Page 1

INST No INE -403-0P0

IR-M2

□□□

Series

INFRARED MOISTURE METER

DESIGNED AS A FIBER OPTIC

(Model : IR-M21

□□

,IR-M22

□□

)

Please be sure to deliver these instructions

with the unit to the end user.

Always keep these instruction with the unit.

Page 2

INST No INE -403-0P0

−C1−

Request to designers, instrument controllers, and sale agents

Delivery this instruction manual to the operator of this instrument without fail.

Request to the operator of this instrument

This instruction manual is necessary for maintenance, too. Keep this manual with due

care until the instrument is discarded.

■

FOR SAFE USE

For the purpose of using this unit safely, observe the following cautions for safety during

the operation, maintenance, and repair of this unit without fail.

Take safety measures separately against wrong operation, troubles, and other circumstances

of this unit.

●The following warning mark is struck to this unit to enable users to use

this unit safely.

●This instruction manual uses the following symbol marks for safe use.

■

PREFACERequests and notices

Thank you for your purchase of IR-M21□□□□, IR-M22□□□□series Infrared

m oisture meter designed as a fiber optic. Please read this instruction manual without fail

for using this instrument correctly and safely and also preventing troubles in advance.

1.For the contents of this manual, alteration is reserved without notice in the future.

2.This manual has been prepared by making assurance doubly sure about its contents.

However, if any question arises or if any error, an omission, or other deficiencies

were found, please inform your nearest CHINO’s sales agent of them.

3.Y ou are requested to understand that CHINO is not responsible for any operation

results.

Note

This warning mark is struck to the portions being subject to an electric shock

acc

ident. Turn off the power supply of the feed source without fail before starting

wiring, maintenance, and repair.

Observe this caution item strictly for avoiding a danger, otherwise

negligence of this caution may possibly cause troubles of this unit and

accidents

Observe this caution item strictly, otherwise negligence of this caution

may cause the damage of the unit or measuring errors.

This mark is described in each title covering or

instructions.

!

War ning

Caution

!

Warning

DANGER

Refere nce

Information that you can use as a reference.

Page 3

INST No INE -403-0P0

−C2−

●

Power supply

Make sure that the power voltage of this unit meets the feed power voltage without fail

before feeding power to this unit.

●

Protective grounding

Perform the protective grounding without fail before turning on the power supply of this

unit for the purpose of preventing an electric shock accident.

●

Necessity of protective grounding

Don’t cut the internal or external protective grounding wire of this unit nor disconnect

the wiring at the protective grounding terminal.

●

A defect of protective functions

Don’t operate this unit, if the protective grounding, fuse, or other protective functions

seem to be defective. Check the protective functions for defects before operating this

unit.

●

Use in a gaseous atmosphere

Never operate this unit at a place where a combustible gas, an explosive gas or their

vapors exist., otherwise a very dangerous accident will occur.

●

Never touch the interior by hand.

This unit is internally provided with high-voltage circuits. Never touch the interior by

hand when the voltage is applied to this unit.

●

External connections

Perform the protective grounding securely without fail before connecting this unit to a

measuring object and/or an external control circuit.

■

CAUTIONS FOR SAFETY

Page 4

INST No INE -403-0P0

−C3−

CONTENTS

1.General

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

1.1Summary

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・

1

1.2Configuration

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・

1

2 .Model s and accessories

・・・・・・・・・・・・・・・・・

2

2.1Models・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2

2.1.1 Detector unit

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・

2

2.1.2 Reflective type fiver

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・

2

2.1.3 Output checker plate for reflective

type fiver optics

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・

2

2.1.4 Reflective type fiver opt ics with lens attachment 2

2.1.5 Output checker plate for reflective

type fiver optics with lens attachment

・ ・・・ ・・・ ・

2

2.1.6 Transparent type fiver optics

・ ・・・ ・・・ ・・・ ・・・

2

2.1.7 Measuring cell for liquids

・ ・・・ ・・・ ・・・ ・・・ ・・

2

2.1.8 Connection cable

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・

2

2.2Accessories

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・

2

3.Setting

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3

3.1Settin g of dispswitches ・・・・・・・・・・・・・・・・・・ 3

3.2Installation of reflective type fiver optics ・・・・・・ 5

3.2.1 Installation of tip part・・・・・・・・・・・・・・・・・・・ 5

3.2.2 Air purge(Only IR-WCRN)・・・・・・・・・・・・・・ 6

3.2.3 Connections with detector unit ・・・・・・・・・・・・ 6

3.2.4 Optical path ・・・・・・・・・・・・・・・・・・・・・・・・・ 7

3.2.5 Measuring place

(for objects of pulverized or granul ar substance) 7

3.2.6 For the objects in sheet state such as paper, etc.7

3.3Installation of transparent type fiver optics ・・・・ 8

3.3.1 Installation of cell for liquids ・・・・・・・・・・・・・・ 8

3.3.2 Connections with detector unit ・・・・・・・・・・・・ 9

3.3.3 Disassemble cleaning ・・・・・・・・・・・・・・・・・・・ 9

3.4Installation of detector unit ・・・・・・・・・・・・・・・10

3.4.1 Outside and mounting dimensions of

detector unit ・・・・・・・・・・・・・・・・・・・・・・・・・10

4. Connections

・・・・・・・・・・・・・・・・・・・・・・・・・

11

4.1Connections

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・

11

4.2Layout of connection cable

・ ・・・ ・・・ ・・・ ・・・ ・・

11

4.3Multi -detector connections

・ ・・・ ・・・ ・・・ ・・・ ・・

12

4.3.1 Connections through relay box

・ ・・・ ・・・ ・・・ ・・・

12

4.3.2 Connections without rela y box

・ ・・・ ・・・ ・・・ ・・・

13

5.Names and functions of component parts

・・・

14

5.1Names and functions of detector unit

・ ・・・ ・・・ ・

14

5.2Names and functions of setting display part

・ ・・・

15

6. Operation

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

16

6.1Confirmation before operation

・ ・・・ ・・・ ・・・ ・・

16

6.2Setting of detector unit number

・ ・・・ ・・・ ・・・ ・・

16

6.3Setting of calibration curve data

・ ・・・ ・・・ ・・・ ・・

16

6.3.1 Setting data

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・

17

6.3.2 Setting of calibration curve data

・ ・・・ ・・・ ・・・ ・

18

6.4Preparation of calibration curbe

by knee point line approximation

・ ・・・ ・・・ ・・・ ・

18

6.4.1 Setting of knee point data

・ ・・・ ・・・ ・・・ ・・・ ・・・

18

6.4.2 Knee point line setting data

・ ・・・ ・・・ ・・・ ・・・ ・・

19

6.4.3 Setting of calibration curbe data

for knee point line approximation

・ ・・・ ・・・ ・・・

20

6.5 Setting of operating conditions

・ ・・・ ・・・ ・・・ ・・・

21

6.5.1 Setting data

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・

21

6.5.2 Setting

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・

23

6.6Calibration

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・

23

6.7Setting of calibration curve number・・・・・・・・・24

6.8Correction of calibration curve

・ ・・・ ・・・ ・・・ ・・

24

7.Preparation of calibration curve

・・・・・・・・・・

25

7.1Sample preparation ・・・・・・・・・・・・・・・・・・・・ 25

7.1.1 Powder or guranular

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・

25

7.1.2 Paper(sheet substance)

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・

26

!

!

!

!

!

!

!

!

!

Page 5

INST No INE -403-

−C4−

7.1.3 Liquid

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・

26

7.2Sample measuremernt ・・・・・・・・・・・・・・・・・・ 27

7.2.1 Powder or granular

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・

27

7.2.2 Paper(sheet substance)

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・

28

7.2.3 Liquid

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・

28

7.3Preparation of calibration curves・・・・・・・・・・・ 29

7.3.1 Computation of regression expression

・ ・・・ ・・・ ・

29

7.3.2 Confirmation of regression expression

・ ・・・ ・・・

30

8.Correction function by sample temprature

from external input (option)

・・・・・・・・・・・・

31

8.1Summary ・・・・・・・・・・・・・・・・・・・・・・・・・・・ 31

8.2Model・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 31

8.3Wiring of detector unit ・・・・・・・・・・・・・・・・・・ 31

8.4S etting of dipswitch ・・・・・・・・・・・・・・・・・・・・ 31

8.5Setting of correction enabled/disabled

by sample temperature ・・・・・・・・・・・・・・・・・ 32

8.5.1 Setting at the detector unit

・ ・・・ ・・・ ・・・ ・・・ ・・・

32

8.5.1 Setting at the display unit

・ ・・・ ・・・ ・・・ ・・・ ・・・

32

8.6Setting of sample temperature scaling

(Only 4 to 20mA DC) ・・・・・・・・・・・・・・・・・・・ 33

8.6.1 Setting at the det ector unit

・ ・・・ ・・・ ・・・ ・・・ ・・・

33

8.6.2 Setting at the display unit

・ ・・・ ・・・ ・・・ ・・・ ・・・

33

8.7Setting of sample temperature ・・・・・・・・・・・・ 33

8.8Setting of calibration curve data ・・・・・・・・・・・ 34

8.9Measurement ・・・・・・・・・・・・・・・・・・・・・・・・ 35

8.10Display of sample temperature Ts ・・・・・・・・・ 35

8.10.1 Display at the detector unit

・ ・・・ ・・・ ・・・ ・・・ ・

35

8.10.2 Display at the set ting display unit

・ ・・・ ・・・ ・・・

35

9.Inspection and maintenance

・・・・・・・・・・・・・

35

9.1Periodical inspection ・・・・・・・・・・・・・・・・・・・ 35

9.2Self-diagnosis function ・・・・・・・・・・・・・・・・・・ 36

9.3 Measures against troubles not included in

self-diagnosis ・・・・・・・・・・・・・・・・・・・・・・・・・ 37

9.4Maintenance parts・・・・・・・・・・・・・・・・・・・・・ 38

9.4.1 List of maintenance parts

・ ・・・ ・・・ ・・・ ・・・ ・・・

38

9.4.2 Repla cement of light source lamp

・ ・・・・・・・・・ ・

38

9.4.3 Replacement of motor

・ ・・・・・・・・・ ・・・・・・・・・

39

9.4.4 Replacement of lithium batterty

・ ・・・ ・・・ ・・・ ・・

40

9.4.5 Replacement of power supply unit

・ ・・・ ・・・ ・・・

41

9.4.5 Ram clearing

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・ ・・・

41

10.Specifications

・・・・・・・・・・・・・・・・・・・・・・・

42

10.1Detector unit ・・・・・・・・・・・・・・・・・・・・・・・・42

10.2Fiver optics ・・・・・・・・・・・・・・・・・・・・・・・・・43

10.2.1 Reflective type fiver optics IR-WCRN

・ ・・・ ・・・

43

10.2.2 Output checker plate for reflective type

fiver optics IR-WCNB

・ ・・・ ・・・ ・・・ ・・・ ・・・ ・

43

10.2.3 Raflective type fiver optics with lens IR-WCRE 43

10.2.4 Output checker plate for reflective type

fiver optics with lens IR-WCREB

・ ・・・ ・・・ ・・・

43

10.2.5 Measuring cell for liquid IR-WCC1

・ ・・・ ・・・ ・

44

10.2.6 Transparent type fiver optics IR-WCT

・ ・・・ ・・

44

10.3Accessories ・・・・・・・・・・・・・・・・・・・・・・・・・44

10.3.1 Power supply unit (conforming to CE) IR-WEP 44

10.3.2 Connection cable IR-WERT

・ ・・・ ・・・ ・・・ ・・・

44

CONTENTS

!

!

!

!

