Page 1

INST.No.INE-374-P5CE CE-Marking

w

A l w a y s k e e p t h e s e i n s t r u c t i o n w i t h t h e u n i t .

P l e a s e b e s u r e t o d e l i v e r t h e s e i n s t r u c t i o n s

i t h t h e u n i t t o t h e e n d u s e r .

IR-AH

□ □

Series

PORTABLE DIGITAL RADIATION THERMOMETER

Model : IR-AHS

□

,IR-AHU

□

,IR-AHT

□

Page 2

INST.No.INE-374-P5CE CE-Marking

CONTENTS

1. Introduction ·······························1

1.1 General··········································· 1

1.2 Configuration ··································· 1

2.Model and accessories···················1

2.1 Model·············································· 1

2.2 Accessories ······································ 1

3. Names and functions of

component parts··············

4. Pre p a r at i o n f o r m e a s u r e m e n t ·······

4.1 Loading batteries ····························· 5

4.2 Start and stop·································· 7

4.2.1 Start ··············································· 7

4.2.2 Stop ················································ 7

4.3 Programming temperature unit·········· 7

2

5

5. Measuring·········································· 8

5.1 Measuring procedure························· 8

5.2 Continuous measurement·················· 8

5.3 Auto power off ································ 8

5.4 Cautions on measurement ················ 9

5.5 Measuring····································· 10

5.5.1 Programming emissivity ··············· 10

5.5.2 Programming signal

modulation mode······· 10

5.5.3 Programming modulation

time constant ··············11

5.5.4 Programming alarms ·······················11

6. Temperature data storage·················12

6.1 Manual storage mode ·······················12

6.2 Storage-with-interval mode ···············13

6.3 Display of data stored ·······················14

6.4 Number of temperature data stored ···14

6.5 Deletion of last storage data··············14

6.6 Deletion of all storage data················15

8. Analog Output···························

8.1 Programming scale·························· 18

8.2 Connections ···································· 18

8.3 Temperature data on

analog output ······· 18

9. Maintenance and chec k···············19

9.1 Self-diagnostic function ···················· 19

9.1.1 Low battery ···································· 19

9.1.2 Abnormal internal temperature ········ 19

9.1.3 EEPROM error ······························· 19

9.1.4 Status display ································· 19

9.2 Storage··········································· 20

9.3 Cleaning of cover glass ····················· 20

9.4 Cleaning of external display and

eyepiece cover······· 20

9.5 Initializing of default condition·········· 20

18

10. Accessories······································21

10.1 Close-up lens··································· 21

10.2 AC adapter····································· 22

10.3 Tripod and Universal head··············· 22

10.4 Data Logging Software····················· 22

1 1. List of starting Models/Screens···23

11.1 Models at start time························· 23

11.2 Table of screens······························· 23

11.2.1 Measuring parameters

programming /display items······· 23

11.2.2 T emperature data storage

programming /display items ·······23

11.2.3 Status display items························· 24

11.2.4 System programming display items··· 24

12. General specifications···············24

12.1 External dimensions························ 24

12.2 Specifications ·································· 25

7. User calibration·························16

7.1 Calibration method ·························16

7.2 Recovery of calibration data ··············17

Caution

Read the items marked with in the title without fail.

These paragraphs comprise item.

13. Emissivity table·······················26

13.1 Emissivity table (

13.2 Emissivity table (

13.3 Emissivity table (

!

Warning

-C4-

λ= 0.65µm)·····26

λ= 0.9µm)······ 27

λ= 1.55µm)···· 27

Page 3

INST.No.IR-374-P5CE CE-Marking

Request and notices

Please read this instruction manual for using the thermometer correctly and safely.

◆

Request to the operator of the thermometer

This instruction manual describes the maintenance of the thermometer, too.

Keep this instruction manual with the thermometer.

If you have unclear points or need technical assistance, please contact CHINO' s sales

agent.

Notices

1. The content s of this instruction manual are subject to change without notice.

2. If any question arises, or if any error, an omission, or other deficiency is found, please inform of it

to CHINO' s sales agent.

3. W e, CHIN O, are not responsible to any operation result s.

- C1 -

Page 4

INST.No.IR-374-P5CE CE-Marking

Preface

To use the thermometer correctly and safely, please keep the following safety measures for the

operation and storage of the thermometer.

!

1 Wo rking conditions and environment

● The thermometer is designed as a handheld type. Use a tripod or a simple type universal head for long term

or fixed mounting measurement.

● The working temperature range of the thermometer is 0 to 50 °C. (No dew condensation)

● Do not use the thermometer in dusty places, etc. Remove the dust after using it.

(As for the cleaning of cover glass, refer to the clause of "9.3 Cleaning of co ver glass".)

● Be careful not to give vibration or impact to the thermometer .

● For preventing the consumption of the batteries, turn the Power Supply Switch of the thermometer off when it

is not used.

● As a glass can not transmit the infrared ray in the measuring wavelength of the thermometer, when the

thermometer measures an object through the glass, the surface temperature of t he glass is measured.

(For Model IR-AHT only)

● When the ambient temperature changes rapidly, the measured value may be influenced. When the

thermometer has been brought to a place where the ambient temperature is greatly different from the former

place, leave the thermometer for one hour and then st art the measur ement. (For Model IR-AHT only)

2 Storage

● Do not store the thermometer in hot and humid places. Make sure to store the thermometer with the lens

cap. Recommend to stores the thermometer in room temperature with a d ry pill.

● Do not leave the thermometer in extreme high ambient temperature such as beside a rear window or inside of

a trunk of cars. The thermometer may have troubles.

● When the thermometer is not used for 2 weeks or more, take out the batteries from it. Otherwise, the

thermometer may be damaged by liquid leakage of the batteries.

● When the thermometer has any trouble, please contact to CHINO' s sales agent.

3 Symbol in this instruction manual

The symbols shown below are used depending on important degrees for using the thermometer safely and

avoiding unexpected situations.

Important

degree

1

2

Symbols Contents

This symbol is attached to a title for the sentence wit h the

!

Warning

For avoiding dangerous accidents (may cause death or

electrical shock, fires, or troubles/damages of the thermometer

Warning

serious injury) like as

3 For avoiding injury or in physical damage to the thermometer.

4 For items that you should know as a supplement for this instru ction manual

5 For items that are convenient as a supplement for this instructio n manual

Caution

Remarks

Reference

- C2 -

Page 5

INST.No.IR-374-P5CE CE-Marking

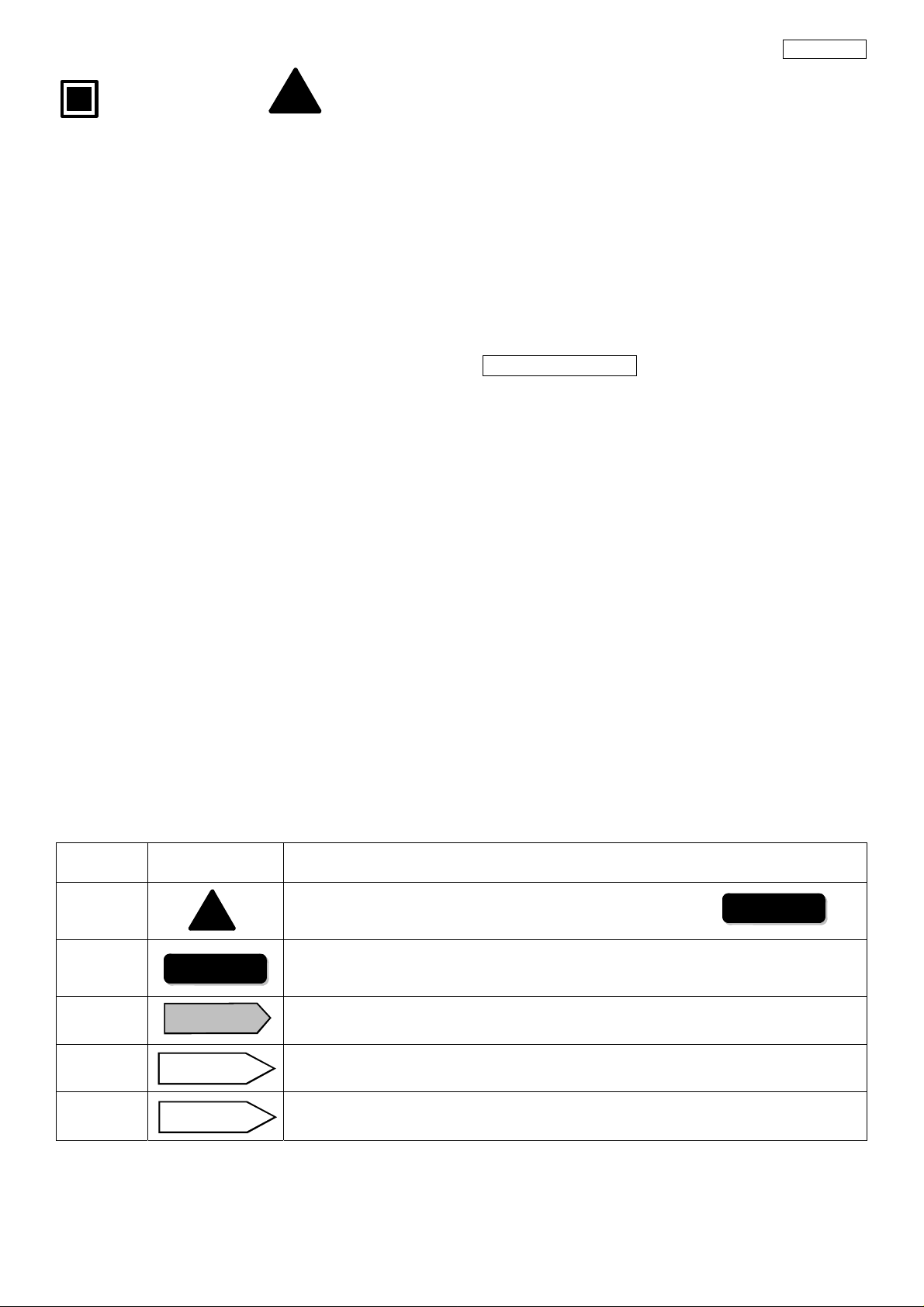

W arnings and Cautions

◆ Please use the thermometer correctly by keeping the following items.

