Page 1

INST.No. INE-866

R

EH3000 series

(DOT-PRINTING TYPE/PEN TYPE)

180 mm ANALOG RECORDE

Instruction Manual

Page 2

Page 3

-CONTENTS-

❐INTRODUCTION / REQUESTS /

WARRANTY / NOTICES ······································· 1

FOR SAFE USE ··············································· 2

WARNING ························································ 3

❐MAIN FEATURES AND FUNCTIONS ·········· 4

1. BEFORE USE ··················································· 5

1.1 Model Check and Information ························· 5

1.2 Attachments and Consumable Parts ············· 8

1.3 Flow Chart to Startup ······································ 10

2. INSTALLATION ··············································· 11

2.1. Mounting Place ·············································· 11

2.2 External Dimensions ······································ 12

2.3 Mounting Method on Panel ····················· 13

2.4 Release of Shipping Status ····················· 14

3. FRONT ····························································· 16

3.1 Names of Front Portions ·························· 16

3.2 Display Operation Part ····························· 17

4. CONNECTIONS ············································· 19

4.1 Terminal Board ·········································· 19

4.2 Cautions on Connection ·························· 20

4.3 Power Supply & Protective Conductor

Terminals

4.4 Measuring Input Terminals ······················ 22

4.5 Alarm Output Terminals (Optional) ········· 26

5. LOADING ························································· 28

5.1 Inkpad Loading (For dot-printing type) ··· 28

5.2 Cartridge Pen Loading (For pen type) ······ 31

5.3 Chart Loading ············································ 34

6. OPERATION/SETTING ································· 37

6.1 Turning Power On/Off ···································· 37

6.2 Operation/Setting Change ····························· 40

6.3 Chart Feed Operation ······························ 44

··················································· 21

6.4 Recording Operation (AUTO CH/

INDICATE Switch) ·········································· 45

6.5 Pen Marker (Only for 2/3 pen type) ········· 47

6.6 Chart Speed Change ····································· 48

6.7 Alarm Specifications ······································· 50

6.8 Alarm Setting ··················································· 51

6.9 Operation/Setting Function Depending on

Application

················································· 58

7. OPERATION ···················································· 60

7.1 Recording Operation (Pen type) ··················· 60

7.2 Alarm Activation/Reset and Behavior ··········· 61

7.3 Behavior on Abnormal Input ·························· 63

8. OPTION ···························································· 64

8.1 Shunt Resistor for Current Input ·············· 64

8.2 Dotting Interval 3 Seconds (Dot-printing

type option) ······················································ 65

9. ADJUSTMENT ················································ 66

9.1 User Indication Adjustment/Indication

Check

························································· 66

9.2 Shift Programming ·········································· 75

10. MAINTENANCE ············································ 80

10.1 Routine Inspection ·································· 80

10.2 Troubleshooting ······································ 83

1

0.3 Recommended Parts Replacement

Intervals

······················································ 85

11. SPECIFICATIONS ········································ 86

11.1 Detailed Specifications ································· 86

11.2 Option Specifications ···································· 88

11.3 Accuracy Rating List ····································· 89

12. DISPOSAL ····················································· 91

The items marked with

in titles contain

Warning

Caution

Read these items without fail.

.

and

Page 4

❐INTRODUCTION / REQUESTS / WARRANTY / NOTICES

Thank you for your purchase of EH3000 Series Analog Recorder (Dot-printing

type/Pen type) with 180 mm recording width.

Make sure to read this instruction manual in advance to understand this

product well and prevent troubles from occurring.

Important Notice

1. To the persons doing instrumentation, installation, and sales

Make sure to provide this instruction manual to the person who uses this product.

2. To the users of this product

Store this instruction manual with care until you scrap this product.

Also, write down the parameter contents set in the product and keep it for your record.

This product is warranted for one year from the date of delivery. If it is damaged during the warranty period,

when used normally based on the cautions in the instruction manual and labels attached to the product, etc., it

will be repaired without any charge (only in Japan). In the case, we are sorry to trouble you, but please contact

your dealer or nearest our sales office.

However, in cases of the followings, it will be repaired at your expense even during warranty period.

1. Failure or damage caused by improper use or connection, or invalid repair or modification.

2. Failure or damage caused by fire, earthquake, wind or flood, thunderbolt, or other extraordinary natural

phenomena, or pollution, salt, harmful gas, abnormal voltage, or use of unspecified power.

3. Replacement of parts or accessories that have reached the end of their life.

Furthermore, the term ‘warranty’ in this sense covers only a CHINO’s product itself. Therefore, we are not

responsible for compensation for whatever the damage that is triggered by failure of our product.

1. No part of this manual can be reproduced or copied in any form without permission.

2. The contents of this manual may be altered without prior notice.

3. This manual has been documented by making assurance doubly sure. However, if any question arises or if any

error, an omission, or other deficiencies are found, please contact your nearest our sales office.

4. CHINO is not responsible for any operation results of this software.

Product warranty scope

Notices

-1-

Page 5

FOR SAFE USE

For correct use of this product, please be sure to read and understand the following cautions.

(1) Preconditions for Use

This product is a general electronic device (measuring instrument) to be used mounted on an indoor instrumentation panel (except for

portable type). Avoid using under other conditions.

Use after the system safety is implemented such as the fail-safe design and periodical inspection on the final product side. Also, for

wiring/adjustment/operation of the product, ask professionals with instrumentation knowledge to perform.

Furthermore, also the person who actually uses the product is required to read this instruction manual to fully understand various

cautions and basic operation.

(2) Labels Employed

For safe use of the unit, the following labels are used.

Label

Name Meaning

(3) Symbols in This Instruction Manual

The cautions to be observed for preventing damages and unexpected accidents are identified by the following symbols according to

their importance degrees to use this product safely.

Symbol Range of cautions

Alert symbol mark Place to be handled with cautions to avoid “electric shock”, “injuries”, etc.

Protective conductor terminal

Caution for high temperature Place to be handled with cautions to avoid “burns”.

This symbol is indicated at the titles (items) where

explained. Make sure to read these explanations.

Cautions are explained to avoid causes for death or serious injuries of users.

Cautions are explained to avoid causes for slight injuries of users or damages of this product or peripheral

devices.

To avoid “electric shock” make sure to connect (ground) protective

conductor of a power supply.

or is

This symbol indicates cautions when this product does not function as specified or when such a possibility

exists.

This reference serves as a supplement for handling (operation) and it is convenient for using.

(4) Request

1. Do not drop the product while taking it out of the box

2. When transporting the unit, pack in the dedicated package box, and put the box in an outer case with a bed of cushion. With the

consideration to the case above, it is recommended that the dedicated package box for the unit is stored.

3. When the unit is removed from the panel and not used for a long time, put it in the dedicated package box, and store it in a place with

normal ambient temperature and less dust.

-2-

Page 6

To avoid severe accidents, make sure to read and understand the following.

(1) Switch and Overcurrent Protective Device

This product is not provided with a replaceable overcurrent

protective device. Prepare an overcurrent protective device

[dot-printing type: 250, 2.5A/pen type: 250V, 3.15A] for the power

supply (circuit breakers, circuit protectors or the like) within 3m of

this unit in a location where the operator can access easily. Use a

switch and an overcurrent protective device conforming to

IEC60947-1 and IEC60947-3. Install a power switch to exterior if

necessary.

(2) Be Sure to Ground

To avoid electric shock, before turning the power on, connect the

protective conductor terminal of this product to the protective

conductor of the power supply equipment, and do not remove it

during use.

(3) Before Turning On the Power First

Make sure that the power voltage is within the range indicated on

the power label and grounding is done etc. before turning on the

power switch.

(4) Protection of the Terminals

For the terminals of this product, to avoid electric shock, install a

safety device so that user of this product will not touch the terminals

directly.

(5) Installing the safety device

Regarding the use of this product that anticipates a big loss due to

failure of the controller and the peripheral device, always install a

safety device for preventing these losses and implement fail safe

design in the final product.

Do not use it in important in facilities like, human life, atomic energy,

aviation and space.

(6) Do Not Put Hands in this Product

Do not put your hands or tools inside of this product. It may cause

electric shock or injuries.

There is no operation such as pulling out an inner unit or using

tools when using this product.

(7) Turn off the power supply if abnormality occurs

Turn off the power supply immediately and contact your local

CHINO’s sales office if any abnormal odor, noise or any smoke

occurs, or if this unit becomes high temperature that is too hot to

touch.

WARNING

Overcurrent

protective

device

[12 points] Specification example

(8) No Repair or No Modification

If repair or modification is necessary, contact your dealer or nearest

CHINO’s sales agent. Persons other than service engineers

authorized by our company must not repair or modify this product

with replacing parts.

(9) Use the unit following the instruction manual

For safe use, use the unit following the instruction manual. Please

note that CHINO does not have any responsibilities for any claims

for failures or damages occurred with abuse or misuse of this

recorder.

L N

Switch

Power label

Power supply/protective

conductor terminals

To protective

conductor of power

source facility

Power source

Power terminals

Protective conductor

terminal

-3-

Page 7

❐MAIN FEATURES AND FUNCTIONS

This product is intended to record the industrial quantities such as temperature, etc. on 180 mm-width chart paper. For the dot-printing

type, up to 12-channel recording and for pen type, up to 3-channel continuous recording is available.

(1) Features

Main features are as follows:

• Recording operation can be started without operations for setting or others depending on specified input conditions.

• Standard input type can be specified among 31 types (18 types for thermocouple, 6 types for DC voltage, and 7 types for resistance

thermometer).

The input type and scale width can be specified from 10 ranges of DC voltage, 26 ranges of thermocouple, and 6 ranges of

resistance thermometer other than standard input types.

• Universal power supply input is available. The measuring power voltage range is 100 to 240 VAC and 50 Hz/60 Hz.

• Any operations can be executed at the front. For inkpad replacement of the dot-printing type, pull out the inner unit to the position of

the middle stopper (it cannot be pulled out after the middle stopper position) then perform the replacement. For cartridge pen

replacement of the pen type, pulling out the inner unit is unnecessary.

(2) Functions

Main functions are as follows:

Display/operation related Instruction/recording related

Dot-printing

type

Pen type

Note 1: Setting of alarm values is required. The alarm output is available only by adding the option of “Alarm output”.

• Indication/recording operation and stop

• Chart speed selection switching

• Lighting of alarm lamp on the front on alarm

activation (Note 1)

• Chart paper lighting (standard provision and

dimming enabled)

• Function of indication adjustment at user area

(ZERO/SPAN adjustment and shift programming)

• Trend recording of 1 to 12 channels by dotter

• Mode for specified channels to be indicated continuously

without recording

• Continuous trend recording by the cartridge pen

• Individual indication/recording operation and switch of stop

by each pens

• Manual pen up lever for all pens correctively

(pen up is available when not recording)

-4-

Page 8

1. BEFORE USE

2

8

1.1 Model Check and Information

After unpacking of this product, make sure to confirm the following before usage. If you have any questions, contact your nearest

CHINO’s sales agent.

Checking item Checking contents Reference

1. Appearance The product has no damage in the appearance.

2. Model code The model code of the product that you purchased is correct. Para. 1.1

There is no shortage of the attachments.

Attachments may be provided separately depending on

3. Attachments

purchased options.

* For current input specification, shunt resisters that are same

numbers of input points are attached.

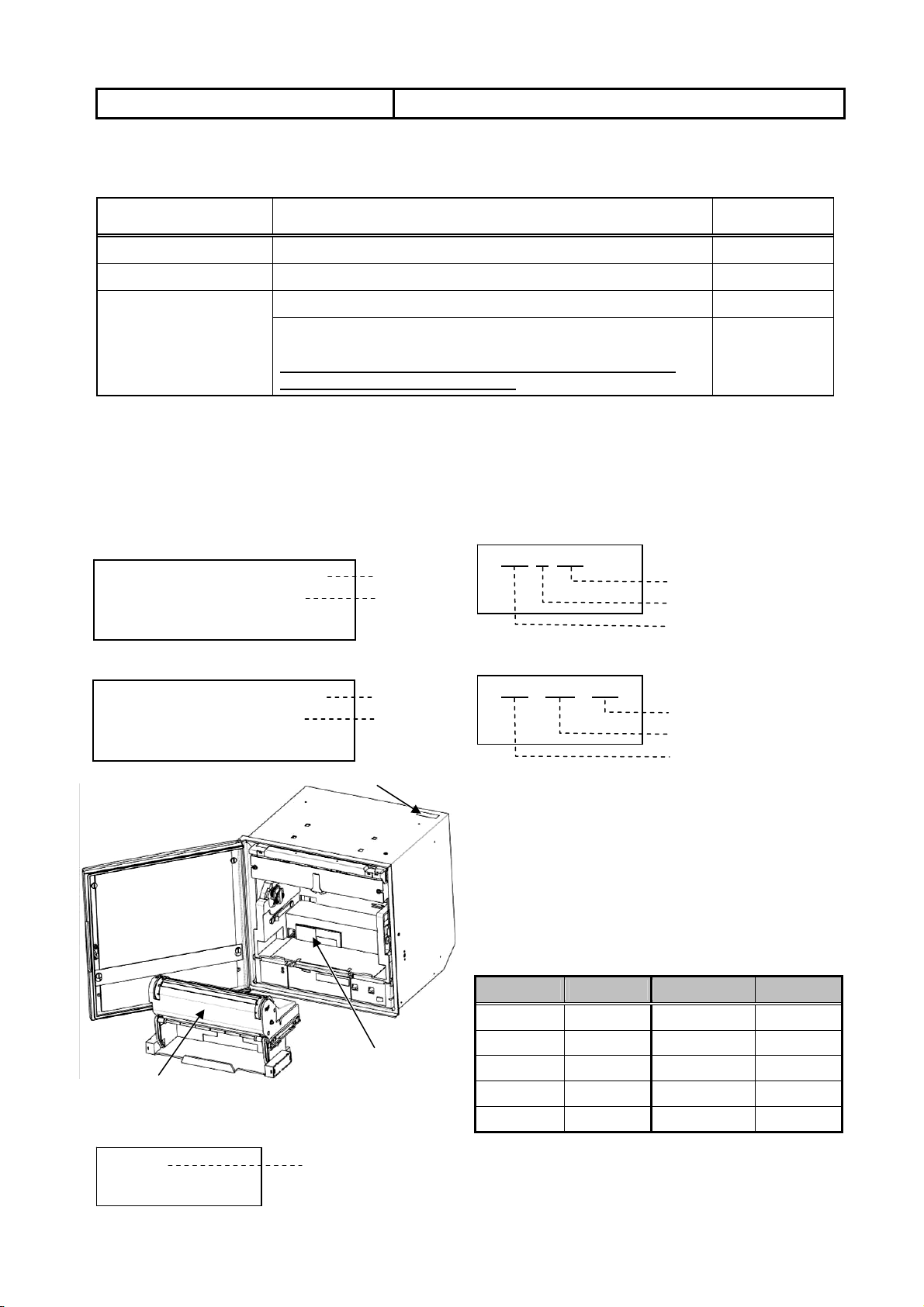

(1) Model Check

Labels indicating model are placed on the upper face of the case

(label 1) and the back of the inner unit which appears when a chart

cassette is pulled out (label 2).

(Refer to 5.2 Chart Loading (1) Drawing out Chart Cassette)

Example of label indication for dot-printing type

Example of label indication for pen type

The Label 2 consists of a label to indicate the model and a label to

indicate input specifications.

K4

EH3D65-000

EN103A001

MADE IN JAPAN

EH3G000-00

FN10XA001

MADE IN JAPAN

Chart cassette

Input code

Model

Serial No.

Model

Serial No.

Label 1

Label 2

Para. 1.

Para.

Input codes include particular codes for the factory administration

(Refer to 11.3 Accuracy Rating List. (1) Standard Input).

Non-standard input may be indicated with “XX”.

Indication example for dot-printing type, dual scale

K6 5 V6

Indication example for pen type (three pen specification)

K6- KC- V6

*The column other than input codes is blanked out.

2nd input code

2nd input starting channel

1st input code

3rd pen input code

2nd pen input code

1st pen input code

(2) Information

1) Chart Paper Attached

The chart paper No. EH01001 (0 to 100) is attached for operation.

For standard input specification, specified chart paper is available.

(Refer to 11.3 Accuracy Rating List (1) Standard Input Chart No)

Example for chart paper corresponding to various scales is shown

below:

Scale Chart No. Scale Chart No.

0 to 100°C EH05001 0 to 400°C EH05040

0 to 150°C EH05044 0 to 600°C EH05038

0 to 200°C EH05043 0 to 800°C EH05037

0 to 250°C EH05042 0 to 1000°C EH05036

0 to 300°C EH05041 0 to 1200°C EH05035

The scales are linear-equal divisions. They are usable irrespective

of the types of thermocouples and resistance thermometers.

For other chart papers, contact your nearest CHINO’s agent.