Page 6

INST No. INE -403-0P0

−1−

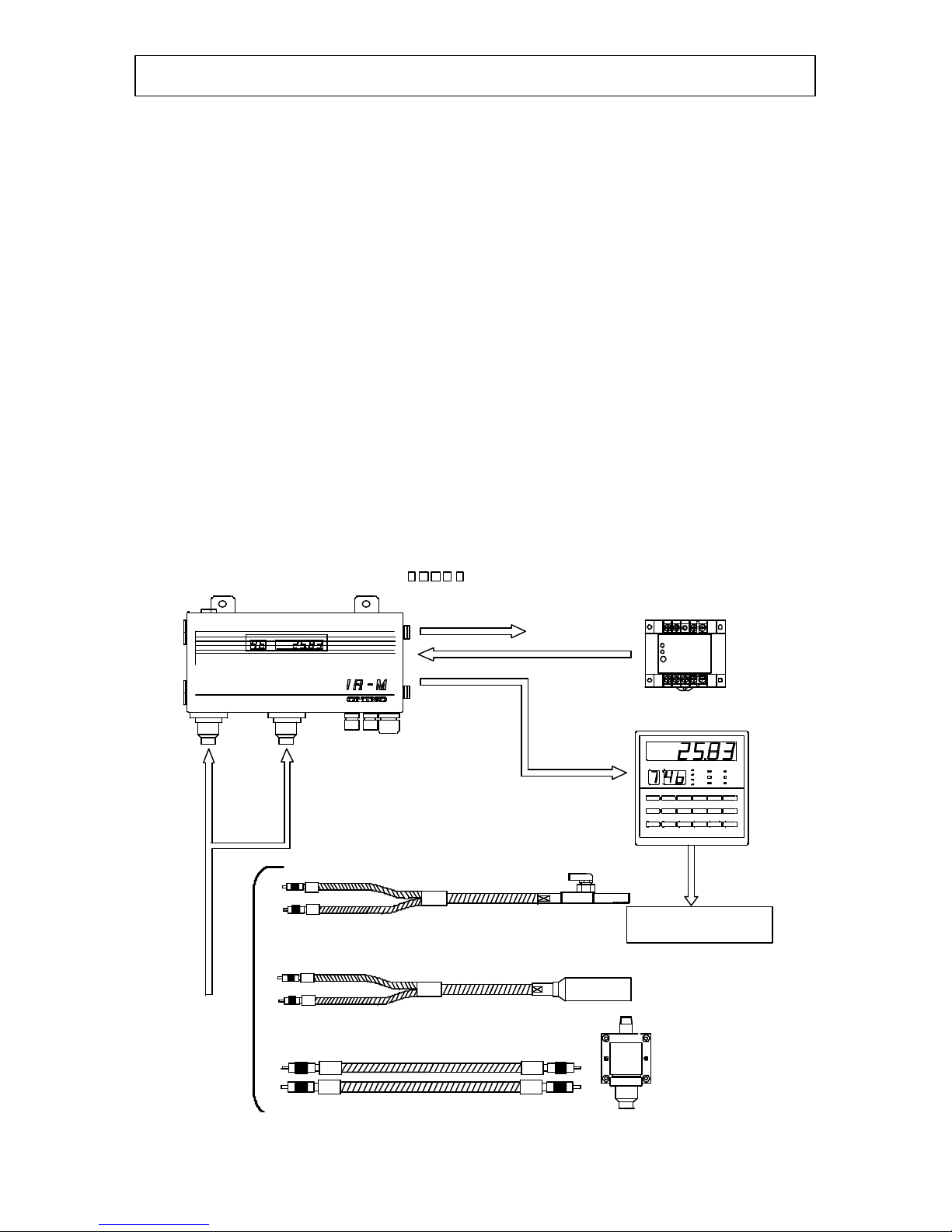

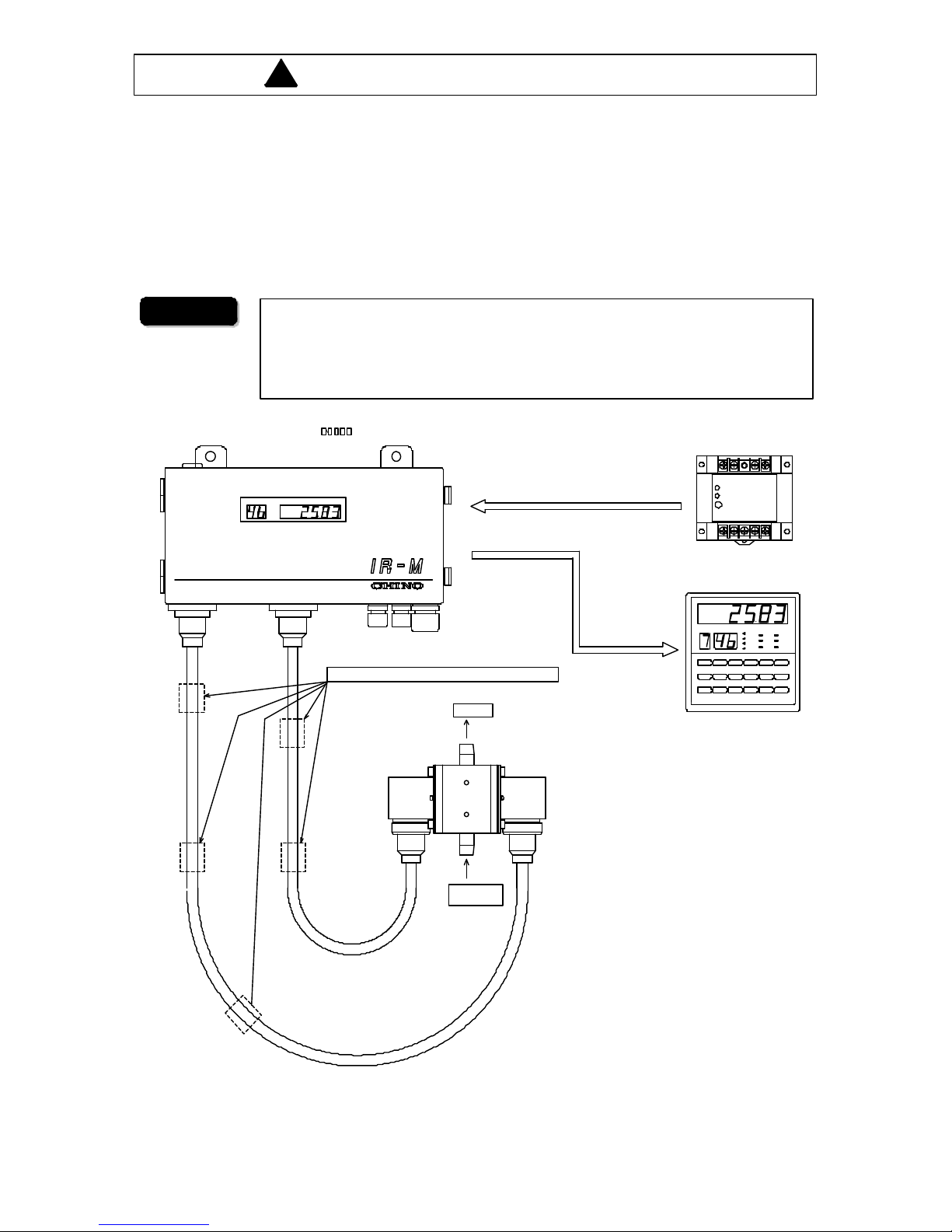

1.1 Summary

The infrared moisture meter IR-M2 series is designed as a fiber optic moisture meter for

on-line moisture meter utilizing infrared absorption of moisture, and it consists of a detector

unit, a fiber optics, a setting display unit and accessories.

The detector unit is provided with 99 built-in calibration curves to output linear analog

signals according to the moisture.

Since the detector unit provides keys, digital displays and communications function, it can be

used as a single unit or combined with a personal computer.

Two kinds of fiber optics, reflective type and transparent type, are available. The reflective

type fiber optics is for moisture measurement in powder state or in sheet state objects and the

transparent type fiber optics is for moisture measurement in liquids by combining with a

measuring cell for liquids.

Up to 9 detector unit can be connected with the setting display unit which can set various

parameters of the detector unit and displays the moisture value digitally.

Accessories including cables and output checker plate are available for various applications.

This manual describes about the detector unit, the fiber optics (reflective type and transparent

type), the measuring cell for liquids and accessories.

For the setting display unit, refer to a separate instruction manual for it.

1.2 Configuration

1. General

C H DATA

Transpa rent type fib er op tics

IR-WCT

Reflective type fiber opticswith lens attachment IR-WCRE

Reflective type fiber opticsIR- WCRN

Measuring

cell fo rliquids

IR-WCC1

Detector:Model for IR-M2

Analog output

IR-WERT

(connection

cable)

24V DC

IR-WEP

(power supply unit)

IR- GMEG1

(settin g displayunit)

Optical

fiber

RS- 485

Communication and

Analogoutput

Page 7

INST No. INE -403-0P0

−2−

2.1 Models

2.1.1 Detector unit IR-M2

Measurement object

1 : Universal type

2 : High moisture type

Fiber optics combined

0 : Reflective type

5 : Transparent type

External input/output

0 : Moisture output 4 to 20mA (Standard)

5 : Correction input 4 to 20mA (Option) *1

8 :Correction input Pt100 (Option) *1

Communications interface

S : RS-485 (Standard) *2

R : RS-232C (Option)

A : RS-422A (Option) *1

Special specification

Blank: None

x: Other special specification

2.1.2 Reflective type fiber IR-WCRN

2.1.3 Output checker plate for IR-WCRNB

reflective type fiber optics

2.1.4 Reflective type fiber optics with lens attachment IR-WCRE

2.1.5 Output checker plate for reflective

type fiber optics with lens attachment IR-WCREB

2.1.6 Transparent type fiber optics IR-WCT

2.1.7 Measuring cell for liquids IR-WCC1

2.1.8 Connection cable IR-WERT

2.2 Accessories

Component name Quantity

Remarks

Power supply unit (IR-WEP) 1no. S82K-05024 (Omron)

Fuse 2 nos. SMP20 (Daito)

Instruction manual 1 copy This document

Communications instruction manual 1 copy Attached to IR-M2R/A only

Inspection certificate 1 copy

2. Models and accessories

*1:

Combination of “5”

or “8” of

optional

external I/O and

communications

interface “A” is not

possible.

*2:Specify “S” for

combination with the

setting display unit.

Page 8

INST No. INE -403-0P0

−3−

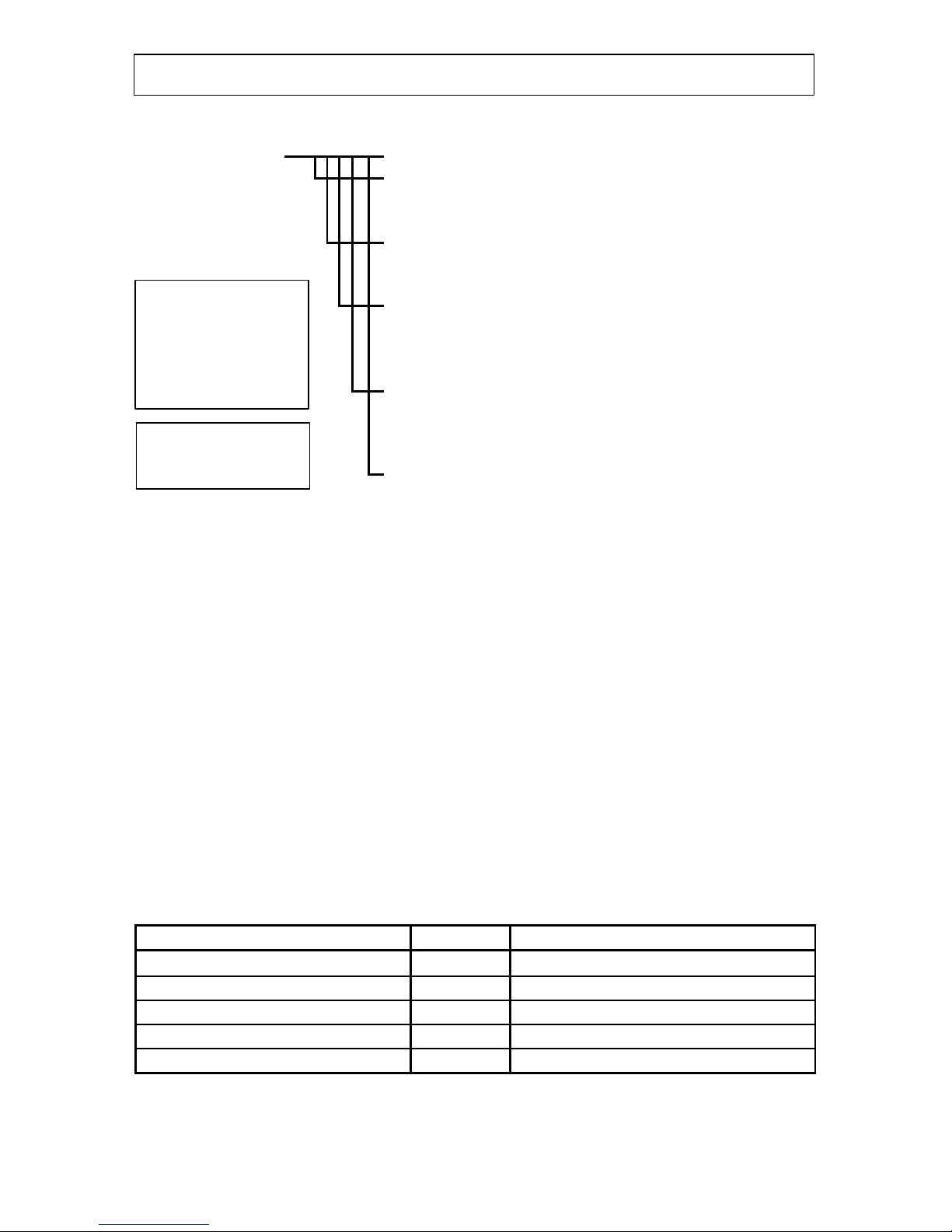

3.1 Setting of dipswitch es

Set the internal dipswitches before installation of the detector unit.

