Page 1

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

- Request to instrumentation engineers, constructors, and sale agents -

Make sure to deliver this instruction manual to the operator of this instrument.

- Request to the operator of this instrument -

This instruction manual is necessary for maintenance, too. Keep this manual

with care until the instrument is discarded.

Graphic Recorder

KR2S/KR3S

【Wiring/Installation】

Thank you for purchasing the KR series graphic recorder.

Before using your new recorder, please be sure to read this instruction manual that will advise

you on how to use the instrument correctly and safely and how to prevent problems.

Instruction Manual

Page 2

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Page 3

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Product warranty scope

This product is warranted for one year from the date of delivery. If it is damaged during the

warranty period, when used normally based on the cautions in the instruction manual labels

attached to the product, etc., it will be repaired without any charge (only in Japan). In the case,

we are sorry to trouble you, but please contact your dealer or nearest our sales office.

However, in cases of the followings, it will be repaired at your expense even during warranty

period.

1. Failure or damage caused by improper use or connection, or invalid repair or modification.

2. Failure or damage caused by fire, earthquake, wind or flood, thunderbolt, or other

extraordinary natural phenomena, or pollution, salt, harmful gas, abnormal voltage, or use of

unspecified power.

3. Replacement of parts or accessories that have reached the end of their life.

Furthermore, the term ‘warranty’ in this sense covers only a CHINO’s product itself. Therefore,

we are not responsible for compensation for whatever the damage that is triggered by failure of

our product.

Important notes for users

1. No part of this manual can be reproduced or copied in any form without permission.

2. The contents of this manual may be altered without prior notice.

3. This manual has been documented by making assurance doubly sure.

However, if any question arises or if any error, an omission, or other deficiencies are found,

please contact your nearest CHINO’s sales office.

4. CHINO is not responsible for any operation results of this software.

Attention while unpacking

1. Do not drop the recorder while taking it out of the box.

2. When transporting this recorder, pack the instrument in the original box and then put it with

cushions in another box. We recommend keeping the original box for transport.

3. When not using the recorder for a while after taking it from the panel, put the recorder in the

original box and store at room temperature and in a dust free atmosphere.

PREFACE

Thank you for purchasing the KR series graphic recorder.

Before using your new recorder, please be sure to read this instruction manual that will advise you

on how to use the instrument correctly and safely and how to prevent problems.

・ All company names and product names in this manual are trademarks or registered

trademarks of their respective companies.

・ Please note that the marks “TM” and “®” are omitted throughout this manual.

-1-

Page 4

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Disposal

Disposal

Separate the box, plastic bags, and cushioning materials the recorder is packaged in according

to the garbage collection method of the each community, and please cooperates to recycle.

Warning

A small amount of hazardous substance below the specified level

with RoHS directive is included in this recorder.

When disposing the recorder always request a professional to do

it or dispose it in accordance with local regulations.

This recorder includes a lithium battery. When disposing the

lithium battery, first remove the battery and always request a

professional to do it.

Caution

Perchlorate Material

This instrument uses battery with Perchlorate Material.

Special handling may apply, see

http://www.dtsc.ca.gov/hazardouswaste/perchlorate

Battery removal method

Do not replace the battery. Doing so might cause damage or malfunction. Do not remove the

battery, except when disposing the recorder.

