Page 1

Please store this instruction

manual in a designated place for

futur

e reference.

INST.No.TPL-02-5A

TP

TPTP

TP-LLLL0260

02600260

0260EN

ENEN

EN

Instruction Manual

CHINO

INSTRUCTION

S

Compact

Thermal Image Sensor

Page 2

Page 3

I

Custom Network Cable

(With a crossing cable and an RJ-45 terminal) 2.5m: 1 piece

* For direct connection to PC

(Refer to Page 6 for details.)

Custom Power/Alarm Output Cable

(With O-tip terminals) 2.5m: 1 piece

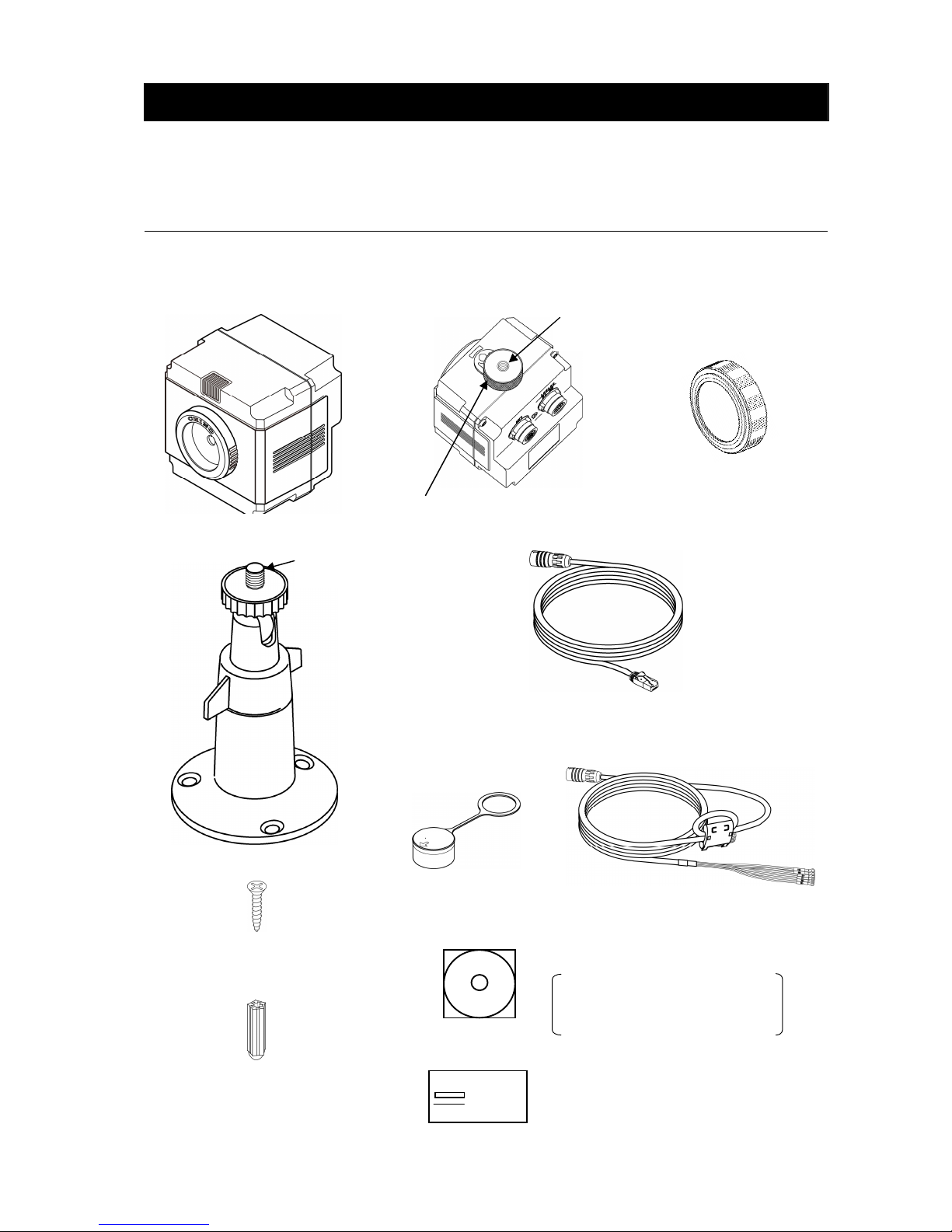

Introduction

Thank you for purchasing a compact thermal image sensor. In order to use this product

safely, please read this instruction manual completely before use and confirm the correct

handling and instructions. In addition, please retain this instruction manual for future

reference.

