Page 1

INST.No. INE-844E

AL4000 (Multi-point type)

Hybrid Memory Recorder

[ General ]

Page 2

1. Introduction .................................................................................................................... 1

2. For Safe Use ................................................................................................................... 4

2-1. Preconditions for Use ......................................................................................................................................... 4

2-2. Symbol Mark....................................................................................................................................................... 4

2-3. Label ................................................................................................................................................................... 4

2-4. Important Explanation ......................................................................................................................................... 5

3. Model Code List ............................................................................................................. 6

4. Mounting and Wiring ..................................................................................................... 7

4-1. External Dimensions ........................................................................................................................................... 7

4-2. Mounting ............................................................................................................................................................. 7

4-3. Wiring ................................................................................................................................................................. 9

5. Part Names ................................................................................................................... 26

5-1. Front Section of Internal Unit ............................................................................................................................ 26

5-2. Operation/Set Keys .......................................................................................................................................... 27

6. Operation ...................................................................................................................... 28

6-1. Preparation for Operation ................................................................................................................................. 28

6-2. Basic Operation ................................................................................................................................................ 30

6-3. Operation .......................................................................................................................................................... 33

7. Factory Default Settings .............................................................................................. 37

7-1. List of Factory Default Settings ......................................................................................................................... 37

8. Setting Method ............................................................................................................. 38

8-1. Basic Rules....................................................................................................................................................... 38

8-2. Input Type Settings “Range” ............................................................................................................................. 40

8-3. Alarm Settings “Alarm” ..................................................................................................................................... 43

8-4. Calculation Settings “Calc” ............................................................................................................................... 50

8-5. Formula Settings “Formula” ................................................................ .............................................................. 54

8-6. Broken Line Approximation Table Settings “Seg.Tbl” ........................................................................................ 61

8-7. Chart Speed Settings “Chart” ........................................................................................................................... 62

8-8. Dot Printing Settings “Dot” ................................................................................................................................ 63

8-9. Subtract Printing Settings “Sub Prt” .................................................................................................................. 64

8-10. Dot Printing Interval Settings “Dot.Int” .............................................................................................................. 66

8-11. Periodic (Data Interval) Data Printing Settings “DataInt” ................................................................................... 67

8-12. Periodic (Specified Time) Data Printing Settings “PrtTime” ............................................................................... 68

8-13. List Printing Settings “ListPrt” ........................................................................................................................... 69

8-14. Message Printing 1 Settings “MsgPrt1” ............................................................................................................ 70

8-15. Message Printing 2 Settings “MsgPrt2” ............................................................................................................ 71

8-16. Recording Format Settings “PrtForm” ............................................................................................................... 72

8-17. Auto Range Settings “A.Range” ....................................................................................................................... 73

8-18. Compressed/Expanded Printing Settings “Cmp&Exp” ...................................................................................... 75

8-19. Zone Printing Settings “ZonePrt” ...................................................................................................................... 77

8-20. SD Card “SD CARD” ........................................................................................................................................ 79

8-21. USB Engineering Port Settings “USB” .............................................................................................................. 85

8-22. Calendar Timer Settings “Timer” ....................................................................................................................... 86

8-23. Fail Output Settings “FailOut” ........................................................................................................................... 87

8-24. Display Settings “Display” ................................................................................................................................. 89

8-25. Measured Value Display Order Settings “D.Order” ........................................................................................... 90

8-26. Date and Time Settings “Date” ......................................................................................................................... 91

8-27. System Settings “System” ................................................................................................................................ 92

8-28. System Information Display “SysInfo” ............................................................................................................... 93

Table of contents

Page 3

9. Adjustment ................................................................................................ ................... 94

9-1. Trace Printing (Dot Printing) Position Adjustment “Rec Adj” ............................................................................. 94

9-2. Input Adjustment “Inp Adj” ................................................................................................................................ 95

9-3. Input Shift Adjustment ....................................................................................................................................... 96

9-4. Wiring and Environment for Input Adjustment................................................................................................... 97

10. Engineering Port (Mini-USB Terminal) ..................................................................... 98

11. Troubleshooting......................................................................................................... 99

11-1. Problems and Remedies .................................................................................................................................. 99

11-2. Abnormal Measured Value ............................................................................................................................. 100

12. Inspection and Maintenance ................................................................................... 101

12-1. Routine Inspection .......................................................................................................................................... 101

12-2. Consumable Parts and Replacement Guideline ............................................................................................. 101

12-3. Disposal .......................................................................................................................................................... 102

13. Option ....................................................................................................................... 104

13-1. External Operation Settings “Dig Inp” ............................................................................................................. 104

13-2. Operation Recording Settings “Ope.Rec” ....................................................................................................... 107

13-3. COM Port Settings “COM1” and “COM2” ....................................................................................................... 108

13-4. IP Address etc… Settings “Ether” ................................................................................................................... 109

13-5. SNTP Settings “SNTP” ................................................................................................................................... 110

13-6. E-mail Settings “E-mail” ................................................................................................................................... 111

14. Specifications ........................................................................................................... 114

Page 4

- 1 -

1. Introduction

Thank you for purchasing AL4000 series (Multi-point Type) with 100mm recording width.

This industrial use instrument records input signals to the chart paper and stores data into the SD card.

Mount this instrument on the indoor instrumentation panel etc. and record signals of temperature sensor, pressure gauge,

hygrometer and flow meter. Reading signals of the recorder are thermocouple, resistance thermometer, DCmV and DCV.

Make sure to read this instruction manual in advance to understand this unit well and prevent troubles from occurring. This

manual is a “General” Instruction manual. For specifications with communications, read the “Communications” instruction

manual separately.

- To the persons doing instrumentation, installation, and sales -

Make sure to provide this instruction manual to the person who uses the unit.

- To the users of this unit -

Store this instruction manual with care until you scrap the unit.

Also, write down the parameter contents set in the product and keep it for your record.

Perchlorate Material

This instrument uses battery with Perchlorate Material.

Special handling may apply, see

http://www. dtsc.ca.gov/hazardouswaste/perchiorate

Warning

Request

1. Microsoft, Windows, Windows XP, Windows Vista, Windows 7, and NET Framework are trademarks of Microsoft

Corporation and the related company.

2. SD Memory Card is the trademark of Panasonic Corporation, SanDisk Corporation in USA, and TOSHIBA

CORPORATION.

3. Other described company names and product names are trademarks and registered products of the respective

companies.

4. Please note that the marks “TM” and “®” are omitted throughout this manual.

Trademark

1. No part of this manual can be reproduced or copied in any form without permission.

2. The contents of this manual may be altered without prior notice.

3. This manual has been documented by making assurance doubly sure. However, if any question arises or if any

error, an omission, or other deficiencies are found, please contact your nearest our sales office.

4. CHINO is not responsible for any operation results of this software.

Notice

This product is warranted for one year from the date of delivery. If it is damaged during the warranty period, when

used normally based on the cautions in the instruction manual labels attached to the product, etc., it will be repaired

without any charge (only in Japan). In the case, we are sorry to trouble you, but please contact your dealer or

nearest our sales office.

However, in cases of the followings, it will be repaired at your expense even during warranty period.

1. Failure or damage caused by improper use or connection, or invalid repair or modification.

2. Failure or damage caused by fire, earthquake, wind or flood, thunderbolt, or other extraordinary natural

phenomena, or pollution, salt, harmful gas, abnormal voltage, or use of unspecified power.

3. Replacement of parts or accessories that have reached the end of their life.

Furthermore, the term ‘warranty’ in this sense covers only a CHINO’s product itself. Therefore, we are not

responsible for compensation for whatever the damage that is triggered by failure of our product.

Product warranty scope

Page 5

- 2 -

Before use

Make sure to check the following before use after unpacking the unit. If you have any question, please contact your dealer

or our nearest office.

1. Exterior check

Check that the appearance of the product has no damage.

2. Model code check

Check that the model code of the purchased product is correct.

Model code label and application place

The label as follows is attached on the upper surface of the product case and the chassis.

A L 4 7 -- ← Model code

R 3 ← Serial number

M A D E I N J A P A N

3. Accessories check

Check the following accessories attached to the product.

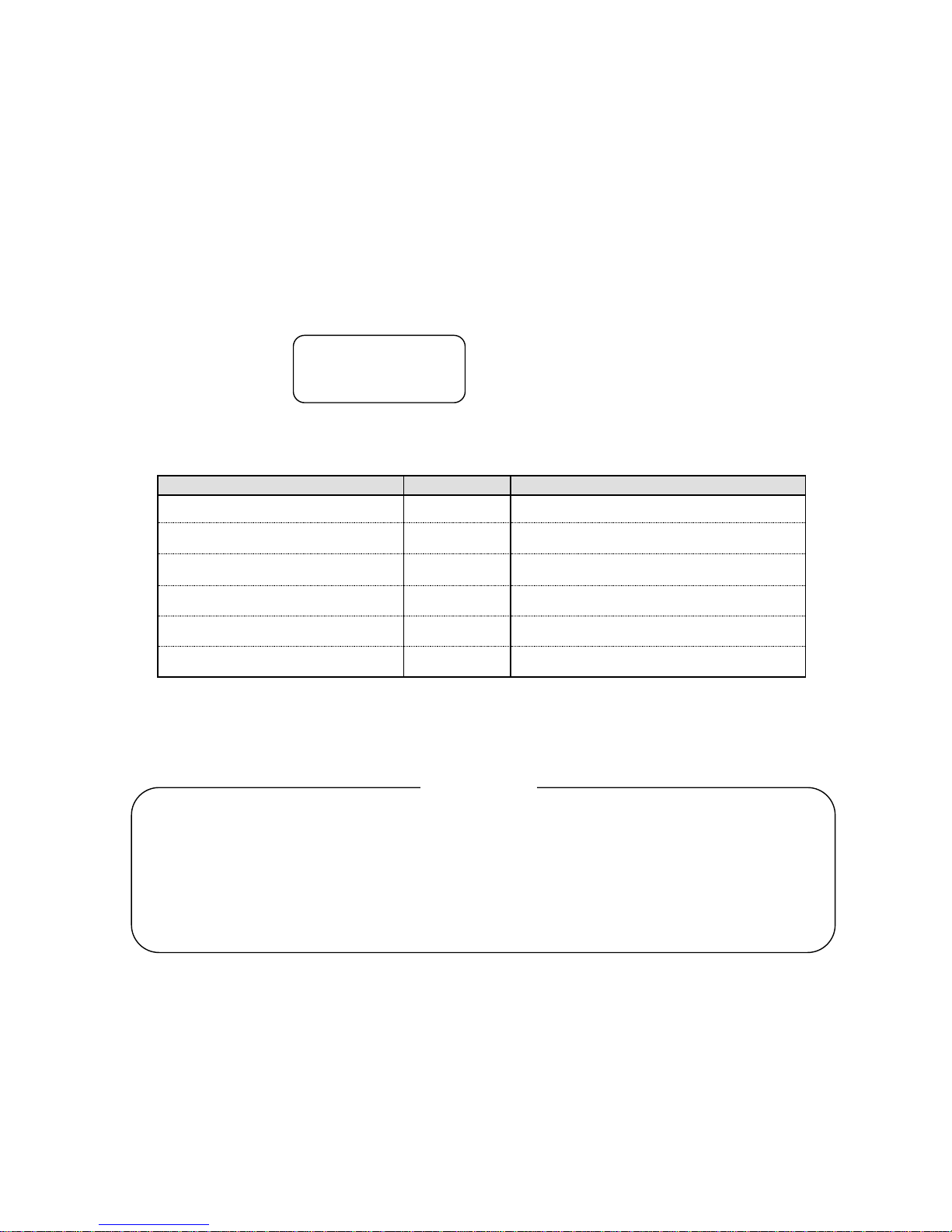

Item

Q'ty

Remarks

Instruction manual

1

CD-R

Instruction manual [Wiring/Installation]

1

Booklet

Bracket

2 (1 set)

For panel mounting, 22025-029001

Terminal screw

5

M3.5, for input terminal (spares for missing)

Chart paper

1

The type depends on the specifications.

Ribbon cassette

1

84-0044

In addition, if accessories are purchased additionally, those products may be attached.

1. Do not drop the product while take it out of the box

2. When transporting the unit, pack in the dedicated package box, and put the box in an outer case with a bed of

cushion.

With the consideration to the case above, it is recommended that the dedicated package box for the unit is

stored.

3. When the unit is removed from the panel and not used for a long time, put it in the dedicated package box, and

store it in a place with normal ambient temperature and less dust.

Request

Page 6

- 3 -

4. About attached chart paper

For the unit, the chart paper No.EM001 (50 equal divisions) is available and delivered. For the case that the chart

paper is to be specified, various scales are available as follows.

Chart Paper for Standard Scale

Standard scale (linear)

Chart paper No.

Standard scale (linear)

Chart paper No.

0 to 50C

0 to 100C

0 to 150C

0 to 200C

0 to 250C

0 to 300C

0 to 400C

0 to 500C

0 to 600C

0 to 800C

0 to 1000C

0 to 1200C

0 to 1400C

0 to 1600C

EL05014

EL05052

EL05034

EL05047

EL05096

EL05124

EL05009

EL05048

EL05168

EL05121

EL05157

EL05116

EL05137

EL05147

-20 to 80C

-50 to 50C

-50 to 150C

0 to 10mV

0 to 20mV

0 to 50mV

-5 to 5mV

-10 to 10mV

1 to 5V

Double to triple scale

Nonstandard scale

EL05035

EL05006

EL05019

EM001*

(Scale with 50-equal

divisions)

* Scale marks

without numeric

values and unit

* The chart paper has the same printed linear scale as the standard scale.

Therefore, it can be shared in regardless of input types (thermocouple, resistance thermometer, or others).

5. Restriction of digital recording/printing function

(1) Data printing requires approximately two minutes. Note that when data printing is executed, the trace printing

stops until the printing is finished.

(2) When the chart speed is set to 251mm/H or more, power-on printing, data printing, list printing, and printing

function for other than time line are disabled.

(3) The trace printing executes dot printing with five seconds interval (standard); however, if time printing is

executed during the trace printing, the dot interval may become longer. The dot interval is extended with the

inserted printing. Therefore, this is not abnormal.

(4) Printing is formed with dots of one pin. Therefore, if the power is turned off while characters are being formed,

they cannot be formed correctly. This is not abnormal.

Page 7

- 4 -

2. For Safe Use

If the unit is used in a manner not specified by manufacturer, the protection provided by the unit may be impaired.

For safe use of the unit, please read and understand the following cautions.

2-1. Preconditions for Use

The unit is a component type general product to be used mounted on an indoor instrumentation panel. Avoid using under

other conditions.

Use after the system safety is implemented such as the fail-safe design and periodical inspection on the final product side.

Also, for wiring/adjustment/operation of the unit, ask professionals with instrumentation knowledge to perform.

Furthermore, also the person who actually uses the unit is required to read this instruction manual to fully understand

various cautions and basic operation.

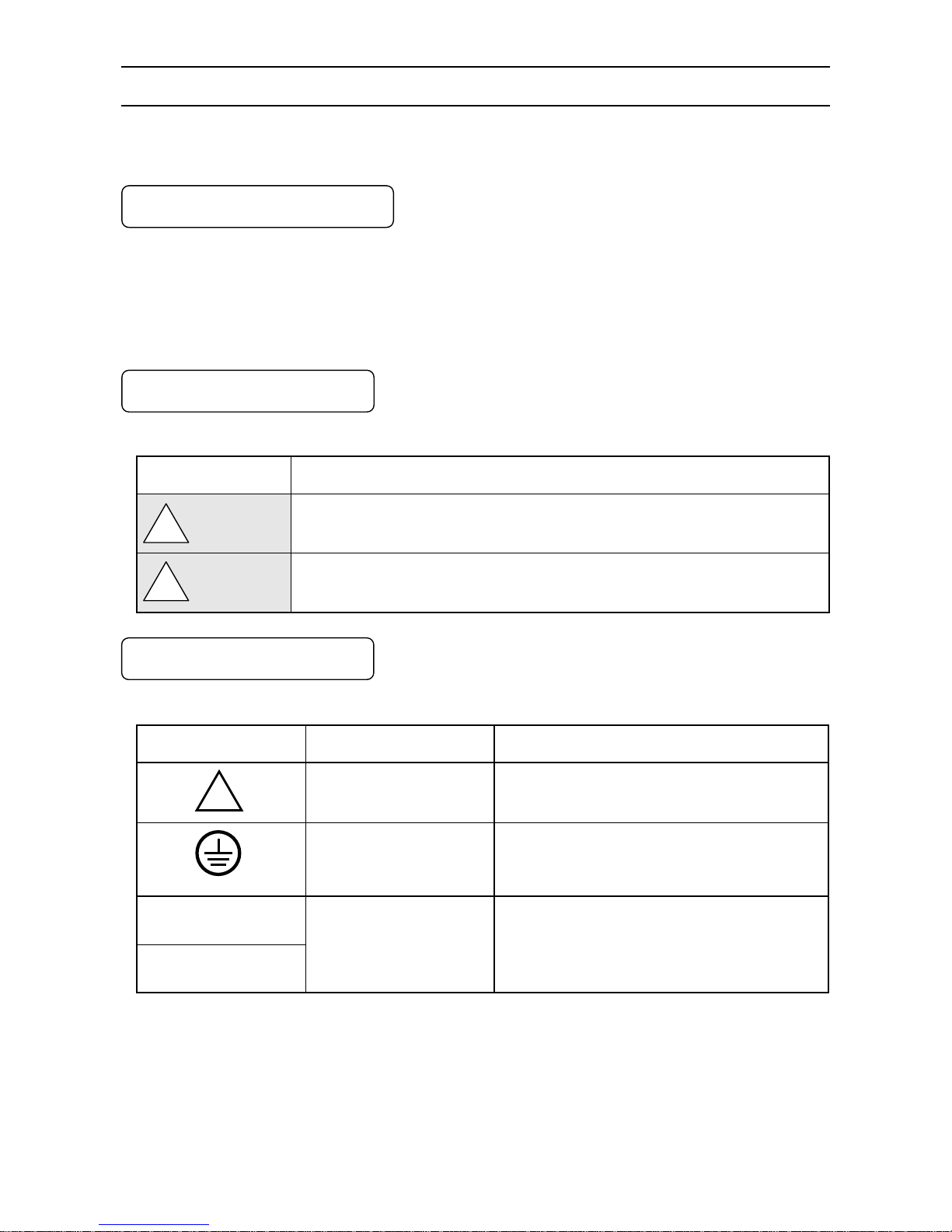

2-2. Symbol Mark

This instruction manual includes the following symbol marks. Make sure to fully understand the meaning of them.