-5-

Page 9

1. BEFORE USE

1.1 Model Check and Information

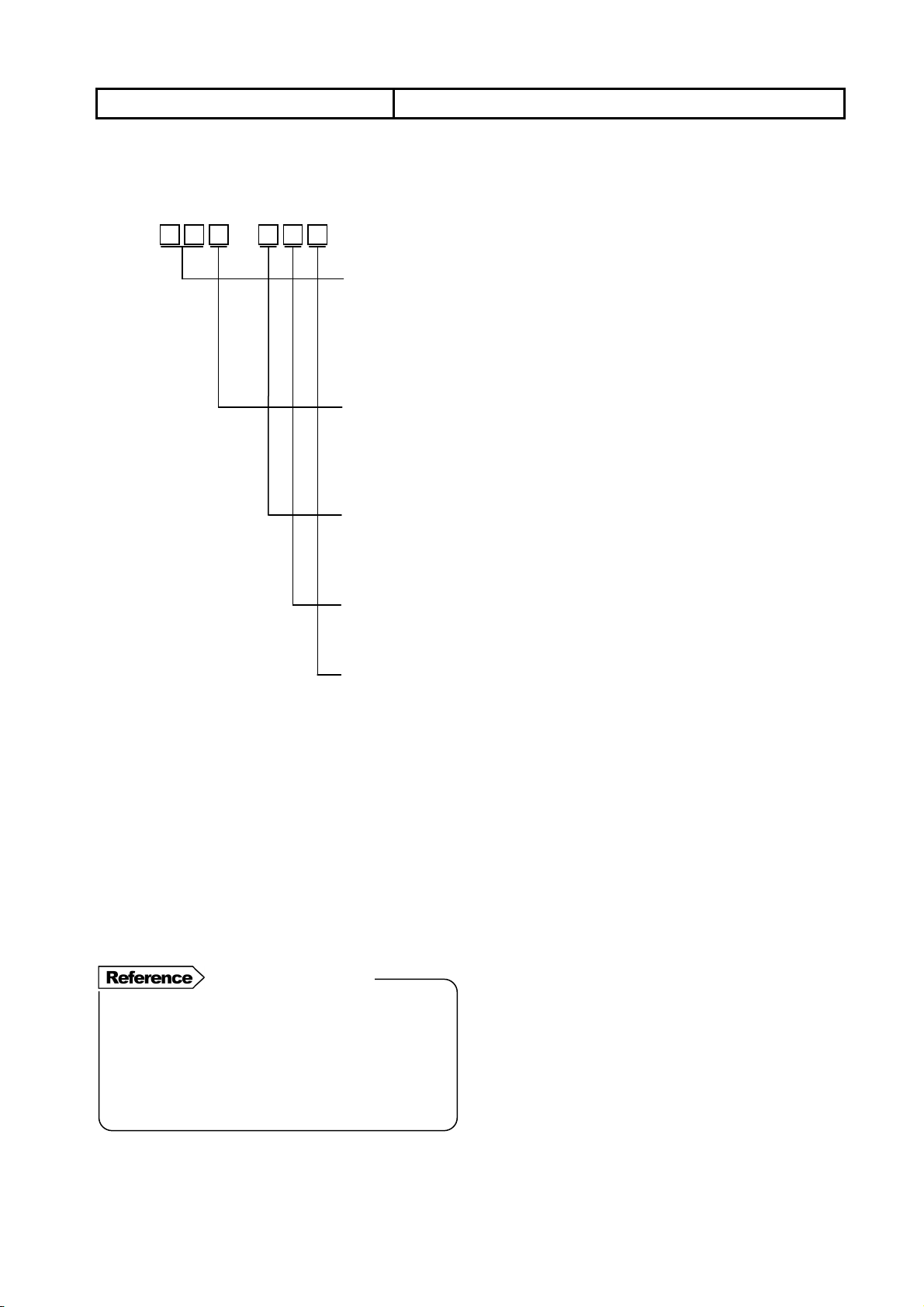

Models

[Dot-printing type]

EH3 —

Number of input points

D1: 1 point

D2: 2 points

D3: 3 points

D6: 6 points

12: 12 points

Input type

5: Thermocouple/DC voltage input

7: Resistance thermometer input

Thermocouple with burnout (optional) *1

DC voltage with built-in voltage divider input (optional) *1

Input and scale plate

0: Standard input + standard scale plate

1: Non-standard input (including current input and built-in voltage divider input)

Non-standard scale plate (optional) *2

Alarm output

0: None

2: Alarm output 2 points (optional))

Chart speed and burnout (optional) *3

0: Standard 6-speed/no specification of burnout

1: Standard 6-speed/Up-scale burnout (optional)

2: Standard 6-speed/Down-scale burnout (optional)

A: 5-speed with hour/minute changeover/no specification of burnout (optional)

B: 5-speed with hour/minute changeover/Up-scale burnout (optional)

C: 5-speed with hour/minute changeover/Down-scale burnout (optional)

*1: The options of built-in voltage divider and burnout for thermocouples/resistance thermometers are only available in the input type “7”.

*2: Up to triple scale is available.

For non-standard inputs and non-standard scale plates, specify an input type and scale.

*3: The burnout is specified for all input points together for thermocouple/resistance thermometer inputs.

The input type and scale plate are fixed with specified

specifications. They cannot be changed.

The contents of types described in the definition (“5” and “7”)

for input types are used for identification control in

manufacturing. Setting change and switching in the types are

disabled.

Input Type and Scale Plate

-6-

Page 10

1. BEFORE USE

1.1 Model Check and Information

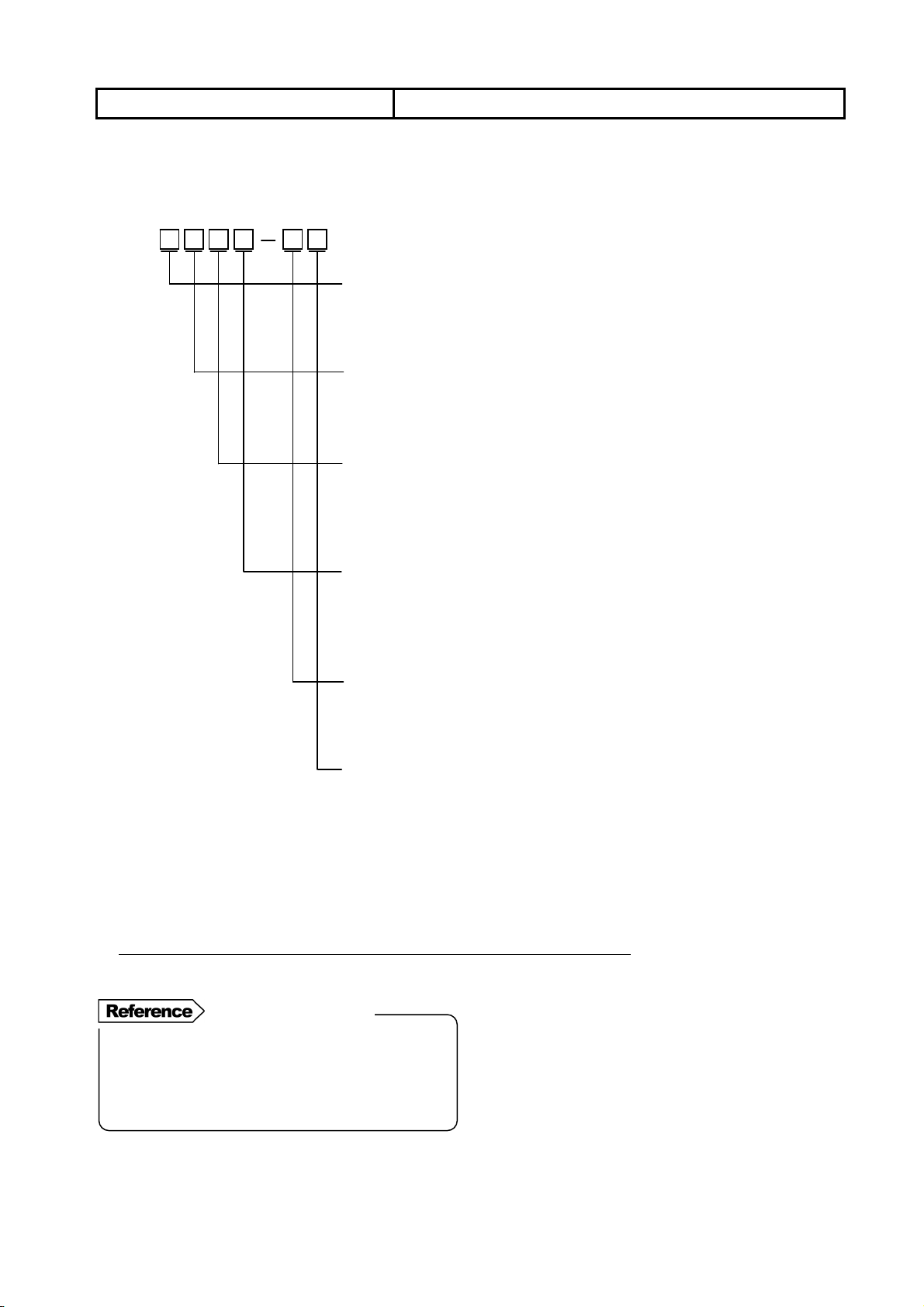

Models

[Pen type]

EH3

Number of input points

P: 1 pen

F: 2 pen

G: 3 pen

1st pen input and scale plate

0: Standard input + standard scale plate

1: Non-standard input (including current input and built-in voltage divider input)

Non-standard scale plate (optional) *1

2

nd pen input and scale plate

N: None (for 1 pen specification)

0: Standard input + standard scale plate

1: Non-standard input (including current input and built-in voltage divider input)

Non-standard scale plate (optional) *1

3 rd pen input and scale plate

N: None (for 1/2 pen specification)

0: Standard input + standard scale plate

1: Non-standard input (including current input and built-in voltage divider input)

Non-standard scale plate (optional) *1

Alarm output

0: None

2: Alarm output 2/4/6 points (optional)

(1 pen type: 2 output, 2 pen type: 4 output, 3 pen type: 6 output )

Chart speed and burnout (optional) *2

0: Standard 6-speed/no specification of burnout

1: Standard 6-speed/Up-scale burnout (optional)

2: Standard 6-speed/Down-scale burnout (optional)

A: 5-speed with hour/minute changeover/no specification of burnout (optional)

B: 5-speed with hour/minute changeover/Up-scale burnout (optional)

C: 5-speed with hour/minute changeover/Down-scale burnout (optional)

*1: For non-standard inputs and non-standard scale plates, specify an input type and scale.

If including the thermocouple input, make sure to specify the thermocouple input to the 1 st pen.

*2: The burnout is specified for all input points together for thermocouple/resistance thermometer inputs.

Input Type and Scale Plate

The input type and scale plate are fixed with specified

specifications. Specifications distinguished by models can not

be changed afterward.

Also change of input type and switching in input are disabled.

-7-

Page 11

1. BEFORE USE

1.2 Attachments and Consumable Parts

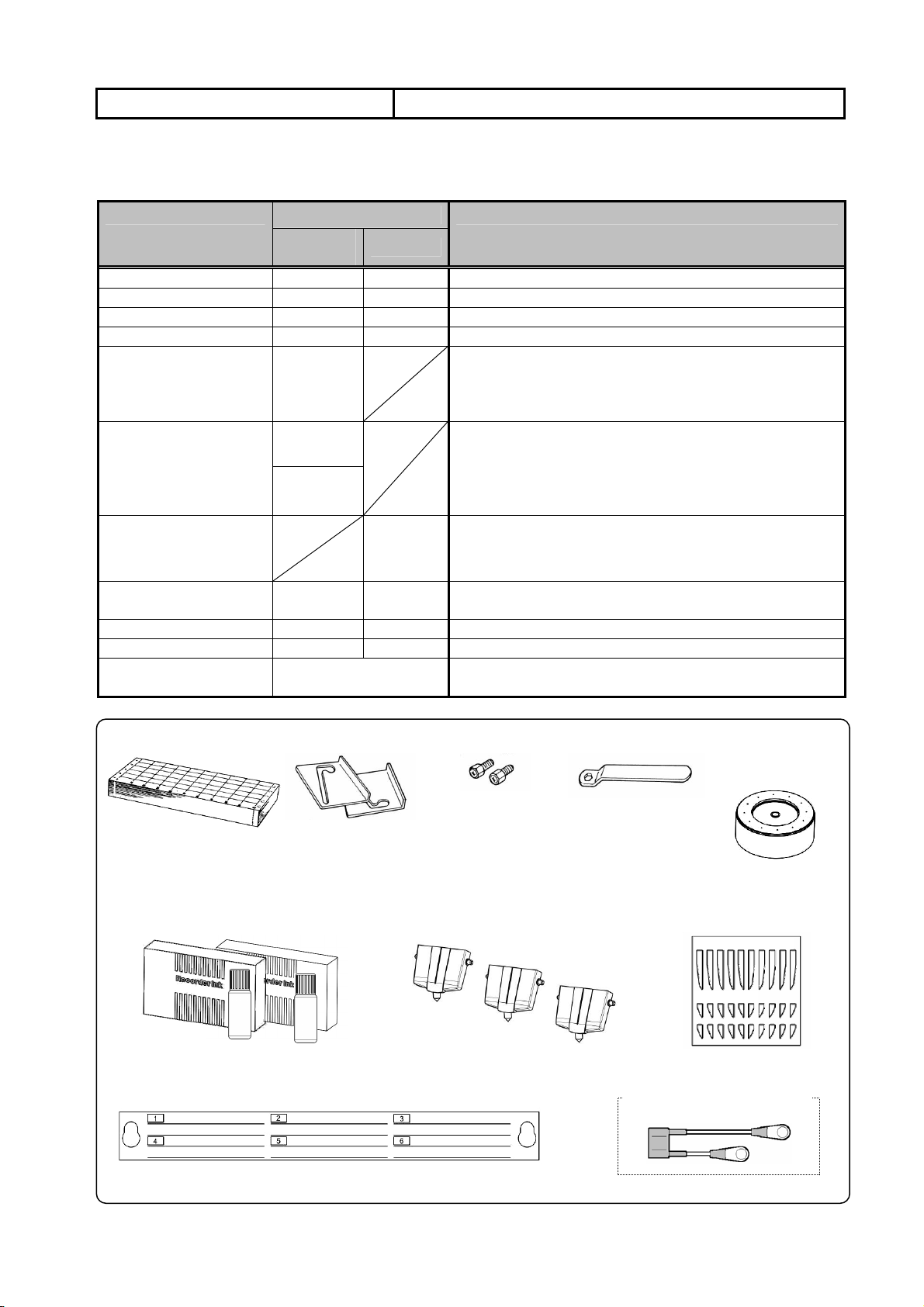

(1) Checking Attachments

The following attachments are contained. Check them.

Quantity

Part name

1. Chart paper 1 pad 1 pad Chart No. EH-01001: 0 to 100 (100 sections), no unit

2. Mounting bracket 2 pieces 2 pieces For mounting on a panel

3. Fixing screw 2 pieces 2 pieces For mounting brackets for panel mounting

4. Screw wrench 1 piece 1 piece For tightening fixing screws

5. Inkpad 1 piece

6. Supplementary ink

7. Cartridge pen

8. Channel indicating card 1 sheet 1 sheet

9. Alarm index seal 1 sheet 1 sheet When alarms are set, paste the seals on a scale plate for their indexes.

10. Instruction manual 1 book 1 book A4 book

* Shunt resister for current

input

1. Chart paper

* For current input specification, shunt resisters which are same numbers of input points are attached (refer to 8.1).

6. Supplementary ink

8. Channel indicating card (Example for 6 points)

Dot-printing

type

1 box

(1 to 6 points)

2 boxes

(12 points)

Number of current input point Shunt resister for current input.

2. Mounting bracket

Pen type

2 pieces for

each colors

Colors specified inkpad

(pull out the inner unit to the position of the middle stopper to perform

replacement)

Filled ink types depend on the specified number of input points.

Supplementary ink for inkpads

Ink which meets the specified input points attached.

7. Cartridge pen (for pen type)

1 point: 1 color x 6 pieces, 2 points: 2 colors x 3 pieces, 3 points: 3

colors x 2 pieces

6 points: 6 colors x 1 piece, 12 points: 12 colors x 1 piece

1 pen specification: 1st pen: red

2 pen specification: 1st pen: red, 2nd pen: green

3 pen specification: 1st pen: red, 2nd pen: green, 3rd pen: blue

Inserted inside the door

(Cards for 3 points/3 pen, 6 points, 12 points are available.)