Before using

Please confirm the contents of packing. If something is missing, please contact to your nearest distributor.

.

Thermal image sensor

Carl plugs for mounting

the universal head

into concrete: 3 pieces

Connector cap: 1 piece

Lens cap: 1 piece

Universal head: 1 piece

Screws for the universal

head: 3 pieces

Mounting screw: 1 piece

This is attached to the sensor

Screw size

1/4-20UNC

Screw size

1/4-20UNC

CD-ROM: 1 piece

Application software

Instruction manuals (For the

sensor and the application

software

Quick manual: 1 sheet

Page 4

II

This product corresponds to Items 10 (2) and 10 (4) of Export allowable items listed in

Appendix No. 1 of the Export Trade Control Ordinance in Japan.

When this product is exported or brought out of Japan, the permission by the Japanese

government is required under this control ordinance.

About this instruction manual

Under absolutely no circumstances may the contents of this instruction manual, in part or

in whole, be transcribed or copied without permission.

The contents in this instruction manual are subject to change without notice in future.

The figures in this instruction manual may be emphasized, simplified or omitted.

Every effort has been made to ensure that the details of this manual are accurate.

However, should any errors be found or important information be omitted, please inform

your nearest distributor.

“Microsoft” and “Windows” are either trademarks or registered trademarks of Microsoft

Corporation, USA.

The company names and brand names used in this manual are the trademarks or

registered trademarks of respective companies.

About exemption from responsibility

Unless otherwise specified in the guarantee clauses, we do not offer any guarantee about

this product.

We shall not be liable to a customer or a third party for any damages or indirect damages

by using this product or by unpredictable defects of the product.

Page 5

III

Safety precautions

The safety precautions shown in this manual indicate the important contents about safety.

Please be sure to understand and follow these precautions.

In this manual, in order to use this product safely, the precautions are described with the

following indications and marks.

This indicates a potentially hazardous

situation that, if not avoided, will result in

death or serious injury.

This indicates a potentially hazardous

situation that, if not avoided, may result in

minor or moderate injury or cause property

damage.

[Safety precautions]

Do not operate this product in a place where flammable gas or explosive gas exists. It is

extreely dangerous to use this product under such environment.

In order to prevent an electric shock, make sure that the power source is turned off before

connecting any wiring.

● Stop using this product immediately, turn off the power source and contact to

your nearest distributor if it is broken or there is smoke/abnormal odor from this

product. Otherwise, it may cause fire.

● Do not repair or modify this product. If it is modified, operation of this product will not

be guaranteed. It may also cause fire/electric shock.

● Avoid the use of this product in the following places.

A place where ambient temperature varies widely

A place where humidity is high

A place where rain/water is splashed

A place where there are dusts like sand or dirt

A place where it is subjected to exposed in scorching heat or direct sunlight

A place where it s subjected to radiation

A place where strong electric circuit exists beside this product

A place where there is any inductive interference

A place where there is mechanical vibration/shock

● If this product is wired with wrong polarity, it may cause trouble or fire.

● Do not aim the sensor to a high temperature object like sun, or the imaging element

may be damaged and it may cause trouble on this product.

● In order to use this product safely, refer to "requirements" and handling methods

mentioned in this manual or it may cause damage or malfunction to this product or

cause damage also to other equipments.

● Optical components have special coating. Be careful that these parts become easily

dirty when they are dew-condensed. In addition, the infrared transmission is

deteriorated under the dew condensation and a clear image is not provided.

Warning

Caution

Warning

Caution

Page 6

IV

When you use accessories connected to this product, follow the instructions relating

toregarding the safety in this manual. If you do not follow these instructions, safety of this

product and the system will not be guaranteed.

Your extra consideration is required when this product is used in an application that may

subject to life threatening to human or property damage. Pay extra attention to safety

measures, avoid usage under extreme environment and build a fail-proof system.

