Page 1

INST.No.INE-477-P1CE Ver. 1.00

IM series

Infrared multiple-constituents analyzer

Operator interface/display unit

Store this manual in a readily accessible

location for future reference.

This manual should be provided to the end user.

Model : IRGMEG2

Page 2

INST.No.INE-477-P1CE Ver.1.00

Preface

Thank you for purchasing the IM series infrared multiple-constituents analyzer

operator interface/display unit IRGMEG2 series.

Read this manual carefully to ensure that you use this product correctly and

safely.

¡ Regarding this manual

(1) This manual should be provided to the end user.

(2) Read this manual carefully to gain a thorough understanding of how to operate this product

before starting operation.

(3) This manual describes the functions and maintenance of this product. Store it in a readily

accessible location for future reference.

(4) If you have unclear points or need technical assistance, please contact your sales agent of

CHINO Corporation.

Notices

1. The contents of this manual are subject to change without notice.

2. Every effort has been made to ensure that the details of this manual are accurate. However,

should any errors be found or importance information be omitted, please contact your

nearest agent of CHINO Corporation.

3. Under absolutely no circumstances may the contents of this manual, in part or in whole, be

transcribed or copied without permission.

-Front1-

Page 3

INST.No.INE-477-P1CE Ver.1.00

Important Operational Instructions

Be sure to read the following safety instructions before attempting to install, operate or

store this product.

!

1. Working conditions and environment

1) This product is designed to be installed on a panel (instrumentation panel). Refer to [3.2

Installation] and fix it securely.

2) Do not install this product in the following l ocations.

Locations filled with dusts or corrosive gas.

Locations where the ambient temperature is higher than 50ºC or lower than 0 ºC, or widely changing.

Very humid locations

Close to power lines or locations disturbed by strong magnetic induction

Locations subjected to vibrations or shocks

3) Do not use this product in locations where volatile, corrosive or flammable gas is

present, or in a location where moisture, chemical or salt water is sprayed.

2. Symbols used in this manual

The following symbols are used depending on important degrees of warnings/cautions to

operate this product safely and to avoid malfunctions or unexpected situation.

Important

degree

Symbols Contents

1

2

3

4

5

Warning

Caution

Remarks

Reference

This symbol is indicated with a title for an explanation

with .

Indicates important information that must be observed to avoid

the risk of fire or electric shock or other dangers that may result

in serious personal injury or death, or damage to this product.

Indicates important information that must be observed to avoid

the risk of personal injury or malfunctions of this product.

Indicates supplementary information that the operator is

recommended to understand.

Indicates supplementary information or a reference to an

operation.

Warning

-Front2-

Page 4

INST.No.INE-477-P1CE Ver.1.00

Warnings and Cautions

!

Please observe the following safety precautions fully to use this product correctly. In addition,

please read this manual carefully and store it in a readily accessible location for future reference.

The mark indicates actions that are prohibited during an operation.

Warning (May cause death or serious personal injury)

Do not operate this product in a location where flammable or volatile gas is present.

The use of this product in such environment may result in the risk of explosion.

If this product emits any smoke, abnormal noise or unusual odor, immediately turn off power.

Do not continue to use this product as it may result in the risk of fire or electric shock. Turn

off the power source to this product and contact your nearest sales agent of CHINO

Corporation. Do not repair this product yourself as it may be dangerous.

Never touch the internal parts of this product.

If you touch the inside of this product, it may result in personal injury by electric circuits or a

moving part

Even when you open the case of this product for maintenance works, never touch the internal

parts.

Do not attempt to repair or modify this product.

Repairing or modification must be carried out by service personnel authorized by CHINO

Corporation.

If you repair or modify this product yourself, it may not fulfill this product’s functions, or it

may result in the risk of electric shock or damage to this product.

Do not touch, with wet hands, the power terminals or plugs of the power cord.

If you touch, with wet hands, the power terminals or plugs of the power cord, it may result in

the risk of electric shock.

If you notice something suspicious, immediately turn off power.

If the temperature of the power cord or other cable is high abnormally, turn off the power

source to this product immediately and contact your nearest sales agent of CHINO

Corporation.

Confirm the grounding.

To avoid the risk of electric shock, before supplying the power to this product, make sure that the

power terminals and the protective ground terminal have been wired correctly and reliably.

Caution (May cause personal injury or property damage )

Confirm the specifications (Model code) of this product.

Before using this product, check that the model code shown in the serial number plate matches your

order.

Separate precautionary safety measures should be provided before using this product.

When this product is used in equipment that needs security measures, provide separate safety

measures with the equipment before using this product, responding to phenomena resulting from

erroneous operations or malfunctions of this product or malfunctions of related instruments.

Use crimp type lugs for termination of wires.

To avoid dropping-out or short-circuit of wires, use crimp type lugs for their termination.

Confirm the power to this product.

Before supplying the power to this product, make sure that the power voltage matches the rated

voltage to this product and that the power terminals and the protective ground terminal have been

wired correctly and reliably.

Do not continue to use this product remaining malfunctioned.

Do not continue to use this product remaining malfunctioned as it may result in the risk of fire

or electric shock. Contact your nearest sales agent of CHINO Corporation for repairing.

Comply with the descriptions in this manual.

Comply with the descriptions and handling instructions in this manual to ensure that you use this

product correctly and safely.

Failure to comply with the descriptions and instructions may result in damage to or functional decline

of this product or damage to the equipment.

-Front3-

Page 5

INST.No.INE-477-P1CE Version 1.00

Contents

1. Introduction ··························································1

1.1 General·························································· 1

1.2 Configuration················································1

2. Models and accessories ········································2

2.1 Models ·························································· 2

2.2 Attachments ·················································· 2

3. Installation and connections································3

3.1 Setting dipswitches ······································· 3

3.1.1 How to pull out the internal unit···················3

3.1.1-1) For this unit not installed on a panel ········· 3

3.1.1-2) For this unit being installed on a panel ·····3

3.1.2 Setting dipswitches ······································· 4

3.2 Installation ···················································· 5

3.2.1 Dimensions and panel cutout························5

3.2.2 How to install················································ 5

3.3 Connections ·················································· 6

3.3.1 Enlarge view of the terminal board················ 7

3.3.2 Communication output terminals··················· 7

3.3.3 Contact input terminals··································7

3.4 Cautions on connections······························· 8

3.5 Analog output and alarm output ················· 9

3.6 Multiple-detector units connection ············· 10

3.6.1 Relaying boxes used ··································· 10

3.6.2 Relaying boxes not used ····························· 10

!

!

!

5.3.1-2)

5.3.2 Setting procedure········································ 16

5.3.2-1)

5.3.2-2)

5.3.2-3) Setting from (4) correction coefficients

5.3.3 Correcting calibration curves······················· 18

5.4 Setting output limit values of

5.4.1 Data for setting limit values of calibration

curves········· 19

5.4.2 Procedure for setting the data for output limit

5.4.2-1)

5.4.2-2) Enabling/disabling the output limit

5.4.2-3) Setting a low limit absorbance value (XL)

Descriptions of the setting data for

calibration curves································ 15

Setting detector unit numbers and (1)

calibration curve numbers to (3)

calibration curve coefficients for

IRMA1000, 2000, 7000 or 8000 series

detector units ······································· 16

Setting detector unit numbers and (1)

calibration curve numbers ~ (3)

calibration curve coefficients for

IRMA5000 or 6000 series detector units

being connected··································· 17

b

~ b2 to (8) water absorbance ············ 18

0

calibration curves················· 19

values of calibration curves················· 20

Setting calibration curve numbers (CH) 20

processing (LM)·································· 20

and a low limit measured value (YL)······ 20

4. Names and functions···········································11

4.1 Names and functions of

displays, lamps and keys····················· 11

5. Operation·····························································13

5.1 Confirmation before operation ··················· 13

5.2 Setting detector unit numbers ····················· 13

5.3 Setting calibration curves ···························14

5.3.1 Data for setting ··········································· 14

5.3.1-1) List of data for setting calibration curves 14

- C1 -

5.4.2-4) Setting a high limit absorbance value (XH)

and a high limit measured value (YH)····· 21

5.4.2-5) Setting output limit values to other

calibration curve numbers ··················· 21

5.5 Selecting calibration curve numbers··········· 22

5.5.1 Selecting calibration curve numbers for

IRMA1000, 2000, 7000 or 8000 series

detector units ······································· 22

5.5.2

Selecting calibration curve numbers for

IRMA5000 or 6000 series detector units 22

Page 6

INST.No.INE-477-P1CE Version 1.00

5.6 Setting operation conditions I

(display/output)······································· 23

5.6.1 List of setting data ··········································· 23

5.6.2 Setting operation conditions·························· 23

5.6.2-1) Time constant ··············································· 23

5.6.2-2) Smoothing/real············································· 23

5.6.2-3) Hold ······························································· 23

5.6.2-4) Preset output················································· 23

5.7 Setting operation conditions II

(MODE setting)······································ 24

5.7.1 List of data for setting operation conditions II· 24

5.7.2 Weight α, calibration constant······················· 26

5.7.3 Decimal place displaying measured values 26

5.7.4 Calibration curve remote contact inputs with

Binary or BCD ········································ 26

5.7.5 Sample temperature correction enabled or

disabled····················································· 27

5.7.6 Sample temperature displaying ····················· 27

5.7.7 Sample temperature input scaling ················ 27

5.7.8 Displaying constituent numbers ··················· 27

5.7.9 Selecting a constituent number for an analog

output and a contact output from a

detector unit ·············································· 28

5.7.10 Selecting a contact output from a

detector unit enabled or disabled and

an output item············································ 28

Contents

5.8.4 Hold ···························································· 30

5.9 Key lock ····················································· 30

5.10 Calibration (For performing a calibration,

read the paragraph [Calibration] in a

separate instruction manual for a

detector unit being connected, too.) ···· 31

5.10.1 Calibration for IRMA1000, 2000, 7000 or

8000 series detector units···················· 31

5.10.2 Calibration for IRMA5000 or 6000 series

detector units······································· 32

6. Creating calibration curves································33

6.1 Sample preparation····································· 33

6.2 Sample measurement·································· 33

6.3 Creating calibration curves························· 33

7. Inspection and maintenance ······························34

7.1 Periodical inspection ·································· 34

7.2 Self-diagnosis function······························· 34

7.3 Measures against troubles not included

with self-diagnosis······························ 35

7.3.1 Measured value remains unchanged··········· 35

7.3.2 Measured value fluctuates ·························· 35

7.3.3 Measured value is slightly higher or

lower than the actual value ················· 35

7.4 Maintenance parts······································· 35

7.5 RAM clearing ············································· 35

5.7.11 Selecting a contact input to a detector unit

enabled/disabled and an input item·········· 28

5.7.12 Displaying a calibration curve number ······ 28

5.7.13 Computing surface water ratio····················· 28

5.7.14 Setting communication conditions·············· 29

5.8 Remote contact inputs ·····································30

5.8.1 Setting detector unit numbers, constituent

numbers and calibration curve numbers ······30

5.8.2 Calibration··································································30

5.8.3 Preset············································································30

- C2 -

8. Specifications ·······················································36

8.1 Operator interface/display unit:

IRGMEG2 ······································ 36

8.2 Outside dimensions ···································· 36

Page 7

INST.No.INE-477-P1CE Ver.1.00

1. Introduction

1.1 General

The infrared multiple-constituents analyzer (hereinafter called “constituent meter”) operator

interface/display unit IR-GMEG2 is used in combination with IRMA series constituent

meter detector units and can communicate with up to nine (9) detector units.