In addition, please read this instruction manual carefully and keep it at the place where you can access easily.

!

!

!

!

For the AC adapter (IR-VHRA), make sure to use 100 V AC. Other voltage may cause electrical

!

!

Warning (May cause death or serious injury)

Make sure not see the sun through the finder of the thermometer. It may cause becoming blind.

Never directly face the objective lens to the sun to protect the detecting element. For the

measurement of high temperature objects, refer t o the clause of "5.4 C autions on measurement".

Never operate the thermometer in places where combustible or volatile gas is existed.

It is extremely dangerous to use the thermometer in such environment.

Never put the batteries into fire, or never charge, short-circuit, heat or disassem bly the batteries.

Breaking or heating of the batteries may cause fire or injury.

shock, fire or trouble.

Never touch the AC ad apter or recept acle by wet ha nds.

Never wet the AC adap ter for avoiding fire.

Wipe the dust on the AC adapter for av oiding fire.

Never use the thermometer if it has been broken, smoking or nasty smelling. These may cause

fire.

When the thermometer is broken, smoking, or nasty smelling, turn the power supply switch off at

once and take out the batteries, and cont act to CHI NO' s sales agent.

!

!

!

!

!

!

!

!

Caution(May cause injury or physical damage)

Do not use other batteries than the batteries specified.

Load the batteries so that their polarities meet the polarity marks on the battery case

polarities may cause fire, injury or damage by burst or liquid leakage of the batterie s.

Do not walk while sighting through the finder of the thermomet er.

It may cause accidents like as fall.

Set the beam attenuation filter selection knob to the beam attenuation side in advance ( in case

of Model IR-AHS on IR-AHU ) for protecting your eyes on the measurement of object exceeding

o

C. [Refer to 5.4 Cautions on measurement]

1500

Never take the thermometer apart or convert it.

These may cause trouble and danger.

Keep the [items] and handling methods described in this instruction manual. When the

thermometer is used without keeping them, the thermometer may be damaged or not be

functioned perfectly, or may damage other equipment.

Dispose the batteries used to places specified with the d isposal proce dure specified .

. Different

!

This thermometer is not of dustproof structure and is not drop of water proof stru cture.

Never operate the thermometer in places where dust, noise or st atic electr ic is existed.

- C3 -

Page 6

INST.No.INE-374-P5CE CE Marking

r

1. Introduction

1.1 General

IR-AH series handheld radiation thermometers can easily measure temperature without any contact

over a wide range from -50

into memory up to maximum 1000 data.

The analysis of the temperature data can be executed easily by combining IR-AH Data Logging

Software (sold separately) with this memory function.

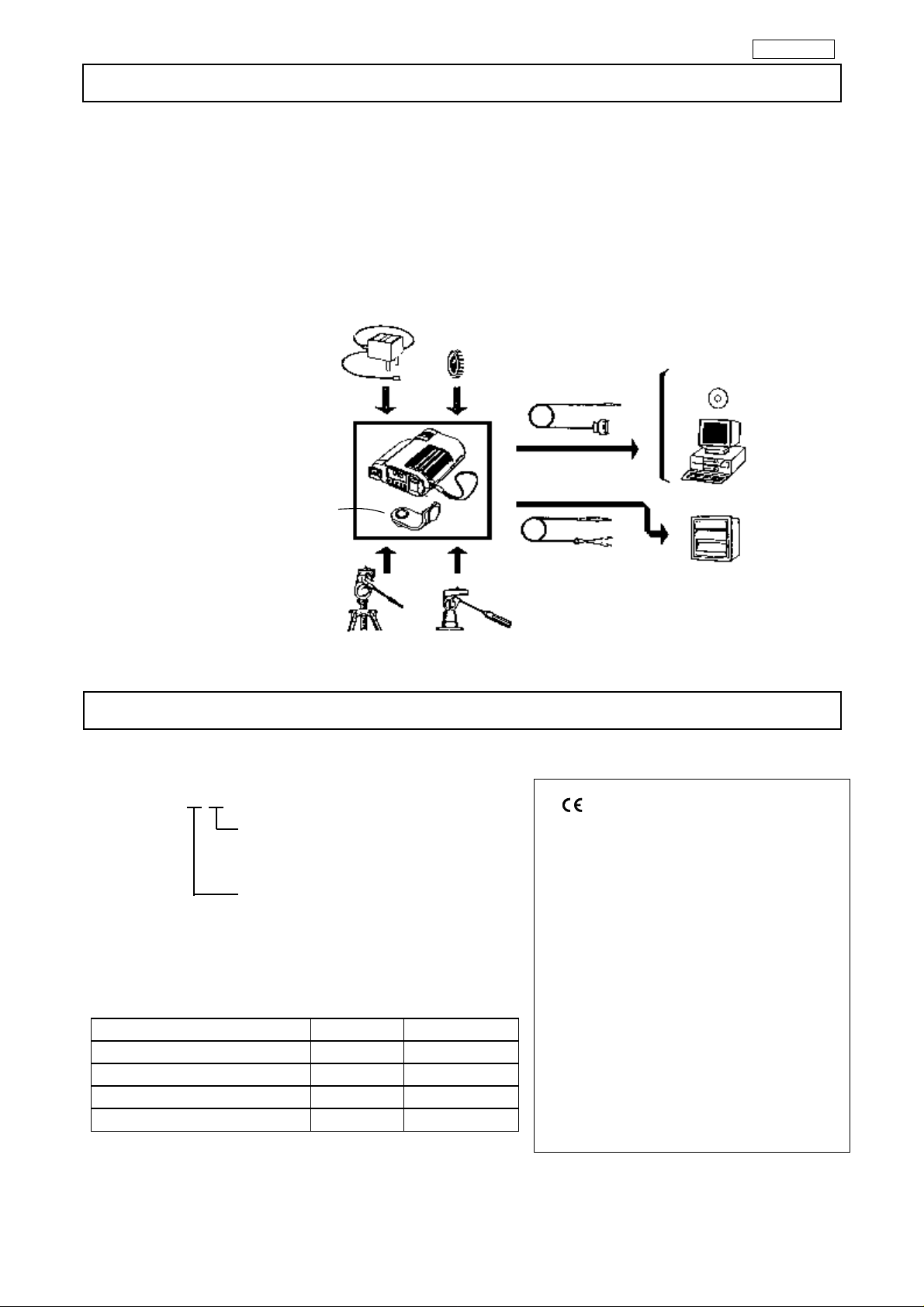

1.2 Configuration

o

C to 3000oC. The thermometers can store the temperature data measured

AC Power adaptor(IR-VHRA)

※

Close-up lens(IR-VHD)

Accessories

Tripod

mounting

adapter

RS-232C onnection cord

※

(IR -VHC)

RS- 232C

Analog output(Option)

Data logging

Software(IR -VXH2E)

Personal compute

Analog output connection cord

※

Marked are not available for CE marking(EMC directive)

Accessories

Tripod(IR-ZBMT)

2. Model and accessories

Univrsal head(IR -VMS)

※

■2.1 Model

I R-AH□□

0: Not provided

2: 0 to 1V DC

Thermometer types

T: For low temperature

Analog output (option)

■ - marking

Above models conform to EMC

directive. (89/336/EEC, 92/31/EEC

amendment, 93/68/EEC amendment)

EN61326 Emission: ClassB

Immunity: Table-Minimum immunity

S: For medium/high temperature

U: For high temperature

2.2 Accessories

Names Quantity Remarks

AA (UM-3) battery 4

Tripod mounting adapter 1

Instruction manual 1 This manual

Housing case 1

Exceptions:

AC powered model ( with AC power

Adaptor ) and analog output model

are excluded from CE-marking.

When the cord (IR-VHC3) for RS232C

is connected to the thermometer, the

thermometer becomes the exclusion

from CE-marking.

Re c eiving ins tr u ment

test requirement.