Symbol mark

Meaning

Cautions are explained to avoid causes for death or serious injuries of users.

Cautions are explained to avoid causes for slight injuries of users or damages of the unit

or peripheral devices.

2-3. Label

For safe use of the unit, the following labels are used.

Label

”Name” and place

Meaning

“Alert symbol mark”

Various terminals

(back side)

Place to be handled with cautions to avoid “electric

shock”, “injuries”, etc.

“Protective conductor

terminal”

Right side of power terminal

(back side)

Terminal to be grounded to avoid electric shock

100 to 240V AC

50/60Hz, 40VA

“Power source specification”

Power conductor terminals

Specification of power (voltage range, frequency,

and power consumption) used for the unit

!

!

Warning

!

Caution

Page 8

- 5 -

2-4. Important Explanation

To avoid severe accidents, make sure to read and understand the following.

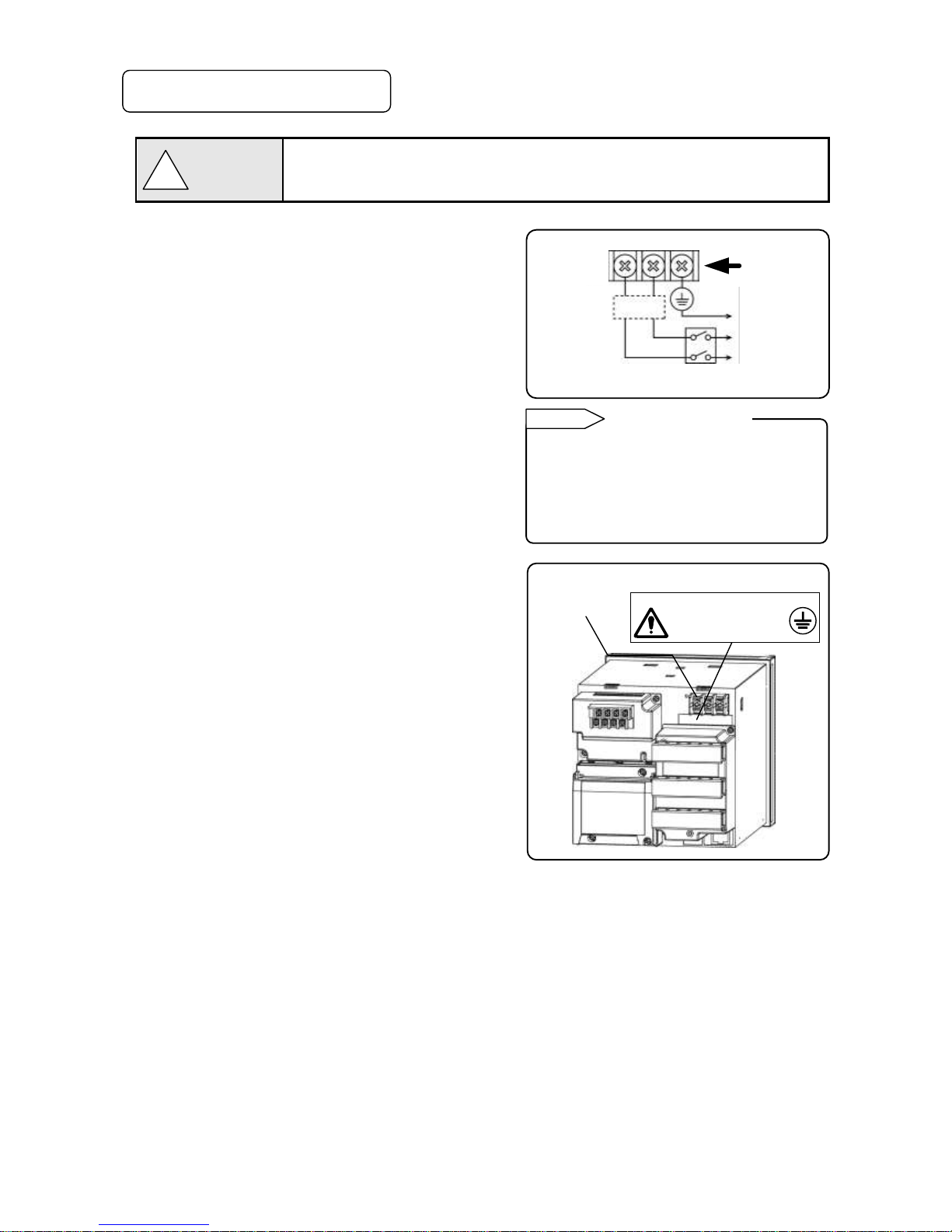

1. Switch and overcurrent protection device

This unit is not provided with a replaceable overcurrent

protective device. Prepare a switch and an overcurrent

protective device for the power supply (circuit breakers,

circuit protectors or the like) within 3m of this unit in a

location where the operator can access easily. Use a switch

and an overcurrent protective device conforming to

IEC60947-1 and IEC60947-3.

2. Be sure to ground this instrument

To avoid electric shock, before turning the power on,

connect the protective conductor terminal of this recorder to

the protective conductor of the power supply equipment,

and do not remove it during use.

3. Before turning on the power supply

For safety, first check that the power source is within the

range indicated on the power label, and then turn on the

external power switch.

4. Avoid repair and modification

Avoid repair and modification with parts replacement by

persons other than service personnel authorized by CHINO.

Not only damage or malfunction of this recorder may occur,

but also dangers such as electric shock may occur. In

addition, the inner unit does not have to be pulled out in the

normal use.

5. Use the unit following the instruction

manual

For safe use, use the unit following the instruction manual.

Please note that CHINO does not have any responsibilities

for any claims for failures or damages occurred with abuse

or misuse of this recorder.

6. Installing the safety device

Regarding the use of a device that anticipates a big loss due to failure of the controller and the peripheral device,

always install a safety device for preventing these losses and implement fail safe design in the final product.

Do not use it in important in facilities like, human life,atomic energy, aviation and space.

7. Turn off the power supply if abnormality occurs

Turn off the power supply immediately and contact your local CHINO’s sales office if any abnormal odor, noise or

any smoke occurs, or if this unit becomes high temperature that is too hot to be touched.

8. Do not put hands in this product

Do not put your hands or tools inside of this product. It may cause electric shock or injuries.

There is no operation such as pulling out an inner unit or using tools when using this product.

Overcurrent

protection

device

Switch

!

Warning

Power terminal

Protective

conductor

terminal

Power label

100 to 240V AC

50/60Hz 40VA

To the protective

conductor of

power supply

facility

Power/protective

conductor

terminal

Power source

For safety, the fuse below is included in the

power unit of the unit. It cannot be replaced.

Manufacturer:Daito Communication

Apparatus Co.,Ltd

Model: SBL32

Fuse in power unit

Reference

Page 9

- 6 -

3. Model Code List

AL47□□-□□□-□□□

Input point

06: 6 points

Communications

N: None

E: Ethernet

R: RS232C

A: RS422A/RS485

Q: RS232C + RS485

C: RS422A/RS485 + RS485

G: Ethernet + RS422A/RS485 + RS485

F: Ethernet + RS422A/RS485 + RS485 + Low-order communications

Alarm output + remote contacts

0: None

2: 2 mechanical relay 'a' contact alarm outputs

4: 4 mechanical relay 'c' contact alarm outputs + 5 remote contacts

A: 6 mechanical relay 'a' contact alarm outputs + 5 remote contacts

Power

A: 100 to 240V AC

For OP/SP

NNN: None

NNP: SD card playback

Page 10

- 7 -

4. Mounting and Wiring

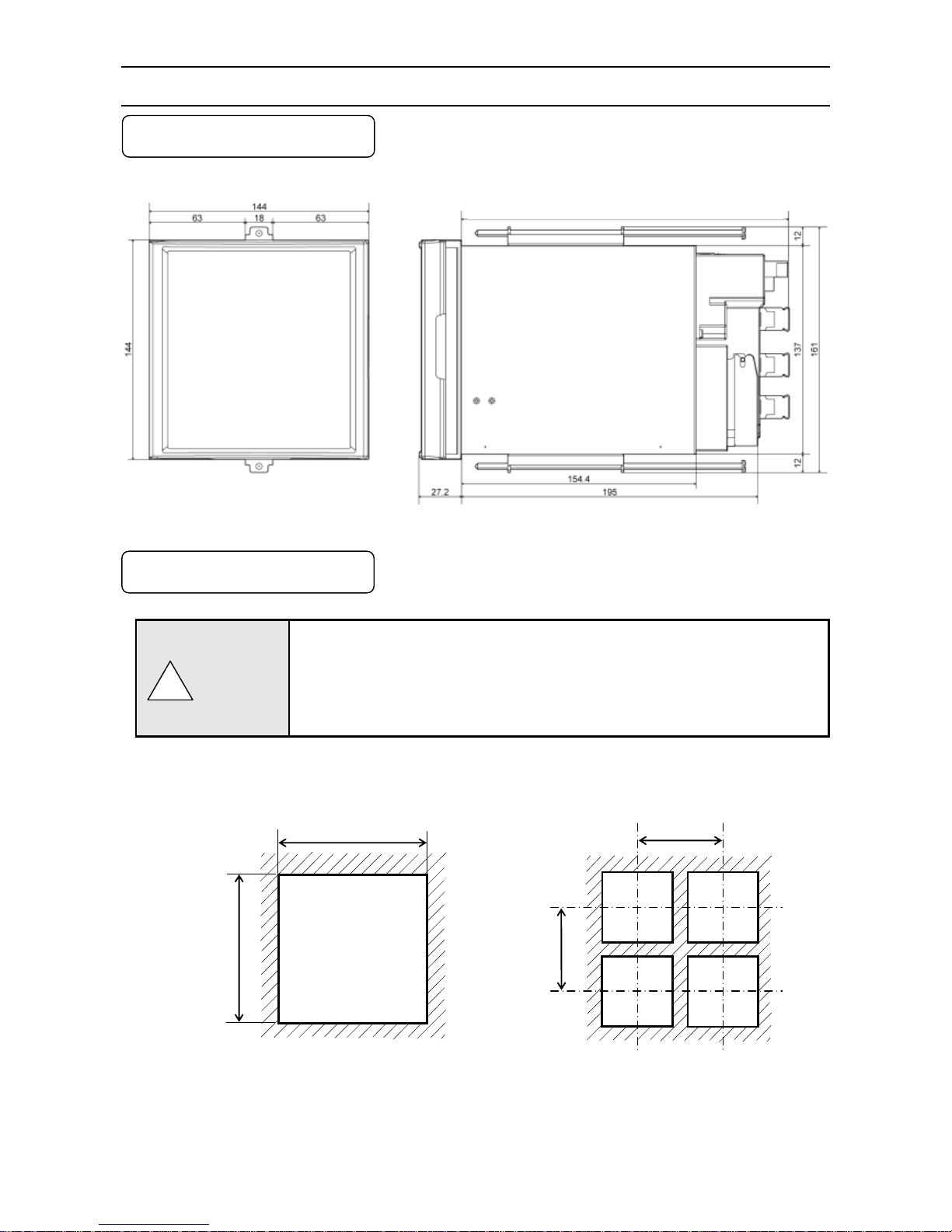

4-1. External Dimensions

Following dimensions are measured while the brackets are attached to the unit.

Unit: mm

4-2. Mounting

(1) Use the recorder mounting on an indoor installed instrumentation panel.

(2) Brackets can be attached to a panel of steel with thickness of 2 to 6mm or

equivalent strength.

Select thickness of a panel considering weight and depth of the unit with panel

formation for actual use.

(3) For mounting the recorder on the panel, be careful of injury by dropping it.

1. Panel cutout and mounting method

Unit: mm

138

+1

0

138

200

200

● Minimum interval on multiple

units mounting

!

Caution

216 When alarm output/remote contacts unit and communication unit are added

Page 11

- 8 -

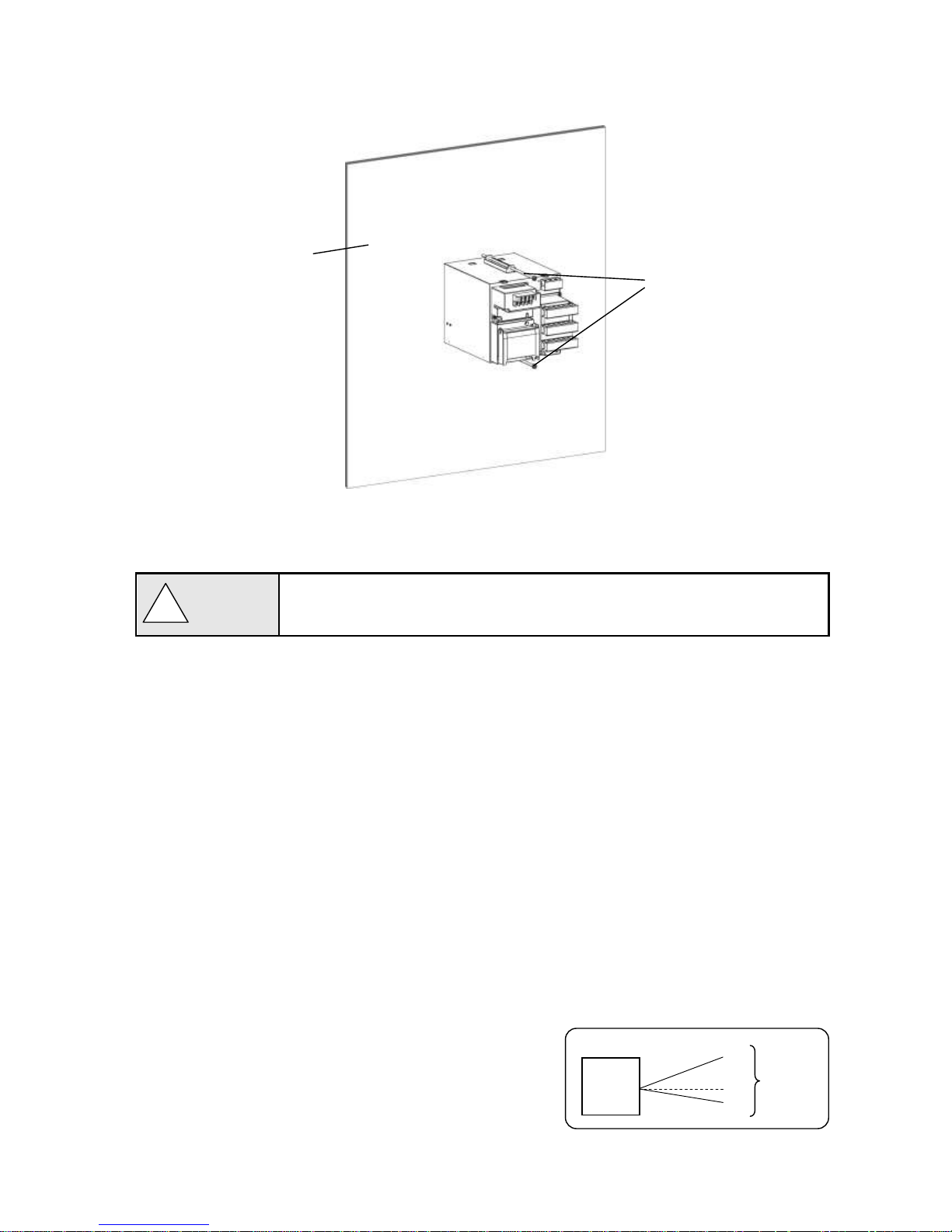

(1) Insert the unit into the panel cutout from the front of the panel.

(2) Fix the unit to the panel using the brackets (tightening torque: 1.0Nm). Brackets are attached to the top and

bottom surfaces.

2. Mounting condition

To avoid accidents, make sure to read and understand the following.

Industrial environment

Select a location distant from sources of electric field or magnetic field and without mechanical vibration or shock.

● Overvoltage category ...... II (EN standard) ● Altitude ........................... 2000m or less

● Pollution degree .............. 2 (EN standard) ● Working place ................ Indoor

Normal operating condition

● Ambient temperature ··· 0 to 50℃(20 to 65%RH,non-condensing)

● Ambient humidity ········· 20 to 80%RH,non-condensing(5 to 45℃)

● Power voltage ············· General specification : 100 to 240V AC ±10%

● Power frequency ········· General specification : 50/60Hz ±2%

Atmosphere

● For safety, avoid a location with corrosive gas, explosive gas, flammable gas and combustible gas.

● Avoid a location with dust, smoke, or steam.

Mounting angle

● Lateral tilting ················ 0 to 10°

● Longitudinal tilting ······· Forward tilting: 0°Backward tilting: 0 to 30°

● View angle ··················· -10 to +30°with the horizon as the standard

Angles other than the above affect the recording operation.

!