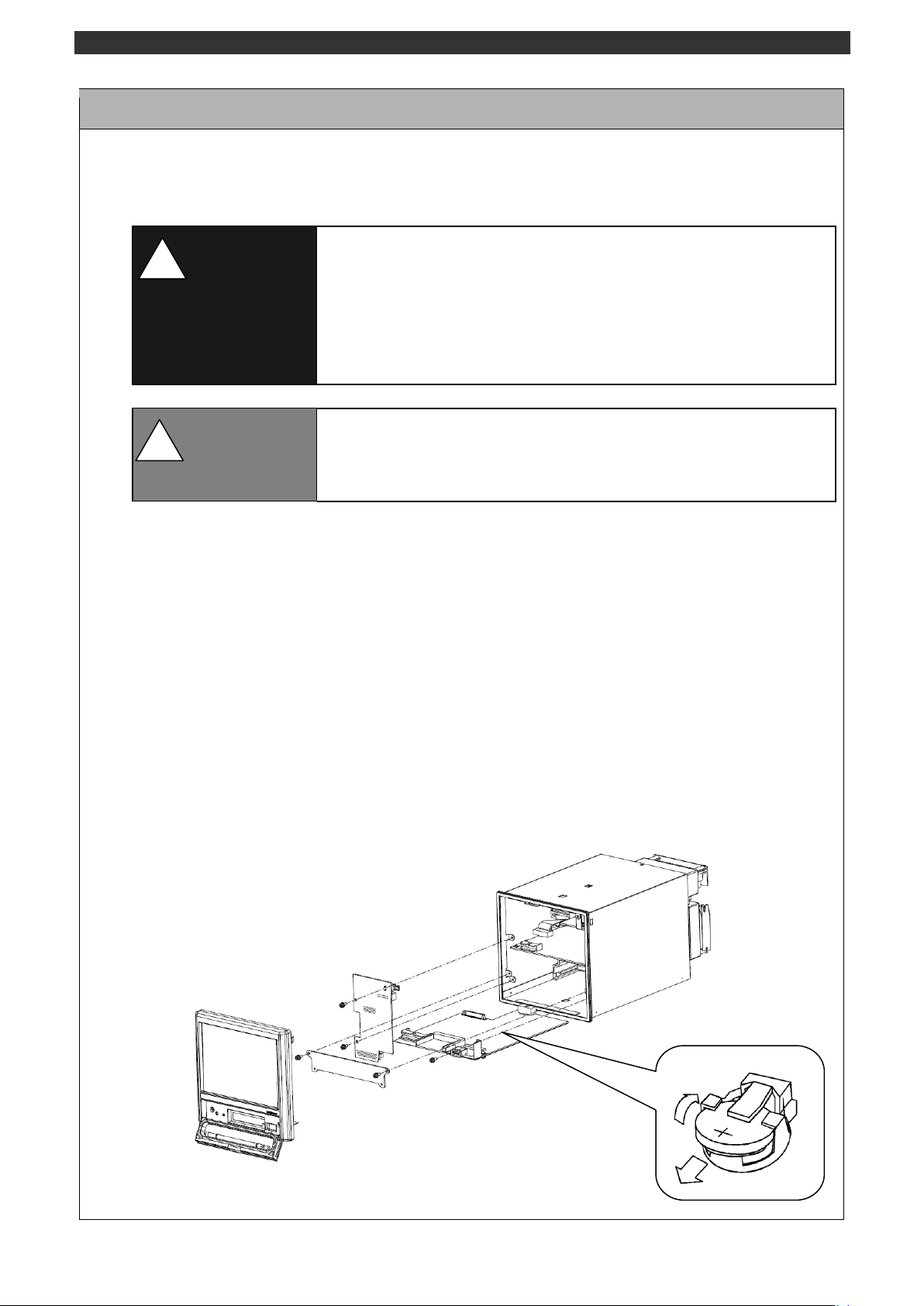

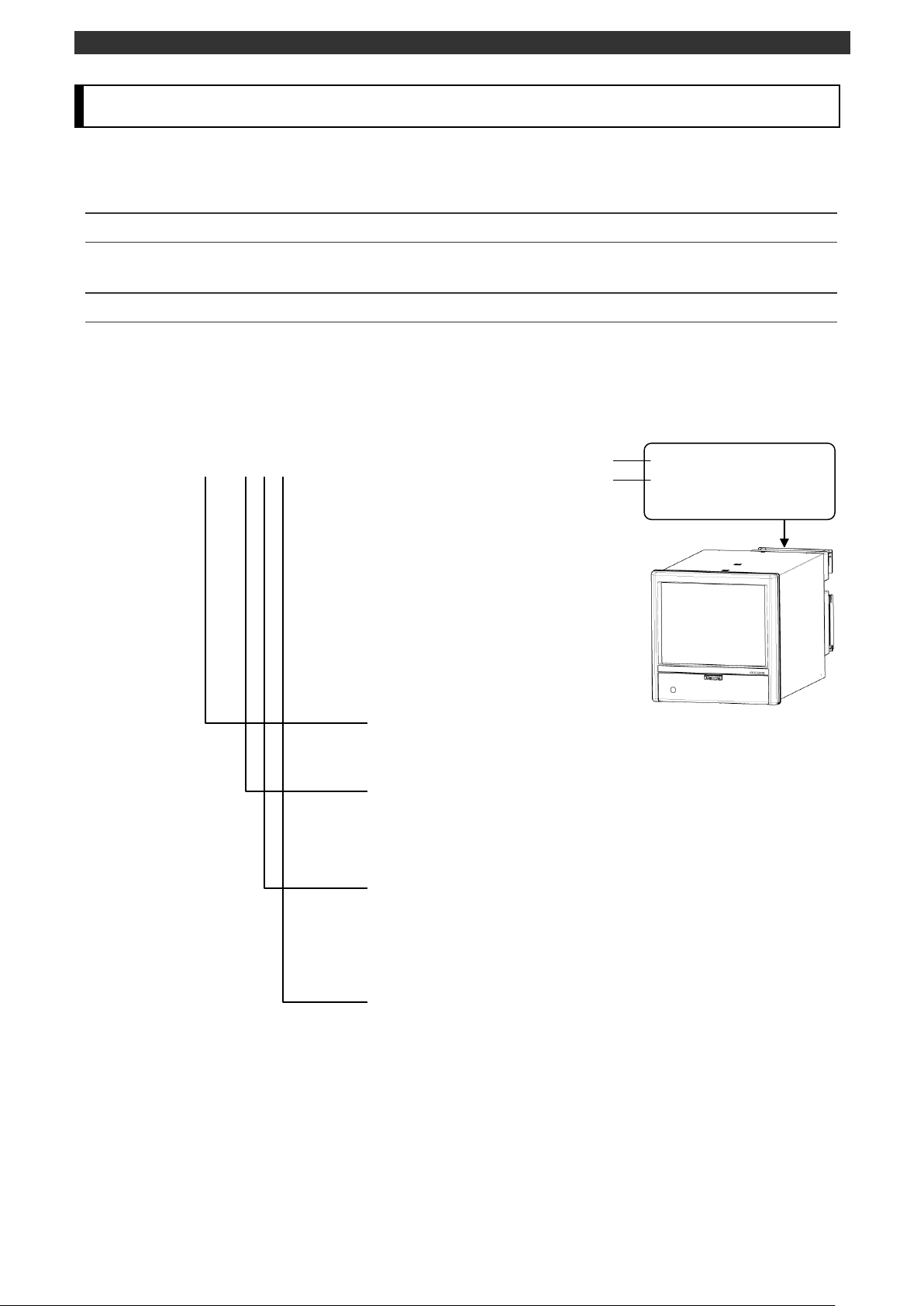

<KR2S>

(1) Open the cover and remove the 2 retaining screws.

(2) Pull the bottom of the front display panel toward you and lift up to remove the front display.

(3) The front display is connected to PWB-B by 1 type of cable. Disconnect it.

(4) Remove the 2 retaining screws holding Bracket and pull it out.

(5) Remove the 2 screws holding PWB-A, and pull it toward you.

(6) Remove the 1 screws holding PWB-B, and pulls it toward you.

(7) The battery holder is attached to the underside of PWB-B. Lift the front of the battery with a

tool having a nonconductive tip and pull the battery out of the holder.

Bracket

PWB-B

PWB-A

!

!