3. Fixing screw

1st pen

2nd pen

3rd pen

Remarks

4. Screw wrench

*Shunt resister for current input

5. Inkpad

(for dot-printing type)

9. Alarm index seal

For dot-printing type/1 pen

For 2 pen/3pen

-8-

Page 12

1. BEFORE USE

1.2 Attachments and Consumable Parts

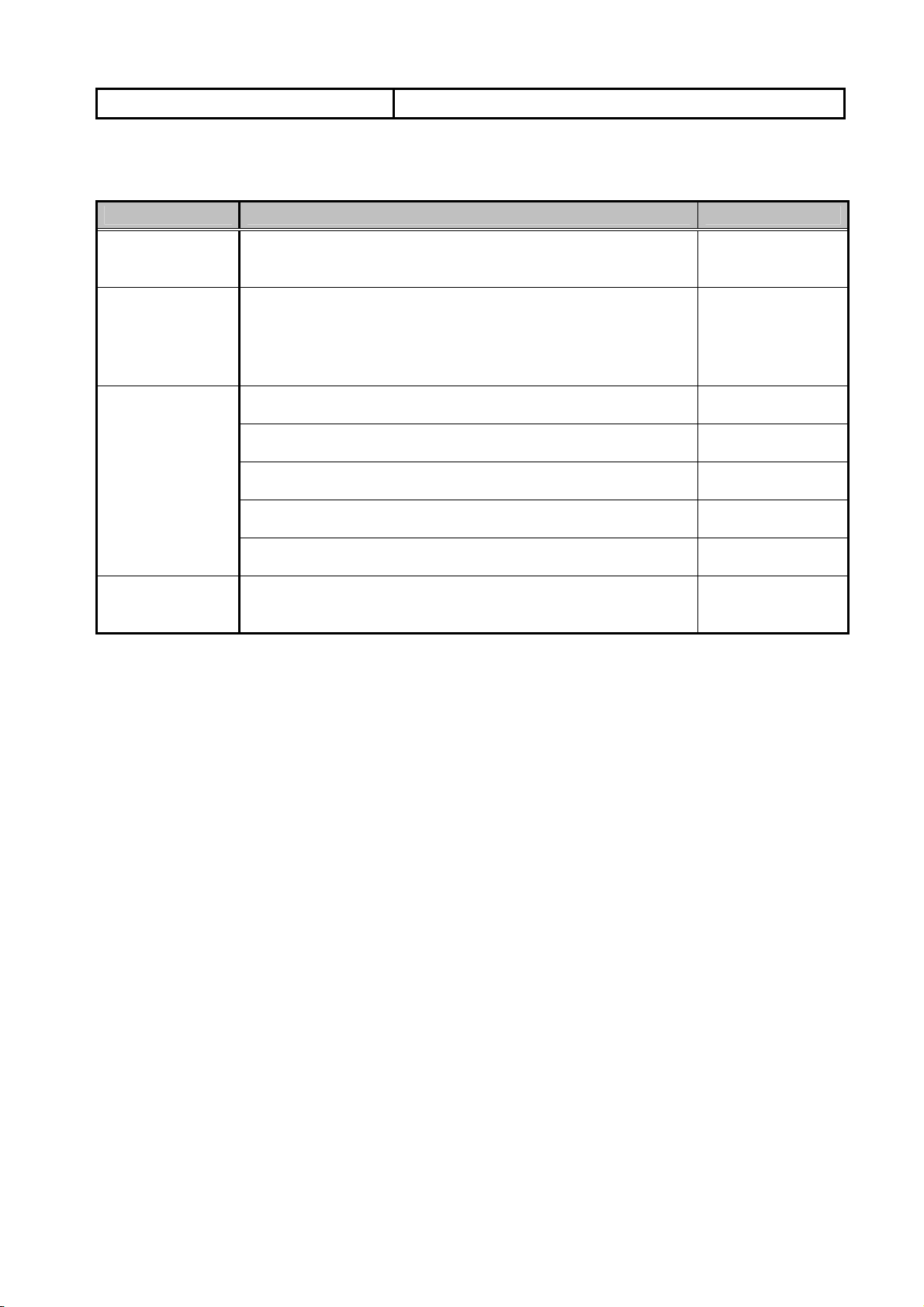

(2) Order of Consumable Parts

Chart papers and inkpads are consumable parts. For ordering these parts, refer to the following table.

Name Article name/specification for ordering Min.qty

Chart No. (Ex: EH01001)

Chart paper

Inkpad

Supplementary ink

Cartridge pen

For standard scale specification, refer to 11.3 Accuracy Rating List. (1) Standard

Input/Chart No.,

1-color inkpad (for 1 point): Stock No. 81-0230

2-color inkpad (for 2 points): Stock No. 81-0241

3-color inkpad (for 3 points): Stock No. 81-0252

6-color inkpad (for 6 points): Stock No. 81-0263

12-color inkpad (for 12 points): Stock No. 81-0274

1-color ink (for 1 point): Stock No. 83-0007

2-color ink (for 2 points): Stock No. 83-0166

3-color ink (for 3 points): Stock No. 83-0177

6-color ink (for 6 points): Stock No. 83-0133

12-color ink (for 12 points): Stock No. 83-0155

For 1st pen: Stock No. 82-0118

For 2nd pen: Stock No. 82-0129

For 3rd pen: Stock No.81-0130

1 box

(15 pads)

1 piece

1 box

(6 pieces)

1 box

(3 pieces/color)

1 box

(2 pieces/color)

1 box

(1 piece/color)

6-color x 2 boxes

(1 piece/color)

1 bag

(5 pieces)

-9-

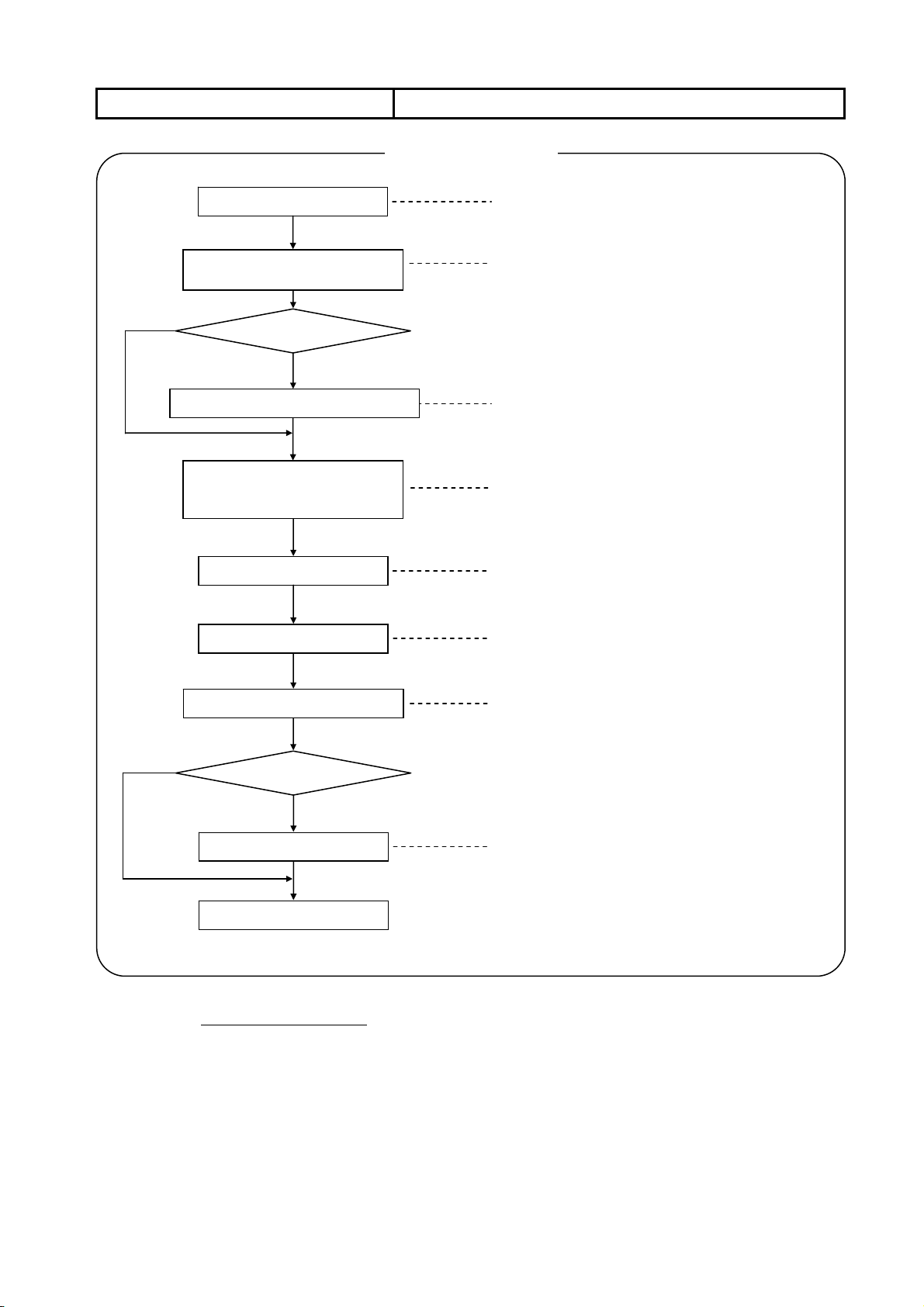

Page 13

1. BEFORE USE

* The above is a simple flow chart to startup. Refer to each paragraph for details for actual work.

NO

Connection to alarm output terminals

NO

Panel mounting

Connection to power and

input terminals

Alarm output?

YES

Inkpad loading

Cartridge pen loading

Chart paper loading

Power ON

Chart speed change

Alarm setting?

YES

Alarm setting

Completed

1.3 Flow Chart to Startup

Flow Chart to Startup

Reference: 2.3 Mounting Method on Panel

Reference: 4.3 Power Supply & Protective

Conductor Terminals

Reference: 4.4 Measuring Input Terminals

Reference: 4.5 Alarm Output Terminals

Reference: 5.1 Inkpads Loading

Reference: 5.2 Cartridge Pen Loading

Reference: 5.3 Chart Paper Loading

Reference: 6.1 Turning Power On/Off

Reference: 6.6 Chart Speed Change

Reference: 6.8 Alarm Setting

-10-

Page 14

2. INSTALLATION

Place this instrument in the following place not to affect the measuring accuracy and recording operation adversely.

2.1. Mounting Place

(1) Industrial Environment

Select a place being separated from electric field and magnetic field generation sources and also free of mechanical vibrations and

shocks.

• Overvoltage category II (EN standard)

• Pollution degree 2 (EN standard)

• Altitude 2000 m or less

• Working place Indoors

(2) Environmental Temperature and Humidity

Avoid exposing this instrument to the direct sunlight, and avoid sealing around it to prevent temperature rise.

• It is desired to place it in where the ambient temperature is stable at about 23 °C and the humidity is stable at about 50 % RH.

• Place it in where free of being exposed to hot blast (70 °C or higher) and not exceeding the condition of ambient temperature (0 to

50 °C) for preventing failure and deformation of it.

• Place it in where being free of a heat source near its terminals and out of the wind for reducing measuring errors.

(3) Atmosphere

• Avoid using this instrument in an inflammable gas atmosphere for safety.

• Avoid using this instrument in any place where dust, smoke, vapor, and other substance exist.

• Substance example: Organic gas, Inorganic substances such as hydrogen sulfide and ammonia gas, and Low-molecular

siloxane

Mechanical relay is used for input switching of this product, and it may cause contact point failure with the above substances.

Many silicone-related materials include low-molecular siloxane; therefore, attention is necessary under the environment where

a lot of silicone-related adhesion bond, coating materials, and others are used. The low-molecular siloxane included in

adhesion bond and coating materials strips in the air for a certain period even during and after hardening.

If you are worried about impact of these substances, contact your nearest CHINO’s sales agent.

After the instrument is exposed in the atmosphere with even slight sulfur components for a long time period in the state of

power switch off, it may not be powered on even the power switch is turned on. This symptom occurs because sulfidizing film

generated on the connection surface of the power switch causes contact failure. If the power switch is turned on and off

several times, the generated sulfidizing film breaks and the instrument recovers.

However, if it is exposed in the atmosphere of sulfur components for a long time period, electronic parts other than the power

switch are affected and cause failures. Avoid using it in the atmosphere of even slight sulfur components.

Substances which Affect Instrument

Impact of Sulfurization by Sulfur Atmosphere

(4) Mounting Angle

• Lateral tilting: 0 to 10 degrees

• Longitudinal tilting: Forward tilting: 0 degrees

Backward tilting: 0 to 30 degrees

A mounting angle other than the specification above may affect

recording performance.

30 degrees or less

-11-

Page 15

2. INSTALLATION

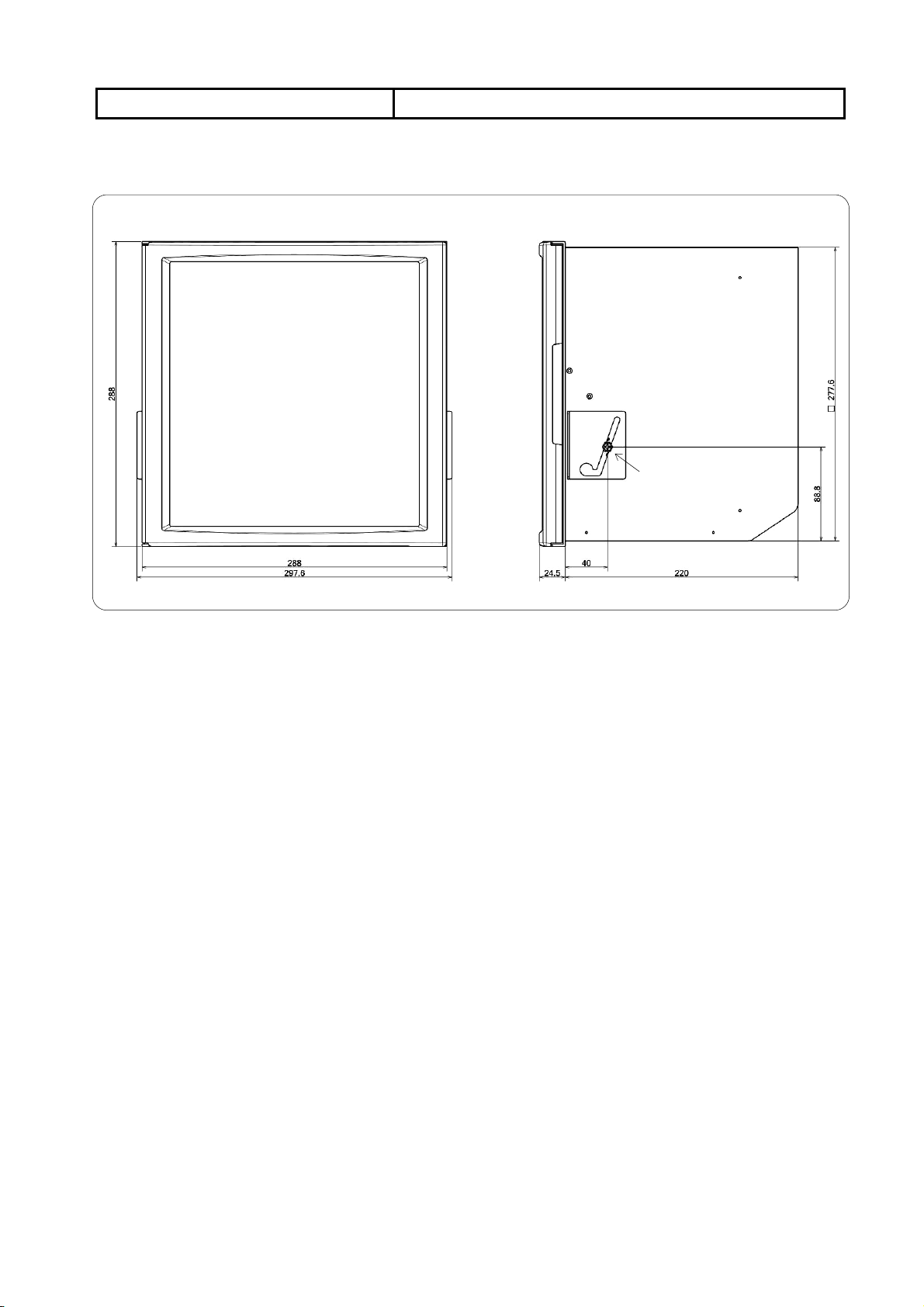

2.2 External Dimensions

(1) External Dimensions

• The following figures show the external dimensions with mounting brackets attached.

External dimensions

Mounting holes for fixing screws for

mounting brackets

(2 locations for left and right)

-12-

Page 16

2. INSTALLATION

1

Use it by mounting it on a panel installed indoor.

Use a panel of steel plate with the thickness of 2 to 6mm or a material with equivalent strength.

Select the thickness of the panel to be used according to weight and depth of the instrument and panel structure.

Use This Instrument by Mounting It on a Panel.

2.3 Mounting Method on Panel

(1) Panel Cutout Size

Standard mounting

±1

281

281

Panel cutout

(2) Mounting Method

1. Insert this instrument into the cutout from the front of the panel.

2. Screw lightly the attached fixing screws into the screw holes

(one hole in each side) of both sides of the case (Figure

below).

3. Insert the hexagon head of the mounted fixing screws into the

round hole of the attached mounting brackets from the both

sides of the case.

4. Like the figure below, slide down the mounting bracket, press

this instrument to the panel from the front for close attachment,

and tighten up the fixing screws with the attached screw

wrench (tightening torque: 2 N・m Figure right).

* The mounting bracket differs between ones for the right and

the left.

The mounting bracket in the figure above is for the right

side from the front.

Panel

Fixing screw

Slide down the mounting

bracket.

Min. clearance for mounting multiple units

±

Unit: mm

Panel cutout

360

360

Panel thickness (2 to 6 mm)

Panel Mounting of Instrument

For mounting the instrument on a panel, it must be carried

out by two persons or more for safety.