Caution

Indicator

View angle

About 30°

About 10°

Panel thickness

(2 to 6mm)

Brackets

Page 12

- 9 -

4-3. Wiring

1. Terminal board diagram

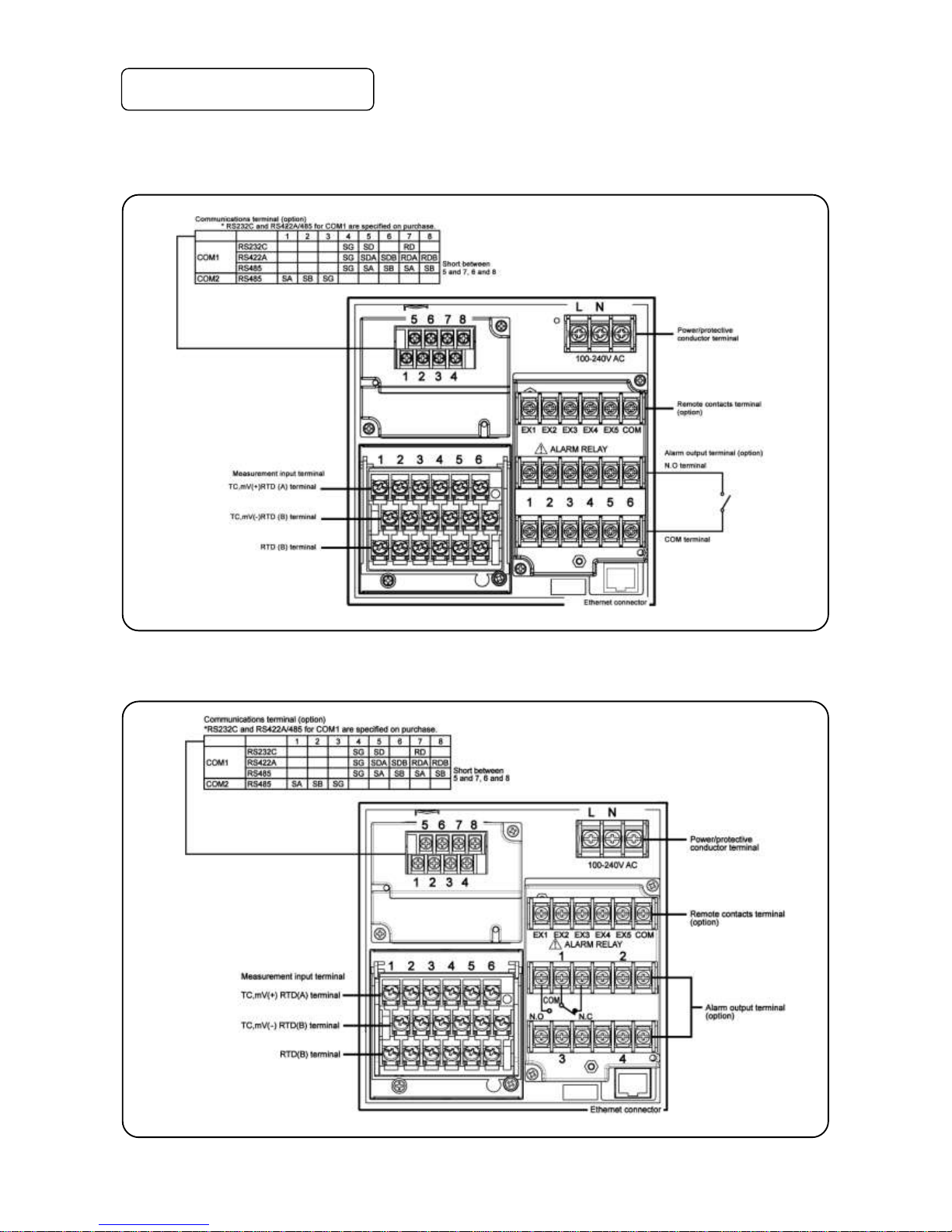

The figure below is the diagram of the terminal board with the option [Alarm relay output (6 points ‘a’ contact) +

remote contacts and communication interface].

The figure below is the diagram of the terminal board with the option [Alarm relay output (4 points ‘c’ contact) +

remote contacts (20 points) and communication interface].

Page 13

- 10 -

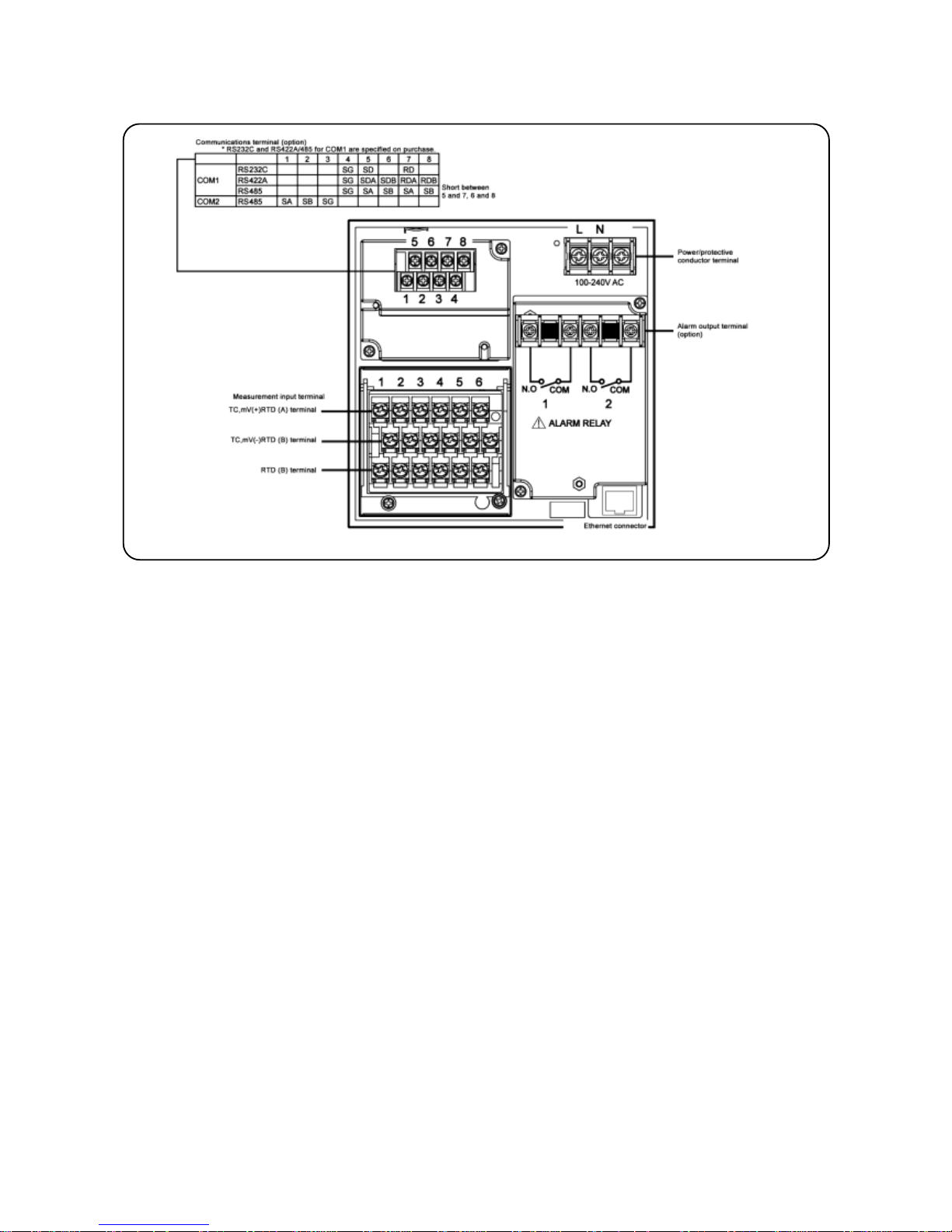

The figure below is the diagram of the terminal board with the option [Alarm relay output (2 points ‘a’ contact) and

communication interface].

Page 14

- 11 -

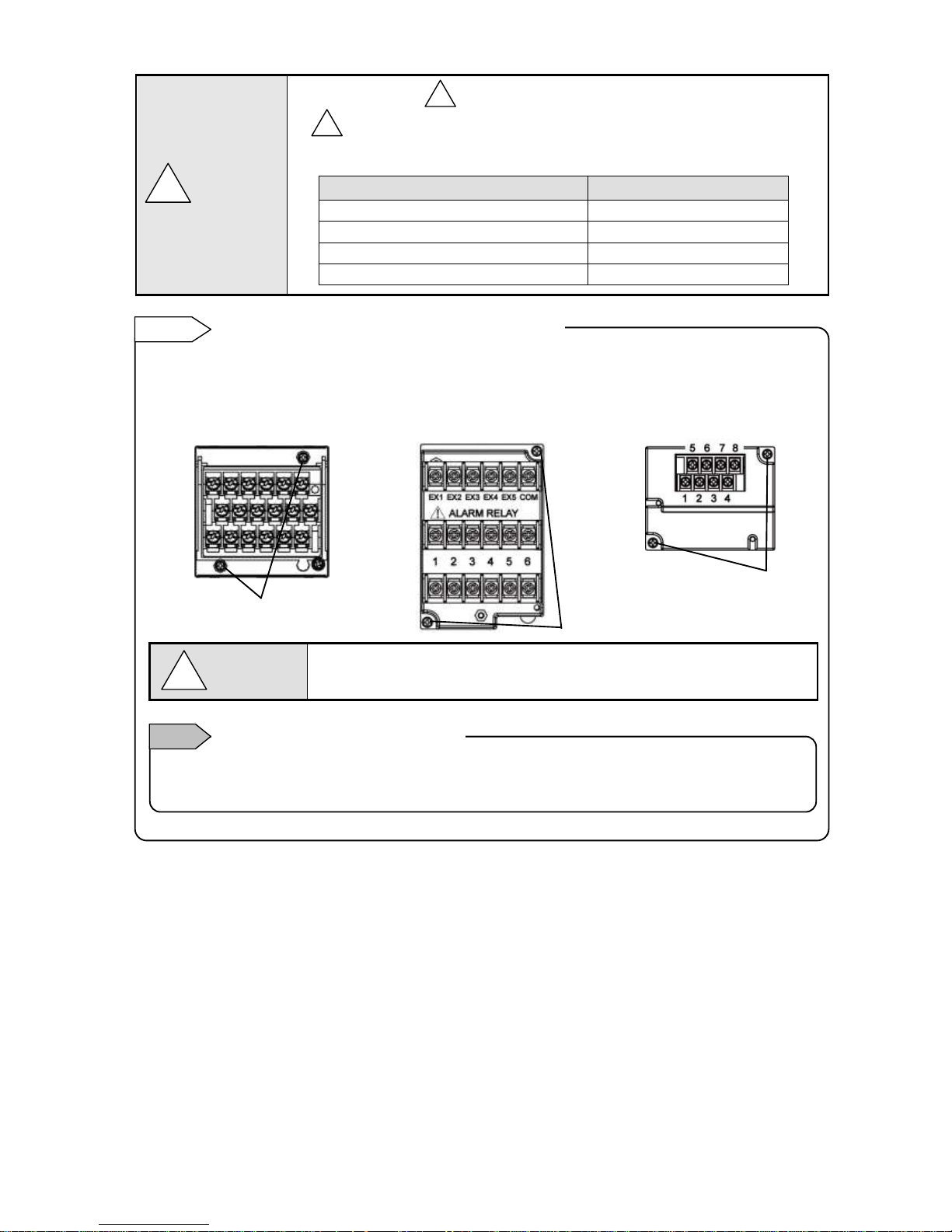

Alert symbol mark ( ) and location

mark is attached to the location to which if human body touches, an electric shock

may be generated.

Terminal name

Location of attached mark

Power terminal

Lower left of power terminal

Measurement input terminal

Upper left of terminal cover

Mechanical relay ‘c’ contact alarm terminal

Upper left of terminal cover

Mechanical relay ‘a’ contact alarm terminal

Lower left of N.O terminal

!

!

!

Warning

For easy wiring, the input unit, alarm output/remote contacts unit, and communication unit are removable.

(1) Every unit can be removed when two mouting screws are removed.

(2) The recorder and each unit are connected with a connector.

Turn off the power and then remove/attach

Make sure to turn off the external power switch before units are removed/attached

to prevent damages on electric circuits.

Input terminal block and alarm terminal block are removable.

Reference

Only thermocouple input unit cannot be replaced with other instrument unit. If done so, measurement errors

are generated.

Note

Thermocouple input unit replacement

!

Warning

[Alarm output/remote contacts unit]

[Input unit]

[Communications unit]

Mounting screws

Mounting screws

Mounting screws

Page 15

- 12 -

2. Precautions on wiring

Precautions on wiring are described below. Observe them to maintain safety and reliability.

1) Feed power source

For the power source for the unit, use the single-phase power source with stable voltage and without

waveform strain to prevent malfunctions.

(1) Switch and overcurrent protective device

Add a switch and overcurrent protective device (250V,3A) to the feed power source

to prevent an electric shock on wiring. The unit has no replaceable fuse.

(2) Connect after the power source is turned OFF

When performing power and input/output wiring, make sure to turn OFF the feed

power source to prevent an electric shock.

2) Separate from strong power circuits

For input/output wiring, avoid adjacency or parallel with strong power circuits such as power lines. Separate

50cm or more for adjacency or parallel.

3) Separate thermocouple input from heat sources.

To reduce reference junction compensation errors for thermocouple input, especially separate terminals

from heat sources (heating body). Also, avoid radiation such as direct sunlight.

4) Separate from noise sources.

Separate from noise sources as much as possible. Unexpected troubles may occur. If separation from

noise sources is disabled, implement countermeasures.

Main source

Countermeasures

Electromagnetic switch or others

Power line with distortion of wave

Inverter

Thyristor regulator

Insert noise filters between power source and input/output

terminals. CR filters are used in many cases.

!

Warning

Page 16

- 13 -

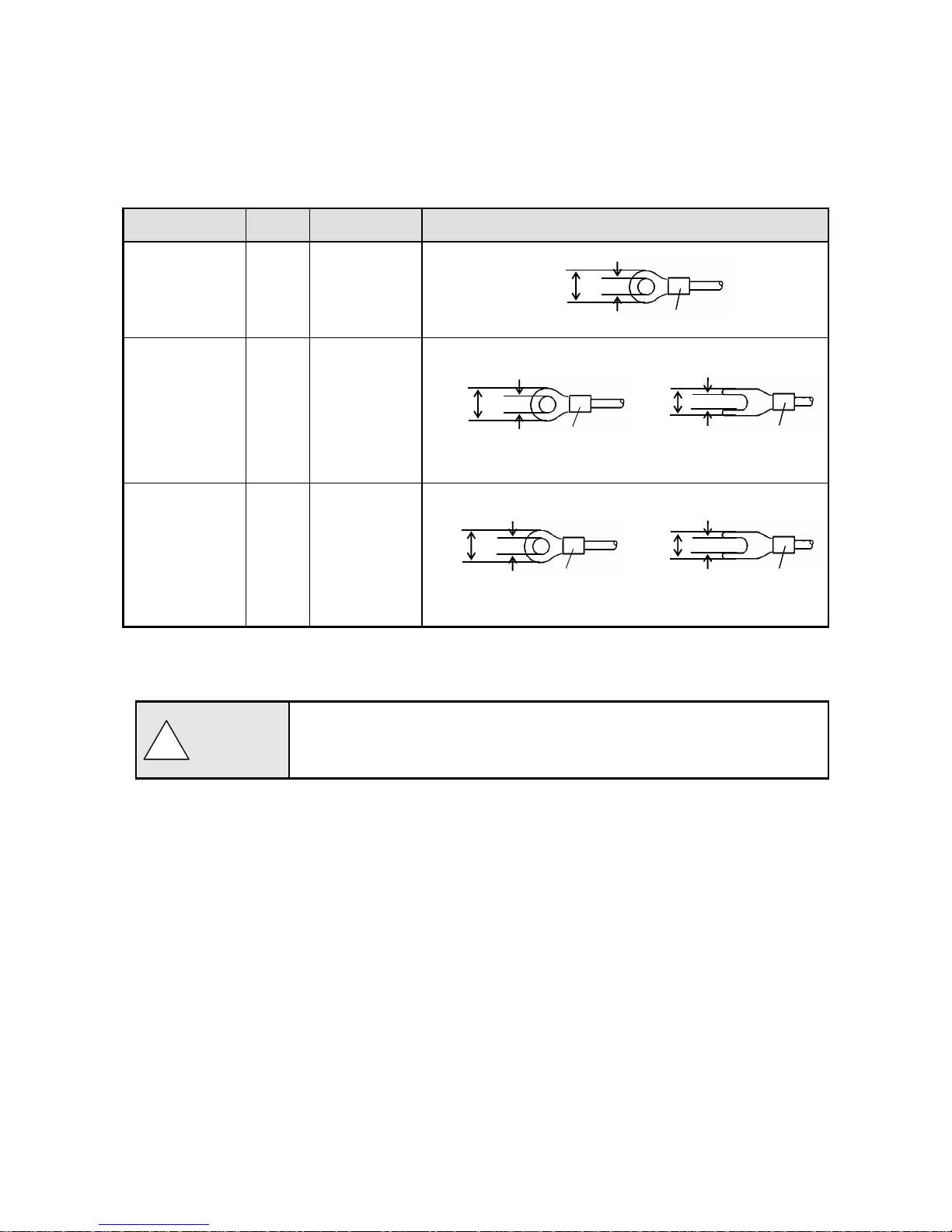

5) Use crimping terminals.

(1) To prevent looseness or disconnection of terminals and short circuit between terminals, install

crimping terminals to termination of connection cables.