The operator interface/display unit digitally displays constituent values including moisture content and

thickness, as well as accessing to parameters of a detector unit. It also provides various functions

including communication and calibration curve switching by a contact signal.

This manual describes about the operator interface/display unit only. In addition to this manual, refer

to a separate instruction manual of [Infrared multiple-constituents analyzer detector unit

IRMA], too.

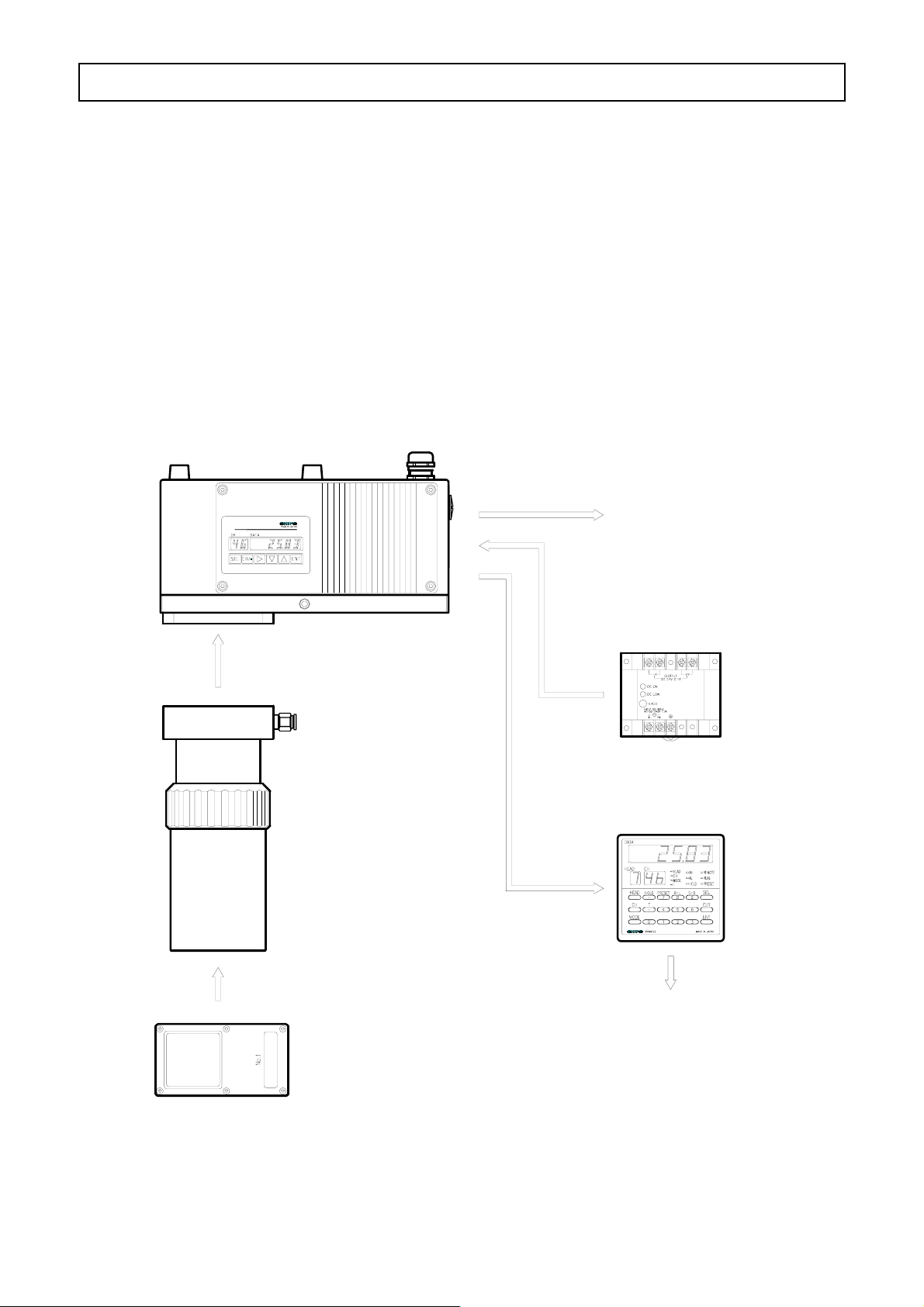

1.2 Configuration

Detector unit

IRMA11, 12, 13

IM

SERIES

(Configuration example in combination with IRMA1)

Analog output

Power unit IR-WEP

(Supplied as an

attachment)

24V DC

Connection cable

IR-WERP

Operator interface

Air-purge hood

IR-WEA

/display unit

IRGMEG2

RS-485

Output checker plate

IR-WEB

(Note) In case of using IRMA data logging software Model for IM-VXA

personal computer and detector unit are a direct communication.

- 1 -

Communication output (Note)

Analog output

, the

Page 8

INST.No.INE-477-P1CE Ver.1.00

)

2. Models and accessories

2.1 Models

IRGMEG2

Operator interface/display unit for

constituent meters Output

2: 4 to 20mA

Communication interface

R: RS-232C (standard)

CE

(Standards)

• EN55011 Group 1 Class A

• EN50082-2 (Industrial environment)

(Directives)

89/366/EEC, 92/31/EEC (amendment)

93/68/EEC (amendment

A: RS-422A

S : RS-485

*In case of connecting with

IM-VXA it is RS-232C.

Special specifications

Blank: Standard

V : Complying with CE

2.2 Attachments

Name Quantity Remarks

Mounting brackets 1 set

Internal unit

pulling-out tool

Ferrite core 3 pieces Attached only for complying with CE

Instruction manual 1 copy This document

Instruction manual for

communications

1 piece

1 piece for the cable IR-WERP

1 piece for a power cable

1 piece for a signal cable

(Refer to [3.3 Connections] and [3.3.1 Enlarge view of the

terminal board] )

Remarks

When 4 pieces of ferrite cores or more are

required, order them separately.

1 copy Separate m anual “ IM series I R MA/IRGMEG2 Communications”

- 2 -

Page 9

INST.No.INE-477-P1CE Ver.1.00

p

3. Installation and connections

3.1 Setting dipswitches

!

Set internal dispswitches before installing this unit.

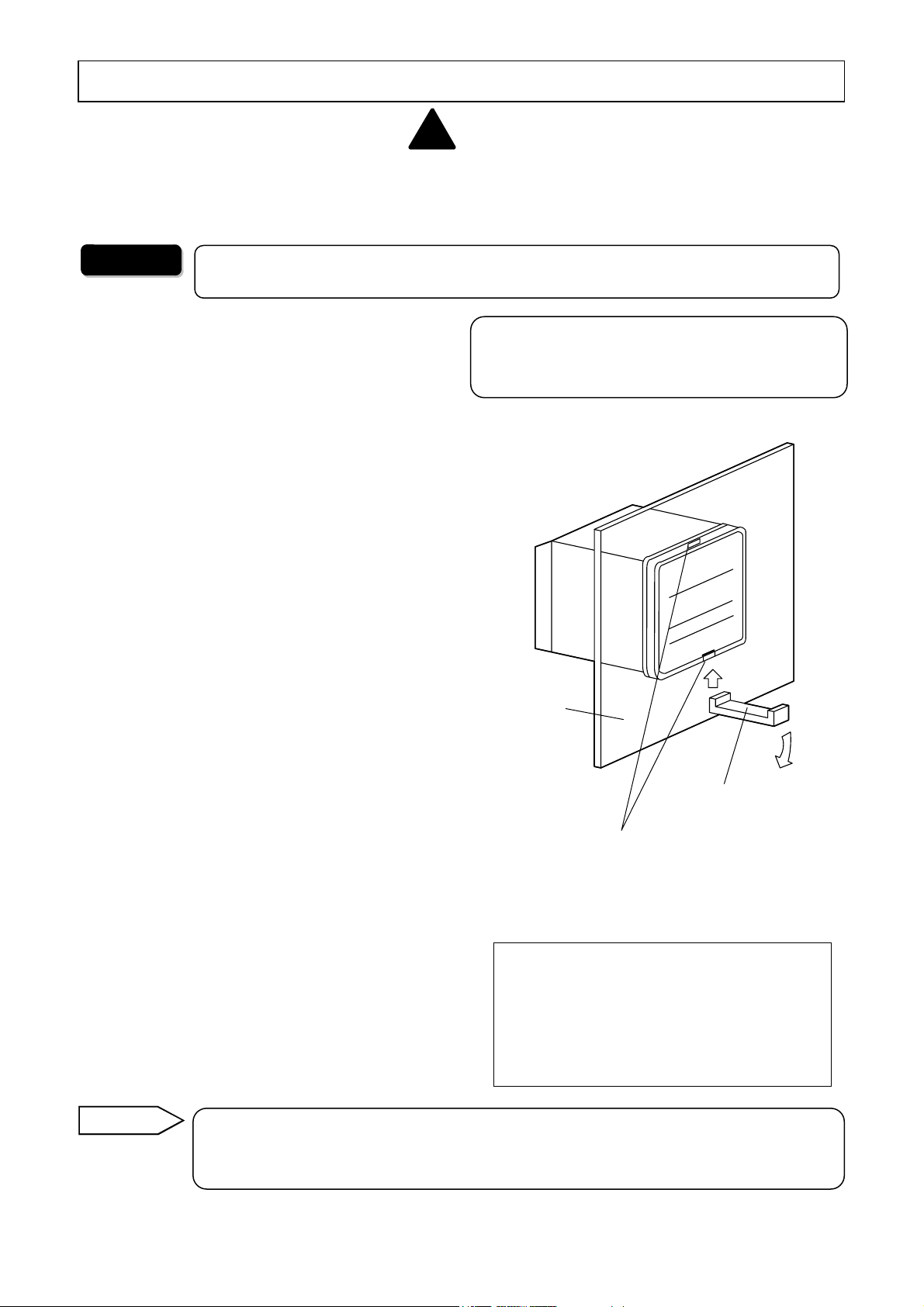

3.1.1 How to pull out the internal unit.

Warning

3.1.1-1) For this u n i t n o t i n s t a l l e d o n a p a n e l

(1) Remove the water-proof gaskets fitted in the

locking portions of the internal unit. Hold this

unit and then insert the L-shaped part of the

supplied pulling-out tool into the lower

locking portion of this unit.

(2) In this state, press the other side of the tool

down to slide the front panel forward 2 to

3mm and then remove the internal unit. (*)

(3) After setting the dipswitches, position the

printed circuit boards of the internal unit with

the guide rails on the inside of the case and

push the internal unit slowly along the guides

until it is locked. Make sure to press the

water-proof gaskets in the locking portions

securely. (Note)

3.1.1-2) For this unit being installed on a panel

For avoiding the risk of electric shock, make sure to turn off the power source to

this unit before pulling out the internal unit.

The front panel of this unit complies with IP65

(IEC529). For this compliance, it may be hard to pull

out the internal unit.

①

Panel

(1) Remove the water-proof gaskets fitted in the

locking portions of the internal unit. Insert

the L-shaped part of the supplied pulling-out

tool for the internal unit into the locking

portion on the lower side of this unit.

(2) In this state, press the other side of the tool

down to slide the front panel forward 2 to

3mm and then remove the internal unit. (*)

(3) After setting the dipswitches, position the

printed circuit boards of the internal unit with

the guide rails on the inside of the case and

push the internal unit slowly along the guides

until the locking portion is activated. Make

sure to press the water-proof gaskets in the

locking portions securely. (Note)

Remarks

(*): Ordinarily the internal unit can be pulled out by only loosening the lower

locking portion of this unit. However, if it is hard to remove it, loosen the upper

locking portion, too.

