operation, otherwise

the zoom and focus motors may be damaged. (Set in Menu>Configuration>Lens Settings>Manual

Zoom/Focus).

• Lens Offset – The motorized lens mount allows vertical and horizontal offset of the displayed image.

• Shutter – Standard on all models, the shutter allows you to turn the screen absolutely black when in the

“Closed” state.

2.2.2 Installation Considerations

Proper installation of your projector will ensure the quality of your display. Whether you are installing a

projector temporarily or permanently you should take the following into account to ensure your projector

performs optimally. Select the installation type that best suits your needs: front or rear screen, floor mount or

inverted mount.

Lifting, Hoisting, and Stacking

3)

For any new installation, you will likely have to safety lift or hoist the projector into place. Keep in mind the

following guidelines for safety.

Lifting Guidelines

All models include handles for convenient hand transport only; such as when a projector is lifted from a

shipping container to a table.

Note the following:

• The handles are intended to support the weight of 1 projector only.

• The handles are intended to support a projector for a brief time only.

• The handles are not safety points; nor points from which to hoist or suspend the projector.

1) The handles cannot support more than 1 projector. 2) Do not use handles for

extended time periods, 3) Do not use the handles as safety points, or as points from

which to suspend or hoist the projector.

Maximum stack = 3 projectors. Stack first, then hoist.