(2) To prevent an electric shock, use crimping terminals with insulation sleeves.

Terminal Type and Termination Treatment

Terminal board

Diameter

Tightening torque

Termination treatment (Unit: mm)

Power/Protective

conductor

M4

1.2Nm

O type

Terminals other

than the above

M3.5

0.8Nm

O type Y type

* Be sure to use O type for the alarm output terminals.

* For other terminals, use also O type as possible.

Communications

terminal

M3

0.5Nm

O type Y type

* Use O type as possible.

6) Unused terminals

Avoid using unused terminals for relaying. Electric circuits may be damaged.

Treat properly the wired cables.

Treat surely wired cables not to get hung up on people and things.

Disconnection of wiring with hanging up may cause an electric shock.

8.5 or less

4.3 or less

t: 0.8

With an insulation sleeve

8 or less

3.7 or more

With an insulation sleeve

8 or less

3.7 ormore

t: 0.8

With an insulation sleeve

5.2 or less

3.2 or more

t: 0.8

With an insulation

sleeve

5.2 or less

3.2 or more

With an insulation sleeve

t: 0.8

!

Warning

Page 17

- 14 -

After wiring, install the

terminal cover.

L

N

Copper cable (green/yellow)

with 2mm2 of wire or more

Make sure to connect to

protective conductor of power

facility.

600V vinyl insulated

cable

Power source

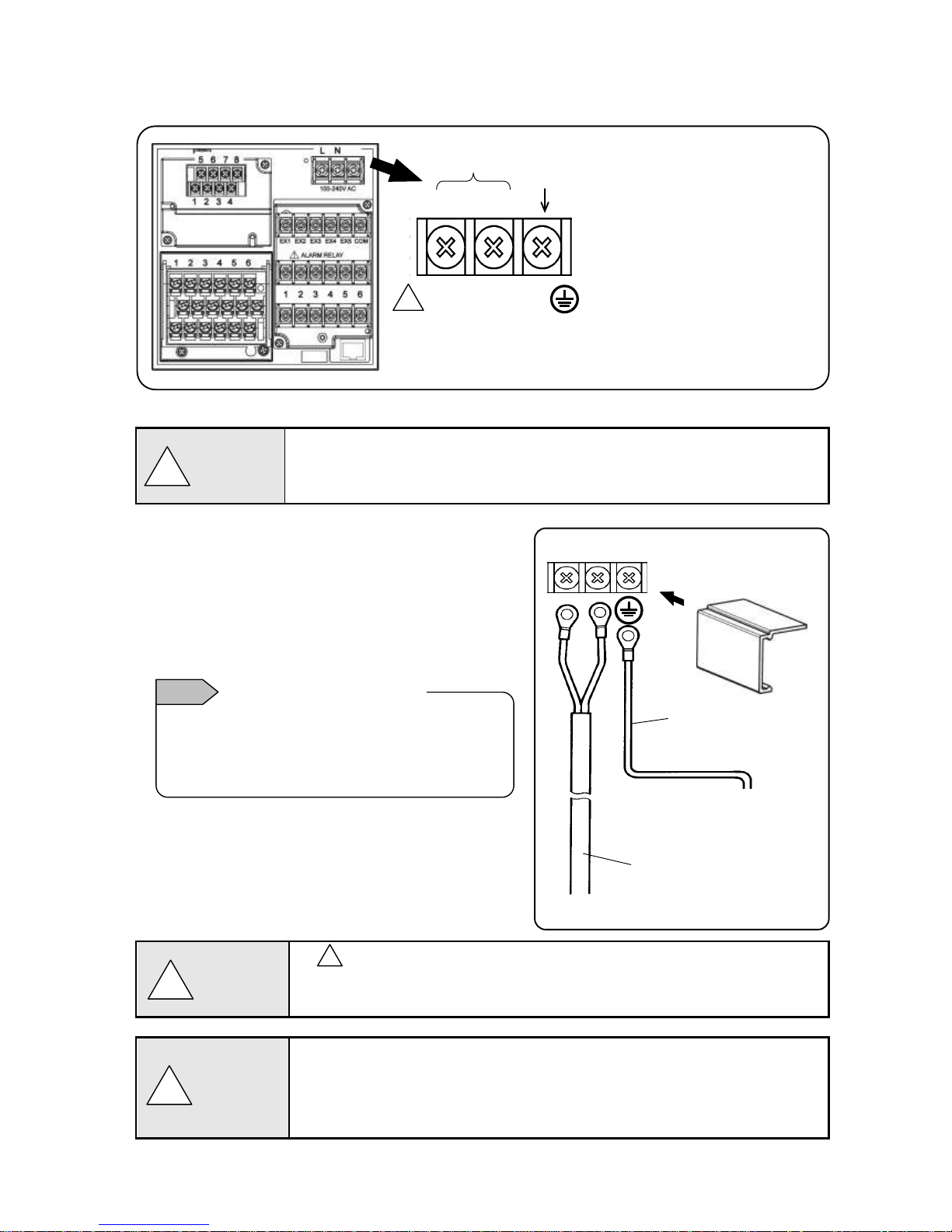

3. Power/protective conductor terminals wiring

1) Power/protective conductor terminals

Turn OFF feed power source.

Before power/protective conductor terminals wiring, make sure to turn off the feed power

source to prevent an electric shock.

2) Power terminal wiring

Using 600V vinyl insulated cables as the power line,

install crimping terminals with insulation sleeves to the

termination for wiring.

Note: Use the following standard cables.

(1) IEC 60227-3

(2) ANSI/UL817

(3) CSA C22.2 No.21/49

3) Protective conductor terminal wiring

Make sure to connect to the protective conductor of the

power equipment. Install crimping terminals with

insulation sleeves for wiring.

Grounding wire: Copper cable with wire diameter

2mm2 or more (green/yellow)

mark at power terminals

After wiring the power terminals have power supply voltage applied. Make sure to install

power terminal covers after wiring to prevent an electric shock.

Pay attention to power supply voltage and noise.

The power supply voltage of the unit is indicated on power terminals. Applying power

other than the indicated one causes accidents or malfunction. In addition, if the power

has noise interference, implement countermeasures such as noise cut transformer

installation.

!

!

Warning

!

Warning

!

Caution

Display based on CSA standard in Canada. The live side

of single-phase AC power supply is L, and the neutral

side is N display. To get sufficient performance, observe

the L/N wiring.

L/N display of power terminal

Note

Power terminal

L

N

Protective

conductor terminal

100 to 240V AC

50/60Hz 40VA MAX

Power (voltage, frequency, and power consumption)

!

Page 18

- 15 -

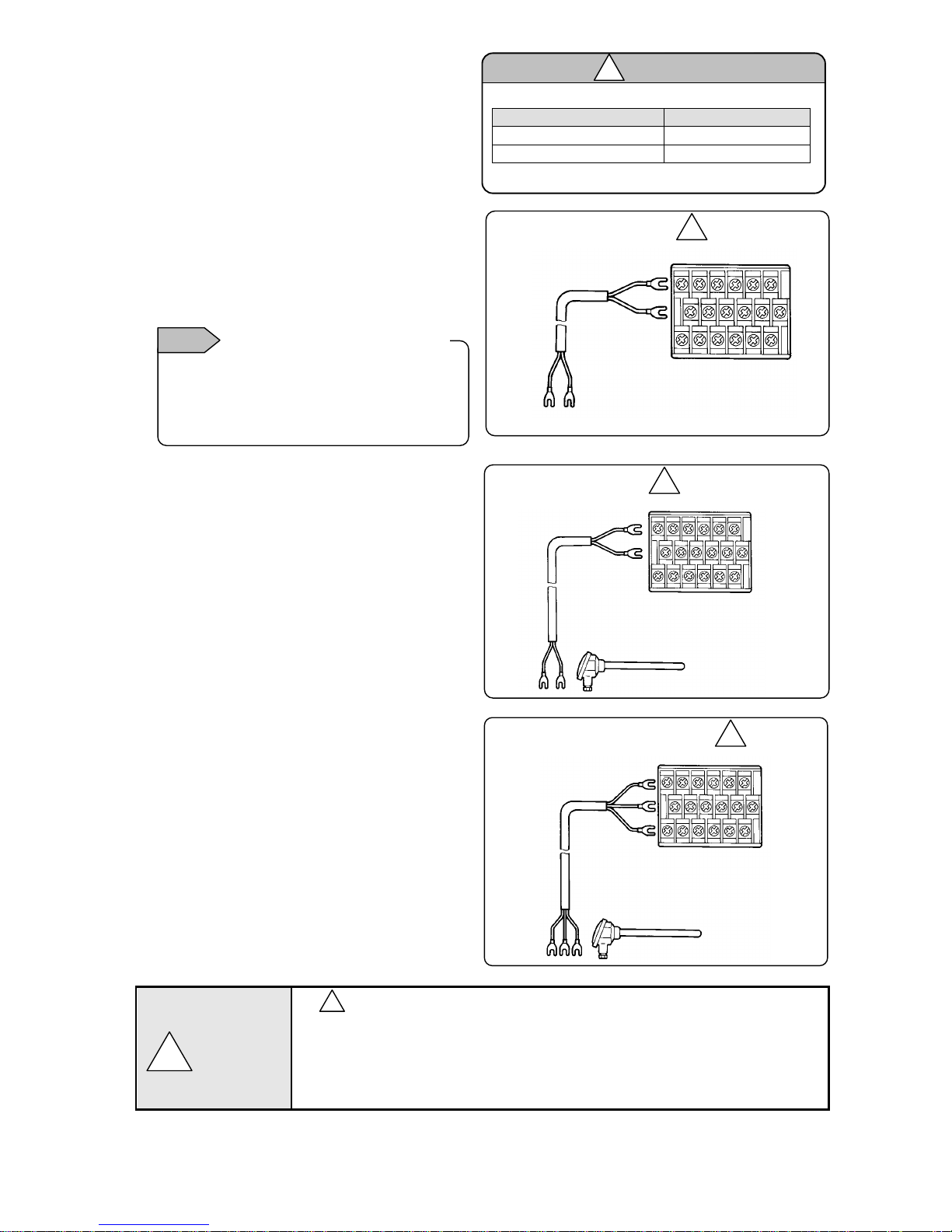

4) Measurement input terminals wiring

1) Measurement input terminal

Turn OFF the feed power source before

wiring to prevent an electric shock.

Install crimping terminals with insulation

sleeves to input terminals for wiring.

2) DC voltage (current) input wiring

Use instrumentation twisted cables for

measures against noise as input cables.

For current input, connect the shunt resistor

for current input to the channel to be

measured before wiring.

3) Thermocouple (TC) input wiring

Make sure to wire thermocouple cable (or

compensation lead wire) to input terminals of

the unit.

If a copper conductive wire is connected

halfway, big measurement error will be

generated.

In addition, avoid parallel connection of a pair

of thermocouple wires with other instruments

(controller or others) that causes troubles.

4) Resistance thermometer (RTD) input wiring

To prevent measurement errors, use 3-core

cables as the input cable in which lines have

the same resistance.

In addition, one resistance thermometer

cannot be connected in parallel with other

instruments (a controller or others).

mark on measurement input terminals

High voltage may be applied to the measurement input terminals due to common mode

noise. Allowable noise value is 30VAC or 60VDC or less. Check that the voltage is equal

to or less than the allowable value. Install terminal covers after wiring to prevent an

electric shock and protect input cables. For thermocouple input, installing terminal

covers reduces reference junction compensation errors.

!

Instrumentation

twisted cable

DC voltage input

(+)

(-)

1 2 3 4 5 6

DC voltage (current) input

!

Resistance thermometer (RTD) input

3-core cable (Same line

diameter, same length)

Note: Cable resistance per 1 cable is 10Ω or less.

3 lines have the same resistance.

1 2 3 4 5 6

Resistance thermometer

A

B

B

!

TC,mV(+) and RTD(A) terminals and TC,mV(-)

and RTD (B “middle”) terminals are insulated

for each channel, and RTD (B”lower”) terminal

shorts internally between channels.

Measurement input termiinsulation

Note

Allowable input voltage

Input type

Allowable input voltage

Voltage, thermocouple input

±10VDC *

Resistance thermometer input

±6VDC

*±60VDC for channels specified with ±10V range or more

Caution

!

Compensation leas wire

Red (+)

White (-)

1 2 3 4 5 6

Thermocouple (TC) input

!

Thermocouple

!

Warning

Page 19

- 16 -

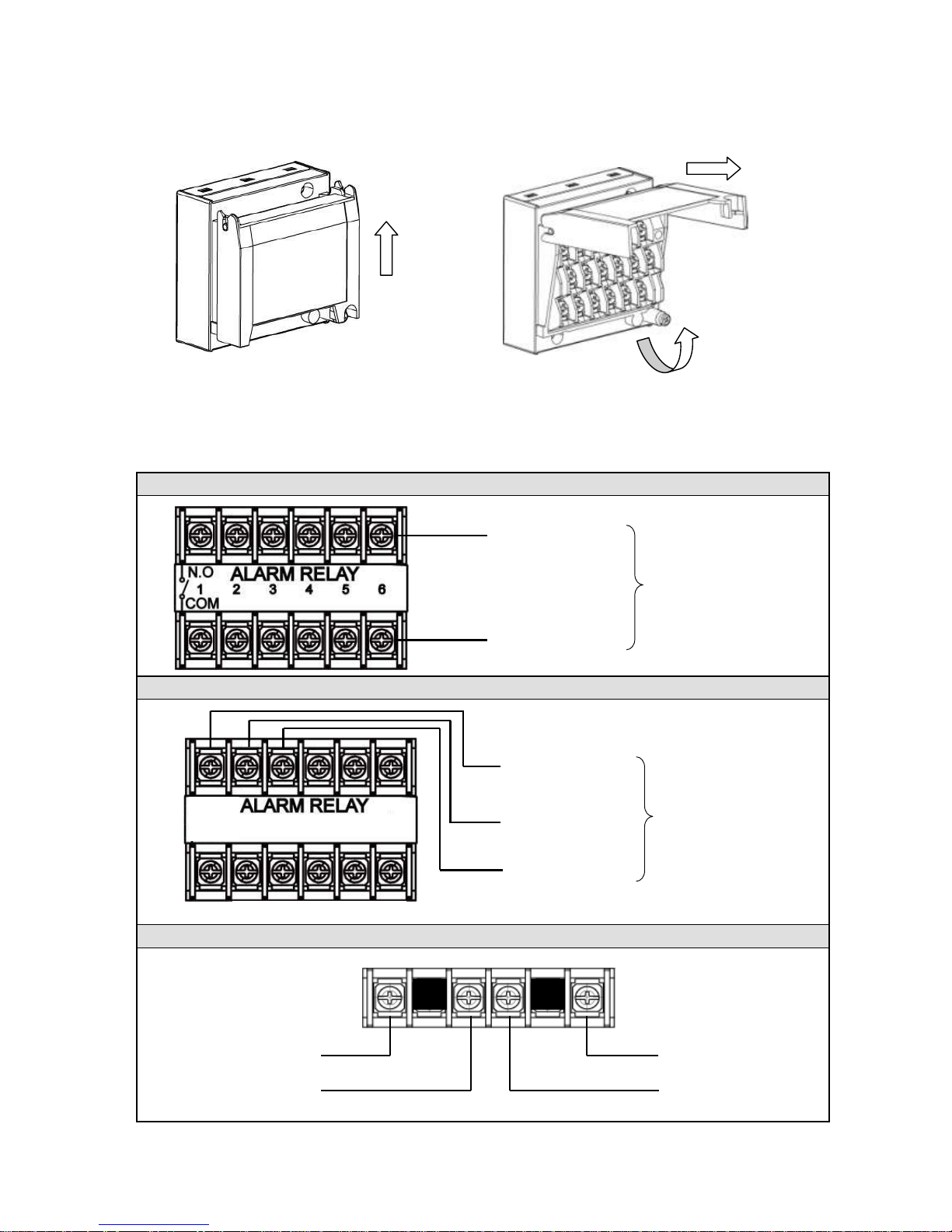

5) Input unit terminal cover mounting/removing

(1) Raise the cover to the direction of the arrow.

(2) Turn to the direction of the arrow.

(3) Pull it to the direction of the arrow to remove.