- 1 -

Page 7

INST.No.INE-374-P5CE CE Marking

M O D E

S e t M e m M I F

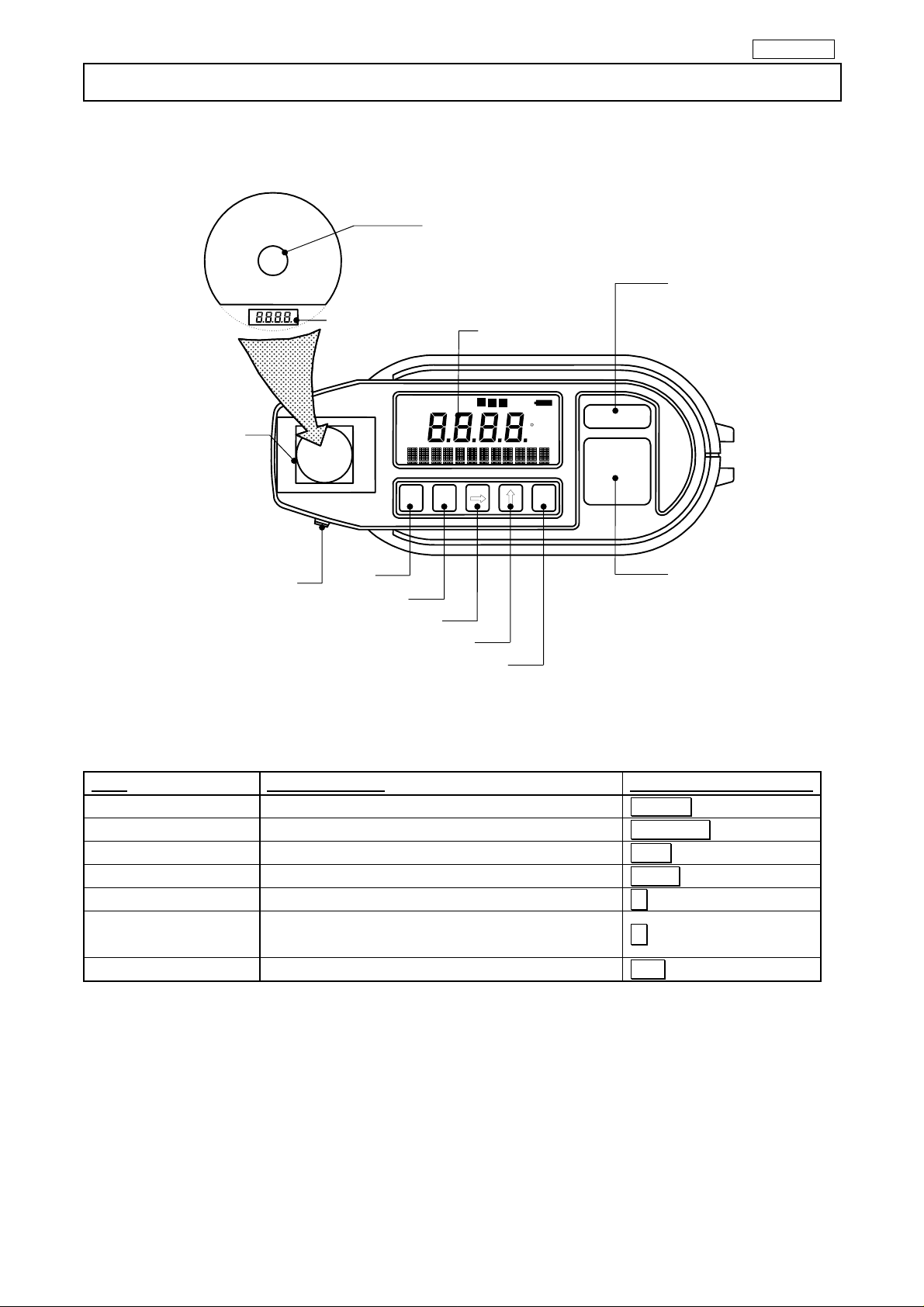

3. Names and functions of component parts

■Front

④

Collimation mark (Page7)

External display

M e a s

A H

A L

M E M

⑤

⑥

E r r o r

℃

F

E N T

⑦

①

O N / O F F

M E A S U R E

②

Viewfinder

Beam attenuation filter

selector knob(IR-AHS,

IR-AHU only) (Page 8)

Internal display

③

●Functions of keys

Keys Major functions Indications in this

Power switch

①

Measure switch

②

Memory key

③

Mode selector key

④

Shift key

⑤

Change key

⑥

Entry key

⑦

Turns on or off the power supply.

Starts or stops measurement.

Stores the measured data into memory.

Selects the screen.

Shifts the digit on programming parameters.

Changes the numeric at the selected digit on

programming parameters.

Stores the parameter programmed.

ON/OFF

MEASURE

MEM

MODE

→

↑

ENT

- 2 -

Page 8

INST.No.INE-374-P5CE CE Marking

A

A

⑨

r

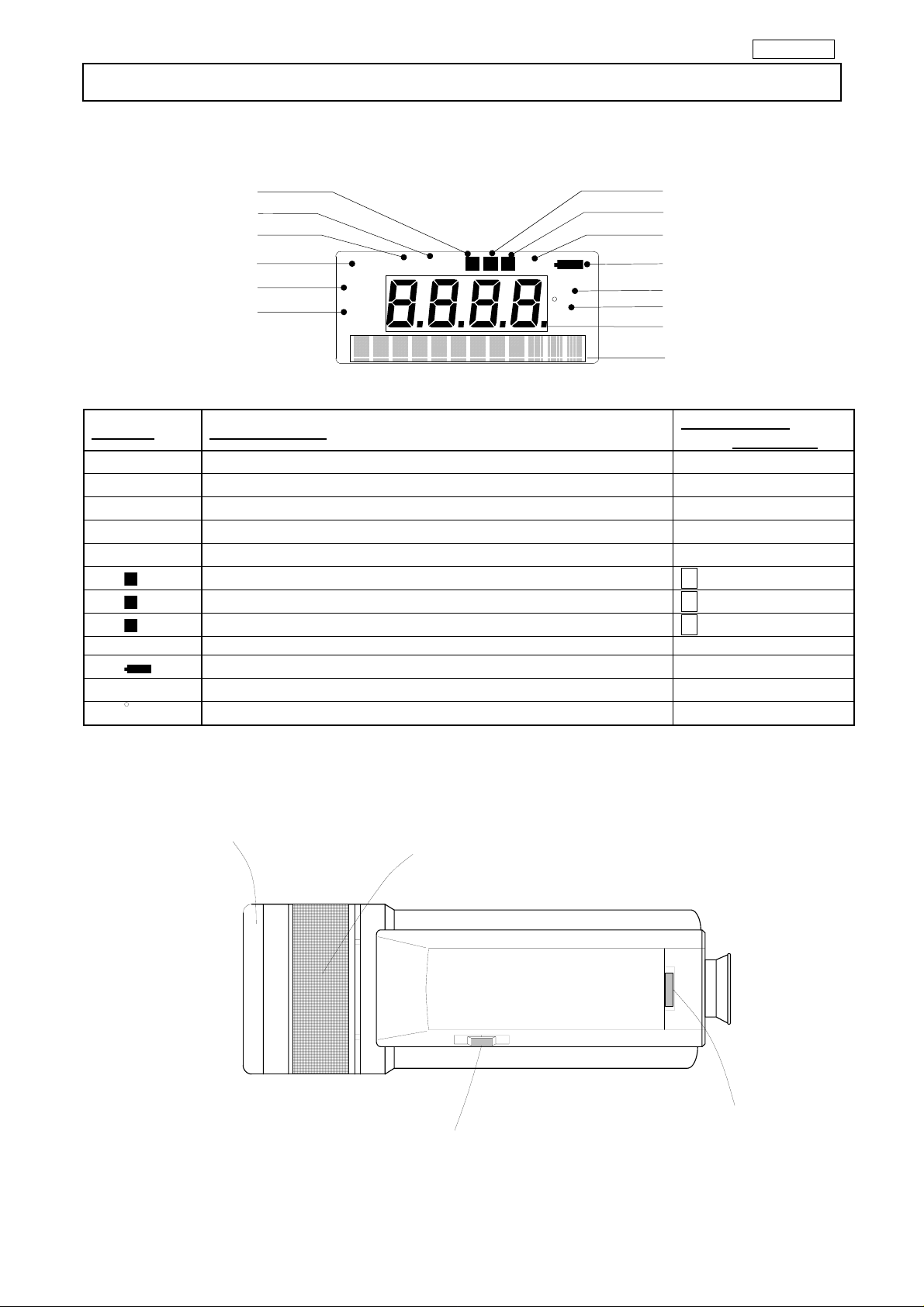

3. Names and functions of component parts

■External display

⑥

⑤

④

③

②

①

●Markers

Markers Major functions

①

②

③

④

⑤

⑥

⑦

⑧

⑩

⑪

⑫

L

H

Meas

Set

Mem

M

I

F

Erro

℃

F

Lights when the low alarm is on.

Lights when the high alarm is on.

Lights in measurement.

Lights on programming parameters or system.

Lights on programming memory or display.

Lights when the memory function is effective.

Lights when the interval memory mode is programmed.

Lights when the memory for data storage has no space.

Lights when the internal temperature of thermometer is abnormal.

Lights on low batteries.

Lights when the temperature is displayed in oC.

Lights when the temperature is displayed in oF.