-2-

Page 5

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

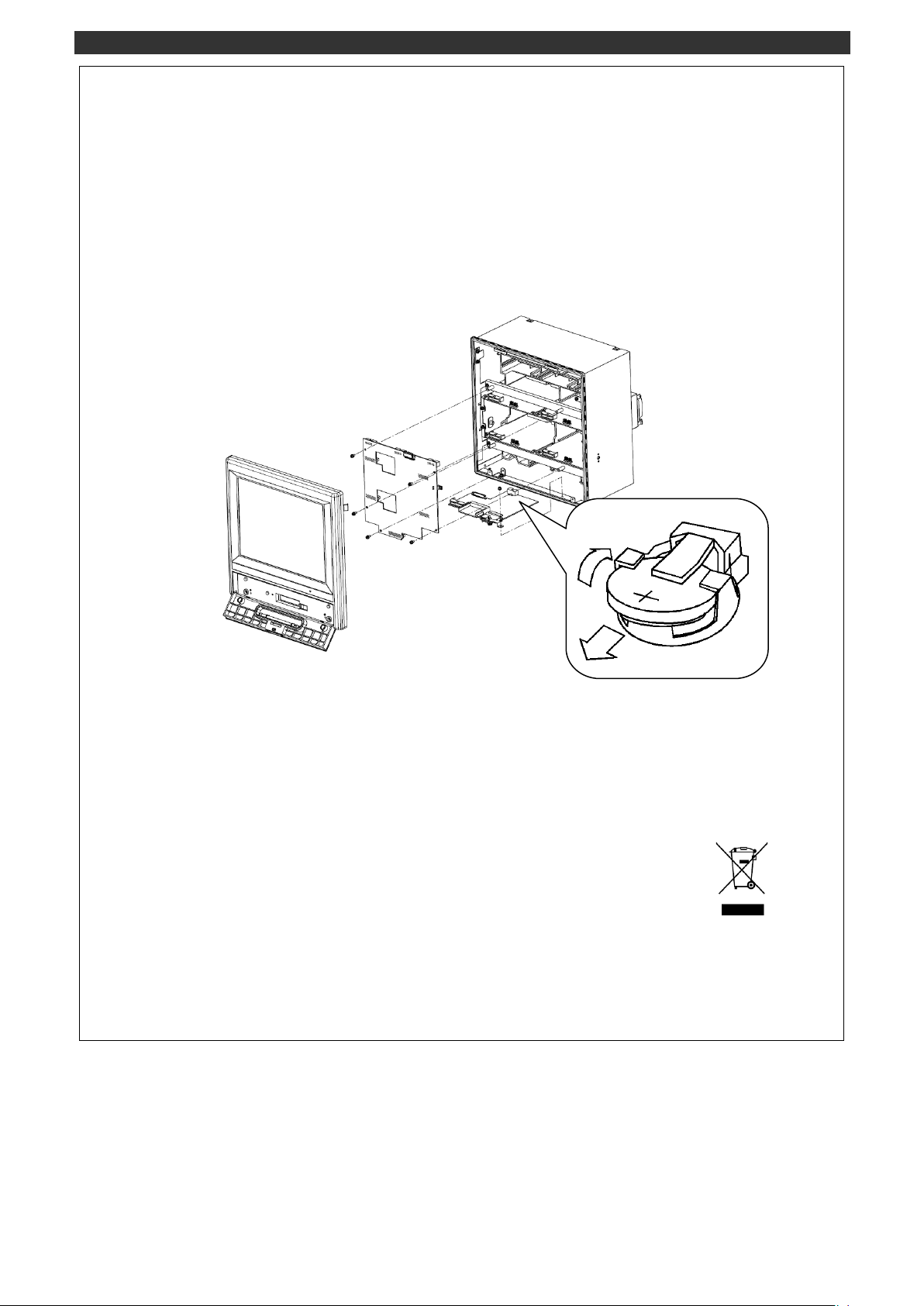

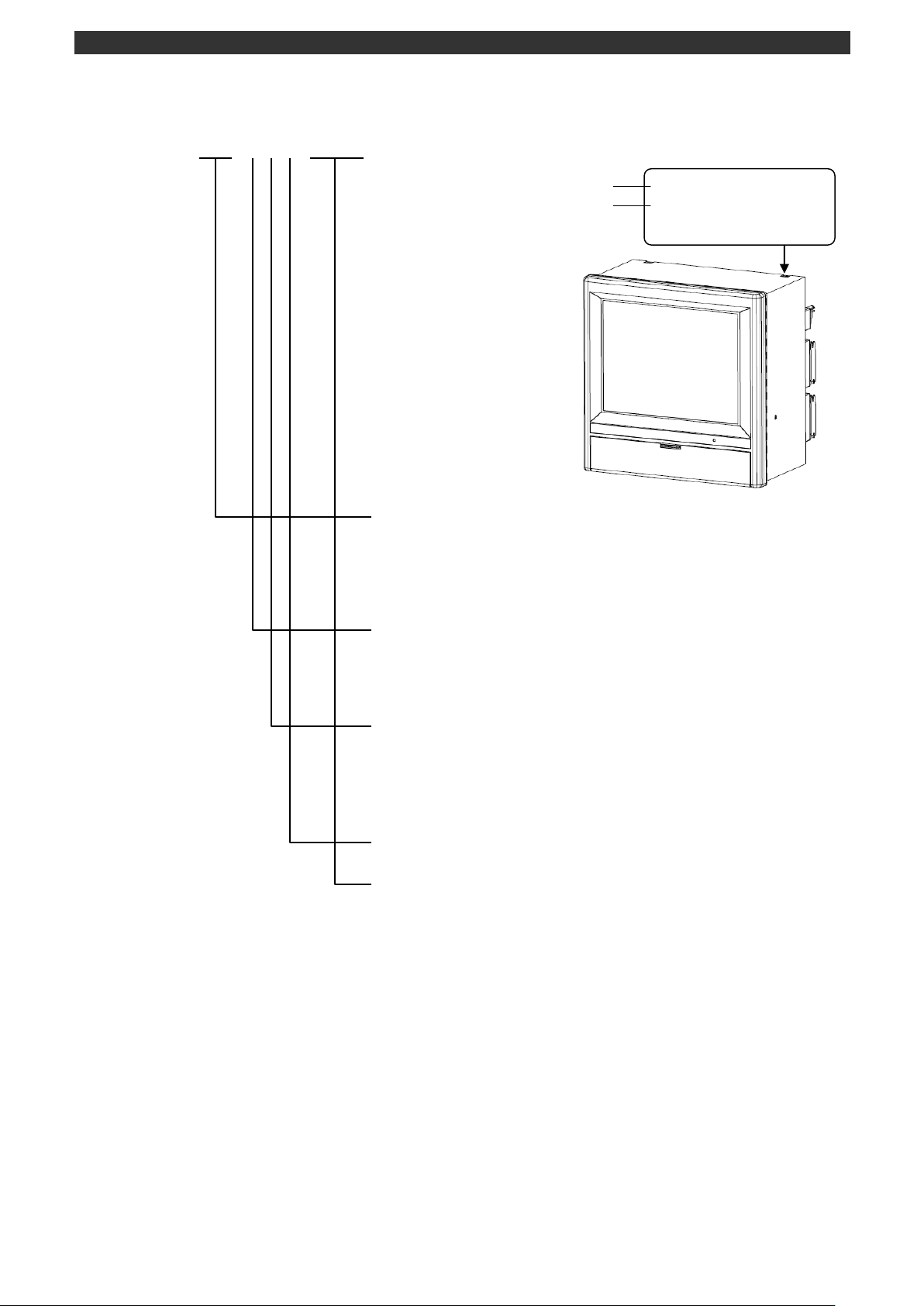

<KR3S>

(1) Open the cover and remove the 2 retaining screws.

(2) Pull the bottom of the front display panel toward you and lift up to remove the front display.

(3) The front display is connected to PWB-B by 1 type of cable. Disconnect it.

(4) Remove the 2 screws holding PWB-A, and pull it toward you.

(5) Remove the 1 screws holding PWB-B, and pulls it toward you.

(6) The battery holder is attached to the underside of PWB-B. Lift the front of the battery with a

tool having a nonconductive tip and pull the battery out of the holder.

Disposal of this recorder

This section describes disposal method of this recorder subjected to the condition stated in

Directive on Waste Electrical and Electronic Equipment (hereinafter referred to as WEEE)

[2002/96/EC]. This directive is valid only in European Union.

● Marking

This recorder is governed and constructed by WEEE [2002/96/EC]

marking requirement. Attached label indicates that this electrical and

electric equipment must not dispose as general household waste.

● Product category

With the reference to the equipment types in WEEE [2002/96/EC] ANNEX I, this recorder is

classified as a “Monitoring and control instruments”. Do not dispose as general household waste.

When disposing discarded recorder, please contact local CHINO sales agent.

