Page 1

SERVICE MANUAL

Page 2

*** CONTENTS ***

1.Safety Instructions

2. General Alignment

3. IC BLOCK DIAGRAM

4. TROUBLE SHOOTING

5. BLOCK DIAGRAM

6. CIRCUIT DIAGRAM

Page 3

* * * WARNING * * *

3

In order to prevent electric shock, do not remove cover.

No user-serviceable parts inside, Refer servicing to qualified service personal.

1. SAFETY INSTRUCTIONS

PRECAUTIONS DURING SERVICING

1. In addition to safety, other parts and assemblies are specified for conformance with such

regulations as those applying to spurious radiation. These must also be replaced only with

specified replacements.

Examples : RF converters, tuner units, antenna selection switches, RF cables, noise-blocking

capacitors, noise-blocking filters, etc.

2. Use specified internal Wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leags

3. Use specified insulating materials for hazardous live parts. Note especially:

1) Insulation Tape

2) PVC tubing

3) Spacers (Insulation barriers)

4) Insulation sheets for transistors

5) Plastic screws for fixing micro switches

4. When replacing AC primary side components (transformers, power cords, noise blocking

capacitors etc), wrap ends of wires securely about the terminals before soldering.

5. Make sure that wires do not contact heat-generating parts (heat sinks, oxide metal film resistors,

fusible resistors, etc.)

6. Check if replaced wires do not contact sharply edged or pointed parts.

7. Make sure that foreign objects (screws, solder droplets, etc.) do not remain inside the set.

MAKE YOUR CONTRIBUTION T O PROTECT THE ENVIR ONMENT

Used batteries with the ISO symbol for recycling as well as small accumulators (rechargeable

batteries), mini-batteries (cells) and starter batteries should not be thrown into garbage can. Please

leave them at an appropriate depot.

WARNING

Page 4

Before servicing this TV receiver, read the X-RAY RADIATION PRECAUTION, SAFETY

4

INSTRUTION and PRODUCT SAFETY NOTICE.

X-RAY RADIATION PRECAUTION

1. Excessively high voltage can produce potentially hazardous X-RAY RADIATION. To avoid

such hazards, the high voltage must not exceed the specified limit. The normal value of the high

voltage of this TV receiver is

The hi

gh voltage must not exceed 29 kV under an circumstances : Each time when a receiver

require servicing, the high voltage should be checked. The reading of the high voltage is

recommended to be recorded as a part of the service record. It is important to use an accurate

and reliable high voltage meter.

2. The only source of X-RAY RADIATION in this TV receiver is the picture tube. For continued

X-RAY RADIATION protection, the replacement tube must be exactly the same type as

specified in the parts list.

3. Some parts in this TV receiver have special safety related characteristics for X-RAY

RADIATION protection. For continued safety, the parts replacement should be under taken only

after referring the PRODUCUT SAFETY NOTICE.

26 kV at ze

ro beam current (minimum brightness).

SAFETY INSTRUCTIONS

The service should not be attempted by anyone unfamiliar with the necessary instructions on this

TV receiver. The following are the necessary instructions to be observed before servicing.

1. An isolation transformer should be connected in the power line between the receiver and the AC

line when a service is performed on the primary of the converter tran sformer of the set.

2. Comply with all caution and safety related provided on the back of the cabinet, inside the

cabinet, on the chassis or picture tube.

3. To avoid a shock hazard, always discharge the picture tube’s anode to the chassis ground before

removing the anode cap.

4. Completely discharge the high potential voltage of the picture tube before handling. The picture

tube is a vacuum and if broken, the glass will explode.

5. When replacing a MAIN PCB in the cabinet, always be certain that all protective are installed

properly such as control knobs, adjustment covers or shields, barriers isolation resistor networks

etc.

6. When servicing is required, observe the original lead dressing. Extra precautio n should be given

to assure correct lead dressing in the high voltage area.