Hoisting Guidelines

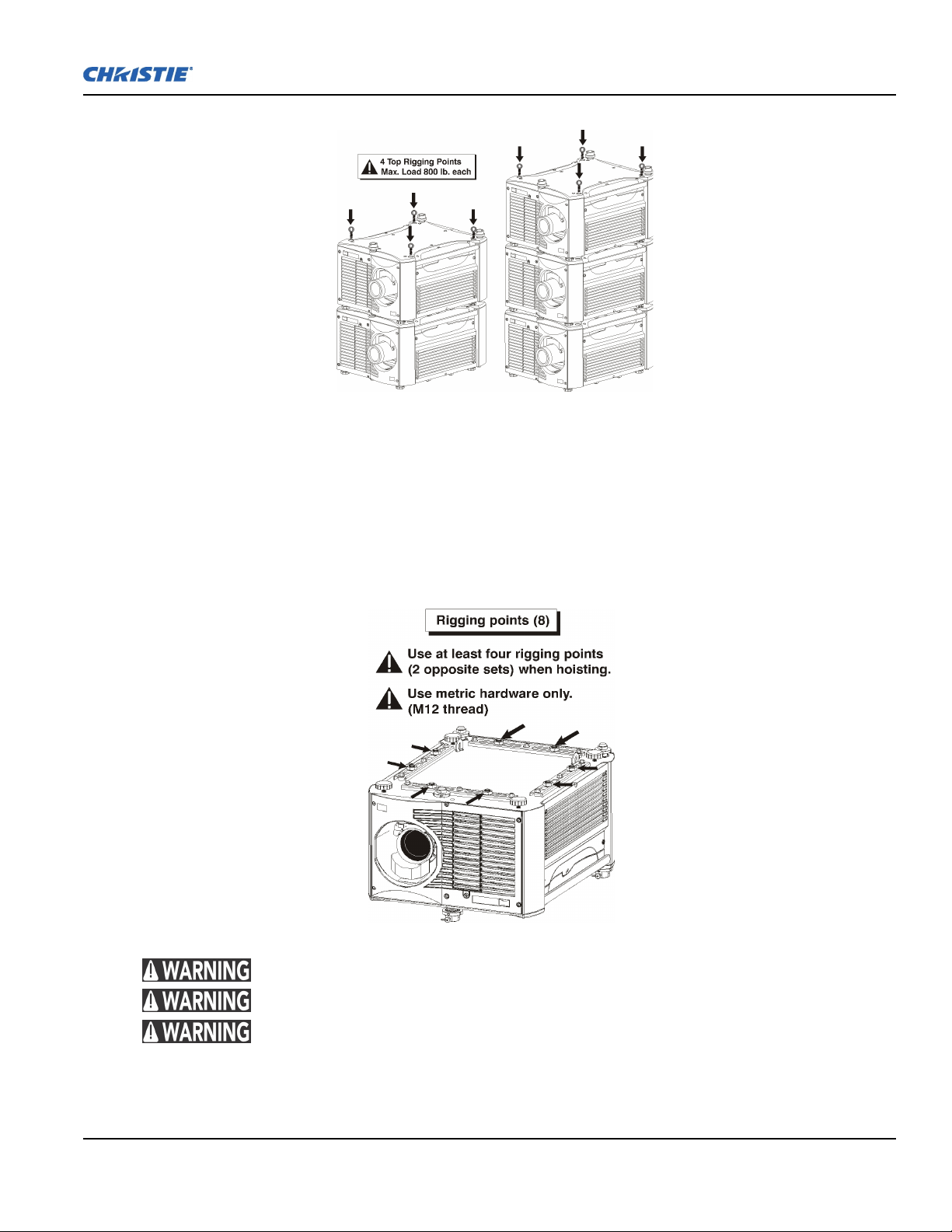

There are 4 integral rigging points on the top of the projector to enable upright or inverted hoisting. See Figure

2-12 For either orientation, hoist an individual projector, or up to 3 projectors in a stack.

2-10 J Series 2.0, 2.4, and 3.0kW User Manual

020-100707-01 Rev. 1 (10-2011)

Section 2: Installation and Setup

FIGURE 2-12

Rules for all hoisting:

• Use at least 4 rigging points for hoisting up to 3 projectors.

• Connect safety cables, and rigging equipment suitable to your application such as clamps, cables, eyebolts,

or straps, which accommodate the load rating. All integral, metric hardware on the projector accepts an M12

thread only.

• Use hoisting and rigging equipment suitable to your application such as clamps, cables, eyebolts, or straps

that accommodate the load rating. All integral, metric hardware on the projector accepts an M12 thread only.

