Page 1

mounting

INST.No.TPL-02-7A

TP

TP----LLLL02

TPTP

Thermal Image Sensor Quick Manual

Introduction

Thank you for purchasing a compact thermal image

sensor. This quick manual explains basic steps of easy

operation and its settings. Please see the manual

provided in the installation CD for detail explanation of

each function on this product.

02**

**EN

EN series Compact

0202

****

series Compact

ENEN

series Compact series Compact

Quick Manual

Quick ManualQuick Manual

Before using

Please confirm the contents of packing. If something is

missing, please contact your nearest distributor.

Names Quantity

Thermal Image Sensor

Custom power/alarm output cable

Custom Network cable

Universal head

Lens cap

Connector cap

Mounting screw 1

Application software(CD)

Instruction manuals

(Sensor and Application software)(CD)

Quick manual (This manual) 1

Adobe Reader is required to read the manual included in the

installation CD.

Safety precautions

The safety precautions shown in this manual indicate the

important contents about safety. Please be sure to

understand and follow these precautions.

In this manual, in order to use this product safely,

precautions are described with the following indications and

marks.

Warning

Caution

Do not operate this product in a place where flammable gas

or explosive gas exists. It is extremely dangerous to use this

product under such environment.

In order to prevent an electric shock, make sure that the

power source is turned off before connecting any wiring.

● Stop using this product immediately, turn off the power source

and contact to your nearest distributor if it is broken or there is

smoke/abnormal odor from this product. Otherwise, it may cause

fire.

● Do not repair or modify this product. If it is modified,operation

of this product will not be guaranteed. It may also cause

fire/electric shock.

This indicates a potentially hazardous situation

that, if not avoided, will result in death or

serious injury.

This indicates a potentially hazardous situation

that, if not avoided, may result in minor or

moderate injury or cause property damage.

[Safety precautions]

Warning

1

1

1

1

1

1

1

Caution

● Avoid the use of this product in the following places.