Precautions for use

This product is a precision instrument. Do not drop it or make a strong impact on it.

Do not use it in water.

Keep this product away from equipments generating strong static electricity and

electromagnetic waves including TVs, microwave ovens and wireless applications, or it may

cause malfunction or trouble on this product.

Keep this product away from equipment generating strong high frequency or surge voltage,

or it may cause malfunction or trouble on this product.

Use neutral detergent for cleaning of this product and wipe it off lightly by rubbing with the

cloth squeezed firmly. Do not use chemicals or bleaches including benzene, thinner and

alcohol.

Do not use or place this product in a place subjected to temperature of lower than -10°C or

higher than 50°C, dew-condensation, or humidity of lower than 10%RH or higher than

80%RH.

Do not use or place this product in a place subjected to direct sunshine, dusty, high

temperature/high humidity or corrosive atmosphere.

When any service including repairs is required, contact to your nearest distributor.

Do not apply too much force on the custom power supply and Network cables. It may cause

damage of the connection which may lead water immersion into the product, and may cause

trouble on this product.

Page 7

【準備・設定編】 Contents

■ Introduction ......................................................... I

■ Safety precautions .............................................. III

■ Precautions for use ............................................ IV

■ Outline of product

1. Configuration........................................... 1

2. Features ............................................... 1

3. Functions ............................................. 1

4. Model/specification.................................. 1

5. Basic configuration ……………………… 2

■ Names and functions ........................................... 4

■ Connection .......................................................... 5

■ Installation ........................................................... 7

■ Operation ............................................................. 8

■ Monitor lamp ........................................................ 8

■ Operation mode...................................................... 8

1. Monitor mode........................................... 8

2. Capture mode ...................................... 8

■ Alarm output ........................................................ 9

■ About reset switch ................................................. 11

■ Specifications ...................................................... 12

■

Precautions (For maintaining measurement accuracy)

......... 14

■Troubleshooting ………........................................ 14

■ External dimensions

1. Thermal image sensor............................ 15

2. Universal head........................................ 15

3. Protective case....................................... 16

Page 8

1

Outline of product

1. Configuration

The system consists of the thermal image sensor utilizing a thermopile array detector and the

application software for displaying thermal images converted from the temperature data from the

sensor..

The application software allows to connect up to 4 thermal image sensors and display thermal

image from these sensors.

2. Features

Built-in thermopile array detector with approximately 2256 pixels. Each pixel can measure

temperature.

Low cost, compact size and lightweight (150g) fixed-mount type thermal image sensor

Robust and dust/splash-proof construction IP-65

Data transmission to a PC via Ethernet (LAN), Thermal image display by the application software

2 built-in circuits of non-voltage contact outputs. The sensor can be used as a fixed-mount type

alarm unit.

(When an alarm is activated, 1 image can be stored in the sensor.)

3. Functions

Alarm can be set from the application software or custom-made commands. The sensor provides

non-voltage contact outputs when the alarm condition is met.

Monitor mode (when the supplied application software is used)

The temperature data of the entire thermopile array can be obtained continuously from the PC.

Capture mode (when the supplied application software is not used)

The temperature data in a single row of the thermopile array can be obtained at a time by a

command from a master unit (e.g. PC or PLC).

When the capture mode is used, a series of communication command is required.

For the communication commands, contact to your nearest distributor.

4. Model/specification

TP-L

□□ □□ □ □

Pixels 02: 2256

View angle 60: 60°

Output E: Alarm + LAN

Specification N: Standard specifications

Page 9

2

DC power supply

(DC12V 1.5A)

5. Basic configuration

5-1. Connection with 1 Thermal Image Sensor to PC (Monitor mode)

5-2. Connection of multiple Thermal Image Sensors (Example: 2 units)

Supplied custom Network cable (Crossing cable)

Custom power/alarm output cable

Power voltage: 12/24VDC

(Min. 9 ~ Max. 30VDC)

(Refer to Page 12 for details.)

PC

Alarm setup or

monitor with the

PC

Alarm contact

outputs from the

thermal image

sensor

LAN

Contact output

* If a HUB without automatic crossing/straight converting function is used, a straight

cable is needed. Connect a crossing/straight converting connector between the custom

Network cable and a HUB. (Refer to Page 3.)