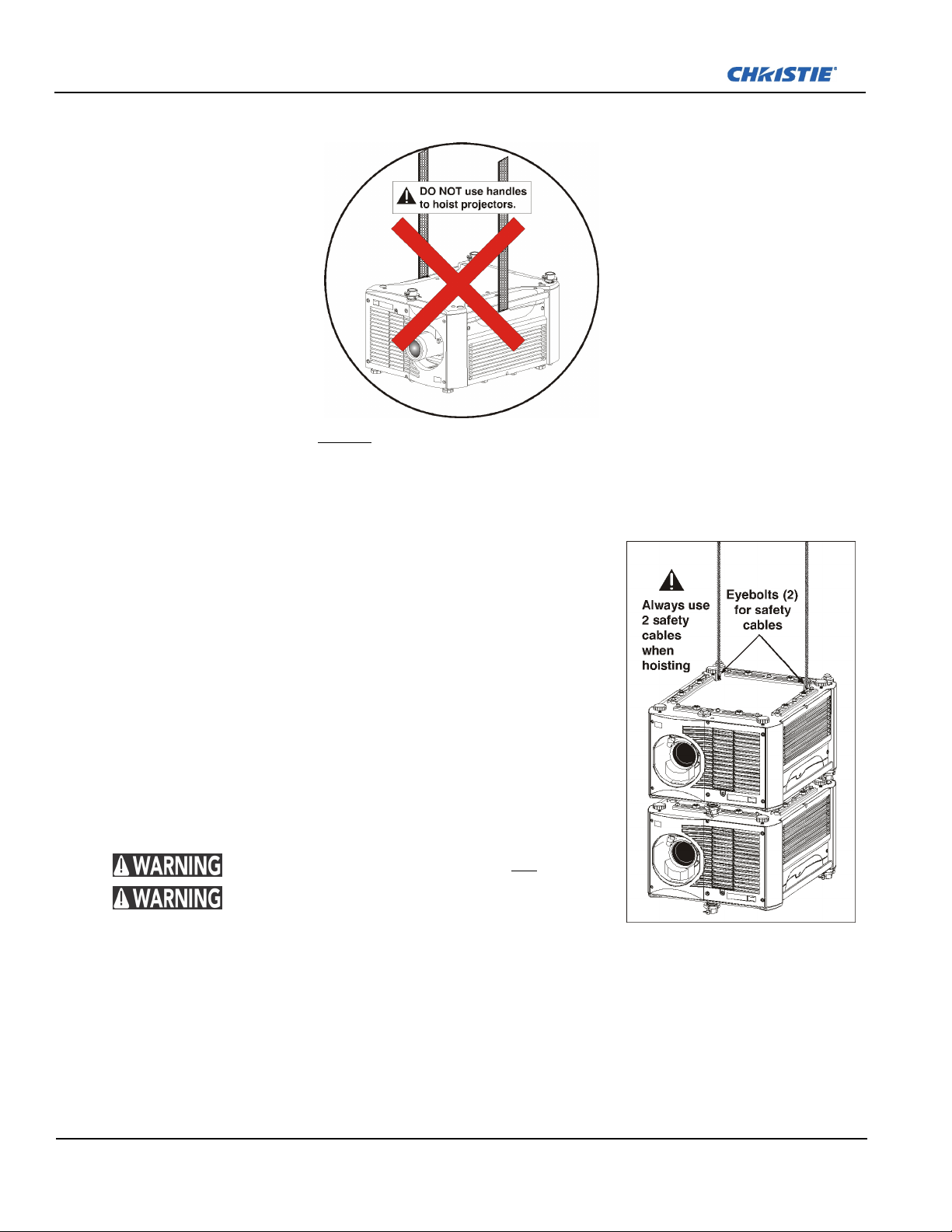

• Never hoist a projector by its feet, handles, or any other component. See Figure 2-13.

FIGURE 2-13

Use metric hardware only.

Never force incompatible threads.

Never hoist a projector by its feet, handles, or any other component.

J Series 2.0, 2.4, and 3.0kW User Manual 2-11

020-100707-01 Rev. 1 (10-2011)

Section 2: Installation and Setup

IMPORTANT! Remove the lens before hoisting the projector.

FIGURE 2-14 NEVER USE HANDLES FOR HOISTING OR SAFETY POINTS

2.2.3 Hoisting Procedure

This procedure applies to one or more projectors. To hoist a stack, first

stack 2 or 3 projectors according to the stacking procedure included in

this manual. Never stack or hoist more than 3 projectors together.

1. Remove lens (recommended)

Remove the projection lens to prevent possible damage during

hoisting. Refer to 5.2 Replacing the Projection Lens.

2. Retract feet.

If the projector is inverted, retract the adjustable feet to prevent the

hoisting hardware from getting caught.

3. Attach safety cables.

Attach a safety cable to each of the 2 eyebolts mounted on the

bottom of the projector. See Figure 2-15. NOTE: Add eyebolts (2)

if non-inverted.

Always use at least 2 safety cables for any hoisting.

Attach safety cables to the 2 eyebolts.

NOTE: When hoisting a non-inverted projector or stack, add 2 safety

eyebolts in the front and rear threaded holes provided on the

top of the projector. Ensure the eyebolts have an adequate rating for the load. Secure safety cabling to

both eyebolts.

Figure 2-15 Attach Safety Cables

2-12 J Series 2.0, 2.4, and 3.0kW User Manual

020-100707-01 Rev. 1 (10-2011)