1) Open a door, remove 4 screws for fixing a setting display part and then remove the setting

display part.

2) The setting display part is connected to the interior through cables. Lift the setting display

part with due care so as not to damage the cable and disconnect the connector for the

setting display part at the position shown in the figure.

3) Set the dipswitches according to the working conditions.

3. Setting

Turn off the power supply before removing the setting display part. War ning

Loosen the se fou rscrews

CH

DATA

△

△▽

SEL

ENT

CH/

□

DIP switch 1

Connector fordisplay

!

Page 9

INST No. INE -403-0P0

−4−

3.1 Setting of dipswitch es

SW Dipswitch

No

Function

OFF ON

Defaults

1 Measurement/

Calibration mode

Measurement

mode

Calibration

mode

OFF (Don’t change.)

2 Mathematical

operation format

Logarithm

operation

Ratio operation ON (Don’t change.)

3 No.2 calibration

enable/disable

Disable Enable OFF

4 Connection

destination

Setting display

unit

PC

OFF : IR-M2 S

ON : IR-M2R

IR-M2A

5 Key/display

enable/disable

Enable Disable OFF

6 Not used OFF

7

Correction input

enable/disable

Disable Enable OFF

8 Correction input 4 to 20mADC Pt100 OFF

3. Setting

1 2 3 4 5 6 7 8

O

N

DIP switch 1

Page 10

INST No. INE -403-0P0

−5−

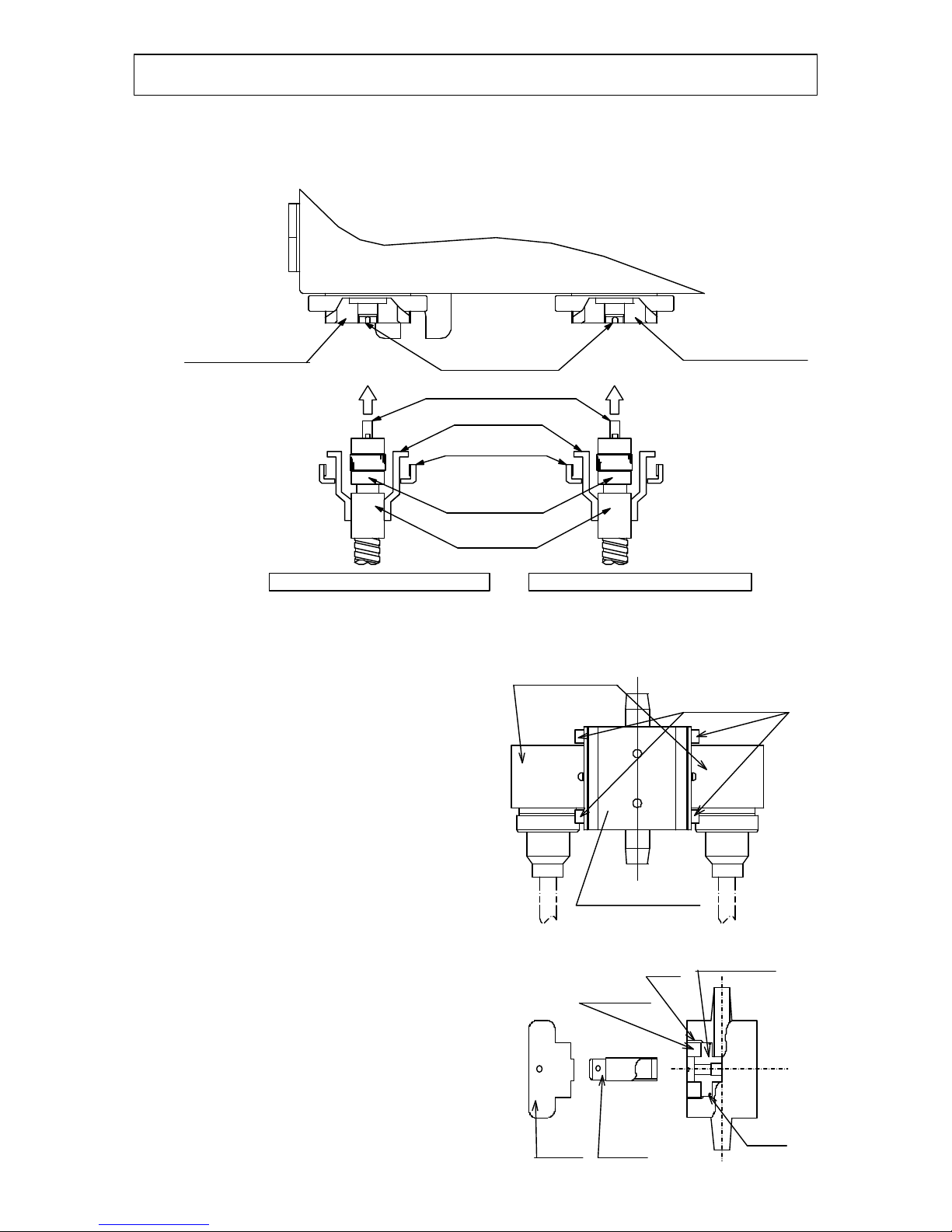

3.2 Installation of reflective type fiber optics

There are two types of reflective type fiber optics. One is “Without lens (IR-WCRN)” and

the other is “With lens (IR-WCRE)”.

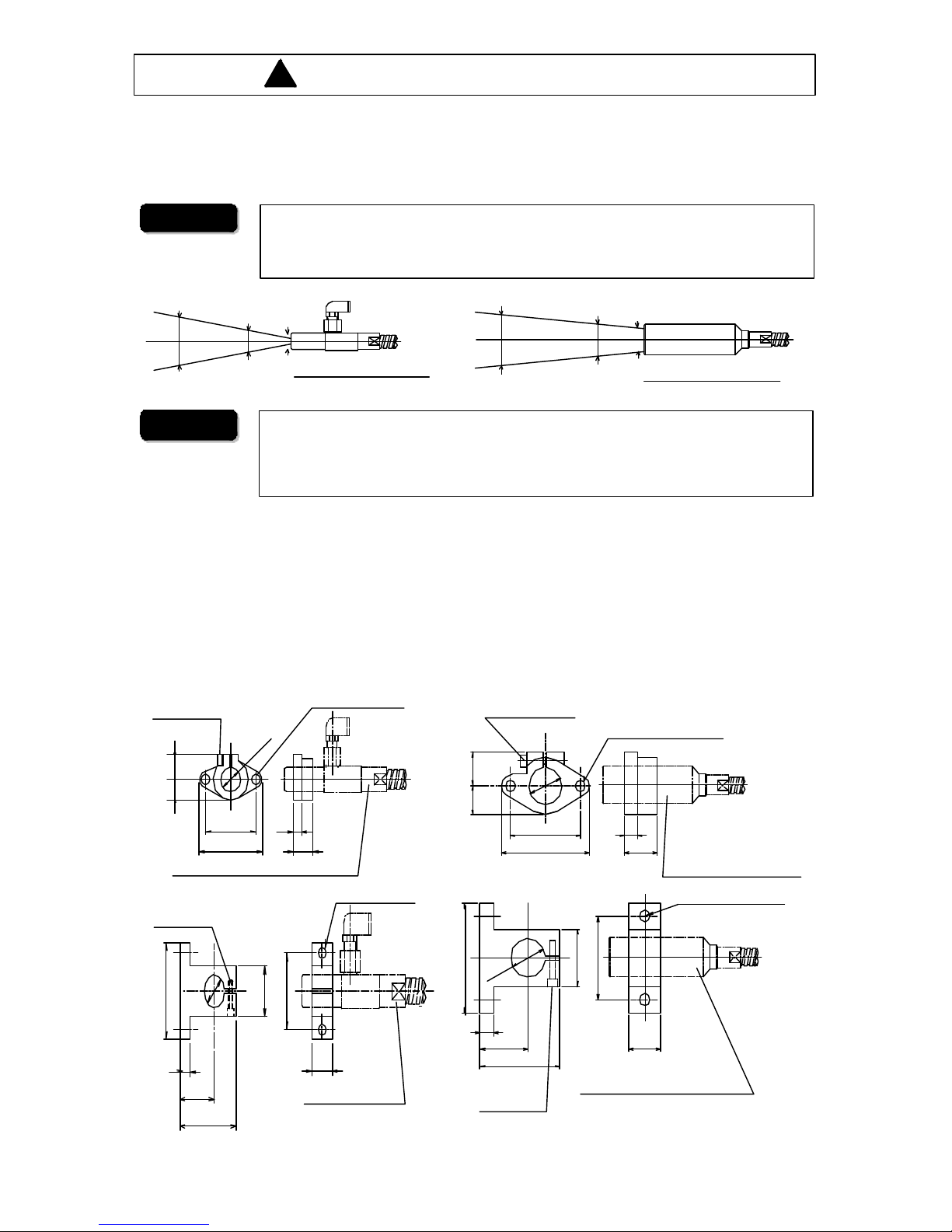

3.2.1 Installation of tip part

Set an attached holder to the installation place first. Insert the tip of fiber optics into the hole

of the holder and fix it by tightening the tip fixing screw. Two types of holder, horizontal

mounting type and flange type are attached.

The tip of reflection

type fiberoptics with

lens attachment

The tip of reflection type

fiber opticswith lens attachment

23 27

84

64

(

Ø

3

0

)

(

Ø

3

0

)

64

80

12

30

42

12

70

28

2-Ø9Mountinghole

2-Ø9Mounting hole

Tipfixing screw

Tipfixing

screw

Place the tip of fiber optics with t

he following measurement distance from

an object. ・Reflective type fiber optics 15 to 50mm

・Reflective type fiber optics with lens 25 to 100mm

War ning

Fix the fiber optics with appropriate metal tools at several places

for

avoiding affect with vibrations, etc. Make sure not to bend the fiber

optics

below its minimum bending radius (100R).

Warning

[ Model for IR-WCRN ]

15mm

Ø

50

Ø

20

Ø

6

[ Model for IR-WCRE ]

100m

25mm

Ø

40

Ø

25

Ø

20

Tipfixing screw

17

14

40

50 16

7

The tip of reflectiontype fiberoptic s

(

Ø

1

6

)

2-Ø6.6Mountingho le

(

Ø

1

6

)

2-

Ø5.5

Mountinghole

The tipof reflection

typefiber optics

44

8

27

16

48

38

25

Tipfixingsc rew

1)Reflection-typefiber

2)Reflectiontypefiberoptics

withlensattachment

3. Setting

!

Page 11

INST No. INE -403-0P0

−6−

Purgeair

inlet

Purge air flow:50 to 200Nl/min

Purge air pressure:Lower than200kPa

3.2.2 Air purge (Only IR -WCRN)

When air purging is required, supply dry air not

containing oil, dust, etc. from a purge air inlet.

Connect a nylon tube of φ6mm in outer diameter and

φ4mm in inner diameter to the purge air inlet.

(When the reflection type fiber optics is used in

ambient temperature more than 60°C, remove the

purge air inlet and pipe to the screw hole of RC1/8

directly .

Purge air flow: 5 to 20NI/min

Purge air pressure: Less than 200kPa (2kgf/cm2)

3.2.3 Connection s with detector unit

Connect the side being separated into two parts of light projecting side and light receiving

side with the fiber optics connectors of the detector unit.

The fiber optics has “Light project ing

side (D)”and “Light receiving side

(E)”and each one has a carved mark. Connect the fiber optics through the

rubber bush as shown in the following figure.

War ning

3. Setting

!

Connector forfiber

[Light projecting side]

Connector forfiber

[Light receivingside]

Dent department

Protrusiondepartment

D E

Rubberbush

Bushfittingring

Connector ring

Optical fiber

D:Connect tolight projectingside E:Connectto light receivingside

Page 12

INST No. INE -403-0P0

−7−

3.2.4 Optical path

Select a place where water drops, dust particles, smoke, water steam, etc. will not enter

between the tip of fiber optics and an object. If these substances cannot be prevented and

their influences are negligible, purge them with air, or other remedial measure is necessary.

If direct current (DC) light like the natural light, which does not change its intensity

momentarily , comes to an object, it does not cause any disturbance in measurement, but

alternate current (AC) light like as electric bulb, flame, etc., causes disturbance. Further,

strong light such as direct sunlight also causes disturbance. In such cases, it is necessary to

shade the disturbing light to prevent it from direct shining on an object.

