Page 1

INST.No.INE-364

LE5100

Hybrid Recorder

LE5200

Operation Type Intelligent Recorder

【I. Instruction Manual】

Page 2

Page 3

◆Introduction/Request, Warranty Period, and Notices

p

Thank you for your purchase of LE5 series hybrid recorder having a 250mm recording width.

Please read this instruction manual without fail for correctly and safely operating this unit and

also

Separate instruction manual

This manual covers the operation of standard specifications and connection methods of a part of options.

For operating each option, please read their instruction manuals together with this manual.

Request

reventing troubles in advance.

1. To instrumentation, installation, and sales contractors

Be sure to pass this instruction manual to the user who uses this unit.

2. To the user

This instruction manual is also necessary for maintenance. Keep this manual

carefully until the unit is discarded.

Notice

1. No part of this manual can be copied or reproduced in any form.

2. Alteration of the description contents in this manual is reserved without notice.

3. For the contents of this manual, we make assurance doubly sure. However, if a doubtful

point, an error, and/or a description failure should have found, please inform your nearest

branch or sales office.

4. You are requested to understand that we are not responsible for any operation results.

Warning

Perchlorate Material

This instrument uses battery with Perchlorate Material.

Special handling may apply, see

http://www.dtsc.ca.gov/hazardouswaste/perchlorate

Page 4

Cautions for safe use

Observe the following cautions for using this unit safely.

1. Mounting place and terminal cover

①Panel mount type

This unit is designed to be mounted on an indoor instrumentation panel. For using this unit, mount it on the

panel without fail. Take an electric shock preventive measure so that the user cannot directly touch any

power supply or input/output terminals.

Portable type

②

Mount an electric shock preventive cover to the terminal block.

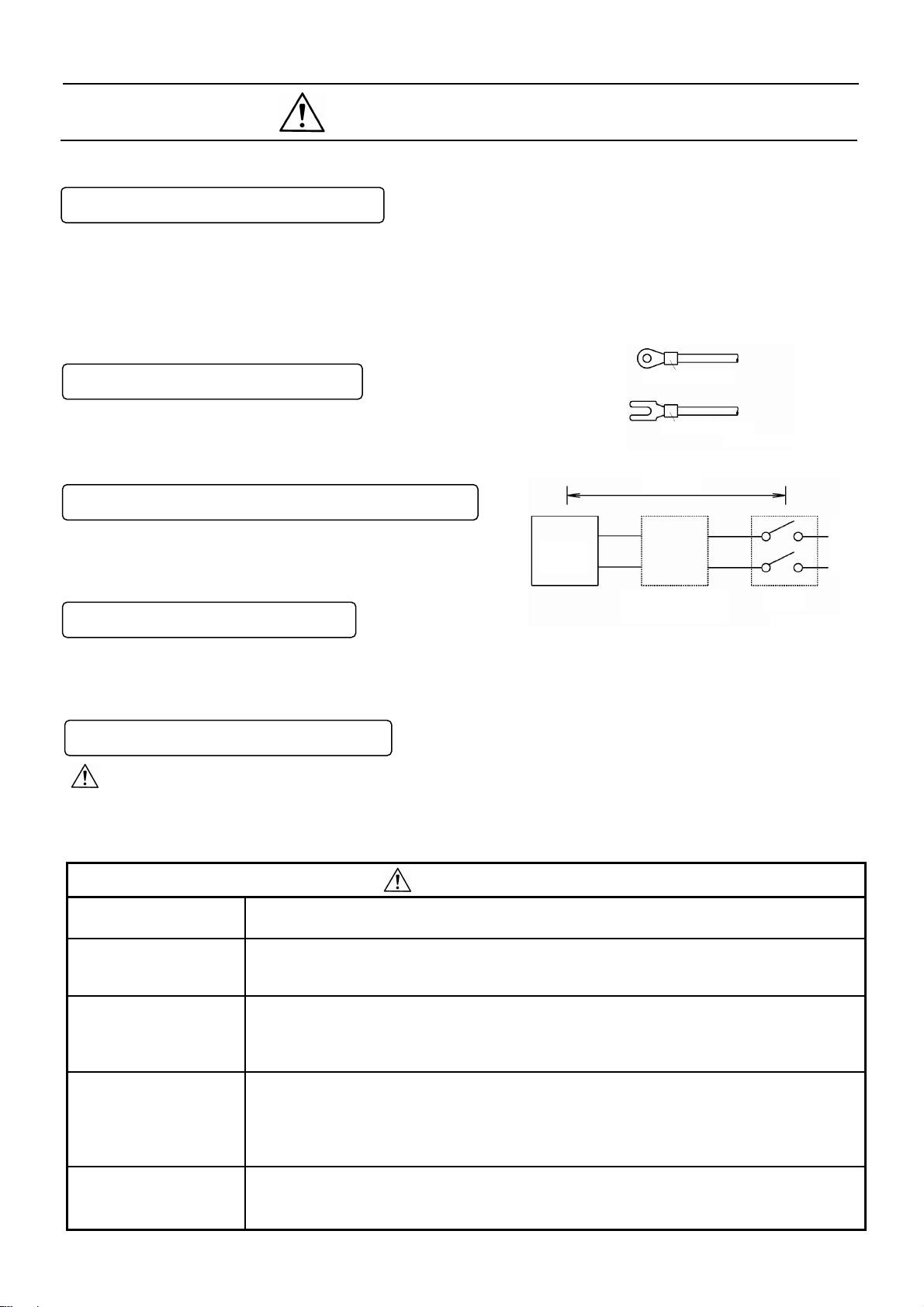

2. Termination of wire connections

For terminating wires to the terminals, use insulation sleeve

crimp style terminals. For power terminals and protective

grounding terminal, use O-type insulation sleeves.

3. Mounting of a breaker to the feed power supply

Mount a switch conforming to the rated power supply of this

unit and an over-current protective device to the power

supply of this unit at an easy-to-access position within 3m.

4. A safety measure to the output

Take a safety measure on the final product side as occasion demands when a control output or an alarm

output is provided, otherwise an output failure of this unit may occur due to wrong operation, troubles, an

abnormal sensor, or other failures.

5. Symbol marks employed in this unit

This symbol mark indicates a position where an electric shock accident may occur. Particularly be careful

not to receive any electric shock during connections, check, and maintenance work.

This symbol shows a protective grounding terminal. Connect the instrument being indicated by this mark to

the protective ground of the power supply equipment before starting its operation.

Type O

Type Y

This unit

Insulation sleeve

Insulation sleeve

Within 3m

An over-current

protective device

Switch

Feed

power

supply

Power voltage and

protective grounding check

Don’t put your hand into

the case

Stop feeding the power

supply if an abnormal

symptom occurs

Repair and modifications

Use according to the

instruction manual

Warnings

Check if connections are correct, the power voltage conforms to the specified voltage, and also the

protective grounding is done without fail before feeding the power supply.

Don’t put your hand into the internal unit (rack) or case, except for the positions where are

necessary for operating the unit, otherwise you may receive an electric shock or you may be

injured.

If abnormal odor, abnormal noises, smoke, or other abnormal symptoms occur or if the unit is too

hot to touch it by hand, these symptoms show a dangerous condition. Turn off the feed power

supply at once, and contact your nearest branch or sales office or the sales agent from which you

have bought your unit.

If repair or modifications are necessary, please contact your nearest branch or sales office or the

sales agent from which you have bought your unit.

<Caution>

Don’t repair the unit by replacing its parts or modify it by any person other than a service

engineer approved by our company.

For using this unit correctly and safely, use it according to this instruction manual.

You are requested to understand that we are not responsible for any injures, damage, loss of

profits or any other claims that were caused by wrong uses.

Page 5

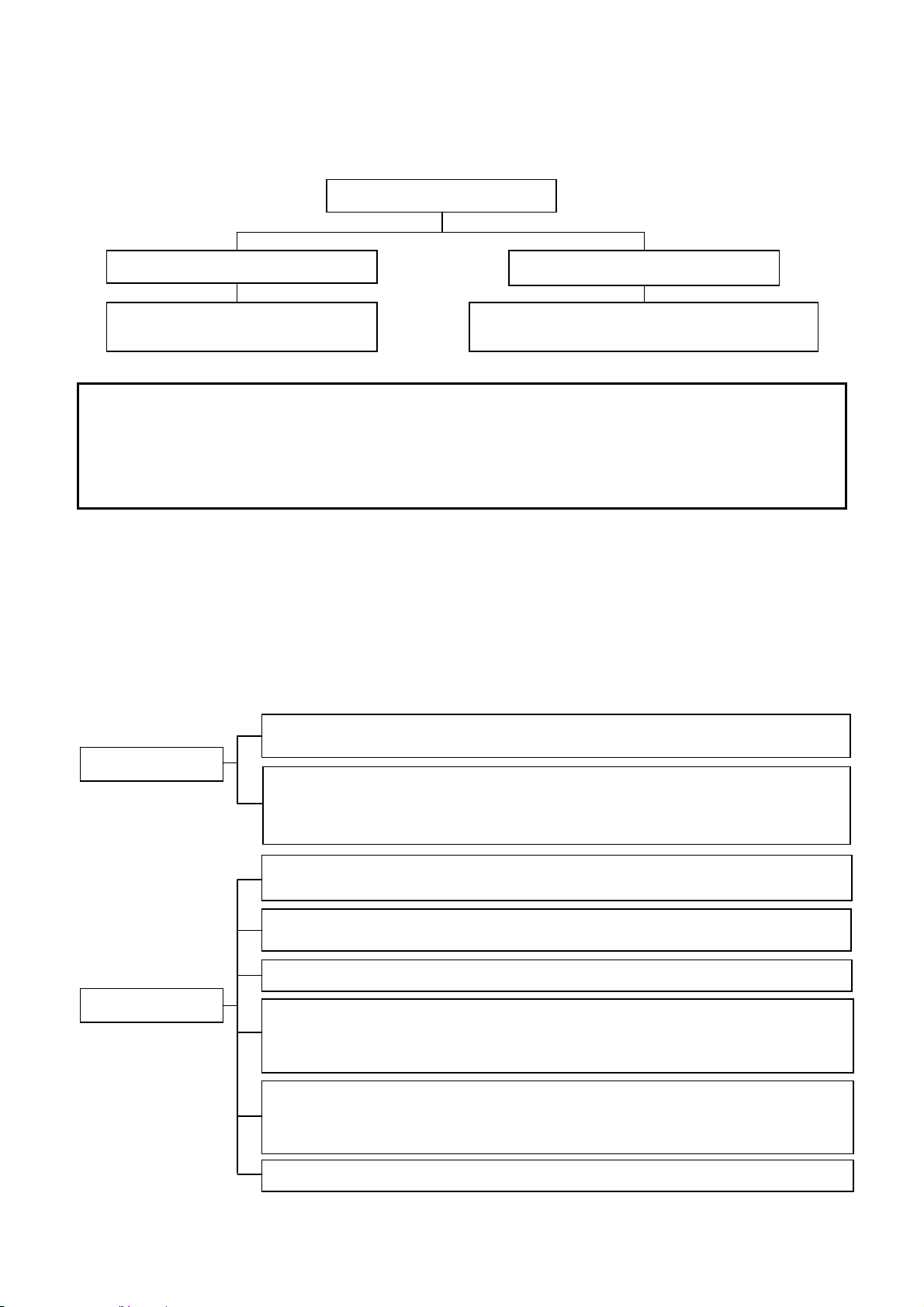

CONTENTS

LE5100

Hybrid Recorder

LE5200

Operation Type Intelligent Recorder

1. Introduction

1-1 LE5100/LE5200 ・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1-2 Profile ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1-3 Input types ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1-4 Check and confirmation

1-4-1 Appearance check ・・・・・・・・・・・・・・・・・・・・・・

1-4-2 Attachments check ・・・・・・・・・・・・・・・・・・・・・

1-4-3 Type code No. check ・・・・・・・・・・・・・・・・・・・・

1-5 Major functions ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

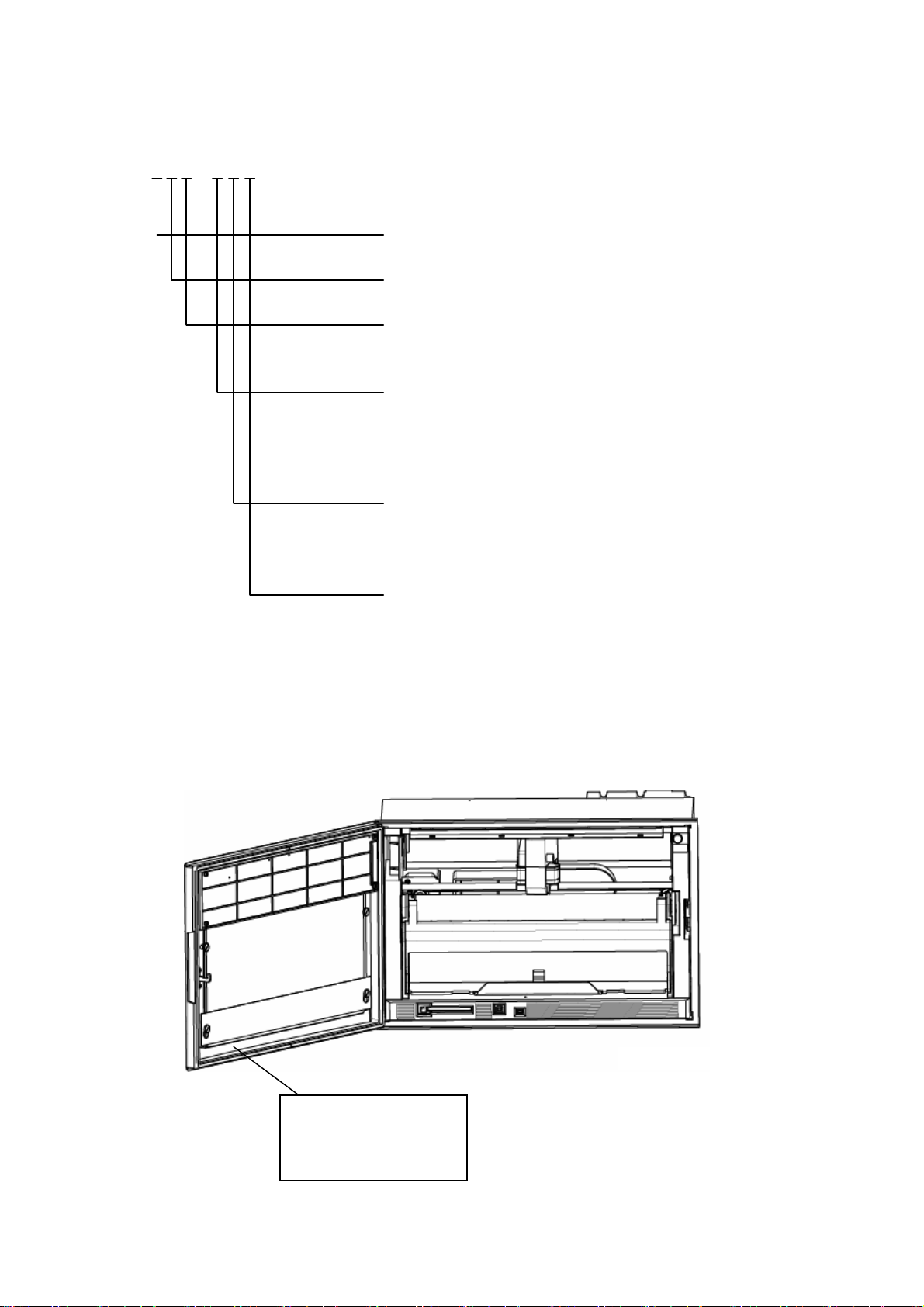

2. Names and functions of components

2-1 Front section ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2-2 Front section of internal unit ・・・・・・・・・・・・・・・・・

2-3 Display (status) ・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2-4 Keyboard ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3. Mounting method