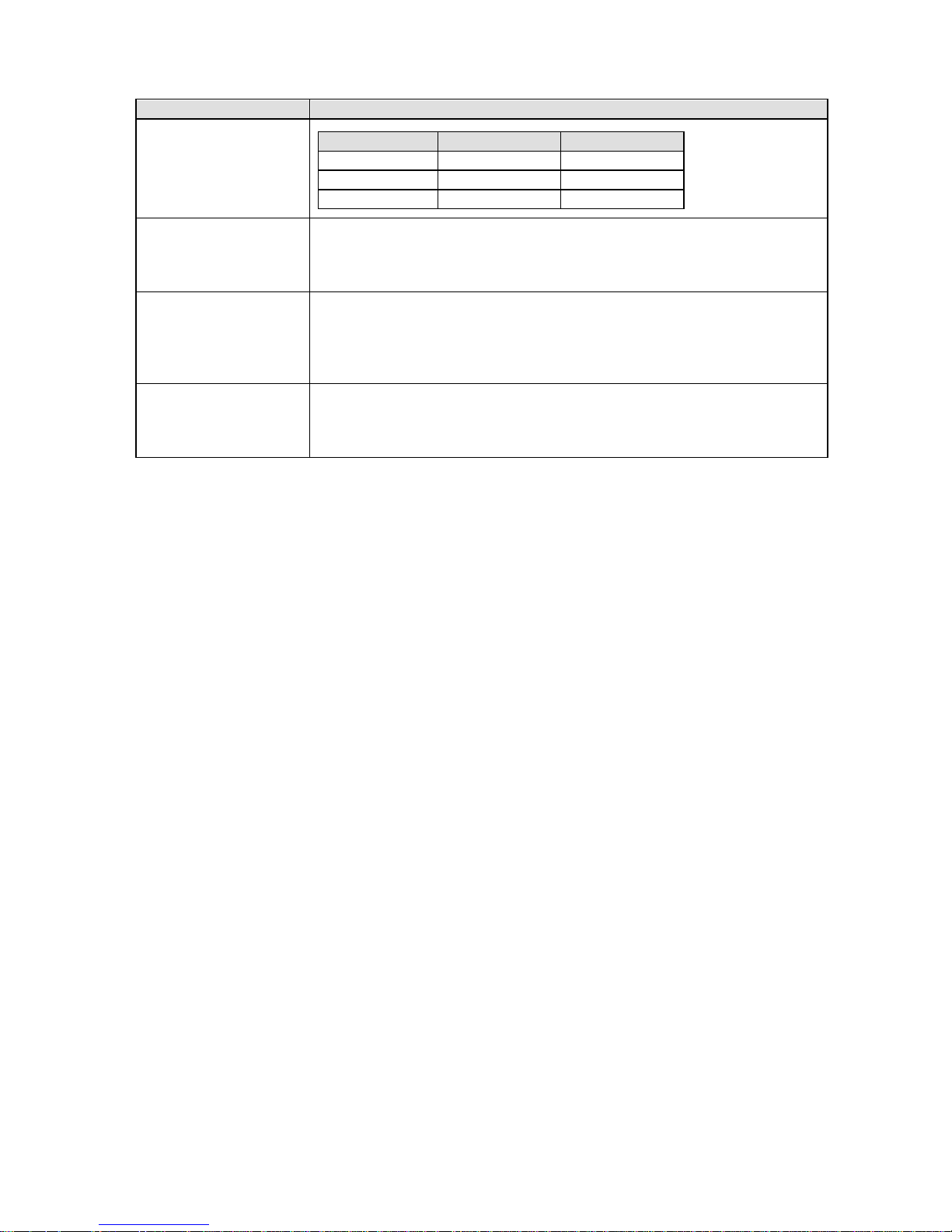

5. Alarm output terminals wiring (option)

1) Alarm output terminals

The terminal configuration depends on the output specification.

Alarm relay output 6 points (‘a’ contact)

Alarm relay output 4 points (‘c’ contact)

Alarm relay output 2 points (‘a’ contact)

(1)

(2)

(3)

N.O terminal (M3.5)

COM terminal (M3.5)

Alarm relay output

(6 points)

COM terminal (M3.5)

N.O terminal (M3.5)

COM terminal (M3.5)

N.O terminal (M3.5)

ALARM RELAY

1

2

N.O terminal (M3.5)

COM terminal (M3.5)

Alarm terminal

(4points)

1 2

3 4

N.C terminal (M3.5)

Page 20

- 17 -

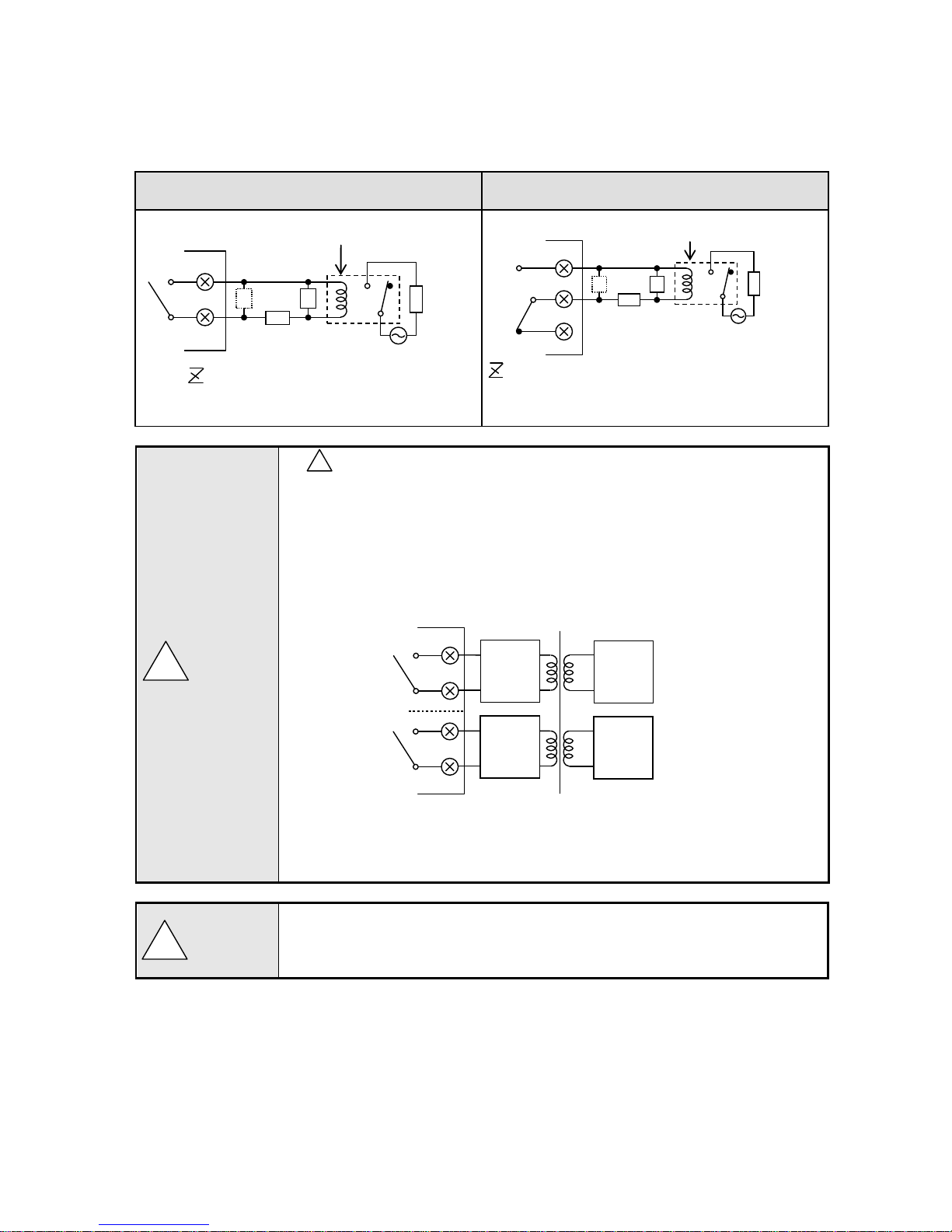

2) Wiring

Turn OFF the feed power source and the power source for buffer relay before wiring to prevent an electric

shock.

(1) Wire the cable to the load via the buffer relay.

(2) To the alarm output terminals, type O crimp style terminal with insulation sleeve which is connected to

double insulated signal wire should be connected. ( Refer to P13 )

Mechanical relay ‘a’ contact output example

Mechanical relay ‘c’ contact output example

* N.C terminal is opened on alarm occurrence in opposite way to N.O terminal.

mark on alarm output terminals

Maximum of 240VAC can be connected to the alarm output terminals of this unit.

Basic insulation (dielectric strength 1390V) is carried out between the alarm output

channels, however, from the malfunction etc. 240VAC may be output to each alarm

output terminals. Double insulation or reinforced insulation to the outside circuit

connected to an alarm output terminal should be set.

A buffer relay power supply is applied to the alarm output terminals after connections

and so creates a risk of electric shock if touched. Terminal cover must be mounted after

connection. Moreover, safety measures to the outside circuit should be set.

Implement safety measures.

The alarm output of the unit may generate output failure with wrong operation, failure,

abnormal input, or others. Double insulation or reinforced insulation in outside circuit side

of all the channels should be set in any system for safety ensuring.

!

!

Caution

!

Warning

: Contact protective element

(Attachment to a side is desirable.)

N.O

COM b a Z Z

Buffer relay

Recorder

Power

Load

: Contact protective element

(Attachment to a side is desirable.)

Buffer relay

Recorder

Power

Load

Z Z N.C

N.O

COM

b

a

240VAC

Max

Load

240VAC

Max

Load

※

Recorder

※Basic insulation between output channels

Double insulation

or

Reinforced insulation

Page 21

- 18 -

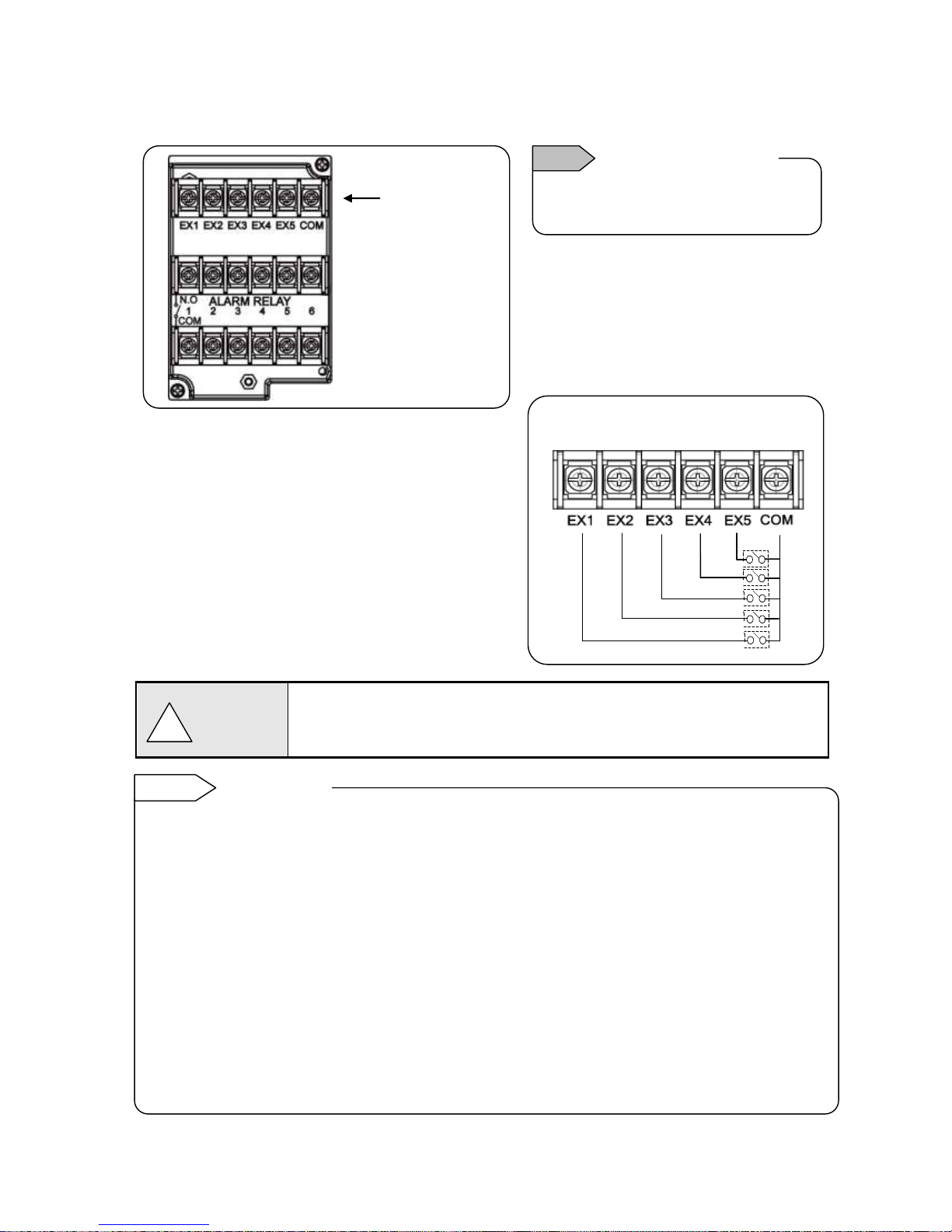

3) Precautions on wiring

The following are precautions on wiring.

Item

Description

Mechanical relay output

specification contact

capacity

(Common to ‘a’ contact

and ‘c’ contact)

Power supply

Resistance load

Inductive load

100VAC

2A

1A

240VAC

2A

1A

30VDC

2A

1A

Contact protective element

Z installation

Install the contact protective element which fits the buffer relay.

It is effective to install the element to the coil side of the buffer relay (see the figure

of mechanical relay ‘a’ contact output example) and prevents wrong operation with

light load.

Selection of buffer relay

Coil rating: Contact capacity or less of output terminals

Contact rating: Double of load current or more

In addition, the coil surge absorption element built-in type relay is recommended. If

there is no buffer relay which meets the load rating, implement another stage of buffer

relay.

Selection of contact

protective element

If there is no surge absorption element built-in buffer relay, install this element.

The element of C/R (capacitor + resistor) is general.

<C/R standard> C: 0.01μF (Rating about 1kv)

R: 100 to 150Ω (Rating about 1W)

(Minimum load)

100μA100mVDC

Page 22

- 19 -

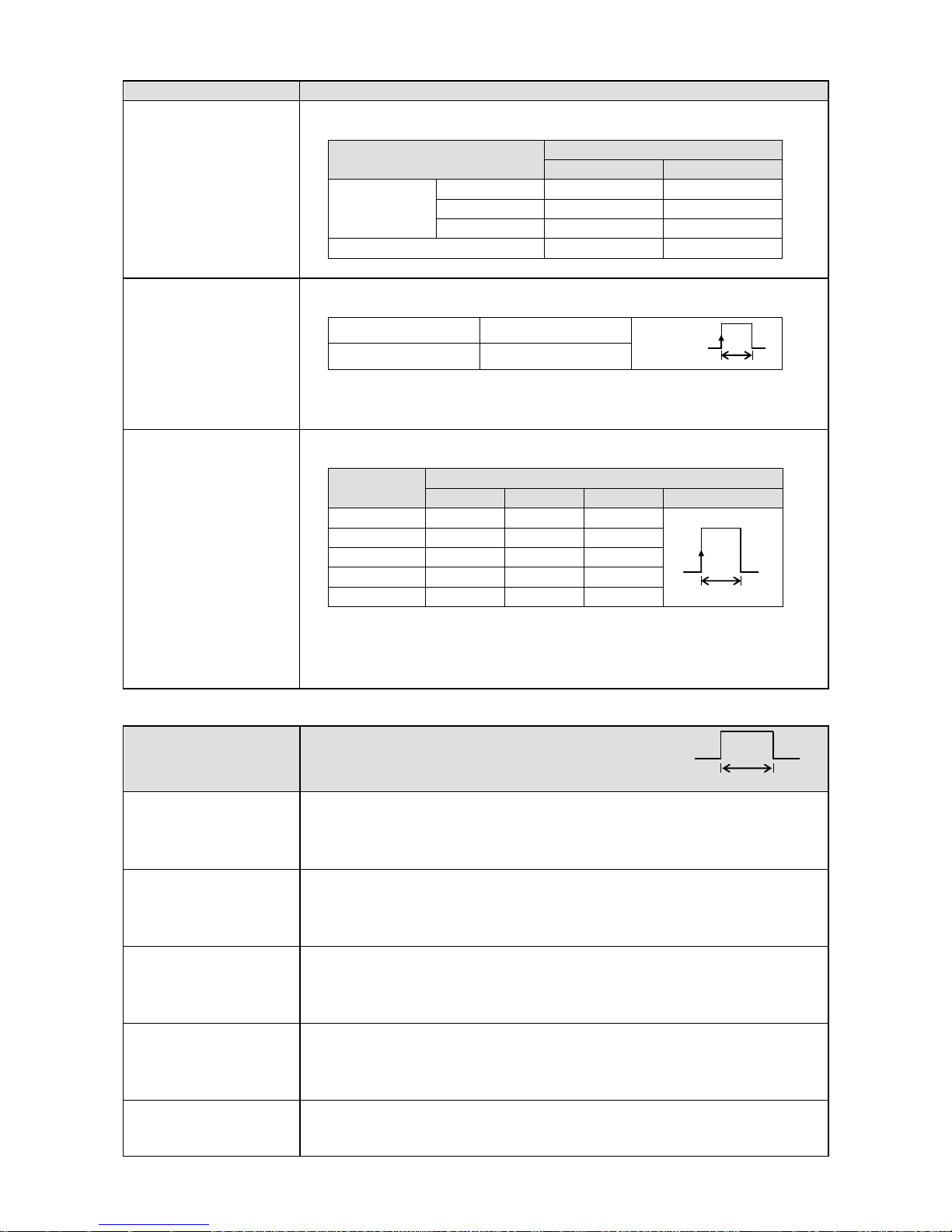

6. Remote contacts terminals wiring and operation selection (option)

Only with remote contacts terminals (option).

1) Remote contacts terminals

2) Wiring

Turn OFF the feed power source before wiring to

prevent an electric shock.

(1) Use no voltage contact signals to be given to the

remote contacts terminals.

(2) Install crimping terminals with insulation sleeves

to remote contacts terminals for wiring.

No voltage contact

For contacts connected to the remote contacts terminals, use switches or relays driven

with voltage level 30VAC or 60VDC or less or manual contacts which support light

load.

■ Wiring example

Voltage on contact open: About 5V

Current on contact short: About 10mA

Note

Characteristics of contact

input terminals

!

Warning

Upper row

Remote contacts

terminals

Remote contact enabled operation name

(1) Recording ON/OFF and three chart speed selection (two terminals of EX1 and EX2 are used)

(2) Messages (No. 01 and 02) selection and printing execution (two terminals of EX1 and EX2 are

used)

(3) Messages (No. 01 to 05) selection and execution (four terminals of EX1 to EX4 are used)

(4) Digital data printing (arbitrary one terminal)

(5) List printing (No. 1 to 3) (arbitrary one terminal for each)

(6) Integration reset (arbitrary one terminal)

(7) Messages No. 01 to 20 printing execution (each arbitrary one terminal)

(8) Time correction execution (arbitrary one terminal)

Each function requires short-circuit for one second or more between COM terminal and each terminal.