A place where ambient temperature varies widely

A place where humidity is high

A place where rain/water is splashed

A place where there are dusts like sand or dirt

A place where it is subjected to exposed in scorching heat or

direct sunlight

A place where it s subjected to radiation

A place where strong electric circuit exists beside this product

A place where there is any inductive interference

A place where there is mechanical vibration/shock

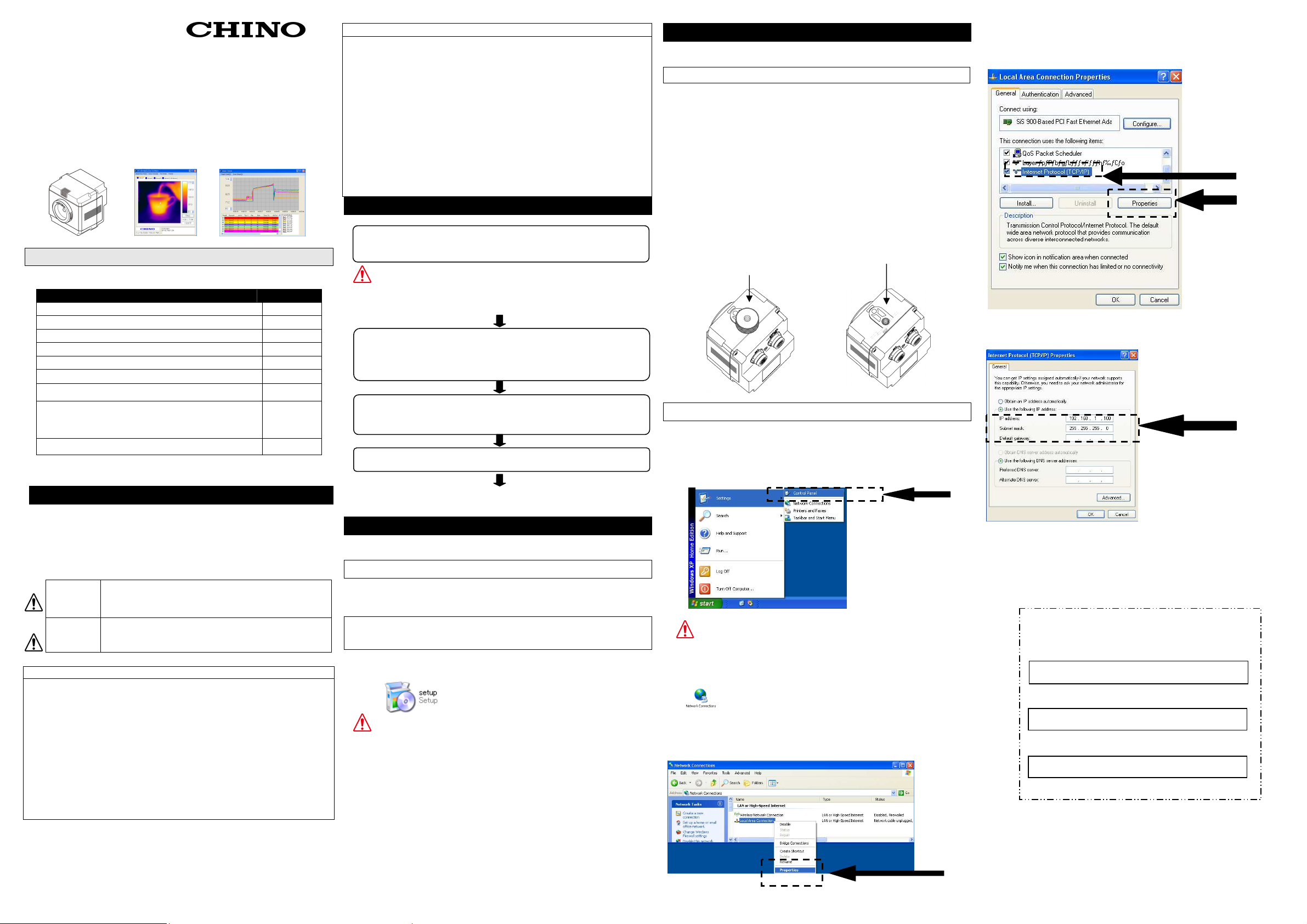

Preparation before using

Installation of this application software to your PC

In order to communicate with the sensor(s), you need to

set IP Address in your PC.

If PC has already been connected to the network,

remove it from the network.

Application software installation

Connection of the thermal image sensor and the PC with

swupplied custom Network cable one to one

Thermal image sensor LAN setting

Running of the application software for initial settings

Application software activation

Application software initial settings

Ready to use

Installation of application software

The following is the installation procedure of the application

software.

(The procedure is for Windows XP.)

1. Start your PC and launch Windows.

Before this application software is installed, close all other

applications that are running. If not, the installation may be

affected from them.

2. Insert the CD with the CHINO application

software.

Setup Wizard should start automatically, if not, double-click

the setup program in the CD to start.

When the OS of your PC is Windows2000, Update

Rollup 1 for SP4 and Internet Explorer (IE) 5.01 or later

are required.

LAN settings of thermal image sensor

When the sensor is used first time, the LAN setting of the

sensor is required.

1. Initialization of thermal image sensor

As received from factory, no initialization is required since all

settings have been initialized.

In case of an error, etc. at the LAN environment settings, the

set values can be reset to the default values as shipped from

factory by removing the mounting screw and then pushing

the reset switch.

Turn the power on while pushing the initial switch for 1

second continuously. Resetting to the default values

becomes effective (The violet monitor lamp flashes 2 times.)

By re-power-on, the set values are reset to the default

values at the shipment from factory. Usually do not push the

initial switch.

Remove the

screw.

Reset switch (behind the screw)

2. PC settings

According to the following procedure, you will need to

change the IP Address of your TCP/IP connection.

Start the PC.

Select [Control Panel] from Start in the menu.

The PC that you’re using now disconnected

from the network.

Take a note of the IP address, etc. and also

consult with your network administrator.

Select [Network Connections].

Select the icon of the LAN network connection (Local area

connection here) and right-click it to open a submenu. Select

Properties in the menu.

Select [Internet Protocol (TCP/IP) in the list of [This

connection uses the following items.] of [General] tab and

click [Properties].

Check [Use the following IP address:] and set the IP address,

subnet mask and default gateway.

Assign an IP address not to conflict with other instruments.

Set the following, [IP address: 192.168.1.100, Subnet mask:

255.255.255.0, Default gateway: Blank] are set. By clocking

[OK], the IP settings are entered.

[Current memorandum]