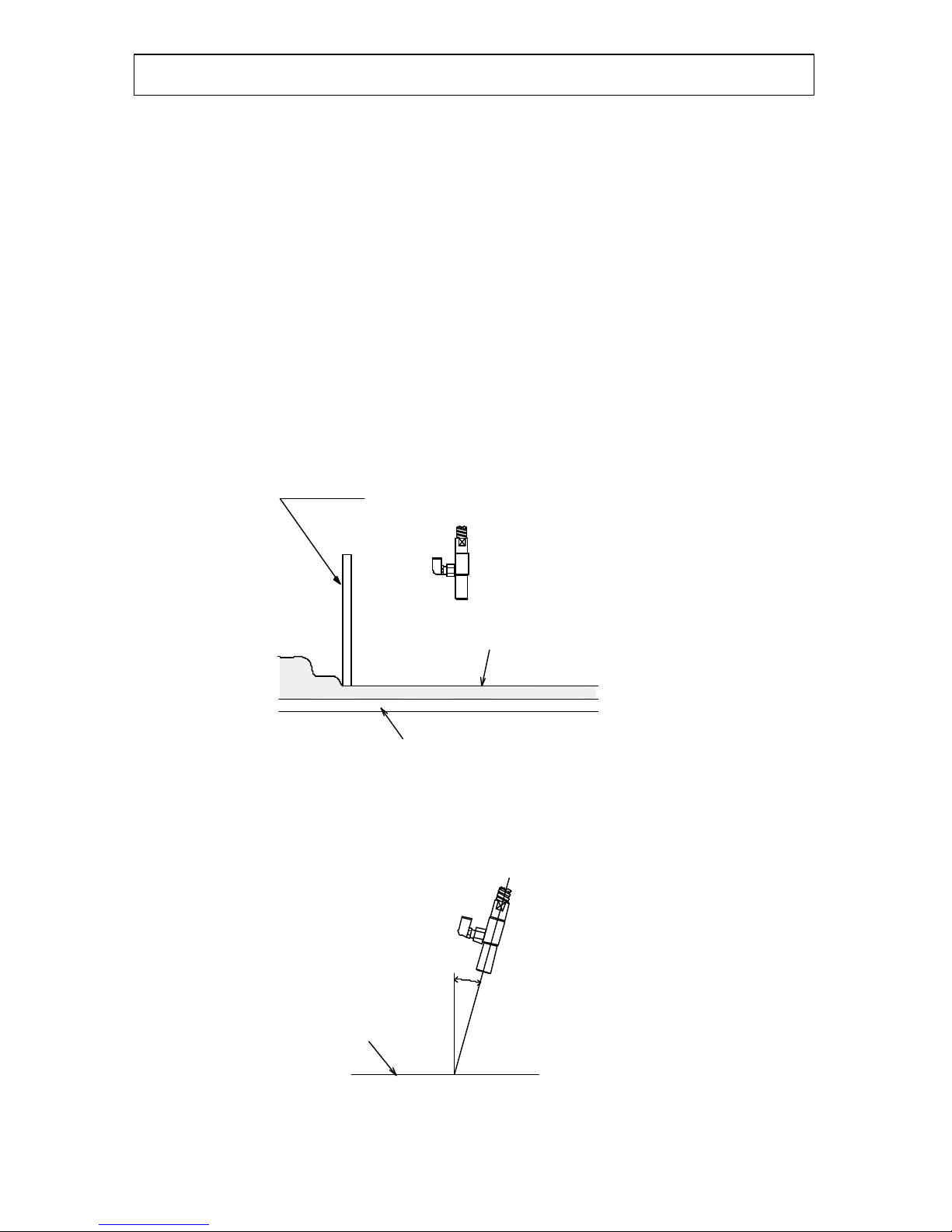

3.2.5 Measuring place (for objects of pulverized or granular substance)

For installation of the tip of fiber optics on on-line, select a place where the moisture

difference is small between the surface and the inside of an object, like as at a hopper outlet

or just behind the conveyor belt transfer place. If such a place cannot be selected, face the

inside to the surface by using a baffle plate during measurement as shown in the figure.

3.2.6 For the objects in sheet state such as paper, etc.

Tilt the tip of fiber optics by 15° from the vertical face as shown in the figure.

3. Setting

Baffle plate

Measuringobject

Belt conveyor

Paperor

othersheets

15°

Page 13

INST No. INE -403-0P0

−8−

3. Installation of transparent type fiber optics

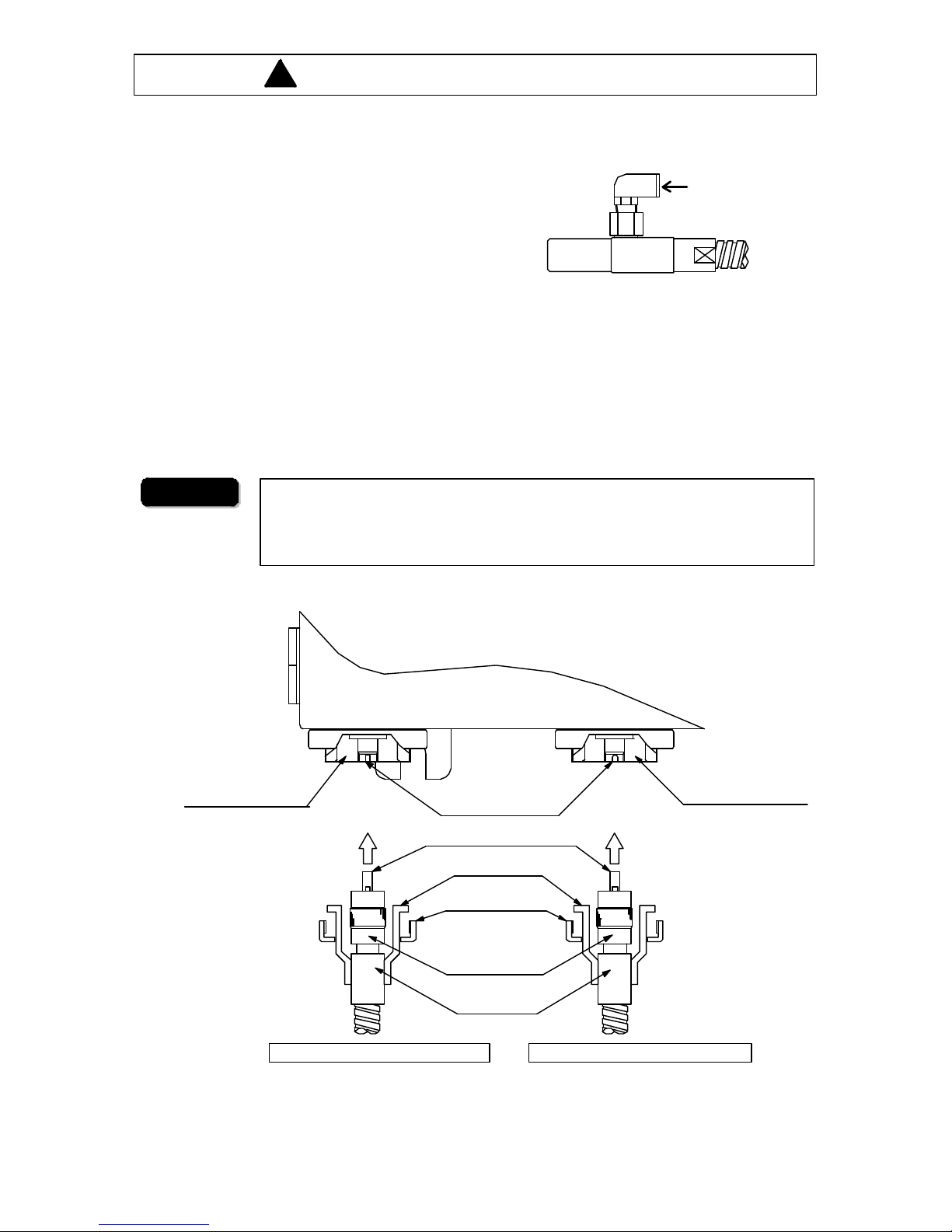

3.3.1 Installation of cell for liquids

Install a measuring cell to flow a sample liquid from down to up. Connect with the fiber optics

between the detector unit and the measuring cell. Make sure to connect the light projecting side

and the light receiving side of the fiber optics to the correct sides of the detector unit and the

measuring cell.

Fix the fiber optics with appropriate metal tools at several places for

avoiding affect with vibrations, etc.

Make sure not to bend the fiber optics below its minimum bending

radius

(250R).

War ning

C H D ATA

Detector:Mode l for IR-M2

Power supply unit:

Model for IR-WEP

Setting display unit:

Model for IR- GMEG1

Measuring cell

Output

Input of

sample liquid

Light receiving side fiber optics

Light projecting side fiber optics

Fixthe fiberoptics with appropriatemetaltools atseveral places.

3. Setting

!

Page 14

INST No. INE -403-0P0

−9−

3.3.2 Connection with detector unit

Connect the fiber optics, as shown in the following figure, through the rubber bush attached

to the detector unit .

3.3.3 Disassemble cleaning

For accurate measurements, recommend periodical cleaning of the cover glass in a liquid

contacting part of the measur ing cell.

1) Remove the fiber optics (both of light

projecting side and light receiving side),

from the measuring cell.

2) Next, remove 4 screws fixing a connecting

part and remove the connecting part from

the liquid-contacting part.

3) Remove a fitting ring by using the tool A.

Then after screwing the tool B into the

cover glass, pull out the cover glass from

the liquid-contacting part.

4) Wipe off dirt on the glass surface with a

gauze, etc.

5) Confirm that an O ring is inserted in

liquid-contacting part and push in the

cover glass to the liquid-contacting part.

6) Match the positions of E and D characters

of the connecting part and the liquid

contacting part, and fix the connecting

part.

7) After the cleaning of the cover glass, make

sure to re-calibrate your moisture meter.

3. Setting

OUT

I N

Connectingpart

4- Fixingscew

Liquidcontacting

part

Tool A

ToolB

Fittingring

Curler

Cover glass

Oring

Connector for fiber

[Lightprojectingside ]

Connector for fiber

[Lightreceiving side]

Dent department

Protrusion department

D

E

Rubberbush

Bushfittingring

Connector ring

Optical fiber

D:Connect to light projectingside E:Connectto light receivingside

Page 15

INST No. INE -403-0P0

−10−

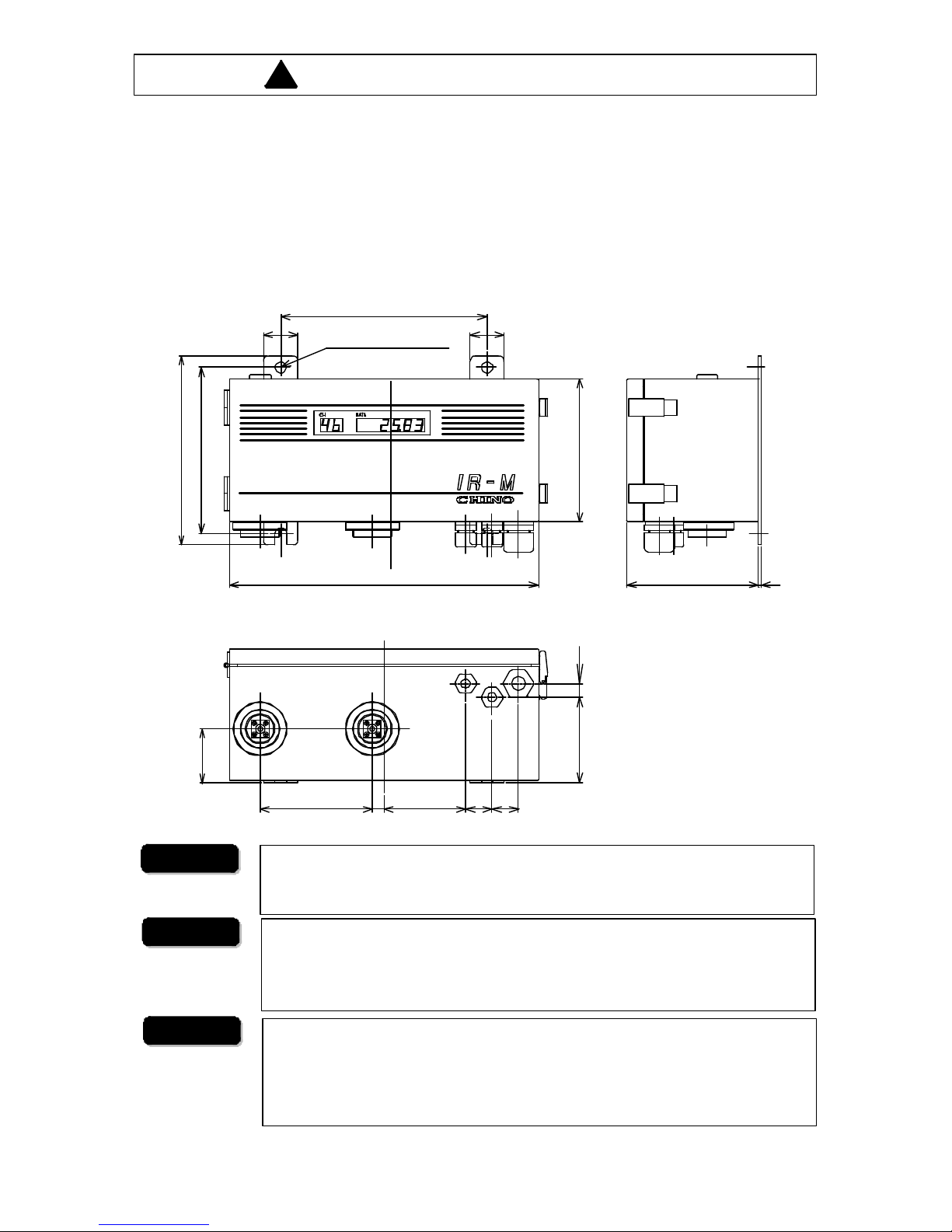

3.4 Installation of detector unit

The detector unit is a wall-mounting type with 4 mounting holes. Fix the detector unit to wall

surface, etc. with 4 pieces of M8 screw. The outside and mounting dimensions are shown in

the figure.