3-1 Selection of mounting place ・・・・・・・・・・・・・・・・・

3-1-1 Ambient temperature and humidity ・・・・・・・

3-1-2 Factory environment ・・・・・・・・・・・・・・・・・・・・

3-1-3 Mounting angle ・・・・・・・・・・・・・・・・・・・・・・・・

3-2 Panel mounting method ・・・・・・・・・・・・・・・・・・・・・

3-2-1 External dimensions ・・・・・・・・・・・・・・・・・・・・

3-2-2 Panel cutout ・・・・・・・・・・・・・・・・・・・・・・・・・・・

3-2-3 Mounting method ・・・・・・・・・・・・・・・・・・・・・・・

4. Connections

4-1 Cautions on connections ・・・・・・・・・・・・・・・・・・・

4-2 Terminal boards (rear panel) ・・・・・・・・・・・・・・・・・

4-3 Connections of each terminal board ・・・・・・・・・・

4-3-1 Measuring input terminal board ・・・・・・・・・・

4-3-2 Power terminals ・・・・・・・・・・・・・・・・・・・・・・・・

4-3-3 Communication I/F terminals, contact output

terminals, and external drive terminals ・・・・

4-3-4 Alarm output terminals ・・・・・・・・・・・・・・・・・・

5. Installation of auxiliary products

5-1 Mounting method of chart ・・・・・・・・・・・・・・・・・・・・

5-2 Ribbon cassette mounting method ・・・・・・・・・・・・

6. Operation

6-1 Turning on the power supply ・・・・・・・・・・・・・・・・

6-2 Display mode selection ・・・・・・・・・・・・・・・・・・・・・

6-3 Recording operation ・・・・・・・・・・・・・・・・・・・・・・・・

7. Initial setting at the delivery time from

the factory

7-1 Setting items at the delivery time from the

factory ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

7-2 Mode change by soft switch ・・・・・・・・・・・・・・・・・

1-1

1-1

1-1

1-1

1-1

1-1

1-2

1-3-4

2-1

2-1

2-1-2

2-3

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-1

4-1

4-1

4-2

4-2

4-2

4-3-4

4-4

5-1

5-2

6-1

6-1

6-2

7-1

7-2

Page 6

8. Setting and changes by key operation

8-1 Basic rules ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1. Setting items and setting parameters ・・・・・・・

2

. Calling of setting items ・・・・・・・・・・・・・・・・・・・

3. Calling of setting parameters ・・・・・・・・・・・・・・

4. Acceptance and acceptance failure of keys

5. No. of parameters by setting items ・・・・・・・・・

6. Confirmation of setting parameters ・・・・・・・・・

7. Setting change ・・・・・・・・・・・・・・・・・・・・・・・・・・

8. Switching of keys ・・・・・・・・・・・・・・・・・・・・・・・・

9. Setting change mark ・・・・・・・・・・・・・・・・・・・・・

10. Setting decision function ・・・・・・・・・・・・・・・・・・

11. Basic entry of setting parameters ・・・・・・・・・・

8-2 Display setting ・・・・・・・・・・・・・・・・・・・・・・・・・・

8-3 Channel parameter setting ・・・・・・・・・・・・・・・

1. Operation recording・・・・・・・・・・・・・・・・・・・・・・・

2. Data communication input・・・・・・・・・・・・・・・・・・

8-4 Dot setting ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

8-5 Chart recording setting ・・・・・・・・・・・・・・・・・・

8-6 Alarm setting ・・・・・・・・・・・・・・・・・・・・・・・・・・・

8-7 Differential recording setting ・・・・・・・・・・・・・・

8-8 Message printing setting ・・・・・・・・・・・・・・・・・

8-9 List printing setting ・・・・・・・・・・・・・・・・・・・・・・

8-10 Data interval recording setting ・・・・・・・・・・・

8-11 Logging recording setting ・・・・・・・・・・・・・・・

8-12 Data print recording setting ・・・・・・・・・・・・・

8-13 Display setting ・・・・・・・・・・・・・・・・・・・・・・・・

8-14 Engineering port setting ・・・・・・・・・・・・・・・・

8-15 Date and time setting ・・・・・・・・・・・・・・・・・・・

8-16 System setting ・・・・・・・・・・・・・・・・・・・・・・・・

8-17 PC card (memory card) setting・・・・・・・・・・・

8-17-1

8-17-2

8-17-3

8-17-4

8-17-5

8-17-6

8-17-7

8-17-8

8-17-9

8-17-10 PC card removing・・・・・・・・・・・・・・・・・・・

Summary・・・・・・・・・・・・・・・・・・・・・・・・・・

Mounting・・・・・・・・・・・・・・・・・・・・・・・・・・

Operation・・・・・・・・・・・・・・・・・・・・・・・・・・

Handling of PC card・・・・・・・・・・・・・・・・・

PC card setting・・・・・・・・・・・・・・・・・・・・・

Setting of measuring data saving by PC

card・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

Setting of set value saving by PC card

Setting of reading out a set value by PC

card・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

PC card format・・・・・・・・・・・・・・・・・・・・・

・

8-1

8-1

8-1

8-1

8-1

8-1

8-1-3

8-4

8-4

8-4

8-4

8-5-6

8-7

8-8-9

8-10

8-11

8-12

8-13-14

8-15-17

8-18-20

8-21

8-22

8-23

8-24

8-25

8-26

8-27

8-28

8-29

8-30

8-30

8-30

8-30

8-31

8-31

8-32

8-33

8-34

8-35

8-36

9. Adjustment function

9-1 Zero and span adjustment of analog

recording ・・・・・・・・・・・・・・・・・・・・・・・・・・・

9-2 Zero and span adjustment of measured

values ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

9-3 Shift adjustment of measured

values・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

9-4 Calibration・・・・・・・・・・・・・・・・・・・・・・・・・・・

10. Troubleshooting

Troubleshooting table ・・・・・・・・・・・・・・・・・・・・

11. Maintenance and check

Maintenance and check ・・・・・・・・・・・・・・・・・・

11-1 Recommendable parts exchange

cycles ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

11-2. Disposal・・・・・・・・・・・・・・・・・・・・・・・・・・・・

12. General specifications

General specifications ・・・・・・・・・・・・・・・・・・・・

13. Option specifications

Option specifications ・・・・・・・・・・・・・・・・・・・・・

13-1. External drive・・・・・・・・・・・・・・・・・・・・・・・

13-2. Alarm output・・・・・・・・・・・・・・・・・・・・・・・・

13-3. Recording format・・・・・・・・・・・・・・・・・・・・

13-3-1. Automatic range selection recording

13-3-2. Partial compression and expansion

recording・・・・・・・・・・・・・・・・・・・・・・・・

13-3-3. Parallel scale recording・・・・・・・・・・・

13-4. Rate-of-change alarm/Differential alarm

13-4-1. Rate-of –change alarm・・・・・・・・・・・・

13-4-2. Differential alarm・・・・・・・・・・・・・・・・・

13-5. Operation ・・・・・・・・・・・・・・・・・・・・・・・・・・

9-1

9-2

9-3

9-4

10-1

11-1

11-2

11-2

12-1-5

13-1

13-2-4

13-5

13-6

13-7

13-8

13-9

13-10

13-10

13-11

13-12-16

Page 7

1. Introduction

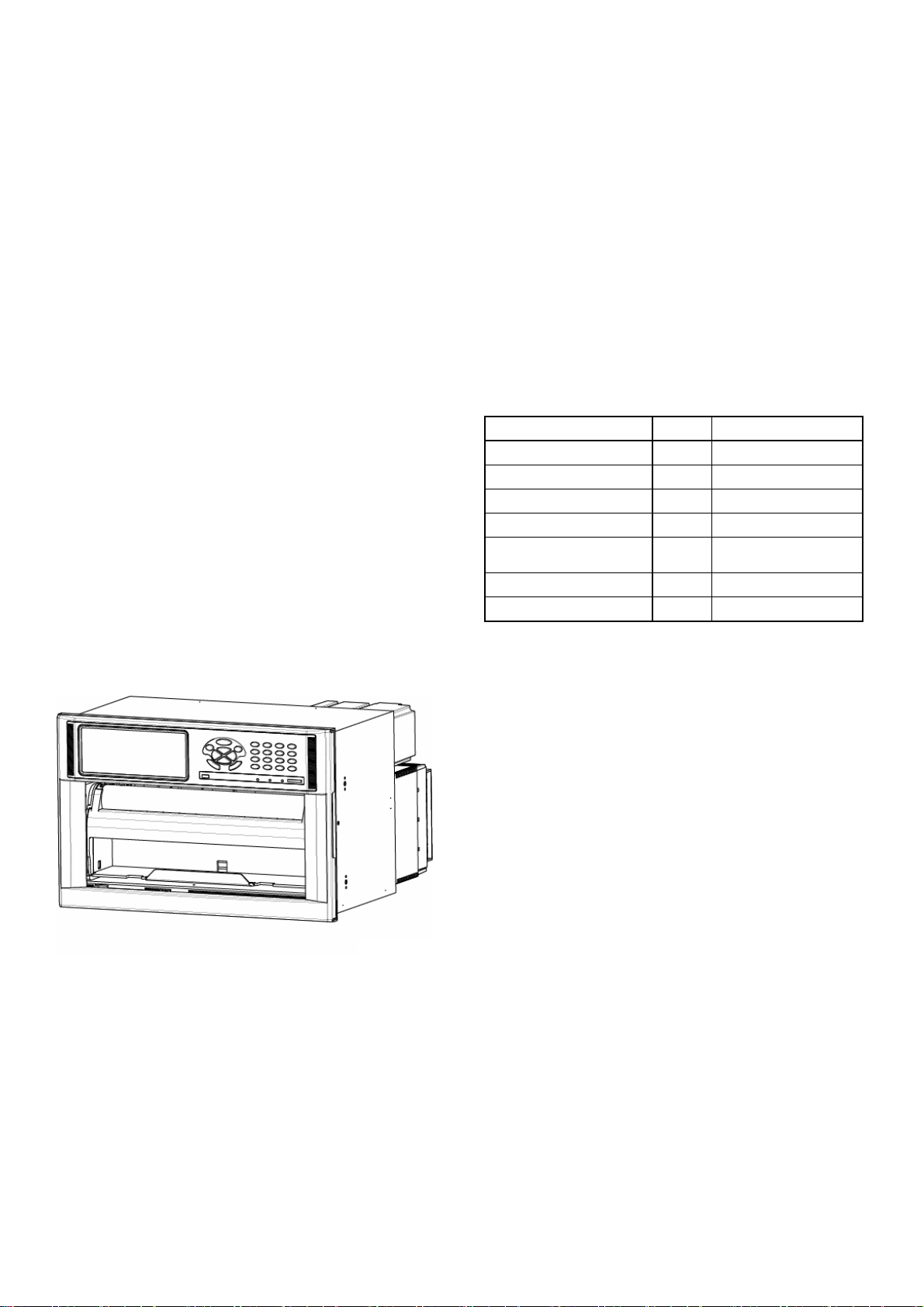

1-1 LE5100/LE5200

This hybrid recorder having a 250mm chart measures

and records temperature (thermocouple, resistance

thermometer bulb) inputs, DC voltage (mV, V) inputs,

and other various industrial variables.

1) High speed input entry and high-speed recording

This unit scans test data, inspection data,

experimental data, and multi-point data in quick

change processes at a ratio of 36 points/100ms, and

records them at a rate of approx. 1 line/3s.

2) High precision

The accuracy rating of measuring ranges is ±0.05%,

and the maximum resolution is 1µV or 0.1℃.

3) Easy operation

Various setting can be done in the conversational

mode without any complicated operation unlike in

general high-grade units. Setting can also be done by

a personal computer or a PC card.

4) Noise resistance

This unit is characterized with a high induction noise

resistance of 130dB in common mode and 50dB in

series mode. For impulse noises, an individual filter is

provided every channel.

1-2 Profile

This unit comprises a 12-point input type, a 24-point

input type, and a 36-point input type. This unit can be

operated and set without opening the door in all

types.

1-3 Input types

This unit is characterized with a full multi range of

thermocouple (TC), resistance thermometer bulb,

and DC voltage (mV, V) inputs.

1-4 Check and confirmation

Check the unit for the following items before

operating it.

1-4-1 Appearance check

After unpacking, check the following items to see if

the unit is normal in appearance.

① Check if the front glass is free of breakage and

flaws.

② Check if the door can be opened and closed

smooth.

③ Check if the entire case is free of flaws and dirt.

1-4-2 Attachments check

The following attachments are contained.

Article names Quantity Remarks

① Ribbon cassette

② Chart ※

③ Lubricating oil (10cc)

④ Terminal screw (spare)

⑤ Mounting bracket and

mounting screw

⑥ Wrench

⑦ Instruction manual

Attachments table

1 pc. For recording

2 boxes Each contains 2 pads

1 bottle For maintenance

5 pcs. M3.5 x 8

4 pcs.

each

1 pc.

1 pad

For mounting the panel

For mounting the panel

※ Standard chart is chart No. LE-01001A. Its ordering

unit is one large box (containing 15 pads).

1-1

Page 8

1-4-3 Type code No. check

The operation may change according to the types. Confirm the type of your unit.

■ Type tab l e

LE5□□□-□□□

Model

1: LE5100 2: LE5200

No. of input points (analog inputs)

0: None 1: 12 points 2: 24 points 3: 36 points

No. of alarm output points (option)

0: None 1: 12 points 2: 24 points 3: 36 points

Alarm output is a mechanical relay ‘a’ contact output.

Communications interface Contact 1 output (option)

N: None

1: Either RS-422A or RS-485 + Ethernet

+ Contact 1 output (Contact 1output is a mechanical relay ‘a’ contact

output)

External drive (option)

N: Not provided

1: Provided

Chart speed selection (3 speeds + stop) Data printing start

Others (option)

N: None

1: Recording format + change ratio/differential alarm

2: Recording format + change ratio/differential alarm

+ arithmetic operation (In case of selecting LE5200 only)

Type: LE52

LE5133-112

LE061A001

MADE IN JAPAN

□□-□□2

When select LE5200 in model, others (option) is fixed [2].

1-2

Page 9

1-5 Major functions

This unit provides various functions. For details of setting and operation, refer to each item No.

Functions Items Contents Page No.

Measuring data in each channel are displayed.

Channel No. (3 digits) + tag (8 digits) + range (3 digits) + measured value (7 digits)

An 8-digit tag can be set and displayed.

In case of collective display of 36 points, 5-digit display is done by justifying left

digits.

A unit can also be displayed instead of the tag, and its display mode is the same

as in the tag. (Simultaneous display of both tag and unit cannot be done.)

1) Each measuring data is fixed or sequentially displayed every channel.

2) 12-point measuring data are displayed collectively.

3) 24-point measuring data are displayed collectively.

4) 36-point measuring data are displayed collectively.

※ The update cycle of 1 channel display is 2 seconds as a factory delivery value

(default).

5) In case of 24 or 36 input points, each measuring data is fixed or sequentially

displayed every 12 points.

※ The update cycle of 12・24・36 points display is 3 seconds as a factory delivery

value (default).

6) The type code, serial No., and version No. of software of this unit are indicated.

The chart speed, date (year, month, day), and time are indicated at all times

in all display modes 1) - 6).

1) KEY LOCK : Indicated when operation keys are locked.

2) CHART END : Indicated when the chart comes to an end.

3) FAIL : Indicated when the unit is in trouble.

1) Measuring data in an alarm channel are displayed red.

※ Red ALM LED flickers.

Setting conditions can be confirmed by displaying various parameters by means

of key operation.

Setting inputs and arithmetic results can be recorded by max. 36 channels,

respectively.

A recording color can be designated optionally every channel (out of 10 colors).

Tag numbers (channel numbers) are printed beside the trend recording at a fixed

interval.

When an alarm occurred or when the alarm was reset, _ (red) or_ (green) mark is

printed beside the trend recording, and also, the time, channel number, and kinds

of levels are printed at the right end of the chart.

A designated channel can be skipped.

Parallel recording, partially compressed/enlarged recording, and automatic range

selection recording can be selected.

Digital recording is done at an optional interval (time and minute) from a

designated start time by overlapping it with analog recording.

Digital recording is done at an optional interval (time and minute) from a

designated start time.

Measuring data, tag number, unit, chart speed, date (year, month, day), and time

are printed. Three kinds of recording formats can be designated optionally.

1) A difference of measuring data between designated channels is recorded in an

optional designated channel.

2) A difference between measuring data of a designated channel and the

reference value (optional setting) can be recorded in an optional designated

channel.

1) The maximum, minimum, average, and total values of measuring data between

designated channels are recorded in an optionally designated channel.

2) A time series change (maximum, minimum, average, and integration) at an

optional interval of measuring data between designated channels can be

recorded in an optional channel from a designated start time.

3) Perform function mathematics which can be shown numerical formula, and

record optional channel.

1. Digital display

2. Analog

recording

3. Digital

recording

4. Arithmetic

results

recording

①Measuring data display

②Display mode

③Status display

④Alarm status display

⑤Setting data display

①No. of recording points

②Recording color

designation

③Tag number printing

④Scale and unit printing A scale and a unit are printed at both ends of the chart every fixed time.

⑤Alarm mark printing

⑥Skip function

⑦Analog recording format

(option)

①Data interval recording

②Data printing Digital recording is done at the requested time while interrupting analog recording.

③Logging recording

④Digital recording format

⑤Skip function A designated channel can be skipped.

①Differential recording

② Arithmetic results

recording (option)

Page 2-2

Page 2-2

Page 2-1

Page 2-2

Page 2-1

Page 2-2

Page 8-1

Page 8-10

Page 8-10

-

-

-

Page 8-10

-

Page 8-21

Page 6-2

Page 8-22

Page 8-21

Page 8-23

Page 8-8

Page 8-16

-

1-3

Page 10

Functions

5. Digital printing

6. Parameter entry

7. Self diagnostic

function

8. Communication

function USB:

Standard

RS-422A/485

Ethernet (option)

9. Auxiliary

functions

Items Contents

① Year, month, day,

and time printing

② List printing

③ Message printing

④Title printing (option)

① Operation keys

② PC card

③ PC setting

①Self check function Instrument conditions are checked by executing self-diagnosis at all times.