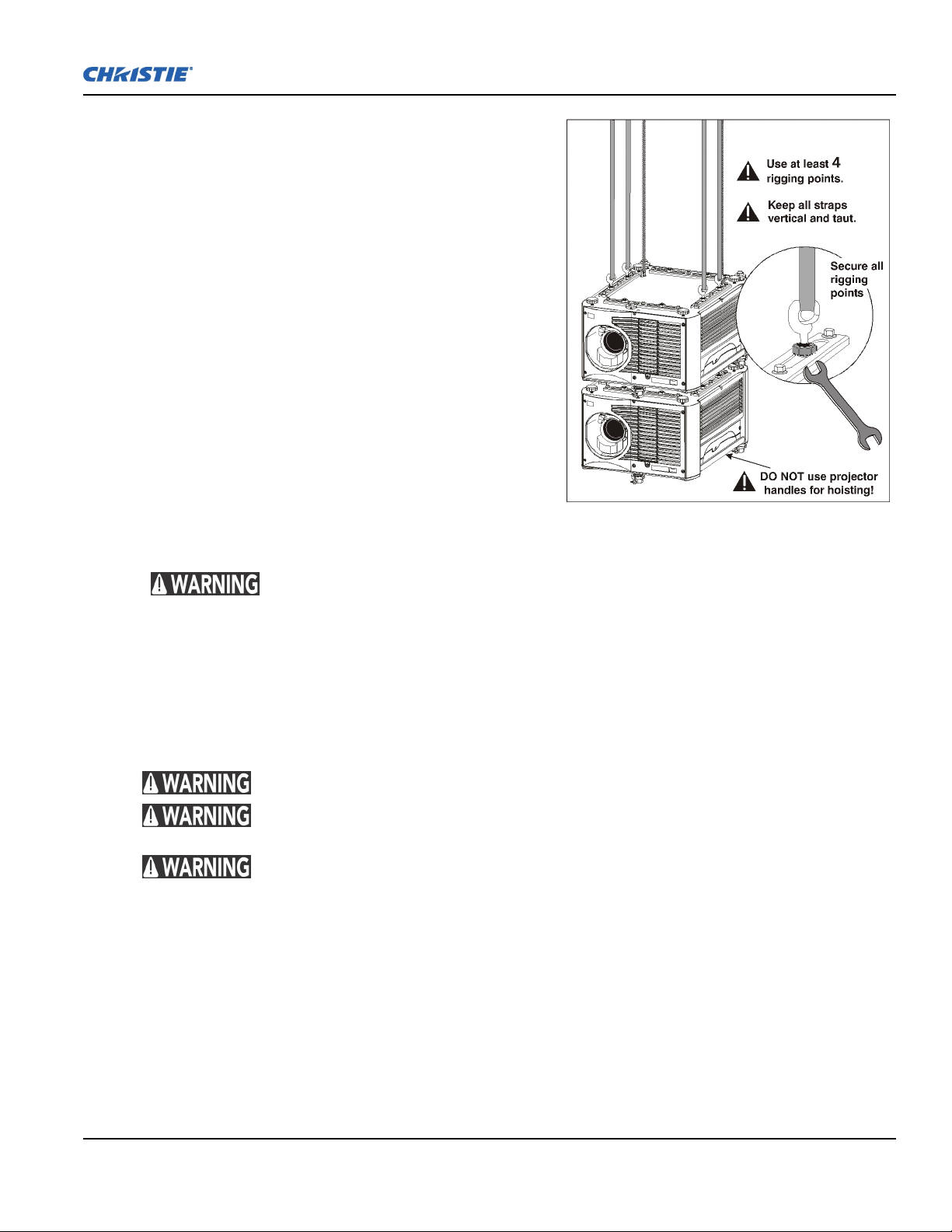

4. Attach rigging hardware.

Attach the rigging hardware by securing your rigging

components to the appropriate rigging points. There

are 8 sliding points provided on the bottom. Tighten

the nut at each required location (Figure 2-16) to

prevent sliding.

NOTES: 1) Use at least 4 rigging points for all hoisting.

2) Use straps, clamps or cabling with load

capacity adequate for the total projector weight.

Refer to Section 7 Specifications. 3) Do not join

the rigging straps or cables to a common point,

keep separated as shown.

Section 2: Installation and Setup

Figure 2-16 Using the Rigging Hardware

• Maximum stack = 3 projectors

2.2.4 Stacking Procedure

NOTES: 1) Installation requires at least 2 people.

Projectors can be stacked in either the upright or inverted position. Do not mix orientations (i.e., inverted

with upright) in a stack. Secure a maximum of 3 projectors with the stacking mounts as described below.

Do not stack more than 3 projectors.

Christie stacking hardware required. The top projector could slide off and cause injury

or death.

Never attempt to manually carry a stack.