Alarm setup or

monitor with the

PC

Alarm contact outputs

from the thermal

image sensor

Alarm contact outputs

from the thermal

image sensor

Thermal image sensor

PC

Thermal image sensor

DC power supply

(DC12V 1.5A)

DC power supply

(DC12V 1.5A)

Contact output

Contact output

LAN

LAN

HUB (*)

Monitor mode (when the supplied application software is used)

The temperature data of entire thermopile array can be obtained from the PC.

Thermal image sensor

Page 10

3

DC power supply

(DC12V 1.5A)

Connection example of HUB (without automatic crossing/straight converting function)

5-3. Stand alone usage of the thermal image sensor

5-4. Connection to PLC (Capture mode)

When the capture mode is used, a series of communication commands are required.

For the communication commands, contact to your nearest distributor.

Custom Network cable (Crossing cable)

HUB

Crossing/straight converting connector

LAN cable (Straight cable)

PC

Alarm contact output

from the thermal

image sensor

For image confirmation and alarm settings only

LAN

Contact output

Contact output

Other alarming devices

PLC

Capture mode (

when the supplied CHINO application software is not used)

The temperature data in a single row of the thermopile array can be obtained

at a time

by a command from a master unit (

e.g. PC or

PLC

).

LAN

DC power supply

(DC12V 1.5A)

Page 11

4

(7)

Names and functions

(1) Monitor lamp

(2) Lens

(4) (5)

Power/alarm output LAN connector

connector

(3) Mounting screw (6) Reset switch

(Behind the screw)

No Name Function

(1) Monitor lamp

The state of alarm and the condition of the sensor is indicated

with colors of blue, red and purple. (Refer to Page 8.)

(2) Lens

For forming image of radiation energy from a measurement

object on the detecting element

(3) Mounting screw For mounting the sensor on a tripod (1/4-20UNC)

(4)

Power/alarm output

connector

For connecting custom power/alarm output cable

(5) I/F connector For connection of custom Network cable

(6) Reset switch

To initialize the sensor to factory default (The switch is located

behind the mounting screw.) (Refer to Page 11 for details.)

(7) Mfg nameplate Serial No., MAC address, etc. are shown.

Page 12

5

[] mark

Connection

● Connect the custom power/alarm output cable and the custom Network cable to this product.

Connect them to align the marks of [] back of this product and [Arrow] on the cable connectors.

To avoid misconnections, the custom Network cable is designed not to connect to the

power/alarm output connector of this product. Similarly, the custom power/alarm output cable

cannot be connected to the LAN connector of this product.

The connections are a quick-disconnect locking type. Insert the plug until it clicks.

To unplug, hold the sliding part (that has the [Arrow] marking on) and pull it outward.

If the “A” part is pulled, and the plug may be damaged.

.

● Plug the connector of the custom Network cable to the Ethernet port of a master unit (PC, etc.)

and connect the O-tip terminals of the custom power/alarm output cable to the terminal block

of

12VDC Power Supply.

Custom Network

cable LAN connector

Custom power/alarm output

cable ring terminals

Insulate the O-tip alarm output

terminals if not used.

[Arrow] mark

LAN port

Terminal block

Plug

A

Page 13

6

[Alarm 1, w/ AC current] [Alarm 1, w/ DC current]

(AC)

(Relay)

(DC)

(Relay)

Connector cap

[Details of custom power/alarm output cable] O-tip terminal 0.5-3.5

Power +

Power -

Alarm 1 +

Alarm 1 -

Alarm 2 +

Alarm 2 -

[Example of contact output circuit]

Use the contact output with a protection device (e.g. fuse) for preventing malfunction.

Max. output load voltage 400V (Peak AC)

Max. continuous load current 0.1A (Peak AC)

Peak load current 240mA (100ms/1 shot)

Output capacity (Per 1 contact)

Max. output loss 300mW

● If the custom Network cable is not used (When using the thermal image sensor stand alone)

Cover the supplied connector cap to the connector marked with [LAN] back of this product.

If you don’t cover the connector with the cap, the waterproofing performance cannot be

satisfied. (It may cause water immersion.)

