Page 1

INST.NO. INE-846B

AL4000/AH4000

Hybrid Memory Recorder

KL4000/KH4000

Hybrid Recorder

[ Communication Interface ]

Page 2

Table of contents

1. Introduction .................................................................................................................... 1

2. For Safe Use ................................................................................................................... 2

2-1. Preconditions for Use ......................................................................................................................................... 2

2-2. Symbol Mark....................................................................................................................................................... 2

3. Overview ......................................................................................................................... 3

3-1. RS232C Communication Interface ..................................................................................................................... 3

3-2. RS422A/485 Communication Interface .............................................................................................................. 3

3-3. Ethernet .............................................................................................................................................................. 3

4. Communications Protocol ............................................................................................ 4

4-1. MODBUS Protocol .............................................................................................................................................. 4

4-2. PRIVATE Protocol............................................................................................................................................... 4

5. Communication Specifications ..................................................................................... 5

5-1. MODBUS ............................................................................................................................................................ 5

5-2. PRIVATE ............................................................................................................................................................. 5

5-3. Ethernet .............................................................................................................................................................. 5

6. Communication Parameter Settings ............................................................................ 8

6-1. Ethernet Settings (AL4000/AH4000 Only) .......................................................................................................... 8

6-2. COM Settings (For AL4000/AH4000) ................................................................................................................. 9

6-3. COM Settings (For KL4000/KH4000) ............................................................................................................... 10

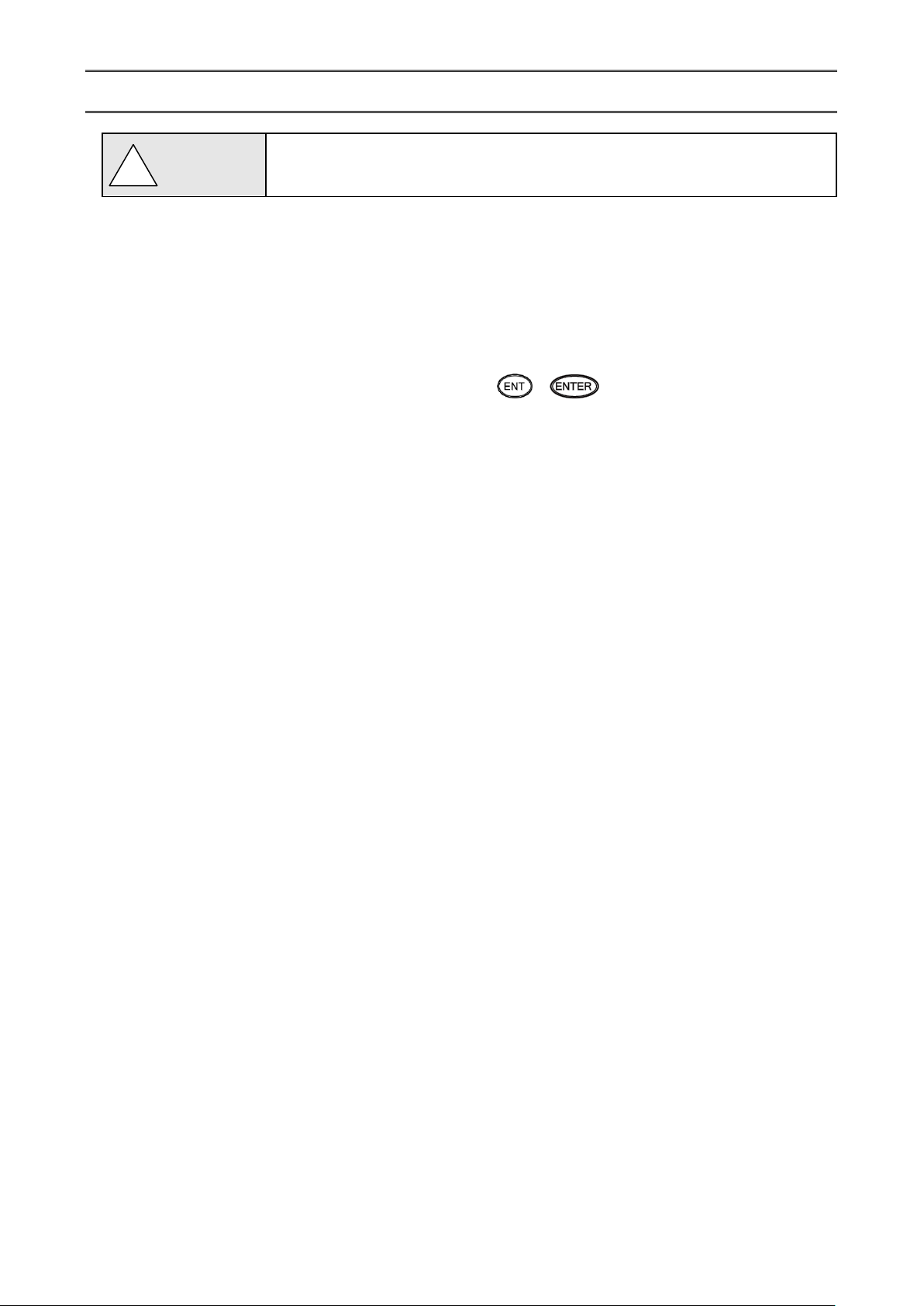

7. Wiring ............................................................................................................................ 16

7-1. Precautions on Wiring ...................................................................................................................................... 16

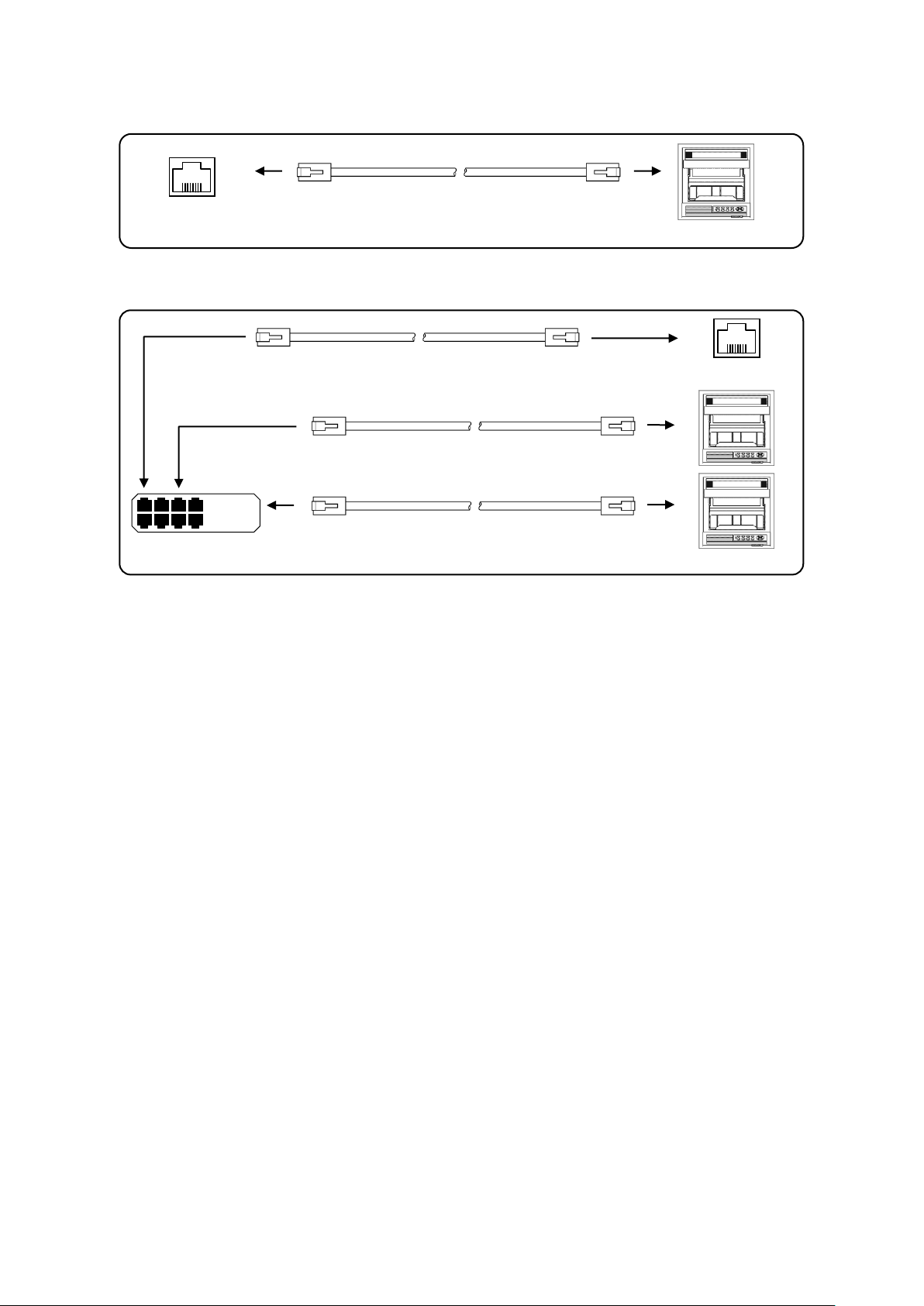

7-2. Communication Cable ...................................................................................................................................... 17

7-3. Communication Line Wiring .............................................................................................................................. 19

8. MODBUS Protocol ....................................................................................................... 22

8-1. Message Transmission Mode ........................................................................................................................... 23

8-2. Data Time Interval ............................................................................................................................................ 24

8-3. Message Structure ............................................................................................................................................ 24

8-4. Message Creation ............................................................................................................................................ 30

8-5. Function Code .................................................................................................................................................. 31

8-6. Response to Abnormal Situation ...................................................................................................................... 39

8-7. Title Printing (Message Printing 2) Function ................................ ..................................................................... 41

8-8. Data Communications Input ............................................................................................................................. 41

8-9. Reference Table ............................................................................................................................................... 42

8-10. Range No. Reference Table ........................................................................................................................... 104

9. PRIVATE Protocol (For AL4000/AH4000) ................................ ................................. 105

9-1. Basic Communication Sequence .................................................................................................................... 106

9-2. Control Character Code .................................................................................................................................. 106

9-3. Data Link ........................................................................................................................................................ 106

9-4. Data Transmission and Reception .................................................................................................................. 108

9-5. Checksum........................................................................................................................................................ 111

10. PRIVATE Protocol (For KL4000/KH4000) ............................................................... 112

10-1. Basic Communication Sequence .................................................................................................................... 113

10-2. Basic Communication Format......................................................................................................................... 113

10-3. Control Character Code .................................................................................................................................. 114

10-4. Communication Address ................................................................................................................................. 114

10-5. Checksum (bc bc) ........................................................................................................................................... 115

10-6. List of Sub Commands ................................................................................................................................... 115

10-7. List of Error Codes ................................................................ ................................................................ .......... 116

10-8. Communication Format Details ...................................................................................................................... 117

11. Web Settings/Display (AL4000/AH4000 Only) ........................................................ 129

Page 3

11-1. Top Page ........................................................................................................................................................ 129

11-2. Display ............................................................................................................................................................ 130

11-3. Parameters Set by Each CH........................................................................................................................... 131

11-4. Calculation ...................................................................................................................................................... 135

11-5. Dotting/Printing ............................................................................................................................................... 137

11-6. Remote Contacts (Option) .............................................................................................................................. 143

11-7. Communication ............................................................................................................................................... 145

11-8. SD Card .......................................................................................................................................................... 149

11-9. System ........................................................................................................................................................... 150

Page 4

1. Introduction

Reuest

Request

This product is warranted for one year from the date of delivery. If it is damaged during the warranty period, when

used normally based on the cautions in the instruction manual labels attached to the product, etc., it will be repaired

without any charge (only in Japan). In the case, we are sorry to trouble you, but please contact your dealer or

nearest our sales office.

However, in cases of the followings, it will be repaired at your expense even during warranty period.

1. Failure or damage caused by improper use or connection, or invalid repair or modification.

2. Failure or damage caused by fire, earthquake, wind or flood, thunderbolt, or other extraordinary natural

phenomena, or pollution, salt, harmful gas, abnormal voltage, or use of unspecified power.

3. Replacement of parts or accessories that have reached the end of their life.

Furthermore, the term „warranty‟ in this sense covers only a CHINO‟s product itself. Therefore, we are not

responsible for compensation for whatever the damage that is triggered by failure of our product.

Product warranty scope

1. No part of this manual can be reproduced or copied in any form without permission.

2. The contents of this manual may be altered without prior notice.

3. This manual has been documented by making assurance doubly sure. However, if any question arises or if any

error, an omission, or other deficiencies are found, please contact your nearest our sales office.