■Left side panel

Cover ring

Meas

Set

AH

AL

Distance adjusting ring

Mem

MI

F

Error

℃

F

⑦

⑧

⑨

⑩

⑪

⑫

Measured value display

Parameters display

Indications in

this manual

“AL”

“AH”

“Meas”

“Set”

“Mem”

M

I

F

“Error”

“℃”

“゜F ”

Diopter adjusting dial

Beam attenuation filter selector knob

(IR-AHS and IR -AHU only)

- 3 -

Page 9

INST.No.INE-374-P5CE CE Marking

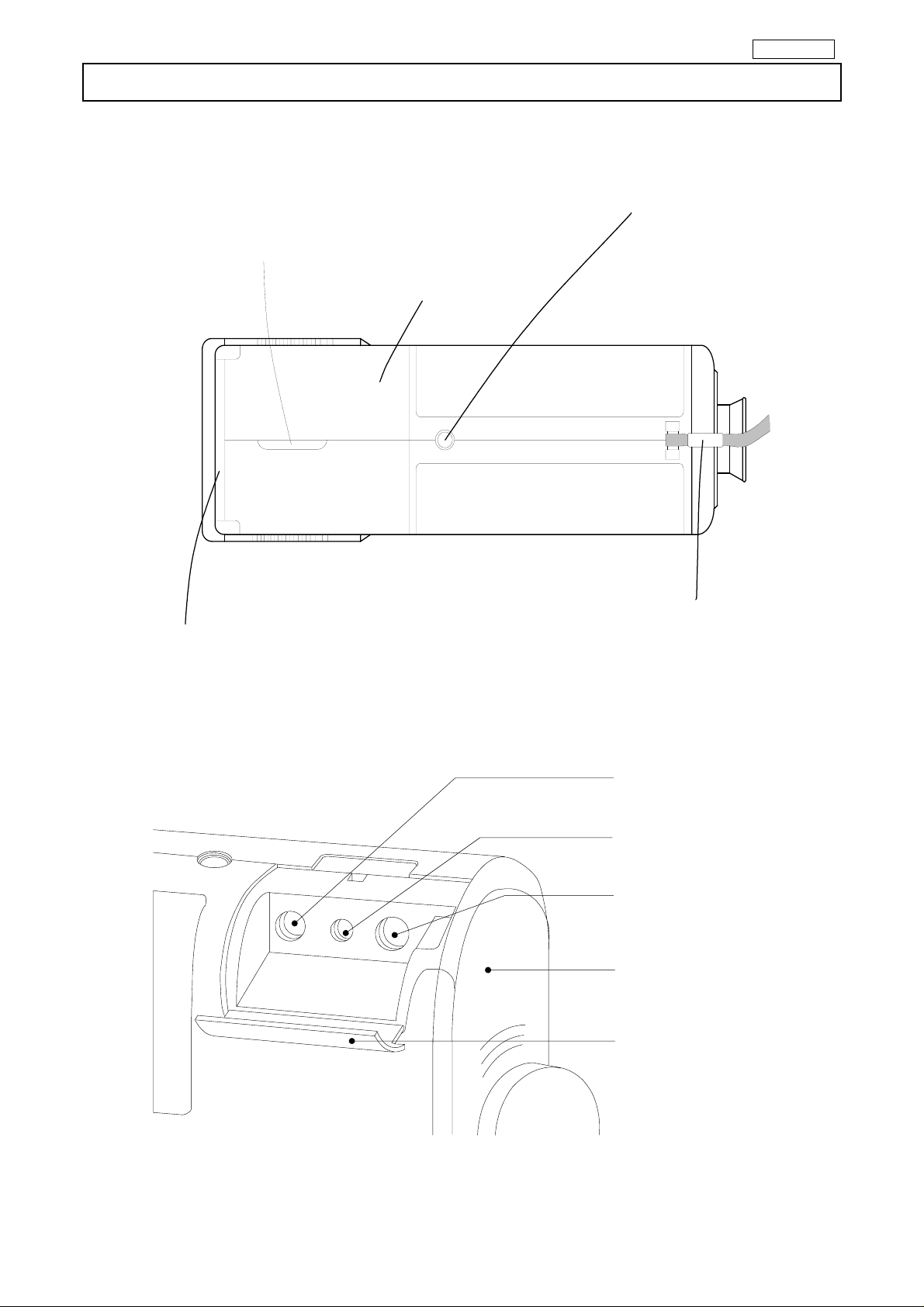

3. Names and functions of component parts

■Right side panel

Connector cover hook

Battery cover

Adapter mounting screw

Connector cover

Hand strap

■Inside connector cover

Analog output jack

(Page 17)

Jack for communications

with a PC (Page 21)

DC power supply

Jack (Page 21)

Battery cover (Page 5)

Connector cover

- 4 -

Page 10

INST.No.INE-374-P4CE CE Marking

4. Preparation for measurement

4.1 Loading batteries

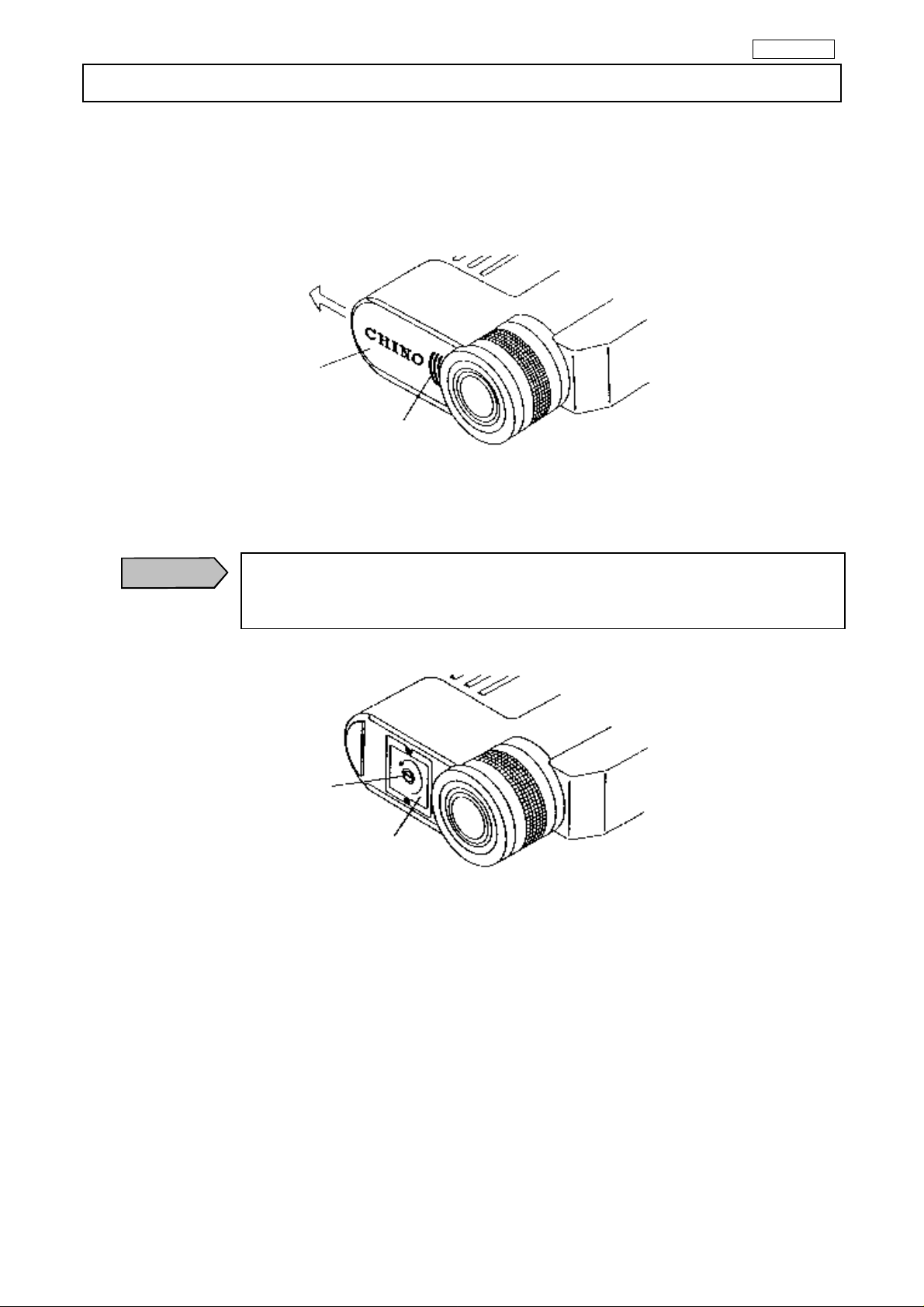

◇ Removing the battery cover

Remove the battery cover by sliding it in the arrow direction while slightly pushing the

asterisked (*) part.

Batteyr cover

※

◇Removing the inside cover

Remove the inside cover by turning the cover fixing screw in the arrow direction by using

a coin.

Caution

If you mistakes polarity and insert of the battery, there is the fear that

the explosion/liquid leakage of the battery occurs and become the cause

of a fire and injury and also contaminate the surroundings.

Cover fixing

screw

Inside cover

- 5 -

Page 11

INST.No.INE-374-P4CE CE Marking

4. Preparation for measurement

◇ Loading batteries

Load the new batteries so that their polarities meet the polarity marks on the battery case.

Caution

Polarity mark

The dimensions of the inside cover is as follows.

Attach and combine the direction of 凹 department ○B of protrusion

department ○A and inside cover of the battery case.

Battery case

A

○

Battery case

◇Mounting the inside cover

Mount the inside cover so that it meets the part.

Inside cover

31

30

B

○

Unit: mm

◇ Mount the battery cover.