② Setting decision

function

③Hardware check

function

① Setting All parameters can be set and confirmed.

② Operation

③ Data output Measuring data are output according to the request from the host CPU.

④Kinds

① Input value

correction function

② Recording correction

function

③ Parameter protection

function

④ Burnout function

Year, month, day, and time (time line) are printed at a designated interval.

1) A list of all parameters is printed at a requested time.

2) A list of designated parameters is printed at a requested time.

1) A message of max. 75 characters can be printed by designating a channel.

2) A message of max. 80 characters can be printed without designating any

channel.

(A message is prepared by alphanumeric characters and symbols being

displayed on the setting keyboard.)

A comment of max 80 characters x 5 lines can be printed.

(A title sentence is English characters (capitals and small letters), numeric

characters, symbols, and others provided on the PC keyboard.)

1) Running operation: Data display selection, recording ON/OFF, data printing,

chart feed.

2) Setting: Time, chart speed, range, and all other functions can be set and

confirmed.

Setting contents can be entered and collectively set to this unit by easy key

operation.

Setting can be done by exclusive engineering software (option) with a PC

employed as the setting tool. Setting contents can be confirmed.

Setting contents are checked to inform of abnormal conditions, if any.

1) Defective contents check

• Format check

• Restriction check

2) A window is opened on the setting screen to display a message of defective

contents.

Hardware conditions of the instrument are checked.

All operation can be done.

1) RS-422A

2) RS-485

3) USB

4) Ethernet

Input values can be corrected every channel by key operation.

Zero point and span point can be corrected by key operation.

1) Setting parameters are protected by EEP-ROM when turning off the power

supply.

2) Clock is backed up for longer than 5 years by a lithium battery.

Thermocouple or resistance thermometer bulb overshoots to its higher-limit,

if broken. (ON-OFF selectable)

Page No.

-

Page 8-20

Page 8-19

-

Page 2-3

-

-

-

Page 8-4

-

-

-

-

-

Page 9-2

Page 9-1

-

Page 8-8

1-4

Page 11

2. Names and functions of components

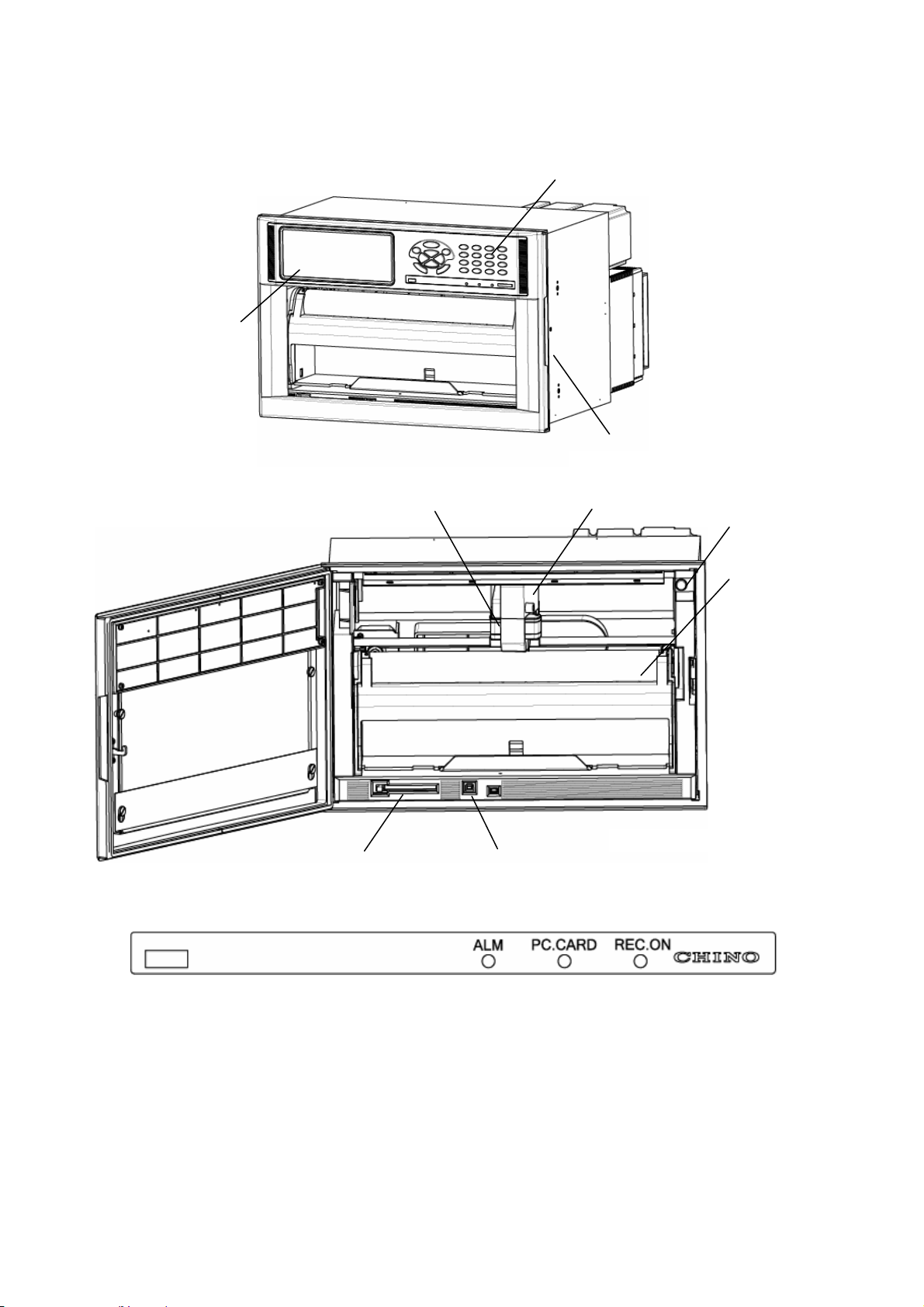

2-1 Front section

Operation and setting can be done without opening the door so that the front section is fully dust-proof.

Display

2-2 Front section of internal unit

Printer head Ink ribbon cassette

PC card insertion part USB communication connector

2-3 Display (status)

・ALM

Red LED flickers in the occurrence of an alarm.

・PC.CARD

Green LED remains lit when PC card is being inserted.

・REC.ON

Green LED lights when recording is turned on. Recording is turned on or off by REC key.

・CHINO

CHINO brand lights when power is turned on.

Operation and setting keys

Door grip

Power switch

Chart rack

2-1

Page 12

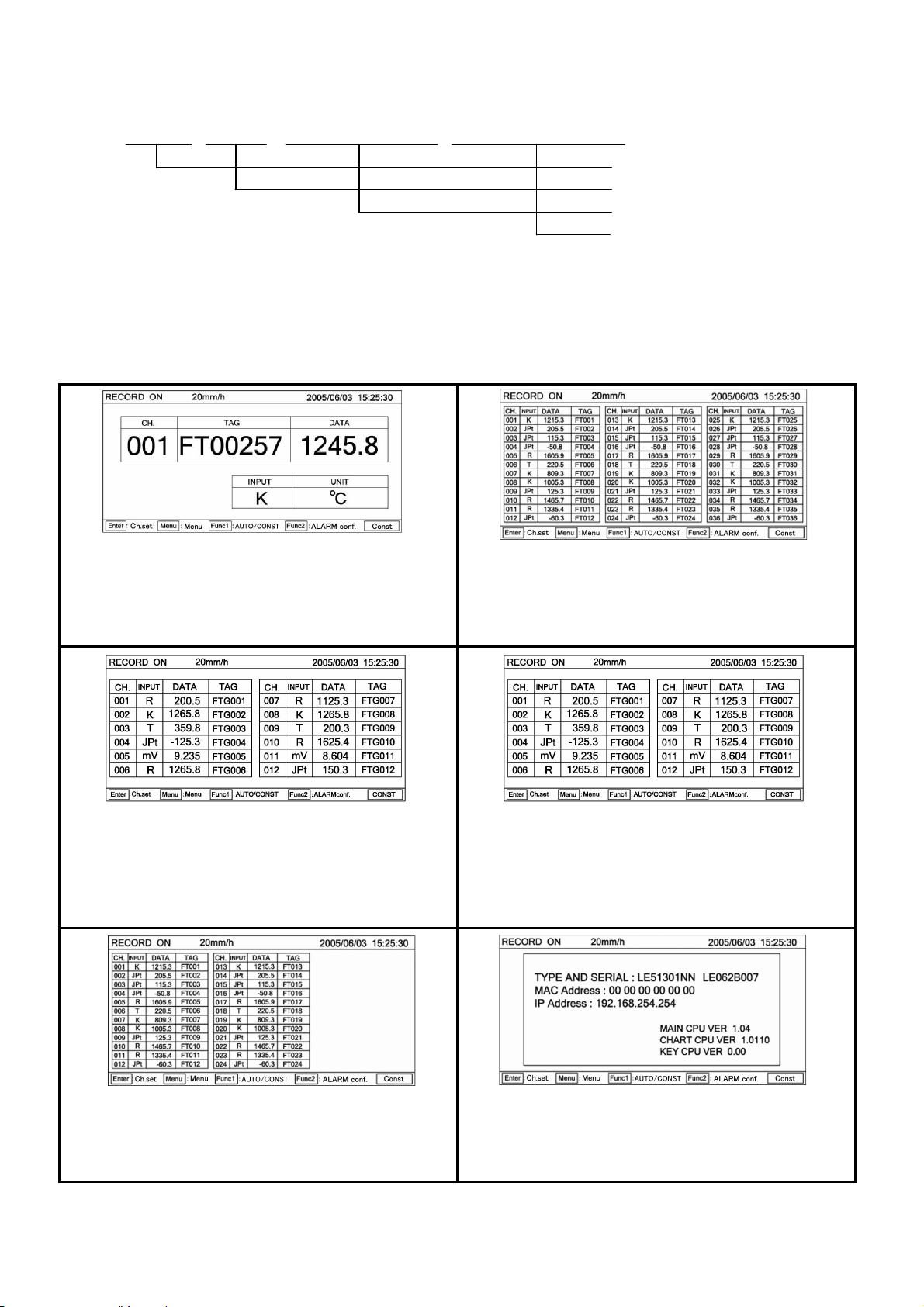

• Indications of the display section

Measuring data display

□□□ □□□ □□□□□□□ □□□□□□□□ :1Measuring data display by 1 channel

Channel display: 3 digits

Range display: 3 digits

Measuring data display 7 digits

Tag No. display: 8 digits or

Digits unit display 8

The following six screens are selectable according to the uses during run.

(Described update cycles show the initial setting values at the delivery time from the factory.)

1.

Measuring data are fixed or sequentially displayed every channel.

These data are updated to the next channel by ▲ or ▼ key.

The above keys can be used for sequentially display.

In the sequential display mode, measuring data are updated to the

next channel at 2-second cycle.

Also, measured values display is updated every second.

2.

Measuring data at 12 points are displayed collectively.

(In case of the instruments where No. of input points is 12 points.)

Skipped channels are kept blank. Each display area is not changed.

The same processing also applies to the channels where no range is

set. Measured values display is updated every second.

3.

Measuring data at 24 points are displayed collectively.

(In case of the instruments where No. of input points is 24 points).

Skipped channels are kept blank. Each display area is not changed.

The same processing also applies to the channels where no range is

set. Measured values display is updated every second.

4.

Measuring data at 36 points are displayed collectively.

(In case of the instruments where No. of input points is 36 points)

Skipped channels are kept blank. Each display area is not changed.

The same processing also applies to the channels where no range is

set. Measured values display is updated every second.

5.

Measuring data are fixed or sequentially displayed every 12 points.

(In case of the units where No. of input points is 24 points or 36 points).

These data are updated to the next 12 points by ▲ or ▼ key.

The above keys can be used for sequentially display.

In the sequential display mode, measuring data are updated to the

next 12 points at 3-second cycle.

Also, measured values display is updated every second.

6.

Type code, serial No., software version number, IP address, and MAC

address of this unit are displayed.

In all screens, various status, chart speed, date (year, month, day), and time are always displayed at the upper part

of the display, while various setting procedures are always displayed at the lower part of the display.

※ 5-digit display in case of collective

display of 36 points

2-2

Page 13

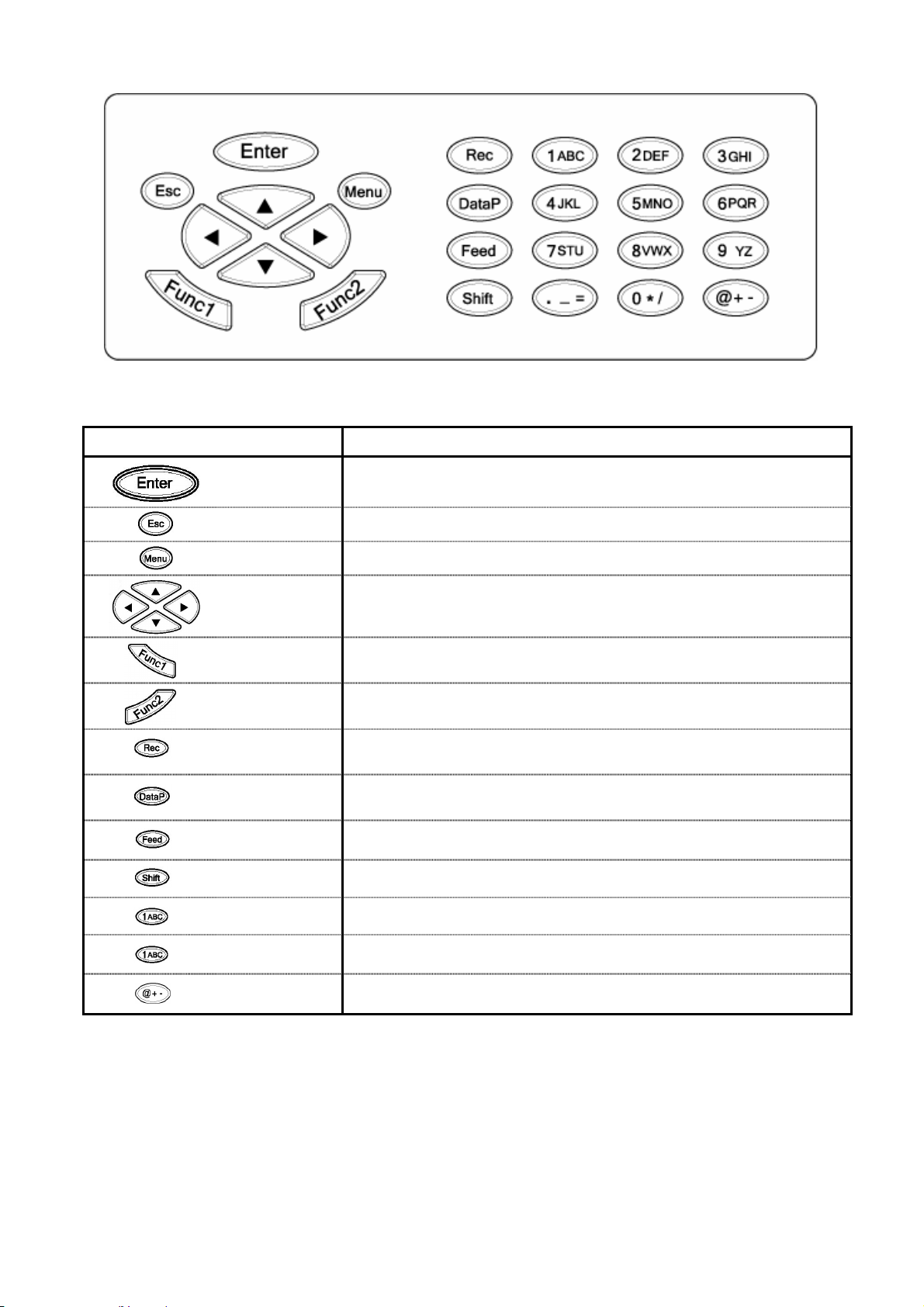

2-4 Keyboard

•

Names and functions of keys

Names of keys Functions

Enter key Enters various setting.

Escape key Returns the screen to the last one each time this key is pressed once.

Menu key Displays various setting items.

Up-Down,

Left-Right keys

Function key 1

Function key 2

Record key

Data print key

Feed key Feeds the chart at a speed of 750mm/min when this key is being pressed.

These keys are used to shift the cursor upward, downward, leftward, or

rightward. They are used for selecting setting items and numeric values.

Switches and sets various functions.

Displays the function at the lower part of display.

Switches and sets various functions.

Displays the function at the lower part of display.

Turns on or off recording.

This key is used together with Enter key.

Prints data momentarily when pressing this key.

This key is used together with Enter key.

Shift key Selects numeric keys and alphabetic or other symbolic keys.

Numeric key

Alphabetic key

Symbol key

Used for inputting a numeric value.

Used for inputting alphabetic characters (together with Shift key).