• Stack first, then hoist

J Series 2.0, 2.4, and 3.0kW User Manual 2-13

020-100707-01 Rev. 1 (10-2011)

Section 2: Installation and Setup

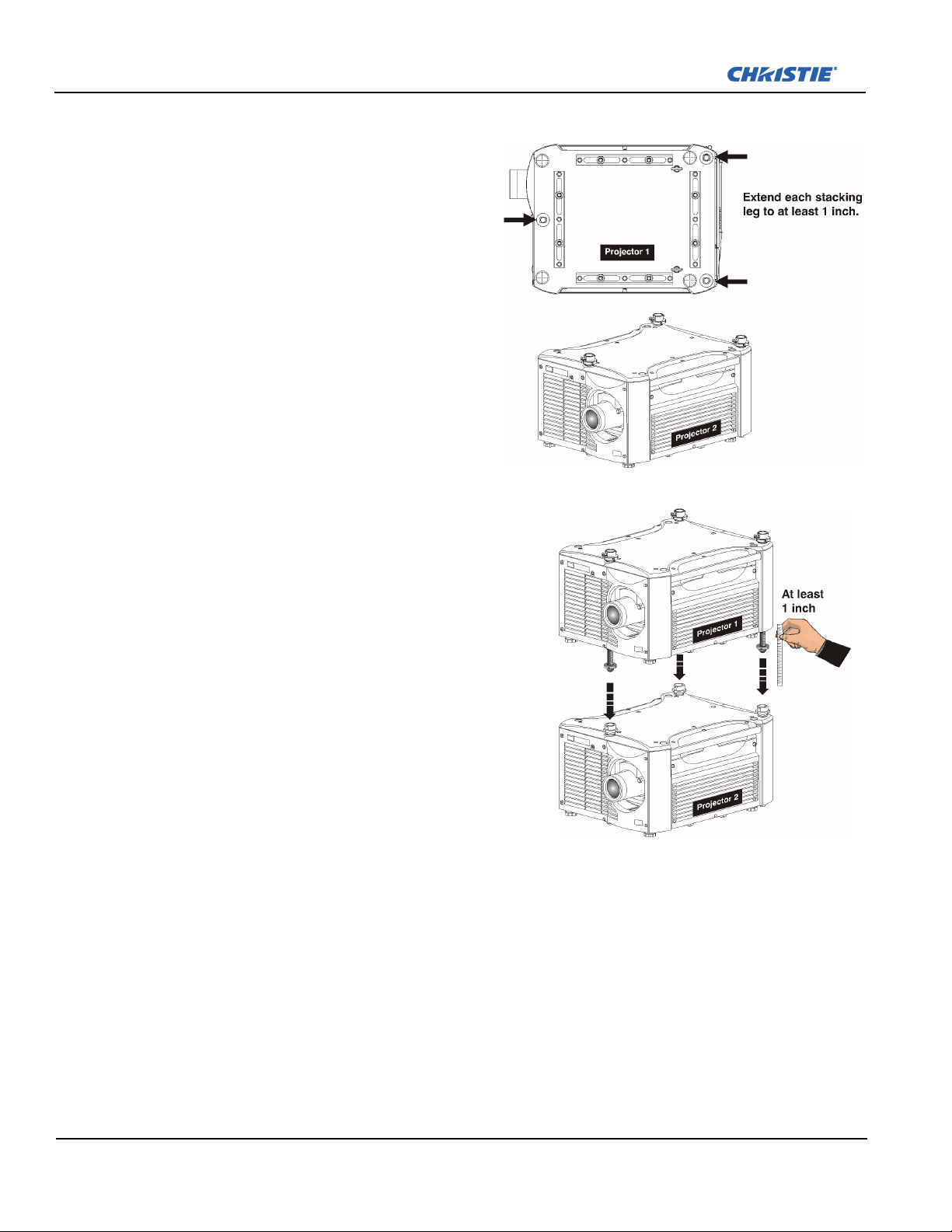

1. Position the projectors.

• Place each projector to be stacked on a secure

table or cart.

• Place 1 projector on its side to access its adjustable feet, and stacking legs (Figure 2-17).

• Orient the other projector in either upright or

inverted position as required (remember, each

projector in a stack must be in the same orientation).

2. Fully retract the 4 adjustable feet.

Fully retract each foot (4) as far as possible by

turning them clockwise.

• If upright, retract the feet on top projector.