- 6 -

Page 12

INST.No.INE-374-P4CE CE Marking

4. Preparation for measurement

4.2 Start and stop

4.2.1 Start

Press ON/OFF key to turn the power supply on.

This thermometer checks the system just after the power supply has been turned on.

The message “System Check” appears on the parameter display during the system is checked.

S y s t h e c e m C k

After the system check is finished, the measurement screen is displayed.

On the measurement screen, the signal modulation mode is displayed at the left side and the

emissivity is displayed at the right side of the parameter display at the measurement screen.

4.2.2 Stop

Press ON/OFF key to turn the power supply off.

Caution

By pressing ON/OFF key, the shutdown processing is executed to save the

system information. Make sure to press ON/OFF key for turning off the power

supply of this thermometer.

℃

4.3 Programming temperature unit

Program the temperature unit by the procedure below.

・Press ON/OFF key while pressing MODE key to turn the power supply on.

・The temperature unit programming screen appears on the parameter display.

U n i t

℃

・Selects o C for Centigrade temperature display or o F for Fahrenheit temperature display by

↑ key.

・Press ENT key to store the temperature unit selected.

・Press ON/OFF key to turn off the power supply once.

The temperature unit stored is displayed in the next start.

Remarks

・The default temperature unit is oC.

- 7 -

Page 13

INST.No.INE-374-P4CE CE Marking

5. Measuring

5.1 Measuring procedure

・Press ON/OFF key to turn the power supply on.

・Set the measuring distance roughly by the distance adjusting ring.

・Adjust the diopter adjusting ring to see the collimation mark on the internal display clearly.

・Adjust the distance measuring ring to see the object measured clearly in the collimation mark.

・Press MEASURE key to start the measurement.

The temperature measured is displayed on the internal and external displays, and the “Meas”

marker lights on the external display.

The “OFL” is displayed if the temperature measured exceeds the measuring range or the “UFL” is

displayed if it is lower than the measuring range.

・Release MEASURE key to stop the measurement. The temperature measured just before

M e a s

℃

℃

stop is held on the internal and external displays.

5.2 Continuous measurement

For the continuous measurement, press ON/OFF key while pressing MEASURE key to turn the

power supply on. Press MEASURE key to start the measurement. The measurement is

continued until MEASURE key is pressed again.

Reference

・Batteries are consumed abruptly on the continuous measurement.

It is recommended to use the AC adapter Model IR-VHR (option) for the

continuous measurement.

5.3 Auto power off

The back-light for internal display lights out in 10 seconds after the stop of measurement.

On the continuous measurement, it lights out in 10 seconds after the start of measurement.

For lighting the back-light again, press ENT key. The back-light lights for 10 seconds.

For saving the battery life, the power supply is turned off automatically if this thermometer is not

operated for 5 minutes

- 8 -

Page 14

INST.No.INE-374-P4CE CE Marking

5. Measuring

5.4 Cautions on measurement

Warning

・Never directly face the objective lens to the sunlight for protecting your eyes

and the detecting element.

・Set the beam attenuation filter selector knob to the beam attenuation side in

advance (in case of Model IR-AHS or IR-AHU) for protecting your eyes on

the measurement of object exceeding 1500oC.

・However , when you feel glare on the measurement of objects lower

then 1500 oC, set the beam attenuation filter selection knob to the beam

attenuation side in advance.

Beam attenuation

!

Caution

・Light path

Be careful not to introduce water drops, dust particles, smoke, steam, or other

foreign substances into the light path between the object measured and the

objective lens of this thermometer.

・Interference causing high indication

Be careful not to apply the direct sunlight, light of an incandescent lamp, flame

or other thermal radiation to the object measured and the objective lens of this

thermometer.

・Abrupt change of ambient temperature

Model IR-AHT uses a thermopile as its detecting element. If the ambient

temperature changes abruptly, it takes time until the indication is stabilized.

If your thermometer is Model IR-AHT and it has been brought into a place

where a temperature difference is noticeable, leave the thermometer for about

one hour before starting the measurement.

- 9 -

Page 15

INST.No.INE-374-P4CE CE Marking

5. Measuring

5.5 Measuring

This thermometer has various measuring parameters.

The list of parameters is shown in [11. List of starting modes/screens]. By pressing MODE key

when the measurement screen is displayed, the measuring parameter programming screen is

appears with the “Set” marker lit. Measuring parameters cannot be programmed in measurement.

For programming the parameters, cancel the measurement once.

5.5.1 Programming emissivity

If the emissivity of object measured is low, the temperature displayed becomes lower than the

actual temperature and the emissivity is to be compensated.

・Press MODE key to get the emissivity programming screen.

E m i . . 0 0 1

・Press → key to shift the digit and press ↑ key to program the emissivity.

・Press ENT key to store the emissivity programmed.

The programming range is 0.10 to 1.99 (0.01 step).

Remarks

Reference

・The default emissivity is 1.00.

・ If you know the emissivity of object measured, program to its value.

If the emissivity is unknown, measure the temperature of object by a thermocouple

or other sensors and program the emissivity to display the same temperature.

The reference table of emissivity is shown in [13. Emissivity table]

5.5.2 Programming signal modulation mode

The maximum value, average value, and minimum value can be extracted continuously from the

measurement signal (real signal).

・Press MODE key to get the signal modulation mode programming screen.

M o d . e a l R

・Press ↑ key to program the mode.

Real

Peak※

Delay※

Valley※

z For the first-order lag degree in peak, delay, and valley, refer to [5.5.3 Programming modulation time

constant].

・Press [ENT] key to store the modulation mode programmed.

Remarks

The temperature measured is displayed on the real signal

without any signal modulation.

When the temperature measured increases, it is displayed

on the real signal. When the temperature measured

decreases, it is displayed on the first-order lag signal by

the time constant being programmed by the modulation

time constant programming.

The temperature measured is displayed on the first-order

lag signal.

When the temperature measured decreases, it is displayed

on the real signal. When the temperature measured

increases, it is displayed on the first-order lag signal by

the time constant being programmed by the modulation

time constant programming.

・The default mode is Real.

Measuring signal

Maxium valuc

Mean value

PEAK

DELAY

REAL

- 10 -

Page 16

INST.No.INE-374-P4CE CE Marking

5. Measuring

5.5.3 Programming modulation time constant

The modulation time constant is programmed on the signal modulation modes. The first-order lag

degree can be adjusted by the modulation time constant. The increase of modulation time constant

makes the first-order lag degree increase and the temperature measured is displayed smoothly.

・Press MODE key to get the modulation time constant programming screen.

T . C . . 9 s 9 9

・Press → key to shift the digit and press ↑ key to program the modulation time constant.

・For programming to Hold, increase the value by ↑ key at the most significant digit to

display “Hold”.

T . C . l d o ? H

・Press [ENT] key to store the time constant programmed.

The programming range of the modulation time constant is 0.0 to 99.9 seconds (0.1 second step)

and

“Hold”.

Remarks

・The default time constant is 0.0 second.

Reference

・Operation when the modulation time constant is programmed to “Hold”.

By programming the signal modulation mode to Peak, the maximum temperature

in measurement is held. By programming the signal modulation mode to Valley,

the minimum temperature in measurement is held.

By programming the signal modulation mode to Delay, the temperature measured

is displayed on condition that the modulation time constant is 99.9 seconds

5.5.4 Programming alarms

Two kinds of high alarm and low alarm can be programmed. If an alarm is on, either the “AH”

(high alarm) or the “AL” (low alarm) marker lights on the external display and the buzzer sounds.

Program to “OFF” if no alarm is required.

・Press MODE key to get either the high alarm programming screen (left figure) or the low

alarm programming screen (right figure).

A l m H f f O A l m L f f O

・Press → key to shift the digit and press ↑ key to program the alarm value

・For programming to OFF, increase the value by ↑ key at the most significant digit to

display “OFF”.

・Press ENT key to store the alarm value programmed.

Alarm programming range

Model High alarm programming range Low alarm programming range

IR-AHT

IR-AHS

IR-AHU

-50〜1000

600〜3000

900〜3000

Remarks

o

C(1oC step)、OFF -50〜1000 oC(1oC step)、OFF

o

C(1oC step)、OFF 600〜3000 oC(1oC step)、OFF

o

C(1oC step)、OFF 900〜3000 oC(1oC step)、OFF

・The default high and low alarms are “OFF”.

- 11 -

Page 17

INST.No.INE-374-P5CE CE Marking

6. Temperature data storage

This thermometer provides a function of storing temperature data measured up to maximum 1000

data into memory.

Two kinds of storage modes are prepared. The manual storage mode is to store the temperature

data being measured at the time pressing [MEM] key, and the storage-with-interval mode is to store

the temperature data being measured at every interval time programmed.

6.1 Manual storage mode

・Press [MODE] key for about 2 seconds on the measurement screen to get the storage mode

programming screen.

M M O D O f f

・Press ↑ key for programming to “Man”.

・Press ENT key to store the manual storage mode.

The M marker lights when the manual storage mode is stored.

Mem

・Press [MODE] key for returning to the measurement screen.

・Press [MEASURE] key to start the measurement.

・In measurement, press [MEM] to store the temperature data being measured at the time

into memory and the message “Data Stored” appears at the temperature data storage.

D a t a r e d S o t

M

In-not-measurement, by pressing MEM key, the temperature data being displayed at the time is

stored into memory. (When a data is stored once in-not-measurement, any data after then can not be

stored until the measurement is executed again.)