3.4.1 Outside and mounting dimensions of detector unit

115

2

270

180

3 03 0

98

10

12

2323

74.5

47

47

165

145

125

4-M8Mountin g hole

Vibrations and impacts

Use the detector unit in a place where is free of any noticeable

vibrations

or impacts.

War ning

Induction

The detector unit is designed for anti-induction. However separate

the

detector unit from induction heating oscillators or power

lines as far as

possible.

War ning

Ambient temperature and humidity

The ideal ambient temperature of the detector unit is 10 to 30°C

and the

ambient humidity as low as possible is recommended. In high

humidity

environment,

you may have error in measurement due to condensation of

steam by change in temperature.

War ning

3. Setting

!

Page 16

INST No. INE -403-0P0

−11−

4.1 Connections

The terminal board is accessible by opening the door of the detector unit. Lead in cables

through a small sized cable inlet at the lower part and connect them to terminals. Lead in the

exclusive cable IR-WERT through the large cable inlet.

4.2 Layout of connection cable

For connection of cables, be careful of the following points.

4. Connections

For preventing electric shock,

make sure to turn the power supply off

before wiring.

Warning

Caution

Use a cable conforming to the applicable outer diameter (φ4.5 to 6.5

mm)

of the small cable inlet; otherwise waterproofing of the

detector unit may

deteriorate. Tighten the nut at the cable inlet securely after connections.

・Separate the cables from induction heating oscillator and power lines.

・Keep the cables free of deposit of water, oil, etc.

・Don’t bend the cables extremely or apply any excessive force to them .

・

For permanent layout, protect the cables with conduits, etc.

SA

(Black)

SB

(White)

SG

(Brown)

G*1

(Green)

P+

(Red)

P(Blue)

P(Blue)

P+

(Red)G(Green)

V+ V-

LN

24V DC

Ground

Power supply

(IR-WEP)

100-120V AC

200-240V AC

Terminal

board

Cable inlet (small):

Outer diameter of

applicable cableØ4.5toØ6.5

Cable inlet (large):

[For IR-WERT]

Outer diameter of

applicable cableØ8.5 to

Ø10

.5

Connection cable

(IR-WERT)

Communication output

forIR-GMEG1, pe rsonal

computerand PLC.

Communication output RS-485

(Optional:RS-232C,RS-42 2A)

*1:

Don't connect this cable usually,

but connect it, if the unitis interfared

withnoises.

SA

SB

SG

OUT

Measuredvalue output :

4 to 20mADC

Loadresistance:Lower than 500

Ω

(Optional:RS- 232C, RS-422A)

P+

P-

24VDC

1.5A

SUPPLY

!

Page 17

INST No. INE -403-0P0

−12−

4.3 Multi-detector connections

By using the setting display unit, you can connect the detector unit up to 9 sets.

Two wiring methods are available. One is wiring through a relay box (IR-WEE) and the other

is without the relay box (IR-WEE).

4.3.1 Connections through relay box

4. Connection

Caution

For

both wiring methods, before connecting with the setting display unit or

before turning on the power supply of the setting display unit,

number

setting to the detector units is required. For the number setting, be careful

not to overlap any detector unit number of each detector unit.

Refer to [6.2 Setting of detector unit number ] for the details.

Caution

1. Shorten the length of exclusive cable (IR-WERT * mark) as much as

possible.

2. For wiring to the relay box, refer to “Instruction manual of relay box”.

Detecto r

IR-WERT*

IR-WERT*

IR-WERT*

Relayin g box

(Power supply unit is built in)

Relayin g box(Power supplyunit isbuilt in)

Relayin g box(Power supplyunit isbuilt in)

2-conductor twisted

cable(withshield)

2-conductor twisted

cable(withshield)

2-conductor twisted

cable(withshield)

100-240 V AC

Detecto r

Detecto r

Setting diplayunit

Page 18

INST No. INE -403-0P0

−13−

4.3.2 Connections without relay box

4. Connection

Detector

Detecto r

Detecto r

IR-WERT*

IR-WERT*

IR-WERT*

Setting diplay unit

100-240 V AC

2-conductor twisted

cable(withshield)

2-conductor twisted

cable(withshield)

2-conductor twisted

cable(withshield)

Taping

Taping

Taping

Connect theP+(Red), P-(Blue),

and G(external shield wire) of

IR-WERT to power supply.

And connect the SA (Black),

SB(White)and SG(internal shield

brown) of signal wire to the

2-conductor twistcable(with shield)

Fasten the signal wires in

IR-WERT (SA, SB andSG)

and thesignal wirein 2-conductor

twist cable(SA,SB and SG)together

at the terminal board of the detector.

Page 19

INST No. INE -403-0P0

−14−

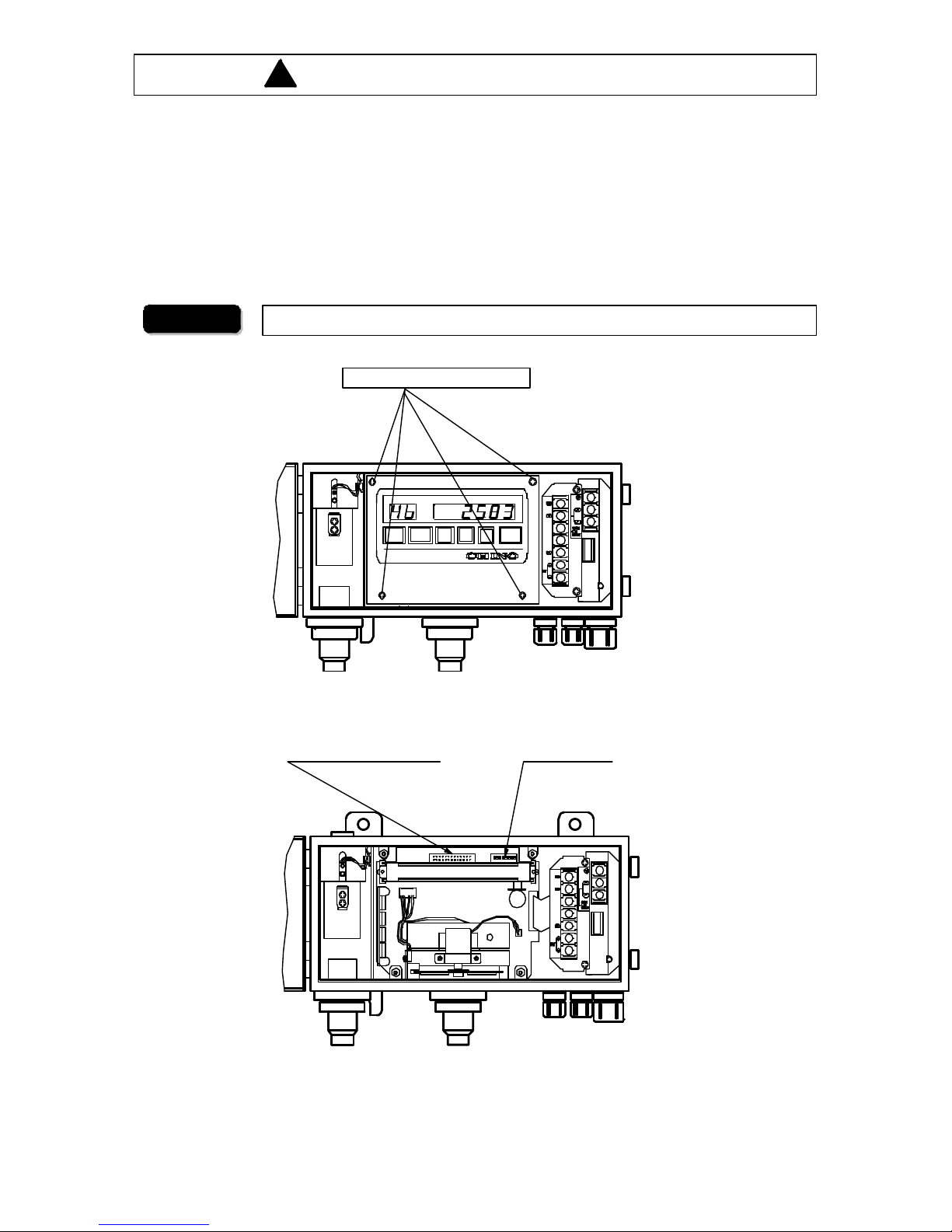

5.1 Names and functions of detector unit

(1) Hole for installation of detector unit: Four M8 holes for installation of the detector unit

to wall surface, etc.

(2) Data display window: Displays calibration curve number and measured value.

(3) Door: By opening the door, key switches and the terminal board are accessible.

(4) Cable inlet (small): Cable inlet for connection cable. Outside diameter of connection

cable applicable to this inlet: φ4.5 to 6.5mm.

(5) Cable inlet (large) Cable inlet for exclusive cable IR-WERT. Outside diameter: φ10mm.

(6) Serial No plate: Serial No plate of this detector.

(7) Connector on light projecting side : Connector for the light projecting side of the fiber

optics. Rubber bush is prepared for the connection.

(8) Connector on light receiving side : Connector for the light receiving side of the fiber

optics. Rubber bush is prepared for the connection.

(9) Setting display: Display part of this detector.

(10) Measurement part : Optical assembly, detector element and electric circuits are built-in.

(11) Lamp housing : Lamp is located inside.

(12) Power supply part: Terminal board for wiring, power fuse, power supply unit and

output board are built in.

(13) Power fuse: A power fuse is mounted to the fuse holder.

Power fuse: Insertion type, 2A, time lag fusion type

(14) Terminal board: For wiring of connection cable. Terminus screw size: M4.

5. Names and functions of component parts

DATACH

SEL CH/・ ENT

DATACH

(1) Detector mounting

screw hole- 2

(2) Data display

window

(3) Door

(5) Connection cableinlet (small)

(6) Connection cableinlet (large)

(6) Manufacturing

nameplate

(8) Connector on lightreceiving side

(7) Connector on lightprojecting side

(11) Lamp (9) Setting display

part

(14) Terminal board

(10) Measuring part

(12) Power supply part

(13) Power

supply

fuse

For preventing electric shock,

make sure to turn the power supply off

before wiring.

War ning

!

Page 20

INST No. INE -403-0P0

−15−

5.2 Names and functions of setting display part

(1) CH display: Displays a calibration curve number in measurement mode and a parameter

item in setting mode.

(2) Data display Displays a measured value in the measurement mode and a parameter in

the setting mode.

(3) Setting keys

SEL : For entering into the setting mode and switching a setting screen.

CH/・ : For setting a calibration curve number in the measurement mode and for

entering a decimal point in the setting mode. When the key is pressed again,

the decimal point disappears.

: For entering into a parameter setting in the setting mode and changing the digit

of the parameter.

: For changing the parameter in the setting mode.

: For changing the parameter in the setting mode.

ENT : For storing the parameter in the setting mode.

5. Names and functions of component parts

CH/・

SEL

ENT

CH

DATA

Setti ng display part

(1) CH Display

(2) DataDisplay

(3) Setting

keys

Page 21

INST No INE -403-0P0

−16−

6.1 Confirmation before operation

Check the following two points before turning on the power supply.

1) Have the dipswitches been set? (Refer to [3.1 Setting of dipswitches])

2) Is wiring correct? (Refer to [4.1 Wiring]).

6.2 Setting of detector unit number

Detector unit number s are for identifying each detector unit when multiple detector units are

connected to the setting display unit. (Refer to [4.3 Multi-detector connection]). Set a

detector unit number before connecting the setting display unit.

1) Enter into the operation condition setting mode by

pressing SEL key and ENT key simultaneously to

set CH display “t” for 2 seconds.

2) Press SEL key 4 times to set CH display to “Hn”.

3) By pressing key, the numeric blinks for entering a

detector unit number.

4) Change the numeric by key or key.

When key is pressed, the num eric is increased.

When key is pressed, the num eric is decreased.

When key is pressed, the blinking digit shifts.

5) When ENT key is pressed, the numeric stops

blinking and the detector number is stored.

6) Return to the measurement mode by pressing SEL

key for 2 seconds.