Used for inputting symbols (together with Shift key).

When alphabetic keys are used for setting the tag, unit, etc., press [Shift] key according to the guidance in the

display unit. The contents being input by pressing keys are switched by pressing [Shift] key.

Example) In case of inputting [C]

Switch the input mode of the key by pressing Shift key.

[C] can be input by pressing [1ABC] key 4 times.

2-3

Page 14

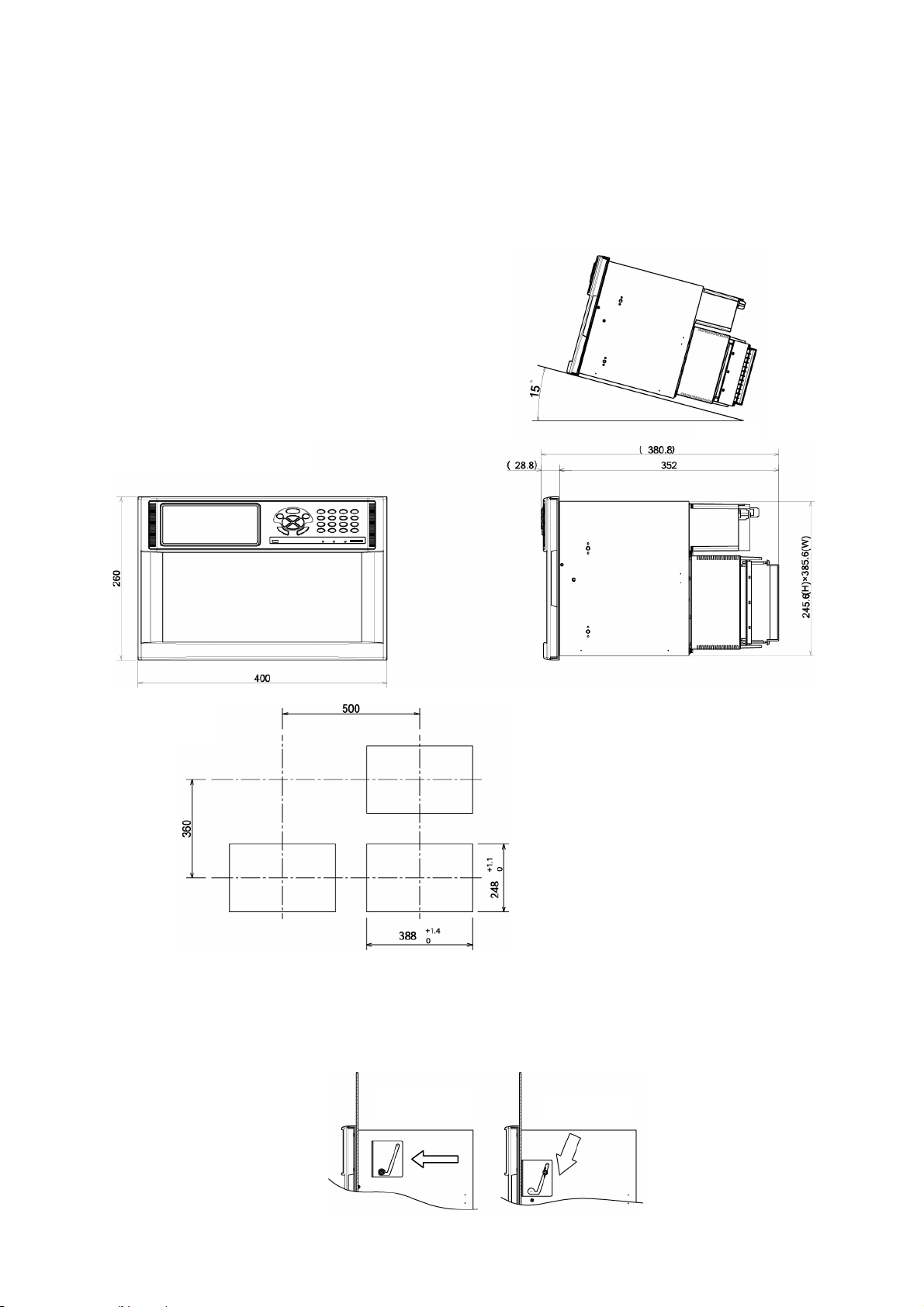

3. Mounting method

This unit can be used on a desk or the like, but it is constructed to be used by mounting it on a panel (instrument panel).

3-1 Selection of mounting place

3-1-1 Ambient temperature and humidity

Temperature range : 0 to 40℃

Humidity range : 20 to 80%RH

A stable place within the above ranges

3-1-3 Mounting angle

Front tilting angle : 0°

Rear tilting angle : 0 to 15°

Lateral angle : 0°

A mounting angle other than specified above

may affect the recording operation.

3-1-2 Factory environment

Select a place being separated from electric

field and magnetic field generation sources and

also free of mechanical vibrations and shocks.

Overvoltage category :

Ⅱ

Pollution degree : 2

Altitude : Lower than 2000m

Working place : Indoors

3-2 Panel mounting method

3-2 Panel mounting method

3-2-1 External dimensions

3-2-1 External dimensions

3-2-2 Panel cutout

3-2-2 Panel cutout

Panel cutout and

Minimum mounting dimensions

3-2-3 Mounting method

Insert this unit into the panel cutout of the instrument panel. Screw in four attached mounting screws into the

screw holes at 2 upper and lower places (4 places in total) on the right and left side panels of the unit. Insert the

mounted hexagonal screw heads into the round holes of the mounting brackets, press the unit toward the

instrument panel securely from the front while sliding it as illustrated below, and fasten the screws by the attached

spanner or plus screwdriver under the above condition. Be careful since the mounting brackets differ from each

other on the right and left sides (Mount the unit by 2 persons)

Slide

3-1

Page 15

4. Connections

4-1 Cautions on connections

1. Feed source power supply

● For feeding power to the unit, use a single-phase power

source having the stable voltage without any distorted

waveform for the purpose of preventing wrong operation.

2. Separate the power supply from strong electric circuits

● Avoid connecting the input /output lines in the vicinity of

and/or in parallel with a drive power line or other strong

electric circuits. Separate the unit from them more than

50cm if the unit is in the vicinity of and/or in parallel with

them.

3. Separate the thermocouple input from a heat source

● Separate the terminals from a heat source (a heating

body) for reducing a reference junction compensation

error. Avoid the solar radiation or the like.

4. Separate the unit from a noise source

● Separate the unit from a noise source as far as possible,

otherwise an unexpected trouble may occur. Take a

noise-preventive measure, if the unit cannot be

separated form a noise source.

Major generation

sources

Countermeasure

5. Use crimp style terminals

① Attach crimp style terminals to the connection cord ends for

preventing terminals from being loosened or disconnected

or a short circuit failure across terminals.

② Use crimp style terminals each having an insulation sleeve

for preventing an electric shock accident.

6. Unused terminals

● Don’t use any unused terminal as a relaying terminal,

otherwise electric circuits may be damaged. For unused

terminals, short plus and minus terminals for preventing

the influences of external noises.

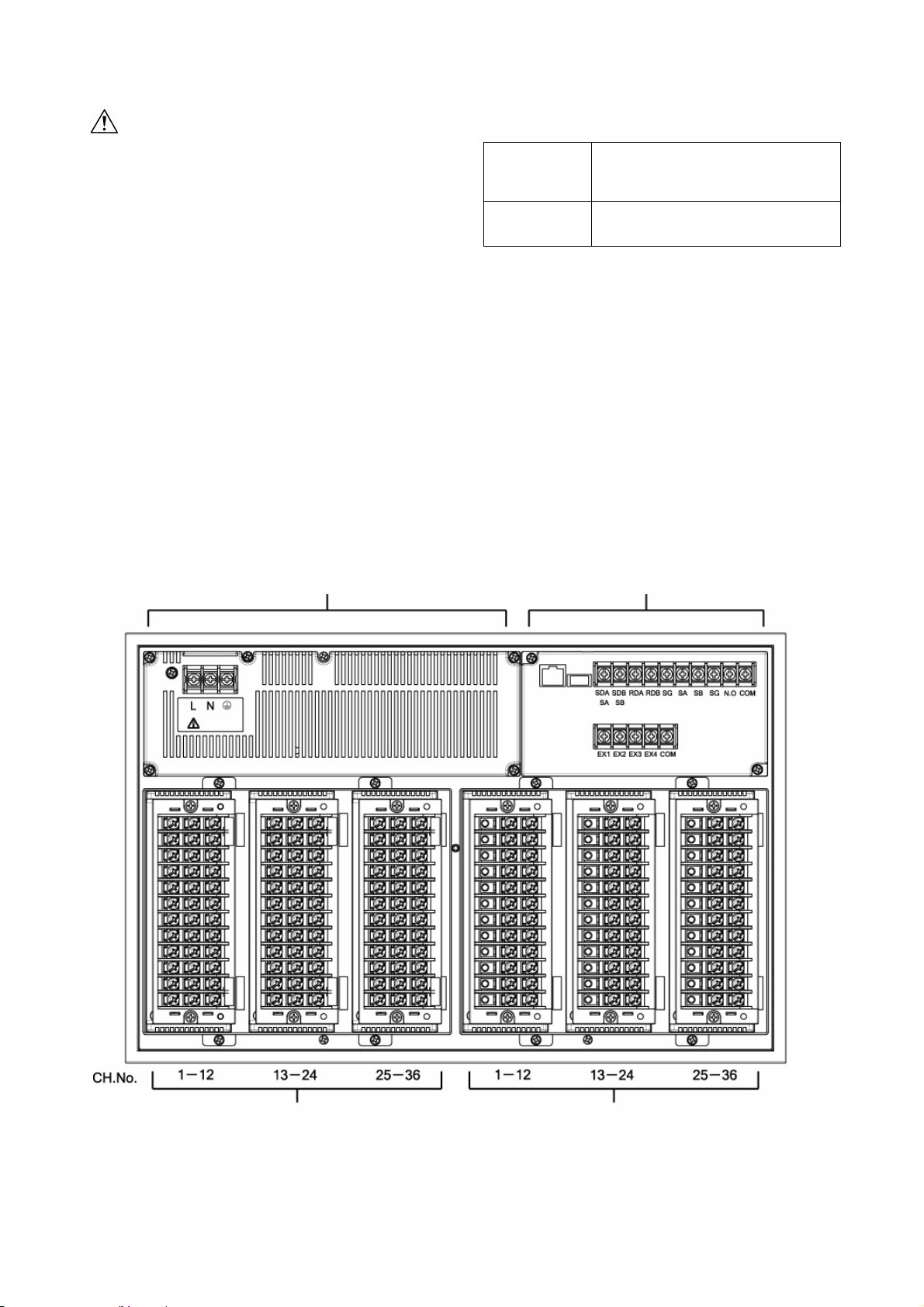

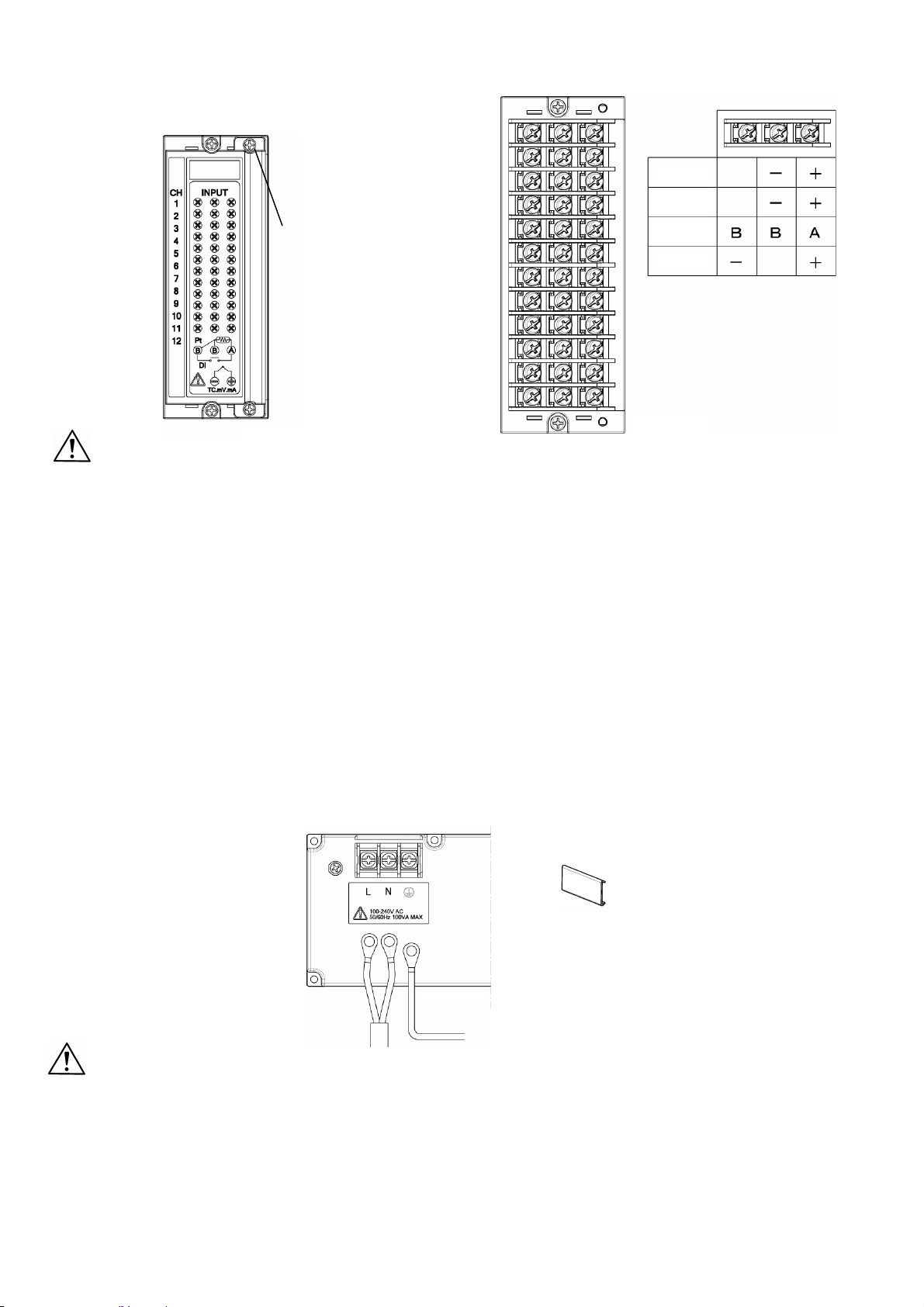

4-2 Terminal boards (rear panel)

The terminal boards are roughly divided into ① measuring input terminals, ② power terminals, ③ communication

I/F terminals, contact output terminals, external drive terminals, and ④ alarm output terminals. Terminals ③ and

④ are not always mounted depending upon the unit because of their option specifications.

②Power terminal board

①Measuring input terminal board

The above figure includes option terminals.

③ Communication I/F terminal, contact output terminal,

and external drive

④Alarm output terminal board

● An electromagnetic switch or the like

● A power line having waveform distortion

● An inverter

● A thyristor regulator

Insert a noise filter between the power

supply and input/output terminals.

A CR filter is used in many cases.

4-1

Page 16

4-3 Connections of each terminal board

g

4-3-1 Measuring input terminal board

Terminal cover mounting screw

(at 2 upper and lower places)

CH1

Volta

e

Thermo-

couple

Resistance

thermometer bulb

Contact

CH12

Cautions

1. Connect a voltage lower than the allowable input voltage to the input terminals.

① Voltage, thermocouple input --------- ±10VDC

② Resistance thermometer bulb ------- ±6VDC

2. Turn off the feed power source before starting connections for preventing an electric shock accident.

3. Mount crimp style terminals each having an insulation sleeve as input terminals.

4. For a DC voltage (current) input, use a twisted wire for instrumentation as a noise preventive measure. Connect a

current input receiving resistor to the channel to be measured before connecting the current input.

5. Connect the thermocouple input by using the thermocouple wire (or compensation lead wire) to the unit without fail.

If a copper wire is connected halfway, a noticeable error occurs. Don’t connect a part of thermocouple wires in

parallel with other instruments (a controller or the like), otherwise a trouble may occur.

6. For connecting the resistance thermometer bulb input, use a 3-conductor cord having an equal resistance value of

each conductor wire. Don’t connect a resistance thermometer bulb in parallel with any other instrument (a

controller or the like)

7. A high voltage may be applied to the measuring input terminals due to common mode noises. The allowable value

of noises is lower than 30VAC or 60VDC. Make sure that noises are lower than specified. After connecting

terminals, mount a terminal cover for preventing an electric shock accident and also protecting the input wires. In

case of the thermocouple input, a reference junction compensation error is reduced by mounting the terminal

cover.

4-3-2 Power terminals

Cautions

Power cable:

600V vinyl insulated wire

Crimp style terminal having an

insulation sleeve.

Note:

Use the following standard

cords ①-③.