To make the memory function disable, program to “Off” in the storage mode programming screen.

MEM key does not function and the temperature data are not stored into memory.

・The default memory mode is “Off”.

Remarks

- 12 -

Page 18

INST.No.INE-374-P5CE CE Marking

6. Temperature data storage

6.2 Storage-with-interval mode

・Press [MODE] key for about 2 seconds on the measurement screen to get the storage mode

programming screen.

M M O D O f f

・Press ↑ key for programming to “Int”.

・Press ENT key to store the storage-with-interval mode.

The I marker lights when the storage-with-interval mode is stored.

Mem

・Press MODE key once to get the interval time programming screen.

I n t : 0 0 : 1 0 0

I

・Press → key to shift the digit and press ↑ key to program the interval time.

・ Press [ENT] key to store the interval time programmed. On this stage, the

storage-with-interval function does not activate.

・Press MODE key for about 2 seconds to get the measurement screen.

・Press MEM key to make the storage-with-interval function activate. The M marker lights in

addition to the I marker on the function activated.

M

I

・ Press MEASURE key to start the measurement. The temperature data at every interval

time programmed are stored into memory and the message “Data Stored” appears each

time at the temperature data storage.

D a t a r e d S o t

・To cancel the storage-with-interval function temporarily, press MEM key. The M marker

lights out.

The programming range of interval time is 1 second to 2 hours (0:00:01 to 2:00:00).

Remarks

・The default interval time is 1 minute (0:01:00).

- 13 -

Page 19

INST.No.INE-374-P5CE CE Marking

6. Temperature data storage

6.3 Display of data stored

・Press MODE key for about 2 seconds on the measurement screen to get the storage mode

programming screen.

・Press MODE key to display the temperature data stored. .

Index numbers (serial number from 1 to 1000 showing data storing numbers) are displayed on the

left side and temperature data are displayed on the right side.

The temperature data stored into memory last is displayed first.

1 0 0 0 1

℃

・Press → key to display the previous temperature data stored before the temperature data

displayed. Press ↑ key to display the next temperature data stored after the

temperature data displayed.

・Press [MODE] key for about 2 seconds to cancel the display of temperature data stored.

The message “No Data” appears if any temperature data have not been stored.

6.4 Number of temperature data stored

Maximum 1000 temperature data can be stored into memory. The temperature data exceeding

1000 cannot be stored and the F marker lights on 1000 temperature data stored.

Meas

To store the temperature data under this condition newly, delete the previous temperature data

referring to [6.5 Deletion of last storage data] and [6.6 Deletion of all storage data].

M

F

6.5 Deletion of last storage data

・The following procedure is to delete the last temperature data stored.

・Press MODE key for about 2 seconds on the measurement screen to get the storage mode

programming screen.

・Press MODE key to get the last temperature data deletion screen.

L D D E S N E O Y L

・Press → key to shift the cursor to “Yes”.

・Press ENT key.

When the data is deleted normally, the message “xxxx Erased” appears. This “xxxx” shows the

index number of the temperature data deleted.

1 0 s e d E a r

The message “No Data” appears if any temperature data have not been stored.

・Press MODE key for about 2 seconds to cancel the last temperature data deletion.

- 14 -

Page 20

INST.No.INE-374-P5CE CE Marking

6. Temperature data storage

6.6 Deletion of all storage data

・The following procedure is to delete all temperature data stored,

・Press MODE key for about 2 seconds on the measurement screen to get the storage mode

programming screen.

・Press MODE key to get all temperature data deletion screen.

A D D E S N E O Y L

・Press → key to shift the cursor to “Yes”.

・Press ENT key.

When the data are deleted normally, the message “All Erased” appears.

1 0 s e d E a r

The message “No Data” appears if any temperature data have not been stored.

・Press MODE key for about 2 seconds to cancel all temperature data deletion.

- 15 -

Page 21

INST.No.INE-374-P5CE CE Marking

7. User calibration

For the routine calibration of this thermometer, the user calibration function is provided to

recalibrate this thermometer by using your black body furnace for calibration.

The calibration is executed on two optional temperature points.

7.1 Calibration method

・Press ON/OFF key while pressing MODE key to turn the power supply on.

・Press MODE key several times to get the zero/span calibration execution screen.

C M P N O O G

・Press → key to shift the cursor to “GO”.

Reference

・Press ENT key to get the zero side calibration data programming screen.

The temperature data being displayed is on the real signal not being converted through emissivity

compensation, signal modulation, and modulation time constant.

Meas

Set

・Measure the temperature of your black body furnace.

・During the measurement of the black body furnace temperature, press → key to shift the

digit and press ↑ key to change the temperature displayed to the calibrated temperature

of black body furnace

Caution

・Press ENT key to store the calibration data at the zero side.

As the confirmation of calibration data storage, the asterisk (*) appears beside the character “Zero”.

Z e r o 0 0

Caution

・Press MODE key once to get the span side calibration data calibration screen.

S p a n 0 0

Press MODE key on this condition, when you want to calibrate the span side

only without calibration the zero side.

℃

Use the ↑ key in the case that the numerical value is set up. However, do it

after the column that sets up the numerical value is selected with the → key.

If push the ↑ key without selecting the column, transferring it to the upper most

column and the numerical value has done UP.

7 *

The auto power off function works when time is required to the span side

calibration work start after zero side calibration ended, and the power supply

becomes the condition of off.

(In the case that there is not key operation for 5 minutes)

0 3

℃

℃

- 16 -

Page 22

INST.No.INE-374-P5CE CE Marking

7. User calibration

・Measure the temperature of your black body furnace, and program and store the calibrated

temperature of black body furnace in the same way as the programming of calibration data

at zero side. Make sure that the calibration data at span side is greater than the calibration

data at zero side

Reference

・Press [MODE] key once more to get the calibration operation execution screen.

C A L . N O O G

・Press → key to shift the cursor to “GO”..

・Press ENT key to start the calibration operation.

・When the calibration operation finishes correctly, the message “Completed” appears

forseveral seconds

C o m p d e e t l

・For making the calibrated data effective, restart this thermometer.

Remark

Set up it so in this case, it becomes span calibration data>zero calibration data.

・If zero/span calibration data are not stored or if the calibration data at zero side

> the calibration data at span side, the message “Data Abnormal” appears

and the calibration operation is not executed.

7.2 Recovery of calibration data

This function is to recover, after the execution of the user calibration, the calibration data to the

previous data.

This thermometer stores the previous calibration data at the execution of the user calibration.

The following procedure is to recover the calibration data to the previous data stored.

・Press ON/OFF key while pressing [MODE] key to turn the power supply on.

・Press MODE key twice to get the zero/span calibration execution screen.

C M P N O O G

・Press → key to shift the cursor to “GO”.

・Press ENT key to get the zero calibration data programming screen.

・Press MODE key three times to get the calibration data recovery screen.

U n d o N O O G

・Press [→] key to shift the cursor to “GO”.

・Press [ENT] key.

After the calibration data recovery finishes correctly, the message “Completed” appears.

C o m p d e e l l

・For making the recovered calibration data effective, restart this thermometer.

Caution

When the recovering to the previous calibration data from the current calibration

data is executed, the current calibration data is erased and the recovering operation

can not be executed again until the next user calibration is executed. For initializing

to the default calibration data, refer to [9.5 Initializing to the default condition.].

- 17 -

Page 23

INST.No.INE-374-P5CE CE Marking

8. Analog Output

If your thermometer is with the optional analog output function, the analog output of 0 to 1V

corresponding to the temperature data measured. (Models IR-AHT2, IR-AHS2 and IR-AHU2)

You can record the temperature data measured on a recorder by this function

8.1 Programming scale

An optional temperature scaling to an analog output of 0 to 1V can be programmed.

・Press ON/OFF key while pressing MODE key to turn the power supply on.

・Press MODE key once to get the high output scaling value programming screen.

O H 0 0

・Press → key to shift the digit and press ↑ key to program the high output scaling value.

・Press ENT key to store the high output scaling value programmed.

・Press MODE key once more to get the low output scaling value programming screen.

O

0 0

L

0 2

0

1

℃

℃

・Press → key to shift the digit and press ↑ key to program the low output scaling value.

・Press ENT key to store the low output scaling value programmed.

・Press ON/OFF key to turn the power supply off.

On the next start-up of this thermometer, you can get the analog output of 0 to 1V within the scaling

range programmed.

The analog output programming range is mentioned below.

Model

High output scaling value programming

range

IR-AHT -50 to 1000 oC(1oC step) -50 to 1000 oC(1oC step)

IR-AHS 600 to 3000 oC(1oC step) 600 to 3000 oC(1oC step)

IR-AHU 900 to 3000 oC(1oC step) 900 to 3000 oC(1oC step)

Remarks

・The default scaling values

o

IR-AHT 1000

IR-AHS 3000

C (Maximum scaling), -50 oC (Minimum scaling)

o

C (Maximum scaling), 600 oC (Minimum scaling)

IR-AHU 3000 oC (Maximum scaling), 900 oC (Minimum scaling)

Low output scaling value programming

range

8.2 Connections

Connect the analog output cable attached to the analog output jack inside the connector cover.

Connect it to the innermost of the jack securely.

For the place of the analog output jack, refer to [3. Names and functions of component parts].