PWB-B

PWB-A

-3-

Page 6

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Table of Contents

PREFACE ............................................................................................................................................................ 1

Table of Contents ................................................................................................................................................. 4

1 For safe use ................................................................................................................. 5

1-1 Preconditions for use ..................................................................................................................................... 5

1-2 Labels on this instrument .............................................................................................................................. 5

1-3 Symbols in this manual ................................................................................................................................. 5

2 Before use .................................................................................................................... 8

2-1 Exterior check ................................................................................................................................................ 8

2-2 Model check................................................................................................................................................... 8

2-3 Checking attachments ................................................................................................................................. 10

3 Installation ................................................................................................................. 12

3-1 Mounting location ........................................................................................................................................ 12

3-2 External dimensions .................................................................................................................................... 13

3-3 Method of mounting the panel .................................................................................................................... 14

4 Connections ............................................................................................................... 16

4-1 Terminal board arrangement ....................................................................................................................... 16

4-2 Precautions while connections .................................................................................................................... 19

4-2-1

Power supply ..................................................................................................................................................... 19

4-2-2

Keep the input/output connections away from a high voltage power circuit ..................................................... 19

4-2-3

Keep the thermocouple input away from a heat source .................................................................................... 19

4-2-4

Keep all connection cables away from noises................................................................................................... 19

4-2-5

Use crimp style terminals................................................................................................................................... 19

4-2-6

Unused terminals ............................................................................................................................................... 20

4-3 Connection of power and protective conductor terminals .......................................................................... 21

4-3-1

Power and protective conductor terminals ........................................................................................................ 21

4-3-2

Connection of power terminals .......................................................................................................................... 22

4-3-3

Connection of protective conductor terminal ..................................................................................................... 22

4-4 Connection of measuring input terminals ................................................................................................... 23

4-4-1

Measuring input terminals ................................................................................................................................. 23

4-4-2

Connections of DC voltage (current) input ........................................................................................................ 23

4-4-3

Connection of thermocouple (TC) inputs ........................................................................................................... 23

4-4-4

Connection of resistance thermometer (RTD) input .......................................................................................... 24

4-5 Connection of alarm output terminals (Option) ........................................................................................... 25

4-5-1

Alarm output terminal ......................................................................................................................................... 25

4-5-2

Connections ....................................................................................................................................................... 26

4-5-3

Precautions for connection ................................................................................................................................ 27

4-6 Connection of digital input terminals and function selection (Option) ........................................................ 28

4-6-1

No-voltage contact input terminal ...................................................................................................................... 28

4-6-2

Connections ....................................................................................................................................................... 29

4-6-3

Functions of terminals ........................................................................................................................................ 29

4-7 Connection of communication I/F terminal (Option) ................................................................................... 30

4-7-1

Connections of High order communication RS-485 .......................................................................................... 30

4-7-2

Connections of low order communication RS-485 ............................................................................................ 31

4-7-3

Ethernet wiring ................................................................................................................................................... 32

-4-

Page 7

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Label

Name

Meaning

Alert symbol mark

Indicates the location which should refer to the

manual in order to prevent an electric shock and

injury.

Protective conductor

terminal

A terminal is provided for connection to the

protective conductor of the power supply facility for

the prevention of an electric shock.

Warning

The nonobservance of information under this symbol may result in

hazardous, critical or serious injury to the user.

Caution

The nonobservance of information under this symbol may result in a

hazardous situation or a light injury to the user or in physical

damage to the property.

Remarks

This symbol shows a caution when the instrument dose not function as specified

or when such a possibility exists.

Reference

This reference servers as a supplement for handling and operation, and it may be

convenient for the user.

!

!

1 For safe use

This section “For safe use” has been compiled to promote the correct use of the instrument in order to

prevent human injury or damage to property before they occur. If this instrument is used other than

description of this document, protection provided by the instrument may be vitiated. Please read the

following information carefully and be sure to observe the warnings and cautions in it.

1-1 Preconditions for use

This instrument is a component type general product to be mounted on an indoor instrumentation

panel. Do not use this instrument in different situations (except for portable type).

Before using this instrument, ensure the system safety by taking appropriate measures such as

fail-safe designing and periodic maintenance for the equipment to which this instrument is

installed. Connection, adjustment or operation of this instrument should be performed by a

professional engineer with knowledge of instrumentation.

Also, a person who handles this instrument should read this instruction manual to fully

understand the cautions and basic operations.

1-2 Labels on this instrument

The following labels are used for safe use.

1-3 Symbols in this manual

The cautions to be observed for preventing the damage of this instrument and unexpected

accidents are sorted by the following symbols according to their importance degrees for enabling

operators to use this instrument safely.