Red

P +

Black

AL1 +

Orange

AL1 -

Pink

AL2 +

Bright

green

AL2 -

Blue

P -

AL1 +

AL1 -

AL1 +

AL1 -

Power

Power

Page 14

7

Installation

By referring the figure below, install the thermal image sensor at the measuring distance that a

measuring object can be imaged at the center of screen as large as possible.

<Relation between a measuring surface and a measuring distance>

D (View width) = 1.4 × L (Measuring distance)

For accurate measurements, 8 x 8 pixels or more for a target is recomended.

1.4m

Do not install the sensor where subjected to vibration/shock or inductive ambient.

1m

3m

5m

29mm

4.2m

88mm

146mm

7.0m

: View per pixel

Page 15

8

Operation

● Install the supplied application software to your personal computer.

(For the details, refer to the instruction manual for the application software.)

● For more accurate measurements, wait 30 minutes after power-on until this product is stabilized.

● Use this product with noiseless and stable power source.

Monitor lamp

The state of product is indicated by 3 colors on the LED indicator; blue, purple and red.

Item Color Specification

Mode is not set (Factory Default) Blue Lit once for 3 seconds

Alarm values are not set Blue Lit once for 3 seconds

Alarm being monitored Blue Lit continuously

Set to Captured Mode Purple Lit continuously

Reboot is required after all settings have

completed

Purple

Lit for 3 seconds twice

Alarm is activated Red Lit continuously

Abnormal internal memory Red

Lit once for 3 seconds

* Refer to Page 14 Troubleshooting.

Abnormal

State

Abnormal internal temperature Red

Lit once for 3 seconds

* Refer to Page 14 Troubleshooting.

Operation mode

1. Monitor mode: When CHINO application software is used

The temperature data is sent continuously to a master unit (e.g. PC) by a command from the

software.(The frame rate of the thermal image on the software is 3fps without any Alarm activated.)

The alarm set on the sensor can provide a non-voltage contact output while sending the

temperature data.(The frame rate goes down to 1fps or less with the alarm set on the sensor.)

2. Capture mode: Without CHINO application software

The temperature data in a single row of the thermopile array can be obtained at a time by a

command from a master unit.

When Capture mode is used, a series of communication commands are required.

For the communication commands, contact to your nearest distributor.

Page 16

9

Alarm output

1. Specifications

Item Specification

Alarm area 1 area

Alarm set value 2 values in a specified area

Setting resolution 1 degree (°C/ºF)

Alarm activation condition

When consecutive 4 frames have satisfied the alarm

condition

Alarm reset condition

When the measured temperature returns from the

alarm set value in 4 images continuously

Output Control Auto Alarm Reset/Manual Alarm Reset

Resetting condition of alarm

output manual reset

Rebooting of the thermal image sensor

Command from a PC

Alarm Output Non-voltage contact output

Number of outputs 2 points [Alarm name: AL1 (alarm 1), AL2 (alarm 2)]

Output logic Output logic selectable (N.O/N.C)

Alarm condition Selectable (high-limit, low-limit)

Alarm condition when power is off Opened

2. Image storage

The image data can be stored when alarm is activated.

Item Content

Number of storage

1 image

An image can be stored by AL1 or AL2 (to be

specified).

Storage medium Built-in EEPROM

Storage data Temperature data (without time stamp)

Storage timing

Every time when the alarm is activated/when the first

alarm is activated only

Selectable by a PC (Refer to Page 10.)