Unit: mm

Fixing screw

Mounting bracket

-13-

Page 17

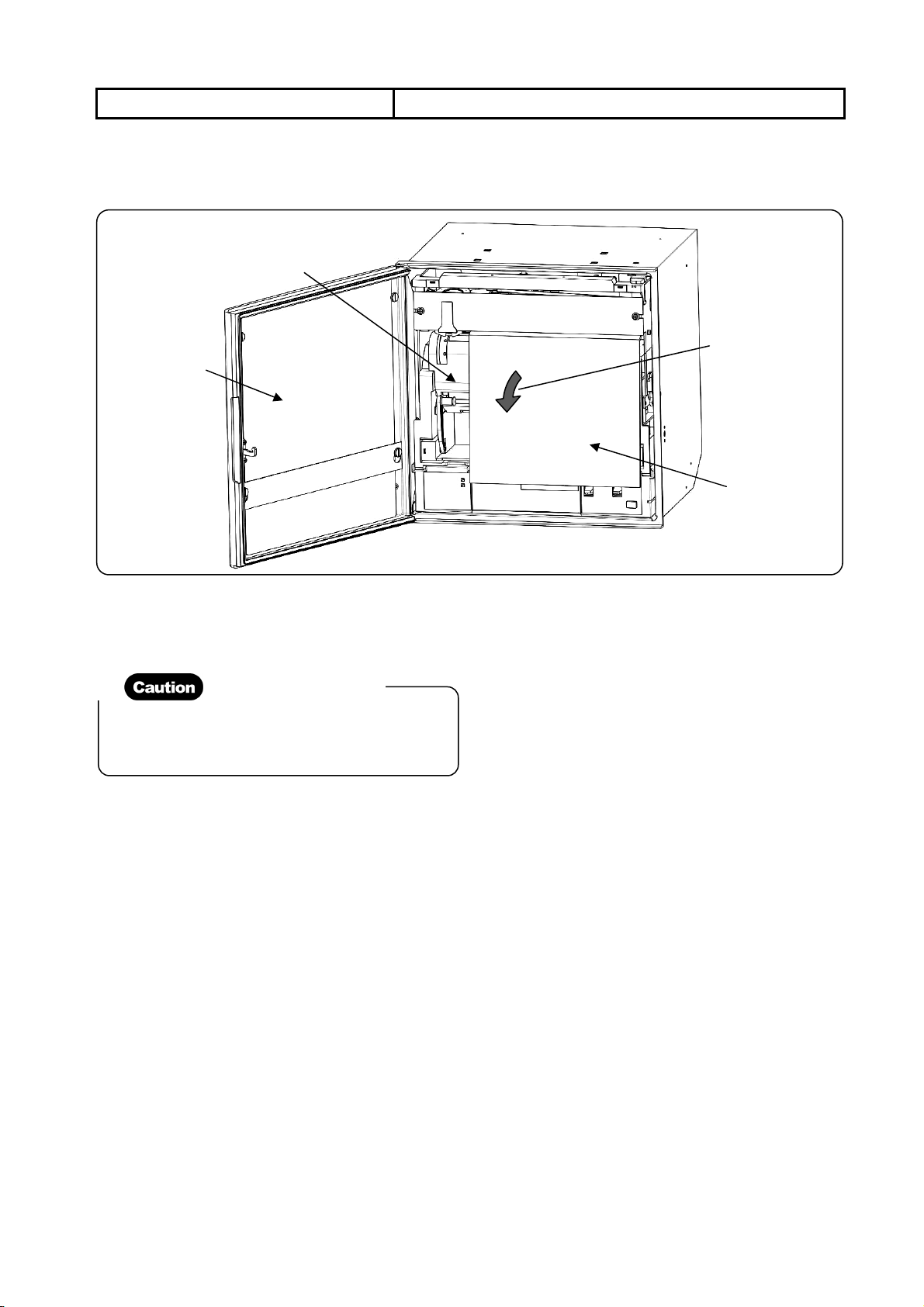

2. INSTALLATION

2.4 Release of Shipping Status

(1) De-installation of Fixing Paper

A fixing paper is installed inside the instrument to prevent damage (damage to the front glass and to recording mechanism) on

transportation (Figure below). It is for the inner unit so as not to fall out and for the recording mechanism so as to be fixed.

[Dot-printing type]

1. Pull down the fixing paper straight tilting it slightly. Do not pull it

2. Store the removed fixing paper with the shipping box.

Door

hard, but pull it out slowly and gradually.

Removing of Fixing Paper

Avoid pulling it upward, downward, or toward you.

When removing, do not pull by force. If it is pulled forcedly,

the instrument may be damaged.

Chart cassette

Direction for Fixing

Paper to be pulled out

Fixing paper

-14-

Page 18

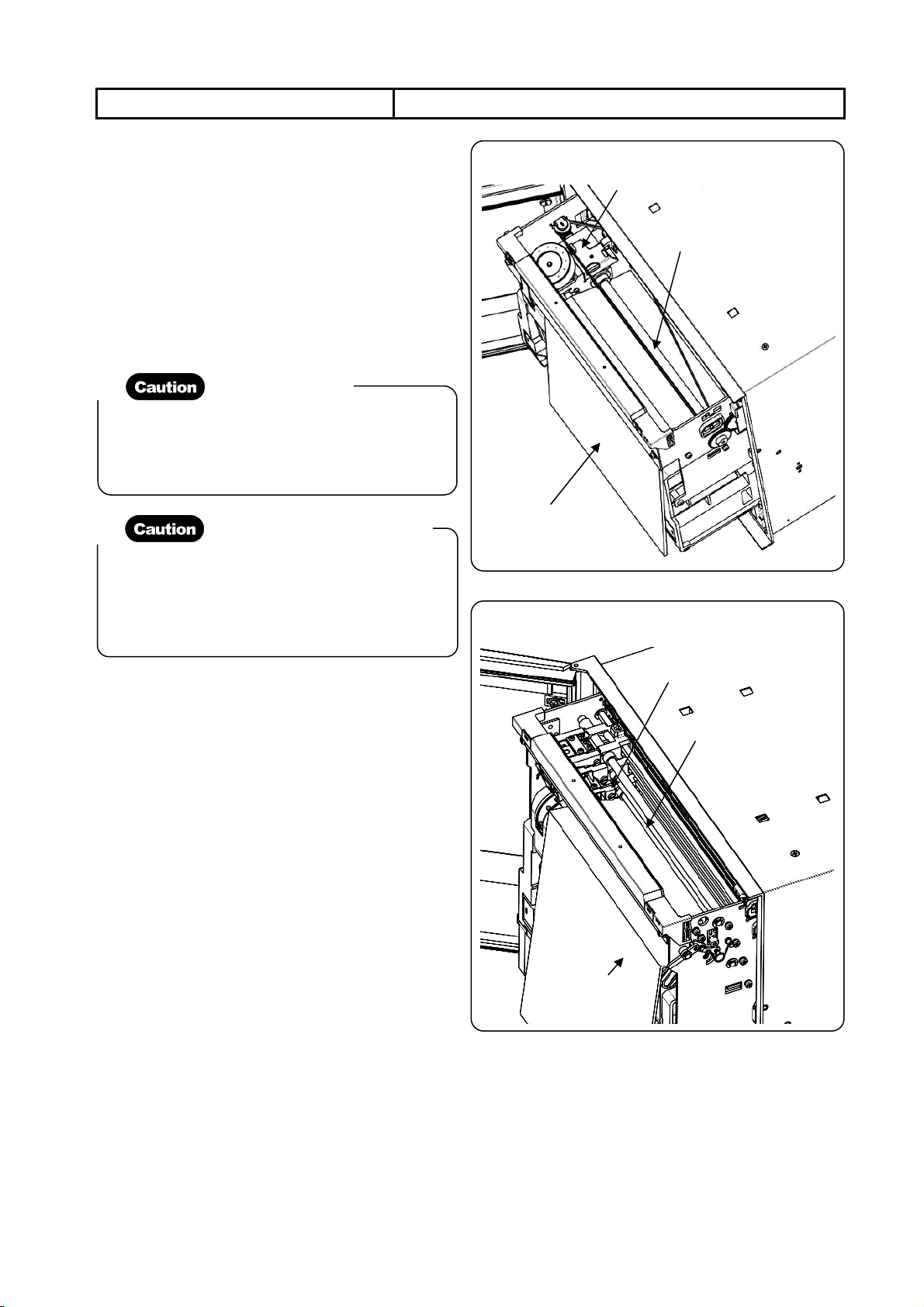

2. INSTALLATION

2.4 Release of Shipping Status

(2) Handling on Reshipping

1. On reshipping, the inkpad/cartridge pen must be removed.

2. Pull put the inner unit. (Refer to 5.1 Inkpad Loading )

z For the multi-point type, insert the fixing paper through under

the main shaft. as shown in figure right (Top view).

z For the pen type, insert the fixing paper through under the

lowest part of the main shaft, just above the chart cassette as

shown in figure lower right (Top view: three pen specification).

3. Check that an inner unit lock lever is open (inner unit is fixed).

Packing on Reshipping

When this product is reshipped, pack it in the state same as

when it was delivered to you. If it is packed in the different

state, it may be damaged by shocks and others on

transportation.

Caution on Installation of Fixing Paper

When moving the dotting mechanism and pen mechanism,

hold the part which fixes and move it quietly. If it is moved by

force or moved holding other parts, it may be damaged.

When the dotting mechanism and pen mechanism are moved,

the chart paper lighting may shine; that is not abnormal.

[Top view: dot-printing type]

Fixing paper

[Top view: pen type (three pen specification)]

Dotting mechanism

Main shaft (rotation shaft)

* Insert the fixing paper

1st pen pen mechanism

through under the main

shaft.

The lowest part of the

main shaft

*Insert the fixing paper

through under the

main shaft (of the 1st

pen).

Fixing paper

-15-

Page 19

3. FRONT

3.1 Names of Front Portions

(1) Front Part

All operations of this instrument including loading of the chart paper and inkpad/cartridge pen can be done from the front.

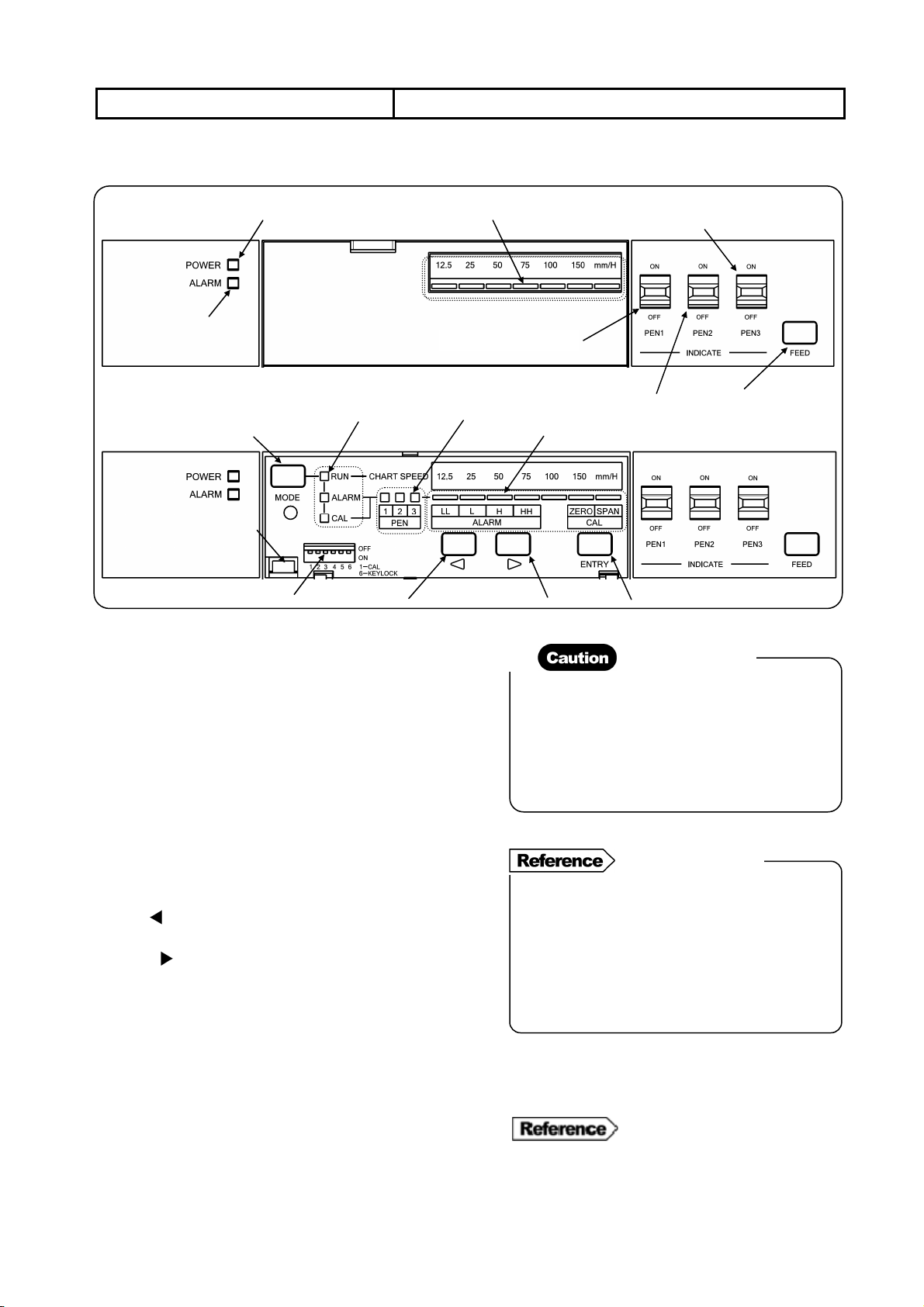

[Dot-printing type]

Door

How to Handle the Door

The front of the door is made of glass. Avoid giving any shock to the glass or giving any strong force to the frame for preventing

any injury due to breakage.

1. Chart Cassette

For loading the chart paper, draw out the chart cassette (Refer to

5.3 Chart Paper Loading.).

2. Display Operation Part

Operate each switch when operation and programming are

executed (Refer to 3.2 Display Operation Part.).

Open the front cover and operate various setting/operation keys

excluding AUTO CH/INDICATE switch, RECORD switch, and

FEED key (To open the cover, pull the convexity in left-of-center

of the front cover top.).

State of front cover opened

Scale plate

Front cover

Channel indicating card

Setting/operation

keys

Chart paper lighting

Power switch

1. Chart cassette

Chart feed gear

Front chart holder axis

Handle

3. Inner unit lock lever

2. Display operation part

3. Inner Unit Lock Lever

Pull out the inner unit for inkpad loading or replacement (For

dot-printing type).

Operate the inner unit lock lever and pull out the inner unit about

6 cm long (Refer to 5.1 Inkpad Loading.). When the inner unit is

pulled out about 6 cm long, it stops with the middle stopper.

It cannot be pulled out more than the middle stopper position.

The inner unit does not have to be pulled out for other than

inkpad loading or replacement.

(2) Channel Number Indication (dot-printing type)

Currently indicated channel number of input can be checked with

the channel number indication of dotter.

Example of Indication Channel “1”

Dotter channel

number indication

Indication channel

-16-

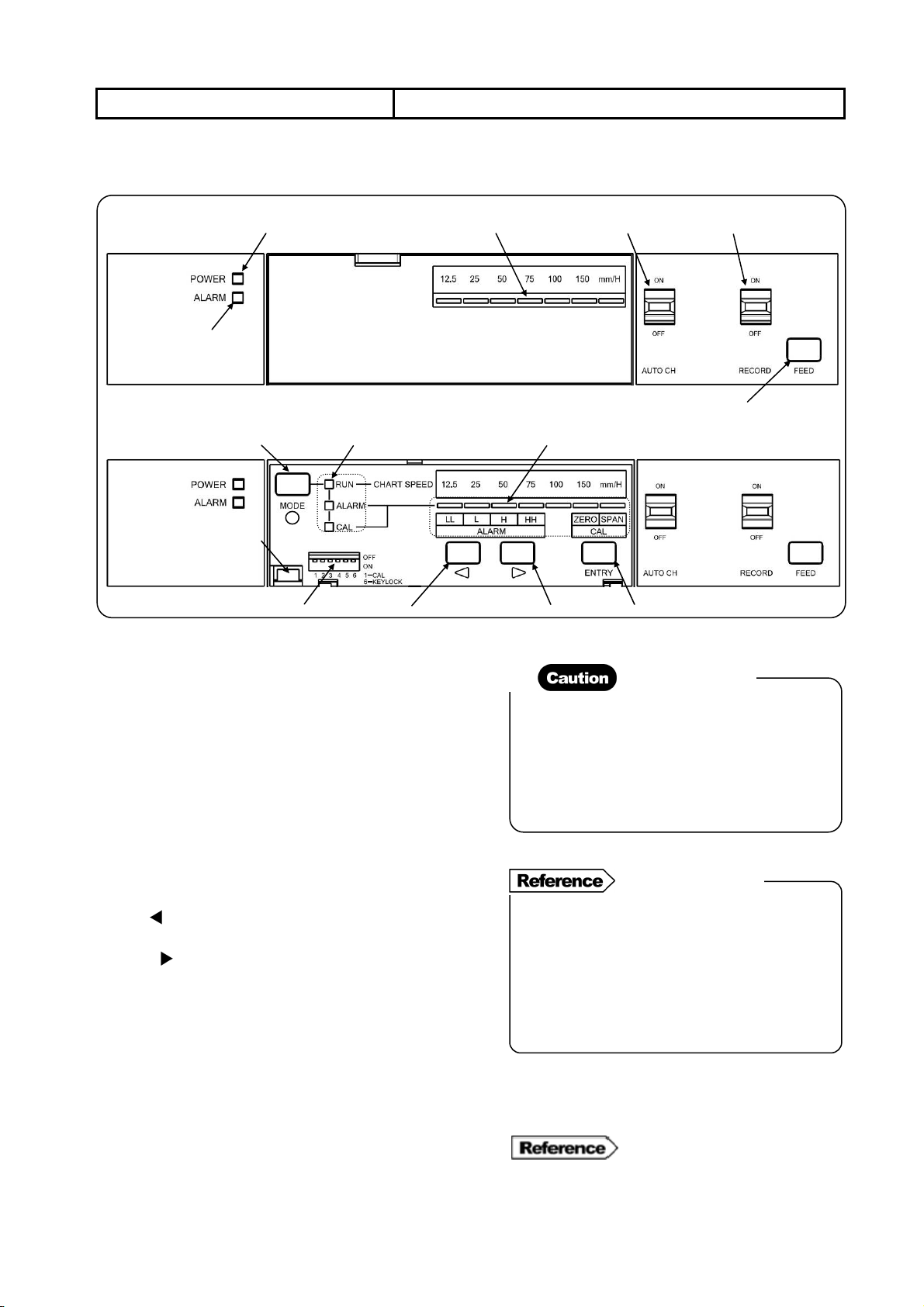

Page 20

3. FRONT

3.2 Display Operation Part

[Dot-printing type]

Detail of Display Operation Part

(1)

1) State of front cover closed

ⅱ

{

2) State of front cover opened

(*1) Engineering connector

Alarm

B

{

MODE

{

3

DIP switch

ⅰ

{

Power supply

(*2)

ⅲ

{

Chart speed

iv

{

Setting mode {vSetting parameter (only during Setting mode)

C

{

Left

(2)

Function of Display Operation Part

1. Switch

1

{

AUTO CH: Switching of Recording mode/1-point indication

mode

2

{

RECORD: Switching of ON/OFF of Indication/Recording

3

{

DIP switch: Refer to 6.2 Operation/Setting Change (3) DIP

Switch Function.