8.3 Temperature data on analog output

The temperature data on analog output are the same as those being displayed and the data are

converted through emissivity compensation, signal modulation, and modulation time constant.

- 18 -

Page 24

INST.No.INE-374-P5CE CE Marking

s

9. Maintenance and check

9.1 Self-diagnostic function

9.1.1 Low battery

The battery warning marker lights on the external display when the battery capacity becomes lower

than a certain level and replace them at once with the new batteries.

Caution

Meas

For replacing the batteries, refer to [4.1 Loading batteries].

Battery warning marker.

9.1.2 Abnormal internal temperature

If the temperature inside this thermometer becomes abnormal, the inside temperature error marker

lights on the external display.

Caution

The inside temperature error marker lights when the inside temperature of

M

I

Error

Inside temperature

thermometer becomes lower than 0oC or higher than 55oC.

Measurement cannot be executed correctly under such an environment.

Check the ambient temperature.

9.1.3 EEPROM error

If EEPROM storing the parameters and the temperature data becomes in error, the message

“EEPROM ERROR” appears at the access timing to EEPROM.

E E P R r r o M E r O

Caution

The parameters and the temperature data can be stored into memory under thi

condition. Contact your nearest CHINO’s sales agent.

9.1.4 Status display

If → key is pressed for about 2 seconds on the measurement screen in the stop condition, the status

of this thermometer are displayed on the external display. Press MODE key to switch the screens.

The following status are displayed.

・Inside temperature

・Model

・Serial number

・Measuring temperature range

・Measuring wavelength

Press → key for about 2 seconds for returning to the measurement screen.

- 19 -

Page 25

INST.No.INE-374-P5CE CE Marking

9. Maintenance and check

9.2 Storage

Caution

・Don’t store this thermometer at a hot and/or wet place.

・Make sure to mount the lens cap for storage.

・Remove the batteries if this thermometer is not used for longer than 2

weeks, otherwise this thermometer may become defective due to an electrolyte

leak failure of the batteries.

9.3 Cleaning of cover glass

Wipe the cover glass inserted into the cover ring periodically with a soft cloth.

In case of Model IR-AHT, the cover glass is mounted at a deep position. Remove the ring from

the thermometer to wipe the cover glass.

9.4 Cleaning of external display and eyepiece cover

Clean them periodically with a soft cloth.

9.5 Initializing to default condition

For initializing this thermometer to the default condition, press ON/OFF key while pressing ENT

and ↑ keys. The message “Initialized” appears to confirm the initialization.

I n i t z e d a i l i

Caution

Remarks

・By this operation, all parameters are initialized to the default condition and

the temperature data stored are erased.

・For the default parameters, refer to [11.2 Table of screens]

- 20 -

Page 26

INST.No.INE-374-P5CE CE Marking

10. Accessories

10.1 Close-up lens (Model: IR-VHD: For IR-AHS and IR-AHU)

This lens is used for the measuring distance less than 0.5m.

The measuring diameter is determined by the distance factor. The measuring diameter is

expressed by the following formula.

(Measuring diameter) / (Measuring factor) – Measur ing diameter ø D (Unit: mm)

(Example) As the distance factor of Model IR-AHS is 100, the relation of measuring

distance and measuring diameter is shown as:

250 to 520/100 = ø2.5 to ø5.4 (Unit: mm)

The measuring distances and the measuring diameters of each model are shown in the table.

In case of Model IR-AHS, it is possible to measure the object with the diameter of ø1 at the

measuring distance of 100 mm.

Model Distance Min. diameter (IR-AHS) Min. diameter (IR-AHU)

IR-VHD13 100 to 130(mm)

IR-VHD18 130 to 180(mm)

IR-VHD29 180 to 290(mm)

IR-VHD54 250 to 540(mm)

φ1 toφ1.3(mm)

φ1.3 toφ1.8(mm)

φ1.8 toφ2.9(mm) φ0.7 toφ1.2(mm)

φ2.5 toφ5.4(mm) φ1.0 toφ2.2(mm)

■Mounting Method

・Remove the cover glass ring from the lens cylinder tip by turning it.

・Mount the close-up lens to the lens cylinder tip by screwing it.

Cover glass ring

Lens cylinder

Remarks

Cover lens

・No cover glass can not be used for the close-up lens.

- 21 -

Page 27

INST.No.INE-374-P5CE CE Marking

10. Accessories

10.2 AC adapter (Model IR-VHRA)

!

The adapter is for operation of this thermometer with AC power supply and is effective for use in

the continuous measurement mode.

For the connection, insert the plug of the adapter into the DC power jack. For the place of the DC

power jack, refer to [Inside connector cover] in [3. Names and functions of component parts].

Warning

・Make sure that 100VAC is used for the AC adapter.

If not, electrical shock, fire, damage may occur.

Caution

・Do not touch the AC adapter or receptacle with wet hands.

・Do not wet the AC adapter. Fire may cause.

・Wipe out the dust on the AC adapter . Fire may cause.

・Connect the AC adapter to this thermometer with the power supply turned off.

10.3 Tripod (Model IR-ZBMT) and Universal head (Model IR-VMS)

These accessories are used for fixing this thermometer for long-term measurement.

Mount the tripod or the universal head via the tripod mounting adapter attached, if required.

Tripod mounting screw(W 1/4)

for d irect fixin g

Tripod mounting adapter

10.4 Data Logging Software (IR-AH Data Logging Software)

Three kinds of data management mode, real-time trend mode, multi-point monitoring mode by

utilizing memory, and 1-point historical trend mode, are available.

Graph display, report creation, printing, and data storage can be easily executed.

The export of the measured data to spreadsheet applications is also possible.

- 22 -

Page 28

INST.No.INE-374-P5CE CE Marking

11. List of Starting Modes/Screens

11.1 Modes at start time

The following operation modes are available by the key combinations at the start time.

Keys Modes Remarks

Press ON/OFF key only

Press ON/OFF while pressing MEASURE key

Press ON/OFF key while pressing MODE key

Press ON/OFF key while pressing ENT and

Standard measurement

Continuous measurement

System programming No measurement can be

Initialization After initialization, the

↑ keys together

11.2 Table of screens

The screens displayed on the external display are the following 4 kinds basically.

Modes

Programming

How-to-display from

measurement screen

Press MODE key.

measuring parameters

Programming and

display on

Press MODE key for 2

seconds.

temperature data

storage

Status display

Press → key for 2

seconds.

Press ON/OFF key while

System programming

pressing MODE key to

turn the power supply on.

For changing screens, press MODE key.

Makers

appeared

"Set"

"Mem"

"Set"

executed.

standard measurement is

executed.

Return to measurement screen

Press MODE key on the low alarm

programming screen.

Press MODE key for 2 seconds.

(Enable from any screen)

Press → key for 2 seconds.

(Enable from any screen)

11.2.1. Measuring parameters programming/display items

Screen Display Programming range Default

Emissivity Emi. 0/10 to 1.99 1.00

Signal modulation mode Mod. Real, Peak, Valley, Delay Real

Signal modulation time constant T.C. 0.0 to99.9 seconds, HOLD 0.0 second

High alarm AlmH -50 to 1000 oC, OFF (IR-AHT)

600 to 3000

900 to 3000

Low alarm AlmL -50 to 1000 oC, OFF (IR-AHT)

600 to 3000

900 to 3000

o

C, OFF (IR-AHS)

o

C., OFF (IR-AHU)

o

C, OFF (IR-AHS)

o

C., OFF (IR-AHU)

OFF

OFF

11.2.2. Temperature data storage programming/display items

Screen Display Programming range Default

Storage mode MMOD OFF, Man, Int OFF

Interval time programming Int 00:00:01 to 02:00:00 00:01:00

Storage data display

Last storage data deletion LDDEL

All storage data deletion ADDEL

The interval time programming screen is only displayed when the storage mode is programmed to

“Int”.

- 23 -

Page 29

INST.No.INE-374-P5CE CE Marking

n

s

11. List of Starting Modes/Screens

11.2.3 Status display items

Screen Display

Inside temperature Dtemp

Model Model

Serial number SN

Measuring temperature range R

Measuring wavelength WL

11.2.4. System programming display items

Screen Display Programming range Default

Temperature unit Unit

Output scaling high limit *1 OH -50 to 1000 oC (IR-AHT)

Output scaling low limit *1 OL -50 to 1000 oC (IR-AHT)

o

C, oF

600 to 3000

900 to 3000

600 to 3000

900 to 3000

o

C (IR-AHS)

o

C (IR-AHU)

o

C (IR-AHS)

o

C (IR-AHU)

Zero/span calibration execution CMP

Calibration data programming at

zero side *2

Calibration data programming at

span side *2

Calibration operation execution

Zero -50 to 1000 oC (IR-AHT)

600 to 3000

900 to 3000

Span -50 to 1000 oC (IR-AHT)

600 to 3000

900 to 3000

o

C (IR-AHS)

o

C (IR-AHU)

o

C (IR-AHS)

o

C (IR-AHU)

CAL

*2

Calibration data recovery *2 Undo

o

C

o

C (IR-AHT)

1000

o

3000

C (IR-AHS)

o

3000

C (IR-AHU)

o

C (IR-AHT)

-50

o

600

C (IR-AHS)

o

900

C (IR-AHU)

o

C (IR-AHT)

-50

o

600

C (IR-AHS)

o

900

C (IR-AHU)

o

C (IR-AHT)

1000

o

3000

C (IR-AHS)

o

3000

C (IR-AHU)

*1: The output scaling high limit and output scaling low limit are only displayed on the

thermometers with analog output (option).