4. CHINO is not responsible for any operation results of this software.

Notice

1. Microsoft, Windows, Windows XP, Windows Vista, Windows 7, and NET Framework are trademarks of Microsoft

Corporation and the related company.

2. SD Memory Card is the trademark of Panasonic Corporation, SanDisk Corporation in USA, and TOSHIBA

CORPORATION.

3. Other described company names and product names are trademarks and registered products of the respective

companies.

4. Please note that the marks “TM” and “®” are omitted throughout this manual.

Trademark

Perchlorate Material

This instrument uses battery with Perchlorate Material.

Special handling may apply, see

http://www. dtsc.ca.gov/hazardouswaste/perchiorate

Warning

Thank you for purchasing KL4000/KH4000 or AL4000/AH4000 series.

Make sure to read this instruction manual in advance to understand this unit well and prevent troubles from occurring.

This manual is a “Communications” instruction manual. For specifications with communications, read the “General”

instruction manual separately.

- To the persons doing instrumentation, installation, and sales -

Make sure to provide this instruction manual to the person who uses the unit.

- To the users of this unit -

Store this instruction manual with care until you scrap the unit.

Also, write down the parameter contents set in the product and keep it for your record.

- 1 -

Page 5

2. For Safe Use

Symbol mark

Meaning

Cautions are explained to avoid causes for slight injuries of users or damages of the unit

or peripheral devices.

!

Caution

For safe use of the unit, please read and understand the following cautions.

2-1. Preconditions for Use

The unit is a component type general product to be used mounted on an indoor instrumentation panel. Avoid using under

other conditions.

Use after the system safety is implemented such as the fail-safe design and periodical inspection on the final product side.

Also, for wiring/adjustment/operation of the unit, ask professionals with instrumentation knowledge to perform.

In communications interfaces, communication errors in some probabilities are unavoidable due to the timing and noise

between instruments.

For your machines and devices, please perform retry processing, fail safe design, safety design and so on.

Furthermore, also the person who actually uses the unit is required to read this instruction manual to fully understand

various cautions and basic operation.

2-2. Symbol Mark

This instruction manual includes the following symbol marks. Make sure to fully understand their meaning.

- 2 -

Page 6

3. Overview

The unit is equipped with the communication interfaces such as RS232C, RS422A, RS485 and Ethernet to communicate

with a personal computer (PC). Receiving measured data, setting various parameters and sending operation commands

can be performed on a PC.

The number of connectable units is one for RS232C, and 31 at maximum for RS422A/485.

3-1. RS232C Communication Interface

RS232C is a data communications standard developed and published by Electronic Industries Association (EIA), which is

equivalent to JIS C 6361 of Japanese standard.

Originally, RS232C is an interface between a modem and connected data terminal equipment, and the standard specifies

electrical and mechanical specifications only.

Currently, there are few RS232C communication interfaces used for PCs or industrial instruments like this unit which meet

the above standard completely. There are cases where the number of signal cables or the connector differs from the

standard.

Also, the standard does not specify software, or “data transmission procedure”, so it means that connection between

devices with RS232C communication interface is not always possible. For this reason, users need to research or check

the specifications and transmission procedures of devices to be connected beforehand. However, a device like PC which

allows arbitrary programming of specifications can be combined with any device by creating an appropriate program.

To research the RS232C standards, referring to JIS C 6361 may be the easiest way.

3-2. RS422A/485 Communication Interface

With RS422A/485 communication interface, multiple units (up to 31) of this series can be connected in parallel to establish

communication using signals conforming to RS422A/485.

There are not many PCs having RS422A/485 communication interface, however, serial communication enables easy

connection setup using a signal converter between RS232C RS422A/485.

A line converter for RS232C RS422A/485 signal conversion (model: SC8-10) is available from us. Contact us when

you need it.

The difference between RS422A and RS485 is that RS422A uses four signal cables whereas RS485 uses only two signal

cables.

3-3. Ethernet

Ethernet is a communication interface standardized as IEEE802, 3 in 1983. It is widely used as the most common

communication medium in small-scale LAN. The AL4000/AH4000 series is connected to LAN constructed by Ethernet to

receive measured data or set various parameters.

- 3 -

Page 7

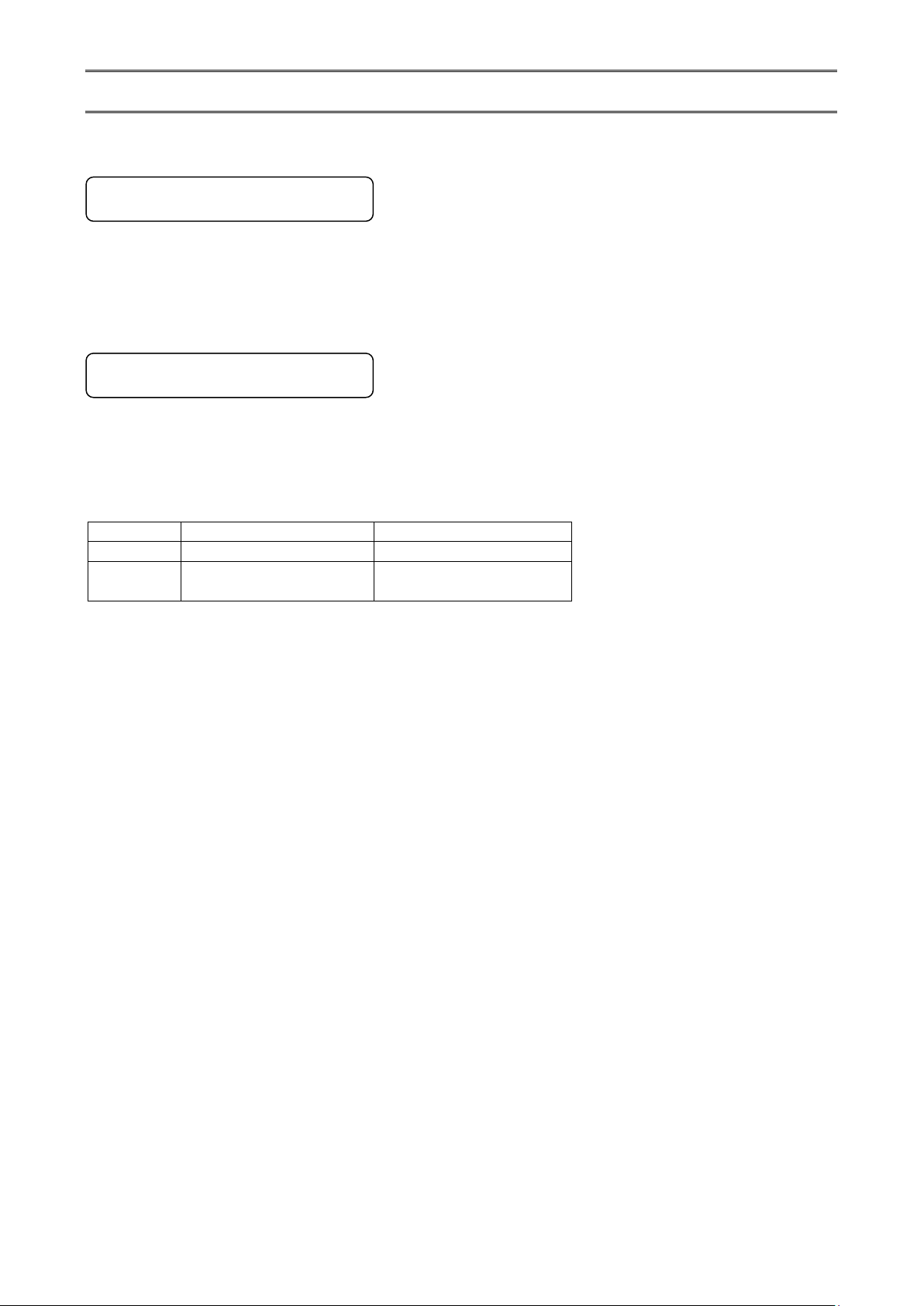

4. Communications Protocol

KL4000/KH4000

AL4000/AH4000

PRIVATE1

No communication address

No connection sequence

PRIVATE2

Communication address

available

Connection sequence

available

The unit has the following two communications protocols which can be switched using the front keys.

4-1. MODBUS Protocol

MODBUS is a registered trademark of Schneider Electric.

MODBUS protocol has RTU mode and ASCII mode which can be selected using the front keys or via communication. This

protocol provides measured data transmission, setting and operating functions.

For Ethernet interface, MODBUS protocol is implemented on TCP protocol packet to establish communication (see

section 5-3).

4-2. PRIVATE Protocol

PRIVATE is a conventionally used protocol by CHINO.

This protocol can be selected using the front keys. It provides measured data transmission, setting and operating

functions.

Two types of modes are available: PRIVATE1 and PRIVATE2, and these can be selected using the front keys.

PRIVATE1: With RS232C, data link is not necessary due to one-to-one communication with the host.

Select PRIVATE1 for RS232C.

PRIVATE2: With RS422A and RS485, data link is required.

Select PRIVATE2 for these interfaces. Also, select PRIVATE2 for RS232C when the software of the host is

shared since data link commands can be received.

The compatibility with our older models can be maintained. However, the parameters which cannot be handled by

PRIVATE are now settable by MODBUS. We recommend MODBUS protocol to customers who construct a new

communication environment.

- 4 -

Page 8

5. Communication Specifications

Communication system

:

Half-duplex start-stop synchronization

Protocol

:

MODBUS protocol

Transmission speed

:

9600, 19200, 38400bps selectable

Start bit

:

1 bit

Data length

:

7 bits (ASCII mode)

8 bits (RTU/ASCII mode)

Parity bit

:

Non (None) /Even/Odd

Stop bit

:

1 bit/2 bits

Transmission code

:

ASCII (ASCII mode)

Binary (RTU mode)

Error check

(Error detection)

:

LRC (ASCII mode)

CRC-16 (RTU mode)

Data transmission procedure

:

None

Used signals

:

Transmitted/received data only (no control signal used)

Communication system

:

Half-duplex start-stop synchronization (polling selecting

system)

Protocol

:

PRIVATE protocol

Transmission speed

:

1200, 2400, 4800, 9600bps selectable

Start bit

:

1 bit

Data length

:

7 bits/8 bits

Parity bit

:

Non (None) /Even/Odd

Stop bit

:

1 bit/2 bits

Transmission code

:

ASCII

Error check

(Error detection)

:

BCC (block check character) checksum

Data transmission procedure

:

None

Used signals

:

Transmitted/received data only (no control signal used)

Medium

:

Ethernet (10BASE-T/100BASE-TX)

Communication mode

:

Full-Duplex/Half-Duplex

Transmission speed

:

10Mbps (10BASE-T)/100Mbps (100BASE-TX)

Note that transmission speed and communication mode are

automatically recognized and cannot be set to fixed value.

Protocol

:

MODBUS (RTU) protocol on TCP/IP

Simultaneous connection

:

1 (in host communication using MODBUS protocol)

TCP/IP model layers

Main protocol used in Ethernet communication

Application layer

MODBUS

Transport layer

TCP

Internet layer

IP, ARP

Physical/data link layer

Hardware (Ethernet)

5-1. MODBUS

5-2. PRIVATE

5-3. Ethernet

Ethernet communication is supported by AL4000/AH4000 only.

The AL4000/AH4000 series provides a Web setting function on Ethernet (see section 11).

The following table shows association with TCP/IP layers in MODBUS communication.

For details of MODBUS protocol, see “8. MODBUS Protocol”.

- 5 -

Page 9

1. Establishing TCP connection

U

R

G

0

A

C

K

P

S

H

R

S

T

S

Y

N

F

I

N

0 0 0 1 0

PC

Client

Unit

Server

(1) SYN

U

R

G

0

A

C

K

P

S

H

R

S

T

S

Y

N

F

I

N

1 0 0 1 0

(2) SYN + ACK

U

R

G

0

A

C

K

P

S

H

R

S

T

S

Y

N

F

I

N

1 0 0 0 0

(3) ACK

TCP header section

TCP data section

MODBUS (RTU) protocol

TCP packet

PC

Unit

Request

Response

Request

Response

To establish communication between a PC (makes data request: client) and the unit (receives data request: server),

establish TCP connection first according to the following procedure.

(1) PC sends a TCP packet with SYN flag set to the unit.

(2) When the unit receives the SYN packet, it sends a TCP packet with SYN + ACK flag set to the PC.

(3) When the PC receives the SYN + ACK packet, it sends a TCP packet with ACK flag set to the unit.