Operation allocation

Setting of allocation of operations to each terminal (EX1 to EX5) is required.

Name of operations which require setting

(1) Recording ON/OFF and three chart speed selection (See 8-7. Chart Speed Settings.)

(2) Message selection and printing execution (See 8-14. Message Printing 1 Settings.)

Remote contact

Reference

Page 23

- 20 -

3) Operation for which terminal No. is decided automatically ON: Short-circuit OFF: Open

Operation name

Terminal contact signal

(1) 3 chart speed

selection

3 chart speed setting other than the setting here is required.

(See 8-7. Chart Speed Settings.)

Recording ON/OFF and 3

chart speed selection

Between COM and EX terminals

EX1

EX2

Recording

ON

CS1

OFF

OFF

CS2

ON

OFF

CS3

OFF

ON

Recording OFF

ON

ON

Chart recording must be ON.

(2) Message printing

(No.01 and 02)

Message setting other than the setting here is required.

(See 8-14. Message Printing 1 Settings.)

Message No. 01

COM and EX1

Message No. 02

COM and EX2

At the point when the trigger signals (1 second or more) are given, the selected

message is printed.

Message printing with key is available.

(3) Message printing

(No. 01 to 05)

Message setting other than the setting here is required.

(See 8-14. Message Printing 1 Settings.)

Message

Between COM and EX terminals

EX1

EX2

EX3

EX4 *

No.01

OFF

OFF

OFF

For trigger

No.02

ON

OFF

OFF

No.03

OFF

ON

OFF

No.04

ON

ON

OFF

No.05

OFF

OFF

ON

* After message No. is selected, when the trigger signals (1 second or more)

are given, the selected message is printed.

Chart recording must be ON.

Message printing with key is available.

4) Operation which can be allocated to arbitrary terminal No. ON: Short-circuit OFF: Open

Operation name

Terminal contact signal

(4) Digital data printing

Turn ON the terminal No. specified to “Digital data printing.”

Chart recording must be ON.

Digital data printing with key is enabled.

Even during execution, the acceptance can be repeated only once.

(5) List printing

(List No.1, 2, and 3)

Turn ON the terminal No. specified to “List 1, List 2, or List 3 printing.”

Chart recording must be ON.

List printing with key is available.

(See 8-13. List Printing Settings)

(6) Integration reset

When “Collective reset with remote contacts (EX)” is selected with “Calculation

programming”, turning ON the terminal No. specified to “Integration reset”

resets the integration value.

(See 8-4. Calculation Settings.)

(7) Message printing

(No.01 to No.20)

Message setting other than the setting here is required.

(See 8-14. Message Printing 1 Settings.)

Turn ON the terminal No. specified to “Message printing (No. 01 to 20).”

Chart recording must be ON. Message printing with key is available.

(8) Time correction

When the current time (second) is within 0 to 30 seconds, the time is corrected

to zero second. When it is within 31 to 59 seconds, the time is put forward one

minute and corrected to zero second.

1 sec.or more

For trigger

1 sec.or more

1 sec.or more

Page 24

- 21 -

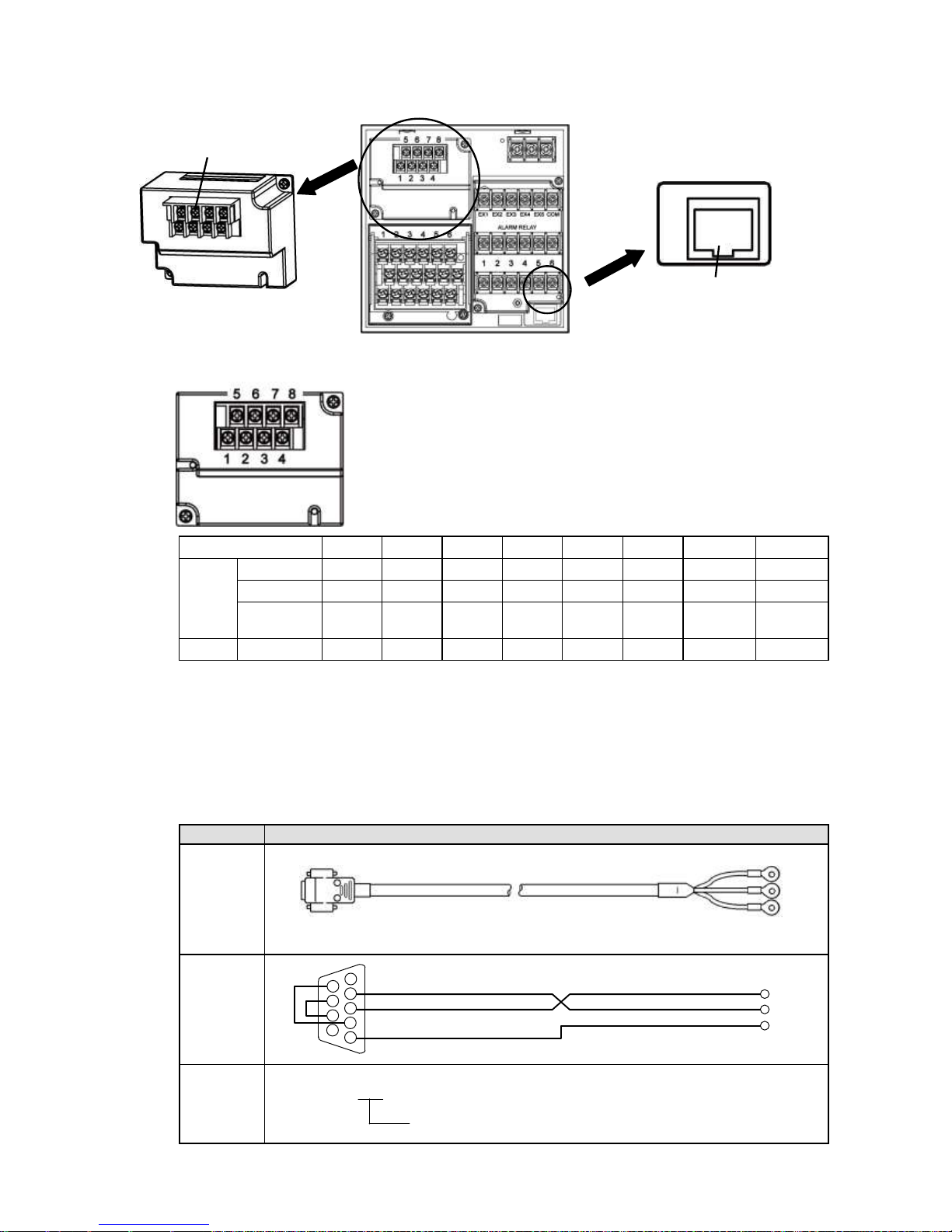

7. Communication I/F terminal wiring (option)

AL4000 can be connected for communications with RS232C, RS422A, RS485, and Ethernet.

1) Communications terminal type (option)

1 2 3 4 5 6 7

8

COM1

RS232C *

SG

SD RD

RS422A *

SG

SDA

SDB

RDA

RDB

RS485 * SG

SA

SB

Short with

SA

Short with

SB

COM2

RS485

SA

SB

SG

* RS232C and RS422A/485 of COM1 are to be specified on purchase.

2) Communications cables

Please prepare communication cables before wiring in advance.

Since exclusive cables are available from us, place an order.

(1) RS232C

Connection between PC and the unit or a line converter

Cable

9-pin connector ↔ Crimp type ring terminals RS232C cable

Shape

Internal

wiring

Model

code

RZ-CRS6□□

Cable length: 01 to 15m (specified)

RD

SD

SG

PC side

9-pin connector

Cable for RS232C (Max.15m)

RD

SD

SG

1

2

3 4 5

6 7 8

9

Ethermet connector

Communications terminals

Page 25

- 22 -

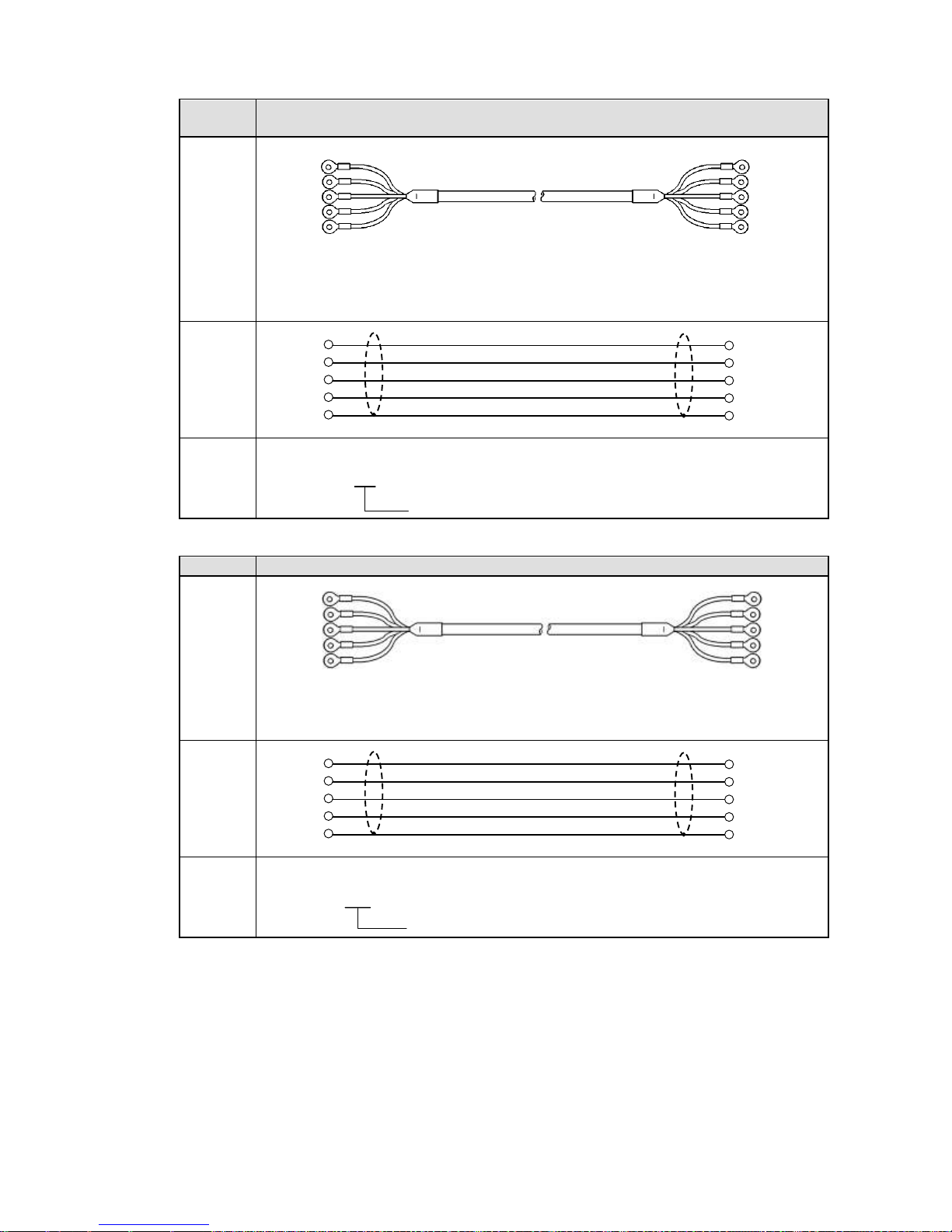

(2) RS422A

Connection between a line converter and the unit

Cable

Crimp type ring terminals ↔ Crimp type ring terminals RS422A cable

(for a line converter)

Shape

4-core cable of twisted 2-core cables of twisted VCTF lines. Each side has a SG

(signal ground) line. Since the line converter has no SG terminal, cut and use the

cable.

Internal

wiring

Model

code

RZ-CRA2□□

Cable length: 01 to 99m (specified)

Connection between the unit and other devices

Cable

Crimp type ring terminals ↔ Crimp type ring terminals RS422A cable (for parallel)

Shape

4-core cable of twisted 2-core cables of twisted VCTF lines. Each side has a SG

(signal ground) line.

Internal

wiring

Model

code

RZ-CRA1□□

Cable length: 01 to 99m (specified)

Line converter side

Recorder side

RDB

RDA

SDA

SDB

SG

SDB

SDA

RDA

RDB

SG

Device side

Recorder side

SDB

SDA

RDA

RDB

SG

SDB

SDA

RDA

RDB

SG

(black)

(white)

(red)

(green)

(blue)

RDA

RDB

SDA

SDB

SG

SDA

SDB

RDA

RDB

SG

(black)

(white)

(red)

(green)

(blue)

(black)

(white)

(red)

(green)

(blue)

SDA

SDB

RDA

RDB

SG

SDA

SDB

RDA

RDB

SG

(black)

(white)

(red)

(green)

(blue)

Page 26

- 23 -

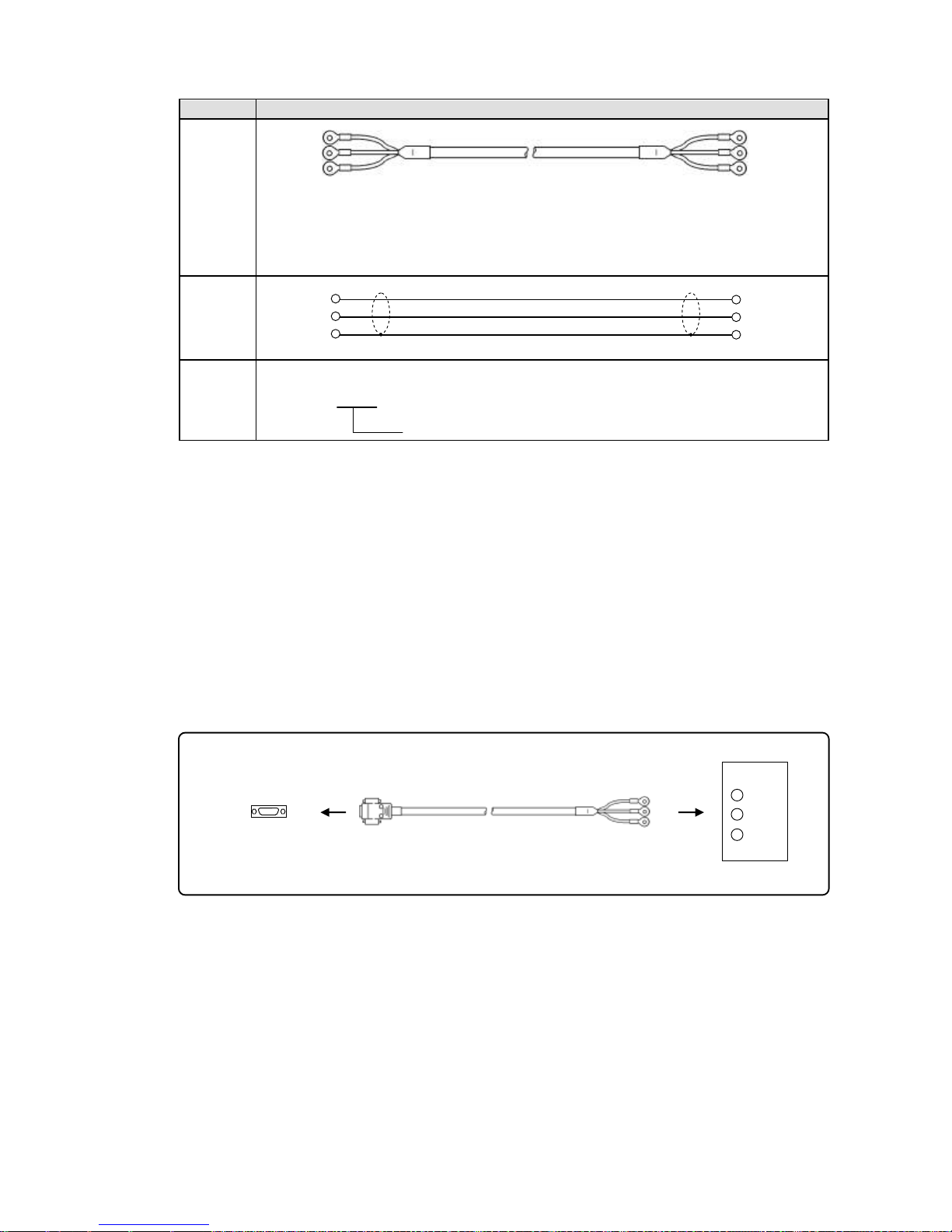

(3) RS485

Connection between the unit and other devices and between a line converter and the unit

Cable

Crimp type ring terminals ↔ Crimp type ring terminals RS485 cable

Shape

2-core cable of twisted CVVS lines. Each side has a SG (signal ground) line. Since

the line converter has no SG terminal, cut and use the cable.

Internal

wiring

Model

code

RZ-LEC□□□

Cable length: 001 to 200m (specified)

(4) Ethernet

Connection between PC and devices

For direct (one-to-one) connection, use crossover twist-pair cables with shield (available locally as

STP cable).

Connection between HUB and devices (multiple devices can be connected)

For (one-to-N) connection between PC and devices via HUB, use straight twist-pair cables with

shield (available locally as STP cable).

3) Communications line wiring

(1) RS232C wiring

PC and devices are connected one-to-one with RS 232C.