Reading of stored data Can be retrieved from a PC

Erasing of stored data

Automatic erasing or erasing by a command with the

alarm setting from a PC

Page 17

10

警報有

警報有警報有

警報有 警報無

警報無警報無

警報無

警報状態

警報状態警報状態

警報状態

警報出力

警報出力警報出力

警報出力

警報出力

警報出力警報出力

警報出力

画像保存

画像保存画像保存

画像保存

画像保存

画像保存画像保存

画像保存

警報状態

警報状態警報状態

警報状態がががが連続

連続連続

連続でででで発生

発生発生

発生した

したした

した場合

場合場合

場合はははは、、、、発発発発

生時

生時生時

生時のののの最初

最初最初

最初のののの画像

画像画像

画像をををを保存

保存保存

保存する

するする

する

画像上書

画像上書画像上書

画像上書きききき

警報有

警報有警報有

警報有

熱画像

熱画像熱画像

熱画像センサ

センサセンサ

センサのののの電源再投入

電源再投入電源再投入

電源再投入又又又又はははは上上上上

位位位位機器

機器機器

機器からの

からのからの

からのコマンド

コマンドコマンド

コマンドまで

までまで

まで受信

受信受信

受信まで

までまで

まで

保持

保持保持

保持する

するする

する

自動復帰

自動復帰自動復帰

自動復帰

保持

保持保持

保持

● Alarm output and storing image

熱画像

熱画像熱画像

熱画像センサ

センサセンサ

センサのののの電源再投入又

電源再投入又電源再投入又

電源再投入又はははは

アプリケーションソフト

アプリケーションソフトアプリケーションソフト

アプリケーションソフトからの

からのからの

からの

警報解除

警報解除警報解除

警報解除まで

までまで

まで保持

保持保持

保持する

するする

する

Alarm state

Auto Reset

Contact output

Image saving

ON

OFF

ON

Image is overwritten.

Manual Reset

Contact output

Image saving

The image is saved only at the time

of when alarming state turns from

Off to On.

Contact output state will be held until

the sensor restarts or you reset the

alarm by clicking [Alarm Reset] button

in Alarm Setup Window.

Page 18

11

Reset

switch

Reset switch

(behind the screw)

Remove the mounting

■ About reset switch

In case of an error, etc. at the LAN environment settings, the set values can be reset to the default

values as shipped from factory by removing the mounting screw and then pushing the reset switch.

Turn the power on while pushing the reset switch for 1 second continuously. Resetting to the

default values becomes effective (The violet monitor lamp flashes 2 times.) By re-power-on,

the set values are reset to the default values at the shipment from factory. Usually do not push

the reset switch.

[Factory Default settings]

Items Specifications

IP address 192.168.1.254

Subnet mask 255.255.255.0

Gateway address 0.0.0.0 (Invalidation)

Sensor number 1

UDP port address 50828 (fixed) *1

Emissivity 1.00 (all pixels)

Alarm setting Alarm invalid

*1

If you use UDP port on your PC and the UDP port address that you are using is

overlapping with this address, change the UDP address that you are using

.

[MEMO]

Page 19

12

■ Specifications

Items Specifications

Detecting element Thermopile array with 48 x 47 pixels

Measurement wavelength Center wavelength 10µm

Measurement view angle 60° x 60°

Temperature measurement

range

-20°C to 300°C

Temperature resolution 0.5°C (at 100°C black body)

Accuracy ratings

±2% of measured value or ±3

°C, whichever is greater

(Ambient temperature 25 ± 2

°C)

Focus Fixed focus

Flame rate 3fps (1fps or slower if alarm function is enabled)

Emissivity correction 0.10 ~ 1.00 (0.01 increment)

Radius resolution 21.8mrad

Working temperature range -10°C to 50°C

Working humidity range 10 to 80%RH (no dew condensation)

Storage temperature range -20°C to 60°C

Housing

IP65 (with custom

cable connection or connector cap, and

mounting screw mounted)

External dimensions W62 x H62 x D59 (mounting screw not included)

Weight About 150g (sensor unit)

Material

Polycarbonate Resin Color: Black

Conforming standard

Influence within 3% of measurement range under the

environment of CE (EN61326-1/Class B)

mounting screw size 1/4-20UNC

Power supply 12 to 24VDC (Min. 9 to Max. 30VDC)

Current consumption *1 Max. 2.5VA at 12VDC

Inrush current *1

Max. 1A at 12VDC

(When power supply S8VM-01512 made in Omron is

used)

Connection Custom-connector connection

Connector name [DC IN/IN/OUT]

*1

The inrush current should be considered for the selection of power source.

Thermal image specifications

General specifications

Power specifications

Page 20

13

Items Specifications

Number of contact output 2 Outputs

Kind of contact No-voltage contact output

Cable terminal names AL1, AL2

Max. output load voltage 400V (Peak AC)

Max. continuous load current 0.1A (Peak AC)

Peak load current 240mA (100ms/1 shot)

Contact Rating (per

contact)

Max. output loss 300mW

Connection Custom-connector connection

Connector name [DC IN/IN/OUT]

Interface standard 10BASE-T/100BASE-TX

Data/Protocol

Data communication by UDP

Measured temperature data → To a master unit (PC, etc.)