-5-

Page 8

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

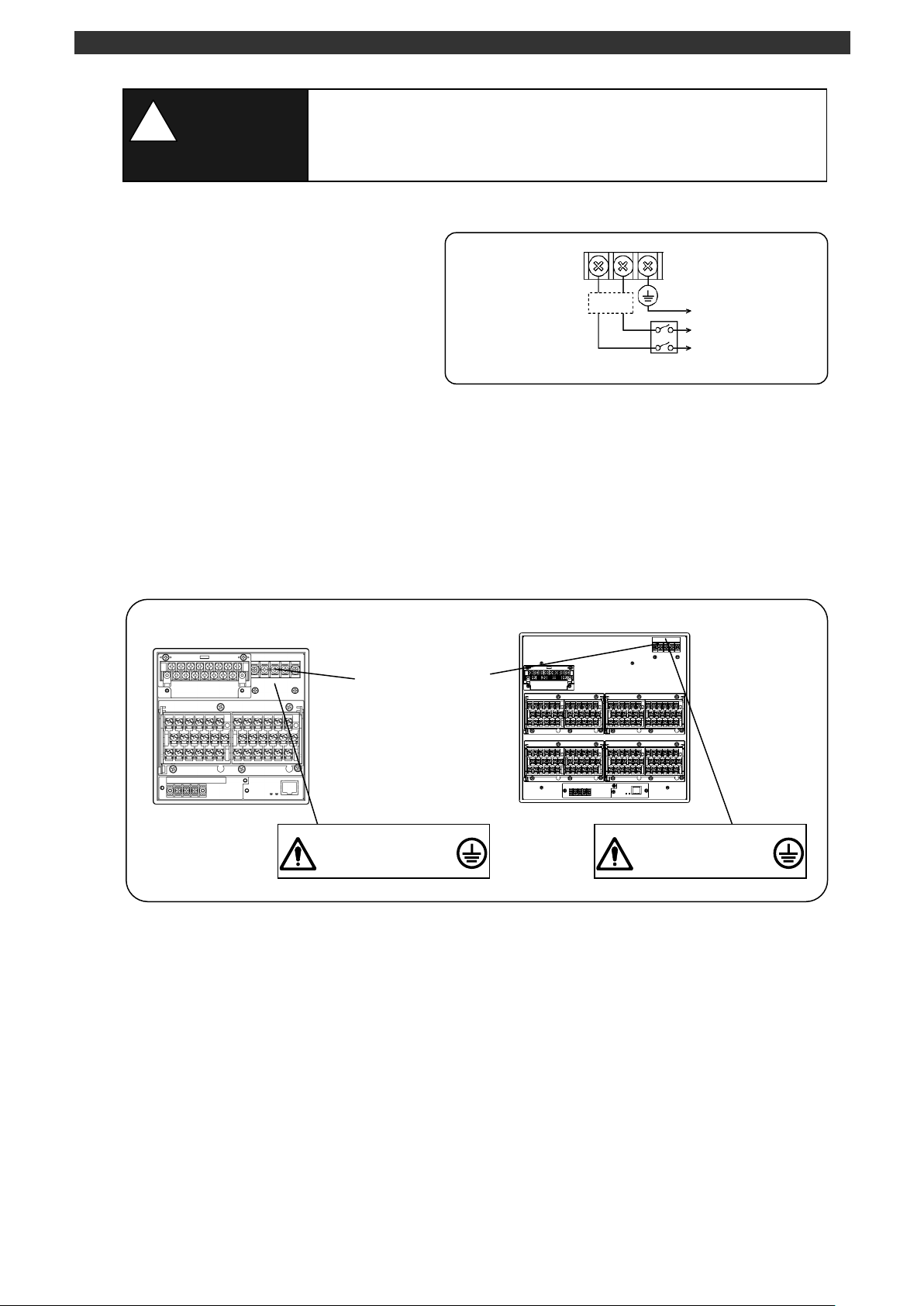

Warning

This paragraph covers important warning for safety to be observed

before reading the instructions. Fully understand the following

warning before reading this manual. These warnings are important

for preventing the damage to human bodies as well as accidents.

!

To the protective

conductor of power

supply facility

Switch

Overcurrent

protective device

(250V 3A)

L N

Power supply

Power terminal /

Protective

Conductor terminal

Power terminal/

Protective conductor

terminal

100-240V AC

50/60Hz 35VA MAX

100-240V AC

50/60Hz 60VA MAX

<KR2S>

<KR3S>

Power supply label

Power supply label

Switch and overcurrent protective device

This recorder is not provided with a

replaceable overcurrent protective device.

Prepare a switch and an overcurrent

protective device for the power supply

(circuit breakers, circuit protectors or the

like) within 3m of this recorder in a location

where the operator can access easily Use a

switch and an overcurrent protective device

conforming to IEC947-1 and IEC947-3.

Be sure to ground this instrument

Before turning the power on, connect the protective conductor terminal of this recorder to the

protective conductor of the power supply facility. In order to prevent an accident by electric shock, do

not disconnect this connection during operations.

Before turning on the power supply

In order to ensure safety, before turning on the external power switch, make sure that the power

voltage is within the range indicated on the power supply label.

Don't repair or modify this instrument

Make sure that any persons other than service engineers approved by CHINO CORPORATION do

not repair or modify this instrument by replacing parts. Otherwise it may be damaged or will not

function normally or an accident such as electric shock and burn may occur by putting your hand and

a tool in the internal unit. For ordinary operation, it is not necessary to pull out the internal unit.

Use this recorder following this instruction manual

Use this recorder correctly and safely by following this instruction manual. CHINO CORPORATION

will not be responsible for any injury, damage, lost profit or any other claim, which may result from

its wrong use.

-6-

Page 9

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Remarks

■

Fuse in the power supply

The following fuse is mounted in the power supply unit of this recorder for safety use.

However, this fuse is not replaceable

<KR2S>Maker: Nippon Seisen Co., Ltd Model: SLT 250V 2.5A

<KR3S>Maker: Littelfuse, Inc Model: 215 250V T3.5AH

Installing the safety device

Regarding the use of devices that anticipates a big loss due to failure of this instrument, always

install a safety device for preventing these losses and implement fail safe design in the final

instrumentation. Do not use this instrument in important in facilities related to, human life, atomic

energy, aviation and space.

Turn off the power supply if an abnormal symptom occurs

Turn off the power supply immediately and contact your local CHINO’s sales agent if any abnormal

odor, noise or any smoke occurs, or if this recorder becomes high temperature that is too hot to be

touched.

-7-

Page 10

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Model (Check with model code.)

Serial No.

KR2S**-***-***

K***********

MADE IN JAPAN

2 Before use

Check the following items before using the recorder. If something is wrong, contact your local CHINO's

sales agent.

2-1 Exterior check

Check that the instrument is not broken on the outer side.

2-2 Model check

The model number and serial number of this recorder can be confirmed by the label on the upper side

of the case.

Check the model of your instrument from the model code before use.

Model code

KR2S□P‐□□□

Measurement point/ Measuring period

6: 6 points/1 sec.

2: 12 points/1 sec.

Communication interface (Option)

N: None

E: Ethernet

R: Low/high order communications (RS-485)

G: Ethernet + low/high order communications (RS-485)

Alarm output, Contact input (Option)

0: None

2: Mechanical relay output (4 points ‘c’ contact)

7: No-voltage contact input (4 points)

8: Mechanical relay output (2 points ‘c’ contact) + No-voltage

contact input (2 points)

Installation type

A: Panel mounting type

T: Portable type (Grip and rubber feet attached)

*If the recording cycle is set less than 0.5 seconds (0.1 to 0.5 seconds), input channel point becomes 4

points automatically.

-8-

Page 11

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Model (Check with model code.)

Serial No.

KR3S**-***-***

K***********

MADE IN JAPAN

<KR3S>

KR3S□□‐□□□‐□□□

Measurement point/ Measuring period

2: 12 points/1 sec.

4: 24 points/1 sec.

6: 36 points/1 sec.

8: 48 points/1 sec.

Communication interface (Option)

N: None

E: Ethernet

R: Low/high order communications (RS-485)

G: Ethernet + low/high order communications (RS-485)

Alarm output, Contact input (Option)

0: None

2: Mechanical relay output (4 points ‘c’ contact)

7: No-voltage contact input (4 points)

8: Mechanical relay output (2 points ‘c’ contact) + No-voltage

contact input (2 points)

Installation type

A: Panel mounting type

Others (Option)

NNN: None

-9-

Page 12

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Parts name

Quantity

Remarks

Instruction

manual

1

INE-861□(General) CD-ROM

INE-863□(Communication interface)

(1 copy)

INE-862□(Wiring/Installation) A4 Booklet

1

RZMC-01-□(CF card)

Mounting

bracket

2

For panel mounting

Terminal screw

5

M3.5 for measuring input terminals (Spares for missing)

CF card

1

RZ-CMC256(256MB)

③Terminal screws

④CF card

②Mounting bracket

①Instruction manual

2-3 Checking attachments

Package contains the following attachments. Please confirm.

<KR2S>

-10-

Page 13

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Parts name

Quantity

Remarks

Instruction

manual

1

INE-881□(General) CD-ROM

INE-883□(Communication interface)

(1 copy)

INE-882□(Wiring/Installation) A4 Booklet

1

RZMC-01-□(CF card)

Mounting

bracket

2

For panel mounting

Wrench

1

Terminal screw

5

M3.5 for measuring input terminals (Spares for missing)

CF card

1

RZ-CMC256(256MB)

④Terminal screws

⑤CF card

②Mounting bracket

③Wrench

①Instruction manual

<KR3S>

-11-

Page 14

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Caution

Make sure to read and understand this instruction manual to

prevent any accident.

●Over voltage category ...... II (EN standard)

●Pollution degree ............... 2 (EN standard)

●Altitude.............................. 2000m or less

●Place of use ....................... Indoor

!

3 Installation

3-1 Mounting location

In order to avoid unfavorable effects on the measurement accuracy and recording operation, install

this recorder at the following locations.