2. Transmitting/receiving data by TCP

Once the connection has been established, various data are transmitted/received between PC (client) and the unit

(server) via MODBUS (RTU) protocol on TCP data.

- 6 -

Page 10

3. Disconnecting TCP connection

U

R

G

0

A

C

K

P

S

H

R

S

T

S

Y

N

F

I

N

0 0 0 0 1

PC

Client

Unit

Server

(1) FIN

U

R

G

0

A

C

K

P

S

H

R

S

T

S

Y

N

F

I

N

1 0 0 0 0

(2) ACK

U

R

G

0

A

C

K

P

S

H

R

S

T

S

Y

N

F

I

N

1 0 0 0 0

(4) ACK

U

R

G

0

A

C

K

P

S

H

R

S

T

S

Y

N

F

I

N

1 0 0 0 1

(3) FIN + ACK

TCP connection is disconnected with the following flow of communications.

(1) PC sends a TCP packet with FIN flag set to the unit (disconnection notice).

(2) When the unit receives the FIN packet, it sends a TCP packet with ACK flag set to the PC.

(3) The unit sends a FIN + ACK packet to the PC (disconnection notice).

(4) The PC sends an ACK packet responding to FIN to the unit.

4. Actions against communication error

When the following communication errors occur on TCP/IP, the unit takes actions described below.

● No response from the device at the other end (PC, etc.)

When the unit sends data to a communication target on Ethernet but no response (ACK) packet is returned, the

unit repeats transmission retry operation (for around three minutes maximum).

The unit disconnects TCP connection if no response is made to the transmission retry packet.

If a communication target makes a TCP connection request before the unit disconnects TCP connection, the unit

sends an RST packet to reject the request.

The unit sends an RST packet in the following situations.

When a TCP packet is received from devices other than that being connected.

When an RST packet is received from a communication target.

● Unexpected reply packet received

Generally, unexpected reply packets are ignored. However, TCP connection is disconnected immediately after

the unit receives an RST packet in situations such as when PC performs a forced disconnection of TCP

connection.

- 7 -

Page 11

6. Communication Parameter Settings

Parameter

Function

Default

Set value

MAC Address

Ethernet MAC address of the unit

Unique value

Setting disabled

IP Address

Set IP address

192.168.254.254

**:**:**:** (each ** area is set to 0 to 255)

Subnet Mask

Set subnet mask

255.255.255.0

**:**:**:** (each ** area is set to 0 to 255)

Default Gateway

Set default gateway address of the

network used

0.0.0.0

**:**:**:** (each ** area is set to 0 to 255)

DNS ON/OFF

Select whether to use DNS (domain

name server)

OFF

OFF (not used), ON (used)

Set server like SNTP and SMTP by the name when

using DNS, or by the IP address when not using

DNS.

[DNS Servers]

Primary Server

Set primary DNS server

0.0.0.0

**:**:**:** (each ** area is set to 0 to 255)

Secondary Server

Set secondary DNS server

0.0.0.0

**:**:**:** (each ** area is set to 0 to 255)

Port No.

Set port No. for socket communication

by TCP/IP

11111

0 to 65535

Password

Set a password consisting of up to 32

characters used for setting on the Web

3571

To use the unit in a small network using a router without connecting to internal LAN or internet, set the IP address as

shown below.

Unit

IP address

Subnet mask

AH4000 A

192.168.254.254

255.255.255.0

AH4000 B

192.168.254.253

255.255.255.0

...

...

...

PC A

192.168.254.1

255.255.255.0

PC B

192.168.254.2

255.255.255.0

...

...

...

Example settings for small network

Reference

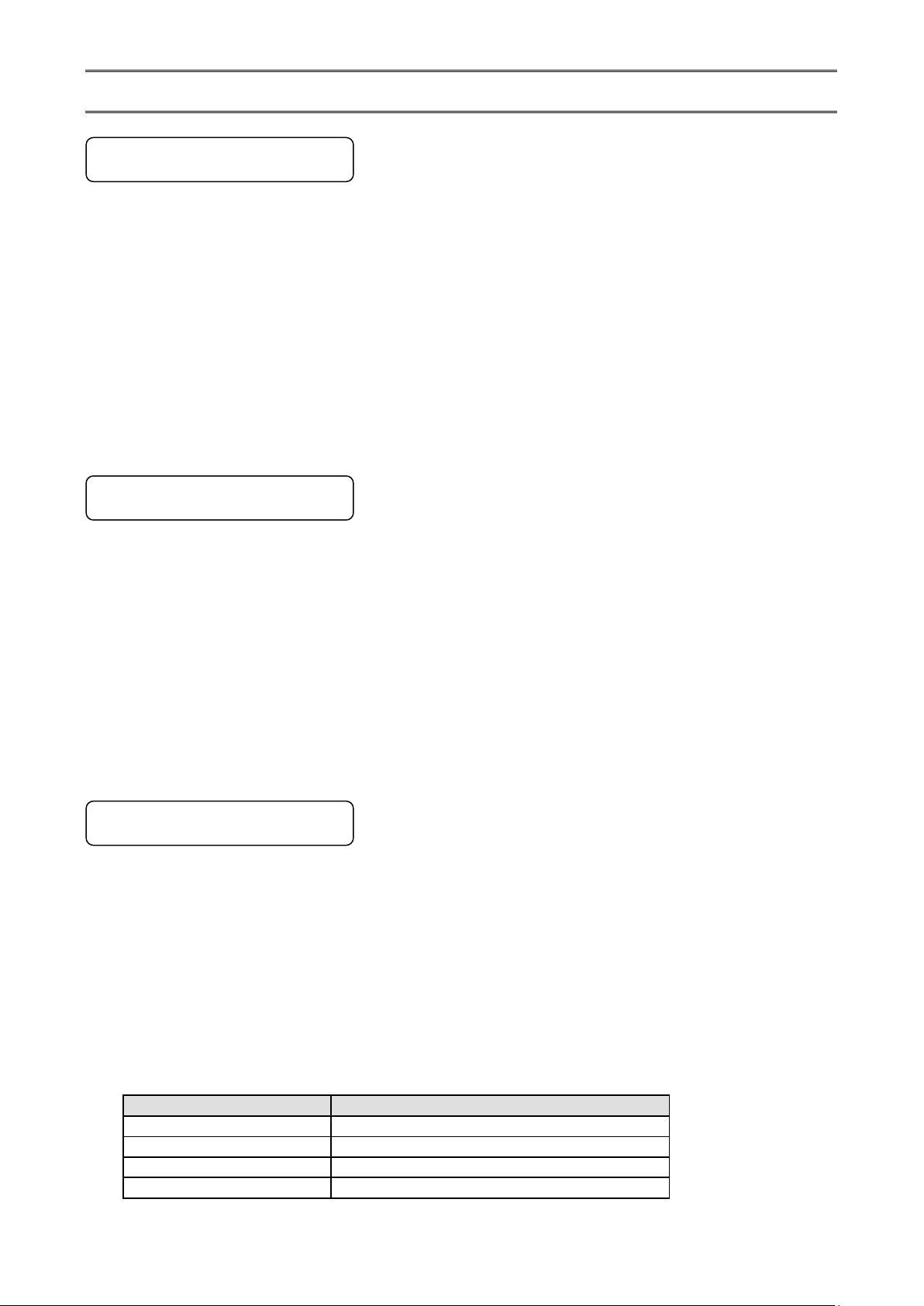

6-1. Ethernet Settings (AL4000/AH4000 Only)

(IP Address etc… Settings)

Set each parameter.

(1) Pressing the key displays the menu

window (list of setting items).

(2) Select “Ether”.

(3) Move the cursor to the parameter to be set

with the ▲/▼// keys.

(4) Press the key to make it available

for setting and then select or enter a value.

(5) After completing the settings of this item,

move the cursor to Set .

(6) Press the key to register the

settings (when chart recording is ON, a

setting change mark is printed). To cancel

the settings, press the key.

Note: Actual windows are separated. Use the ▲/▼ keys to scroll and continue settings.

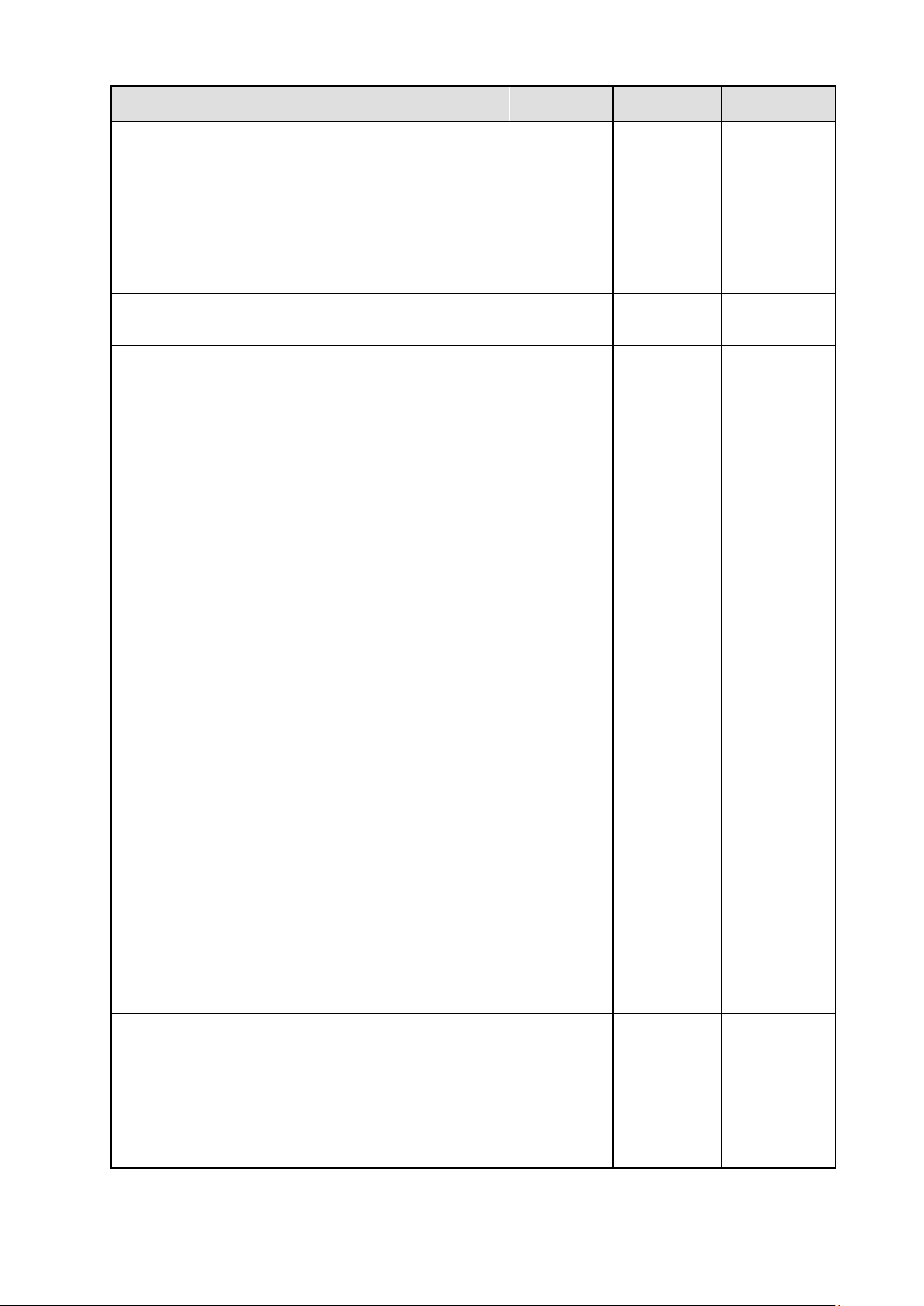

[List of Ether setting parameters]