*2: The screens for the zero side calibration data programming, the span side calibration data

programming, the calibration operation execution and the calibration data recovery are only

displayed when you select “GO” on the zero/span calibration execution screen.

12. General Specificatio

12.1 External dimensions

135

60

- 24 -

175

Un it:mm

Page 30

INST.No.INE-374-P5CE CE Marking

n

s

12. General Specificatio

12.2 Specifications

Model IR-AHS IR-AHU IR-AHT

Measuring System Narrow band radiation thermometer

Detecting Element Si Thermopile

Measuring

Wavelength

Measuring Range 600 to 3000°C 900 to 3000°C -50 to 1000°C

Accuracy Ratings

Repeatability 1°C ± 1digit

0.96µm 0.65µm 8 to 13µm

Lower than 1500°C: ±0.5% of measured value ± 1digit

1500°C to 2000°C: ±1% of measured value ± 1digi0t

Higher than 2000°C: ±2% of measured value ± 1digit

(ε= 1.0, Reference operating condition: 23°C ± 5°C, 35 to 75%RH)

1) Temperature drift:0.015% of measured value / °C

Stability

Resolution 1°C 1°C (More than 50°C)

Response Time 0.5 second 1 second

Emissivity

Compensation

Signal Modulation

Display System LCD digit al 4 digi ts , Di spl ayed in the finder and on the panel board

Data

StorageFunction

Users’ Calibration

Function

Output Signal Digital transmission(RS-232C),Analog output(0 to 1V DC, option)with a cord

Communications

Function

Optical System Focusable lens type

Distance Factor

2) Stability: ±5°C under EMC test environment

=1.00 to 0.10 (0.01 increment)

ε

modulation : Real, Peak, Delay, and Valley .

modulation ratio:0 to 99 seconds, 1-sec increment

Peak hold, Valley hold, Hold with the measuring switch turned off.

Maximum 1000 data

Calibration at zero and span

RS-232C (The data logging software is sold separately.)

100(Measuring distance

L / Measuring diameter D)

250 (Measuring distance

L / Measuring diameter D)

Wide band radiation

thermometer

Lower than 200°C: ±2°C ±

1digit

High than 200°C: ±1% of

measured value ± 1digit

1) T emperature drift:

Lower than 300°C: 0.15°C/°C

300-700°C:0.05

Higher than 700°C: 0.025

2)Stability: ±15°C underEMC

Cassegrain focusable mirror

type

40 (Measuring distance

L / Measuring diameter D)

% of

measured value /°C

% of

measured value /°C

test environment

Measuring Distance L = 500mm to ∞ L = 700mm to ∞

Measuring

Diameter

Collimation Direct viewing finder

Lens Diameter Ø30mm Ø40mm

Other Functions

Ambient

Temperature

Power Supply AA (UM-3) battery, 4 pieces (about 20 hours for continuous measurement)

Casing Material

and Color

Outside Dimensions

and Weight

Attachment 4 pieces of AA (UM-3 battery), Adapter for tripod, Housing case

D = L / 100(ø, mm) D = L / 250(ø, mm) D = L / 40(ø, mm)

Auto-power-off, Continuous measurement, °C / °F selection, Battery check,

High / low alarms

0 to 50°C

ABS resin, Gray

W135 x H60 x D175mm, About 700g (thermometer only)

- 25 -

Page 31

INST.No.INE-374-P5CE CE Marking

13. Emissivity table

The emissivity are values determined by the material of object, profile of its surface, surface

roughness, oxidized or not, measuring temperature, measuring wavelength and other factors.

They are represented by the thermal radiation ratio "ε" when a black body furnace at the same

temperature is measured in the same wavelength band.

The emissivity "ε" is generally known by a value at the wavelength of 0.65µm when an optical

pyrometer is used. The emissivity changes according to the above factors even in case of the same

material. Please use the following table as a reference.

13.1 Emissivity table (λ= 0.65µm)

Metal

Zinc 0.42

Alumel 0.37

Aluminum 0.17 0.12

Antimony 0.32

Iridium 0.30

Yttrium 0.35 0.35

Uranium 0.54 0.34

Gold 0.14 0.22

Silver 0.07 0.07

Chromium 0.34 0.39

Chromel P 0.35

Cobalt 0.36 0.37 Yttrium oxide 0.60

Constantan 0.35 ― Uranium oxide 0.30

Zirconium 0.32 0.30 Cobalt oxide 0.75

Mercury

Tin 0.18

Carbon 0.8 to 0.9

Tungsten 0.43

Tantalum 0.49

Cast iron 0.37 0.40 Iron oxide 0.63 to 0.98

Titanium 0.63 0.65 Copper oxide 0.60 to 0.80

Iron 0.35 0.37 Thorium oxide 0.20 to 0.57

Copper 0.10 0.15 Vanadium oxide 0.70

Thorium 0.54 0.34 Beryllium oxide 0.07 to 0.37

Nickel 0.36 0.37 Magnesium oxide 0.10 to 0.43

80Ni /20Cr 0.35

60Ni / 024Fe / 16Cr 0.36

Platinum 0.30 0.38

90Pt / 10Rh 0.27

Palladium 0.33 0.38

Vanadium 0.35 0.35

Bismuth 0.29

Beryllium 0.61 0.61

Manganese 0.59 0.59

Molybdenum 0.37 0.40

Rhodium 0.24 0.30

Emissivity

Solid Liquid

― Alumel(*)

― Chromel(*)

―

― Cast iron(*)

―

―

0.23 Columbium oxide 0.55 to 0.71

―

―

―

―

―

―

―

―

Oxide Emissivity

0.87

0.87

Constantan(*)

Ceramics 0.25 to 0.5

55Fe. 37.5Cr. 7.5Al(*)

70Fe. 23Cr. 5Al. 2Co(*)

80Ni. 20Cr(*)

60Ni. 24Fe. 16Cr(*)

Stainless steel(*)

Aluminum oxide 0.22 to 0.4

Zirconium oxide 0.18 to 0.43

Tin oxide 0.32 to 0.60

Cerium oxide 0.58 to 0.82

Titanium oxide 0.50

(*) : Oxidized on surfaces

0.84

0.70

0.78

0.75

0.90

0.83

0.85

- 26 -

Page 32

INST.No.INE-374-P5CE CE Marking

13. Emissivity table

13.2 Emissivity table (λ= 0.9µm)

Metal Emissivity

Aluminum 0.10 to 0.23

Gold 0.015 to 0.02

Chrome 0.36

Cobalt 0.28 to 0.30

Iron 0.33 to 0.36

Copper 0.03 to 0.06

Tungsten 0.38 to 0.42

Titanium 0.50 to 0.62

Nickel 0.26 to 0.35

Platinum 0.25 to 0.30

Molybdenum 0.28to 0.36

Alloy Emissivity

Inconel X 0.40 to 0.60

Inconel 600 0.28

Inconel 617 0.29

Inconel 0.85 to 0.93

Incoloy 800 0.29

Kanthal 0.80 to 0.90

Stainless steel 0.30

Hastelloy X 0.3

Semi conductor Emissivity

Silicon 0.69 to 0.71

Germanium 0.60

Gallium arsenic 0.68

Ceramics Emissivity

Silicon carbide 0.80 to 0.83

Titanium carbide 0.47 to 0.50

Silicon nitride 0.89 to 0.90

Other Emissivity

Carbon pigment 0.90 to 0.95

Graphite 0.87 to 0.92

13.3 Emissivity table (λ= 1.55µm)

Metal Emissivity

Aluminum 0.09 to 0.40

Chrome 0.34 to 0.80

Cobalt 0.28 to 0.65

Copper 0.05 to 0.80

Gold 0.02

Steel plate 0.30 to 0.85

Lead 0.28 to 0.65

Magnesium 0.24 to 0.75

Molybdenum 0.25 to 0.80

Nickel 0.25 to 0.85

Palladium 0.23

Platinum 0.22

Rhodium 0.18

Silver 0.04 to 0.10

Tantalum 0.20 to 0.80

Tin 0.28 to 0.60

Titanium 0.50 to 0.80

Tungsten 0.30

Zinc 0.32 to 0.55

Alloy Emissivity

Brass 0.18 to 0.70

Chromel, Alumel 0.30 to 0.80

Constantan, Manganin 0.22 to 0.60

Inconel 0.30 to 0.85

Monel 0.22 to 0.70

Nickel Chrome 0.28 to 0.85

Ceramics Emissivity

Alumina ceramics 0.30

Red brick 0.80

White brick 0.35

Silicon brick 0.60

Sillimanite brick 0.60

Ceramics 0.50

Other Emissivity

Asbestos 0.90

Asphalt 0.85

Carbon 0.85

Graphite 0.80

Soot 0.95

Cement, Concrete 0.70

Cloth 0.80

- 27 -

Page 33

32-8, KUMANO-CHO, ITABASHI-KU, TOKYO 173-8632

Telephone: +81-3-3956-2171

Facsimile: +81-3-3956-0915

Web site http://www.chino.co.jp/

INE-374-P5CE Aug-'03 IR-AH□□Series PORTABLE DIGITAL RADIATION THERMOMETER Printed in Japan ( Kuki )

Loading...

Loading...