1. Industrial environment

Select a place away from a source generating an electric field and/or a magnetic field and where

mechanical vibrations/shock is not existed.

2. Ambient temperature/humidity

Keep away from direct sunlight and do not close an area around this recorder to avoid

temperature increase.

●Place with stable ambient temperature of around 23°C and humidity 50%RH

●Place not exposed to hot blast (50°C or more) for avoiding deformation of the front panel

●Place where there are no wind and no heat source near terminals for avoiding measurement

errors.

3. Atmosphere

●Avoid a place where flammable gases and explosive gases exist.

●Avoid a place with dust, smoke, vapors, oil, chemical, corrosive gas, saline, iron, conducting

substance(carbon and iron), etc.

4. Mounting angle

●Lateral tilting ················0°

●Longitudinal tilting ········Forward tilting: 0°, Backward tilting: 0-20°

Mounting angle other than the above angles will have unfavorable effects on recording operation.

-12-

Page 15

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

3-2 External dimensions

The following figure shows the dimensions of this recorder with its mounting brackets.

<KR2S>

Unit : mm

<KR3S>

Unit : mm

-13-

Page 16

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Caution

Mount on the panel and use

This instrument has been designed to be mounted on an indoor

instrumentation panel.

Use a panel made of a steel plate of 2mm to 6mm in thickness or a

panel equivalent in strength. Please consider the instrument's

dimensions and its weight when you select the panel thickness

along with the panel structure.

When you attach this instrument to a panel, be careful of the

injury by fall.

!

パネルカット

パネルカット

360

360

281

+1

0

281

+1

0

●Minimum interval for installation of multiple instruments

(Unit: mm)

(Unit: mm)

パネルカット

パネルカット

200

200

138

+1

0

138

+1

0

●Minimum interval for installation of multiple instruments

(Unit: mm)

(Unit: mm)

3-3 Method of mounting the panel

1. Panel cutout size

<KR2S>

<KR3S>

-14-

Page 17

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Mounting bracket

Mounting bracket

Panel thickness (2 to 6 mm)

Mounting bracket

Mounting bracket

Panel thickness (2 to 6 mm)

2. Mounting method

<KR2S>

(1) Insert this recorder into the panel cutout from the front of the panel.

(2) Insert the mounting brackets into the holes of the top and bottom sides, and fix them with

screws using a Phillips screwdriver. Set the tightening torque on screws to 1.0 N•m (when

using Phillips-head screwdriver).

<KR3S>

(1) Insert this recorder into the panel cutout part of an instrument panel.

(2)Since there is a screw hole each (a total of two holes) in the right and left sides of this recorder,

screw 2 fixing screws attached in two holes lightly.

(3)Next, put the hexagon head of this screw to the circular hole of the mounting bracket and

push the recorder to the instrument panel firmly (from front) while making the mounting

bracket slide as shown in the figure. On this condition, tighten the fixing screw with the

attached wrench or a Phillips screwdriver.

Set the tightening torque on screws to 2.0 N•m (when using Phillips-head screwdriver).

*Note that the mounting brackets used at the right and left sides are different (mounting work

should be performed by two persons).

-15-

Page 18

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

RS-485

Ethernet Connector

Measurement input terminal

TC / mV(+) / RTD(A)

TC / mV(-) / RTD(B)

RTD(B)

Alarm output(option)

‘c’ contact output:

4points/terminal block

Communications terminals(option)

[CH1~12]

[CH13~24]

[CH25~36]

[CH37~48]

Power terminal

Protective conductor terminal

Alarm output(option)

‘c’ contact output:

4points/terminal block

Power terminal

Protective conductor terminal

RS-485

Ethernet Connector

Communications terminals(option)

Measurement input terminal

TC / mV(+) / RTD(A)

TC / mV(-) / RTD(B)

RTD(B)

4 Connections

4-1 Terminal board arrangement

The following diagram shows the terminal board arrangements in which option (Mechanical relay

output [4 points ‘c’ contact], communication interface) are mounted.

<KR2S>

<KR3S>

-16-

Page 19

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

SA SB SG

Ethernet connector

[Option terminal block]

Alarm relay output (4 points ‘c’ contact)

No-voltage contact input(4 points)

Alarm relay output (2 points ‘c’ contact) + No-voltage contact input(2 points)

Communication terminals

-17-

Page 20

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Warning

Alert symbol marks

( )

and places

The alert mark is pasted at danger places where may causes

electric shock. (See the following table).

Name of terminals

Places marked with the symbol

Power terminals

Lower left of power terminals

Measurement input terminals

Upper left of terminal cover

Mechanical relay ‘c’ contact

alarm terminals

Lower left of terminal cover

Reference

Input terminal block is removable

The input terminal block is removable for easy connections.

(1) Each terminal block can be removed by removing mounting screws.

(2) Each terminal block is connected to the recorder by a connector.

Input 12 points

Input 6 points

Caution

Turn off the power supply in advance

For mounting or dismounting the terminal block,

turn off the external power switch to prevent the

electric circuits from being damaged.

Remarks

■

Replacement of input terminal block

Input terminal block cannot be replaced by other terminal block.

If replaced measurement error occurs.

!

!

Mounting screws

Terminal block

Mounting screws

Terminal block

-18-

Page 21

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Warning

A switch and an overcurrent protective device

Prepare a switch and an overcurrent protective device (3A) to

the power supply for preventing an electric shock accident

during connection work. This recorder is not provided with any

replaceable fuse.

Turn off the power supply before connections

Be sure to turn OFF the power supply before connecting cables

to the power and the input/output terminals to prevent an

electric shock.

Major noise sources

Counter measures

●Electromagnetic switch, etc.

●Power line having waveform distortion

●Inverter

●Thyristor regulator

Insert noise filters between power terminals

and input/output terminals. A CR filter is often

used.

!

4-2 Precautions while connections

Observe the following cautions during connections for securing safety and reliability.

4-2-1

Power supply

Use a single-phase power supply having a stable voltage without any waveform distortion for the

purpose of preventing wrong operations.

4-2-2

Keep the input/output connections away from a high voltage power circuit

Don’t place the input/output cables close or in parallel with any strong power circuits including

power line. Place the cables 50 cm or more away from high voltage power circuits when they are

placed close or in parallel to other circuits.

4-2-3

Keep the thermocouple input away from a heat source

For thermocouple inputs, keep the input terminals away from a heat source (a heating body) to

reduce a reference junction compensation error.

Don’t expose the input terminals to direct sunlight, etc.

4-2-4

Keep all connection cables away from noises

Keep all connection cables away from noise source as far as possible, otherwise unexpected

malfunction may occur. Provide a solution if the cables cannot be separated from a noise source

due to unavoidable circumstances.

4-2-5

Use crimp style terminals

Fix crimp style terminals to termination of connection cables for preventing the looseness or

disconnection of terminals and a short-circuit failure between terminals.

Use the crimp style terminals with insulation sleeve for preventing an electric shock.

-19-

Page 22

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Warning

■Secure the connected cables properly.