②

Internal unit pulling-out tool

Internal unit locking portion

(The water-proof gasket is fitted in.)

(Note)

When this unit is used in the state that the

locking portion is not activated, it may cause

display fluctuation by contact failure of

terminal metals. In addition, the

effectiveness of water-proofing may become

aired.

im

- 3 -

Page 10

INST.No.INE-477-P1CE Ver.1.00

3. Installation and connections

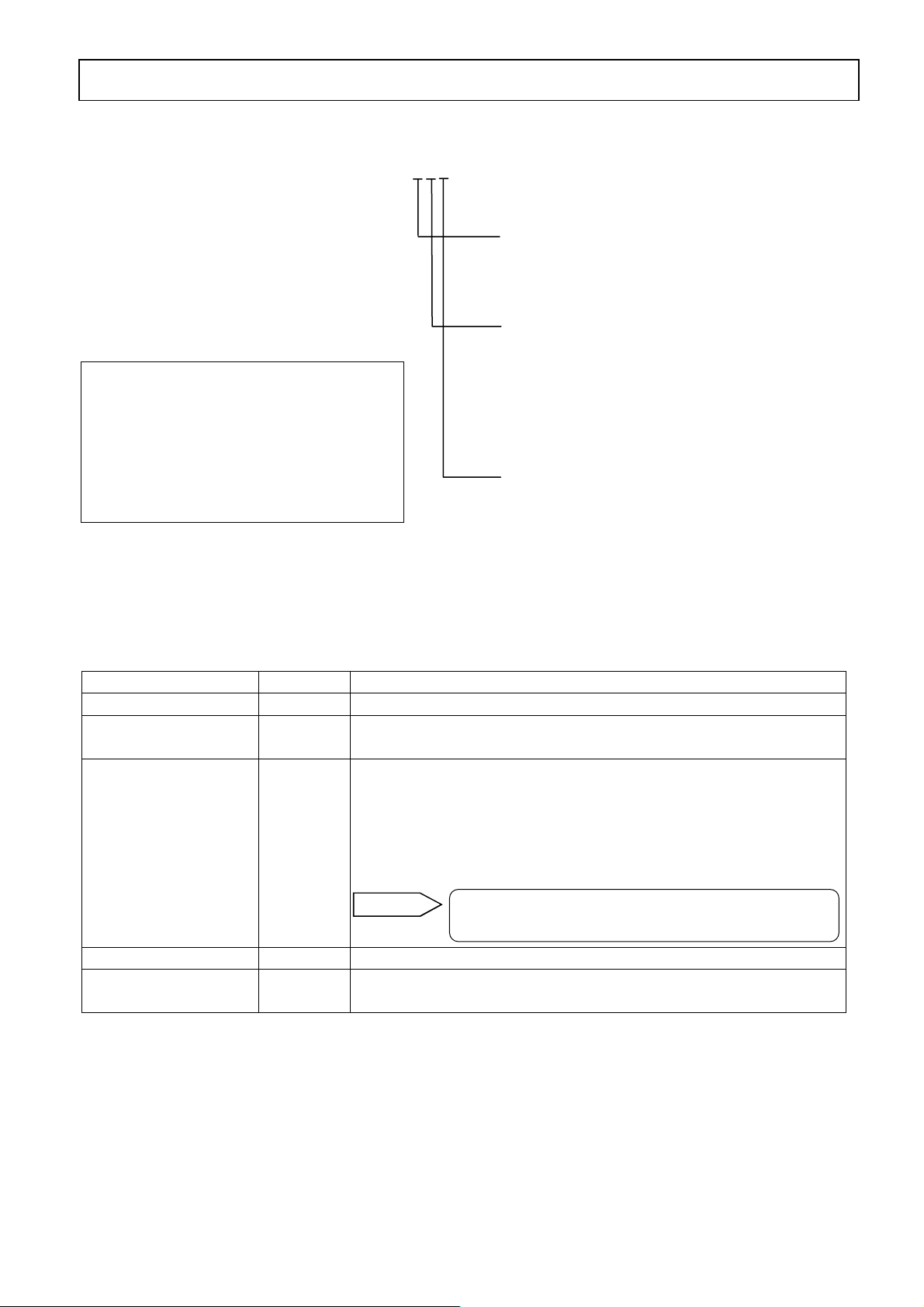

3.1.2 Setting dipswitches

Set the dipswitches depending on the quantity of the detector units to be connected.

Position of dipswiches Dipswitch

OFF ON

No.

1

Function

Quantity of the

detector unit to be

connected

1 set

(Single-detector-unit

connection)

2 Not used Not used (remaining at OFF)

3

4

Not used

Not used

Not used (remaining at OFF)

Not used (remaining at OFF)

[Internal unit pulled out]

1234

[Enlarged view of dipswitches]

OFF

1234

ON

2 sets or more

(Multiple-detector-units

connection)

Default

settings

OFF

OFF

OFF

OFF

- 4 -

Page 11

INST.No.INE-477-P1CE Ver.1.00

n

j

r

t

3. Installation and connections

3.2 Installation

This unit is designed to be installed on a panel (instrumentation panel).

Set the supplied mounting brackets (2 pieces) in place on the top and bottom of this unit, and then

tighten the screws of the brackets until they turn free.

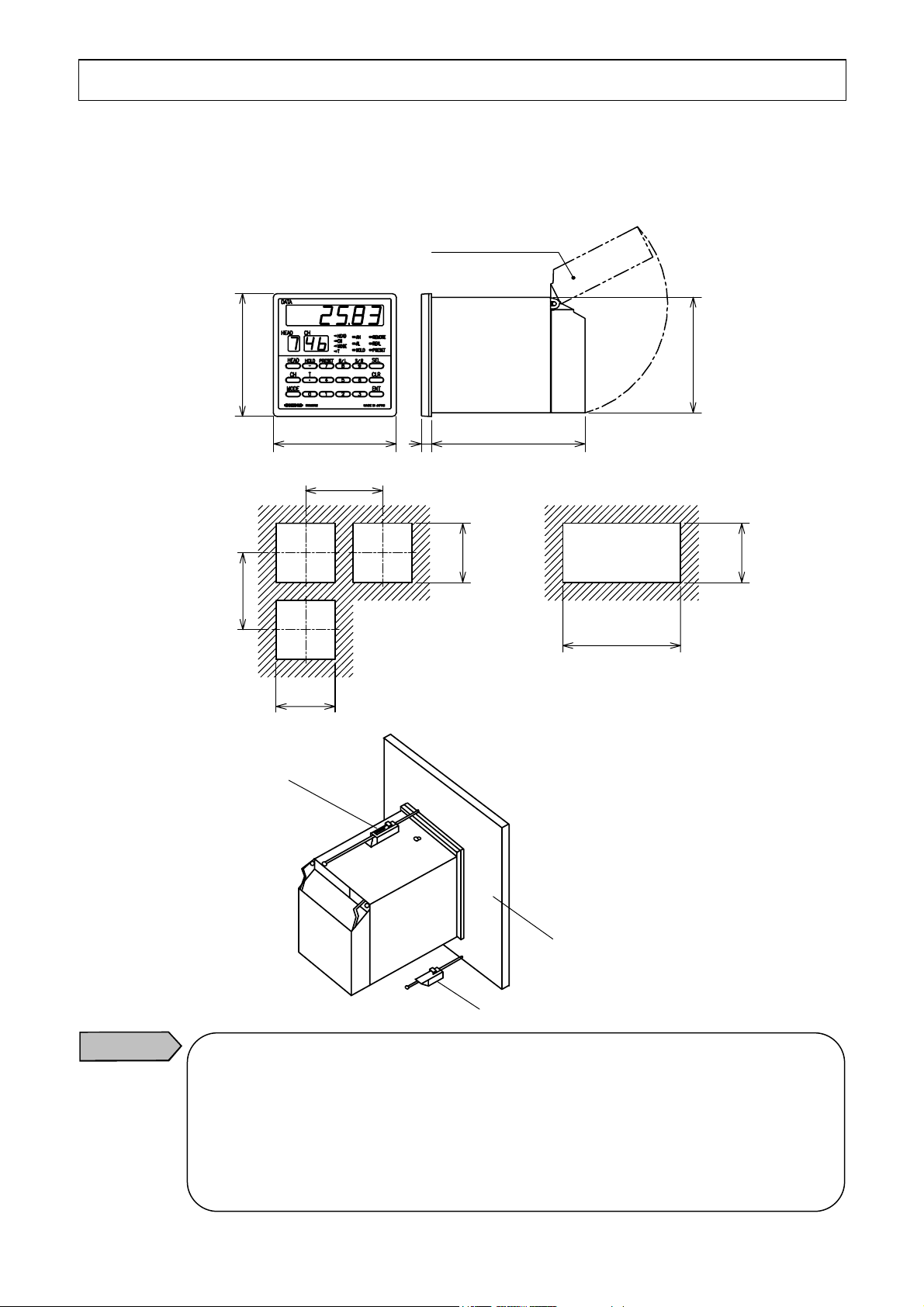

3.2.1 Dimensions and panel cutout

96

96

120

120

92

+0.8

0

3.2.2 How to install

Caution

Mounting bracket

Do not install this product in the following locations.

• Locations filled with dusts or corrosive gas.

• Locations where the ambient temperature is higher than 50 ºC or lower than 0 ºC, or widely

changing.

• Very humid locations

• Close to power lines or locations disturbed by strong magnetic induction

• Locatio

s sub

ected to vibrations or shocks

Terminal cove

8

0

+0.8

92

Mounting bracke

120

Panel

96×N−4

0

‑1

0

‑1

□91 ×91

0

+0.8

92

0

‑2

Unit : mm

- 5 -

Page 12

INST.No.INE-477-P1CE Ver.1.00

g

(

(

)

(

)