①IEC 227-3

②ANSI/UL817

③CSA C22.2 No.21/4

Power terminal cover

Grounding wire:

Connect to the protective conductor of the power supply

equipment.

Crimp style terminal having an insulation sleeve

A copper cable each having a wire diameter of 2mm

Green/yellow

2

at least

1. Turn off the feed power source without fail before connecting the power terminals and protective conductor

terminals for the purpose of preventing an electric shock accident.

2. The power voltage of this unit is indicated at the power terminal block. If a voltage other than indicated should be

applied, a trouble or an operation failure occurs. If power noises are introduced, take a preventive measure by

connecting a noise cutting transformer to the ground or other preventive means.

3. A 100-240V AC voltage is applied to the power terminals after connections. Mount the power terminal cover

without fail after connections for preventing an electric shock accident.

4-2

Page 17

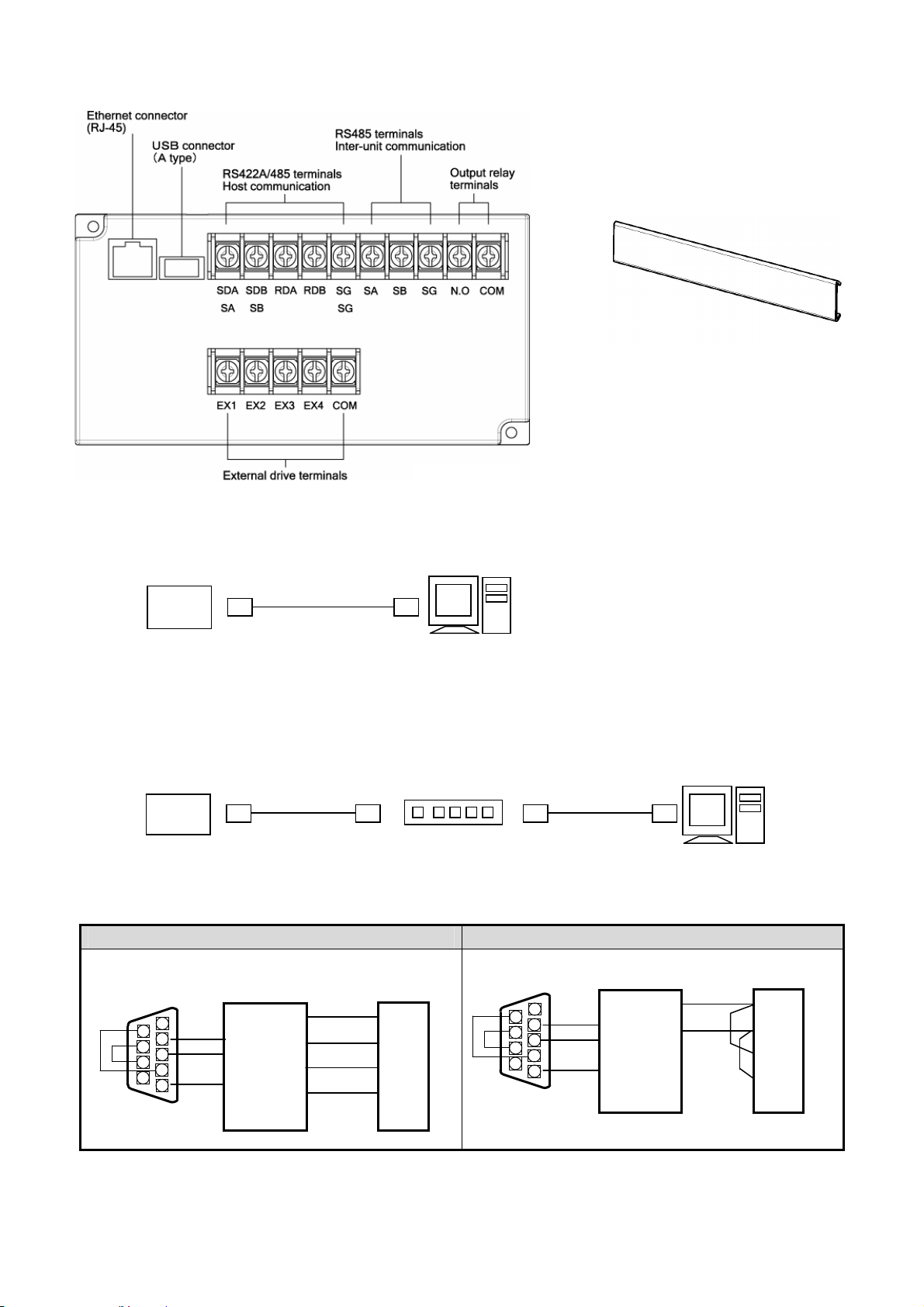

4-3-3 Communication I/F terminals, contact output terminals, and external drive terminals

g

g

resp

Output relay terminals Contact capacity 100V-240V AC

3V resistive load

Terminal cover

1. Ethernet connection (host communication)

[For connecting to PC at a ratio of 1 to 1]

Setting of alarm output and fail output such

as chart end and equipment abnormality

are available from output relay terminal.

Fail output is outputted in spite of not

setting, but in the case of outputting of

alarm, refer to 8-6 [Alarm setting], and set

[800] for output relay No..

For connecting the Ethernet IF to PC at a ratio of 1 to 1, use a cross type STP cable.

LE

STP cross cable

(

PC

A LAN function is attached)

[For connecting to PC at a ratio of N to N]

For connecting to plural PC units or existing LAN, use a switching hub, and connect a straight type STP cable

between the switching hub and the Ethernet unit.

LE

STP strai

ht cable

Hub

Twisted paired

strai

ht cable

A LAN function is attached)

(

PC

2. RS422A/RS485 terminal connections (host communication)

RS422A connection RS485 connection

PC side

9 pins connector

1

6

2

7

3

8

4

9

5

Line converter

SC8-10

RDA

SD

RDB

RD

SDA

SG

SDB

LE

SDA

SDB

RDA

RDB

SG

PC side

9 pins connector

1

6

2

7

3

8

4

9

5

For RS485, short SDA and RDA, and also, SDB and

RDB

Line converter

SC8-10

SD

RD

SG

ectively.

RDA

RDB

LE

SDA

SDB

RDA

RDB

SG

4-3

Page 18

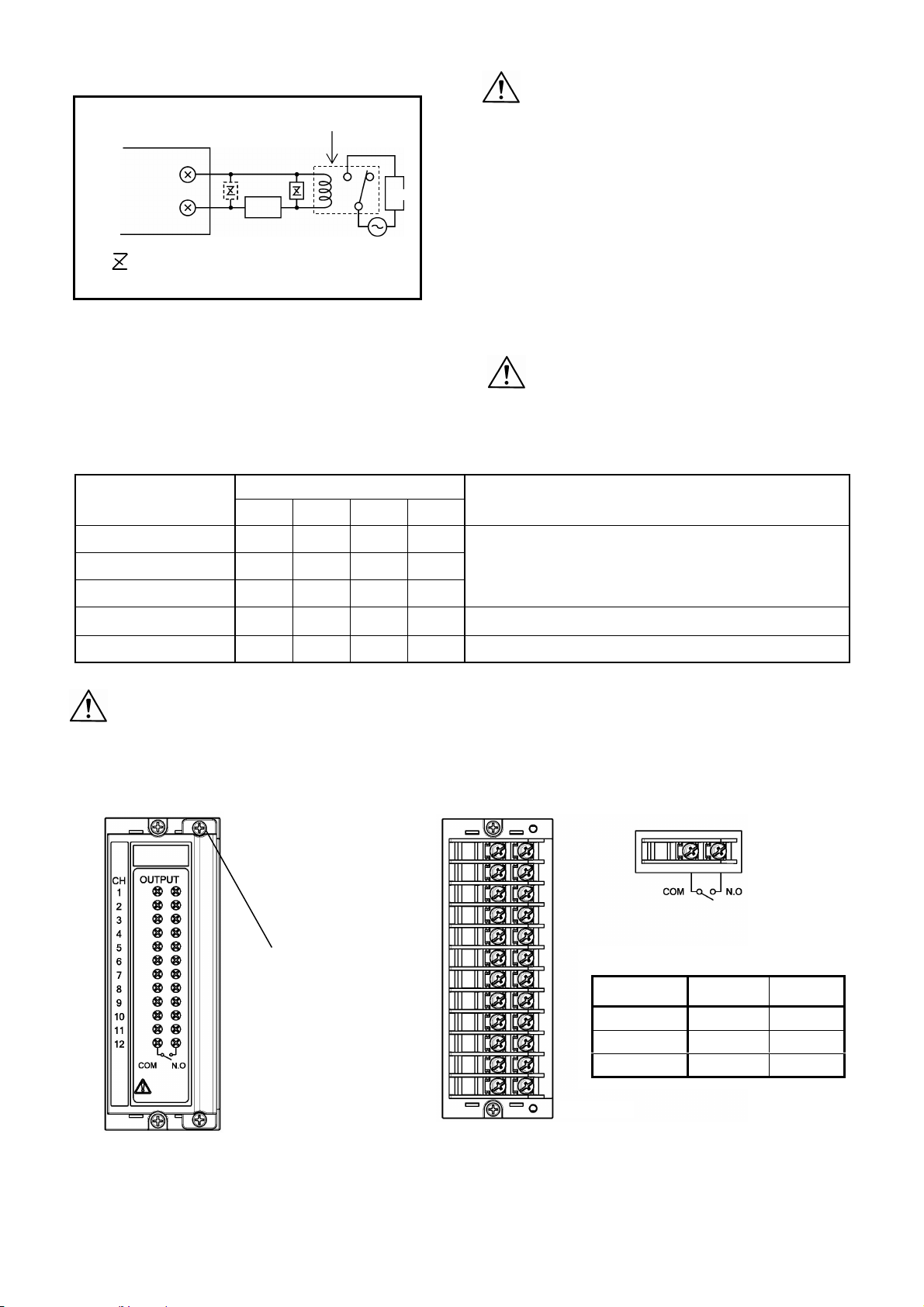

3. Output relay terminal connections

Power

supply

Buffer relay

a

Load

This unit

N.O

COM

b

: Contact protective device

(Mounting on “a” side is desirable)

4. External drive connections and operation selection

The following operation can be executed by contact

signals from the terminals.

① Selection of 3 chart speeds (speed numbers)

② Recording execution and stop

③ Data printing

External drive functions and inter-terminal conditions

External drive functions

Across COM – EX□ terminals

EX1 EX2 EX3 EX4

Cautions

1. Connect a load of less than the designated contact

capacity to the output relay terminals.

2. Turn off the feed power source and buffer relay

power supply before starting connections for

preventing an electric shock accident.

① Connect output relay terminals to the load via a

buffer relay.

② For connection to the output terminals, use crimp

style terminals each having an insulation sleeve.

3. The buffer relay power supply is applied to the

output relay terminals after connections and an

electric shock accident occurs if you should touch

these terminals. Mount a terminal cover without fail

after connections.

Cautions

Turn off the feed power source before starting

connections of external drive terminals for

preventing an electric shock accident.

Remarks

ON : Shorted

OFF : Open

Chart speed 1

Chart speed 2

Chart speed 3

Recording execution

and stop

Data printing

※)Data cannot be printed unless recording is being executed.

Cautions

OFF OFF OFF OFF

ON OFF OFF OFF

OFF ON OFF OFF

OFF OFF ON OFF

OFF OFF OFF ON

Receiving and feed operation by setting keys are effective.

For changing the selected chart speed number and chart

speed, refer to the instruction manual, option volume.

Receiving and feed operation by setting keys are ineffective.

Keep ON time for longer than 1 second.

For the contacts being connected to the external drive terminals, use contacts of a switch, a relay, or the like

which is driven by lower than 30V AC or 60V DC or use manual contacts.

4-3-4 Alarm output terminals

CH1

Terminal cover screw

(Remove two upper and

lower screws respectively)

CH12

Power supply

100VAC 0.5A 0.2A

メカリレー出力の接点容量

240VAC 0.2A 0.1A

30VDC 0.3A 0.1A

Resistive

load

(Caution 1) The alarm output is a mechanical relay “a” contact output. For connections, refer to

[3. Connections of output relay terminals].