Page 5

7. Keep wires away from high voltage or high temperature components.

5

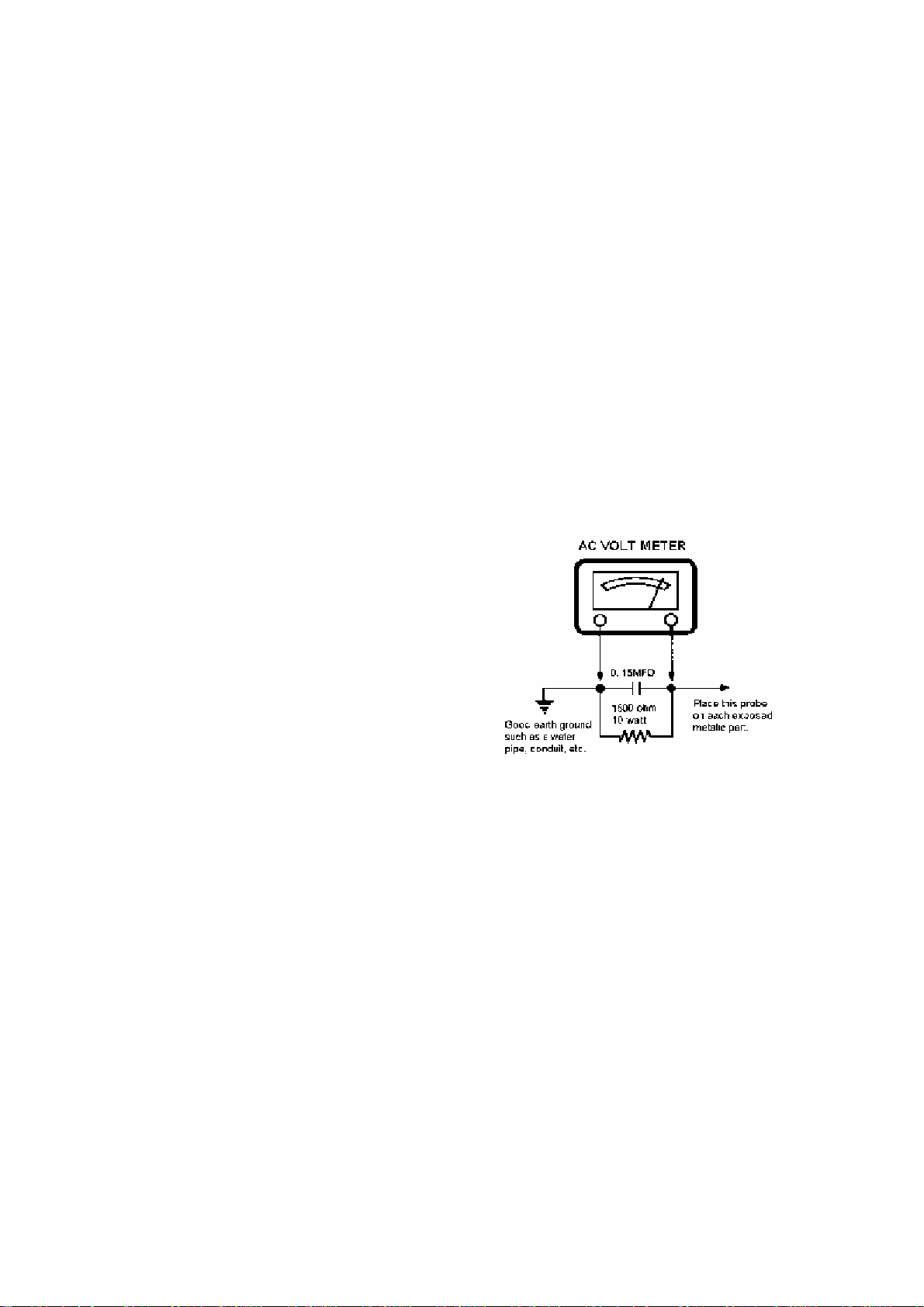

8. Before returning the set to the customer, always perform an AC leakage current check on the

exposed metallic parts of the cabinet, such as antennas, terminals, screw heads, metal overlays,

control shafts etc., to be sure the set is safe to operate without danger of electrical shock. Plug

the AC line cord directly to the AC outlet (do not use a line isolation transformer during this

check). Use an AC voltmeter having 5k ohms per volt sensitivity or more in the following

manner. Connect a 1.5k ohm 10 watt resistor paralleled by a 0.15uF AC type capacitor, between

a good earth ground (water pipe, conductor etc.) and the exposed metallic parts, one at a time.

Measure the AC voltage across the combination of 1.5k ohms resistor and 0.15uF capacitor.

Reverse the AC plug at the AC outlet and repeat AC voltage measurements for each exposed

metallic part. The measured Voltage must not exceed 0.3V RMS. This corresponds to 0.5mA AC.

Any value exceeding this limit constitutes a potential shock hazard and must be corrected

immediately.

The resistance measurement should be done

between accessible exposed metal parts and

power cord plug prongs with the power

switch “ON”. The resistance should be more

than 6M ohms.

PROODUCT SAFETY NOTICE

Many electrical and mechanical parts in this TV receiver have special safety-related

characteristics. These characteristics are often passed unnoticed by a visual inspection and th e

protection afforded by them cannot necessarily be obtained by using replacement components

rated for higher voltage, wattage, etc. Replacement part which have these special safety

characteristics are identified in this manual and its.

Supplements : Electrical components having such features are identified by shading on the

schematic diagram and the part list. Before replacing any of these components, read the parts

list in this manual carefully. The use of substitute replacement parts which do not have same

safety characteristics as specified in the parts list may create shock, fire or other hazards.