6.3 Setting of calibration curve data

The output characteristic of infrared moisture meter depends upon measuring objects. It may

also change according to the process conditions and sample moisture measuring conditions.

Therefore, it is necessary for accurate moisture measurements to perform a sample test of the

object and obtain the correlation (This is called as calibration curve.) between the moisture value

(%H2O) obtained by a drying method or other measuring methods and the absorbance “x”

measured by the moisture meter.

This paragraph describes the setting method for calibration curve data, assuming that calibr ation

curves have been already created.

When the calibration curves have not been created yet, refer to [7. Creation of calibration

curves].

Refere nce

The default number of the detector unit is “1”.

For using it with a number other than 1, set the detector unit number

by

following order.

CH

DATA

t 0.0

CH

DATA

Hn

1

Detector No

6. Operation

Page 22

INST No INE -403-0P0

−17−

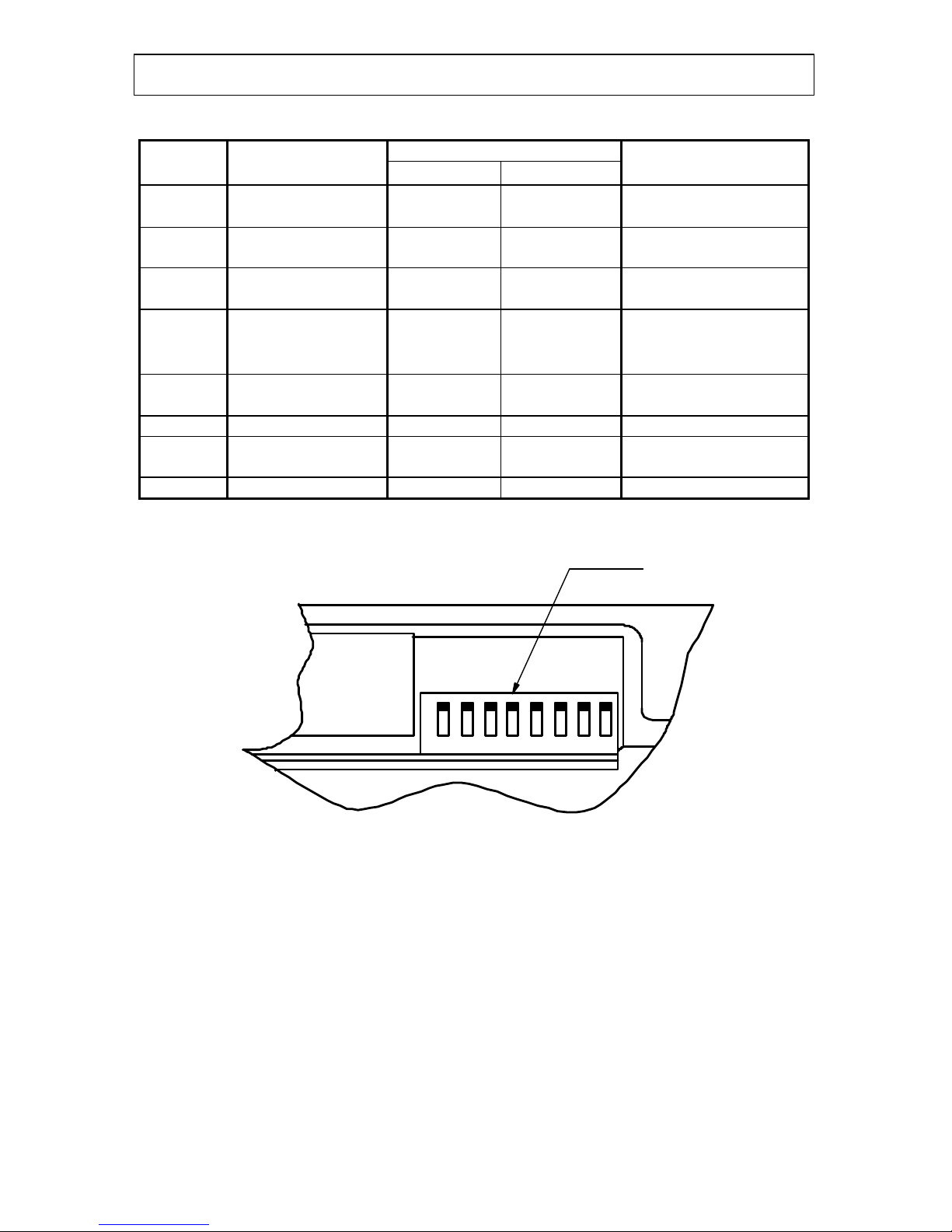

6.3.1 Setting data

The followings are the setting data of calibration curve.

Data name Disp

lay

Setting

range

Defaul

t value

Remarks

(1) Calibration curve No. CH 1 to 99 1

(2) Polynomial coefficient a0 A0 0 to ±99999 0.0000 Effective numeric: 5 digits

(2) Polynomial coefficient a1 A1 0 to ±99999 0.0000 Effective numeric: 5 digits

(2) Polynomial coefficient a2 A2 0 to ±99999 0.0000 Effective numeric: 5 digits

(2) Polynomial coefficient a3 A3 0 to ±99999 0.0000 Effective numeric: 5 digits

(3) Correction expression coefficient b0 B0 0 to ±9999.9 0.0000 Effective numeric: 5 digits

(3) Correction expr ession coefficient b1 B1 0 to ±9999.9 1.0000 Effective numeric: 5 digits

(4) Output low limit moisture Hi 0 to 9999.9 0.00

Decimal digit depends on

specification.

(4) Output high limit moisture Hi 0 to 9999.9 100.00

Decimal digit depends on

specification.

(5) Low limit alarm moisture AL 0 to 9999.9 0.00

Decimal digit depends on

specification.

(5) High limit alarm moisture AH 0 to 9999.9 100.00

Decimal digit depends on

specification.

(6) Preset moisture PS 0 to 9999.9 0.00 Decimal digit depends on

specification.

(1) Calibration curve number

An optional number from 1 to 99 can be designated as the calibration curve. It is

designated sequentially from “1” usually.

(2) Polynomial coefficient “a0 to a3”

Assume that the calibration curve is represented by third-degree or lower-degree

polynomial as shown below.

y = a3x3 + a2x2 + a1x + a0

where, “y” is the moisture value (%H2O) and “x” is the absorbance (“CH0” data of this

moisture meter).

(3) Correction expression coefficient “b0 to b1”

These coefficients are provided for primary expression correction (zero and span

correction) with reference to moisture value “y”. Assuming that the moisture value after

correction be “Y”, we obtain,

y = b1y + bo

(4) Output low limit moisture, output high limit moisture

These moisture values are specified as the output low limit and output high limit on the

analog output scaling. These values are scaled to be 4mA at the output low limit moisture

and 20mA at the output high limit moisture.

(5) Low limit alarm moisture, high limit alarm moisture

The low limit alarm activates when a measured value is lower than the low limit alarm

moisture, while the high limit alarm activates when a measured value is higher than the

high limit alarm moisture. Since the detector unit does not provide any alarm output

function, the setting display unit is required when an alarm output is necessary.

(6) Preset moisture

By turning on the preset output by key operations or through communications, the

moisture value being set as preset moisture is displayed and output, regardless of the

measured value.

6. Operation

Page 23

INST No INE -403-0P0

−18−

y

1

y

2

y

3

y

4

y

5

y

7

99.999

y

6

-10

0

10

x

1

x2x3x

4

x5x

6

x

7

6.3.2 Setting of calibration curve data

1) Press SEL key for 2 seconds to enter into the calibration

curve data setting mode.

2) By pressing key, a numeric blinks for entering a

calibration curve number.

3) Change the numeric by key, key or key.

When key is pressed, the numeric is increased.

When key is pressed, the numeric is decreased.

When key is pressed, the blinking digit shifts.

4) When ENT key is pressed, the numeric stops blinking

and the calibration curve number is stored.

5) Press SEL key to enter into the setting mode for

polynomial coefficient a0.

6) Enter into a numeric setting mode by pressing key.

Change the numeric by key or key and store it by

pressing ENT key.

For entering a decimal point, press CH/・ key at the

blinking digit.

7) Press SEL key to enter into the next data setting mode.

8) Repeat the above procedure to set all data.

9) After the above setting procedure is completed, return to the measurement mode by

pressing SEL key for 2 seconds. The automatic return is made if no key is pressed for one

minute.

6.4 Preparation of calibration curve by knee point line approximation

When a calibration curve is obtained in a graph but it cannot be expressed in third-degree or

lower-degree polynomial, the calibration curve can be created by broken line approximation.

6.4.1 Setting of knee point data

1) Supposing that the calibration curve graph

is as shown in the following figure.

2) Divide the calibration curve graph

appropriately and express it with broken

line approximation.

3) In this case, the first junction point and the

last junction point should sufficiently

include the measuring range. You can plot

up to 20 junction points including the first

junction point and the last junction point.

Determine intermediate junction points

appropriately according to the

approximation accuracy.

4) Supposing that the junction point data

obtained by the above are as shown below.

First junction point D1: (x1, y1)

D2: (x2, y2)

Last junction point Dn: (xn, yn)

↑

Setting data number

displayed

CH

DATA

CH 0

Blinking Detector No

CH

DATA

CH 0.0000

Setting data

displayed

CH

DATA

CH 0

6. Operation

Data number

Page 24

INST No INE -403-0P0

−19−

6.4.2 Knee point line setting data

The following data is necessary for the creation of the calibration curve by knee point line

approximation.

Data name Display Setting

range

Default

value

Remarks

(1) Calibration curve

number

CH 1 to 99 1

(2) Data count N 3 to 20 3

(3) Data number Dn 1 to 20 1

(3) Sample data

xn

Hn 0 to ±9999.9 0.0000 Valid number 5 digits

(3) Sample data

yn

yn 0 to ±9999.9 0.0000 Valid number 5 digits

(4) Regression/Broken

line

Pb 1 to 4 1

1 to 3:

Polynomial expression degree

(Regression operation)

4: Broken line approximation

(5) Standard deviation Sd 0 to 999.99 0.0000

Setting not required in broken line

approximation

(1) Calibration curve number: Calibration curve number can be specified in optional

numbers from 1 to 99 but usually it is specified in order

from 1.

(2) Data count: It is the number of knee point data and the maximum is 20 points.

(3) Data number, sample data x

n,

sample data yn:

Enter the knee point data obtained in [6.4.1 Setting of knee point data].

(4) Regression/knee point line: With entering 1, 2 or 3, the polynomial expression with that

degree can be obtained according to the above sample data

by regression operation. When 4 is entered, knee point line

approximation is obtained.

(5) Standard deviation: When the regression operation is specified, standard deviation is

displayed. This setting is not required in knee point line

approximation.

6. Operation

Page 25

INST No INE -403-0P0

−20−

6.4.3 Setting of calibration curve data for knee point line approximation

(1) Setting of calibration curve number

1) Press SEL key and CH/. key simultaneously for

2 seconds to enter into the sample data setting mode.

2) By pressing key, a numeric blinks for entering a

calibration curve number.

3) Change the numeric by key, key or key.

When key is pressed, the numeric is increased.

When key is pressed, the numeric is decreased.

When key is pressed, the blinking digit shifts.

4) When ENT key is pressed, the numeric stops blinking

and the calibration curve number is stored.

(2) Setting of data count

1) Press SEL key to enter into the data count setting

mode.

2) Change a numeric by the procedure mentioned in the

above “(1) Setting of calibration curve number 2) and

3)” and store it with ENT key.

(3) Setting of data number, sample data xn and

sample data yn

1) Press SEL key to enter into the data number setting

mode.

2) Change a numeric by the procedure mentioned in the

above “(1) Setting of calibration curve number 2) and

3)” and store it with ENT key.

3) After setting the above, press SEL key for entering

into the sample data xn setting mode.

4) After setting the above, press SEL key for entering

into the sample data yn setting mode.

5) After setting the above, press CH/. key to return to

“1) Data number setting mode” and then set the next

data number.

6) Repeat the above procedures for setting all junction point

data.

(4) Regression/Knee point line

1) After completing the setting of knee points, press SEL

key to enter into the regression/knee point line setting

mode.

2) Enter “4” in the selection of regression/knee point line.

3) After the settings are completed, press SEL key for 2

seconds to return to the measurement mode.

Automatic return to the measurement mode is made if

any key is operated for 1 minute.

CH

DATA

Dn 0.0000

CH

DATA

yn 0.0000

CH/・ SEL

CH

DATA

pb 4

CH

DATA

CH 1

CH

DATA

CH 01

Detector No

Blinking

CH

DATA

n 4

Setting data

displayed

Setting data number

displayed

CH

DATA

Dn 1

6. Operation

Page 26

INST No INE -403-0P0

−21−

6.5 Setting of operating conditions

Set the operating conditions including time constant and decimal place in the display.