IP address

Subnet mask

Default gateway

Page 2

Iron Rainbo

w

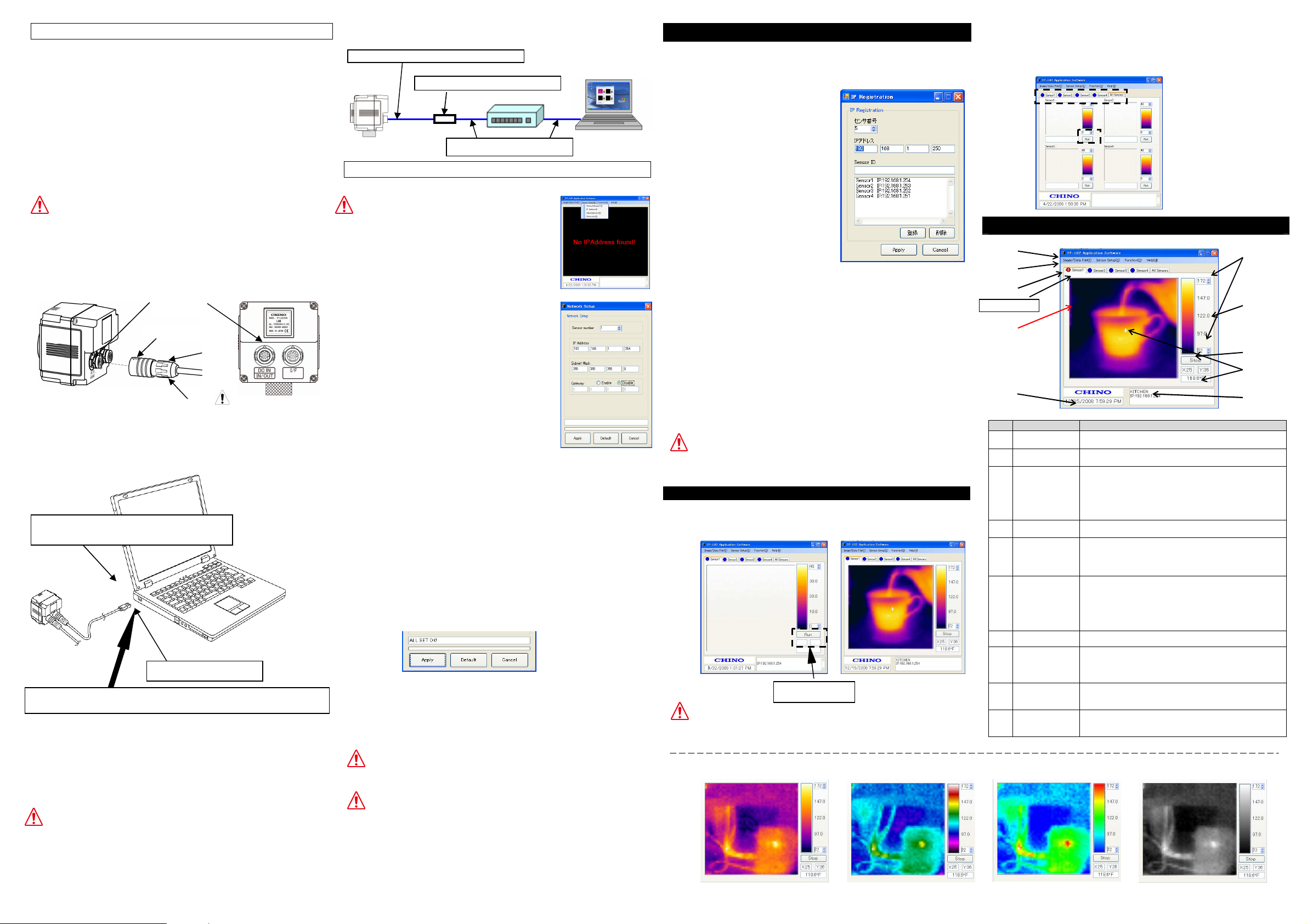

3.Connection of thermal image sensor and PC

Connect the thermal image sensor

directly to

the PC by

④ ⑤

⑧ ⑨

HUB

Connect the custom power/alarm output cable and the

custom Network cable to the sensor.

Connect them to align the marks of [] back of the

sensor and [Arrow] on the cable connectors.

To avoid misconnections, the custom Netowrk cable is

designed not to connect to the power/alarm output

connector of the sensor. Similarly, the exclusive

power/alarm output cable cannot be connected to the

LAN connector of the sensor.

The connections are a quick-disconnect locking type.

Insert the plug until it clicks.

To unplug, hold the sliding part (that has the

[Arrow] marking on) and pull it outward.

If the “A” part is pulled, the plugs may be damaged.

Plug the connector of the custom Network cable to the

Ethernet port of a master unit (PC, etc.). And connect

the O-tip terminals of the custom power/alarm output

cable to the terminal block

Custom Network cable LAN connector

Make sure to connect the thermal image sensor to the

PC directly for LAN settings. When other instruments (in

cluding other thermal image sensors) are connected via

a hub, etc., remove them from the network to configure

so that one set of the thermal image sensor is only

connected to the PC on the network.

If the LAN settings are performed when multiple thermal

image sensors have been connected on the

not connecting

may not be configured correctly.

[] mark

[Arrow] mark

A

Plug

of 12VDC Power Supply.