- 8 -

Page 12

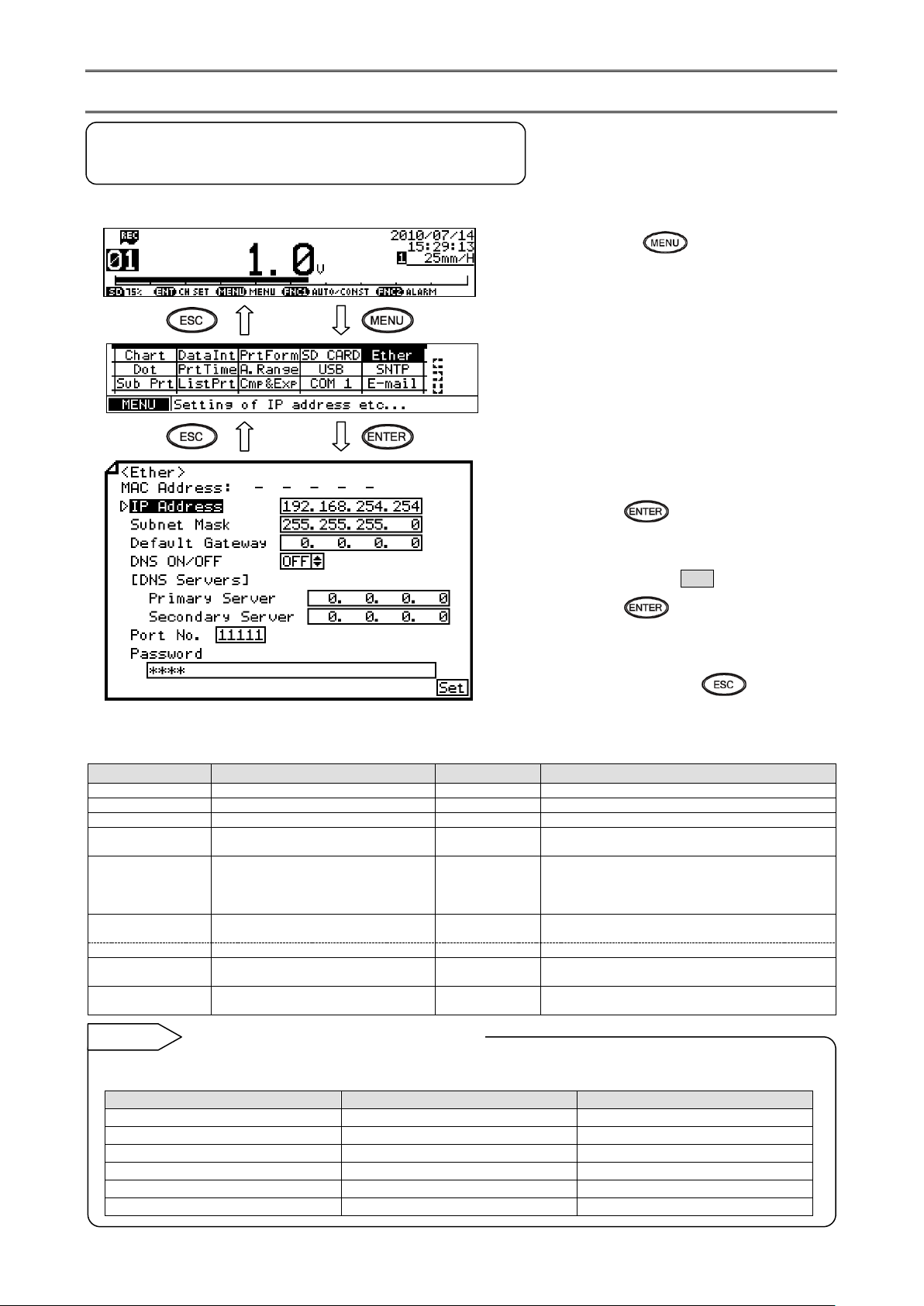

6-2. COM Settings (For AL4000/AH4000)

Parameter

Function

Default

Set value

Mode

Communication mode

Low(To PC etc…)

Fixed to Low (To PC etc…)

Protocol

Select communication

protocol

MODBUS RTU

MODBUS RTU, MODBUS ASCII, PRIVATE1 (without

connection sequence), PRIVATE2 (with connection

sequence)

Address

Set communication

address of the unit

01

01 to 99

Baudrate

Set communication speed

9600

PRIVATE: 1200, 2400, 4800, 9600bps

MODBUS: 9600, 19200, 38400bps

Changes to “9600” when changing from PRIVATE to

MODBUS or vice versa.

Character

Set transmission character

8N1

7E1, 7E2, 7O1, 7O2, 8N1, 8N2, 8E1, 8E2, 8O1, 8O2

Check SUM

Select whether to add

checksum code

*

OFF, ON

Settable only when Protocol is set to “PRIVATE”.

Note: Actual windows are separated. Use the ▲/▼ keys to

scroll and continue settings.

Codes are used to represent characters. MODBUS RTU mode can set only 8-bit characters (see section 8-1).

Code

Character length

Parity

Stop bit

Code

Character length

Parity

Stop bit

7E1

7-bit

Even

1

8N2

8-bit

Non

2

7E2

7-bit

Even

2

8E1

8-bit

Even

1

7O1

7-bit

Odd 1 8E2

8-bit

Even

2

7O2

7-bit

Odd

2

8O1

8-bit

Odd

1

8N1

8-bit

Non

1

8O2

8-bit

Odd

2

Character selection

Reference

Set each parameter.

(1) Pressing the key displays the menu

window (list of setting items).

(2) Select “COM1” or “COM2”.

(3) Move the cursor to the parameter to be set

with the ▲/▼/ / keys.

(4) Press the key to make it available

for setting and then select or enter a value.

(5) After completing the settings of this item,

move the cursor to Set .

[List of COM1 and COM2 setting parameters]

(6) Press the key to register the

settings (when chart recording is ON, a

setting change mark is printed). To cancel

the settings, press the key.

* When connecting via Ethernet, communication protocol and communication address are fixed to “MODBUS RTU” and

“01” respectively.

* Use the unit and PC at the same communication speed (use the default speed 9600bps in normal case).

* For RS422A/485, a communication address of the unit needs to be set. Make sure that one or more units connected to

a PC have unique communication address and no overlap occurs.

For RS232C, only one unit is connected, but communication address needs to be set (use the default address 01 in

normal case).

- 9 -

Page 13

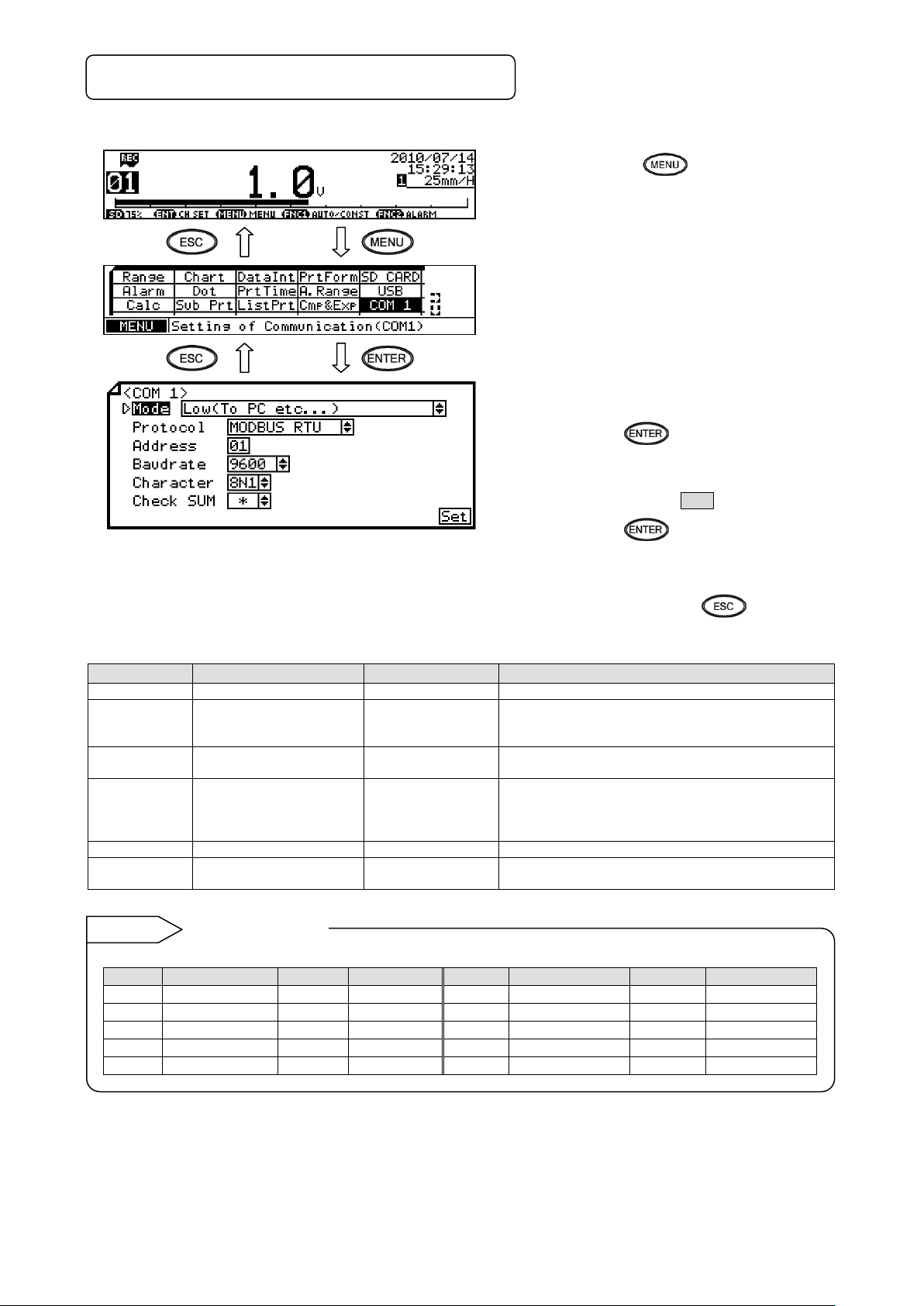

Communication

specifications

Enter [ENG2 mode]

[Display mode]

Option

Go to 2. Communications

protocol

Go to 4. Communication

address

Go to 5. Communication

character

Start setting

2 sec or more

or no key operation for 1

min or more

+

2 sec or more

Go to 3. Transmission

speed

Switching between [Display mode] and [ENG1

mode] can be done by the

key instead of the

key.

Note

Substitution key

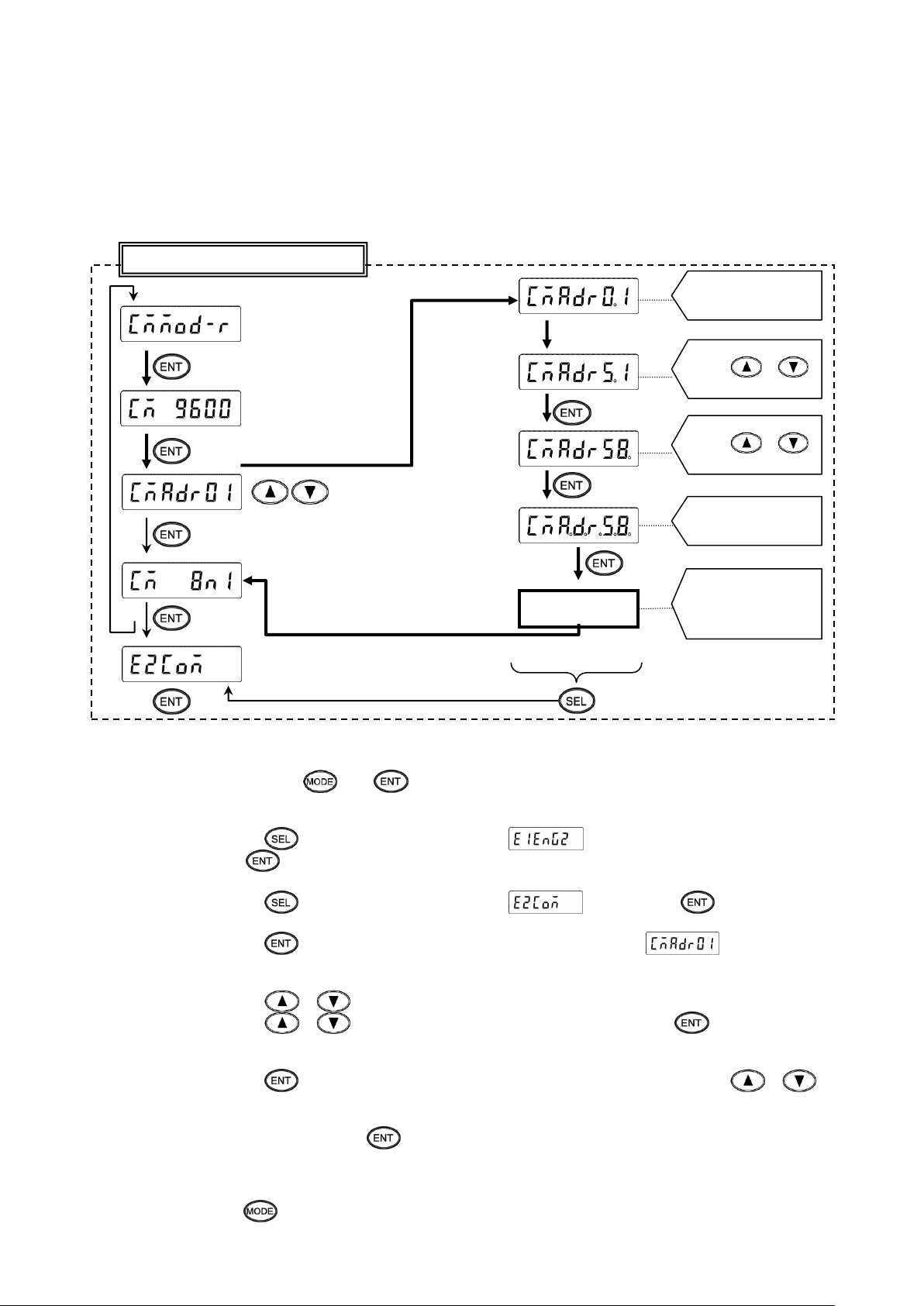

6-3. COM Settings (For KL4000/KH4000)

Communication settings are performed with [ENG2 mode] which can be entered from a [ENG1 mode] item.