Secure the connected cables so as not to allow them to be hooked by

a person or a substance, otherwise the connections may be cut and

disrupted that may cause an electric shock or other accidents.

Terminal name

Screw

diameter

Tightening

torque

Termination (Unit: mm)

Power and

protective

conductor and

communication

terminal

M4

1.2N・m

Type O

Input terminal

M3.5

0.8N・m

Type O

Type Y

*Use Type O whenever possible.

Alarm relay

output,

non-voltage

contact input

terminal

M3.5

0.8N・m

Type O

Type Y

*Use Type O whenever possible.

Communication

terminal

M3

0.5N・m

Type O

Type Y

*Use Type O whenever possible.

!

More than 3.7

Less than 7.0

Less than 7.0

t:0.8

t:0.8

With an insulation sleeve

With an insulation sleeve

More than 3.7

More than 3.2

Less than 6.2

Less than 6.2

t:0.8

t:0.8

With an insulation sleeve

With an insulation sleeve

More than 3.2

More than 4.3

Less than 8.0

With an insulation sleeve

t:0.8

More than 3.7

Less than 8.0

Less than 8.0

t:0.8

t:0.8

With an insulation sleeve

With an insulation sleeve

More than 3.7

4-2-6

Unused terminals

Don’t use any unused terminals for relaying; otherwise the electric circuits may be damaged.

Kinds of terminals and termination

-20-

Page 23

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Warning

Turn off the power supply

Be sure to turn off the power supply before connecting the cable to

the power supply and protective conductor terminals to prevent an

electric shock.

!

Protective conductor terminal

Power terminals

L N

Power supply (voltage, frequency, power consumption)

100-240V AC

50/60Hz 35VA MAX

Protective conductor terminal

Power terminals

L N

Power supply (voltage, frequency, power consumption)

100-240V AC

50/60Hz 60VA MAX

4-3 Connection of power and protective conductor terminals

4-3-1

Power and protective conductor terminals

<KR2S>

l

<KR3S>

-21-

Page 24

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Warning

mark at power terminals

A voltage of 100 to 240 V AC is applied to the power terminals after

connection. Be sure to mount the power terminal cover to prevent an

electric shock.

Caution

Be careful with the power voltage and noise

The power voltage of this instrument is indicated beside the power

terminals.

Don’t apply any voltage other than indicated; otherwise a

malfunction may result.

If noise is generated at the power supply, provide a noise reduction

transformer, etc.

Remarks

L/N indication of power terminals

This indication conforms to the CSA standard, Canada. The live side of the

single-phase AC power supply is indicated as L, and the neutral side is indicated as

N. Observe the L and N connections for obtaining satisfactory performance.

!

!

4-3-2

Connection of power terminals

For connection to the power terminals, use a 600 V PVC insulated cable terminated by the crimp

style terminals with insulation sleeve.Note) Use the cords approved by the following standards.

(1) IEC 227-3

(2) ANSI/UL817

(3) CSA C22.2 No.21/49

4-3-3

Connection of protective conductor terminal

Be sure to connect this terminal to the protective conductor of the power supply facility. For this

connection, use a cable terminated by the crimp style terminals with insulation sleeve.

・Grounding wire: Copper wire 2 mm2 or more (green/yellow)

L N Mount the terminal cover after connections.

A copper wire with 2 mm2 or more (green/yellow)

Be sure to connect to the protective

conductor of the power supply facility.

600 V vinyl insulated cable

Power supply

-22-

Page 25

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Caution

Allowable input voltage

Input type

Allowable input voltage

Voltage, thermocouple input

±

10VDC*

Resistance thermometer input

±

6VDC

*

±

60 VDC with channel settings to the

±

5 V or higher range.

Remarks

Isolation of measured input terminal

TC, mV(+), RTD(A) terminal and TC, mV(-), RTD(B) terminal are insulated each

channels but RTD(B) terminal is short-circuited between channels.

!

(+)

(-)

DC voltage input

Twisted cable for instrumentation

4-4 Connection of measuring input terminals

4-4-1

Measuring input terminals

Be sure to turn off the power supply to prevent an electric shock.

For the connections to the input terminals, use cables terminated by the crimp style terminals

with insulation sleeve.

4-4-2

Connections of DC voltage (current) input

Use twisted cables for instrumentation as the input cables for the purpose of suppressing noises.

For current inputs, mount shunt resistors to the channels to be measured before connections.

●DC voltage (Current) input

1 2 3 4 5 6

4-4-3

Connection of thermocouple (TC) inputs

Be sure to use thermocouple wires (or extension wires) to the input terminals of this recorder. If a

copper wire is used halfway, a noticeable measuring error occurs. If using a pair of thermocouple

wire in parallel, it may have an influence on the measurement.

When it is necessary to operate the instrument in this situation, check for no influence while

operating the instrument before using.

●Thermocouple (TC) input

1 2 3 4 5 6

(+)

(-)

Extension wire

Thermocouple

-23-

Page 26

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Warning

mark of measuring input terminals

A high voltage may be applied to the measuring input terminals due

to common mode noises. The allowable noise value is lower than 30

VAC or lower than 60 VDC. Make sure that the noises are lower

than the allowable values. Mount the terminal cover after

connections for the purpose of preventing an electric shock and to

protect the input wires. In the case of thermocouple input, the

mounting of the terminal cover can reduce the reference junction

compensation error.

!

4-4-4

Connection of resistance thermometer (RTD) input

Use a 3-core cable where each lead wire has an equal resistance value. Don’t use one resistance

thermometer in parallel with other instruments (controller, etc.).

●Resistance thermometer (RTD) input

1 2 3 4 5 6

A

B

B

3 core cable (Same diameter, same length)

Resistance thermometer

*The resistance of each cable is less than 10 Ω. All the

3 wires should be of the same resistance value.

-24-

Page 27

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Alarm relay output 4 points (‘c’ contact)

Alarm relay output 2 points (‘c’ contact)

DO1 DO2 DO3 DO4

DO1 DO2

4-5 Connection of alarm output terminals (Option)

This is for the recorder with alarm output terminals (Option).

4-5-1

Alarm output terminal

The terminal arrangement depends upon the type of alarm output.

-25-

Page 28

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

*N.C terminal - Open relay contact at alarm activation that

is the reverse action to N.O terminal.

N. O

COM

N. C

*

Load

This recorder

: Contact protective element (It is recommended to

mount this element on the a side)

b

Buffer relay

Power Supply

a

Warning

mark of alarm output terminals

Connect a load not exceeding the specified contact capacity to the

alarm output terminals. If the voltage more than 30VAC/60VDC is

to be applied to the alarm output terminal, use type O crimp style

terminal with an insulation sleeve to connect double-insulated

wires (dielectric strength of 2300 VAC or more) for the signal wires

and for the other signal wire use basic insulated wires (dielectric

strength of 1390 VAC), If the voltage more than 30VAC/60VDC is

to be applied to either alarm output terminal of channel, use

double-insulated wires or reinforced insulation for external circuit

of all the channels. A buffer relay power supply is applied to the

alarm output terminals after connections. Do not touch these

terminals since an electric shock will occur. Be sure to mount the

terminal cover after connections.