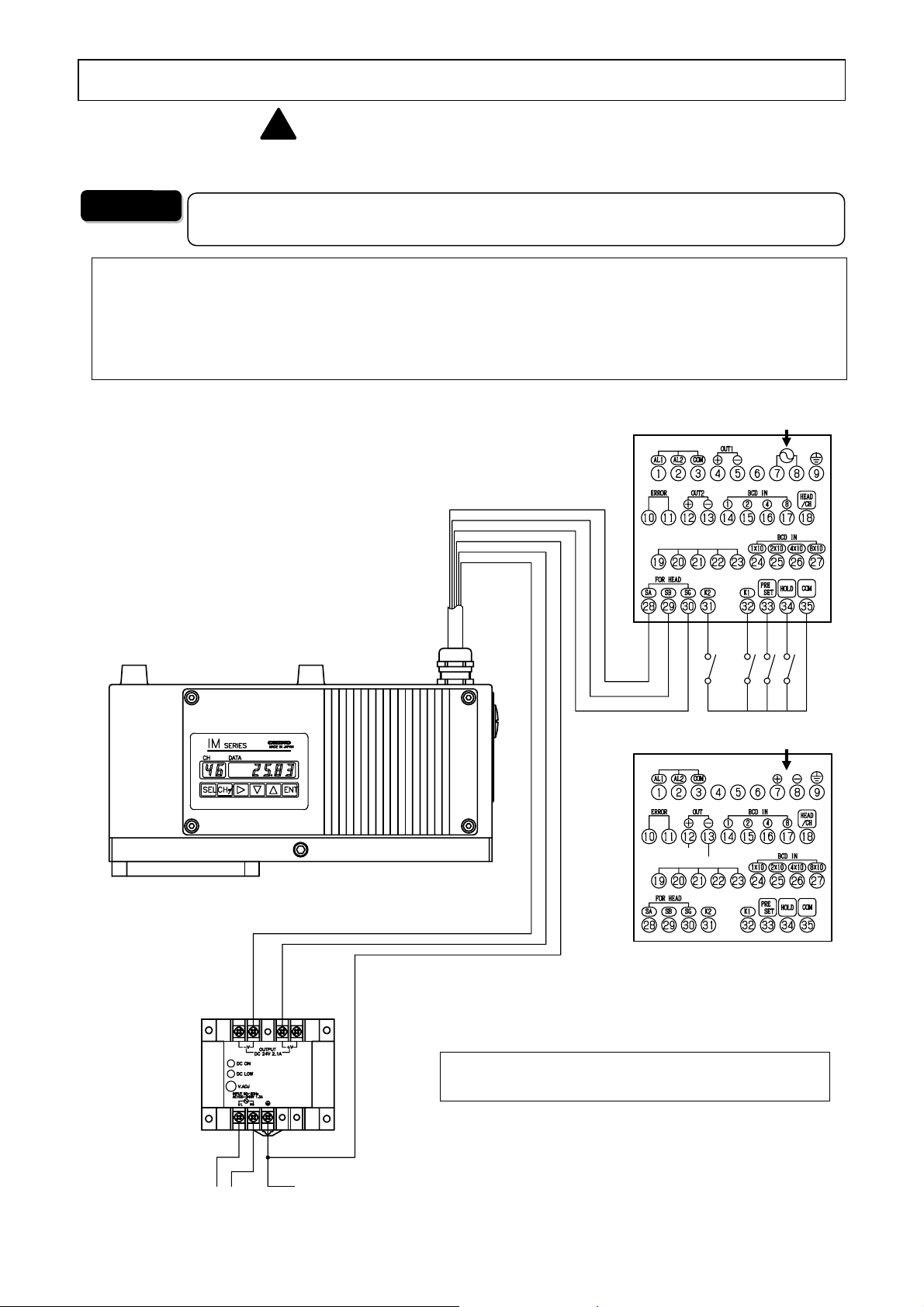

3. Installation and connections

3.3 Connections

!

Wire to the terminals on the rear of this unit as shown in the following terminal wiring diagrams.

Before carrying out wiring, turn off the power source to this unit.

Warning

For avoiding the risk of electric shock, make sure to turn off the power source to this

unit before wiring to the power terminals.

For complying with CE (IRGMEG2V)

1) Attach the supplied ferrite cores (3 pieces attached as standard), at a place as close as the

terminal board (within 10cm), to bind up each cable to be connected. (→For the details of

attaching ferrite cores, refer to [3.3.1 Enlarge view of the terminal board].)

2) The connection cable should be used indoors and its length should be up to 30m.

[ IRGMEG2 ]

Contact rating

Resistive load

100V AC 0.5A

200V AC 0.2A

Inductive load

100V AC 0.2A

200V AC 0.1A

Minimum load

5V DC 10mA

[ IRGMEG2V ]

Contact rating

Resistive load

30V AC 0.5A

24V DC 0.2A

Inductive load

30V AC 0.2A

24V DC 0.1A

Minimum load

5V DC 10mA

Cable

IR-WERP

Operator interface/display unit

[IRGMEG2]

Comm output

Note

Detector unit

IRMA

[IRGMEG2V]

Note

Power 24V DC

P- (Blue)

Red)

P+

G (Green)

Comm output

Power unit

IR-WEP

(Note) 100-240V AC for IRGMEG2

24V DC for IRGMEG2V (complying with CE)

100-120V AC

200-240V AC

Protective

round

- 6 -

Page 13

INST.No.INE-477-P1CE Ver.1.00

)

)

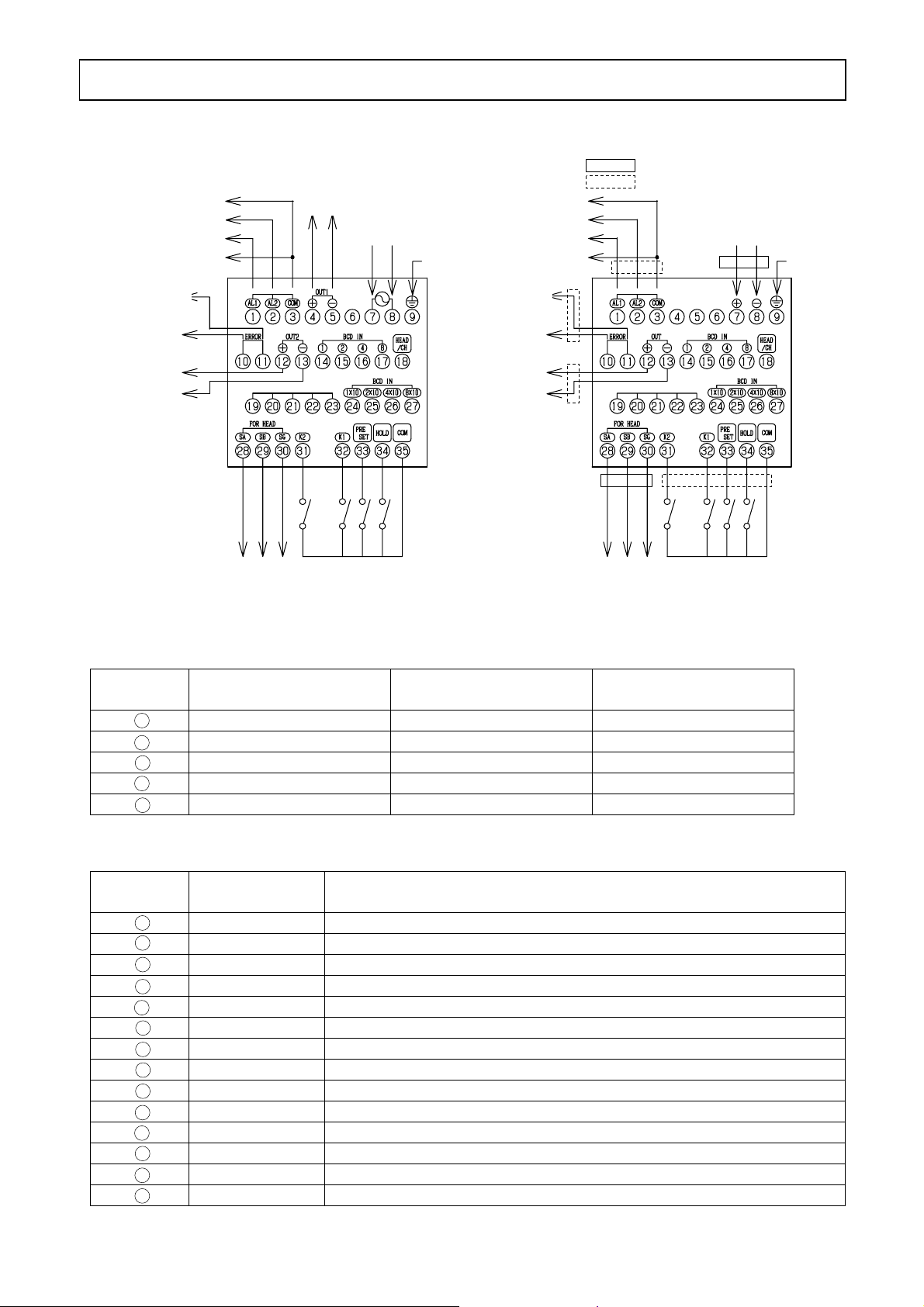

3. Installation and connections

3.3.1 Enlarge view of the terminal board

*1 : Refer to [3.4 Cautions on connections] (3) Power

*2 : Refer to [3.5 Analog output and alarm output]

Output 1 (*2)

AL2 low alarm output (*2)

AL1 high alarm output (*2)

Self-diagnosed (*2)

abnormal

Alarm output Contact (*2

OFF when an

abnormal condition

occurs.

Output 2 (*2)

4 to 20mA DC

SA (black)

To the

detector unit

4 to 20mA DC

Comm output

SB (white)

SG (brown)

Contact input

IRGMEG2

Power (*1)

100 to 240V AC

Protective

ground

AL2 low alarm output (*2)

AL1 high alarm output (*2)

Self-diagnosed (*2)

abnormal

Alarm output Contact (*2

OFF when an

abnormal condition

occurs.

Output 1 (*2)

4 to 20mA DC

(Note) If 4 pieces or more are required, order them separately.

Example of attaching places of ferrite cores

(3 pieces attached as standard)

: To be attached absolutely

: At any place (Note)

Power (*1)

24V DC

Protective

ground

Comm output

To the

detector unit

Contact input

IRGMEG2V (complying with CE)

3.3.2 Communication output terminals

Terminal

No.

19

SD SDA SA

-- SDB SB

20

21

RD RDA --

22

-- RDB - SG SG SG

23

IRGMEG2R

RS-232C communication

IRGMEG2A

RS-422A communication

3.3.3 Contact input terminals

Terminal

No.

14

BCD IN 1 Detector unit No./Calibration curve No./Constituent No. 1-input

15

BCD IN 2 Detector unit No./Calibration curve No./Constituent No. 2-input

16

BCD IN 4 Detector unit No./Calibration curve No./Constituent No. 4-input

BCD IN 8 Detector unit No./Calibration curve No./Constituent No. 8-input

17

HEAD/CH Switching of the detector unit No. and the calibration curve No.

18

24

BCD IN 1 x 10 Detector unit No./Calibration curve No. 1 x 10-input

BCD IN 2 x 10 Detector unit No./Calibration curve No. 2 x 10-input

25

26

BCD IN 4 x 10 Detector unit No./Calibration curve No. 4 x 10-input

BCD IN 8 x 10 Detector unit No./Calibration curve No. 8 x 10-input

27

K2 Constituent No. input command

31

K1 No. 1 side calibration with the contact ON

32

PRESET Preset output with the contact ON

33

HOLD Hold with the contact ON

34

COM Common contact terminal

35

Item Explanation

IRGMEG2S

RS-485 communication

- 7 -

Page 14

INST.No.INE-477-P1CE Ver.1.00

g

3. Installation and connections

3.4 Cautions on connections

!

Warning

For avoiding the risk of electric shock, make sure to turn off the power source to this

unit before wiring to the power terminals.

Before carrying out wiring, observe the following precautions.

(1) Terminating wires

Use crimp type lugs covered with the insulation sleeve to prevent wires from dropping off or contacts

of wires. (The terminal screws are M3.5.)

(2) Mounting a power switch and a fuse

Neither power supply nor fuse is built in this unit. You are required to prepare them separately.

(3) Power

[IRGMEG2]

• The power to IRGMEG2 is universal from 100 to 240V AC but avoid the following powers;

(1) Powers whose voltage fluctuates greatly.

(2) Powers whose waveform distortion is big.

[IRGMEG2V (complying with CE)]

• The power to IRGMEG2 V (complying with CE) is 24V DC (within ±10%).

Ordinarily supply the power to this unit from the power unit IR-WEP.

Caution

The power to IRGMEG2 V (complying with CE) is DC.

Observe the following cautions.

1) Ensure correct polarity.

2) The connection with reverse polarity may cause a failure of this unit.

3) Make sure not to supply AC power to this unit. If AC power is supplied by mistake, this unit

will be dama

ed.

(4) Noise source

Separate this unit from strong power circuits or powerful noise sources as far as possible.

- 8 -

Page 15

INST.No.INE-477-P1CE Ver.1.00

3. Installation and connections

3.5 Analog output and alarm output

This unit is designed for use with multiple-constituents analyzer detector units connection and can

connect plural constituent meter detector units.