The [ENG2 mode] provides items for checking remote contact specifications and setting communication parameters.

Set communication parameters according to the flow chart.

1. Checking/setting items of communication specifications

- 10 -

Page 14

2. Setting communications protocol

(4)

(5)

(6)

Communication specification items

Register

Save in the memory

and print setting

change mark

Start setting

Decimal points of all

digits flash

ON:

Flash:

Reference

Decimal

point

1) Setting range

2) Setting flow chart

<Example> Mode is changed from MODBUS RTU to MODBUS ASCII.

* Communications protocol is selected by the key in this example, but you can also use the key

to reverse.

3) Setting procedure

(MODBUS RTU mode)

(PRIVATE1: No communication address)

(MODBUS ASCII mode)

(PRIVATE2: Communication address available)

(1) Enter [ENG1 mode]

Press and hold the and keys for two seconds or more to change from [Display mode] to

[ENG1 mode].

(2) Enter [ENG2 mode]

Pressing the key changes ENG1 item. Select .

Press the key to enter [ENG2 mode].

(3) Select communication specification

Pressing the key changes ENG2 item. Select and press the key.

(4) Start communications protocol setting

Pressing the / key displays the cursor (flashing decimal point). Select .

(5) Check selection

Pressing the key flashes decimal points of all digits. If an error is found, press the /

key to reset.

(6) Register setting

When set correctly, press the key. The setting is saved in the memory and setting change mark is

printed.

(7) End

The setting window of transmission speed will be displayed. Also, the mode returns to [Display mode]

when the key is pressed and held for two seconds or more on any setting display window, or keys

are not operated for one minute or more.

- 11 -

Page 15

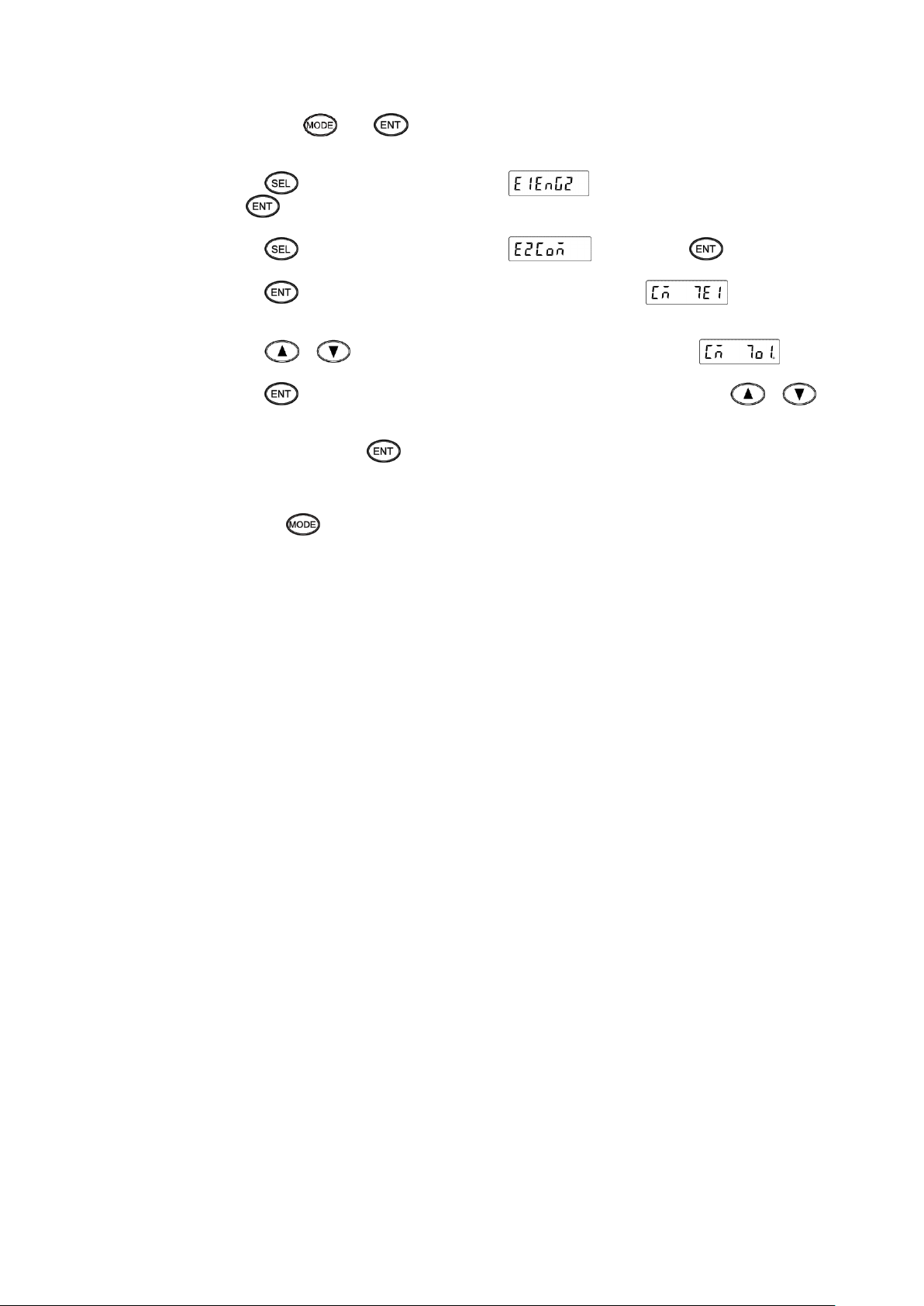

3. Setting transmission speed

(7)

(6)

(5)

(4)

Communication specification items

Save in the memory

and print setting

change mark

Start setting

Register

Decimal points of all

digits flash

1) Setting range

MODBUS: 9600, 19200, 38400bps

PRIVATE: 1200, 2400, 4800, 9600bps

2) Setting flow chart

<Example> Transmission speed of MODBUS protocol is changed from 9600 to 19200bps.

* Transmission speed is selected by the key in this example, but you can also use the key to

reverse.

3) Setting procedure

(1) Enter [ENG1 mode]

Press and hold the and keys for two seconds or more to change from [Display mode] to

[ENG1 mode].

(2) Enter [ENG2 mode]

Pressing the key changes ENG1 item. Select .

Press the key to enter [ENG2 mode].

(3) Select communication specification

Pressing the key changes ENG2 item. Select and press the key.

(4) Select transmission speed

Pressing the key changes communication specification item. Select (previous set

value is displayed).

(5) Start setting

Pressing the / key displays the cursor (flashing decimal point). Select .

(6) Check selection

Pressing the key flashes decimal points of all digits. If an error is found, press the /

key to reset.

(7) Register setting

When set correctly, press the key. The setting is saved in the memory and setting change mark is

printed.

(8) End

The setting window of communication address will be displayed. Also, the mode returns to [Display mode]

when the key is pressed and held for two seconds or more on any setting display window, or keys

are not operated for one minute or more.

- 12 -

Page 16

4. Setting communication address

(7)

(5)

(6)

(4)

Communication specification items

Save in the memory

and print setting

change mark

Register

Press

/

Decimal points of all

digits flash

Cursor appears on

the tens place

Start setting

Press

/

1) Setting range: 01 to 99

* For RS422A/485, a communication address of the unit needs to be set. Make sure that one or more units

connected to a PC have unique communication address and no overlap occurs. For RS232C, only one unit is

connected, but communication address needs to be set (use the default address 01 in normal case).

2) Setting flow chart <Example> Communication address is changed from 01 to 58.

3) Setting procedure

(1) Enter [ENG1 mode]

Press and hold the and keys for two seconds or more to change from [Display mode] to

[ENG1 mode].

(2) Enter [ENG2 mode]

Pressing the key changes ENG1 item. Select .

Press the key to enter [ENG2 mode].

(3) Select communication specification

Pressing the key changes ENG2 item. Select and press the key.

(4) Select communication address

Pressing the key changes communication specification item. Select (previous set

value is displayed).

(5) Start setting

Pressing the / key displays the cursor (flashing decimal point) on the tens place.

Pressing the / key increases/decreases numeric value. Press the key to move the

cursor right, and set the ones place likewise.

(6) Check set value

Pressing the key flashes decimal points of all digits. If an error is found, press the /

key to reset.

(7) Register setting

When set correctly, press the key. The setting is saved in the memory and setting change mark is

printed.

(8) End

The setting window of communication character will be displayed. Also, the mode returns to [Display mode]

when the key is pressed and held for two seconds or more on any setting display window, or keys

are not operated for one minute or more.

- 13 -

Page 17

5. Setting communication character

Display

Character length

Parity

Stop bit

7E1

7-bit

Even

1

7E2

7-bit

Even

2

7O1

7-bit

Odd

1

7O2

7-bit

Odd

2

8N1

8-bit

Non

1

8N2

8-bit

Non

2

8E1

8-bit

Even

1

8E2

8-bit

Even

2

8O1

8-bit

Odd

1

8O2

8-bit

Odd

2

(7)

(6)

(5)

(4)

Stop bit

(1: 1 bit, 2: 2 bits)

Parity

(E: EVEN, O: ODD, N: NON)

Character length

(7: 7-bit, 8: 8-bit)

Display and meaning

Reference

Communication specification items

Register

Save in the memory

and print setting

change mark

Start setting

Decimal points of all

digits flash

1) Setting range

* MODBUS RTU mode can set only 8-bit characters (see section 8-1).

2) Setting flow chart

<Example> Communication character is changed from 7E1 to 7O1.

* Communication character is selected by the key in this example, but you can also use the key

to reverse.

- 14 -

Page 18

3) Setting procedure

(1) Enter [ENG1 mode]

Press and hold the and keys for two seconds or more to change from [Display mode] to

[ENG1 mode].

(2) Enter [ENG2 mode]

Pressing the key changes ENG1 item. Select .

Press the key to enter [ENG2 mode].

(3) Select communication specification

Pressing the key changes ENG2 item. Select and press the key.

(4) Select communication character

Pressing the key changes communication specification item. Select (previous set

value is displayed).

(5) Start setting

Pressing the / key displays the cursor (flashing decimal point). Select .

(6) Check selection

Pressing the key flashes decimal points of all digits. If an error is found, press the /

key to reset.

(7) Register setting

When set correctly, press the key. The setting is saved in the memory and setting change mark is

printed.

(8) End

The selection window of communication specification will be displayed. Also, the mode returns to [Display

mode] when the key is pressed and held for two seconds or more on any setting display window, or

keys are not operated for one minute or more.