Caution

Take a safety measure.

An alarm output of this recorder may become defective caused by

wrong operation, failures, and other abnormal inputs.

Take a safety measure against an output failure before use as

occasion calls.

Example of mechanical relay ‘c’ contact outputs

!

!

4-5-2

Connections

Turn off the power supply and buffer relay power supply before connections to prevent an electric

shock.

(1) Connect cables to the load via a buffer relay.

(2) Use cables with the crimp style terminals with insulation sleeves for the alarm output

terminals. Only one crimp style terminal is allowed to connect to the terminal.

-26-

Page 29

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Item

Contents

Contact rating of

Mechanical relay outputs

(‘c’ contact)

Power

supply

Resistive

load

Inductive

load

100V AC

3A

1.5A

240V AC

3A

1.5A

30V DC

3A

1.5A

Mounting of contact

protective element Z

●Mount a contact protective element conforming to the buffer

relay. The relay is broken, if a signal exceeding the contact rating

is applied even if momentarily.

●To prevent a malfunction being caused by a light load, the most

effective mounting position for the element is on the coil side of

the buffer relay (refer to “4-5-2 Connection” example of

mechanical relay ‘c’ contact outputs diagrams)

Selection of buffer relay

(1) Coil rating .......... Less than the contact rating of output

terminals

(2) Contact rating ... More than twice the load current

A coil surge absorption element built-in type relay is

recommendable. Mount an additional buffer relay if a buffer

relay satisfying the load rating is not available.

Selection of contact

protective element

Mount a contact protective element if a surge absorption element

built-in buffer relay is not available. This element is generally

composed of C (capacitor) and R (resistor).

<Reference values of C•R> C: 0.01 µF(Rating about 1 kV)

R:100 to 150 Ω(Rating about 1 W)

(Minimum load)

100mA 5VDC

4-5-3

Precautions for connection

Be careful with the following cautions for connections.

-27-

Page 30

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

No-voltage contact input(4 points)

No-voltage contact input(2 points)

Remarks

Features of digital input terminal

Voltage when the contact is open. : Approx. 5 V

Current when the contact is short. : Approx. 2 mA

DI1 DI2

DI1 DI2 DI3 DI4

4-6 Connection of digital input terminals and function

selection (Option)

This is for the recorder with digital input terminals (Option)

4-6-1

No-voltage contact input terminal

-28-

Page 31

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Caution

No-voltage contacts

For the contacts to be connected to the Digital input terminals, use a

switch or relay driven at lower than 30 V AC or lower than 60 V DC,

or manual contacts for very light loads.

Example of connections(No-voltage contact input(4 points))

!

COM

DI1 DI2 DI3 DI4

4-6-2

Connections

Turn off the power supply before connections to prevent an electric shock.

Apply a no-voltage contact signal to digital input terminals.

Use cables terminated by crimp style terminals with insulation sleeves for the digital input

terminals.

4-6-3

Functions of terminals

Digital input ······ ON/OFF (short/open) state can be measured. Select the range type as DI.

(Refer to ‘9-1 input operation settings’.)

Pulse input ········ Used as the pulse input. Select the range type as Pulse (+) and Pulse (-).

(Refer to ‘9-1 input operation settings’.)

Totalizer reset ···· he reset of totalizer is executed. When the digital input terminal specified

becomes ON, the totalizer reset is executed.

(Refer to ‘9-6 Totalizer reset settings’.)

Marker ·············· The writing of marker. The marker can be written on the trends when the

digital input terminals become ON.

(Refer to ‘9-8 Marker text settings’.)

File drive ··········· The recording start/stop of data file in the internal memory is executed.

The recording starts or stops when the digital input terminals become ON or

OFF.

(Refer to ‘9-5 File settings’.)

●Each function requires a short circuit of 0.1 second or more between the COM terminal and

each terminal.

-29-

Page 32

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Turn the switch of RS-422A/RS-485

to RS-485.

Avoid connecting SG line to FG terminal or ground terminal of the

device.

Termination

resistor

100Ω

Device side

Protocol converter

SC8-10

1

2

3

4

5

6

7

8

Cable for RS-232C(Max. 15m)

RZ-CRS6□□

Communication port

PC side

RD

SD

SG

RD

SD

SG

RDA

RDB

SA

SB

SG

SA

SB

SG

SA

SB

SG

4-7 Connection of communication I/F terminal (Option)

The KR can be communicated with a master unit (high order instrument) via Ethernet and RS-485,

and with a slave unit (low order instrument) via RS-485.

*Ethernet and RS-485 communication function are optional.

RS-485 terminal Ethernet connector

SA SB SG LAN Active LED(Green) LINK LED(Orange)

4-7-1

Connections of High order communication RS-485

The RS-485 communications interface is connected to a personal computer via a protocol converter.

Three signals of SA, SB and SG are used between the protocol converter and a personal computer

and a control signal is not used. Wiring process of connector differs from how the personal computer

uses the control signal hence please understand your personal computer.

-30-

Page 33

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

SA

SB

SG

Avoid connecting SG line to FG terminal or ground terminal of the device.

Termination

resistor

100Ω

This recoder

Termination

resistor

100Ω

SE3000, MELSEC, etc

AL3000, etc.

SA

SB

SG

RDA

RDB

SDA

SDB

SG

Turn the switch of RS-422A/RS-485

to RS-485.

Avoid connecting SG line to FG terminal or ground terminal of the device.

Termination resistor

100Ω

This recorder

Line converter

SC8-10

Cable for RS-232C(Max.15m)

RZ-CRS6□□

Communications port

SYSMAC CPU unit

Internal RS-232C port

(D-SUB 9-pin receptacle)

RD

SD

SG

RDA

RDB

SA

SB

SG

RD

SD

SG

1

2

3

4

5

6

7

8

4-7-2

Connections of low order communication RS-485

Connect SA1, SB1 of KR3S and SA, SB of low order connected instrument like the following figure.

Refer to instruction manual of each instrument for detail method of low order instrument connection.

Example of terminal connection 1

Example of terminal connection 2(SYSMAC)

-31-

Page 34

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Device side

HUB

Straight twist-pair cable

with shield(Max.100m)

PC side

HUB

Straight twist-pair cable

with shield(Max.100m)

Straight twist-pair cable

with shield(Max.100m)

Crossover twist-pair cable

with shield(Max.100m)

Device side

PC side

4-7-3

Ethernet wiring

① Example of connection between PC and Ethernet devices(one-to-one connection)

② Example of connection between PC and HUB/Ethernet devices(one-to-N connection)

-32-

Page 35

INST.No.INE-882A KR2S/KR3S【Wiring/Installation】Instruction Manual

Page 36

32-8,KUMANO-CHO,ITABASHI-KU,TOKYO 173-8632

Telephone :81-3-3956-2171

Facsimile :81-3-3956-0915

E-mail: inter@chino.co.jp

Printed in Japan

Loading...

Loading...