Example of terminal connection

RDA(black)

RDB(white)

SG(green)

(black)SA

(white)SB

(green)SG

Device side, Line converter side

Recorder side

RDA

RDB

SG

SA

SB

SG

SD

RD

SG

Cable for RS232C (Max.15m)

Device side

RZ-CRS6

Communications port

RD

SD

SG

PC side

Page 27

- 24 -

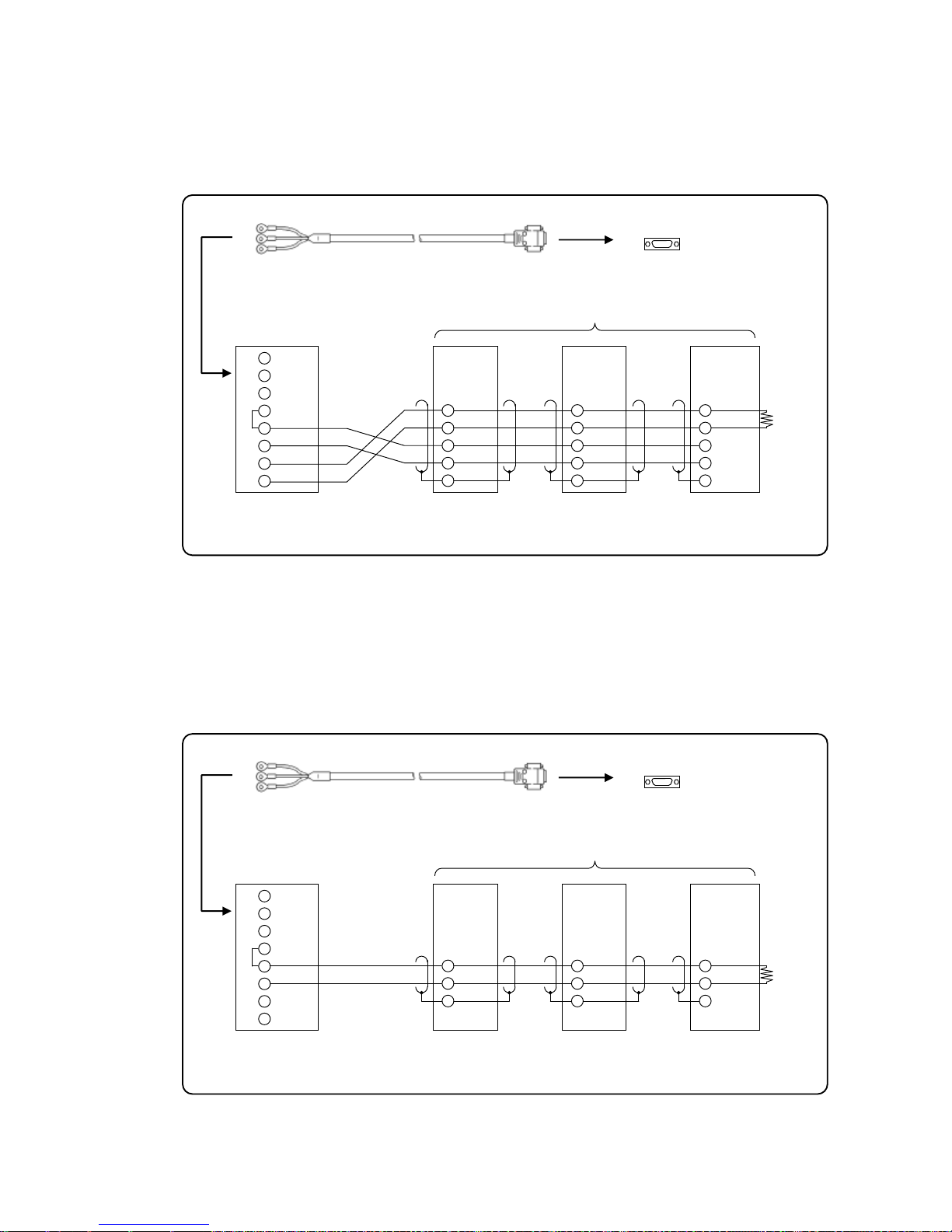

(2) RS422A wiring

PC and multiple devices are connected with RS422A. A line converter is required.

RS422A cable is within 1.2km of total extension and up to 31 devices can be connected.

Install a resistor of 100Ω to the last edge of the transmission line device side.

(General metal film resistors will be fine. They are available from us, place an order.)

Example of terminal connection

(3) RS485 wiring

PC and multiple devices are connected with RS485. A line converter is required.

RS485 cable is within 1.2km of total extension and up to 31 devices can be connected.

Install a resistor of 100Ω to the last edge of the transmission line device side.

(General metal film resistors will be fine. They are available from us, place an order.)

Example of terminal connection

Turn the switch of RS422A/RS485

to RS422A.

Avoid connecting SG line to FG terminal or

gound terminal of the device.

RDB

RDA

SDA

SDB

SG

Termination

resistor

100Ω

Device side

Line converter

SC8-10

RDB

RDA

SDA

SDB

SD

RD

SG

1

2

3

4

5

6

7

8

Cable for RS232C (Max. 15m)

RZ-CRS6

Communications port

PC side

SD

RD

SG

RDB

RDA

SDA

SDB

SG

RDB

RDA

SDA

SDB

SG

SG

RDB

RDA

SD

RD

SG

Turn the switch of RS422A/RS485

to RS485.

Avoid connecting SG line to FG terminal or

gound terminal of the device.

SA

SB

Termination

resistor

100Ω

Device side

Line converter

SC8-10

1

2

3

4

5

6

7

8

Cable for RS232C (Max. 15m)

RZ-CRS6

Communications port

PC side

SD

RD

SG

SA

SB

SG

SA

SB

SG

Page 28

- 25 -

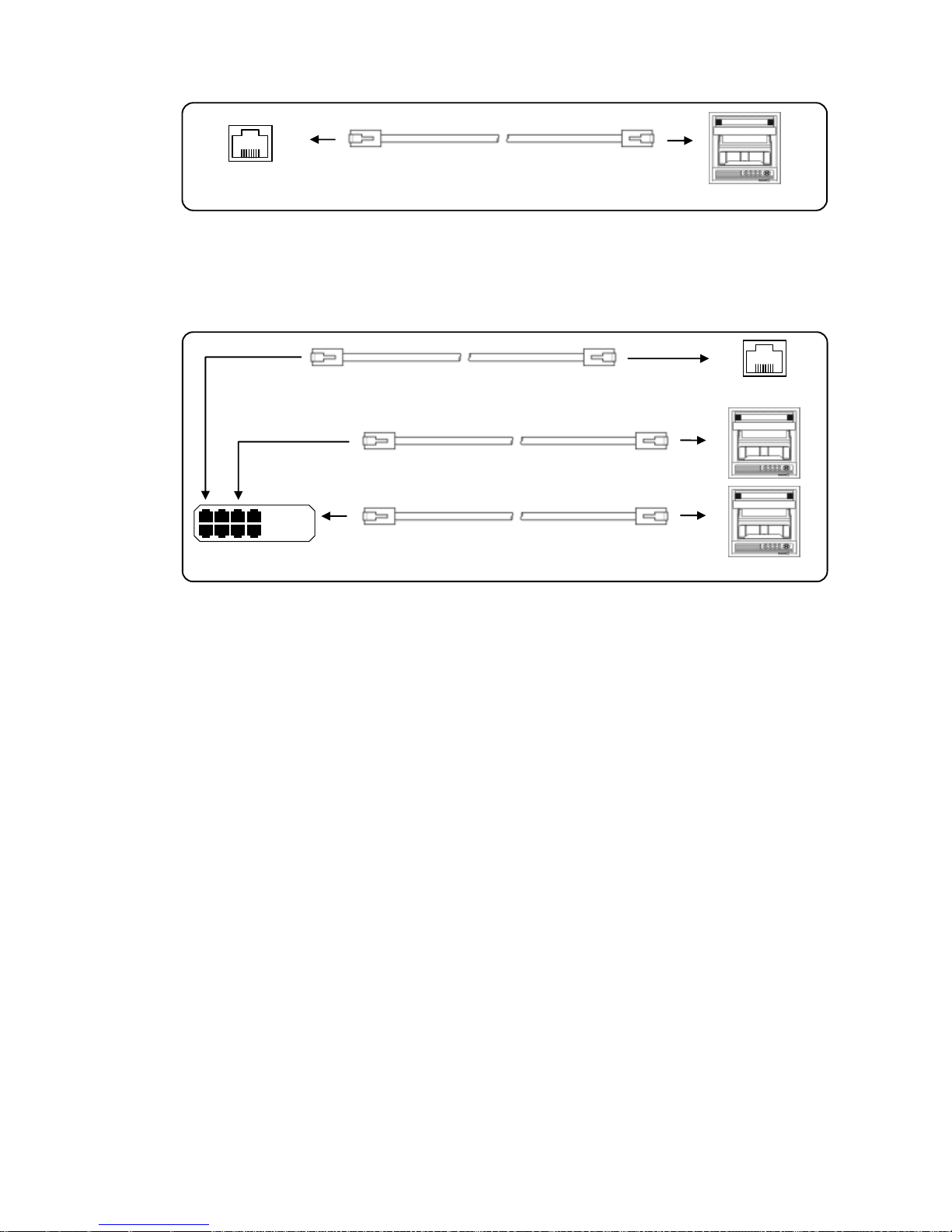

(4) Ethernet wiring

Example of connection between PC and Ethernet devices (one-to-one connection)

Example of connection between PC and HUB/Ethernet devices (one-to-N connection)

Crossover twist-pair cable

with shield (Max.100m)

Device side

PC side

Device side

HUB

Straight twist-pair cable

with shield (Max.100m)

PC side

HUB

Straight twist-pair cable

with shield (Max.100m)

Straight twist-pair cable

with shield (Max.100m)

Page 29

- 26 -

5. Part Names

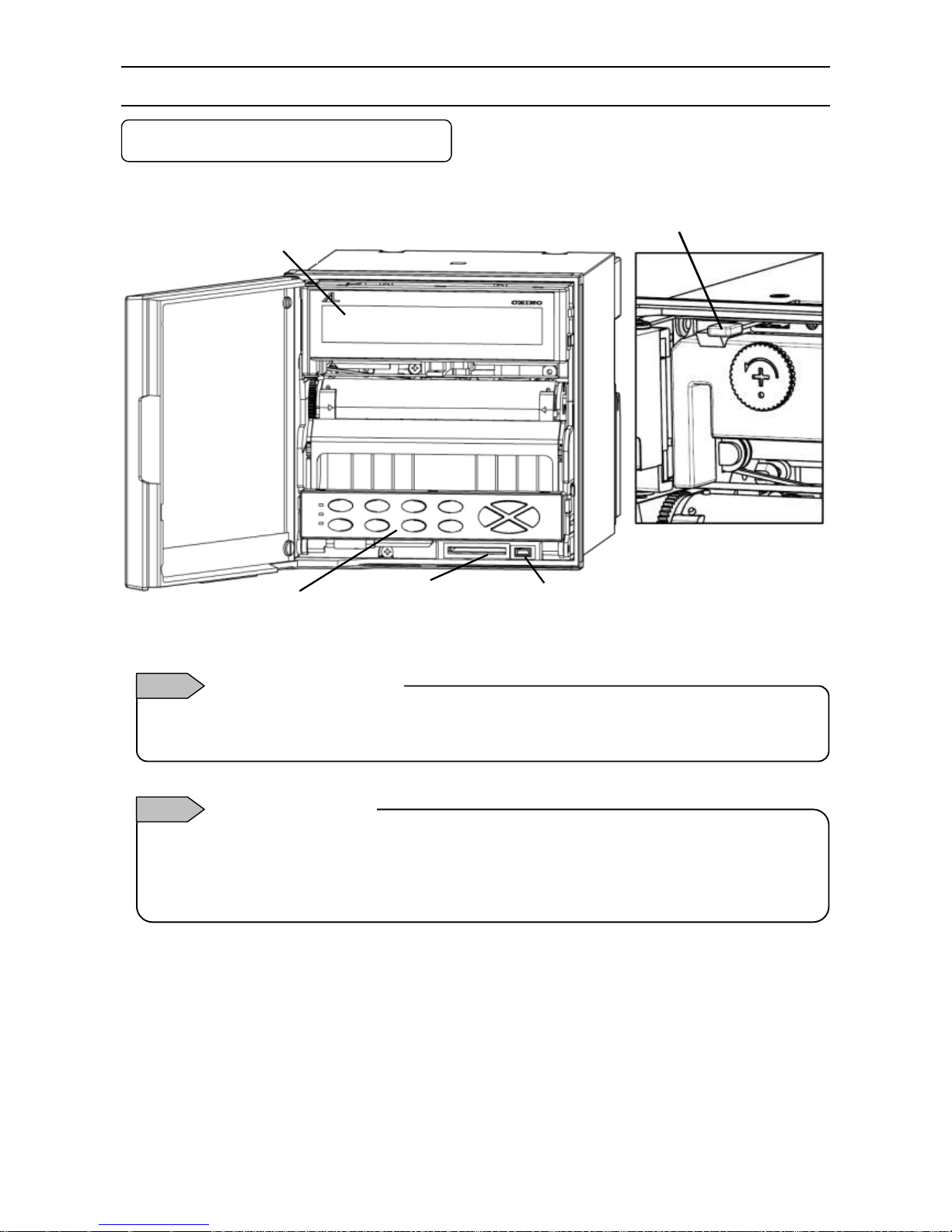

5-1. Front Section of Internal Unit

Enlarged view of power switch

Power switch

Open the display board in the direction same as the unit door.

The power switch is located at the upper left of the unit.

Display

Engineering port

USB communication connector

SD card

slot

Operation/set keys

The front of the door is made of glass. Avoid giving any shock to the glass or giving any strong force to the frame

for preventing any injury due to breakage.

How to handle the door

Note 1

Avoid closing the door in the state of operation/set keys opened. If the door is closed in the state of the

operation/set keys opened, the mechanism of the operation/set keys allows the operation/set keys to be lifted to

the direction for closing to prevent damage; however, behavior for protection is not guaranteed. If the door is

closed forcedly or fast, it may be damaged.

Operation/set key

Note 2

Page 30

- 27 -

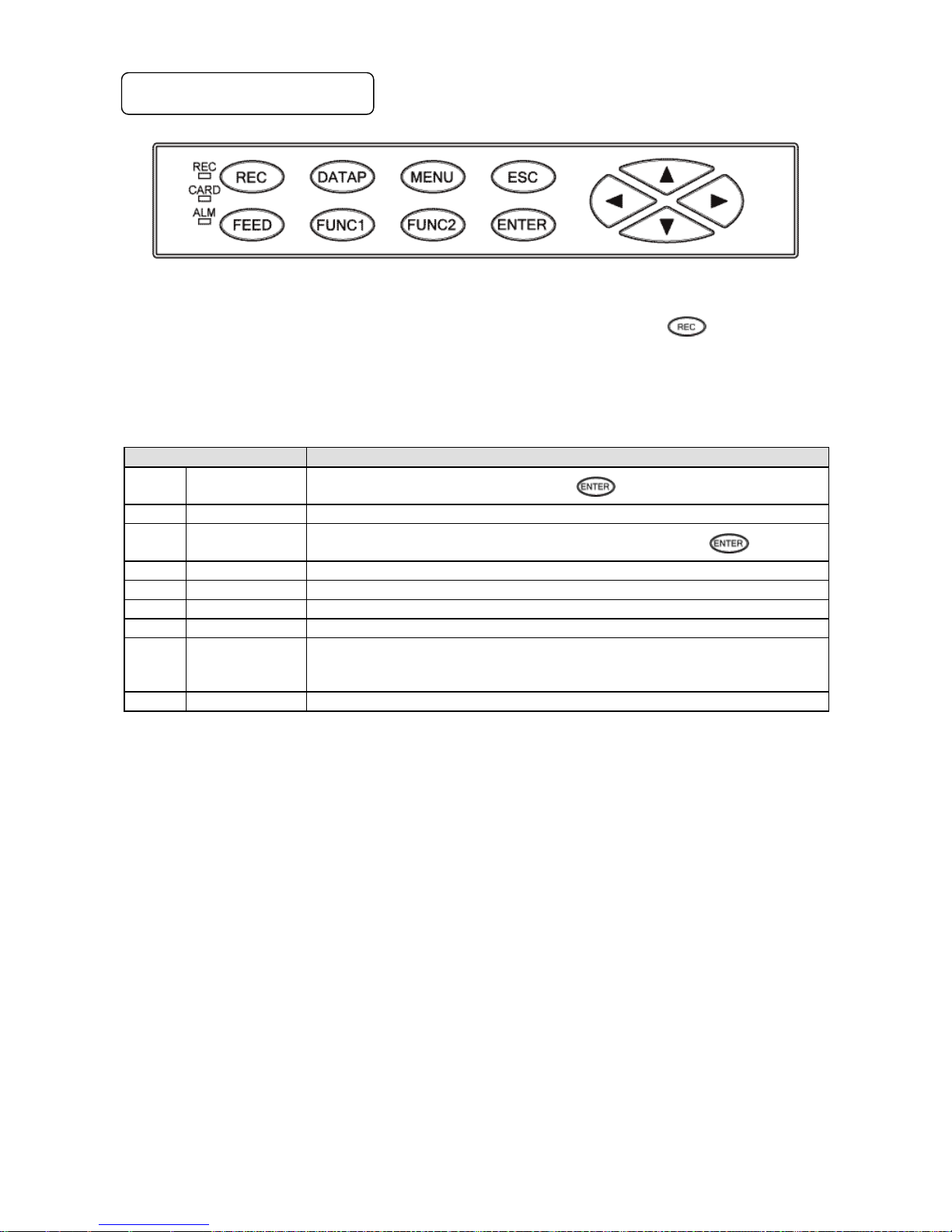

5-2. Operation/Set Keys

Status LED

REC

Lights in green while recording is on. Recording is turned ON/OFF by the

key.