- 15 -

Page 19

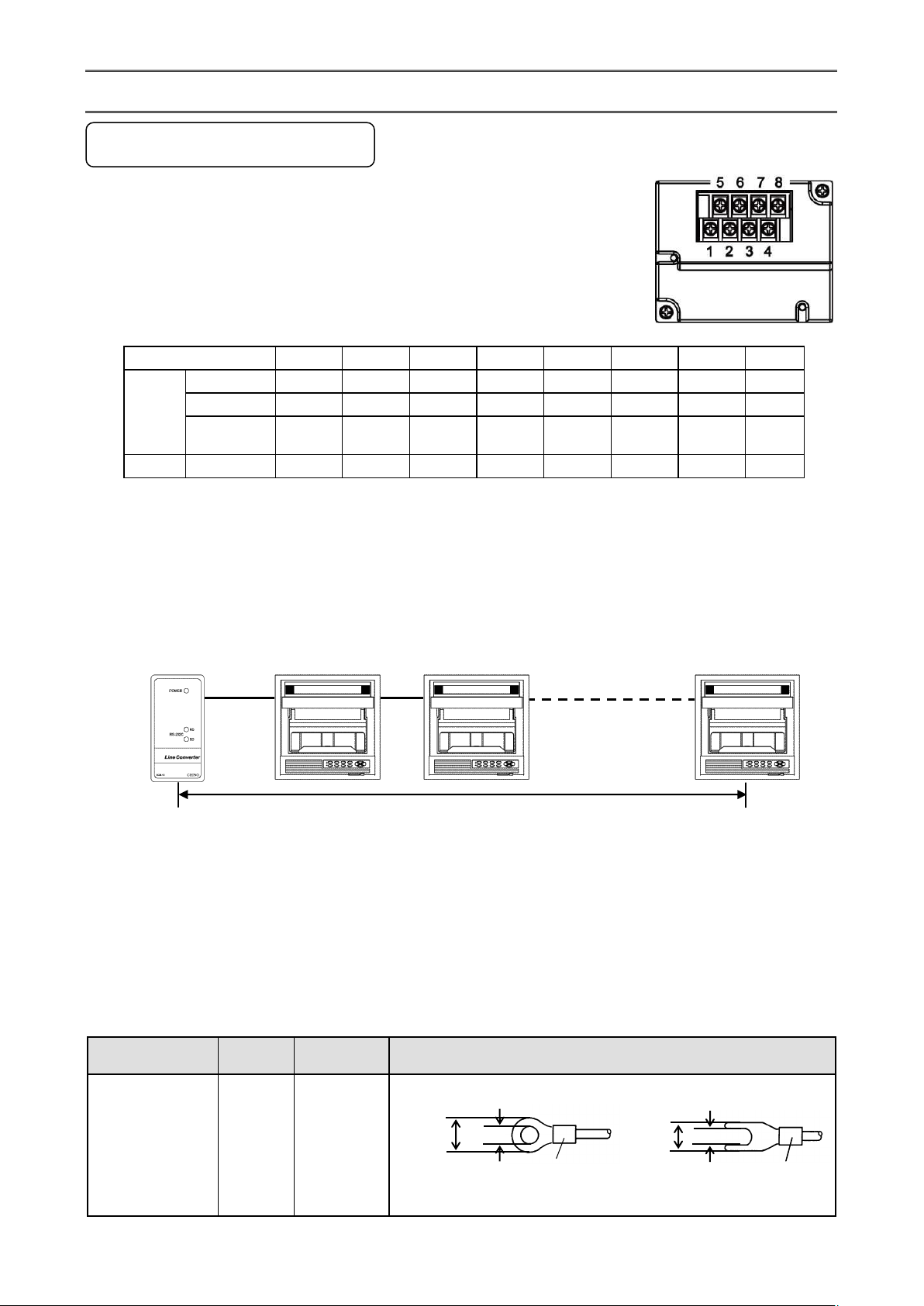

7. Wiring

1 2 3 4 5 6 7

8

COM1

RS232C

SG

SD RD

RS422A SG

SDA

SDB

RDA

RDB

RS485 SG

SA

SB

Short

with SA

Short

with SB

COM2

RS485

SA

SB

SG

Terminal board

Diameter

Tightening

torque

Termination treatment (unit: mm)

Communications

terminal

M3

0.5 N∙m

O type Y type

* O type is preferred.

Total cable length: 1.2km or less

5.2 or less

3.2 or more

t: 0.8

With an insulation sleeve

5.2 or less

3.2 or more

With an insulation sleeve

t: 0.8

7-1. Precautions on Wiring

1. Communication terminal

Terminal layout depends on the selection of communication interface.

* RS232C and RS422A/485 of COM1 are specified on purchase.

* COM2 is supported by AL4000/AH4000 only.

2. RS422A/485 communication cable extended up to 1.2km

The interval between instruments can be decided freely, however, note that the total cable length should be 1.2km or

less.

Line converter Unit

3. Take measure against noise

To avoid interference from noise, keep the communication cable separated from the power or other communication

cables, with a gap of at least 50cm between them.

4. Make sure to use crimping terminals

One of the causes of communication failure is a disconnection of cables. Make sure to install an O type or Y type

crimping terminal with insulation sleeve to the end of communication cable.

- 16 -

Page 20

5. Add termination resistor

The number of connectable units specified above is based on the use of communication

IC conforming to the communication standards. However, the number of units or

distance ensuring high quality communication varies depending on the type of

communication cable and other connected devices.

Cable

9-pin connector Crimp type ring terminals RS232C cable

Shape

Internal

wiring

Model

code

RZ-CRS6□□

Cable length: 01 to 15m (specified)

RD

SD

SG

1

2

3 4 5

6 7 8

9

RD

SD

SG

Cable for RS232C (Max. 15m)

PC side

9-pin connector

!

Caution

For RS422A/485 communications, install a 100Ω resistor to the unit which is located at the last edge of the

communication line.

(See section 7-3.2 and 7-3.3.)

6. Number of connectable units

RS232C: One unit

RS422A/485: Up to 31 units

7-2. Communication Cable

Prepare a communication cable before wiring. Dedicated cables are available from us. Contact us when you need it.

1. RS232C

Connection between PC and the unit or a line converter

- 17 -

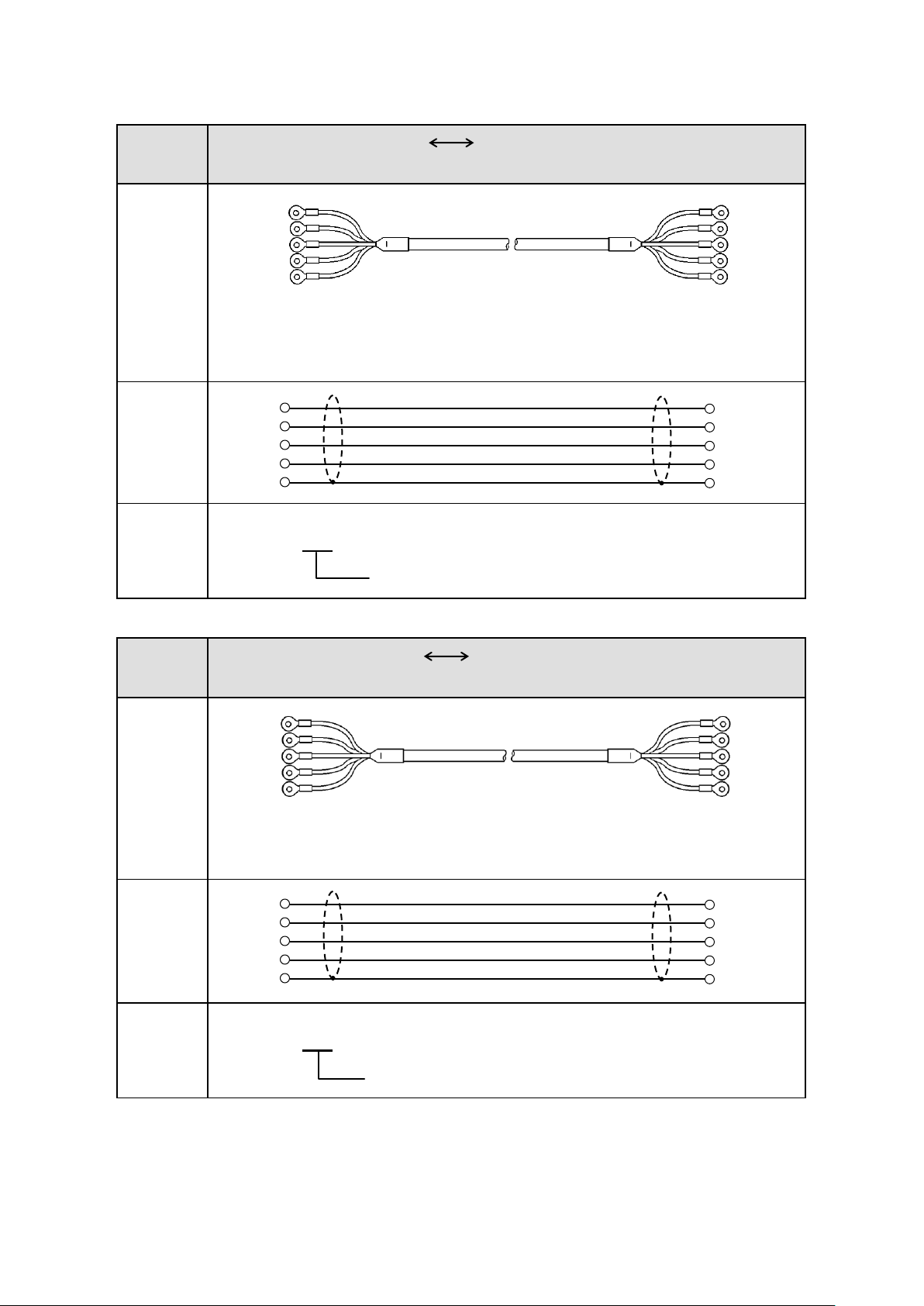

Page 21

2. RS422A

Cable

Crimp type ring terminals Crimp type ring terminals RS422A cable

(for a line converter)

Shape

4-core cable of twisted 2-core cables of twisted VCTF lines. Each side has a SG

(single ground) line. Since the line converter has no SG terminal, cut and use the

cable.

Internal

wiring

Model

code

RZ-CRA2□□

Cable length: 01 to 99m (specified)

Cable

Crimp type ring terminals Crimp type ring terminals RS422A cable

(for parallel)

Shape

4-core cable of twisted 2-core cables of twisted VCTF lines. Each side has a SG

(single ground) line.

Internal

wiring

Model

code

RZ-CRA1□□

Cable length: 01 to 99m (specified)

Line converter side

Recorder side

RDB

RDA

SDA

SDB

SG

SDB

SDA

RDA

RDB

SG

SDB

SDA

RDA

RDB

SG

SDB

SDA

RDA

RDB

SG

RDA (black)

RDB (white)

SDA (red)

SDB (green)

SG (blue)

(black) SDA

(white) SDB

(red) RDA

(green) RDB

(blue) SG

Device side

Recorder side

SDA (black)

SDB (white)

RDA (red)

RDB (green)

SG (blue)

(black) SDA

(white) SDB

(red) RDA

(green) RDB

(blue) SG

Connection between a line converter and the unit

Connection between the unit and other devices

- 18 -

Page 22

3. RS485

Cable

Crimp type ring terminals Crimp type ring terminals RS485 cable

Shape

2-core cable of twisted CVVS lines. Each side has a SG (single ground) line. Since

the line converter has no SG terminal, cut and use the cable.

Internal

wiring

Model

code

RZ-LEC□□□

Cable length: 001 to 200m (specified)

SD

RD

SG

Cable for RS232C (Max.15m)

Device side

RD

SD

SG

RZ-CRS6

Communications port

PC side

RDA

RDB

SG

SA

SB

SG

Device/line converter side

Recorder side

RDA (black)

RDB (white)

SG (green)

(black) SA

(white) SB

(green) SG

Connection between the unit and other devices and between a line converter and the unit

4. Ethernet (AL4000/AH4000 only)

● Connection between PC and device

When connecting a device to a PC directly (one-to-one), use a shielded, crossover twisted pair cable

(commercially available STP cable).

● Connection between HUB and device (multiple devices can be connected)

When connecting devices to a PC via HUB (one-to-N), use a shielded, straight twisted pair cable (commercially

available STP cable).

7-3. Communication Line Wiring

1. RS232C wiring

PC and device are connected one-to-one in RS232C communication.

Example of terminal connection

- 19 -

Page 23

2. RS422A wiring

Turn the switch of

RS422A/RS485 to RS422A.

Avoid connecting SG line to FG terminal or

ground terminal of the device.

RDB

RDA

SDA

SDB

SG

終端抵抗

100Ω

Device side

Line converter

SC8-10

RDB

RDA

SDA

SDB

SD

RD

SG

1

2

3

4

5

6

7

8

Cable for RS232C (Max. 15m)

RZ-CRS6

PC side

SD

RD

SG

RDB

RDA

SDA

SDB

SG

RDB

RDA

SDA

SDB

SG

Turn the switch of RS422A/RS485

to RS485.

Avoid connecting SG line to FG terminal or

ground terminal of the device.

SA

SB

SG

終端抵抗

100Ω

Device side

Line converter

SC8-10

RDB

RDA

SD

RD

SG

1

2

3

4

5

6

7

8

Cable for RS232C (Max. 15m)

RZ-CRS6

PC side

SD

RD

SG

SA

SB

SG

SA

SB

SG

Termination

resistor

100Ω

Communications port

Communications port

Termination

resistor

100Ω

PC and multiple devices are connected in RS422A communication. A line converter is required.