6.5.1 Setting data

Set the following data in operating conditions.

However, the number of displayed setting data varies depending on the setting of dipswitches.

Data name Display Setting range Default value Remarks

(1) Time constant t 0 to 9, 9 to 99 0.0 Unit: Seconds

(2) Hold ON/OFF Hd ON, OFF OFF

(3) Preset output ON/OFF PS ON, OFF OFF

(4) Decimal place in display Dt 0 to 4 1

(5) Detector unit number Hn 1 to 9 1

(6) Communications

speed *1

SP

1200, 2400, 4800,

9600, 19200

9600

(6) Parity *1 P None

odd

EVEn

EVEn nonE :Non parity

odd : Odd parity

EVEn :Even parity

(6) Data length *1 D 7, 8 7

(6) Stop bit length *1 B 1 to 2 1

(6) BCC enable/disable *1 Bc ON, OFF OFF (disable)

(7) Sample temperature

correction enable/disable

St ON, OFF OFF (disable)

(8) Correction input

scaling L*2

TL -999 to 999 0

(8) Correction input

scaling H*2

TH -999 to 999 100

〔Engineering mode

〕

(9) Weightα

Af 0 to 1.000 0.500

(10) Calibration constant k1 k1 0 to ±9.9999 1.0000

(11) Calibration constant

k2 *3

k2 0 to ±9.9999 0.0000

(

Note) The setting data of *1 to *3 is displayed or not depending on the setting of

dipswitches.

Displayed data Setting of dipswitch 1 Contents

*1 Setting data No. 4 : ON Connection destination: Personal computer

*2 Setting data No. 7 : ON No. 8 : OFF Corrected input: Enable

Corrected input specification: 4 to 20mADC

*3 Setting data No. 3 : ON No. 2 Calibration: Enable

6. Operation

Page 27

INST No INE -403-0P0

−22−

(1) Time constant:

If a measured value fluctuates noticeably, the signal can be set to be dull by delaying the

response of this moisture meter. Set the smoothing time (equivalent to the time constant of

analog instrument) in 0.1-second increment for less than 10 seconds and in 1-second

increment for more than 10 seconds.

(2) Hold ON/OFF:

When holding of measured value is desired, turn it ON. At this time, analog output will

also be held.

(3) Preset output ON/OFF:

By turning on the preset output, this moisture meter displays the preset moisture value and

the analog output becomes the value corresponding to the preset moisture value.

(4) Decimal place in moisture display:

The decimal place can be set for easily monitoring the moisture value measured.

(5) Detector unit number:

This is the number for identifying the detector unit for connection of multiple detector units.

This setting has been completed in [6.2 Setting of detector unit number].

(6) Communications speed, Parity, Data length, Stop bit length, BCC enable/disable:

These are for communications with a personal computer, a sequencer or other similar

devices. These data are not necessary to set for combining this moisture meter with the

setting display unit.

(7) Sample temperature correction enable/disable:

These are used for sample temperature correction enabled.

(8) Correction input scaling L, Correction input scaling H

These are used for scaling of 4 to 20mA correct ion input.

(9) Weight á

In 3-wavelength operation, the ratio of 2 comparative wavelengths is determined by this

value.

(10) Calibration constant K1:

This is the calibration constant at the time of zero side calibration.

(11) Calibration constant k2:

This is the calibration constant at the time of span side calibration.

6. Operation

Page 28

INST No INE -403-0P0

−23−

6.5.2 Setting

1) Press SEL key and ENT key simultaneously for 2

seconds to enter into the operation condition setting

mode.

2) By pressing key, a numeric blinks for entering a data.

3) Change the numeric by key, key or key.

When key is pressed, the blinking digit shifts.

For entering the decimal point, press CH/. key.

4) When ENT key is pressed, the numeric stops blinking

and the data is stored.

5) Press SEL key to enter into the setting mode of the

next data. Repeat the above procedures to set all data

except the engineering mode.

6) For setting of data in the engineering mode, press ENT

key in the screen shown in the right side to enter into the

setting mode of the engineering mode.

7) After the settings are completed, press SEL key for 2

seconds to return to the measurement mode. Automatic

return to the measurement mode is made if any key is

operated for 1 minute.

6.6Calibration

For using this moisture meter accurately, regular calibration once in three months is requested.

1) Supply power more than one hour to this moisture meter

before calibration.

2) Turn the calibration curve number to 0. (For the change

in calibration curve number, refer to [6.7 Setting of

calibration curve number]. By this setting, absorbance

“x” is displayed as a data.

3) Execute the calibration by pressing the three keys SEL , , and ENT

simultaneously .

Make sure that light absorbance “x” is within 0.00000±0.0010. The calibration is

completed.

CH

DATA

Eng

CH DATA

t 0.0

Setting data

displayed

Setting data number

displayed

CH

DATA

0 0.0021

Refere nce

・For the reflective type fiber, place the output checker plate

at the tip of

fiber to see the plate.

Refere nce

・For the transparent type fiber, disassemble the measuring cell

to be

empty.

6. Operation

Page 29

INST No INE -403-0P0

−24−

6.7 Setting of calibration curve number

Set the calibration curve number according to the

measuring object.

1) By pressing CH/. key, a numeric blinks for entering a

calibration curve number.

2) Change the numeric by key, key or key.

3) When ENT key is pressed, the numeric stops blinking

and this moisture meter becomes the measurement mode

at the calibration curve number changed.

6.8 Correction of calibration curve

If the actual moisture value is different from the moisture value being preset due to the

difference of one-line and off-line, or other causes, correct it by the correction coefficients b0

and b1 in [6.3 Setting of calibration curve data]. Usually, the shift correction is done with

b0 only.

CH

DATA

01 10.0

Blinking

Refere nce

[Example]

When the measured moisture before correction is 15(%H2O)

and actual

moisture value is 13 (%H2O),

Set b0 = -2(%H2O) .

6. Operation

Page 30

INST No INE -403-0P0

−25−

7. Preparation of calibration curves

The output characteristics of the moisture meter depend upon the measuring objects. Also, the

output characteristics may also change according to the process conditions and moisture

measurement conditions of samples for certain measuring objects.

Therefore, for accurate measurement of moisture, it is necessary to carry out the sample tests

of each measuring object in advance and obtain the relative relation (this is called as

calibration curve) between the moisture value (%H2O) obtained by the drying method or other

measuring methods and the absorbance "x" measured by the moisture meter This chapter

describes the measurement of the moisture value by the drying method. However, the method

of creation of the calibration curves is same even if the moisture value is measured by the

Karl Fischer method or other methods.

7.1 Sample preparation

7.1.1 Powder or granular

(1) Take a sample of about 2 to 4 liters from the measuring object.

(2) Dry up the sample up to the absolute dry condition by a dryer. Particularly be careful with

the heating temperature so as not to denature the sample.

(3) Divide the dry sample every 100 to 200cc into 5 to 6 samples separately, although it is

recommendable to divide the sample into many samples.

(4) Add water to these 5 to 6 samples bit by bit so that the moisture values of each sample

divides the measuring range almost evenly.

(5) Stir each sample with water addition sufficiently, and put it into a polyethylene bag and

seal it tightly.

(6) Leave each sample for about 2 days until its moisture is stabilized.

If a sample cannot be heated or if it is hardened by adding water and thus

can ’

t be measured, adjust the moisture correspondingly according to the

procedure in case of a paper s hown below.

Caution

7. Preparation of calibration curves

1

2 3 N

Page 31

INST No INE -403-0P0

−26−

7.1.2 Paper (sheet substance)

(1) Cut a sample to have a size of about 100 x 100mm by using a cutter or the like. (Number

of samples: 9 sheets)

(2) Divide nine sheets of the sample into 3 groups with 3 sheets in each group. Adjust the

moisture of each group under the following conditions.

Drying : Leave the samples in a desiccator containing silica gel for 2 days. In case of

papers, the moisture becomes about 4%H2O.

In the air: Leave the samples in an indoor atmosphere.

In case of papers, the moisture becomes about 7%H2O in summer or about

5%H2O in winter.

Moistening: Leave the samples in a desiccator containing salt water for 2 days.

In case of papers, the moisture becomes 8 to 9%H2O usually or

maximum about 11% H2O.

7.1.3 Liquid

(1) Prepare 500 to 1000cc of sample dried nearly up to the lower limit moisture of the

measuring range.

(2) Prepare 5 to 10 containers (with lid) of 100 to 200cc capacity and put the above sample

till the containers are full.

(3) Add water to these 5 to 10 samples bit by bit so that the moisture values of each sample

divides the measuring range almost evenly.

(4) Stir each sample with water addition sufficiently, and put a lid on the container tightly.

Wear clean gloves when handing samples so as not to touch them by

naked hands directly.

It is convenient for you to mark the samples for identifying

its front and

back surfaces and its flow direction.

Caution

If a sample is with strong moisture absorption and low moisture less than

few % is required, even if water is not added,

the moisture of the sample

may reach to its level by absorption of moisture only.

For such samples, adjust moisture by changing a moisture absorption time.

Caution

7. Preparation of calibration curves

1

2

3

4

5

6

Withsilicagel

Withsalt water

Page 32

INST No INE -403-0P0

−27−

w1-w2

w1-w0

×100

(%H2O

)

7.2 Sample measurement

Be careful with the following cautions during measurement.

(1) Before measurement, warming-up of this moisture meter more than 1 hour is required.

(2) Place a sample at the same position as in actual measurement, set the calibration curve

number to 0, and read the display (absorbance "x").

(3) Perform the measurement rapidly.

7.2.1 Powder or granular

(1) Prepare the trays (Diameter 100 to 150mm, Depth about 20mm) by the same quantity as

the measuring sample quantity.

(2) Weigh the weight w0 of each tray.

(3) Spread the sample being sealed in the polyethylene bag on the tray it till the surface

becomes flat and the bottom cannot be seen.

(4) Put the tray at the measuring position, set the calibration curve number to 0, and read the

display (absorbance "x"). If the measured value cannot be read easily, delay the response

by the smoothing function.

(5) Stir the sample rapidly with a spoon and measure it again. Repeat this measurement 2 or

3 times per sample.

(6) Weigh the weight w1 of the tray together with the sample.

(7) Perform the same measurement sequentially about all samples.

(8) Put each sample together with its tray into a dryer, and dry it out to be the absolute dry

condition (for longer than 2 hours at 105 to 110ºC usually).

(9) Cool down the sample after drying, and weigh the weight w2 of each tray together with

the sample.

(10) Record the measured value in the following table every measurement, and obtain the

moisture value by the following formula.

No. Absorbance "x" w0 W1 w2 Moisture value (%H2O)

1 x1 y1

2 x2 y2

3

:

x3

:

y3

:

N xn y4

7. Preparation of calibration curves

Page 33

INST No INE -403-0P0

−28−

7.2.2 Paper (Sheet substance)

(I) Weigh the weight w1 of a sample before measurement.

(2) Hold the sample by a paper holder, put it by tilting at 15º to the measuring position, set

the calibration curve number to 0, and read its display (absorbance "x"). In this case,

match its front and back surfaces and flo w direction of the samples.

(3) Weigh the weight w

2

of the sample after measurement. Perform the measurement from

(1) to (3) as quickly as possible.

(4) Perform the same measurement sequentially for all samples.

(S) Put each sample into a dryer, and dry it out to be the absolute dry condition (for longer

than 2 hours at 105ºC usually by using paper stand).

(6) Cool down all samples in a desiccator containing silica gel after drying.

(7) Weigh the weight w3 of each sample.

(8) Record the measured value in the following table every measurement, and obtain the

moisture value by the following formula.

No. Absorbance "x" w0 W1 w2 Moisture value (%H2O)

1 x1 y1

2 x2 y2

3

:

x3

:

y3

:

N xn y4

7.2.3 Liquid

Execute the measurement in order from the object of low moisture to the object of high

moisture.

1) Put a sample into the measuring cell, set the calibration curve number to 0, and read the

display (absorbance "x").

If the measured value cannot be read easily, delay the response by the smoothing function.

2) With the Karl Fischer method or other methods, measure moisture value of the sample put

in the measuring cell.

3) Repeat the above measurements of 1) and 2) for 2 or 3 times per sample.

4) Record the measured value of all samples by the same measuring procedure in the

following table, and obtain the average value.

Absorbance "x" No.

1 2 3 Average

Moisture

(%H2O)

1 x1 y1

2 x2 y2

3

:

x3

:

y3

:

N xn y4

(w1+w2)/2-w3

(w1+w2)

×100

(% H2O

)

・For taking out a sample from a

container, shake the container well to

uniform the moisture in the container and then take the sample out.

・When the next sample is measured, throw away the sample

already

contained completely and wash the measurement cell

for two or

three times for the next measurement.

Caution

7. Preparation of calibration curves

Page 34

INST No INE -403-0P0

−29−

Absorbance (x)

M oisture value (y)

(%H2O

)

7.3 Preparation of calibration curves

Create a calibration curve by plotting data obtained by

[7.2 Sample measurement] on a graph. Plot the

absorbance "x" of this moisture meter on the X-axis

and also plot the moisture value (%H2O) on the Y-axis.