LAN port

supplied cable.

the settings of thermal imaging sensor

network,

◆

Connection example of HUB (when a HUB without

automatic crossing/straight converting function is used)

Custom Network cable (Crossing cable)

Crossing/straight converting connector

PC

LAN cable (Straight cable)

4.LAN settings of thermal image sensor

Start this application software.

A warning by security software may

appear at the initial startup. Set it

up to allow the communication via this

application software

Select [Sensor Setup]

→ [Network(Sensor)] in the menu.

The following screen will appear.

Enter information into the following set

ting items.

●Sensor number

A Numbers to be assigned to each

sensor

Enter the numbers from 1 to 4.

When one sensor is only used, enter 1.

When multiple sensors are used, assign

the numbers from 1 to 4 not to overlap

each other.

●IP address

IP addresses to be allocated to sensors. Assign a unique IP

Address to the sensor(s) not to conflict with other

instruments.

●Subnet mask

Data to specify the address of network from the IP address.

Enter an arbitrary subnet mask.

●Gateway

IP address of a relaying unit in case that there is not the

designation IP address on the subnet.

When the gateway is not used, select [Disable].

After entering addresses, click [Apply].

When the transmission is completed properly, [ALL SET

OK!] is displayed on the message box.

If the data is not transmitted, confirm the connection of

network, etc. and click [Apply] button again.

By the above procedure, the LAN settings of the thermal

image sensor are completed.

Please reboot the sensor because when LED

indicator of the sensor blinks twice in purple.

When multiple thermal image sensors are used,

perform the same settings for each thermal image

sensor. In case of multiple sensors being used,

perform the LAN settings of each sensor connected to

the PC separately.

.

Initial settings of application software

These steps described here will register the sensor to be

connected

to the application software.

Select [Sensor Setup] → [IP Address] in the menu.

The following screen will appear.

Enter the following items.

●Checkboxes for Sensor 1 to

Sensor 4

Check () the checkboxes of the

sensor numbers that you want to

communicate with.

For example, when 2 thermal

image sensors are used and “1”

and “2” are allocated to these

sensors in the LAN setting of the

sensors, check () the [Sensor

1] check box and [Sensor 2]

checkbox.

●IP address

Enter the IP addresses assigned to each sensor with

the Network settings procedure.

●Sensor ID

You can give each sensor a name here.

For example, you can use location names such as furnace-1,

furnace-2, etc.

After the above items are entered, click [Apply].

By the above procedure, the initial settings of the application

software are completed.

■Displaying of thermal image

◆Color pallet

When the LAN settings of the sensors are changed,

change these settings as well, otherwise

, image and data will not be displayed correctly.

Start Application Software and he following screen will

appear. Click [Run] button on the screen.

When the IP registration to the application software

is not completed yet, the message of [No IP

Address found] will appear. Complete the

registration of IP.

[RUN] button

[When multiple sensors are connected]

When multiple sensors are connected, click the tab of the

sensor number you want to display and then perform the

above [1] and [2].

■Screen configuration and explanation

①

⑩

②

Origin (0,0)

③

No

Main Menu

①

②

Thermal Image

③

Current Time The current time of the PC is displayed.

④

Temperature

⑤

Color Palette

⑥

⑦

Temperature

Value and

⑧

Coordinate of

⑨

Indicator for

Alarm from

⑩

名 称 説 明

Bar

Sensor Tabs For selecting the sensor to be displayed

Screen

Scale

Run/Stop Run/Stop for communication.

the pixel

Sensor ID

Sensor

Gradation

Various functions offered by this application software

can be selected.

Display a 2-dimensional thermal image based on

temperature from each pixel in a 48x47 array. The frame

rate of the display is 3fps.

The coordinates of pixels displaying temperature

values are (X=0, Y=0) as the origin at the top-left

and (X=47, Y=46) at the bottom-right.

Maximum and minimum values of the temperature

scale being displayed currently. To change values,

click the Up/Down arrows mark or enter values from

the keyboard after clicking the box.

The temperature of temperature scale is displayed by

256 colors. By clicking the color palette, the

displaying color pattern of thermal image can be

changed. The default is the iron. The display pattern

can be selected from 4 kinds of iron, rainbow,

gradation and gray.

The coordinate and temperature value selected by

the sensor are displayed.

The name and IP address of the sensor displaying

the thermal image are indicated. (Enter the

sensor name in the sensor IP registration screen.)

The red/yellow colors are flashed when the alarm set

on the sensor(s) is activated. (The alarms are

displayed at the upper side of the tab of sensor.)

Gray Scale

⑥

⑦

Loading...

Loading...