Inductive

load

4-4

Page 19

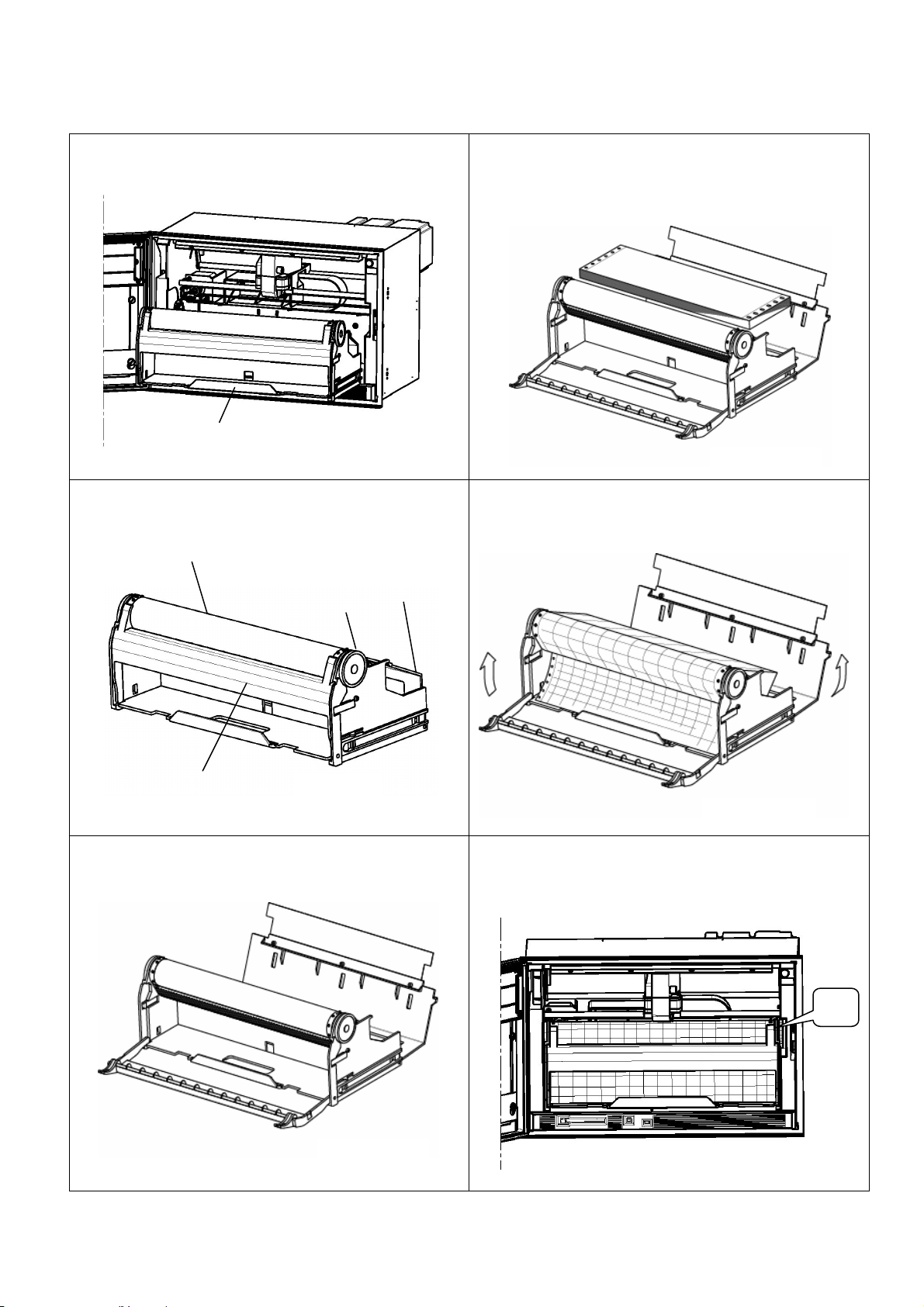

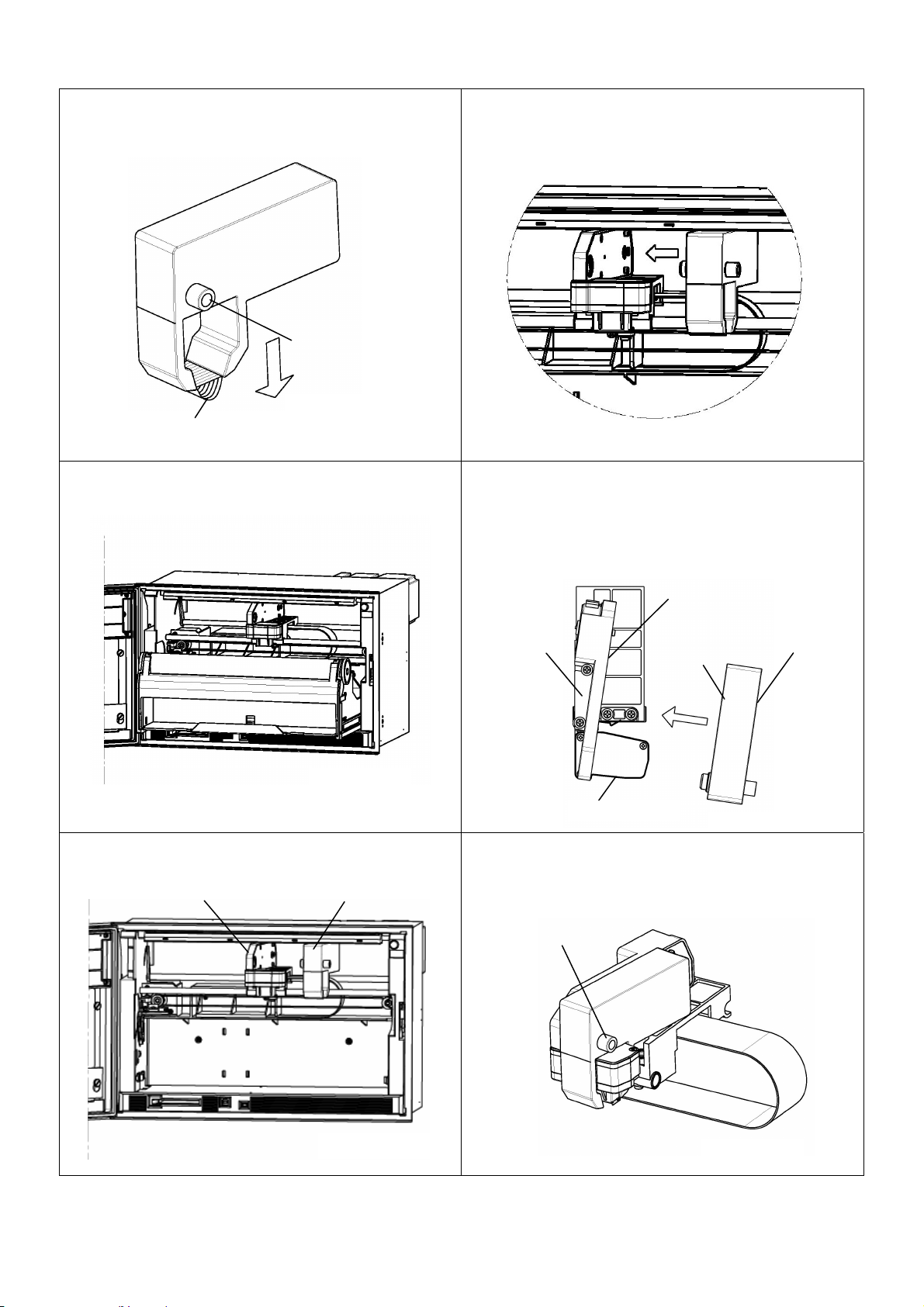

5. Installation of auxiliary products

5-1 Mounting method of chart

① After opening the door, take out the chart rack by pulling it

this side.

④ The chart is provided with circular holes at the left end and

elliptic holes at the right end. Put the chart into the chart

loading section horizontally under the condition.

※ Shuffle the chart sufficiently before setting the chart for

preventing a double feed.

Chart rack pull-out grip

② Chart rack unit

Chart drum

Front chart holder

③ Pull down the front chart holder and chart holder before

setting the chart.

Chart holder

Knob

⑤ Fit the holes at both ends of the chart to the chart drum

sprocket. After setting the chart, reset the front chart holder

and chart folder to their original positions from being tilted

down conditions in ③.

⑥ Mount the chart rack unit to the chassis, and fold the chart

by 2-3 by turning the knob by means of fingers. In this case,

set the chart fold to meet the convex and concave marks at

the right end of the chart.

Knob

5-1

Page 20

5-2 Ribbon cassette mounting method

① Prepare the ribbon cassette. Loosen the ribbon cassette

about 10mm by pressing it in the arrow direction using the

shaft of a ball-point pen or the like.

Ribbon knob

Ribbon

④ Keep the printer carriage unmovable by pressing it with

the left hand, and mount the ribbon cassette in the arrow

direction by the right hand.

② After opening the door, turn off the power switch and draw

out the chart.

⑤ Refer to the top view shown below. The ribbon cassette is

mounted diagonally as illustrated below. Make sure that

face A of the printer carriage and face B of the ribbon

cassette are mounted without any clearance.

When the ribbon cassette is mounted completely, a click is

heard by the locker spring.

Printer carriage

Face A

Face B

Ribbon cassette

Printer head

③ Move the printer carriage to about the center by hand. ⑥ After the ribbon cassette has been mounted normally,

straighten the ribbon by turning the ribbon knob clockwise

Printer carriage Ribbon cassette

1-2 turns. Reset the chart rack unit to the chassis.

Ribbon knob

5-2

Page 21

6. Operation

6-1 Turning on the power supply

1) Confirm the connections.

2) After opening the door, turn on the power switch at the upper right of the chassis.

(Caution1 ) Setting information and clock are backed up. Also, the display mode is backed up, but the channel number is

Also, data are displayed by turning on the power supply again after turning it off once under the setting check

(Caution 2) If recording is turned off, a date (year, month, day) is not printed when turning on the power supply.

<Display>

— LE Series —

After about 5 seconds,

data are displayed.

not backed up. Accordingly, the range-set lowest channel number data are displayed in case of one-point

continuous display. In the same way, data are displayed starting with the range-set lowest channel number in

case of the multi-point sequential display.

condition.

(See caution 1)

6-2 Display mode selection

This unit provides 6 kinds of display modes, although this depending upon the number of input points.

1) Each measuring data is fixed and displayed every channel.

2) Each measuring data is sequentially displayed every channel.

3) All input points are displayed collectively. (12-point collective display in case of 12-point unit, 24-point collective display

in case of 24-point unit, 36-point collective display in case of 36-point unit)

4) 12-point measuring data are collectively fixed and displayed. (24-point and 36-point units excluding 12-point unit)

5) 12-point measuring data are collectively and sequentially displayed. (24-point and 36-point units excluding 12-point unit)

6) Type code, serial number, software version number of this unit are displayed.

Display update cycle

Display modes

Display update cycle of measuring data:

1 second

Display update cycle of input channels:

2 seconds (Setting of this factory delivery value can be changed.)

Collective display update cycle of 12 point data:

3 seconds (Setting of this factory delivery value can be changed.)

1-point fixed display mode: Fixed display of an optional channel.

Stepwise forward move by ▲ key and stepwise backward move by ▼ key

1-point sequential display mode: Input channels are displayed sequentially every 2 seconds.

Stepwise forward move by ▲ key and stepwise backward move by ▼ key

Collective display mode of all points.

12-point fixed display mode: Fixed display of 12 points.

Stepwise forward move by ▼ key and stepwise backward move by ▲key

Collective forward move of 12 points by ► key and collective backward move of

12 points by ◄ k e y

12-point sequential display mode: Sequential display of 12 points.

Stepwise forward move forward by ▼key and stepwise backward move by ▲key

Collective forward move of 12 points by ► key and collective backward move of

12 points by ◄ k e y

Power ON

<Printer>

Initial position detection

Date, time, chart speed, and [POWER ON ***]

are printed and the chart is fed about 3mm.

(See caution 2)

Model code, serial number, software version number display mode

6-1

Page 22

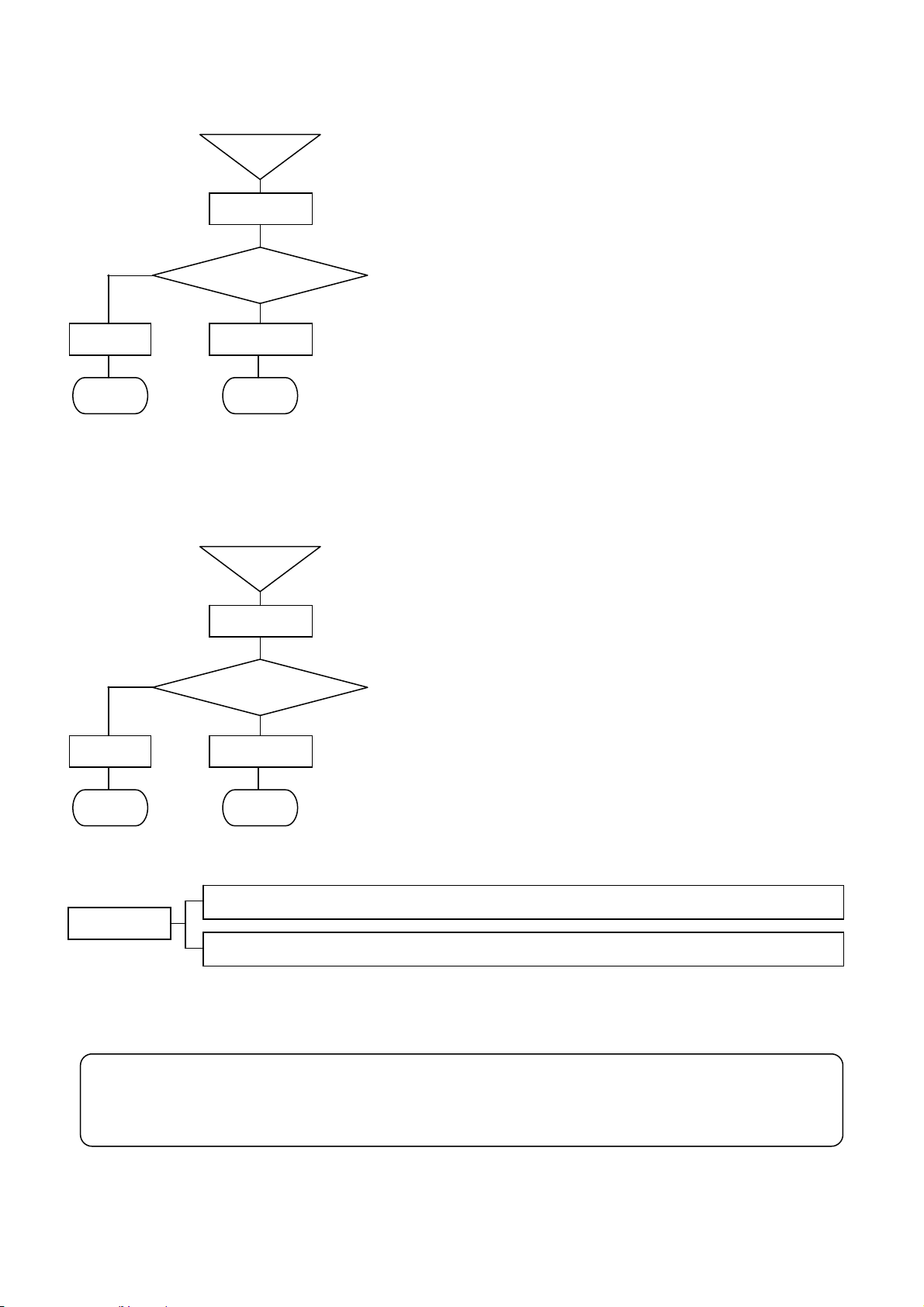

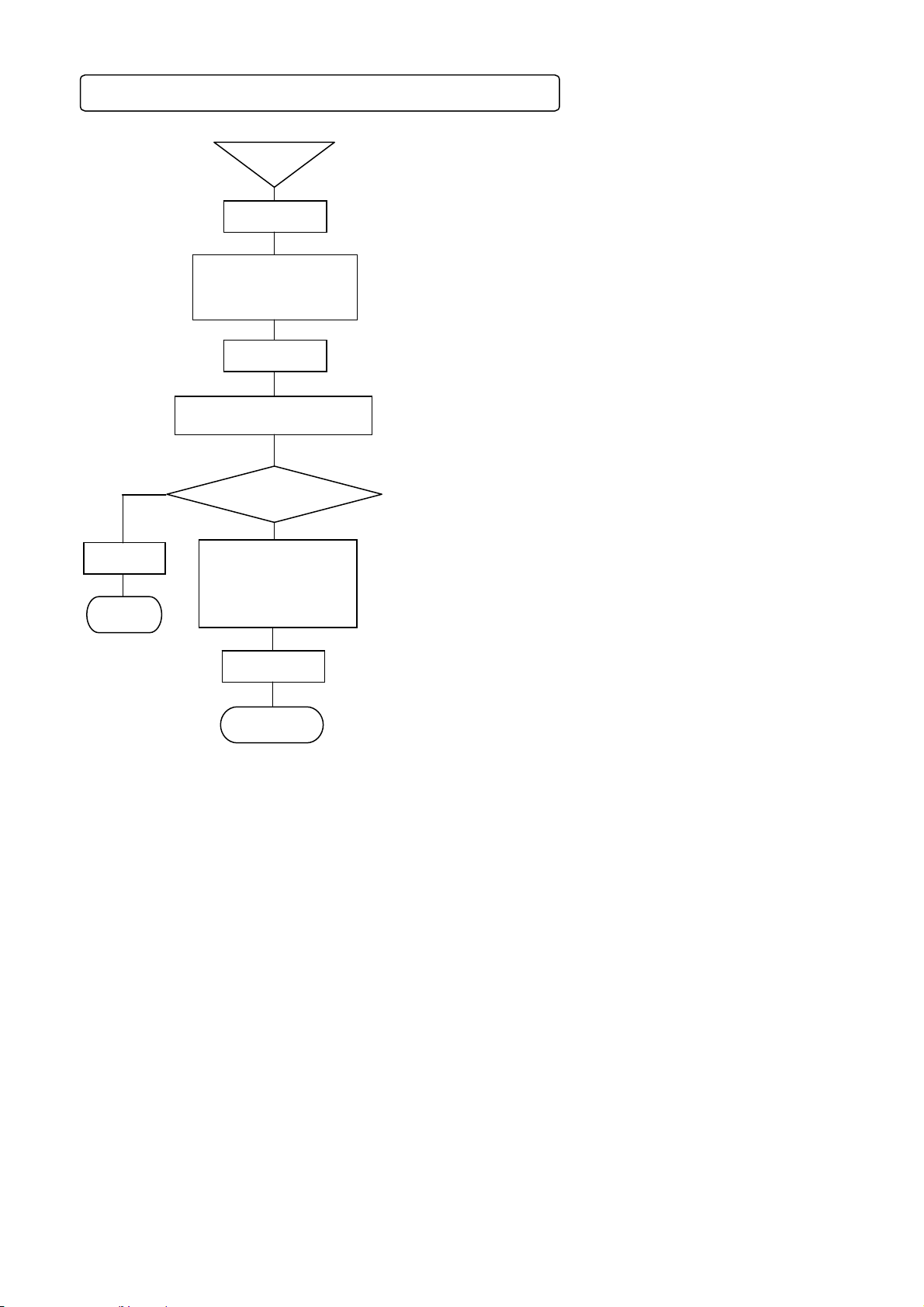

6-3 Recording operation

Start

y

y

y

y

y

y

1) Recording ON-OFF

Recording can be turned on and off by Rec key and Enter key.

①

③

Esc ke

End

NO

Rec ke

Set?

YES

②

Enter ke

End

2) Data printing

Latest measuring data are digitally recorded by interrupting the present analog recording.

NO

Esc ke

End

②

Start

DataP ke

Set?

Enter ke

End

YES

①

③

① By pressing Rec key under Rec. ON condition, a message [Do

you terminate chart recording?] is displayed on the display unit.

By pressing Rec key under Rec. OFF condition, a message [Do

you start chart recording?] is displayed on the display unit.

② For stopping the setting, the screen returns to the last one, each

time Esc key is pressed once.

③ Terminate the setting by pressing Enter key. ON and OFF are

switched from each other by pressing Enter key.

(Caution 1)

REC. ON green LED lights in the status display unit under the

recording ON condition.

(Caution 2)

Recording is stopped under the recording OFF condition, but the

input entry, data update, and alarm, etc. operation are executed.

(Caution 3)

The following functions are not employable under the recording

OFF condition.

• Data printing • List printing

• Logging recording

① By pressing DataP key, a message [Do you start data printing ?]

is displayed on the display unit.

② For stopping the setting, the screen returns to the last one, each

time Esc key is pressed once.

③ Terminate the setting by pressing Enter key.

By pressing Enter key, the latest scan data at that time are

digitally recorded.

(Caution 1 )

Format is set by [DATA PRINT] of the menu.

(Caution 2 )

If digital recording is necessary at a fixed interval, use either data

interval recording or logging recording.

(Caution 3 )

Not employable under the recording OFF condition.

Two kinds of digital recording formats are available. These formats can be set optionally according to uses.

TAG+DATA+UNIT(10CH/1LINE) 10 channels/line (Max 11 digits per channel)

Format

TAG+DATA+UNIT(6CH/1LINE) 6 channels/line (Max 19 digits per channel)

3) Chart feed

The chart (recording paper) can be fed by Feed key.

The chart is fed at a speed of 750mm/min when Feed key is being pressed.

Use this function when measured objective and/or measuring conditions have been changed.

The chart can also be fed manually by the knob. However, it is possible that the chart is not fed by several

mm due to a mechanical reason of this unit. It is, therefore, recommended to feed the chart by Feed key.