Setting data ← From a master unit (PC, etc.)

Setting data IP address/alarm setting information, etc.

DHCP

Not supported

Thermal image sensor IP

address

192.168.1.254 (default at shipment)

Thermal image sensor

subnet mask

255.255.255.0

Default gateway 0 or FFFF (Not set)

Connection Custom-connector connection

Connector name [I/F]

■ Accessory (sold separately)

Protective case: Model: TP-ZCC1 (Refer to Extrernal Dimension.)

■ Minimum requirements for the CHINO application software

Compatible PC: DOS/V computers with PC/AT compatible

* The LAN port is required.

* Display resolution: 800 x 600 pixels or more recommended

* .NET Framework 2.0 or later has been installed and runs correctly.

Compatible OS: Windows 2000 (SP4 or later)/XP/Vista

* Windows XP or later recommended

* .NET Framework 2.0 or later required

Contact output specifications

Ethernet specifications

Page 21

14

Precautions (For maintaining measurement accuracy)

Pay attention to the followings for maintaining the measurement accuracy.

Vibration and shock

Vibration and shock causes not only a damage to the thermal image sensor in a long term but in

stability of the measurement. When vibration is present, anti-vibration/shock absorber may be

required between the thermal image sensor and a mounting plate or between the mounting

bracket and a mounting plate.

Inductive condition

The thermal image sensor is designed to be inductivity-resistant. However, it is recommended to

keep the sensor from induction heaters or power lines as much as possible.

IR energy path between measuring targets and the sensor

Avoid places where water drops, dusts, smoke, steam, etc. can be present between the thermal

image sensor and a measurement surface. If it is impossible to avoid such places, consider

utilizing an air purge system or equivalent system. The optional protective case is recommended.

Disturbances causing higher temperature indication

Avoid places where high temperature heat source such as sunlight, light/flame of incandescent

electric lamps is not reflecting on a measurement surface and the thermal image sensor. If such

condition is present, cover the area with an opaque object.

■ Troubleshooting

If you are experiencing difficulties with the sensor or noticing an abnormality on its operation, refer

to the followings. If the difficulties or abnormality is still present, contact to your nearest distributor.

Symptoms Causes Measures

The custom power cable is

not connected properly.

Connect the custom power cable

properly.

Indicator lamp is

not lit

The power for equipment is

not turned on.

Turn the power for the equipment.

The custom Network cable is

not connected correctly.

Connect the custom Network cable

properly.

The application software is

not installed.

Install the software.

Refer to the instruction manual for the

application software.

No

Communications

The IP address has not been

set.

Refer to the instruction manual for the

application software.

Image/temperature

value abnormally

fluctuates.

Strong statistic electricity,

electromagnetic wave or high

frequency may be present

around the sensor.

Keep this product away from an

equipment generating strong static

electricity or electromagnetic wave.

Indicator lamp

is

red

Alarm is activated (Not

abnormal)

Automatic reset: Resets automatically.

Manual reset: Resets by re-boot or a

command from a master unit (PC,

etc.).

Indicator lamp

flashes red once

Internal memory abnormality Contact to your nearest distributor.

Indicator lamp

flashings red twice

Internal temperature

abnormality

Use this product within its operating

temperature range.

Contact to your nearest dirtributor.

Page 22

15

φφφφ58

5858

58

■External dimensions

1. Thermal image sensor

2. Universal head

When the thermal image sensor is installed with the universal head, mount the mounting bracket

with 3 pieces of screws through the 3 holes on the bracket. If the universal head needs to be

mounted on concrete surface, drill holes with 6.5mmø and 25mm depth on the concrete and push

the Carl plugs into the holes, and then mount the universal head.

Carl plugs

For mounting on

concrete

(The plugs are not

used for usual

installation.)

Screw size

1/4-20UNC

Page 23

16

3. Accessory

Protective case: Model TP-ZCC1

Hole for air purge (PT1/8)

Loading...

Loading...