However, the analog outputs and alarm outputs are configured by setting the dipswitches as shown

below. (Refer to [3.1 Setting dipswitches].)

Position of the dipswitch No. 1: OFF Position of the dipswitch No. 1: ON

Item

Connected

detector

OUT1 Analog output from the

OUT2 (*) Analog output from the

AL1 High limit alarm signal

AL2 Low limit alarm signal

ERROR Self-diagnosed abnormal

(*) Available in IRGMEG2 only [OUT 2 is not available in IRGMEG2V (complying with CE).]

Detector unit: 1 set(Single-detector-unit connection) Detector unit: 2 sets or more

(Multiple-detector-units connection)

IRMA1000,2000,

7000,8000 series

1 constituent specification

2 or more constituents

specification of

IRMA5000,6000 series

IRMA1000,2000,7000,8000 series

IRMA5000,6000 series

of IRMA5000,6000 series

constituents No. 1 of

detector unit No. 1

constituents No. 1 of

detector unit No. 1

from the detector unit No. 1

from the detector unit No. 1

condition signal from the

detector unit No. 1

Analog output from the

constituents No. 1 of

detector unit No. 1

Analog output from the

constituents No. 2 of

detector unit No. 1

High limit alarm signal

from the detector unit No. 1

Low limit alarm signal

from the detector unit No. 1

Self-diagnosed abnormal

condition signal from the

detector unit No. 1

Analog output from the constituents

No. 1 of detector unit No. 1

Analog output from the constituents

No. 1 of detector unit No. 2

High limit alarm signal from the

detector unit No. 1

Low limit alarm signal from the

detector unit No. 1

Self-diagnosed abnormal condition

signal from all detector units connected

- 9 -

Page 16

INST.No.INE-477-P1CE Ver.1.00

3. Installation and connections

3.6 Multiple-detector-units connection

In the multiple-detector-units connection, the following two connection systems are available. For

either connection system, before turning on the power to this unit, set detector unit numbers not to

overlap them each other.

For the settings of detector unit numbers, refer to the separate manual for a detector unit.

3.6.1 Relaying boxes used

Remarks

Caution

3.6.2 Relaying boxes not used

Remarks

Detector unit

IRMA

IM

SERIES

IM

SERIES

IM

SERIES

Cable

IR-WERP *

Cable

IR-WERP *

Cable

IR-WERP *

24V DC (Note)

Operator interface/

display unit

IRGMEG2

Relaying box

IR-WEE

(The power unit is built in.)

2-conductor twisted cable

(with shield)

2-conductor twisted cable

(with shield)

2-conductor twisted cable

(with shield)

100-240V AC

(Note): 24V DC at CE marking (In case of using IRGMEG2V)

(*): The connection cable should be indoors and its length should be up to 30m.

・For wiring to the relaying box, refer to the separate manual for the relaying box.

Detector unit

IRMA

IM

SERIES

IM

SERIES

IM

SERIES

Cable

IR-WERP *

Cable

IR-WERP *

Cable

IR-WERP *

Operator interface/

display unit

IRGMEG2

Power unit IR-WEP

-V +V

OUTPUT

DC24V2.1A

DCON

DCLOW

V.ADJ

INPUT50/60Hz

AC100-240V1.3A

-V +V

OUTPUT

DC24V2.1A

DCON

DCLOW

V.ADJ

INPUT50/60Hz

AC100-240V1.3A

-V +V

OUTPUT

DC24V2.1A

DCON

DCLOW

V.ADJ

INPUT50/60Hz

AC100-240V1.3A

24V DC (Note)

100-240V AC

(Note): 24V DC at CE marking (In case of using IRGMEG2V)

(*): The connection cable should be indoors and its length should be up to 30m.

- 10 -

Page 17

INST.No.INE-477-P1CE Ver.1.00

4.各部の名称と機能4. Names and Functions

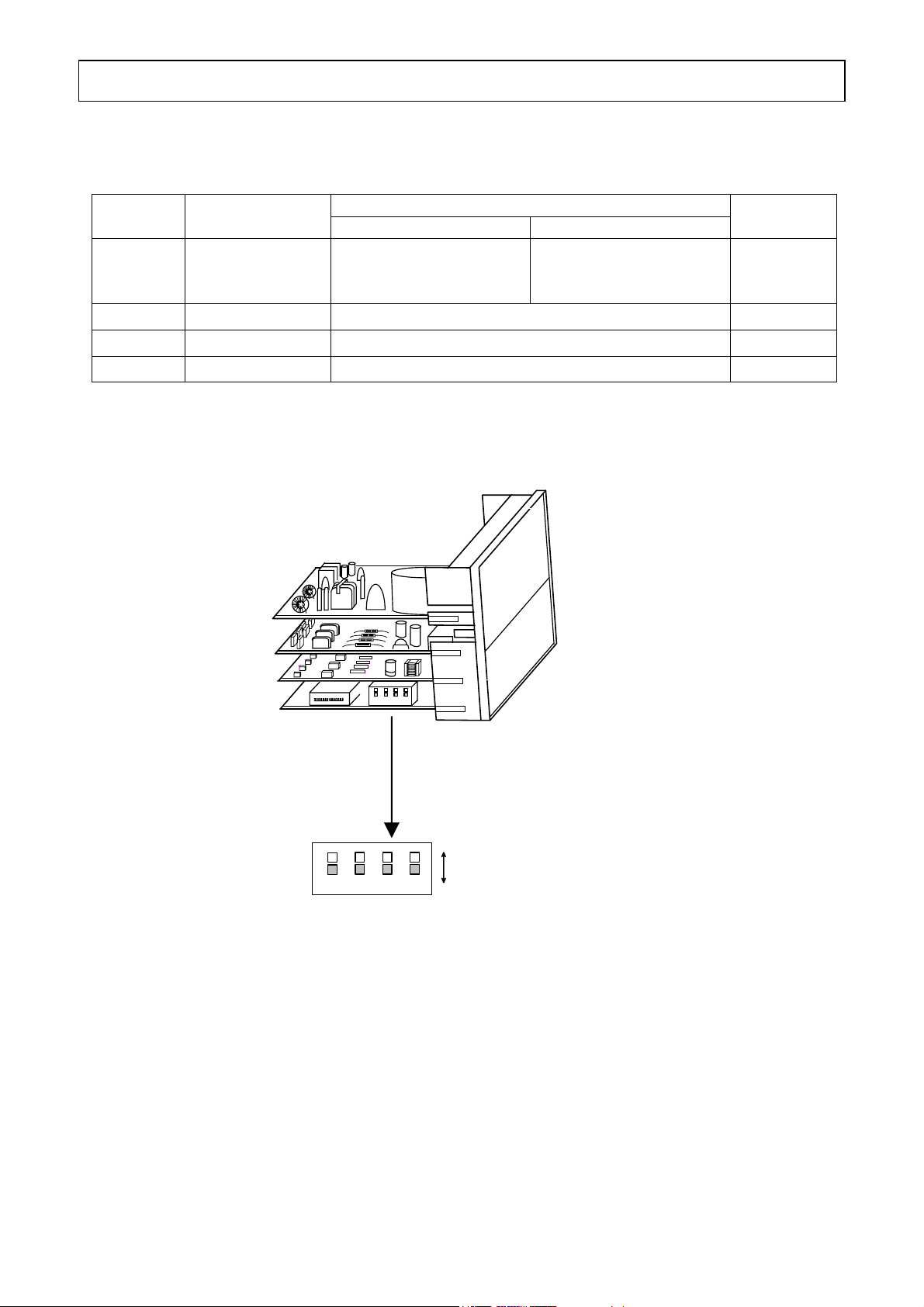

4.1 Names and functions of displays, lamps and keys

(1) Data display

DATA

(4) Setting status

lamps

(2) Detector unit

number display

(3) Calibration curve

number display

HEAD CH

HEAD

MODE

HOLD

CH

HEAD

CH

MODE

T

PRESET

T

R/L

AH

AL

HOLD

S/R

REMOTE

REAL

PRESET

SEL

CLR

ENT

(5) Measurement

status lamps

(6) Key-lock

indicator

(7) Function keys

IRGMEG2

MADE IN JAPAN

Name Function

(1) Data display Displays a constituent value in the measurement mode and a parameter data in

the setting mode.

When a self-diagnosed abnormal condition is occurred, an error number

corresponding to an abnormal condition is displayed.

(2) Detector unit number

display

Displays a detector unit number of the constituent meter currently indicating a

constituent value in the data display. When the detector unit number is

changed, a constituent value being measured by the detector unit with the

changed number will be displayed.

(3) Calibration curve display

Displays a calibration curve number in the measurement mode, the calibration

curve setting mode, a mode number during the mode setting, and a time

constant during the time constant setting.

The first-digit decimal point indicates the key-lock activated.

(4) Setting status lamps HEAD: Lights during the detector unit number setting.

CH: Lights during the calibration curve number setting.

MODE: Lights during the mode number setting.

For IRMA5000 or 6000 series detector units being connected,

this lamp lights during the setting of the constituent number whose

calibration curve or time constant is set.

T: Lights during the time constant setting.

(5) Measurement status lamps AH: Lights when a high limit alarm is activated.

AL: Lights when a low limit alarm is activated.

HOLD: Lights in the hold mode.

REMOTE: Lights during the remote setting of a calibration curve number.

REAL: Lights during the real (without smoothing) measurement mode.

PRESET: Lights during the preset output.

(6) Key-lock indicator The first-digit decimal point indicates the key-lock activated.

- 11 -

Page 18

INST.No.INE-477-P1CE Ver.1.00

4.各部の名称と機能4. Names and Functions

4.1 Names and functions of displays, lamps and keys

Name Function

HEAD

CH

DATA

HEAD

CH

MODE

CH

HOLD

T

IRGMEG2

HEAD

CH

MODE

T

PRESET R / L

HEAD

Is used to set a detector unit number.

Is used to set a calibration curve number.

AHALREMOTE

REAL

PRESET

HOLD

SEL

S/R

CLR

ENT

MADE IN JAPAN

(7) Function keys

(7) Function keys

MODE

HOLD

PRESET

0

―

7

R/L

8

S/R

9

T

•

〜

SEL

CLR

ENT

6

Is used to set a mode number.

Switches the HOLD to ON or OFF in the measurement mode.

Is used to enter (―) in the setting mode.

Switches the PRESET to ON or OFF in the measurement mode.

Is used to enter the numeric of 7 in the setting mode.

Switches the calibration curve setting to REMOTE or LOCAL in the

measurement mode.

Is used to enter the numeric of 8 in the setting mode.

Switches the measurement mode to REAL or SMOOTHING in the

measurement mode.

Is used to enter the numeric of 9 in the setting mode.

Is used to set the time constant in the measurement mode.

Is used to enter the decimal point in the setting mode.

Is used to enter the numeric from 0 to 6 in the setting mode.

Is used to enter into the setting mode or switch setting screens.

Is used to clear a data being set.

A data is cleared from the least significant digit, each time this key is pressed

once.

Is used to store a parameter data.

- 12 -

Page 19

INST.No.INE-477-P1CE Ver.1.00

)

5

. Operation

5.1 Confirmation before operation

Check the following three points before turning on the power.

1) Have the dipswitches been set? (Refer to [3.1 Setting dipswitches].)

2) Are all of connections correct? (Refer to [3.3 Connections])

3) In the multiple-detector-units connection, have detector unit numbers been set?

(Refer to the separate instruction manual for [Infrared multiple-constituents analyzer detector unit

IRMA].)

Caution

Turn on the power to this unit concurrently with or after turning on the power to

detector units.