2. Setting/operation key

A

{

FEED: Feeding of chart papers with key operation

B

{

MODE: Operation on transition to Setting mode

C

{

Left ( ): Switching/selection operation on various

operation/setting

D

{

Right ( ): Switching/selection operation on various

operation/setting

E

{

ENTRY: Fixing operation for selection parameters on

various setting

3. Indication lamp

ⅰ

{

Power supply: Indication of power supply On/Off

ⅱ

{

Alarm: Indication of alarm occurrence (for all channels)

ⅲ

{

Chart speed: Indication of chart speed and unit

iv

{

Setting mode: Indication of various setting modes

v

{

Setting parameter: Indication of selection parameters on setting mode

(Chart speed lamp is used also for this purpose.)

(*1) Engineering connector is for maintenance. It is not used -on normal

operation.

1

{

AUTO CH

D

{

Right

Front Cover Protection

Avoid closing the door in the state of front cover opened.

If the door is closed in the state of the front cover opened,

the mechanism of the front cover allows the cover to be

lifted to the direction for closing to prevent damage;

however, behavior for protection is not guaranteed. If the

door is closed forcedly or fast, it may be damaged.

Setting information and various statuses information of

the instrument is stored in the nonvolatile memory

(EEP-ROM) within the instrument.

When the setting information of the instrument is

changed, the alarm lamp blinks for about 3 seconds.

When the status information of the instrument is changed,

the alarm lamp blinks for about 1.5 seconds.

(*2) it is a screw hole for front cover fixing. It is not used on

normal specification (refer to 6.9 Operation Setting Function

Depending on Application (2) Key Lock Function

2

{

RECORD

A

{

FEED

E

{

ENTRY

Blinking of Alarm Lamp

Another Key Lock Method).

-17-

Page 21

3. FRONT

3.2 Display Operation Part

[Pen type]

Detail of Display Operation Part

(1)

1) State of front cover closed

(*1) Engineering connector

ⅱ

{

2) State of front cover opened

Alarm

B

{

MODE

○4DIP switch

ⅰ

{

Power supply

(*2)

iv

{

Setting mode

C

{

Left

ⅲ

{

Chart speed

1

{

1st pen INDICATE

○viPen selection

(2) Function of Display Operation Part

1. Switch

1

{

1st pen INDICATE: Switching of ON/OFF of Indication/Recording of

the 1st pen

2

{

2nd pen INDICATE: Switching of ON/OFF of Indication/Recording of

the 2nd pen

3

{

3rd pen INDICATE: Switching of ON/OFF of Indication/Recording of

the 3rd pen

○4 Refer to 6.2 Operation/Setting Change (3) DIP Switch Function

2. Setting/operation key

A

{

FEED: Feeding of chart papers with key operation

B

{

MODE: Operation on transition to Setting mode

C

{

Left ( ): Switching/selection operation on various

operation/setting

D

{

Right ( ): Switching/selection operation on various

operation/setting

E

{

ENTRY: Fixing operation for selection parameters on

various setting

3. Indication lamp

ⅰ

{

Power supply: Indication of power supply On/Off

ⅱ

{

Alarm: Indication of alarm occurrence (for all channels)

ⅲ

{

Chart speed: Indication of chart speed and unit

iv

{

Setting mode: Indication of various setting modes

v

{

Setting parameter: Indication of selection parameters on setting mode

(Chart speed lamp is used also for this purpose.)

○vi Pen selection: Indication of selection pen number on setting mode.

(*) Engineering connector is for maintenance. It is not used on normal operation.

3

{

3rd pen INDICATE

2

{

2nd pen INDICATE

v

{

Setting parameter (only during Setting mode)

D

{

Right

Front Cover Protection

Avoid closing the door in the state of front cover opened.

If the door is closed in the state of the front cover opened,

the mechanism of the front cover allows the cover to be

lifted to the direction for closing to prevent damage;

however, behavior for protection is not guaranteed. If the

door is closed forcedly or fast, it may be damaged.

Setting information and various statuses information of

the instrument is stored in the nonvolatile memory

(EEP-ROM) within the instrument.

When the setting information of the instrument is

changed, the alarm lamp blinks for about 3 seconds.

When the status information of the instrument is changed,

the alarm lamp blinks for about 1.5 seconds.

(*2) it is a screw hole for front cover fixing. It is not used on

normal specification (refer to 6.9 Operation Setting Function

Depending on Application (2) Key Lock Function

E

{

Blinking of Alarm Lamp

Another Key Lock Method)

ENTRY

{

A

FEED

.

-18-

Page 22

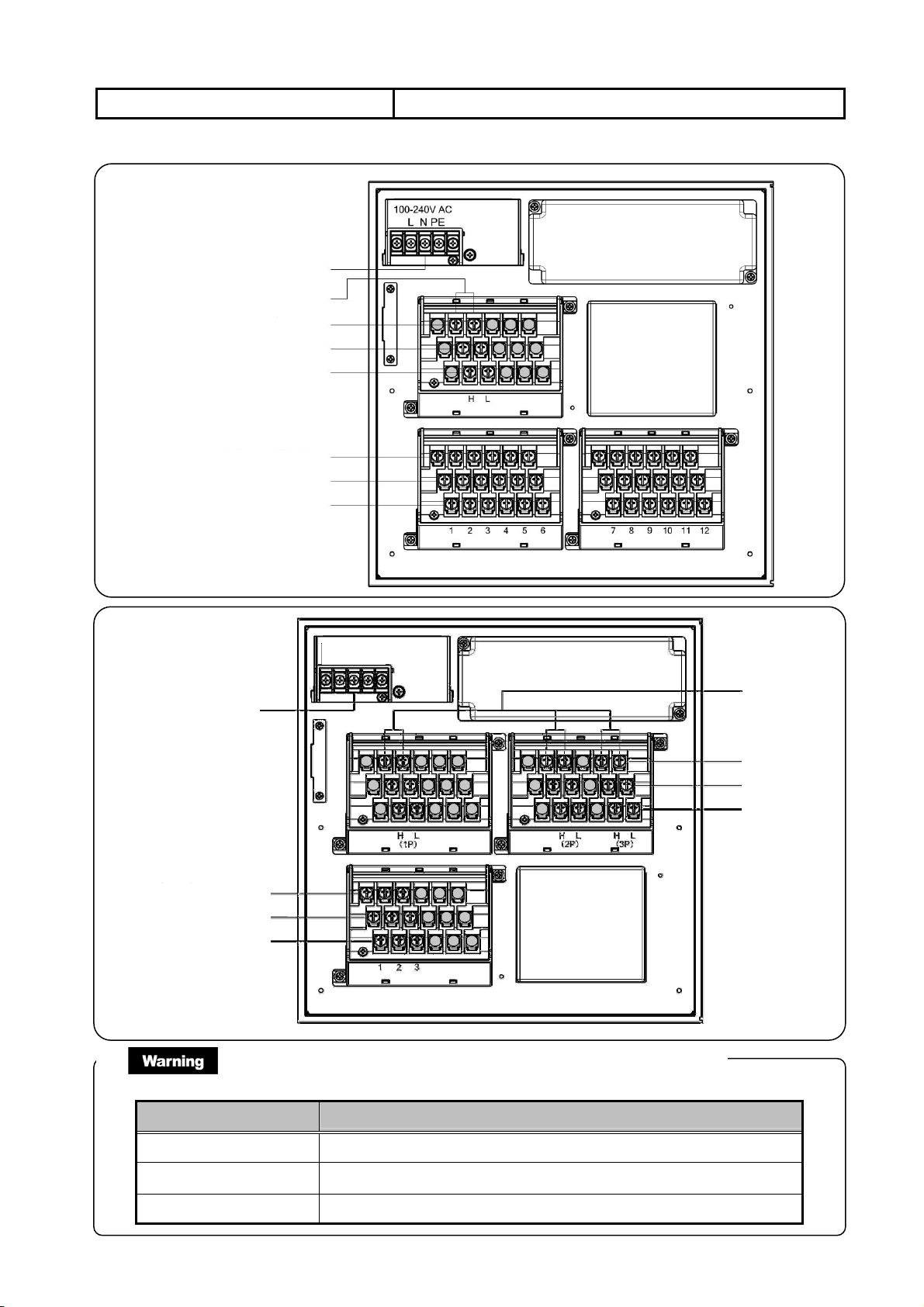

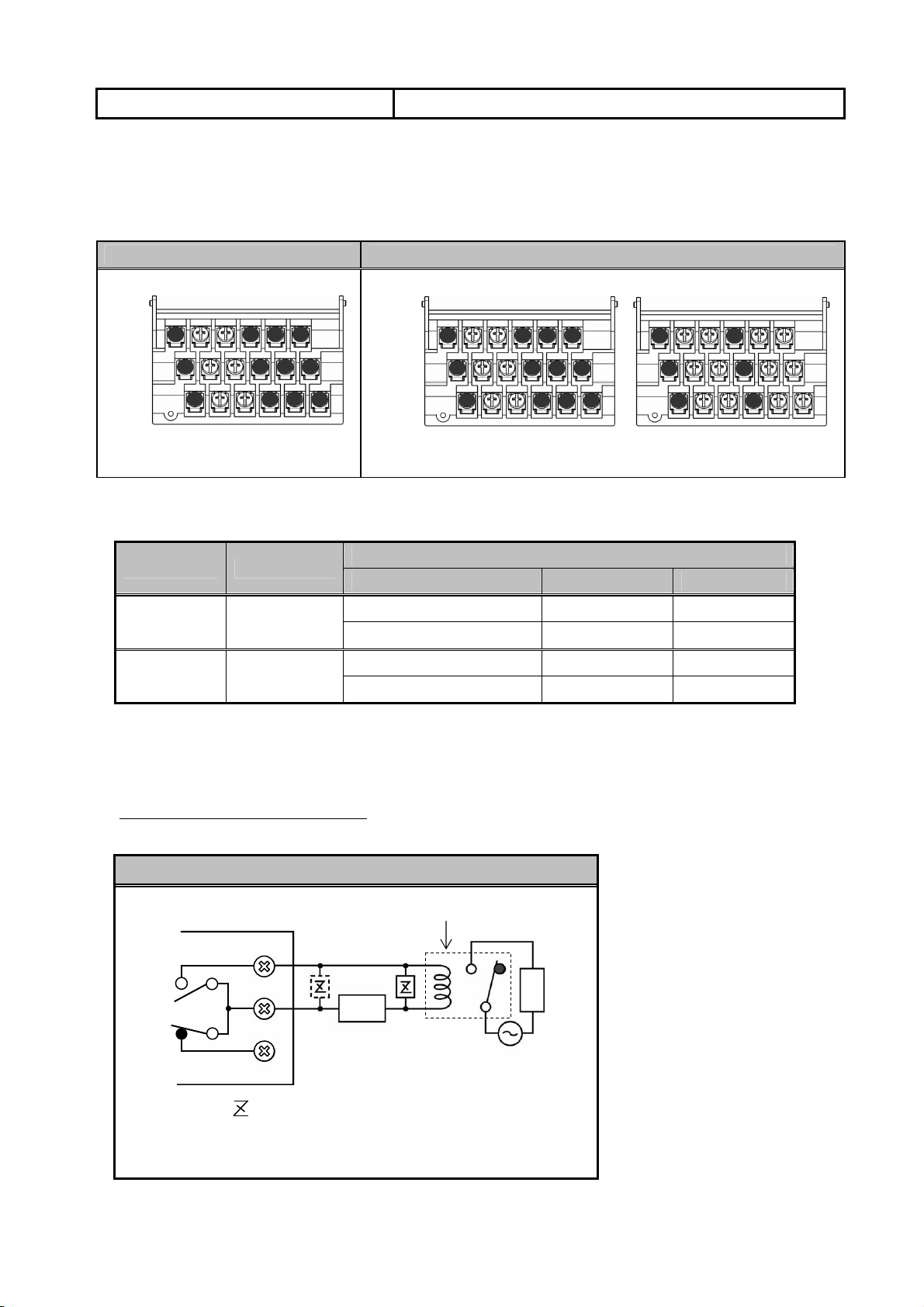

4. CONNECTIONS

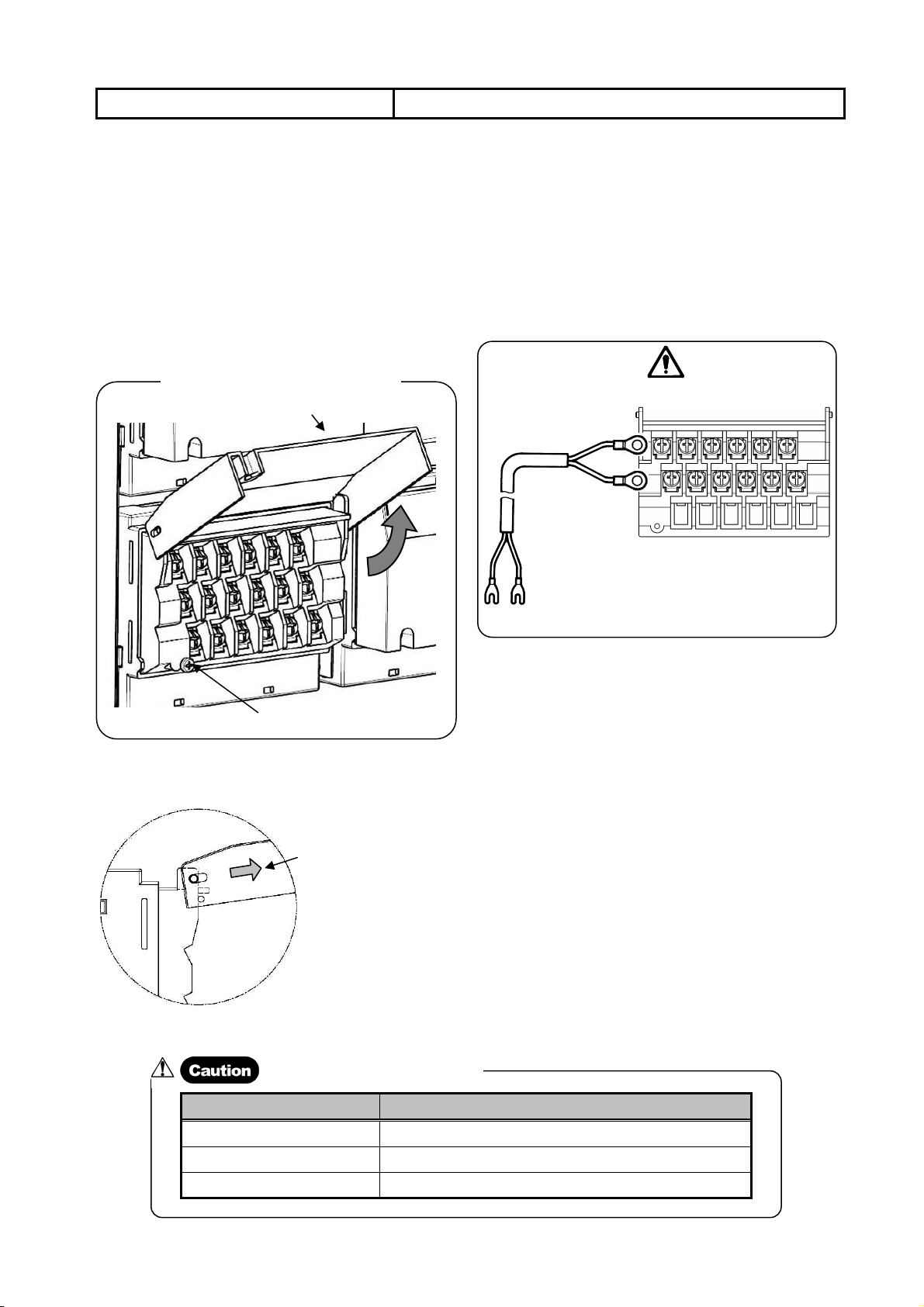

The figure below shows the terminal board with option (alarm output).