• If inverted, retract the feet on bottom projector

3. Extend the 3 stacking legs.

Figure 2-17 Adjust the Feet

Extend the stacking legs (3) by turning them so that at

least 1 inch of thread is visible on each. This clearance

accommodates the up-or-down movement for aligning

the images from the stacked projectors. Ensure that you

extend all 3 legs equally (see Figure 2-18) so they are

level.

• If upright, extend legs on top projector (shown)

• If inverted, extend legs on bottom projector

IMPORTANT!

Extend the stacking legs equally by at least

1 inch.

Figure 2-18 Extend 3 Stacking Legs

(UPRIGHT STACK SHOWN)

2-14 J Series 2.0, 2.4, and 3.0kW User Manual

020-100707-01 Rev. 1 (10-2011)

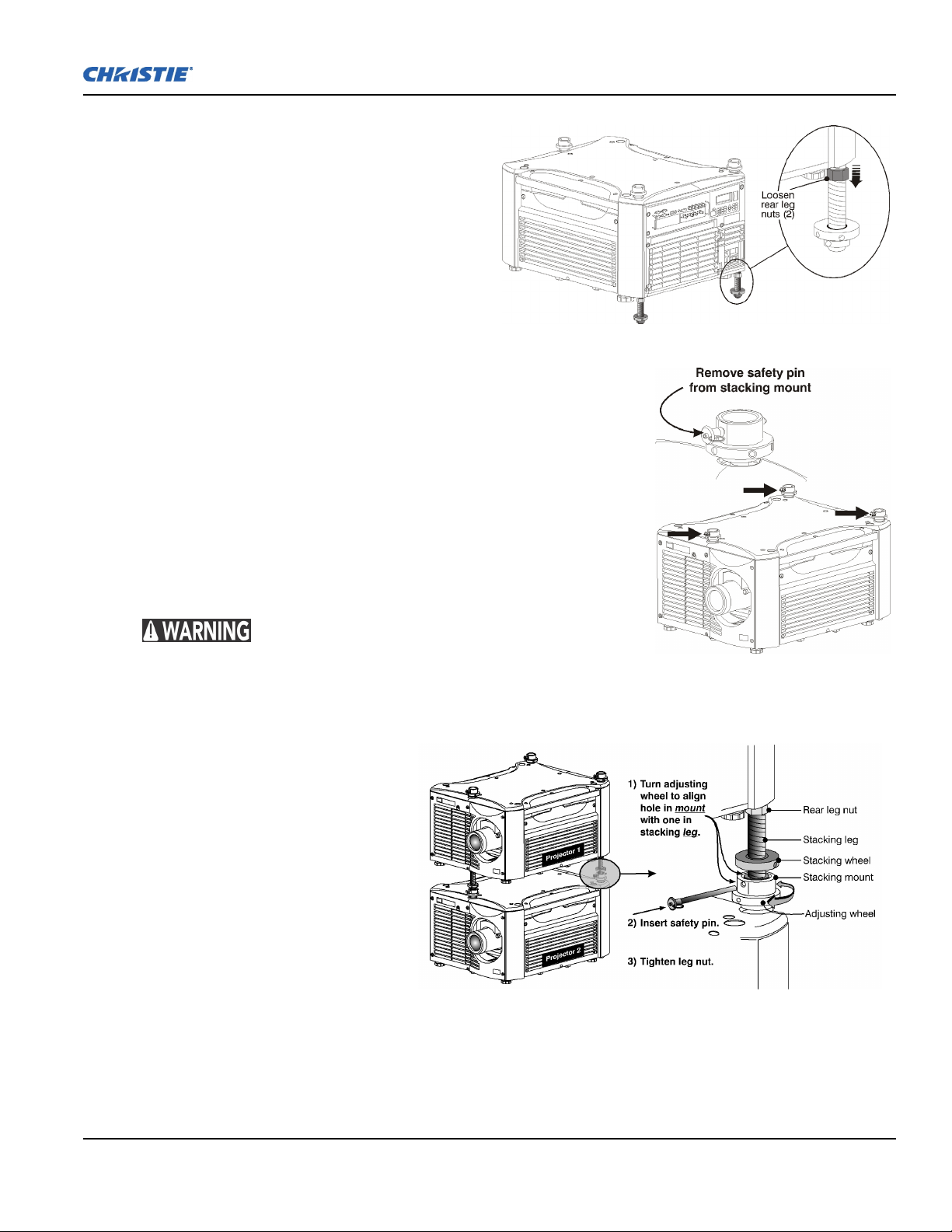

4. Loosen the rear stacking leg nuts

On the rear stacking legs (Figure 2-19), loosen

the nuts so the legs have some lateral

movement for easier alignment with the

stacking mounts on the other projector.