If the power to this unit is turned on before turning on detector units, this unit can

not recognize the detector units and will display the error code Er18 (detector unit

number error

.

5.2 Setting detector unit numbers

When the power to this unit is turned on, data

measured by the constituent meter with the detector

unit number being indicated in “HEAD” will be

displayed.

The following procedure is for changing a detector

unit number.

(1) Press HEAD key to enter into the detector unit

number setting mode with the setting lamp

“HEAD” lit.

(2) Press the numeric keys 1 to 9 to enter a detector

unit number.

(3) By pressing ENT key, the data measured by the

constituent meter with the changed detector unit

number will be displayed. The calibration curve

number and the constituent value displayed this

time are under the conditions set in the changed

constituent meter. (Time constant, decimal places

of constituent values displayed, etc.)

DATA

CH

HEAD

HOLD

HEAD

CH

T

MODE

IRGMEG2

HEAD CH DATA

PRESET

HEAD

CH

MODE

T

R/L

AHALREMOTE

REAL

PRESET

HOLD

SEL

S/R

CLR

ENT

MADE IN JAPAN

1 1 12.3

Detector unit No. Calibration curve No. Constituent value

HEAD CH DATA

2 12 54.32

Detector unit No.

The calibration

curve No.

changes, too.

The constituent

value changes,

too.

- 13 -

Page 20

INST.No.INE-477-P1CE Ver.1.00

5

b

. Operation

5.3 Setting calibration curves

Output characteristics of detector units depend upon measuring objects. It may also change according

to process conditions or constituent measuring conditions of samples.

Accordingly, for accurate measurements, it is required to perform beforehand sample tests of each

object and obtain, for moisture measurements, a relationship (This is called as a calibration curve.)

between moisture contents (%H2O) obtained by a drying method or other measuring methods and

absorbance “x” measured by a detector unit] or, for thickness measurements, a relationship (This is

called as a calibration curve.) between thickness (µm) obtained by a micrometer or other measuring

methods and absorbance “x” measured by a detector unit].

Reference

5.3.1 Data for setting

5.3.1-1) List of data for setting calibration curves

The followings are data for setting calibration curves.

Setting items available differ depending on specifications (number of wavelengths and number of

constituents) of a detector unit being connected.

Setting data name Display

(1) Calibration curve No. CH 1 to 99 1

(2) Computing mode Md 1 to 4 1 (*1)

Calibration curve coefficient a0 A0 0 to ±9999.9 0.0000

(3)

Calibration curve coefficient a1 A1 0 to ±9999.9 1.0000

Calibration curve coefficient a2 A2 0 to ±9999.9 0.0000

Calibration curve coefficient a3 A3 0 to ±9999.9 0.0000

The followings are used in the mode 4 only. The numeric from 4 to 10 indicates the number of wavelengths. (*1)

Calibration curve coefficient a4 A4 0 to ±9999.9 0.0000

Calibration curve coefficient a5 A5 0 to ±9999.9 0.0000

Calibration curve coefficient a6 A6 0 to ±9999.9 0.0000

Calibration curve coefficient a7 A7 0 to ±9999.9 0.0000

Calibration curve coefficient a8 A8 0 to ±9999.9 0.0000

Calibration curve coefficient a9 A9 0 to ±9999.9 0.0000

Calibration curve coefficient a

(4) Correction expression coefficient b0

Correction expression coefficient b

Correction expression coefficient b

High limit output

High limit alarm

(7) Preset value PS 0 to 9999.9 0.0000

(8) Water absorbance Ab 0 to ±9999.9 0.0000 Effective numeric: 5 digits (*2)

*1: Displays and settings of these items are only available for IRMA5000 or 6000 series detector

units being connected.

*2: For measuring the moisture content of sands, etc., the water absorbance is required to be set. The

display and the setting of this water absorbance are only enable when the surface water ratio

computation shown in [5.7.12 Computing surface water ratio] is set to ON.

This paragraph describes the setting method of calibration curve data, assuming

that calibration curves have been already created. When the calibration curves have

not been created yet, refer to the paragraph [Sample preparation] in the separate

instruction manual of the detector unit IRMA

Setting range

of data

AA 0 to ±9999.9 0.0000

10

b0 0 to ±9999.9 0.0000

1

b1 0 to ±9999.9 1.0000

2

b2 0 to ±9999.9 0.0000

Lo 0 to 9999.9 0.0000 (5) Low limit output

Hi 0 to 9999.9 100.00

AL 0 to 9999.9 0.0000 (6) Low limit alarm

AH 0 to 9999.9 100.00

Default value Remarks

eing connected.

Effective numeric: 5 digits

Effective numeric: 5 digits

Effective numeric: 5 digits

For IRMA1000,2000,7000,8000

-Specify the number of decimal

places.

For IRMA5000,6000

-Effective numeric : 5 digits

- 14 -

Page 21

INST.No.INE-477-P1CE Ver.1.00

5

. Operation

5.3.1-2) Descriptions of the setting data for calibration curves

Setting data name Function

(1) Calibration curve

number

(2) Computing mode (*) The computing modes selectable differ depending on specifications (number of wavelengths and

(3) Calibration curve

coefficient

to a

(*)

a

0

10

(4) Correction expression

coefficient b

to b2

0

(5) Low limit output

High limit output

(6) Low limit alarm

High limit alarm

(7) Preset value By setting the preset output to ON by key operations or through communications, the value being

(8) Water absorbance Decide a water absorbance to compute a surface water ratio for measuring moisture contents of

(*): Selectable computing modes differ depending on models of the constituent meter detector units.

Refer to the table shown below for your selection of a computing mode.

IRMA1 IRMA2 IRMA5 IRMA6 IRMA7 IRMA8

An optional number from 1 to 99 can be designated as a calibration curve. Ordinarily it is

designated sequentially from “1”.

number of constituents) of a detector unit being connected.

The computing modes 1 to 3 are 3-wavelength ratio processing (R1, S1 and R2) in each group in

the table shown below.

• Computing mode 1: 3-wavelength ratio processing (λ1, 2, 3) in Group 1

• Computing mode 2: 3-wavelength ratio processing (λ4, 5, 6) in Group 2

• Computing mode 3: 3-wavelength ratio processing (λ7, 8, 9) in Group 3

• Computing mode 4 is multiple regression computation using each wavelength. The number of

the wavelengths differs depending on specifications of the detector unit and up to 10

wavelengths are available.

Each computing expression of the calibration curve is shown in the next column.

Wavelength λ1 λ2 λ3 λ4 λ5 λ6 λ7 λ8 λ9 λ10

GROUP 1 GROUP 2 GROUP 3

Computing mode 1 R1 S1 R2

Computing mode 2 R1 S1 R2

Computing mode 3 R1 S1 R2

Computing mode 4 λ1 λ2 λ3 λ4 λ5 λ6 λ7 λ8 λ9 λ10

These coefficients are provided for the following computing expressions to compute a calibration

curve.

1) Computing mode 1, 2, 3

A calibration curve is computed by the cubic or lower-degree polynomial.

x3 + a2x2 + a1x + a0,

y = a

3

where, “y” is a measured value and “x” is an absorbance (data of constituent 0).

2) Computing mode 4

A calibration curve is computed by the multiple regression computation at each wavelength.

+ a1LOG(λ1) + a2LOG(λ2) + …………. + a10LOG(λ10)

y = a

0

Note that settable coefficients differ depending on number of wavelengths being used.

These coefficients are provided for the quadratic expression correction against a measured value “y”.

Assuming that a measured value after the correction be “Y”, we obtain “Y = b2y2+b1y + bo”.

These specify measured values at a low limit output and a high limit output on the analog output

scaling. The output is scaled to 4mA at the low limit measured value and 20mA at the high limit

measured value.

A low limit alarm is activated when a measured value is lower than a low limit alarm setpoint.

A high limit alarm is activated when a measured value is higher than a high limit alarm setpoint.

set as a preset value is displayed and outputted, regardless of measured values.

sands, etc.

The relation between a measured moisture content (%: mass basis moisture content), a surface

water ratio (%) and a water absorbance (%) is;

y Surface water ratio = (Moisture content – Water absorbance) / (1 + (Water absorbance / 100)

Computing mode 1

Computing mode 2

Computing mode 3

Computing mode 4

{ { { { { {

― ―

― ―

― ―

(2 constituents or more) (2 constituents or more)

(3 constituents or more) (3 constituents or more)

(2 constituents or more) (2 constituents or more)

- 15 -

― ―

― ―

― ―

Page 22

INST.No.INE-477-P1CE Ver.1.00

5

. Operation

5.3.2 Setting procedure

The setting procedures for (1) calibration curve numbers, (2) computing modes and (3) calibration

curve coefficients a0 to a

depending on specifications (number of wavelengths and number of constituents) of a detector unit

being connected.

The followings are these setting procedures.

5.3.2-1) Setting detector unit numbers and (1) calibration curve numbers to (3) calibration curve coefficients for IRMA1000, 2000, 7000 or 8000 series detector units

shown in [5.3.1-1) List of the setting data for calibration curves differ

10

1) Use the numeric keys 1 to 9 to set a detector unit

HEAD CH DATA

number.

HEAD xx ENT

2) Press SEL key for 2 seconds to display "CH" in

the CH display for entering into the calibration

curve number setting mode.

3) Use the numeric keys 1 to 9 to set a calibration

curve number.

11 1

HEAD CH DATA

1CH 1

Calibration curve

number setting mode

xx xx ENT

4) Press SEL key to display "A0" in the CH display

for entering into the calibration curve coefficient

a0 setting mode.

HEAD CH DATA

1 A0 0.0000

5) Use the numeric keys 1 to 9 to set a calibration

curve coefficient a0.

Setting data name Setting data

xx xx xx xx xx ENT

Reference

Press T/• key to enter a decimal point.

6) Press SEL key to display “A1" in the CH display for entering into the

calibration curve coefficient a1 setting mode.

HEAD CH DATA

Calibration

curve number

〜

7) Set a calibration curve coefficient a1 with the

same key operation.

8) Repeat 6) and 7) to set calibration curve

coefficients a2 to a3.

- 16 -

1 A3 0.0000

Setting data name Setting data

Page 23

INST.No.INE-477-P1CE Ver.1.00

5

. Operation

5.3.2-2) Setting detector unit numbers and (1) calibration curve numbers ~ (3) calibration curve

coefficients for IRMA5000 or 6000 series detector units being connected

1) Use the numeric keys 1 to 9 to set a detector unit

number.

HEAD xx ENT

HEAD CH DATA

11 1

HEAD CH DATA

2) Press SEL key for 2 seconds to display "CH" in

the CH display for entering into the calibration

curve number setting mode.

3) Use the numeric keys 1 to 9 to set a calibration

curve number.

xx xx ENT

4) Press SEL key to display "Md" in the CH

display for entering into the computing mode

selection.

5) Use the numeric keys 1 to 4 to set a computing

mode.

xx ENT

6) Press SEL key to display "A0" in the CH display

for entering into the calibration curve coefficient

a0 setting mode.

7) Use the numeric keys 1 to 9 to set a calibration

curve coefficient a0.

xx xx xx xx xx ENT

Reference

Press T/• key to enter a decimal point.

8) Press SEL key to display “A1" in the CH display

for entering into the calibration curve coefficient

a1 setting mode.