[Dot-printing type]

(12 points specification) example

[Pen type]

(3 pen specification)

example

Power supply/protective

Conductor terminals (M4)

Measuring input terminals (M4)

TC mV (+), RTD (A) terminals

TC mV (-), RTD (B) terminals

The symbol marks are pasted on the locations where electric shock may occur if touched (Table below).

Power supply/protective

conductor terminals (M4)

Alarm output terminals (M4)

Measuring input terminals (M4)

TC mV (+), RTD (A) terminals

TC mV (-), RTD (B) terminals

RTD (b) terminals

(Optional)

N.O terminals

COM terminals

N.C terminals

RTD (b) terminals

Alert Symbol Marks () and Places

Name of terminal

Power terminals Top of the power terminals

Measuring input terminals Top of the measuring input terminal cover

Alarm output terminals Top of the alarm output terminal cover

4.1 Terminal Board

mark pasted location

-

Alarm output

terminals (M4)

(Optional)

N.O terminals

COM terminals

N.C terminals

-19-

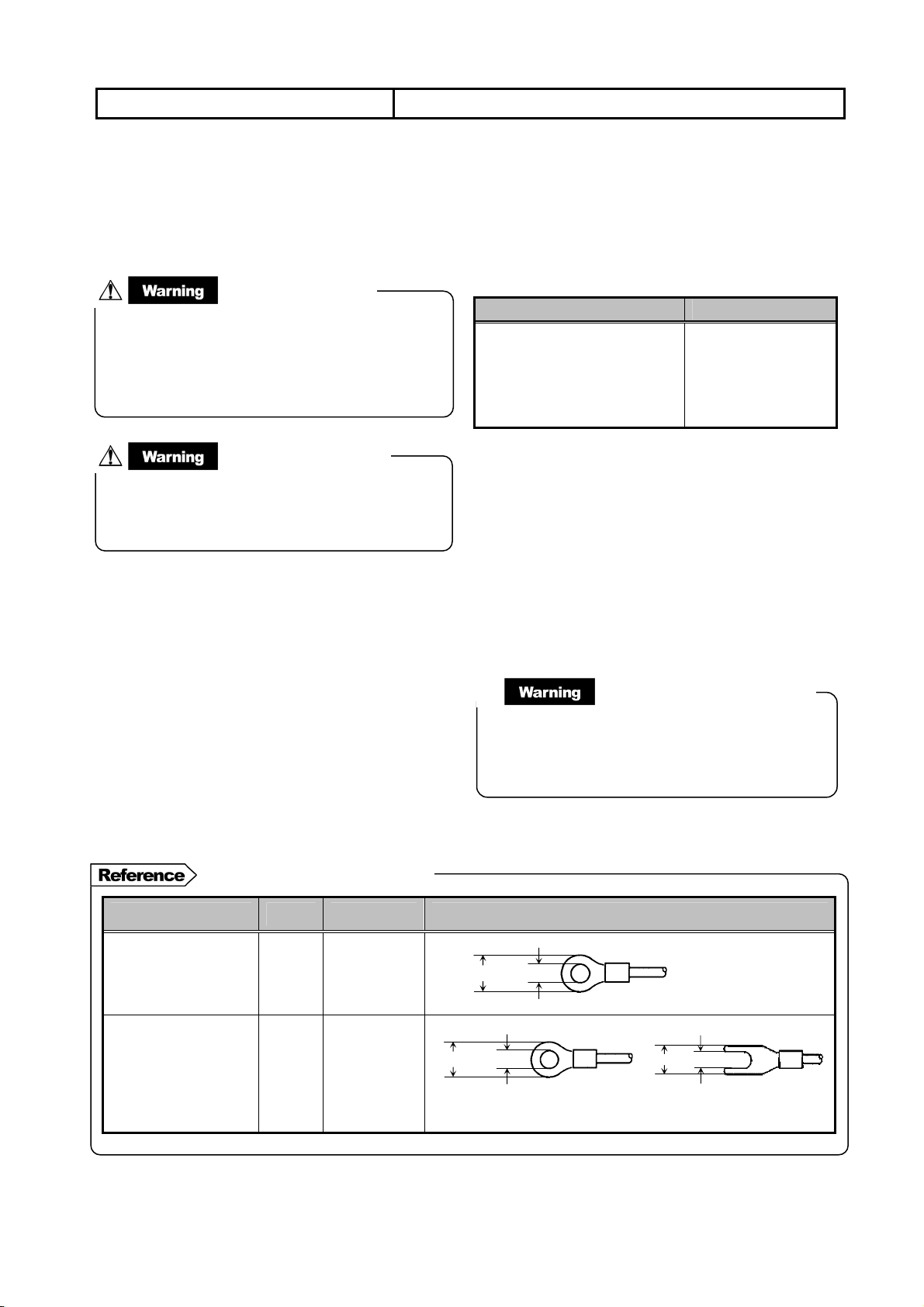

Page 23

4. CONNECTIONS

The following are cautions before connections. Make sure to observe them for securing safety and reliability.

(1) Power Source

Use a single-phase power that has a stable voltage and no

distorted waveform to prevent the wrong operation.

Switch and Overcurrent

Add a switch and overcurrent protective device

(multi-point type: 250 V, 2.5 A/pen type: 250V, 3.15A)

to the power source for preventing an electric shock

during connection work.

This product has no replaceable fuse.

Turn off the Power Source

Before connecting to the power supply and

input/output terminals, make sure to turn off the power

source for preventing an electric shock.

(2) Keep away from Strong Power Circuit

Avoid placing the input/output cables to be close to or in

parallel with any strong power circuits including power line.

Keep them more than 50 cm away from the circuits if close

to or in parallel with the circuits.

(3) Keep away from Heat Source

(Thermocouple Input)

For thermocouple inputs, keep the terminals away from a

heat source (a material generating heat) for reducing an

error of reference junction compensation. In addition,

avoid exposing the terminals to the radiation of direct

sunlight or place them where wind blows.

Protective Device

before Connections.

4.2 Cautions on Connection

(4) Avoid Noise Source

Keep connection cables from a noise source as far as

possible. Otherwise an unexpected trouble may occur.

Take a remedial measure if the cables cannot be kept

away from a noise source.

Major noise source Measure

Electromagnetic switch

Power line having distorted

waveform

Inverter

Thyristor regulator

(5) Use Crimp Style Terminals

1. Mount a crimp style terminal as a connection cables’

termination for preventing the looseness or

disconnection of terminals and a short-circuit failure

between terminals.

2. For the crimp style terminal, use an insulation sleeve for

preventing an electric shock.

(6) Unused Terminals

Avoid using any unused terminals for relaying. Otherwise,

electric circuits may be damaged.

Treat connected cables securely so as not to allow

them to be hooked by a person or a substance.

Otherwise, the connections may be disconnected or

cut and cause an electric shock or other accidents.

Treat Connected Cables Properly

Insert noise filters

between the power

supply and

input/output

terminals.

Terminal board Dia. Torque Termination (Unit: mm)

Power

supply/protective

conductor terminals

Terminals other than

the above

Types of Terminals and Termination

M4 1.2N•m

M4 1.2N•m

8.5 or less

8.5 or less

Use of “O-chip (left side)” recommended.

-20-

4.3 or more

4.3 or more

t: 0.8 with insulation sleeve

8.5 or less

t: 0.8

with insulation sleeve

4.3 or more

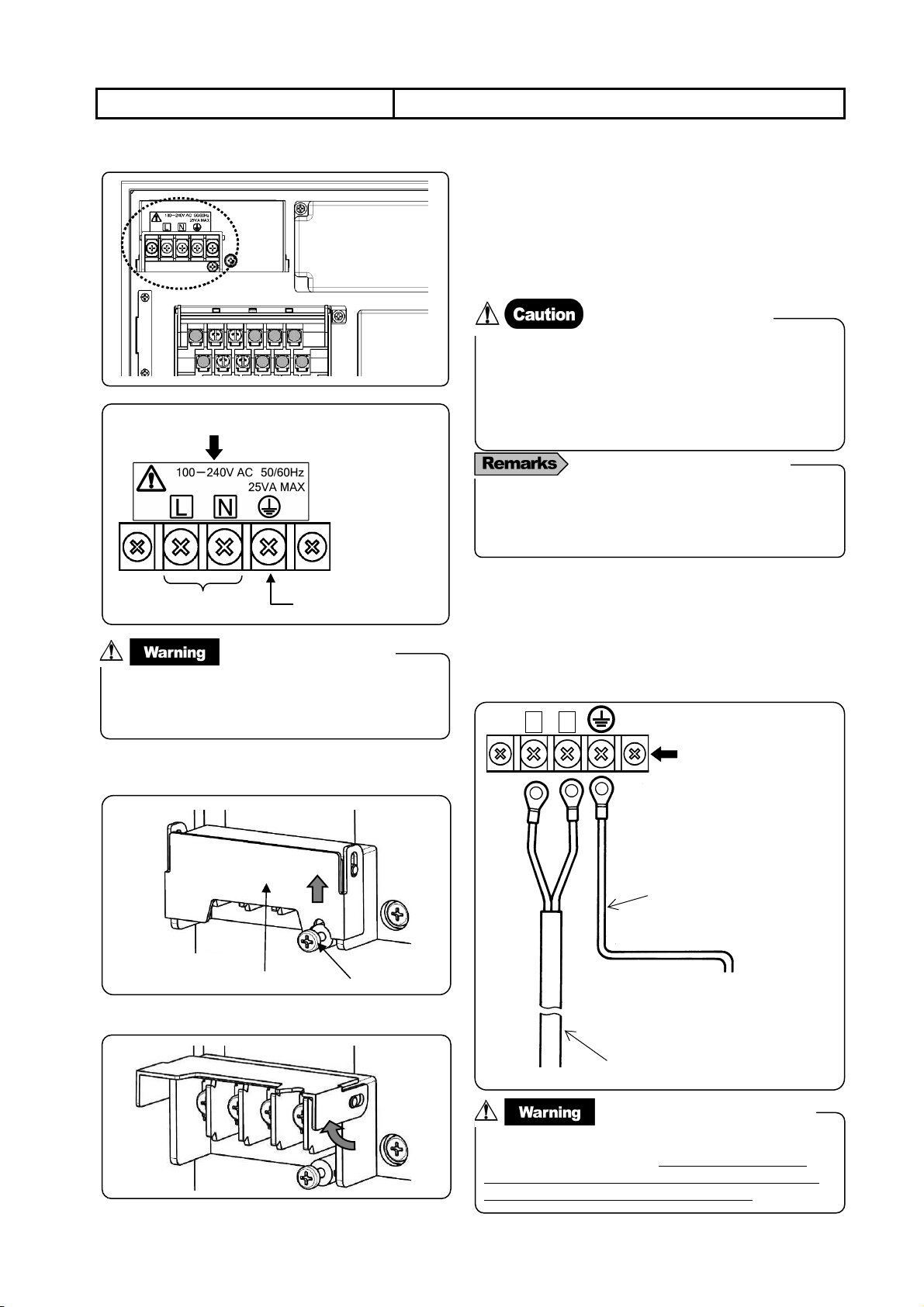

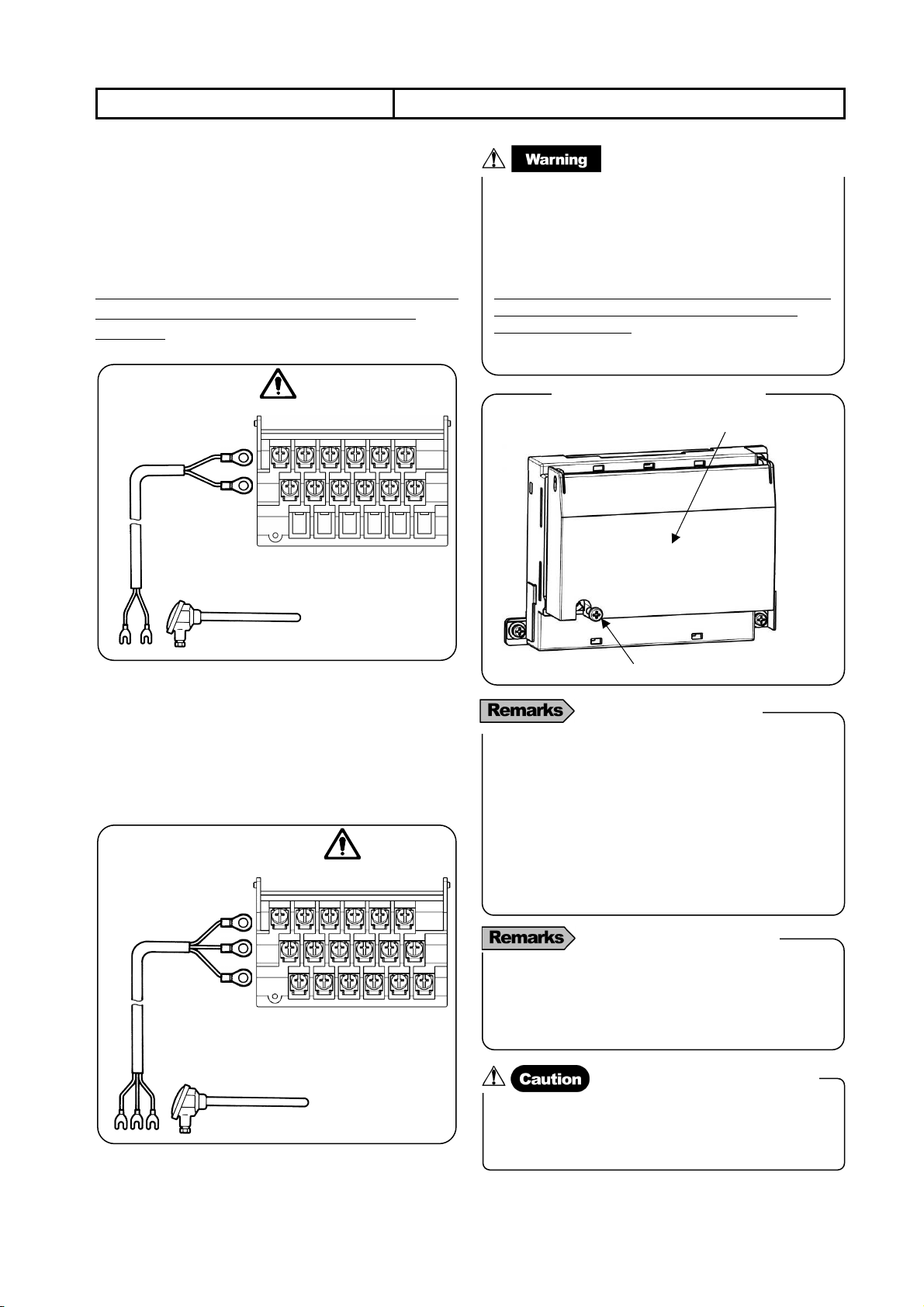

Page 24

4. CONNECTIONS

r

A

A

y

(1)

Power Supply/Protective Conductor Terminals

P/S (Voltage, frequency, and power consumption):

Before connecting to the power supply and protective

conductor terminals, make sure to turn off the power

source for preventing an electric shock.

1. Loosen the fixing screw of the power terminals cover.

2. Slide the cover up.

Power terminals cove

3. Open the cover up until horizontal position.

displa

Power terminals

example of dot-printing type

Protective conductor

terminal

Turn off the Power Source.

4.3 Power Supply & Protective Conductor Terminals

Fixing screw

(2)Connection to Power Terminals

For the connection to power terminals, use a 600 V vinyl

insulated cord (Note 2) with the crimp style terminals and

an insulation sleeve.

Note 2: Use the cords approved by the following

standards.

1) IEC 60227-3

2) ANSI/UL817

3) CSA C22.2 No. 21/No. 49

Be Careful with the Power

The power voltage of this product is indicated beside the

power terminals.

Avoid applying any voltage other than indicated,

otherwise a serious accident occurs or malfunction

results. In addition, if noises are mixed into the power,

take a remedial measure, such as the addition of a

noise cut transformer, etc.

These are indications according to CSA Standard,

Canada. L is for single-phase AC power, and N is for

neutral. To secure the performance of this instrument,

connect the terminals appropriately.

(3)

Connection to Protective Conductor Terminals

Make sure to connect this terminal to the protective

conductor of the power source facility. For this connection,

use a cable with a crimp style terminal with an insulation

sleeve.

• Grounding wire: A copper wire having a wire diameter

of larger than 2 mm

L N

Power supply

A voltage of 100 to 240 VAC is applied to the power

terminals after connections. Make sure to close and

mount the power terminal cover with a screw after the

connection for preventing an electric shock.

Voltage and Noises.

L/N Indication of Power Terminals

2

(green/yellow)

fter connections,

mount the terminal

cover with screws.

copper wire having a wire

diameter of larger than 2

2

(green/yellow)

mm

Make sure to connect this terminal

to the protective conductor of the

power source facility.