RS422A cable is within 1.2km of total extension and up to 31 devices can be connected.

Install a resistor of 100Ω to the last edge of the transmission line device side.

(General metal film resistors will be fine. They are available from us, so contact us when you need it.)

Example of terminal connection

3. RS485 wiring

PC and multiple devices are connected in RS485 communication. A line converter is required.

RS485 cable is within 1.2km of total extension and up to 31 devices can be connected.

Install a resistor of 100Ω to the last edge of the transmission line device side.

(General metal film resistors will be fine. They are available from us, so contact us when you need it.)

Example of terminal connection

- 20 -

Page 24

4. Ethernet wiring (AL4000/AH4000 only)

HUB

Shielded, straight twisted pair cable

(Max. 100m)

PC side

HUB

Shielded, straight twisted pair cable

(Max. 100m)

Shielded, straight twisted pair cable

(Max. 100m)

Shielded, crossover twisted pair cable

(Max. 100m)

PC side

Device side

Device side

● Example of connection between PC and Ethernet device (one-to-one connection)

● Example of connection between PC, HUB and Ethernet device (one-to-N connection)

- 21 -

Page 25

8. MODBUS Protocol

Make sure to read and understand this section to avoid any troubles.

!

Caution

1. Requesting data immediately after power-on generates an error

The unit is always ready for communications and responsive to data request from PC. However, after power-on, the

unit does not respond normally until channel data becomes ready.

For example, it takes about 20 seconds for a 24-point AH4000 recorder to have the data ready. When a data request

is received during this period, the unit returns an error.

2. Keys restricted in parameter setting (writing)

When operating the unit from PC to set parameters, etc., the / key becomes temporarily unavailable

while a setting window is displayed. The key will be available again by changing the window displayed.

3. RS232C requires communication address

Although PC and the unit are connected one-to-one in RS232C communication, a communication address needs to

be set to establish communication.

4. Be careful about command re-transmission as no control signal line is used

The serial interface of the unit makes communication without using a control line. Therefore, attention should be paid

when re-transmitting a command since reception failure may occur depending on the unit condition.

5. Do not disconnect communication cable or device, or turn ON/OFF the power

during communication

Disconnecting the cables or devices constituting the serial interface, or turning ON/OFF the devices during

communication may stop operation or generate an error. If this happens, all the devices constituting the serial

interface need to be reset to start the operation from the beginning.

6. Make sure that communication driver has been turned OFF before sending next

command

For RS422A/485 communication, multiple devices are connected in the same communication line, but only one

device whose communication address is specified by PC passes through the communication line. To send all

characters safely to PC, the communication line driver is turned OFF a few moments (about 5ms) after sending the

last character. If a PC sends a command to the next device before the driver is turned OFF, signals will interfere with

each other resulting in communication failure.

- 22 -

Page 26

Item

RTU mode

ASCII mode

Interface

RS232C, RS422A, RS485

Communication system

Half-duplex start-stop synchronization

Transmission speed

9600, 19200, 38400bps

Transmission code

Binary

ASCII

Error check

(Error detection)

Vertical

Parity

Horizontal

CRC-16

LRC

Character

configuration

Start bit

1 bit

Data length

8 bits

7 bits, 8 bits

Parity bit

None, odd, even

None*, odd, even

Stop bit

1bit/2 bits

Message start code

None

: (Colon)

Message end code

None

CR, LF

Data time interval

28-bit time or less

1 second or less

Example: RTU mode

ASCII mode

67H

36H (“6”)

89H

37H (“7”)

ABH

38H (“8”)

39H (“9”)

41H (“A”)

42H (“B”)

RTU mode

ASCII mode

Message

:

Message

CR

LF

8-1. Message Transmission Mode

Two types of message transmission mode are available: RTU (Remote Terminal Unit) mode and ASCII mode, which can

be selected using the front keys.

Comparison between RTU and ASCII modes

* For the case of 7-bit data, parity bit cannot be “None”.

1. Transmission data

The RTU mode transmits binary data. The ASCII mode divides the 8-bit binary data of RTU into high-order four bits

and low-order four bits, and turns them into characters (0 to 9, A to F).

The RTU mode enables more efficient transmission since its message is half in length compared to the ASCII mode.

2. Message frame structure

With RTU mode, the message frame consists of message section only.

With ASCII mode, the message frame consists of start character “: (colon, 3AH)”, message and end characters “CR

(carriage return, 0DH) + LF (line feed, 0AH)”.

The ASCII mode makes troubleshooting easier since it uses a message start character “:”.

- 23 -

Page 27

Slave address

Function code

Data

Error check

Code

Function

Unit

MODBUS original function

(reference)

01

Read digital (ON/OFF) settings

1 bit

Read coil status

02

Read digital input data

1 bit

Read input relay status

03

Read analog settings

16 bits

Read holding register contents

04

Read analog input data

16 bits

Read input register contents

05

Write digital setting

1 bit

Change single coil status

06

Write analog setting

16 bits

Write to single holding register

08

Send received data (for diagnosis)

Loop-back test

16

Write multiple analog settings

Write to multiple holding registers

70

Read floating data

Arbitrary command of vendors

71

Write floating data

Arbitrary command of vendors

8-2. Data Time Interval

RTU mode: 28-bit time or less (9600bps: 2.8msec, 19200bps: 1.4msec, 38400bps: 0.7msec)

ASCII mode: One second or less

When sending a message, keep the time interval between data constituting one message no longer than the time

specified above. If it is longer than the time specified above, the receiver side (the unit) recognizes that transmission of

data from the sender side is complete, and the data is handled as an abnormal message.

While the RTU mode requires continuous transmission of message characters, the ASCII mode allows for a maximum

interval of one second between characters, making it possible to use a master (PC) with a relatively slow processing

speed.

8-3. Message Structure

MODBUS message has the following structure which is applied to both RTU and ASCII modes.

1. Slave address

A slave address can be set in advance using the front keys within the range of 1 to 99. Normally, master device

communicates with a single slave device. Only a slave device whose address matches the slave address in a

command message from the master device sends a response.

The slave address “0” is used for a message addressed to all slave devices (broadcast) from the master device. In

this case, the slave devices do not send a response.

2. Function code

Function codes represent the functions to be executed by slave devices. The data is generally classified as shown in

the table below. The table also shows the comparison between MODBUS original functions and

MODBUS-compatible CHINO device functions (see section 8-9).

Function code table

- 24 -

Page 28

(1) Digital settings: Parameters mainly used to change functions such as recording ON/OFF and data printing

The data field may contain the data like input data which assigns a specific numeric

value as error data. When handling such data, perform error judgment on the data

before combining with decimal point data.

When decimal point data is combined first, error data is recognized as normal data.

Data type

Reference No.

Relative No.

MODBUS original function

(reference)

Digital settings

1 to 10000

Reference No. - 1

Coil

Digital input data

10001 to 20000

Reference No. - 10001

Input relay

Analog input data

30001 to 40000

Reference No. - 30001

Input register

Analog settings

40001 to 50000

Reference No. - 40001

Holding register

Floating data

(Floating point data)

50001 to 60000

Reference No. - 50001

!

Caution

execution.

(2) Digital input data: Event status, etc.

(3) Analog settings: Information of various settings

Within the range of 16-bit numeric values (-32768 to 32767)

(4) Analog input data: Measured data, unit specifications, etc.

Outputs a numeric value within the 16-bit range

(5) Floating data: When the data cannot be expressed by a numeric value within the 16-bit range (-32768 to

32767), floating data is used.

3. Data field

Data components depend on the function code. A master request consists of the code number of read/write target

data (a relative number obtained from reference number described in the following section) and the number of data

pieces. A slave response consists of the data responding to request.

Basic MODBUS data consists of 16-bit integers only, and the use of sign is specified for each data piece. Therefore,

real number data such as measured data is expressed by assigning the decimal point position to a separate address

to express an integer value, or by fixing the decimal point position and normalizing with the scale upper and lower

limits.

This unit employs the system of assigning the decimal point position to a separate address.

The numeric data which cannot be expressed by 16-bit integers can be read or written using floating data.

4. Reference number.

All the data handled by the unit has “reference number” assigned, and this number is required when reading/writing

data.

The data is classified into “Digital settings”, “Digital input data”, “Analog input data”, “Analog settings” and “Floating

data (floating point data)” by its type.

A “relative number” corresponding to the reference number is specified in a message.

Reference numbers and corresponding relative numbers

For example, a relative number of “Reference No. 30101 (CH1 data)” described later is “100”.

- 25 -

Page 29

Quick search table for reference No.

Data type

Parameter

Reference No

Applicable

Function code

Reference table

Digital settings

Key lock

Message printing 1

Recording ON/OFF

Feed

List printing

Title printing (message printing 2)

Data printing

Recording to SD card ON/OFF

Fast dot printing

SNTP time setting

01 to 95

01 (READ)

05 (WRITE)

See section 8-9.1

Digital input data

Remote contact status

Measured data status

Alarm status

10009 to 10480

02 (READ)

See section 8-9.2

Analog input data

Device information

Measured data

30001 to 30028

30101 to 30148

04 (READ)

See section 8-9.3

Analog settings

Channel parameters

Date and time setting

Chart speed setting

Dot printing interval setting

Periodic data printing setting

Recording format selection

Zone printing setting

Display setting

Unit-tag switch setting

Range setting

Scale setting

Burnout setting

Sensor correction setting

Recording color setting

Subtract printing setting

Unit setting

Tag setting

Alarm setting

Calculation setting

Compressed/expanded printing setting

Automatic range-shift setting

Display and recording ON/OFF setting

Communication setting

Calendar timer setting

Broken line approximation table setting

SD card setting

Measured value display order setting

Title printing (message printing 2)

Remote contact setting

Operation recording setting

Message printing 1 setting

Periodic (specified time) data printing setting

Formula setting

Data communications input setting

Fail out setting

Communication parameter setting

40001 to 44394

45001 to 45487

46501 to 46574

47001 to 47412

47906 to 47915

47931 to 47954

48001 to 48038

48069 to 48088

48101 to 48181

48202 to 48400

48501 to 48549

48601 to 48900

49001 to 49048

49101 to 49119

49902 to 49923

03 (READ)

06 (WRITE)

16 (WRITE)

See section 8-9.4

Floating data

(Floating point data)

Measured data

Data communications input

Parameters set by each channel

Range setting

Scale setting

Alarm value

Calculation setting

Compressed/expanded printing setting

Automatic range-shift setting

50101 to 50124

50201 to 50224

50301 to 51499

70 (READ)

71 (WRITE)

See section 8-9.5

- 26 -

Page 30

5. Error check

The type of error check performed on transmission frame depends on the transmission mode.

RTU mode: CRC-16

ASCII mode: LRC

1) CRC-16 calculation

In CRC system, the data to be transmitted is divided by a generating polynomial and the resulting remainder is

appended to the data. The generating polynomial is shown below.

1 + X2 + X15 + X16

Calculation is performed to the part from slave address to the end of data according to the following procedure.

(1) Initialize CRC-16 data (referred to as X) (= FFFFH)

(2) Exclusive logical sum (EX-OR) between data 1 and X → X

(3) Shift X one bit to the right → X

(4) When a carry is generated, perform EX-OR with A001H. If not, go to step (5) → X

(5) Repeat steps (3) and (4) until eight shifts have been performed.

(6) EX-OR between the next data and X → X

(7) Same as steps (3) to (5)

(8) Repeat until the last data.

(9) Create a message of the calculated 16-bit data (X). The low-order portion is followed by the high-order

portion.

Example: For [02H] [07H] data, CRC-16 value becomes 1241H therefore the error check data will be [41H] [12H].

- 27 -

Page 31

Reference: CRC-16 calculation program

/***** CRC-16 calculation program (C language) *****/

#include <stdio.h>

#include <conio.h>

void main(void)

{

/*** Internal variable declaration ***/

unsigned intiLoopCnt;/* Loop counter*/

unsigned shortusData;/* Input data*/

unsigned shortusCrcData;/* CRC-16 data*/

unsigned shortusErrChkData;/* Error check data*/

intiDummy;/* Dummy varialbe*/

/* Initialze CRC-16 output data */

usCrcData = 0xffff;

printf(“Enter hexadecimal data (exit by [q]) >¥n”);

while( scanf(“%x”,&usData) != 0 )

{

/* Perform exclusive OR between CRC output result and input data */

usCrcData = usData ^ usCrcData;

/*** Perform CRC calculation ***/

/* Repeat until 8 bits have been shifted */

for( iLoopCnt = 0 ; iLoopCnt < 8 ; iLoopCnt++ )

{

/* Check if carry is generated */

if( usCrcData & 0x0001 )

{

/* Carry generated */

/* Shift CRC output result 1 bit to the right */

usCrcData = usCrcData >> 1;

/* Perform exclusive OR with A001H */

usCrcData = usCrcData ^ 0xa001;

}

else

/* Carry not generated */

/* Shift CRC output result 1 bit to the right */

usCrcData = usCrcData >> 1;

} /* for */

} /* while */

printf( “CRC-16 data is %xH.¥n”, usCrcData );

iDummy = getch();

}

/* Create error check data */

usErrChkData = ( usCrcData >> 8) | ( usCrcData << 8 );

printf( “Error check data is %xH.”, usErrChkData );

- 28 -

Page 32

2) LRC calculation

Calculation is performed to the part from slave address to the end of data according to the following procedure.