1CH 1

Calibration curve

number setting mode

HEAD CH DATA

Calibration

curve number

1Md 1

Setting data name Setting data

HEAD CH DATA

1 A0 0.0000

Setting data name Setting data

〜

HEAD CH DATA

1 AA 0.0000

9) Set a calibration curve coefficient a1 with the

same key operation. (Refer to. 7) )

10) Repeat 8) and 9) to set calibration curve

coefficients a2 to a10. (A2 to AA in the CH

display)

- 17 -

Setting data name Setting data

Page 24

INST.No.INE-477-P1CE Ver.1.00

5

. Operation

5.3.2-3) Setting from (4) correction coefficients b0 ~ b2 to (8) water absorbance

1) Press SEL to enter into the next data setting mode.

2) Set from (4) correction coefficients b0 ~ b2 to (4) water absorbance with the same key operation as

the above [5.3.2.-2].

5.3.3 Correcting calibration curves

If an actual constituent value (moisture content or thickness) does not correspond with a constituent

value (moisture content or thickness) on a calibration curve being preset due to the difference of

one-line and off-line measurements, or other causes, correct it with correction coefficients b0, b1 and

b2. These coefficients are provided for the quadratic expression correction against a measured value

“y”. Assuming that a measured value after correction be “Y”, we obtain,

Y = b2y2 + b1y + bo

Usually, a shift correction is done with b0 only. (b1 = 1, b2 = 0)

Remarks

[Example 1]

[Example 2]

When a measured moisture content before correction is 15 (%H

actual moisture content is 13 (%H

= 0, b1 = 1, b0 = -2)

(b

2

When a measured thickness before correction is 25 (µm) and an actual

thickness is 23.5 (µm), “-1.5µm should be set.

(b

= 0, b1 = 1, b0 = -1.5)

2

O), “-2%H2O should be set.

2

O) and an

2

- 18 -

Page 25

INST.No.INE-477-P1CE Ver.1.00

5

. Operation

5.4 Setting output limit values of calibration curves

A measured value can be fixed by low limit and high limit absorbance values.

When an absorbance becomes less than a low limit

absorbance value, a measured value is fixed to YL

as shown right.

Also, when an absorbance becomes more than a

high limit absorbance value, a measured value is

fixed to YH.

5.4.1 Data for setting limit values of calibration curves

The followings are data for setting calibration curve output limit values.

Setting data name Display Setting range

of data

(1) Calibration curve number CH 1 to 99 1

(2) Output limit processing

enabled/disabled

Low limit absorbance value XL 0 to ±9999.9 0.0000 Effective numeric: 5 digits

(3)

Low limit measured value YL 0 to ±9999.9 0.0000 Effective numeric: 5 digits

High limit absorbance value XH 0 to ±9999.9 9.9999 Effective numeric: 5 digits

(4)

High limit measured value YH 0 to ±9999.9 9999.9 Effective numeric: 5 digits

Setting data name Description

(1) Calibration curve number Any calibration curve number in 1 to 99 can be specified,

(2) Output limit processing enabled/

disabled

(3) Low limit absorbance value XL

Low limit measured value YL

(4) High limit absorbance value XH

High limit measured value YH

LM OFF (disabled),

ON (enabled)

but it is normally specified from 1 sequentially.

Set the output limit processing enabled or disabled.

When ON (enabled) is set, a measured value is outputted

corresponding to limit values being set.

When OFF (disabled) is set, a measured value is

outputted corresponding to data of a calibration curve.

Enter data to fix a measured value at a low limit side.

Enter data to fix a measured value at a high limit side.

YH

YL

Measured

value

0

XL

Default

Absorbance

Remarks

value

OFF 0: OFF, 1: ON

XH

- 19 -

Page 26

INST.No.INE-477-P1CE Ver.1.00

5

. Operation

5.4.2 Procedure for setting the data for output limit values of calibration curves

5.4.2-1) Setting calibration curve numbers (CH)

1) Use the numeric keys 1 to 9 to set a detector unit

number.

HEAD xx ENT

2) Press SEL key and CH key simultaneously for 2

seconds to display "CH" in the CH display for

entering into the calibration curve number setting

mode for the calibration curve output limit

values.

3) Use the numeric keys 1 to 9 to set a calibration

curve number.

xx xx ENT

5.4.2-2) Enabling/disabling the output limit processing (LM)

1) Press SEL key to display “LM" in the CH

display for entering into the output limit

processing enabled/disabled setting mode. Use

the numeric key 0 or 1 to set the processing

enabled or disabled.

Enter 0 for OFF (disabled) and 1 for ON

(enabled).

xx ENT

5.4.2-3) Setting a low limit absorbance value (XL) and a low limit measured value (YL)

1) Press SEL key to display “XL" in the CH

display for entering into the low limit

absorbance value XL setting mode. Use the

numeric keys 0 to 9 to set a low limit

absorbance value XL.

Reference

Press T/• key to enter a decimal point.

2) Press SEL key to display “YL" in the CH

display for entering into the low limit measured

value YL setting mode. Use the numeric keys 0

to 9 to set a low limit measured value YL.

Reference

Press T/• key to enter a decimal point.

HEAD CH DATA

1CH 1

Calibration curve

number setting mode

HEAD CH DATA

Calibration

curve number

1LM OFF

Setting data name Setting data

HEAD CH DATA

1LM ON

Setting data name Setting data

HEAD CH DATA

1 XL 0.0

Setting data name Setting data

HEAD CH DATA

1 YL 0.0

Setting data name Setting data

- 20 -

Page 27

INST.No.INE-477-P1CE Ver.1.00

5

p

. Operation

5.4.2-4) Setting a high limit absorbance value (XH) and a high limit measured value (YH)

1) After the above settings [5.4.2-1)] to 5.4.2-3)],

press SEL key to display “XH" in the CH

display for entering into the high limit

absorbance value XH setting mode. Use the

numeric keys 0 to 9 to set a high limit

absorbance value XH.

Reference

Press T/• key to enter a decimal point.

2) After the above setting, press SEL key to display

“YH" in the CH display for entering into the high

limit measured value YH setting mode. Use the

numeric keys 0 to 9 to set a high limit measured

value YH.

Reference

Press T/• key to enter a decimal point.

5.4.2-5) Setting output limit values to other calibration curve numbers

HEAD CH DATA

1 XH 1.000

Setting data name Setting data

HEAD CH DATA

1 YH 50.0

Setting data name Setting data

1)After the above settings [5.4.2-1)] to 5.4.2-4)],

press SEL key to display “CH" in the CH display

for returning to the calibration curve number

setting mode.

2)Enter other calibration curve number for setting

output limit values.

3) Repeat the above procedure [5.4.2-1)] to

5.4.2-4)] to set output limit values to other

calibration curve numbers.

Remarks

After the above setting procedure is completed, return to the measurement mode

by pressing SEL key for two seconds, or the automatic return is made if no key is

ressed for one minute.

HEAD CH DATA

1CH 1

Calibration curve

number setting mode

Calibration

curve number

- 21 -

Page 28

INST.No.INE-477-P1CE Ver.1.00

5

. Operation

5.5 Selecting calibration curve numbers

DATA

This is for selecting a calibration curve number whose data

for computing moisture contents, thickness or constituent

values have been set in [5.3 Setting calibration curves].

5.5.1 Selecting calibration curve numbers for

IRMA1000, 2000, 7000 or 8000 series

detector units

1) Press CH key to light the setting status lamp “CH”.

2) Enter a calibration curve number by using the numeric

HEAD CH DATA

HEAD CH

HEAD

CH

MODE

HOLD

IRGM EG2

HEAD

AHALREMOTE

CH

MODE

T

PRESET

R/L

T

HOLD

S/R

MADE IN JAPAN

REAL

PRESET

SEL

CLR

ENT

keys 1 to 9 . After entering it, the setting status lamp

“CH” will go off and the mode will go to the

1 1 5.25

measurement mode.

[Going to the absorbance display mode]

Setting data name Setting data

HEAD CH DATA

By entering 0 in the calibration curve number selection and

pressing ENT key, the setting status lamp “CH” will go

off and the mode will go to the absorbance display mode.

1 2 7.12

HEAD CH DATA

1 0 0.0123

5.5.2 Selecting calibration curve numbers for IRMA5000 or 6000 series detector units

After selecting a constituent number you want to set, set a calibration curve number.

Settable constituent numbers differ depending on constituent specifications of a detector unit being

connected.

Data name Display Setting range Default value Remarks

Constituent number

Calibration curve number

C0

CH

[Changing constituent numbers]

1) Press CH key to light the setting status lamps “CH”

and “MODE”.

2) By entering a constituent number 1 to 4 by using the

numeric keys 1 to 4, “C1” to “C4” corresponding to

the constituent number entered will be displayed in

the CH display.

3) Press ENT key. The calibration curve number being

currently set will be displayed in the CH display and

the setting status lamp “MODE” will go off.

0 to 4 1 0: Absorbance display mode

1 to 99 1

HEAD CH DATA

1 C1 10.25

Setting data name Setting data

HEAD CH DATA

1 1 10.25

[Changing calibration curve numbers]

4) After the above settings, enter a calibration curve

number by using 1 to 9. After entering it, the setting

status lamp “CH” will go off and the mode will go to

the measurement mode.

5) For setting a calibration curve number for each

constituent number, repeat the above procedure.

[Going to the absorbance display mode]

When 0 is entered by using the numeric key 0 in the above

2) for entering a constituent number, “C0” is displayed in

the CH display. Then, by pressing ENT key, the setting

status lamps “MODE” and “CH” will go off and the mode

will go to the absorbance display mode.

- 22 -

HEAD CH DATA

1 2 5.25

HEAD CH DATA

1 C0 5.25

Page 29

INST.No.INE-477-P1CE Ver.1.00

5

. Operation

5.6 Setting operation conditions I (display/output)

This is for setting display/output conditions of a detector unit by this unit.

5.6.1 List of setting data

Setting data name Lamp Setting range of data Default value

(1) Time constant T lights.

(2) Smoothing/real

(3) Hold

Preset output

(4)

ON/OFF

REAL

lights.

HOLD

lights.

PRESET

lights.

0.1 to 9.9 (less than 10 sec)

1 to 99 (10 sec or more)

Smoothing/real switching

HOLD activated/released

ON/OFF

0.2

(T goes off.)

Smoothing

(REAL goes off.)

HOLD released

(HOLD goes off.)

OFF

(PRESET goes off.)

5.6.2 Setting operation conditions

5.6.2-1) Time constant

When a measured value fluctuates quickly, the signal can be dulled by delaying a response time of a

constituent meter detector unit. A smoothing time (equivalent to a time constant of analog

instruments) can be set with 0.1-second increment for shorter than 10 seconds and 1-second increment

for 10 seconds or longer.

DATA

HEAD CH

HEAD

CH

MODE

HOLD

IRGM EG2

HEAD

AHALREMOTE

CH

MODE

T

PRESET

R/L

T

HOLD

S/R

MADE IN JAPAN

REAL

PRESET

SEL

CLR

ENT

<For IRMA1000, 2000, 7000 or 8000 series detector units being connected>

1) Press T/• key to display the setting status lamp “T”.

HEAD CH DATA

2) Enter a time constant by using the numeric keys 0 to 9

and press ENT key. The setting status lamp “T” will go

1 0.2 10.25

off and the mode will return to the measurement mode.

<For IRMA5000 or 6000 series detector units being connected>

Setting data name Setting data

HEAD CH DATA

1) Press T/• key to display the setting status lamp

“MODE”.

1 1 10.25

2) Enter a constituent number for setting a time constant

by using the numeric keys 1 to 4 and press ENT key.

HEAD CH DATA

The setting status lamp “MODE” will go off and the

time constant being currently set will be displayed in

the CH display.

1 C1 10.25

HEAD CH DATA

3) Enter a time constant by using the numeric keys 0 to

9 and press ENT key. The setting status lamp “T”

will go off and the mode will return to the

measurement mode.