Flashes when chart ends.

CARD

Lights in green when SD card is recognized by the unit, or flashes in a recognition process.

ALM

Flashes in red when alarm occurs.

Key names

Functions

REC

Record key

Turns ON/OFF recording. Used with the key.

FEED

Feed key

Feeds chart at a speed of 600mm/min while this key is pressed.

DATAP

Data print

Prints the data at the time of pressing this key. Used with the key.

FUNC1

Function 1 key

Switches and sets functions (function is shown on the display).

FUNC2

Function 2 key

Switches and sets functions (function is shown on the display).

MENU

Menu key

Displays various setting items.

ESC

Escape key

Returns to the previously displayed screen.

▲/▼

/

Up/Down

Left/Right

Moves the cursor up/down and left/right.

Used also to select setting items or values.

Used also to advance the channel number.

ENTER

Enter key

Used to register various settings.

Page 31

- 28 -

6. Operation

6-1. Preparation for Operation

1. How to set chart paper

1. Pulling out the chart cassette

(1) Open the unit door and pull the operation/set

keys part.

(2) Hold the chart cassette grip and pull it toward

you.

2. Setting chart paper

(1) Open the chart guide and chart feeding holder.

(2) Loosen the both ends of chart to prevent double

feed.

(3) Set chart in the chart housing at the back of the

chart cassette. The “round” hole and “oval” hole

should be at the left and right side of the chart

respectively.

(4) Draw out chart approximately 20cm and set

holes on the both ends to the sprockets of the

chart drum. Put two or three folds of chart in the

chart tray at the front of the chart cassette and

then close the chart guide and chart feeding

holder opened in the step (1).

(5) Turn the thumb wheel downward and make sure

that the holes on the both ends of chart are not

released from the sprockets, and feeding is

smoothly done.

3. Returning the chart cassette to the inside of

the unit

(1) Align the guide of the chart cassette with the

guide rail located at the both sides of the

internal chassis and then insert the cassette

until it is locked.

(2) Put back the operation/set keys part.

(3) Operate the key to check if the chart is

fed properly and smoothly. If not, reset the chart

again.

Chart feeding holder

Chart guide

Thumb wheel

Chart cassette grip

Operation/set keys part

Be careful of injury by dropping the chart cassette after

pulling it from inner unit. Take care not to catch your

fingers in the unit when putting the chart cassette back.

Handling of chart cassette

Note

Page 32

- 29 -

2. How to attach ribbon cassette

1. Preparation

(1) Make sure that the unit is turned ON and then

press the key (recording OFF).

(2) The printer stops around the center and the

ribbon holder moves backward.

(3) Prepare a ribbon cassette.

(4) Open the unit door.

(5) Open the display board in the direction same

as the unit door.

2. Attaching ribbon cassette

(1) Insert a ribbon cassette to the left holder

locker.

(2) Put the ribbon under the printer and push the

right side of the ribbon cassette.

(3) Insert the ribbon cassette to the right holder

locker.

(4) Make sure that the ribbon cassette is properly

held by the left and right holder lockers.

(5) Turn the winding knob counterclockwise.

(6) Return the display board in place.

(7) Make sure that the unit is turned ON and then

press the key (recording ON)

(8) Feed the ribbon a few centimeters while recording

is ON. Check the ribbon feeding condition.

3. Preparation for ribbon cassette replacement

(1) Move the printer to the center and the ribbon

holder backward as in the case of attaching a

ribbon cassette.

(2) Open the display board in the direction same as

the unit door.

4. Removing ribbon cassette

(1) Pull the right side of the ribbon cassette to remove

it from the right holder locker (see below tips for

removal).

(2) Pull the ribbon out of the printer.

(3) Pull the left side of the ribbon cassette to remove

it from the left holder locker.

Drive gear

Ribbon

Winding knob

Direction of ribbon

feed

Right

Left

Draw out the ribbon from

the left side and then wind

up by turning the winding

knob.

When winding failure occurs

Ref 1

Left holder locker

Right holder locker

Put the tip of your

index finger on

the top of the

ribbon cassette

and roll it

downward.

Under standard operating conditions

(temperature: 23 ±2°C, humidity: 55 ±10%RH), it

can last about three months. However, it may be

shortened depending on temperature, humidity

or use of the unit (chart speed, intervals of

periodic data printing, etc.).

Replacement cycle of ribbon cassette

Ref 2

When replacing the ribbon cassette, be careful not to

catch your fingers in the unit.

Replacement of ribbon cassette

Note

Page 33

- 30 -

6-2. Basic Operation

1. Power on

Turn the power switch to ON.

Data will be shown on the display after about 10 seconds.

After detecting the initial position, the printer prints the date and time and then feeds chart about 5mm.

2. Switching of display

The unit can provide three display modes.

Either fixed or sequential display can be selected for each display mode (pressing the key switches the

display between AUTO (sequential) and CONST (fixed).

With the sequential display, channel number advances every two seconds (factory default which can be changed).

While holding down the key, press the

/

key to change the display mode.

See “8-24. Display Settings” to set default display mode at power-on.

CH NO.

Measured value

Chart end/recording ON

SD card remaining amount

AUTO/CONST

Data print/list print

CH NO. Chart end/recording

ON

TAG SD card remaining

amount

Measured value

Chart speed

Unit Recording point

indicator

Date/time Key guide

AUTO/CONST

Data print/list print

CH NO.

Measured value

Chart end/recording ON

SD card remaining amount

AUTO/CONST

Data print/list print

↓: ESC + ▲ ↑: ESC + ▼

To switch from “1-point display” to “1-point + bar display”, press the key while holding down the key.

To switch from “1-point display” to “6 point display”, press the key while holding down the key.

The date/time printing is not performed at power-on.

Note 2

While recording is OFF

Backup of settings, clock and display mode are made.

However, channel number is not saved so the data

with smallest channel number within set range will be

dsplayed.

Display backup

Note 1

6-point display

1-point display

1-point + bar display

Page 34

- 31 -

3. Chart recording operation

Recording ON

Recording OFF

* Any of the above settings can be cancelled by pressing the key.

(The setting is cancelled also after around 10 seconds without key operation.)

1) Turning ON/OFF chart recording

Recording can be turned ON/OFF by pressing the key → key.

While recording is ON, the “REC” status LED lights up.

Recording is not performed while it is OFF, but reading inputs, updating data and calculating alarms are

performed. Data printing, list printing and message printing are unavailable.

2) Data printing

Currently executing trace printing is interrupted to print numeric values of the latest measurement data as

shown in the below example.

Press the key → key to perform data printing.

Use the periodic data printing function to perform data printing periodically.

This cannot be performed while recording is OFF or keys are locked.

Colors used for printing changes every time data printing is executed in the following order: red → black →

blue → green → brown → purple (repeated).

Example of data printing

“*** Quit recording? ***”

Pressing the key turns recording OFF.

“*** Start Digital data printing? ***”

Press the key to start.

“*** Start recording? ***”

Pressing the key turns recording ON.

(1) Key operation is unavailable when is shown on the display indicating that keys are locked.

(2) When using remote contacts (optional), key operation becomes unavailable when recording is turned OFF by a

remote contact terminal.

Pressing the key → key becomes invalid in some cases

Note

Operation: Operations including measurement continue without being interrupted.

Cancel: To stop data printing halfway through, press the key → key. The unit will be put into

recording OFF status when the currently printing line is finished. However, the behavior depends on the

unit condition when the instruction is received.

Pressing the key → key later returns to the previous printing status.

Operation during printing and print cancel

Reference

Page 35

- 32 -

3) Chart feed

Chart can be fed using the key.

While the key is pressed, chart is fed at a speed of 600mm/min. When fast-feeding chart,

recording (dot-printing) is stopped.

Feed chart when a measurement target or measurement condition is changed.

4) Aligning time line

When operating the unit with a chart speed of multiples of 10 (mm/H), it is advisable to align the time line

print with the time scale of chart for easier view of the result.

The following shows a bad example.

Time line (print)

Time scale

This is useful only when you use a chart with 10mm-pitch time scale.

(1) There is a time line setting mark () on the right side of the chart guide located at the front of the chart

cassette.

Time line setting mark

(2) Align a time scale line with the setting mark () as viewed from the front by pressing the key

(do not align it manually).

(3) It may be a good idea to set a time scale line 1 to 2mm above the setting mark () to perform a fine

adjustment later.

(4) Press the key and turn off the “REC” status LED.

(5) Press the key at a desired time <xxh 00min> and turn on the “REC” status LED.

(6) After a few hours, check to see if the time line print is aligned with a time scale line. If the time line print

comes behind a time scale line, press the key briefly and see how it works. If it comes ahead,

remove the chart and set it back for a few hours and then try again.

Due to the mechanical nature of the unit, a few millimeters of chart may not be fed. Therefore, we recommend that

chart be fed by the key.

Also, for the same reason, use the key to feed when new chart is set.

Feeding chart

Reference

1 to 2mm above

the setting mark

10mm

Subsidary time scale

Page 36

- 33 -

6-3. Operation

1. Types and contents of chart recording

There are two types of chart recording: trace printing and digital recording/printing. Without setting particular items,

trace printing, channel number printing and fixed time printing are performed while recording is ON.

Item

Contents

Chart recording

Trace printing

Records a trend for each channel by dot printing with different color.

The color can be specified arbitrarily (six colors in total).

Digital recording/printing

Channel number printing

Prints channel number interlocking with chart speed.

Alarm printing

Prints time or alarm point when alarm is generated/cleared.

Periodic data printing

Adds digital record/print on a trace print in desired intervals.

Data printing

Performs digital recording/printing when required, suspending trace

printing.

List printing

Prints a list of all or specified parameters when required.

Fixed time printing

Prints date, time/time line, max/min chart record, channel number,

tag and unit interlocking with chart speed.

Message printing

Prints a message which can contain up to 40 characters.

Calendar timer printing

Prints data when both calendar timer and printing are set to ON.

Operation recording

When using remote contacts (optional), the status of remote input

No. (ON/OFF) is printed at the specified position with a bar line.

Setting change mark

When setting is changed, “Δ” is printed at the right side of chart.

Power-on time printing

Date and time are printed at power-on.

Example of trace printing and fixed time printing

Page 37

- 34 -

2. Fixed time printing interval

When recording is ON at the time of power-on, fixed time printing is performed first.

The following table shows printing intervals which vary depending on the printing item.

Time and time line

Channel number

Chart speed

Max/min chart record, tag

and unit

Varies depending on

the chart speed

At approx. 6mm intervals,

in order of ascending

channel number

At approx. 84mm

intervals

At approx. 42mm intervals,

in order of ascending

channel number

1) Printing intervals of time and time line

Time and time line are printed at the following intervals which vary by the chart speed. The start point of the

intervals is 00h 00min.

Chart speed (mm/H)

Time and time line (*)

Time line only

Year/month/date

1 - 9

12h 00min only

6h

00h 00min only

10 - 15

4h

2h

16 - 30

2h

1h

31 - 60

1h

←

61 - 119

1h

30min

120 or higher

30min

←

(*) When periodic data printing occurs at the same time, only time line is printed.

2) Printing interval of channel number

(1) Channel number is printed beside the trace

printing (normally at the right of it) at 6mm

intervals in order of ascending channel number,

using the color same as the trace printing.

(2) The interval between channel 6 and 1 is

approx. 12mm.

(3) When you skip channels, there will be

additional break interval (in addition to the

12mm-break), according to the number of

channels skipped.

3) Printing interval of chart speed

Chart speed is printed in black at the left side of chart after every two cycles (approx. 84mm) of channel

number.

4) Printing interval of max/min chart record, tag and unit

(1) These items are printed at the left and right sides of chart in order of ascending channel number after

every single cycle (approx. 42mm) of channel number.

(2) In accordance with the channel number, maximum/minimum chart record, tag and unit are printed

using the color same as the dot printing.

(3) Tag is not printed if not specified.

(4) When you set the recording format, printing contents vary depending on the selected format.

Standard (Standard), automatic range-shift (Auto Range)

Note: When Auto Range is used, the max/min chart record of the range (one of the ranges R1 to R5) used at

the time of printing will be printed.

Compressed/expanded printing (Comp. & Exp.Print)

Zone printing (Zone Print)

+ + …*

1: TIC1 °C

0.0/200.0/400.0/500.0

zero

1st break point 2nd break point

span

+ + …*

1: TIC1 °C

0.0 500.0

* A “+” mark is printed at the first and second break

points.

* A “+” mark is printed at the edge of the printing area

to indicate it.

Tag

Channel No.

Minimum chart record

Channel No.

Maximum chart record

Unit

Trace printing

1: TIC1

0.0

1

500.0

°C

6 1 2 3 4

5

(Without skipping)

Printing channel number

(Skipping channel 4)

1

2

3 5 6

One cycle ≈ 6mm x 7 ≈ 42mm

Page 38

- 35 -

3. Restrictions on recording

1) Digital recording/printing unavailable at certain chart speeds

When chart speed is set to 251mm/H or higher, all digital recordings/printings will not be performed and

only trace printing is performed. However, time line printing, power-on printing, data printing and list printing

can be performed.

2) Dotting interval

Dot printing is performed at intervals of 5sec/point at normal speed, and 2.5sec/point at high speed. To

prevent damage to chart caused by overlapping of dots, dotting interval becomes longer as chart speed

decreases.

The chart speed interlock mode is also available, which performs dot printing depending on the chart

speed.

Normal dot printing (approx. 5sec/point)

Fast dot printing (approx. 2.5sec/point)

The restriction expressed by the following will be placed when chart speed drops below a certain value.

Dot printing interval (sec/point) ≈

<Without skipping>

CS (mm/H)

Interval

CS (mm/H)

Interval

1

Approx.

30sec

5

Approx.

6sec

2

Approx.

15sec

6

Approx.

5sec

3

Approx.

10sec

7

4

Approx.

8sec

8

For 6mm/H or higher CS, interval is fixed to approx.

5sec/point.

<Without skipping>

CS(mm/H)

Interval

CS(mm/H)

Interval

1

Approx.

30sec

6, 7

Approx.

5sec

2

Approx.

15sec

8, 9

Approx.

4sec

3

Approx.

10sec

10, 11

Approx.

3sec

4

Approx.

8sec

12, 13

Approx.

2.5sec

5

Approx.

6sec

14 -

For 12mm/H or higher CS, interval is fixed to approx.

2.5sec/point.

3) Overlapping of digital recording/printing

The following order of priority is used for printing generally when printing positions of different items

overlap.

(1) Data printing/list printing > time line printing > periodic data printing > alarm printing = fixed time

printing = message printing

(2) The order of priority for fixed time printing is as follows:

Time line > time = channel number = chart speed = max/min chart record, unit and tag

Examples and special cases are described below.

Case 1: Data printing/list printing occurs while recording/printing.

Currently executing printing process is interrupted to execute data printing/list printing.

Note: Printing characters will be split due to the interruption.

Case 2: Time line/time printing occurs while periodic data printing is in progress.

Only time line is printed. Time is not printed.

Case 3: Fixed time printing occurs when periodic data printing has short intervals.

The intervals of fixed time printing may be extended, or the printing itself may not be performed.

Case 4: Alarm printing overlaps with max/min chart record, unit and tag.

The max chart record and unit are replaced by alarm print.

180 CS: chart speed

CS x CH CH: number of channels

Page 39

- 36 -

4. Abnormal input

1) Out-of-range input

When an input is out of the chart printing

range or measuring range, the unit indicates it by

the following display or printing.

Measuring range: determined by the input type

described in “8-2. Input Type

Settings”.

Chart printing range: trace printing range described

in “8-2. Input Type Settings”.

No.

Input status

Display

Printing

Digital

Digital

Trace

(1)

Input under the lower limit of

measuring range*

-OVER

-OVER

Downscale burnout

(2)

Input under the lower limit of

chart printing range

Normal display

Normal print

(3)

Input over the upper limit of

chart printing range

Normal display

Normal print

Upscale burnout

(4)

Input over the upper limit of

measuring range*

+OVER

+OVER

* Digital display/printing is available for an input outside the measuring range if it is within ±10% of the span.

2) Disconnection of input signal

Display and printing made at a disconnection of input signal depends on the “Burnout” setting.

Burnout setting

Display

Printing

Digital

Digital

Trace

None

Undefined

Undefined

Undefined

Down

BURN

BURN

Downscale burnout

UP

BURN

BURN

Upscale burnout

Input status

Chart

printing range

Measuring range

(1)

(2)

(3)

(4)

Page 40

- 37 -

7. Factory Default Settings

7-1. List of Factory Default Settings

Item

Default value

(1) Time

Current time (year/month/date: Japan time)

(2) Range

(1) Input type

(2) RJ

(3) Chart printing

V : -50.00 to 50.00

None

-50.00 to 50.00

(3) Scale

-50.00 to 50.00

(4) Unit

V

(5) Tag

Not set

(6) Display/printing On and OFF

(1) Display

(2) Trace printing (dot printing)

(3) Digital printing

(4) SD card recording

All channels ON

All channels ON

All channels ON

All channels ON

(7) Chart speed

20mm/H

(8) Digital recording/printing

Data interval

None

(9) Trace printing

Color and printing ON/OFF

Channel number

Color

Printing ON/OFF

1

Red

All ON

2

Black

3

Blue

4

Green

5

Brown

6

Purple

* Printing colors can also be specified arbitrarily.

(10) Alarm settings

Not set

(11) Subtract printing settings

Not set

(12) Message settings

Not set

(13) Password

3571

Page 41

- 38 -

8. Setting Method

8-1. Basic Rules

The following provides general information on setting operations.

Pressing the key can return to the measured value display from any window.

1. Setting items and parameters