Feed the chart by Feed key due to the same reason when a new chart has been mounted.

6-2

Page 23

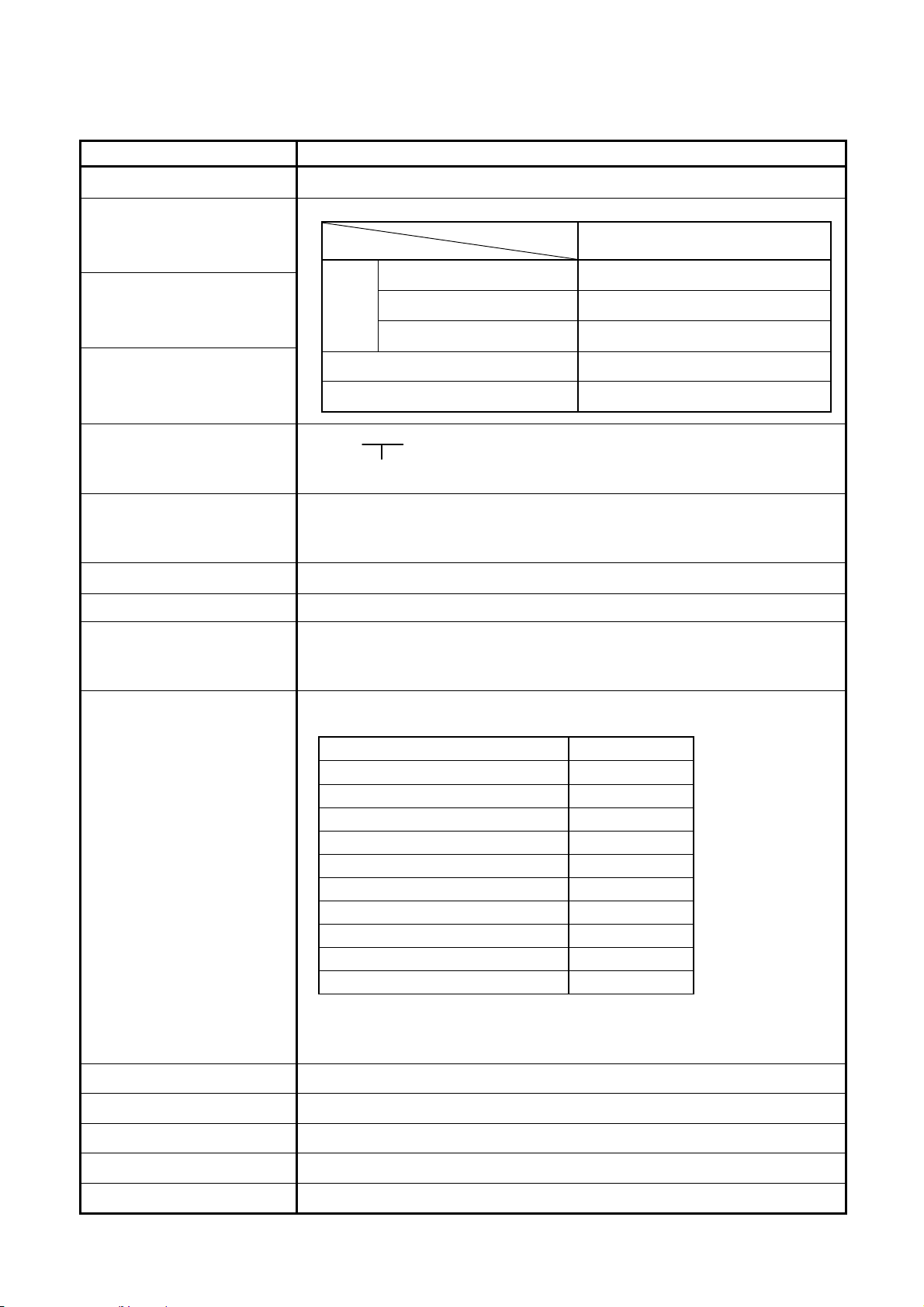

7. Initial setting at the delivery time from the factory

r

7-1 Setting items at the delivery time from the factory

Items Initial setting items

(1) Time

(2) Range

(3) Scale

(4) Unit

(5) Tag number

(6) Skip

(7) Chart speed

(8) Scan cycle (Input entry cycle) Automatic development value of chart speed (28.8sec)

(9) Digital recording format

(10) Analog recording format

(11) Dots All OFF

Present time (year, month, day, Japanese time)

Item

① Input type V(-10.000 to 10.000)

(2)

Range

(3) Scale

(4) Unit

*01-*□□□

Channel numbe

①Display skip

②Digital printing skip

③Memory card recording skip

25mm/h Dotting cycle : Chart speed interlocking cycle

①Data interval (Data I)

②Logging recording

③Data printing (Data P)

①Format : Standard

②Recording colors

1・11・21・31・41・51・61・71

2・12・22・32・42・52・62・72

3・13・23・33・43・53・63

4・14・24・34・44・54・64

5・15・25・35・45・55・65

6・16・26・36・46・56・66

7・17・27・37・47・57・67

8・18・28・38・48・58・68

9・19・29・39・49・59・69

10・20・30・40・50・60・70

● Channels 37-72 are mounted as auxiliary channels.

They are used as differential recording channels, etc.

● Recording colors are those in initial setting and they can also be designated

optionally.

② RJ

③ Analog recording range -10.000 to 10.000

Channel numbers Recording colors

Models

Not provided ( external)

-10.000 to 10.000

① Model LE511 : *001-*012

② Model LE512 : *001-*024

③ Model LE513 : *001-*036

: Not set in all channels

: Not set in all channels

: Not set in all channels

: Not set

: Not set

: 1 line/6 channels printing

Green

Yellowish green

Orange

Red

Reddish purple

Brown

Bluish green

Purple

Bluish purple

Black

LE5100/LE5200

V

(12) Alarm setting Not set

(13) Differential recording setting Not set

(14) Message setting Not set

(15) Password setting

3571

7-1

Page 24

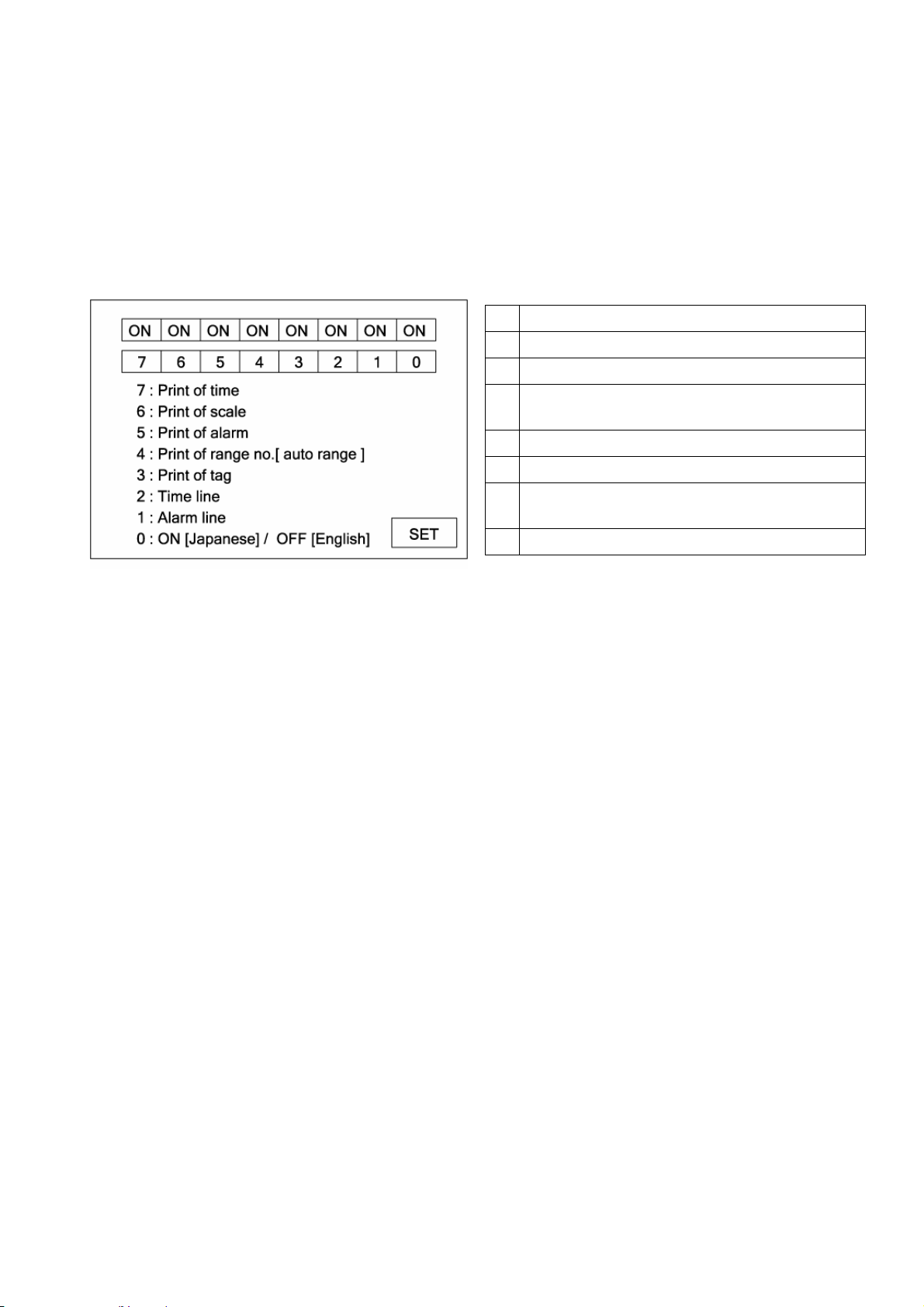

7-2 Mode change by soft switch

The LE5000 series is able to select ON/OFF (show/not show) of various printing by initial settings.

Refer to below for setting as required. Initial setting in factory delivery is all [ON].

1. Indication method of setting screen

When turn on the power supply of instrument, [LE Series] is displayed in the display screen. Enter [332] by setting

key of recorder while [LE Series] is displayed.

2. Detail setting

When enter [332], display a screen like below, so setup according to the following procedure.

When select [7] to [0] by key, and then press [enter] key, ON/OFF are switched every pressing [enter] key.

After every selects are done, cursor is moved to [SET] by key, and press [Enter] key to terminate the setting.

7

Time printing ON/OFF

6

Scale printing ON/OFF

5

Alarm activation/reset printing

Range No. printing ON/OFF at automatic range

4

switch

3

Tag printing ON/OFF

2

Time line printing ON/OFF

Alarm activation/cancellation mark printing

1

ON/OFF

0

Switch Japanese/English in setting screen

7-2

Page 25

8. Setting and changes by key operation

8-1 Basic rules

Read these rules without fail before starting setting

This paragraph describes general common items in setting operation.

1. Setting items and setting parameters

In measurement and recording, versatile recording results and data are obtained according to various

conditions setting of this unit.

Measuring and recording conditions such as the range, speed, chart speed, etc are called setting items.

Individual definite contents of these setting items are called setting parameters or merely parameters.

2. Calling of setting items

All calling is started with Menu key. By pressing Menu key, various setting items are displayed. Select a setting

item by ◄•►•▲•▼ keys and define it by Enter key. Certain setting items are displayed over several

hierarchies.

3. Calling of setting parameters

When the items to be set are defined, a window opens to be ready for setting the setting parameters.

4. Acceptance and acceptance failure of keys

If the cursor does not move by ◄•►•▲•▼ keys or the parameter setting window is not opened by Enter key, it

is caused by an acceptance failure. Check if these keys are pressed securely.

5. No. of parameters by setting items

Number of setting parameters depends upon the setting items. One parameter is provided for time and chart

speed, while several parameters requiring the designation of channels are provided for ranges, scales, and

alarms.

6. Confirmation of setting parameters

Setting parameters can be set in two ways. One is the list printing to confirm all setting items or designated

setting items by printing them, while the other is the display confirmation to confirm the setting parameters by

calling them to the display section. The [Display confirmation] method will be described here.

For the [List printing], refer to 8-9.

Setting parameter

confirmation

Display confirmation

All items list

List printing

Designated items list

When plural setting parameters are called, the preset lowest channel number is displayed.

After designating the channel number to be confirmed, press Enter key, and parameters of the channel are

displayed.

For confirming the other channel, return to the last screen by Esc key, select the channel by ◄•►•▲•▼ keys,

and press Enter key again to display the parameters of the channel.

If setting (change, addition) is not executed, irrespective of the number of setting parameters, press Esc key,

and the screen returns to the last one. Continue pressing Esc key until the mode returns to the normal display

mode.

8-1

Page 26

Start

y

y

y

1. Confirmation method in case of one setting parameter

◄•►

①

②

③

⑤

Esc ke

End

NO

Menu ke

Selection of setting items

by

◄•►•▲•▼ keys

Enter ke

Setting parameter display

④

Setting (change,

addition) by using

•▲•▼ keys, numeric

keys, etc.

Set?

YES

① Select the setting display mode by pressing Menu key.

A window opens to display a list of setting items.

② Move the cursor by ◄•►•▲•▼ keys and select an item to

be confirmed.

③ Select the setting mode of the desired setting item by

pressing Enter key.

A window opens to display various setting parameters.

④ If setting (change or addition) is not done after confirming

various setting parameters, return to the last screen by

pressing Esc key.

In case of the left procedure example, the screen is reset

to the start screen by pressing Esc key twice.

⑤ If setting (change or addition) is done after confirming

various setting parameters, use ◄•►•▲•▼ keys and

numeric keys.

⑥ Press Enter key to terminate the setting (change, addition).

Enter key

Setting end

⑥

8-2

Page 27

y

y

y

y

2. Confirmation method in case of plural setting parameters

Selection of setting items

by ◄•►•▲•▼ keys

Selection of channel number

by

Setting parameter display

NO

Esc ke

⑥

addition) by using

•▲•▼

End

Start

Menu ke

Enter ke

◄•►•▲•▼keys

Enter ke

Setting (change,

Set?

YES

◄•►

keys, numeric

keys, etc.

①

②

③

④

⑤

⑦

① Select the setting display mode by pressing Menu key.

A window opens to display a list of setting items.

② Move the cursor by ◄•►•▲•▼ keys and select an item to

be confirmed.

③ Select the setting mode of the desired setting item by

pressing Enter key.

A window opens to display channel numbers.

④ Move the cursor by ◄•►•▲•▼ keys and select a channel

to be confirmed.

⑤ Select the setting mode of the desired setting item by

pressing Enter key.

A window opens to display various setting parameters.

⑥ For advancing the channel forward or backward after

confirming the setting parameters of the channel to be

confirmed, press Esc key to return to the last screen, and

repeat steps ④-⑥.

Press Esc key if setting (change, addition) is not done.

In case of the left procedure example, the screen is reset

to the start screen by pressing Esc key twice.

⑦ If setting (change or addition) is done after confirming

various setting parameters, use ◄•►•▲•▼ keys and

numeric keys.

⑧ Press Enter key to terminate the setting (change, addition).

Enter key

Setting end

⑧

8-3

Page 28

7. Setting change

For setting change, shift the cursor to a desired point to be changed.

For moving the selection system parameters by cursor, ▲•▼ keys are used. However, ◄•► key is

normally used. Setting can be changed by the substitution method, edition method by shifting the cursor,

and new setting method after erasing all setting.

Setting change

Substitution method

Edition method

New setting method

Change or erase by moving the cursor to the position to be changed

Edition by moving the cursor to the position to be changed

New key input after erasing all setting

1) Substitution method

Select a setting parameter to be changed. The selected setting parameter is high-lighted like 150 .

Input the parameter by keys directly after the selected setting parameter has been high-lighted as shown in

the example.

2) Edition method

Select a setting parameter to be changed. The selected setting parameter is high-lighted like 150 .

Press ◄•► key after the selected setting parameter has been high-lighted as shown in the example.

The high-lighting is reset and

150l cursor is displayed.

Edit the parameter by shifting the displayed cursor using ◄•► key.

By pressing Esc key under the 150l condition, 150l returns to 150 .

▲ key serves as the back space key while ▼ key serves as the delete key in this edition mode.

3) New setting method

Select a setting parameter to be changed. The selected setting parameter is high-lighted like 150 .

Erase the setting parameter by using ▲ key (back space key) or ▼ key (delete key) after the selected

setting parameter has been high-lighted as shown in the example. Then, input new parameter directly.

8. Switching of keys

When alphabetic keys or symbol keys are used, switch them by pressing [Shift] key.

This switching can be done only when alphabetic or symbol keys are necessary for [Units], [Tags],

[Messages], etc.

(Example: Setting of message printing)

By pressing [Enter] key after bringing the

cursor to the message, Shift : numeric

characters/alphanumeric characters are

displayed at the lower part of the display.

If [1] is high-lighted, numeric keys only

can be input. When [Shift] is pressed, [A]

is high-lighted to be ready for inputting

alphanumeric characters.