• If upright, release on top projector

• If inverted, release on bottom projector

5. Release and remove three safety pins.

The 3 safety pins must be removed from the stacking mounts so that

the stacking legs can fit into the mounts (Figure 2-20).

• If upright, remove the pins from the mounts on the bottom projector

• If inverted, remove the 3 safety pins from the mounts on the top

projector

6. Place top projector on bottom projector.

Section 2: Installation and Setup

Figure 2-19 Loosen 2 Nuts

With 1 person on each side, lift the top projector on to the bottom

projector, aligning all 3 stacking points between projectors. The legs

(4) should fit inside the stacking mounts.

Minimum of 2 people required.

7. Align the holes in the 3 stacking mounts and 3 stacking legs.

On each stacking mount, turn

the adjusting wheel slightly

until the hole in the top portion

of the mount lines up with the

hole in the stacking leg (Figure

2-21). NOTE: You can

increase leverage by using a

screwdriver in the holes.

Figure 2-21 Align Holes in Mounts and Legs, and LOCK with Pin

Figure 2-20 Remove Safety Pins

8. Insert 3 safety pins and LOCK all.

J Series 2.0, 2.4, and 3.0kW User Manual 2-15

020-100707-01 Rev. 1 (10-2011)

Section 2: Installation and Setup

Critical Safety Procedure.

At each of the 3 stacking points, insert the safety pin fully through the holes in the stacking mounts and

stacking legs (Figure 2-21). Ensure that each pin is fully inserted to engage the safety lock and secure the

projectors together. Failure to engage the safety lock could cause the projectors to separate and result in

injury or death.

Failure to engage the safety lock could cause the projectors to separate and result in injury or

death.

9. Leg Nuts.

Before hoisting, firmly tighten the nuts on the 2 rear stacking legs (Figure 2-21). If you are ready to align

the projectors to one another, leave these nuts slightly loose until after the alignment.

10. Repeat steps 1–9 if stacking a third projector.

Never stack more than 3 projectors.

2.2.5 Alignment Procedure

Stacked projectors must be correctly aligned to one another so that the resulting display is optimized and as

sharp as possible. If you are also hoisting the stack, hoist the stack into place first and then align. Lock all

stacking hardware into place to maintain your alignment.

IMPORTANT! Ensure the stacking legs are extended at least 1 inch and are slightly loosened. Refer to

Figure 2-18.

Before You Begin

• Always align to the fixed projector. In floor-mount or table-mount (i.e., non-hoisted) stacks, you will align to

the bottom projector as shown in drawings below. In hoisted stacks, align to the top projector.

• Leg nuts must be loosened before alignment; otherwise the stacking mounts will not turn and allow movement of the projector.

Alignment Procedure:

1. Position the first image (fixed projector).

Position the fixed projector (first) image as desired and align the other image(s) to it as described below.

2. Display the grid test pattern.

Display the Grid Test Pattern. To distinguish each image, enable “Red” for 1 display and “Green” for the

other. Refer to 3.7 Image Settings Menu if you need help enabling colors.

3. Adjust Focus.

Focus the images for both projectors.

4. Coarse Alignment.

Adjust the Zoom and Offset on the top projector to precisely move its test pattern display on to the bottom

test pattern. When properly aligned, all red/green grid lines in the combined image will turn yellow.

• If all lines are well aligned, skip to Step 6. b. to lock all stacking mounts.

• If alignment needs fine adjustment, proceed with the next step.

2-16 J Series 2.0, 2.4, and 3.0kW User Manual

020-100707-01 Rev. 1 (10-2011)

Loading...

Loading...