1 0.2 10.25

HEAD CH DATA

1 1 10.25

5.6.2-2)Smoothing/real

This is for switching the smoothing processing (The setting of time constant is effective.) of measured

values or the real processing (Time constant = 0.0 second) of them. The setting status lamp “REAL”

turns on to indicate the real processing. By pressing S/R/9 key, the processing becomes the smoothing

processing and the setting status lamp “REAL” will go off.

This setting will be reflected in analog outputs and displays.

5.6.2-3) Hold

This is used to hold a measured value.

1) By pressing HOLD/― key, a measured value will be held and an analog output will be held, too.

2) By pressing HOLD/― key again, the holding condition will be released.

In the holding condition, the setting status lamp “HOLD” will light.

5.6.2-4) Preset output

This is used to display the constituent value being set as a preset value. With the display of the preset constituent

value, an analog output corresponding to the preset constituent value will be outputted.

1) By pressing PRESET/7 key, the preset output will be activated.

2) By pressing PRESET/7 key again, the preset output will be released.

In the preset output condition, the setting status lamp “PRESET” will light.

- 23 -

Page 30

INST.No.INE-477-P1CE Ver.1.00

D

g

5

p

. Operation

5.7 Setting operation conditions II (MODE setting)

For setting various operation conditions of this unit and a detector unit, use the MODE setting.

The MODE setting is only available in the absorbance display mode.

Remarks

Caution

5.7.1 List of data for setting operation conditions II

The followings are data for setting operation conditions II.

Setting items available differ depending on number of constituents.

MODE

No.

6

14

17

19

20

21

*1: (1) Weight α1: The 3-wavelength processing and the 2-wavelength processing can be changed by setting the weight α1.

*2: (1) Weight α2: The 3-wavelength processing and the 2-wavelength processing can be changed by setting the weight α2.

*3: (1) Weight α3: The 3-wavelength processing and the 2-wavelength processing can be changed by setting the weight α1.

Setting data name

Weight α, Calibration constant

Computation

mode 1

Computation

mode 2

Computation

mode 3

Decimal place displaying

measured values

Calibration curve remote inputs

with Binary or BCD

Sample temperature correction

enabled or disabled

(For detector units for 1

constituent in IRMA series)

Sample temperature displaying

Sample temperature input scaling Lo, Hi Lo

When α1 is set to 0.5, the processing becomes the 3-wavelength processing that is the ratio processing of three

wavelengths.

When α1 is set to 0 or 1, the processing becomes the 2-wavelength processing.

(α1: 1 - the ratio processing of λ1 and λ2, α1: 0 - the ratio processing of λ2 and λ3)

(2) Calibration constant k1: This constant is automatically obtained in [5.10 Calibration].

When α1 is set to 0.5, the processing becomes the 3-wavelength processing that is the ratio processing of three

wavelengths.

When α1 is set to 0 or 1, the processing becomes the 2-wavelength processing.

(α1: 1 - the ratio processing of λ1 and λ2, α1: 0 - the ratio processing of λ2 and λ3)

(2) Calibration constant k2: This constant is automatically obtained in [5.10 Calibration].

When α1 is set to 0.5, the processing becomes the 3-wavelength processing that is the ratio processing of three

wavelengths.

When α1 is set to 0 or 1, the processing becomes the 2-wavelength processing.

(α1: 1 - the ratio processing of λ1 and λ2, α1: 0 - the ratio processing of λ2 and λ3)

(2) Calibration constant k3: This constant is automatically obtained in [5.10 Calibration].

For exiting the MODE setting, press SEL key for 2 seconds or the automatic return to the

measurement mode is made if no key is pressed for one minute.

If an invalid MODE number is entered, “Er” will be displayed in the CH display.

After one second, the automatic return to the measurement mode is made if no key is

ressed for one minute.

Settin

isp.

Weight α1 1A*10 to 1.000 0.500

Calibration constant K1 1K

Weight α2 2A*20 to 1.000 0.500

Calibration constant K2 2K

Weight α3 3A*30 to 1.000 0.500

Calibration constant K3 3K

*1

*2

*3

d□ 0 to 4 1

0, 1 0

0, 1 0

range

of data

0 to ±9.9999 1.0000

0 to ±9.9999 1.0000

0 to ±9.9999 1.0000

Default

value

Remarks

0.5: 3-wavelength processing

0 or 1: 2-wavelength processing

0.5: 3-wavelength processing

0 or 1: 2-wavelength processing

0.5: 3-wavelength processing

0 or 1: 2-wavelength processing

0: Not displays after the decimal point

1: Displays 1 decimal place

2: Displays 2 decimal places

3: Displays 3 decimal places

4: Displays 4 decimal places

0: Binary

1: BCD

0: Disable

1: Enable

When 1(enable) is selected in Mode

19, this mode is effective

Lo: Analog input scaling low limit value

Hi: Analog input scaling high limit value

Para.

5.7.2

5.7.3

5.7.4

5.7.5

5.7.6

5.7.7

- 24 -

Page 31

INST.No.INE-477-P1CE Ver.1.00

D

g

5

. Operation

MODE

No.

30

31

32

33

35

40

80

Setting data name

Displaying a constituent number

(For IRMA5000 or 6000 series

detector units only)

Selecting a constituent number

for an analog output and a contact

output from a detector unit

(For detector units for 2 or more

constituents in IRMA5000 or

6000 series only)

Selecting of a contact output from

a detector unit enabled or

disabled and an output item

Selecting of a contact input from

a detector unit enabled/disabled

and an input item

Displaying a calibration curve

number

(For detector units for 2 or more

constituents in IRMA5000 or

6000 series only)

Computing surface water ratio 0, 1 0

Setting communication conditions

(1) Protocol Pr 1, 2 1

(2) Communication speed SP 1, 2 1

(3) Parity P 1 to 3 2

(4) Data length d 7, 8 8

(5) Stop bit length Sb 1, 2 1

(6) BCC use/no use BC 0, 1 0

Settin

isp.

of data

0 to 4 1

1 to 4 1

0 to 2 0

0 to 3 0

0, 1 0

range

Default

value

Remarks

0: Cycle (Circulating display)

1: C1 (Constitute number 1)

2: C2 (Constitute number 2)

3: C3 (Constitute number 3)

4: C4 (Constitute number 4)

1: C1 (Constitute number 1)

2: C2 (Constitute number 2)

3: C3 (Constitute number 3)

4: C4 (Constitute number 4)

0: none (disabled)

1: ALARM

2: ERRoR

0: none (disabled)

1: HoLd

2: PrSEt

3: SMt.rL

0: OFF

1: ON

0: OFF

1: ON

1: rtU

2: PriV

1: 9600

2: 19200

1: nonE

2: EVEn

3: odd

7: 7 bits

8: 8 bits

1: 1 bit

2: 2 bits

0: no

1: YES

ara.

5.7.8

5.7.9

5.7.10

5.7.11

5.7.12

5.7.13

5.7.14

- 25 -

Page 32

INST.No.INE-477-P1CE Ver.1.00

g op

]

5

. Operation

5.7.2 Weight α, calibration constant

The weights “α” are values to decide a ratio of 2 wavelengths in 3-wavelength processing.

The calibration constants are values obtained in [5.10 Calibration] which have been automatically stored.

For setting, press MODE , 6 and then ENT .

“1A” will be displayed in the CH display and its setting data will be displayed in the DATA display.

The following items will be displayed in circle by pressing SEL key.

1A: Computing mode 1 weight α1

1K: Computing mode 1 calibration constant K1

2A: Computing mode 2 weight α2

2K: Computing mode 2 calibration constant K2

3A: Computing mode 3 weight α3

3K: Computing mode 3 calibration constant K3

Reference

For the details of the weight α1 to α3, refer

to *1 to *3 on the margin of [5.7.1 List of

data for settin

eration conditions II

HEAD CH DATA

11A 0.5

Setting data name Setting data

〜

HEAD CH DATA

1 3K 0.0009

5.7.3 Decimal place displaying measured values

The decimal place of a measured value can be set for better

viewing of the data displayed.

For setting, press MODE , 1 , 4 and then SEL.

“d1” will be displayed in the CH display and its setting data will

be displayed in the DATA display.

d1: Decimal place displaying a measured value of the

constituent 1.

(Decimal place displaying a measured value of the

constituent 1 for IRMA5000 or 6000 series detector units)

For IRMA5000 or 6000 series detector unit, the following items

will be displayed in circle by pressing SEL .

d2: Decimal place displaying a measured value of the

constituent 2.

(This will be displayed for the number of constituents is

2 or more and settable.)

d3: Decimal place displaying a measured value of the

constituent 3.

(This will be displayed for the number of constituents is

3 or more and settable.)

d4: Decimal place displaying a measured value of the

constituent 4.

(This will be displayed for the number of constituents is

4 and settable.)

Setting range: 0 to 4

For storing, press xx and then ENT .

HEAD CH DATA

1 d1 25.83

Setting data name Setting data

5.7.4 Calibration curve remote contact inputs with Binary or BCD

This is for setting the processing of calibration curve remote contact inputs to this unit.

Processing with the binary code or the BCD code of remote contact input data can be selected.

For setting, press MODE , 1 , 7 and then ENT .

Setting range: 0 to 1 (0: Binary, 1: BCD)

For storing, press xx and then ENT .

- 26 -

Page 33

INST.No.INE-477-P1CE Ver.1.00

5

. Operation

5.7.5 Sample temperature correction enabled or disabled

(This is effective for IRMA1000, 2000, 7000 or 8000 series detector units, or for detector units

for 1 constituent in IRMA5000 or 6000 series.)

Select the sample temperature correction by a detector unit is enabled or disabled.

For setting, press MODE , 1 , 9 and then ENT .

Setting range: 0 or 1 (0: disabled, 1: enabled)

For storing, press and then ENT .

5.7.6 Sample temperature displaying

When 1 (Enabled) in selected in [5.7.5 Sample

temperature correction enabled or disabled], sample

temperature is displayed in this unit.

MODE , 2 , 0 and then ENT .

5.7.7 Sample temperature input scaling

Set a scaling of an analog input to a detector unit for the

sample temperature correction.

For setting, press MODE , 2 , 1 and then ENT .

“Lo” will be displayed in the CH display and its setting

data will be displayed in the DATA display.

The following items will be displayed in circle by pressing

SEL .

Use the number keys 0 to 9 the set a low limit value for

an analog input scaling and high limit value for an analog

scaling.

Reference

Press HOLD/ - key to enter a minus ( - )

HEAD CH DATA

1 Lo -10

Setting data name Setting data

Lo: Low limit value for an analog input scaling

Hi: High limit value for an analog input scaling

Setting range: -999 to 999

5.7.8 Displaying constituent numbers

(For IRMA5000 or 6000 series detector units)

Select a constituent number to be displayed on a detector unit and this unit.

For setting, press MODE , 3 , 0 and then ENT .

Setting range: 0 to 4

[0: CYCLE (circulating display), 1: C1, 2: C2, 3: C3, 4: C4]

For storing, press and then ENT .

Remarks

This setting is invalid [Er] for IRMA1000, 2000, 7000 or 8000 series detector

units, or detector units for 1 constituent in IRMA5000 or 6000 series detector units.

- 27 -

Page 34

INST.No.INE-477-P1CE Ver.1.00

5

. Operation

5.7.9 Selecting a constituent number for an analog output and a contact output from a detector unit

(For detector units for 2 or more constituents in IRMA5000 or 6000 series only)

Select a constituent number for an analog output and a contact output from a detector unit.