Obtain a curve with minimize errors from this graph as

a calibration curve. Usually the curve with minimize

errors is obtained by the regression operation. For the

creation of a calibration curve by the regression

operation, refer to [7.3.1 Computation of regression

expression] and [7.3.2 Confirmation of regression

expression].

If a graph contains inflection points, use the creation of

a calibration curve by broken line approximation. For

the creation of a calibration curve by broken line

approximation, refer to [6.4 Creation of calibration

curve by broken line approximation].

7.3.1 Computation of regression expression

This moisture meter has regression operation function by the minimum mean square method.

By this function, first-degree to third-degree polynomials can be obtained by entering the data

obtained in [7.2 Sample measurement].

Assume that there are “n” sets of sample data ("xn, yn). (in condition that “n” is 20 or less)

(1) Setting of calibration curve number

1) Press SEL key and CH/. key simultaneously

for 2 seconds to enter into the sample data setting mode.

2) By pressing key, a numeric blinks for entering a

calibration curve number.

3) Change the numeric by key, key or key.

When key is pressed, the numeric is increased.

When key is pressed, the numeric is decreased.

When key is pressed, the blinking digit shifts.

4) When ENT key is pressed, the numeric stops blinking

and the calibration curve number is stored.

(2) Setting of data count

1) Press SEL key to enter into the data count setting

mode.

2) Change a numeric by the procedure mentioned in the

above “(1) Setting of calibration curve number 2) and

3)” and store it with ENT key.

CH

DATA

CH 0

CH

DATA

CH 00

CH

DATA

n 3

Setting data

displayed

Setting data number

displayed

Blinking

Calibration

Curve number

7. Preparation of calibration curves

Page 35

INST No INE -403-0P0

−30−

(3) Setting of data number, sample data xn and sample

data yn

1) Press SEL key to enter into the data number setting

mode.

2) Change a numeric by the procedure mentioned in the

above “(1) Setting of calibration curve number 2) and

3)” and store it with ENT key.

3) After setting the above, press SEL key for entering

into the sample data xn setting mode.

4) After setting the above, press SEL key for entering

into the sample data yn setting mode.

5) After setting the above, press CH/. key to return to

“1) Data number setting mode” and then set the next

data number.

6) Repeat the above procedures for setting all sample data.

(4) Computation of regression expression

1) After completing the setting of sample data, press SEL

key to enter into the regression/ broken line setting mode.

2) Enter “1, 2 or 3” in the selection of regression/broken line.

A polynomial with corresponding degree can be obtained.

3) By pressing SEL key, the standard deviation

(approximate accuracy of the regression expression) of

the above regression expression is displayed.

3) After the settings are completed, press SEL key for 2

seconds to return to the measurement mode.

Automatic return to the measurement mode is made if any

key is operated for 1 minute.

7.3.2 Confirmation of regression expression

The coefficient of the regression expression obtained by

the above can be confirmed by the following procedure.

1) Press SEL key for 2 seconds to enter into the

calibration curve setting mode.

2) Set calibration curve number, for which the regression

expression is obtained.

3) Press SEL key to display the coefficient a0 of the

regression expression.

4) For displaying a1 to a3, press SEL key in the same way.

5) After the confirmation is completed, press SEL key for 2

seconds to return to the measurement mode.

Automatic return to the measurement mode is made if any

key is operated for 1 minute.

CH

DATA

dn 1

CH DATA

Hn 1

CH

DATA

yn 1

CH/・ SEL

CH

DATA

pb 1

CH

DATA

Sd 0.12

CH

DATA

CH 1

CH DATA

A0 1.2544

7. Preparation of calibration curves

Page 36

INST No INE -403-0P0

−31−

Absorb ance (x)

M oisture value (y)

Calibrationcurveof

sample temperature"T3"

Calibrationcurveof

sampletemperature"T2"

Calibrationcurveof

sample temperature"T1"

8.1 Summary

When a calibration curve changes at the sample

temperature Ts, this function enables to change the

calibration curve to other one at this sample

temperature. For the input of the sample

temperature, a platinum resistance thermometer

(Pt100), a radiation thermometer or a

temperature/voltage converter with the output of 4

to 20mADC can be used. By utilizing this function,

10 calibration curves in one group (9 curves only

in the group 10) are changed with the sample

temperature Ts. Since 99 calibration curves can be

stored, up to 10 groups can be set.

8.2 Model

This is an optional function. The model number of the detector unit with this optional function

is as follows: IR-M2

External input

5: Correction input 4 to 20Ma

8: Correction input Pt100

Communications

S: RS-485

R: RS-232C

8.3 Wiring of detector unit

8.4 Setting of dipswitch (Ref to [3.1 Setting of dipswitches])

(1) Turn off the power supply of the detector unit and the setting display unit.

(2) Switch the dipswitch 7 (Correction input enable/disable) of the detector unit to ON side.

(3) For 4 to 20mA input: Switch the dipswitch 8 (Correction input)

to OFF side

(4 to 20mADC).

For Pt100 input: Switch the dipswitch 8 to ON side (Pt100).

(4) Turn on the power supply of the detector unit and then turn on the power supply of the

setting display unit.

[For Pt100

input]

SA

SB

SG

A

B

B

Correction

input

Pt100

[For 4 to

20mAinput ]

SA

SB

SG

-

Correction

input

4 to 20mA

+

I N

(mA)

8. Correction function by sample temperature from external input

Page 37

INST No INE -403-0P0

−32−

8.5 Setting of correction enabled/disabled by sample temperature

Execute this setting to either the detector unit or the setting display unit. When the correction

is disabled, the operation is normal which means the calibration curve is not changed

according to the sample temperature. When it is enabled, the calibration curve is changed

with the sample temperature.

8.5.1 Setting at the detector unit

(1) Enter into the operating condition setting mode.

SEL + ENT for 2 seconds

(2) Enter into the correction enable/disable setting mode (St). SEL Several times

(3) Select the correction enabled or disabled.

ENT (OFF) Correction OFF (disable)

ENT (ON) Correction ON (enable)

* For the setting of sample temperature scaling as the next step, skip (4) and step to (2) of [8.4

Setting of sample temperature scaling].

(4) Return to the measurement mode.

SEL for 2 seconds

8.5.2 Setting at the setting display unit

(1) Set the calibration curve number to 0.

CH 0 ENT

(2) Enter into the correction enable/disable setting mode (St).

MODE 1 9 ENT

(3) Select the correction enabled or disabled.

0 ENT (OFF) Correction OFF (disable)

1 ENT (ON) Correction ON (enable)

* For the setting of sample temperature scaling as the next step, skip (4) and step to (2) of [8.4

Setting of sample temperature scaling].

(4) Return the calibration curve number to the original one.

8. Correction function by sample temperature from external input

Page 38

INST No INE -403-0P0

−33−

8.6 Setting of sam ple temperature scaling (Only 4 to 20mA DC)

In case of using radio thermometer or thermoelectric converter, it is necessary to match the

temperature range of their 4 to 20mA DC output and the temperature range of 4~20mA DC

input of this instrument.

Carry out scaling in either detector unit side or setting display unit side, following the main

points given below.

8.6.1 Setting at the detector unit

(1) Enter into the operating condition setting mode.

SEL + ENT for 2 seconds

(2) Enter into the setting mode of sample temperature scaling low limit (tL).

SEL Several times

(3) Set the low limit (tL) of sample temperature scaling.

(Setting range: -999.9 to 999.9)

(4) Enter into the setting mode of sample temperature scaling high limit (tH). SEL Once

(5) Set the high limit (tH) of sample temperature scaling.

(Setting range: -999.9 to 999.9)

8.6.2 Setting at the setting display unit

(1) Set the calibration curve number to 0.

CH 0 ENT

(2) Enter into the sample temperature scaling setting mode

MODE 2 1 ENT

(3) Set the low limit (tL) of sample temperature scaling.

(Setting range: -999.9 to 999.9)

(4) Enter into the setting mode of sample temperature scaling high limit (tH). SEL Once

(5) Set the high limit (tH) of sample temperature scaling.

(Setting range: -999.9 to 999.9)

8.7 Setting of sample temperature

The key operation for this setting is common on the detector unit and the setting display unit.

(1) Enter into the calibration curve setting mode.

SEL for 2seconds

(2) Enter into the sample temperature set ting mode (tS).

SEL several times

(3)Set the sample temperature.(Setting range: -999.9 to 999.9)

8. Correction function by sample temperature from external input

Page 39

INST No INE -403-0P0

−34−

8.8 Setting of calibration curve data

(1) Specify a group for calibration curve number to be used.

The groups are from 1 to 10 and each one corresponds to the following calibration curve

numbers respectively.

Group 1: Calibration curve number 1 to 10 Group 6: Calibration curve number 51 to 60

Group 2: Calibration curve number 11 to 20 Group 7: Calibration curve number 61 to 70

Group 3: Calibration curve number 21 to 30 Group 8: Calibration curve number 71 to 80

Group 4: Calibration curve number 31 to 40 Group 9: Calibration curve number 81 to 90

Group 5: Calibration curve number 41 to 50 Group 10: Calibration curve number 91 to 99

(2) Example: Select the group 1.

Set the following calibration curve at the sample low limit temperature T1 to the

calibration curve No. 1.

Y = a3X3 + a2X2 + a1x + a0

Only the calibra tion curve by polynomial expression can be used. (The calibration curve

by broken line approximation cannot be used.)

Further, set the sample temperature T1. For its setting, refer to [8.7 Setting of sample

temperature].

(3) Set the calibration curves at the sample temperature Ti ( i = 2 to 10) to the calibration

curve numbers 2 to 10.

However, Ti should fulfill the following expression.

T1 (Sample low limit temperature) T2 ………. T9 T10 (Sample high limit

temperature)

(4) Enter 999.9 at the Ti, which is not used. Be careful that, if this value is not entered, a

calibration curve not used is computed as a data.

* The default of the sample temperature Ti is 999.9.

(5) For the correction expression coefficient s b1 and b0 and the constants (low limit range,

high limit range, low limit alarm, high limit alarm and preset value), use the values for

the first calibration curve number in a group.

Group 1: Calibration curve number 1 Group 6: Calibration curve number 51

Group 2: Calibration curve number 11 Group 7: Calibration curve number 61

Group 3: Calibration curve number 21 Group 8: Calibration curve number 71

Group 4: Calibration curve number 31 Group 9: Calibration curve number 81

Group 5: Calibration curve number 41 Group 10: Calibration curve number 91

8. Correction function by sample temperature from external input

Page 40

INST No INE -403-0P0

−35−

8.9 Measurement

(1) When the correction by sample temperature ON (enable) is selected and one calibration

curve number in a group is set, the calibration curve number changes automatically

corresponding to sample temperature.

For example, when the sample temperature Ts fulfills the following expression, the

calibration curve number becomes “i”.

T1 ….. Ti Ts < Ti + 1 ….. T10

(2) However, the measured value Y is not the measured value T1 on the calibration curve No.

“i”. The measured value Y becomes the following value interpolated from the measured

value Yi and the measur ed value Y

i+1

on the calibration curve No. “i+1”.

(3) When the sample temperature Ts is lower than the sample temperature of the first

calibration curve number in the group or when it is higher than the sample temperature of

the last calibration curve number, the following error display appears.

However, the calibration curve, of which sample temperature is set as 999.9, is ignored.

* For the sample temperature lower than the sample temperature of the first calibration

curve number in the group Er15 (Sample temperature too low)

* For the sample temperature higher than the sample temperature of the first calibration

curve number in the group Er14 (Sample temperature too high)

8.10 Display of sample temperature Ts

8.10.1 Display at the detector unit

(1) Set the calibration curve number to 0. CH 0 ENT

(2) For canceling of the sample temperature display SEL for 2 seconds or CH 2 for seconds

8.10.2 Display at the setting display unit

(1) Set the calibration curve number to 0. CH 0 ENT

(2) For displaying the sample temperature display MODE 2 0 ENT

(3) For canceling of the sample temperature display SEL for 2 seconds or CH for 2 seconds

9.1 Periodical inspection

The following inspection is required periodically.

(1) Cleaning of tip of fiber optics (for reflective type fiber optics)

Keep the tip of fiber optics clean.

If any dirt or dust is noticed, remove it with gauze etc. If the gauze is dipped in alcohol, it

is more effective.

(2) Disassemble cleaning of measuring cell (for transparent type fiber optics)

Regular cleaning of the cover glass in a liquid-contacting part of the measuring cell is

required by disassembling the measuring cell.

(3) Installation

Check the detector unit is installed firmly.

(4) Wiring

Check the wirings to the terminals of the detector unit, the setting display unit and other

instruments are connected completely.

(5) Calibration

Regular calibration one in 3 months is required.