600 V vinyl insulated cable

-marking on Power Terminals

-21-

Page 25

4. CONNECTIONS

4.4 Measuring Input Terminals

(1) Connection of Measuring Input Terminals

Make sure to turn off the power source before connection for

preventing an electric shock.

1. Loosen the fixing screw of the input terminals cover and slide the

cover up.

2. Open up the input terminals cover slightly (the cover is removed

from fixing screw) and slide back down (prior to the slide up

position).

3. In the state of slid down position, open the cover up until it stops

(Figure below).

4. The input terminals cover stops at middle position easily (Refer to

figure below: side view).

5. For this connection, use a cable with a crimp style terminal with

an insulation sleeve for the input terminal.

State of Input Terminals Cover Opened

Input terminals cover

Fixing screw

The input terminals cover

stops easily when slided to

the direction of an arrow.

Maximum Permissible Input Voltage

Voltage and thermocouple input ±10VDC or less (Input scale of ±5V or less)

Resistance thermometer input ±6VDC or less

Input type Permissible input voltage

Voltage-divided input ±60VDC or less (Input scale of exceeding ±5V)

(2) Connection of DC Voltage (Current) Input

Use a twisted cable for instrumentation as the input cable for

suppressing noises.

For the current input (optional), mount a shunt resistor for current

input (Refer to 8.1 Shunt Resister for Current Input) to the channel

to be measured before connections.

Avoid using this instrument in parallel with other instruments,

otherwise troubles may occur (Indication fluctuation, indication

errors, and others may occur.).

z DC voltage (current) input

Twisted cable for

instrumentation

DC voltage input

123456

(+)

(-)

Channel

-22-

Page 26

4. CONNECTIONS

A

4.4 Measuring Input Terminals

(3) Connection of Thermocouples (TC) Input

Use a thermocouple wire (or compensation lead wire) to the input

terminals of this instrument. If a copper wire is used halfway, a

noticeable measuring error occurs.

Avoid using a pair of thermocouple wires in parallel with the other

instruments (controllers, etc.), otherwise troubles may occur

(Indication fluctuation, indication errors, and others may occur.).

If the instrument has the burnout function (optional), avoid using it in

parallel with other instruments (otherwise it may affect other

instruments).

• Thermocouple (TC) input

Compensation

lead wire

Red (+)

White (-)

123456

Thermocouple

Channel

(4) Connection of Resistance Thermometer (RTD)

Input

For preventing measuring errors, use a 3-core code of which each

wire has equal resistance value.

Avoid using one resistance thermometer in parallel with other

instruments (controllers, etc.).

• Resistance thermometer (RTD) input

3-core cord

(Same diameter and length)

B

b

Note: The resistance value for one code is

Resistance thermometer

123456

10Ω or less. Use 3 codes which have

the equal resistance value.

Channel

A high voltage may be applied to the measuring input

terminals due to common mode noise (common mode voltage

applied between the measuring input terminal and protective

conductor terminal). The tolerance of the common mode

voltage is 30VAC or 60VDC or less. Make sure that the

common mode voltage is lower than the tolerance.

Make sure to close and mount the terminal cover with a screw

after the connection for preventing an electric shock and

protection of input cables. Closing and mounting the terminal

cover allows reducing errors of reference junction

compensation.

For the terminals for DC voltage and thermocouple input,

channels are insulated (functional insulation, Note 3); however,

for the terminals for resistance thermometer, channels have

equal potential (All b terminals are connected within the

instrument.).

Note 3) Functional insulation: Insulation necessary for normal

operation of instruments without protective function against

electric shocks (avoiding ground loop formulation of

instruments)

If input is opened in the state of no burnout function,

indication/recording values become unstable.

Indication/recording may be placed in the lower limit position, or

in the higher limit position temporarily; however, that state is not

guaranteed.

Input Terminals for 1-, 2-, 3-point Types

The input terminals arrangements for 1-, 2-, 3-point type

specification and pen type differ. Refer to the input terminals

diagram on the back of the instrument and (5) Measuring Input

Terminals Arrangement mentioned later.

Fixing of the Input Terminals Cover

Insulation between Channels of

Measuring Input Terminals

Indication/recording on Input Open

-marking on Measuring Input Terminals

Input terminals cover

Fixing screw

-23-

Page 27

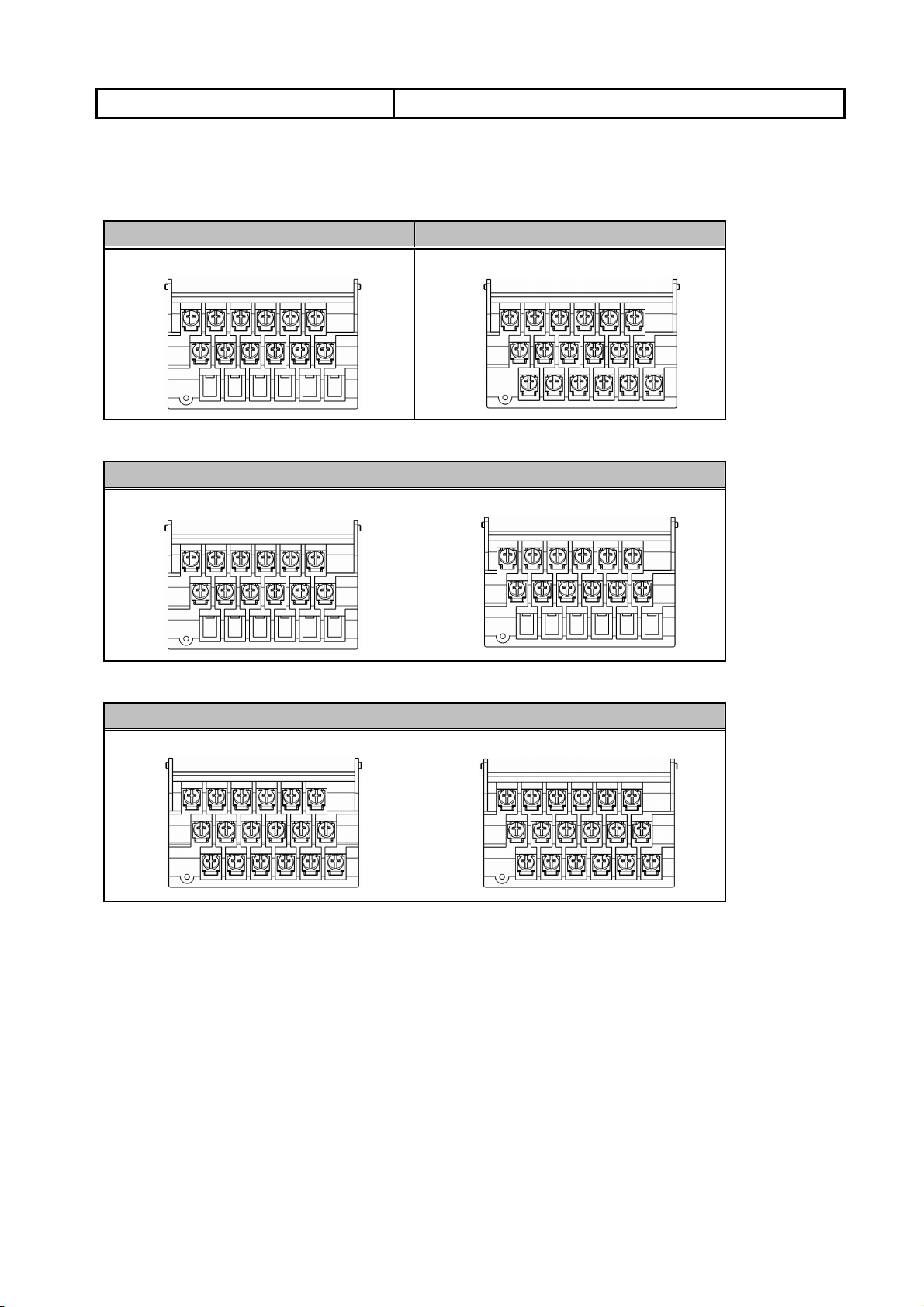

4. CONNECTIONS

4.4 Measuring Input Terminals

(5) Measuring Input Terminals Arrangement

[Dot-printing type]

1. Dot-printing type, 6 locations

DC voltage (current) and thermocouple (TC) input Resistance thermometer (RTD) input

Channel

1 2 3 4 5 6

(+)

(-)

Channel

1 2 3 4 5 6

(A)

(B)

(b)

2. Dot-printing type, 12 locations, DC voltage (curren t) and thermocouple (TC) input

DC voltage (current) and thermocouple (TC) input

Channel

(+)

(-)

1 2 3 4 5 6

Channel

7 8 9 10 11 12

(+)

(-)

3. Dot-printing type, 12 locations, Resistance thermometer (RTD) input

Resistance thermometer (RTD) input

Channel

1 2 3 4 5 6

Channel

7 8 9 10 11 12

(A)

(B)

(b)

(A)

(B)

(b)

-24-

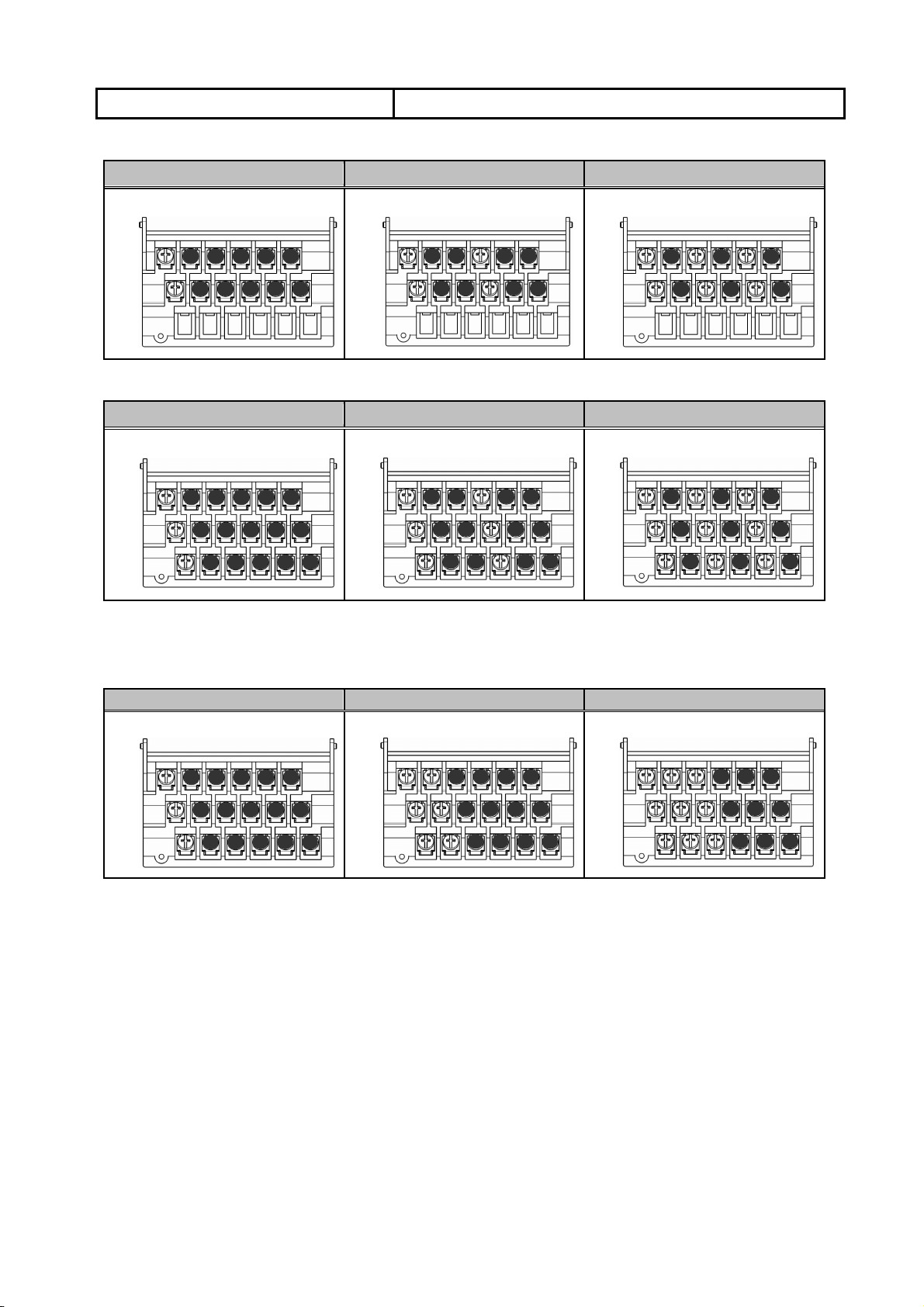

Page 28

4. CONNECTIONS

4. Dot-printing type, 1/2/3 locations, DC voltage (current) and thermocouple (TC) input

1 location 2 locations 3 locations

Channel

1

4.4 Measuring Input Terminals

Channel

1 2

Channel

1 2 3

(+)

(-)

(+)

(-)

(+)

(-)

5. Dot-printing type, 1/2/3 locations, Resistance thermometer (RTD) input

1 location 2 locations 3 locations

Channel

Channel

1

Channel

1

(A)

(B)

(b)

1 pen 2 pen 3 pen

Channel

(A)

(B)

(b)

[Pen type]

1. Pen type input

1 2

1 2

Channel

1 2 3

(A)

(B)

(b)

Channel

1 2 3

(A)

(B)

(b)

(A)

(B)

(b)

(A)

(B)

(b)

* DC voltage (current) of pen type input and (b) terminal of thermocouple (TC) input channel are embedded with push rivets.

-25-

Page 29

4. CONNECTIONS

L

Alarm output comes with only when alarm output (optional) is specified. The alarm output element is by a Form 1a1b contact

mechanical relay output.

4.5 Alarm Output Terminals (Optional)

(1) Alarm Output Terminals

Dot-printing type 3 pen type

H

H L

H L H L

N.O

COM

N.C

Common output

N.O

COM

N.C

1st pen

output

2nd pen

output

(2) Alarm Output

Alarm type Alarm mode

Output terminal OFF ON

N.O to COM terminals Open Short

“H” alarm Upper limit alarm

N.C to COM terminals Short Open

N.O to COM terminals Open Short

“L” alarm Lower limit alarm

N.C to COM terminals Short Open

Alarm output behavior

(3) Connections

Make sure to turn off the power source and a buffer relay before connections for preventing an electric shock.

1. Connect the cables to a load via a buffer relay.

2. Connect the cables with the crimp style terminal covered by an insulation sleeve to the alarm output terminals.

Connection example for Form 1a1b contact mechanical relay output

The instrument

N.O

COM

N.C

b

Power

supply

*

: Contact protective element (It is recommended to mount it

at the ‘a’ side.)

* N.C terminals have the reverse phase output to N.O terminals;

therefore, they are opened on alarm occurrence.

Buffer relay

a

Load

3rd pen

output

-26-

Page 30

4. CONNECTIONS

2

Connect the load which is equal or less than the specification ( ) to the alarm output terminals.

After connections, the power for the buffer relay is applied to the alarm output terminals and an electric shock occurs if you touch these

terminals. Make sure to close and mount the terminal cover with a screw after the connection.

Take Safety Measures

The alarm outputs of this product may become defective due to wrong operation, failures, abnormal inputs, or others. Take safety

measures separately before use if required.

-marking on Alarm Output Terminals

4.5 Alarm Output Terminals

(4) Cautions on Connection

Remarks and references for connections are as follows.

Remarks1

Power supply Resistive load Inductive load

Remarks2

250VAC

100VAC

* Minimum application load: 5 VDC, 10 mA (Reference

value)

Reference value of switchable lower limit. It may depend

on use conditions, environment conditions, and others;

therefore, check it under actual use conditions.

• Mount a contact protective element matching to the buffer

relay.

• It is effective to mount the element at the coil side of the

buffer relay for preventing a wrong operation due to a light

load (refer to (3) Connections ‘a’ in the figure in

“Connection example for Form 1a1b contact mechanical

relay output”).

Caution on Contact Behavior Timing

The alarm output of this product is by a Form 1a1b contact.

With the 1a1b contact output type, ‘a’ contact side and ‘b’

contact side may turn ON simultaneously on operation and

return.

Confirm operational conditions or others of load side fully

before use.

Contact Ratings of Alarm Output Relay

30VDC 2.0A 1.0A

Mounting of Contact Protective Element Z

2.0A 1.0A

Reference1

• Coil rating: Equal to or less than contact ratings of output

terminals

• Contact ratings: Twice the load current or more

A relay with a built-in element for coil surge absorption is

recommended.

Mount an additional buffer relay if a buffer relay satisfying the

load rating is not available.

Reference

Mount a contact protective element if a buffer relay with a

built-in element for surge absorption is not available.

The element is generally composed of C (Capacitor) and R

(Register).

<Reference values for C and R>

C: 0.01 μF (Rating: About 1 kV)

R: 100 to 150Ω (Rating: About 1 W)

Selection of Buffer Relay

Selection of Contact Protective Element

-27-

Page 31

5. LOADING

5.1 Inkpad Loading (For dot-printing type)

[Dot-printing type]

(1) Preparation

1) Preparation of Inkpad

Take out the inkpad from the accessory box.

Inkpads are colored in advance by ink listed in the table below.