When [A] is high-lighted, [1 ABC] key is

switched in the order of 1 → A → B → C

→ a → b → c → 1.

9. Setting change mark

When a setting parameter is entered, a setting change mark is printed at the right end of the chart.

A changed item is printed on the right side of [<] as a setting mark.

For changing each channel, [<S] is printed in case of [<C] system (chart speed, etc.).

10. Setting define function

By pressing Enter key, the setting contents are checked by the unit. If an error occurs when checking the

setting contents, the status part at the lower part of the display turns red, and the error contents are

displayed.

8-4

Page 29

11. Basic entry of setting parameters

When various setting parameters are entered, a window opens to display a setting parameter entry screen.

The basic common operation in the setting parameter entry screen is as shown below.

Example 1: Chart recording setting screen; In case of selection of setting parameters by ▲・▼ keys.

1. ①, ③, ⑤, and ⑦ are called a setting item ,while ②, ④,

and ⑥ are called a parameter input area.

2. When the setting parameter entry screen is displayed,

chart speed ① is high-lighted (A cursor is present on the

chart speed). Set the cursor to meet the dot

synchronization by ▲・▼・◄・► keys under the above

condition.

Press Enter key. Parameter input area ④ is high-lighted to

be ready for selection (input).

3. A window as shown in ⑧ is displayed when selecting

setting parameters as shown in this example. Select a

setting parameter by using ▲・▼ keys in this window.

For setting the chart speed, bring the cursor to meet the

chart speed by ▲・▼ keys and press Enter key.

4. By pressing Enter key after setting the parameter input

area ④, optional cycle ⑤ is high-lighted. By pressing

Enter key under this condition, parameter input area ⑥

is high-lighted to be ready for input.

5. By pressing Enter key after parameter input area ⑥ has

been set, define ⑦ is high-lighted. When no error occurs

in setting parameters of all setting items, press Enter key,

and the setting ends.

If a setting item is in error to move to the other setting

item, press ▲・▼ keys, and the move can be done to each

setting item on condition that Enter key is not pressed yet.

(Point 1)

When the cursor is present on a setting item, the setting

item can move to individual setting items by ▲・▼・◄・

► keys.

8-5

Page 30

Example 2: Display mode setting screen; In case of inputting a setting parameter by using keys

1. When the setting parameter entry screen is displayed,

AD ① is high-lighted. (The cursor is present on AD)

By pressing Enter key under this condition, parameter

input area ② is high-lighted to be ready for input.

2. Input a setting parameter by numeric keys, etc. under

the high-lighted condition of parameter input area ②.

Cursor [ | ] in the parameter input area can be moved

by ◄・► key under this condition. Press Enter key

after the end of input.

3. By pressing Enter key after setting the parameter input

area ②, month ③ is high-lighted.

By pressing Enter key after parameter input area ⑫

has been set in the same way, define ⑬ is high-lighted.

When no error occurs in setting parameters of all setting

items, press Enter key, and the setting ends.

If a setting item is in error to move to the other setting

item, press ▲・▼ keys, and the move can be done to

each setting item on condition that Enter key is not

pressed yet.

(Point 1)

When the cursor is present on a setting item, the setting

item can move to individual setting items by

► keys.

(Point 2)

By pressing ◄ key or ► key when the parameter input

area is high-lighted, cursor [ | ] is displayed in the

parameter input area to be ready for moving by◄・►

key.

(Point 3)

When cursor [ | ] is displayed in the parameter input

area to be ready for moving by◄・►key, ▲key serves

as Back Space key, while ▼ key serves as Delete key.

(This is not applicable if the parameter input area

adopts the selection method.)

▲・▼・◄・

8-6

Page 31

8-2 Display setting

y

y

y

This unit comprises 4 kinds of display modes. The present display mode is [12CH], but the other display mode is

settable as occasion demands.

Esc ke

End

NO

Selection of setting items

by

⑤

Start

Menu ke

◄•►•▲•▼ keys

1CH・12CH・

Set?

YES

Enter ke

Setting end

①

④

(Caution 1)

If skip is designated, data in skip designation

channels are not displayed.

(Caution 2)

The update cycle of data display is 1 second,

and the input loading cycle is 0.1 second

fixation. The data update cycle and the input

loading cycle are not synchronized.

(Caution 3)

Channels can be moved forward or backward

by ◄•►•▲•▼ keys even in case of the

sequential display mode.

(Caution 4)

By turning off the power supply, the one-point

fixed display mode is held, but the data

display channel number is reset to the lowest

channel number in range setting.

③

① Select the setting display mode by pressing Menu key.

A window opens to display a setting items table.

② Move the cursor by ◄•►•▲•▼ keys and select an item to be

confirmed.

③ Select 1CH, 12CH, or 36CH.

④ After selection, the desired display mode to be set is defined.

Either fixed display or sequential display is selectable in each

②

display mode.

(AUTO: Sequential/CONST: Fixed are switched from each

other, each time Func1 key is pressed once.)

⑤ For stopping the setting, the screen returns to the last one,

each time Esc key is pressed once.

A list of the kinds of display

11CH

2 1CH

3 12CH

4 12CH

5 1・12・36CH

6 1・12・36CH

1-point fixed display

1-point sequential display

12-point fixed display

12-point sequential display

All-point fixed display

All-point sequential display

Display mode

Tag

Unit

For details, refer to 8-13 [Display].

Channel number + Range + Measuring data + Tag

Channel number + Range + Measuring data + Unit

※) If 1CH display is set, the display mode is limited to one

kind of [Channel number + Tag + Measuring data +

Range + Unit].

※) If SYS.DISP is set, system information about this

instrument is displayed. For details of display, refer to page

2-2.

8-7

Page 32

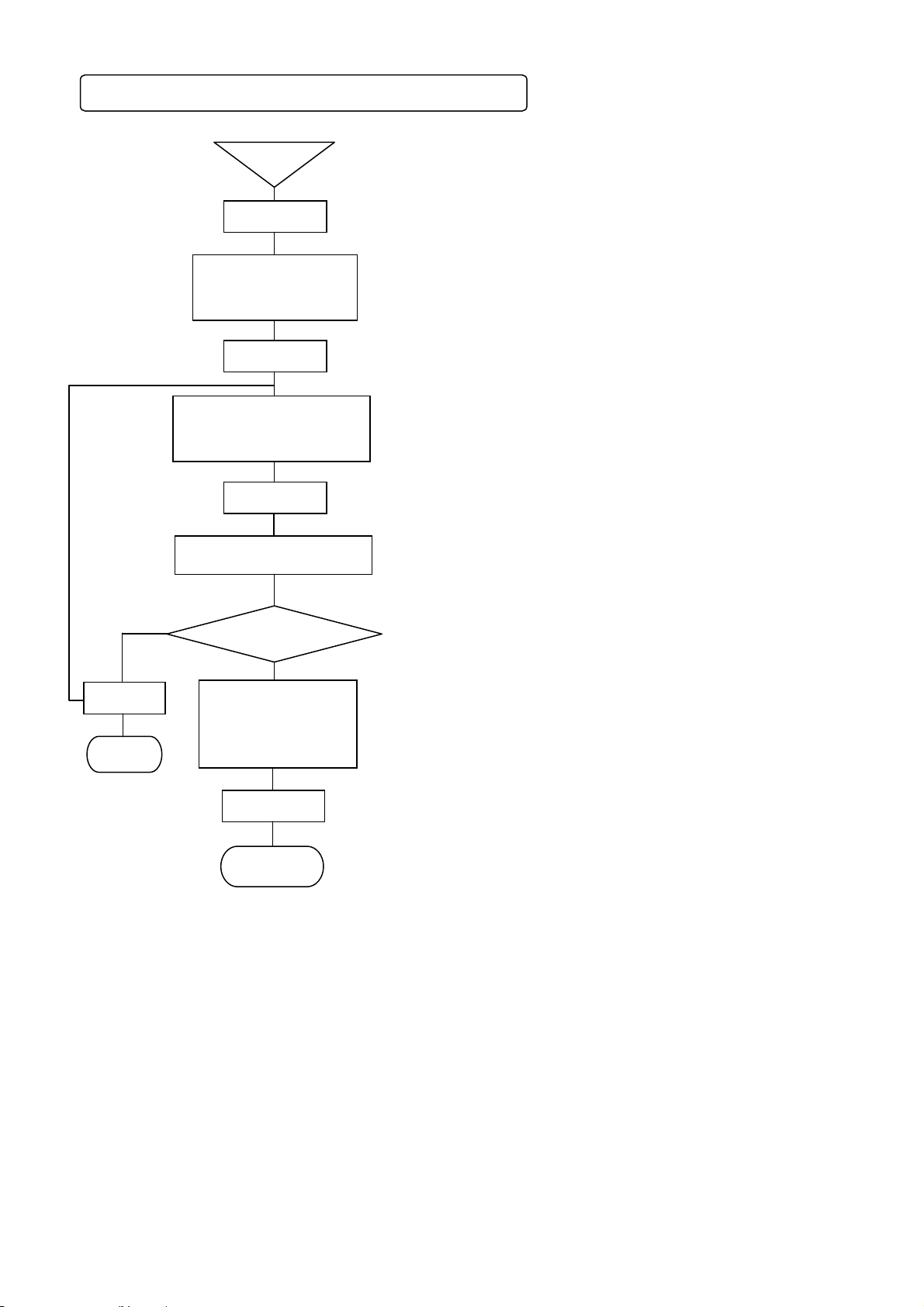

8-3 Channel parameter setting [CH PARAM.]

Start

y

y

y

y

y

Range, RJ (internal/external switching of reference junction temperature compensation), scale, unit, etc. of each

channel can be set collectively every channel.

NO

Esc ke

End

NO

Selection of setting items

◄•►•▲•▼ keys

by

CH PARAM.

Setting table display

(Collective setting of 12 points)

⑤

Select a channel by

using

Setting parameter display

Setting (change, addi-

tion) by using

item by◄•►•▲•▼

keys, numeric keys, etc.

Do you continue

Setting end

Menu ke

Enter key

Set?

YES

▲・▼ keys.

Enter ke

Set?

YES

setting

Enter ke

setting?

Esc ke

NO

①

③

④

⑦

YES

⑨

① Select the setting display mode by pressing Menu key.

A window opens to display a setting items table.

② Move the cursor by ◄•►•▲•▼ keys and select an item to be

confirmed.

③ Select CH PARAM.

④ Press Enter key to enter the setting table display. (For the setting

table display (collective 12 points) screen, refer to ⑥.)

⑤ For stopping the setting, the screen returns to the last one each

②

time Esc key is pressed once.

⑥ Move the cursor to a desired channel number to be set by ▲•▼

keys. The cursor does not move to any item other than CH No.

⑦ Select a channel to be set and press Enter key.

⑥

A window opens to display a setting parameter entry screen.

(For the setting parameter entry screen, refer to ⑧.)

⑧ Move the cursor to a desired item to be set by ◄•►•▲•▼ keys.

The cursor moves in the sequence of Input → RJ → Burn →

⑧

Filter → Range MIN → Range MAX → Scale MIN → Scale

MAX → Correction → Unit → Lower-limit of chart recording →

Higher-limit of chart recording → Tag → Display skip → Digital

printing skip → Memory card recording skip → Set, each time

Enter key is pressed once.

CH No. is fixed to the channel number selected in the setting

table display (collective 12 points) screen. For the parameter

input areas for input, RJ, burn, filter and various skips, setting

parameters are selected. Select them by ▲・▼ keys after the

window has opened. For the MIN and MAX of Range,

correction, MIN and MAX of scale, and MIN and MAX of chart

recording, input their setting parameters by using numeric

keys. For the unit and tag, input their setting parameters by

using numeric keys or other keys.

After the end of setting in this screen, bring the cursor to

Set .

⑨ Terminate the setting (change, addition) by pressing Enter key.

Press Esc key if the setting contents are not saved.

8-8

Page 33

⑩ By pressing Func1 in the screen display in ⑥ above,

r

the following screen is displayed. Screens ⑥, ⑩

are used for confirming the setting and copying the

setting items in the setting screen to the other

channels.

For returning to screen ⑥ from screen ⑩, press

Func1 key again.

Screen ⑧ can also be displayed by pressing Enter

key after moving the cursor to a desired channel

number to be set by ▲•▼ keys in this screen.

⑪ For copying channel parameters to the other

channel, press Func2 key in either screen ⑥ or ⑩.

⑫ Move the cursor to a desired item to be copied by ◄

•►•▲•▼ keys.

Each time Enter key is pressed once, [レ]/[ ] is

repeated.

Select [レ] for a desired setting item to be copied, and

select [ ] for a setting item to be not copied.

Press Enter key after moving the cursor to the copy

source.

After inputting a desired channel number as the copy

source by numeric keys, press Enter key, and the

cursor moves to the copy destination. By pressing

Enter key furthermore, the channel number at the

copy destination can be input by numeric keys.

By pressing Enter key after inputting a channel

number at the copy destination, the cursor moves to

[~]. Press Enter key, and the channel number at the

copy destination can be input by numeric keys.

After the end of setting on this screen, bring the

cursor to Copy

.

⑬ Terminate the copy by pressing Enter key.

※)When the input kind, scale lower-limit, and scale

higher-limit are changed in the setting of a channel

parameter, other settings (set value, dead band etc.)

may be influenced.

※)Resolution of analog recording depend on setting

value of scale lower-limit/higher-limit, not depend on

setting of chart recording lower-limit/higher-limit.

[Points] Channel parameter setting short-cut

Items ①-⑥ on the last page can be short cut so long as

the channel parameter setting is concerned. Bring the

cursor to a desired channel to be set by ◄•►•▲•▼

keys in each display mode of one-point display, 12-point

collective display, or all-point collective display, and then,

press Enter key.

Screen ⑧ on the last page is displayed and the setting

can be done by the same operation.

1. In case of one-point display, no cursor is displayed, but

the channel in which Enter key was pressed can be set.

2. In 12-point collective display/all-point collective display,

the cursor is present on a channel number. Move the

cursor by pressing ◄•►•▲•▼ keys.

3. When the channel parameter setting short-cut was used,

no copy function is provided on the setting screen.

4.For setting [℃], bring the cursor to the unit, and press

the Enter key for enabling the parameter input. [Shift] is

displayed below the setting screen (refer to page 8-4: 8.

Switching of keys). Press the shift key and high-light [A],

and press the key of right next shift key 4 times. Then,

input C and press Enter key for termination setting unit.

[Setting example]

Setting relation of [Scale lower-limit], [Scale higher-limit],

[Chart recording lower-limit] and [Chart recording higherlimit].

• Use K (-200.0 to 500.0) for input.

• Set [Scale lower-limit] to -200.0.

• Set [Scale higher-limit] to 500.0.

• Set [Chart recording lower-limit] to -100.0.

• Set [Chart recording higher-limit] to 300.0.

The recording range is reflected by each setting as

shown in the following figure.

Scale lower-limit Scale higher-limit

Scale zero

Chart recording

lowe

-limit

Scale span

Chart recording

higher-limit

Recording zero Recording span

(Caution 1)

Range lower-limit and higher-limit, scale higher-limit and

lower-limit, and chart recording lower-limit and higher-limit

can be set up to max. 5 digits (or can be set up to max. 6

digits if minus [-] is included).

If a numeric value includes a decimal point, however, the

numeric value excluding the decimal point is limited up

to ±30000.

Example: Settable up to ±300.00

If 500.00 is set, a message [The input value is

abnormal] is displayed and the setting is not

acceptable. Units and tags can be set up to max. 8

digits.

(Caution 2)

For moving between channels, use ▲・▼ keys.

In the channel parameter setting mode, channels 1-12

are displayed. For moving to channels 13-24, move the

cursor to channel 12, and press ▼ key. For moving to

channels 1-12 under the displayed condition of channels

13-24, on the contrary, press ▲ key.

8-9

Page 34

1.Operation recording

Operating conditions of peripheral units or the like are recorded at an optional position of the chart as operation

recording. This function is provided as a relative recording function between system conditions and measuring

data.

Max. 36 records can be marked on the chart.

Contact input Data display Digital recording Analog recording

Communication

output

Open

Short

【Note】 When the parallel scale recording of recording format is used, the recording positions

are % to the span of each area

OFF OFF

ON ON

Designated position (range setting)

2% (5mm) to the span (right) direction

The chart recording lower-limit is set to

[50] and the higher-limit is set to [52] at

the delivery time from our factory as

recording positions. By setting the chart

recording lower-limit to an optional

value, its set value +2 is automatically

expanded as the higher-limit.

Since the recording width can be

changed optionally, the chart recording

higher-limit value can be set optionally

in the same way as in the lower-limit.

If the chart recording higher-limit value

is smaller than the lower-limit value

ON/OFF recording positions are

reversed.

0

1

【Setting method】

1)This operation is done by setting channel parameters. (Ⅰ. Instruction Manual 8-2 [CH. PARAM.] )

2)For input, select ON/OFF (1:ON / 0:OFF).