(1) Create a message in RTU mode.

(2) Add up the data from the start (slave address) to the end → X

(3) Complement X (bit inversion) → X

(4) Add 1 (X = X + 1)

(5) Append X as LRC value to the message.

(6) Convert the whole data to ASCII characters.

Example: For [02H] [07H] data, LRC value becomes F7H therefore the binary message will be [02H] [07H]

[F7H] and the ASCII message will be [30H] [32H] [30H] [37H] [46H] [37H].

6. Precautions on data processing

(1) Since the measured data and decimal point position are assigned to separate numbers, the both pieces of

information are required at data replay.

(2) Since a single data access (change) is available, attention should be paid to the settings of related data. For

example, a change of measuring range causes the related data to be initialized.

(3) Read or write data within the range specified by reference numbers. Writing data to an undefined reference

number may affect the instrument operation.

(4) When reading consecutive reference numbers, the data of undefined reference number becomes “0”.

(5) When an error is detected while writing to consecutive reference numbers, all the settings will be invalid.

- 29 -

Page 33

Transmission mode

Number of data pieces

RTU

120

RTU (floating data)

ASCII

60

02H

[ : ]

CR

04H

00H

64H

00H

02H

94H

LRC

CR

LF

8-4. Message Creation

A message consists of (1) slave address, (2) function code, (3) data field and (4) error check code (see section 8-3).

The number of data pieces read/written at one time is as follows:

The following shows an example of creating a message.

Example: Reading “CH1” measured data of an AL4000/AH4000 unit with “slave address 02”.

1. RTU mode message

(1) Slave address: 02 [02H]

(2) Function code: 04 [04H]

The task is “Read analog input data (input register contents)”. For the case of function code “04”, specify

“relative number of data in two bytes” and “number of data pieces in two bytes” to be read in the data field (see

section 8-5, or 8-5.4 for “Function code: 04”).

* The number of data bytes needs to be checked.

(3) Data field: First relative number 100 ([00H] [64H]), number of data pieces 2 ([00H] [02H])

Measured data (analog input data) is saved through reference numbers “30001 to 40000” (see section 8-3.4).

The reference table shows that the integer part of CH1 is saved through “30101” and the decimal point position

through “30102” (see section 8-9, or 8-9.3 for “Reading measured data”).

A relative number of the first reference number “30101” is: 30101 – 30001 = 100, and it can be expressed as

[00H] [64H] by two bytes (see section 8-3.4).

The number of data pieces to be read is “two”, the integer part of CH1 and the decimal point position, which can

be expressed as [00H] [02H] by hex two bytes.

(4) Error check: CRC-16 calculation result 2730H ([30H] [27H])

Error check in RTU mode uses CRC-16 calculation (see section 8-3.5).

From steps (1) to (3), the basic part of the message is [02H] [04H] [00H] [64H] [00H] [02H], and the CRC-16

value becomes 2730H. The error check data therefore becomes [30H] [27H].

(5) Message: [02H] [04H] [00H] [64H] [00H] [02H] [30H] [27H]

Create a message according to the message structure (see section 8-3).

2. ASCII mode message

Perform LRC calculation as error check on the basic part of a message. The LRC value becomes 94H (see section

8-3.5). Convert each data piece of the basic part to ASCII code. Convert also the LRC value to ASCII code and

append it to the basic part. Add a start character “:” and end characters “CR” and “LF” to the message.

Example: 02H, 04H, 00H, 64H, 00H, 02H, 30H, 27H

[3AH] [30H] [32H] [30H] [34H] [30H] [30H] [36H] [34H]

[30H] [30H] [30H] [32H] [39H] [34H] [0DH] [0AH]

- 30 -

Page 34

Reference No.

8 9 10

11

12

13

14

15

16

17

Data

ON

Master → Device

Device → Master (normal)

Slave address

02H Slave address

02H

Function code

01H Function code

01H

Start No. (H)

00H Data count

02H

Start No. (L)

07H First 8 data bits

00H

Number of data

pieces (H)

00H Next 8 data bits

02H

Number of data

pieces (L)

0AH CRC (L)

7CH

CRC (L)

0DH CRC (H)

3DH

CRC (H)

FFH

LRC

ECH LRC

F9H

Recording

ON

0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

0

First 8 data bits

15

Reference No.

8

Next 8 data bits

16

Reference No. 17

(00H)

(02H)

8-5. Function Code

Response to each function code is described below (see 8-3.2, or 8-6 for response to abnormal situation).

1. Read digital settings (read coil status)

Function code: 01 [01H]

This function reads the designated quantity of consecutive digital settings (ON/OFF) starting from the specified

number. A single data piece (one byte) contains eight ON/OFF data bits arranged in numerical order to form a

response message. LSB (D0 side) of each data piece indicates digital data of the smallest number. When the number

of readings is not a multiple of eight, unnecessary bit becomes 0.

Example: Reading 10 digital settings (reference No. 8 to 17) from slave 2

Since no reference number exists, 0 is returned.

<RTU mode>

<Error check in ASCII mode>

The error check section of CRC (L) and CRC (H) is replaced with the following.

Note: Start No. (relative number) is “reference number – 1”.

(Decimal value 7 (= 8-1) → hexadecimal value 07H)

Note: Data count means the number of data bytes.

(This is different from the required number of data pieces. In above example, the required number of data

pieces is 10, and the data count is two.)

- 31 -

Page 35

2. Read digital input data (read input relay status)

Reference No.

10109

10110

10111

10112

10113

10114

10115

10116

Data

ON

OFF

ON

OFF

Master → Device

Device → Master (normal)

Slave address

02H Slave address

02H

Function code

02H Function code

02H

Start No. (H)

00H Data count

01H

Start No. (L)

6CH First 8 data bits

05H

Number of data

pieces (H)

00H CRC (L)

61H

Number of data

pieces (L)

04H CRC (H)

CFH

CRC (L)

B9H

CRC (H)

E7H

LRC

8CH LRC

F6H

Since no reference number exists, 0

is returned.

0 0 0 0 0 1 0

1

First 8 data bits

10109

Since reference numbers 10113 to 10116

do not exist, 0 is returned.

(05H)

Reference No. 10112

Function code: 02 [02H]

This function reads the designated quantity of consecutive digital input data (ON/OFF) starting from the specified

number. A single data piece (one byte) contains eight ON/OFF data bits arranged in numerical order to form a

response message. LSB (D0 side) of each data piece indicates digital data of the smallest number. When the number

of readings is not a multiple of eight, unnecessary bit becomes 0.

Start No. (relative number) is “reference number – 10001”.

Example: Reading four digital input settings (reference No. 10109 to 10112) from slave 2

Level 1 Level 2 Level 3 Level 4

CH1 event

<RTU mode>

status

<Error check in ASCII mode>

The error check section of CRC (L) and CRC (H) is replaced with the following.

Note: Start No. (relative number) is “reference number – 10001”.

(Decimal value 108 (= 10109-10001) → hexadecimal value 6CH)

Note: Data count means the number of data bytes.

(This is different from the required number of data pieces. In above example, the required number of data

pieces is four, and the data count is one.)

- 32 -

Page 36

3. Read analog settings (read holding register contents)

Reference No.

40104

40105

40106

Data

0

(0000H)

1000

(03E8H)

1

(0001H)

Master → Device

Device → Master (normal)

Slave address

02H Slave address

02H

Function code

03H Function code

03H

Start No. (H)

00H Data count

06H

Start No. (L)

67H Lower limit data (H)

00H

Number of data

pieces (H)

00H Lower limit data (L)

00H

Number of data

pieces (L)

03H Upper limit data (H)

03H

CRC (L)

B4H Upper limit data (L)

E8H

CRC (H)

27H Decimal point data

(H)

00H

Decimal point data

(L)

01H

CRC (L)

74H

CRC (H)

35H

LRC

91H LRC

09H

← Data example for 0.0 to 100.0

Function code: 03 [03H]

This function reads the designated quantity of consecutive analog settings (two bytes: 16 bits) starting from the

specified number. The data is divided into high-order eight bits and low-order eight bits, and then arranged in

numerical order to form a response message.

Start No. (relative number) is “reference number – 40001”.

Example: Reading CH1 range upper/lower limits and decimal point from slave 2

(Reading three analog settings (reference No. 40104 to 40106) from slave 2)

<RTU mode>

<Error check in ASCII mode>

Note: Start No. (relative number) is “reference number – 40001”.

(Decimal value 103 (= 40104-40001) → hexadecimal value 67H)

Note: Data count means the number of data bytes.

(This is different from the required number of data pieces. In above example, the required number of data

pieces is three, and the data count is six.)

Note: The number of data pieces in a message which can be received (transmitted by the unit) at one time is limited

(see section 8-4).

4. Read analog input data (read input register contents)

Function code: 04 [04H]

This function reads the designated quantity of consecutive analog input data (two bytes: 16 bits) starting from the

specified number. The data is divided into high-order eight bits and low-order eight bits, and then arranged in

numerical order to form a response message.

A response example is the same as “Function code 03”, though the Start No. (relative number) becomes “reference

number – 30001”.

- 33 -

Page 37

5. Write digital setting (change single coil status)

Master → Device

Device → Master (normal)

Slave address

02H Slave address

02H

Function code

05H Function code

05H

Setting No. (H)

00H Setting No. (H)

00H

Setting No. (L)

13H Setting No. (L)

13H

Setting status (H)

FFH Setting status (H)

FFH

Setting status (L)

00H Setting status (L)

00H

CRC (L)

7DH CRC (L)

7DH

CRC (H)

CCH CRC (H)

CCH

LRC

E7H LRC

E7H

Function code: 05 [05H]

This function makes the digital setting of specified number the specified status (ON/OFF).

Example: Executing message printing on slave 2

(Setting the digital setting (reference No. 20) of slave 2 to ON)

<RTU mode>

<Error check in ASCII mode>

Note: Normal response is the same as command message.

Note: Setting No. (relative number) is “reference number – 1”.

(Decimal value 19 (= 20-1) → hexadecimal value 13H)

Note: Set “FF00H” to execute.

For the case of key lock and recording ON/OFF, set “0000H” to turn OFF or “FF00H” to turn ON.

Note: When the slave address is set to 0, all the slave devices execute the command, but no response is made from

any of them.

- 34 -

Page 38

6. Write analog settings (write to single holding register)

Master → Device

Device → Master (normal)

Slave address

02H Slave address

02H

Function code

06H Function code

06H

Setting No. (H)

00H Setting No. (H)

00H

Setting No. (L)

6EH Setting No. (L)

6EH

Setting status (H)

00H Setting status (H)

00H

Setting status (L)

14H Setting status (L)

14H

CRC (L)

E8H CRC (L)

E8H

CRC (H)

2BH CRC (H)

2BH

LRC

76H LRC

76H

Master → Device

Device → Master (normal)

Slave address

02H Slave address

02H

Function code

08H Function code

08H

Diagnosis code (H)

Fixed

00H

Diagnosis code (H)

Fixed

00H

Diagnosis code (L)

00H

Diagnosis code (L)

00H

Arbitrary data

* Received arbitrary

data

*

Arbitrary data

* Received arbitrary

data

*

CRC (L)

* CRC (L)

*

CRC (H)

* CRC (H)

*

LRC

*

LRC

*

Function code: 06 [06H]

This function changes the analog setting of specified number to the specified value.

Example: Setting CH1 sensor correction value of slave 2 to 20

(Setting the analog setting (reference No. 40111) of slave 2 to “20”)

<RTU mode>

<Error check in ASCII mode>

Note: Normal response is the same as command message.

Note: Setting No. (relative number) is “reference number – 40001”.

(Decimal value 110 (= 40111-40001) → hexadecimal value 6EH)

Note: When the slave address is set to 0, all the slave devices execute the command, but no response is made from

any of them.

7. Loop-back test

Function code: 08 [08H]