Number of

input points

1 point Red

2 points (1) Red (2) Black

3 points (1) Red (2) Black (3) Sky blue

6 points

12 points

Type and Recording Color

Recording channel number and recording

color

(1) Red (2) Black (3) Sky blue (4) Green (5)

Brown (6) Purple

(1) Red (2) Black (3) Sky blue (4) Green (5)

Brown (6) Purple (7) Orange (8) Gray (9) Blue

(10) Brownish green (11) Scarlet (12) Pansy

For Inkpad Loading

Make sure to pull out the inner unit first when loading or replacing

the inkpad.

Do not load or replace the inkpad by just taking out the scale plate

without pulling out the inner unit. Scale plate is placed at adjusted

position and it may cause indication error. Also, depending on the

placement status, not only it may operate normally but also it may

cause failures.

(2) Inkpad Loading

Attached Inkpad

• Appropriate quantities of ink are filled in advance. Avoid filling

ink in that state. Otherwise the inkpad with too much ink may

have ink drops and others which cause failures.

• Although the period depends on use conditions, the inkpad

can be used for about 2 months with standard specifications and

under standard operational conditions.

Attachment/removal of Inkpad

When attaching or removing the inkpad for loading/replacement

and ink filling, make sure to turn the power off or to be in the

state of RECORD OFF.

Otherwise the indication mechanism operates during inkpad

being attached/removed and unexpected force is applied to the

mechanical parts then the instrument may be damaged.

Replacing the inkpad at the state of RECORD OFF, do not

move indication mechanism manually. It may cause failures.

1) Pulling out the Inner Unit

Pressing the both of levers (Inner unit lock levers) of the right

and left under the rack inward (to the direction of the arrows in

the figure below), hold the right side of the chart cassette (the

part directed by the hand in the figure below) and pull it out.

Pulling out Inner Unit

Pulling out the inner unit fast may damage the inner unit and

the instrument.

When the inner unit is pulled out quietly about 6 cm long, it

stops with the middle stopper. Avoid pulling it out further.

Otherwise it may be damaged.

2) Inserting Inkpad

In the state of the inner unit being pulled out to the middle

stopper, insert the inkpad to the pad axis of the dotting

mechanism.

3) Loading Inkpad

In the state of the inkpad inserted, turn the inkpad with fingers

slowly. When the pin part of the inkpad meets the pad chase

of the dotting mechanism, the inkpad falls and gets loaded.

In the state of the inkpad being loaded normally, the inkpad

does not turn. When it can be turned by a finger easily, it is not

loaded normally. In this case, check the state of the inkpad

falling down turning it slowly.

-28-

Page 32

5. LOADING

e

part

5.1 Inkpad Loading (For dot-printing type)

• Before inkpad loaded

Inkpad

Pin

Dotting mechanism pad

axis

Pad chas

• After inkpad loaded

Dotting mechanism

4) Placing Back the Inner Unit

Press the both sides of the chart cassette until the both levers of

the right and left under the rack are opened outward making a

sound of “click”.

The levers are to secure the inner unit; therefore press them all

the way to lock the unit.

Handling of Pointer

・

Avoid touching the pointer. If force is added, the pointer may be

damaged.

Filling up Ink

• Filling up Ink

When the recording color of points becomes light, add 1 or

2 drops of the attached supplementary ink to the pad

(cotton of the inkpad to apply ink).

At this time, avoid pressing the top of the supplementary ink

to the pad, otherwise the pad is damaged and the ink

cannot be attached easily on recording. In addition, the filled

amount of ink cannot be seen, so overfilling of ink may

happen.

On filling the ink, make sure not to mix up the colors of the

inkpad and the supplementary ink. Pay attention especially

to blue/purple and red/scarlet which are easy to be mixed

up.

Check carefully the number (recording channel number) of

the supplementary ink and the number of the inkpad

recording color.

In addition, the type of supplementary ink depends on the

number of input points. Refer to “Reference: Type and

Recording Color”, (1) Preparation, mentioned early and (3)

Ink Filling Color of Inkpad mentioned later.

• Duration of Use

When ink is filled, the duration of use is half or less

compared with the one when the ink was filled initially (The

duration varies depending on the ink colors.).

• It is Important Not to Add Ink Too Much

When ink is added, note not to add it too much once (1 or 2

drops are enough). Make sure to drop it. Excess ink

generates drops and attachment of ink, and then causes

failures of mechanical parts.

• Life of Inkpad

When ink filling is repeated, ink absorption of the inkpad is

degraded.

If the inkpad is used continuously in that state, recording

quality is degraded, drops and attachment of ink are

generated, and then failures of mechanical parts occur.

Replace an inkpad with new one when ink is filled four or

five times.

The consumption level of inkpads depends on use

conditions. Early replacement is recommended when

recording state gets worse and ink absorption is degraded

on ink filling.

-29-

Page 33

5. LOADING

k

k

k

2

2

2

k

k

2

2

3

3

k

2

5

6

4

3

k

4

3 2 9

2

0

6

7

8

5

(3) Ink Filling Color of Inkpad

[1 point]

1

Red

Red

1

[2 points]

Blac

Red

1

[6 points]

Blac

Sky

blue

*Diagram which can be seen from the side of inkpad

supplementary ink filling.

1

Red

Red

Red

1

Red

Blac

1

Red

Green

Red

1

Blac

Red

1

Purple

Brown

Pin

1

Without a pad

(cotton)

1

With a pad (cotton)

[3 points]

Blac

Sky

blue

[12 points]

Sky

blue

Green

Brown

Red

Red

1

Red

Blac

Purple

Orange

5.1 Inkpad Loading (For dot-printing type)

1

Sky

blue

Blac

1

1

Pansy

11

Scarlet

Brownish

1

Green

Blue

Gray

-30-

Page 34

5. LOADING

5.2 Cartridge Pen Loading (For pen type)

[Pen type]

(1) Preparation

1. Preparation of Cartridge Pen

Take out the cartridge pen from the accessory box.

Inks are colored in advance by ink listed in the table below.

Type

1 pen Red

2 pen (1) Red (2) Green

3 pen (1) Red (2) Green (3) Blue

Type and Recording Color

Recording channel number and recording

color

(2) Scale Plate and Pointer

Positions of scale plate and pointer (index) differ by each type.

[1 pen specification]

[2 pen specification]

1st pen pointer

[3 pen specification]

1st pen scale plate

1st pen index

1st pen pointer

2nd pen scale plate

2nd pen pointer

2nd pen scale plate

1st pen scale plate

2nd pen pointer

3rd pen scale plate

3rd pen pointer

1st pen scale plate

(3) Cartridge Pen Loading

1) Pen Replacement Mode

Pen replacement mode moves cartridge pen to the position

where is easy to load/replace the cartridge pen.

If each pen is at the position of 20 to 80% of recording range,

this operation is unnecessary. If the position of the each pen is

overlapped, remove from the 3rd pen and load from the 1st

pen.

Attachment/removal of Cartridge Pen

When loading or replacing the cartridge pen, make sure to turn

the power off, be in the state of RECORD OFF (all pens are

INDICATE OFF) or perform under the pen replacement mode.

Otherwise the dotting mechanism operates during cartridge pen

replacement and unexpected force is applied to the mechanical

parts then the instrument may be damaged.

1. Bring the cartridge pen DOWN by pulling down the pen lift lever

down located at right side of the inner unit.(refer to (4) Pen Lift

Lever operation mentioned later)

2. Turn the power ON. (refer to 6.1 Turning Power On/Off, 6.2

Operation/Setting Change)

3. While pressing down “◄”

keys simultaneously).

* Perform key operation while front cover is open.

4. Release “◄”

5. “RUN lamp” is off and pointer of the 1st pen, 2nd pen and 3rd

pen move to the position approx. 25%, 50% and 75% of the

scale plate (pen replacement mode).

key and “ENTRY” key.

key, press “ENTRY” key (Press two

Load/replace the cartridge pen at this state.

-31-

Page 35

5. LOADING

e

5.2 Cartridge Pen Loading (For pen type)

Note) If the pen pointer do not move to the specified position,

“ENTRY ” key may not be pressed while pressing down the

key (in this case, it may be in the Chart Speed Change

“◄”

mode, refer to 6.6 Chart Speed Change). Operate from

Operation mode again.

2) Lift up of the 1st pen scale plate

Only for the 1st pen scale plate of the 3 pen specification,

structure allows scale plate to move.

For 3 pen specification, when replacing the cartridge pen of the

1st pen, lift the scale plate up and perform cartridge pen loading.

For lifting up the scale plate of the 1st pen, lift up lower part ((the

part directed by the hand in the figure below) of lower limit side

(left side) of the scale plate. The scale plate would be up until

lower part of the scale plate of 2nd plate.

3 pen specification: the scale plate of the 1st pen is lifted up

For moving scale plate

For lifting up the 1st pen scale plate of the 3 pen specification,

make sure to perform operation at the far left side. If the

operation is done by position other than this, scale plate may be

deformed and cause errors and failures.

Also, the scale plate stops at the stopper position. If the scale

plate is lifted up more than stopper position, it may cause failure

and damage.

Do not move blank scale plate (without scale printing) of the 2

pen specification located at the bottom. The scale plate may be

deformed and cause errors and failures.

3) Load /Replacement of the Cartridge Pen

1. Remove the cap of the pen, bring the color line in the front then

insert protruding portion of the right side into the hole of the pen

holder. Turn the cartridge pen clockwise to load to the pen

holder.

At this time, state of lifting the cartridge pen slightly while

protruding portion of the right side of the cartridge pen is inserted

into the hole of the pen holder creates easy performance.

2. To remove the cartridge pen, turn the cartridge pen

counterclockwise with slightly pushing the protruding portion of the

left side of the cartridge pen.

Removing the pen cap

Do not load the cartridge pen while pen cap is on. It may cause

errors and failures.

Pen cap is used when not recording for long time so keep the pen

cap carefully.

Figure of cartridge pen loading

Color lin

Handling of the pen tip

Tip of the cartridge pen is made of nylon fiber. Do not crush the tip

of the pen.

4) Return to the Operation Mode

1. After loading/replacement of the cartridge pen, press “MODE”

key.

2. Finish the pen replacement mode and return to the operation

mode.

Pen holder

Cartridge pen

Pen cap

-32-

Page 36

5. LOADING

5.2 Cartridge Pen Loading (For pen type)

Remarks

Except for the 1st pen of 3 pen specification, it is easy to

perform cartridge pen loading at the pen up state.

Also, pen up state prevent ink stain by the cartridge pen on the

chart paper (refer to (4) Pen Lift Lever Operation mentioned

later).

Handling of Recording Structure

Avoid moving recording structure right/left by force. If moving

recording structure is needed for loading /replacement of the

cartridge pen use the “Pen Replacement Mode Function” (refer

to Pen Replacement Mode mentioned earlier)

Remarks

For new cartridge pen, ink may not come out easily. Before

loading the cartridge pen, write with the cartridge pen manually

on the paper.

Remarks

The cartridge pen is disposable. Ink consumption level varies

by usage. However, it can be used for about 1.5 months under

standard environment. (Continuous recording of about 600 to

1000m)

Handling of Pointer

Do not touch the pointer. Putting the force to the pointer may

cause indication error and damage.

Remarks

Stop operating and not using for long term or using the unit just

for indication and recording is unnecessary, remove the

cartridge pen and put the pen cap on then store to prevent

drying out of the pen tip and prolong the life of the ink.

Cartridge Pen Loading

Before Replacing the Cart ridge Pen

Ink Consumption Level

Not Recording for Long Term

(4) Pen Lift Lever

• Pen lift lever is located at right side of the inner unit. Bringing

the lever down let cartridge pen down status and raise up the

lever let cartridge pen up status (refer to the figure below).

When recording, let the cartridge pen down status. On the

cartridge pen down status, all the tips of the pens are

contacted on the chart paper and confirm that recording is

done normally.

• Raising up the pen lift lever prevent ink staining on the chart

paper on not recording for temporally and such cases. This

can be resulted in saving ink consumption.

Pen lift lever operation

Pen lift lever

Operation on Pen UP status

Indication operation is enabled while cartridge pen is UP status,

however, performance is not guaranteed.

Also, do not perform indication operation for a long time when

pen is UP status.

-33-

Page 37

5. LOADING

e

(1) Chart Cassette Removal

1) Open the Door.

Door

2) Remove the Chart Cassette.

Grasp the handle on the chart cassette and pull it out.

Check the State of Dotter

[For dot-printing type]

Pull out the chart cassette while RECORD switch is off

(recording off) or power is off for the dot-printing type.

If the chart cassette is pulled out in the state of the dotter

down during power off (The state which top of the dotter

touches the chart. This state may happen if the power is

turned off while the dotter operates.), the dotter may be

damaged.

When the dotter is down, turn the power on once, and when

“initial operation of the dotter” ends, turn the power off (Refer

to 6.1 Power On/Off.).

Guid

Handle

5.3 Chart Loading

[For pen type]

Pen lift is automatically operates itself at the time of pulling

out the chart cassette and putting back into the inner unit

Pen lift lever operation is unnecessary, however, there might

be a possibility that ink stain of the cartridge pen left on the

chart. Let the cartridge pen UP status by the pen lift lever

then load the chart prevent leaving ink stain on the chart.

(2) Chart Paper Setting

1) Open the Chart Paper Holder.

Open the front chart holding axis in the front side and the rear

stripper plate in the rear side.

Front chart holder axis

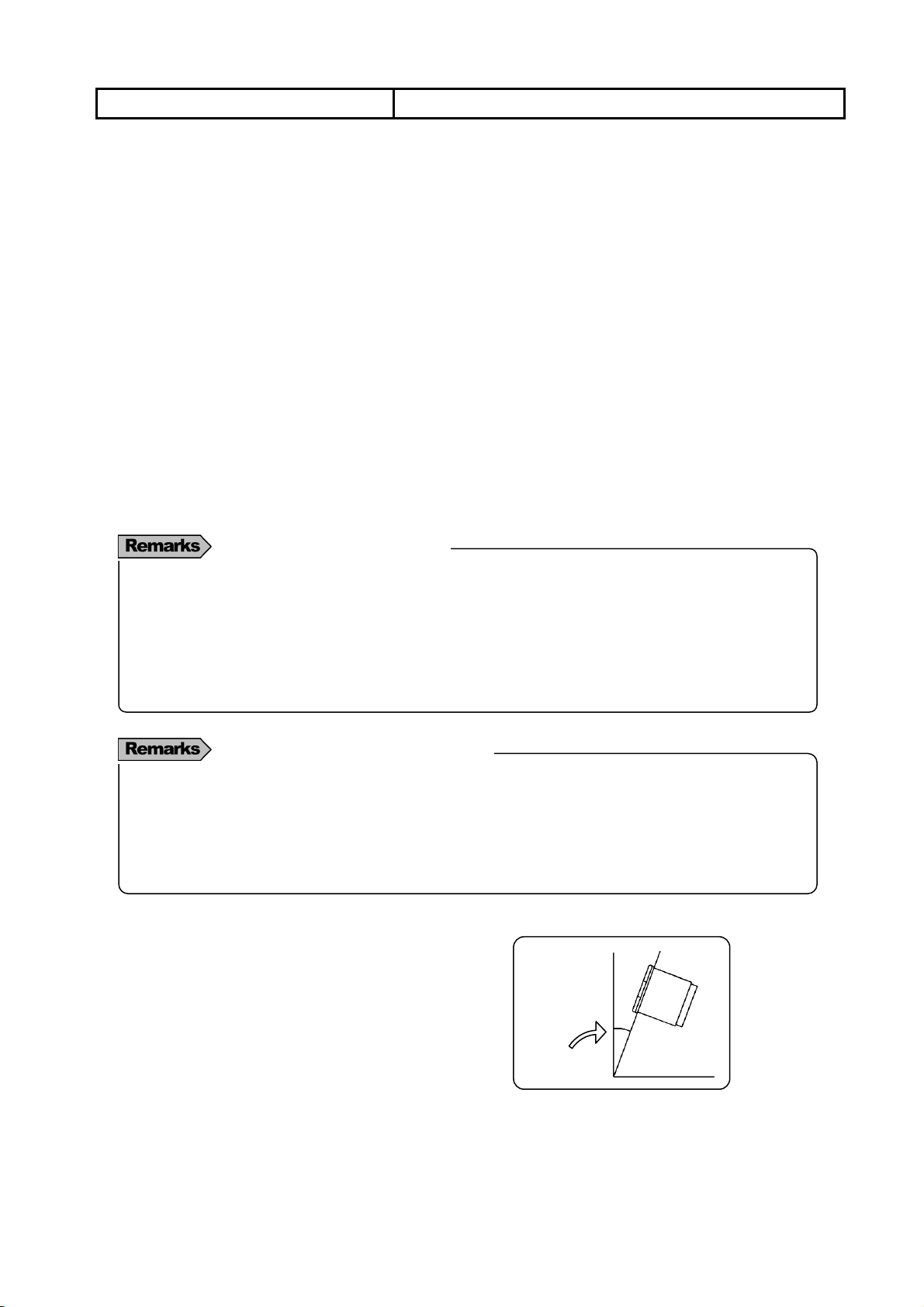

2) Prepare a Chart Paper.

To prevent double feeding, disentangle the both ends of paper

well.

Pen Lift Lever Operation

Rear stripper plate

-34-

Page 38

5. LOADING

3) Put the Chart Paper in the Container.

Sprocket holes on the right and left of the chart paper are