Page 6

2. GENERAL ALIGNMENT

6

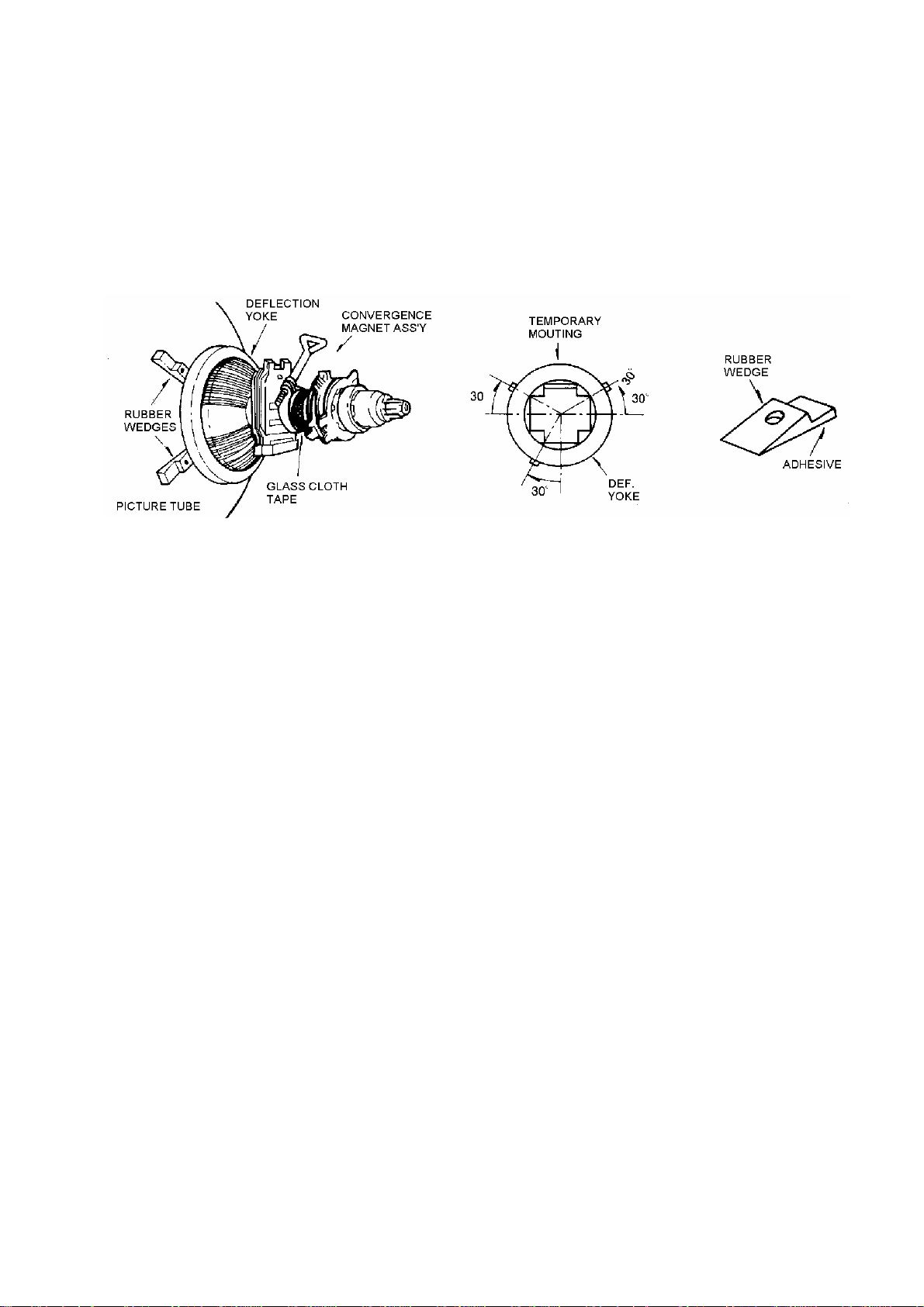

CPT MAGNET ADJUSTMENT

CONVERGENCE MAGNET ASSEMBLY POSITIONING

Convergence magnet assembly and rubber wedges need m echani cal posi t i oni n g follo wi n g fig ure 1.

FIG 1 Rubber Wedges Location

COLOR-PURITY-ADJUSTMENT

NOTE : Before attempting any purity adjustments, the receiver should be operated for at least 15

minutes.

1. Demagnetize the picture tube and cabinet using a degaussing coil.

2. Turn the CONTRAST and BRIGHTNESS controls to maximum.

3. Adjust RED and BLUE Bias controls to provide only a green rather.

4. Loosen the clamp screw holding the yoke, and slide the yoke backward to provide vertical green

belt(zone) in the picture screen.

5. Remote the Rubber Wedges.

6. Rotate and spread the tabs of the purity magnet(See figure 2) around the neck of the picture tube

until the green belt is in the center of the screen. At the same time, center the raster vertically.

7. Move, the yoke slowly forward until a uniform green screen is obtained. Tighten the clamp screw

of the yoke temporarily.

8. Check the purity of the red and blue raster by adjusting the BIAS controls.

9. Obtain a white raster, referring to "CTR GRAY SCAL ADJUSTMENT".

10. Proceed with convergence adjustment

Page 7

7

FIG 2

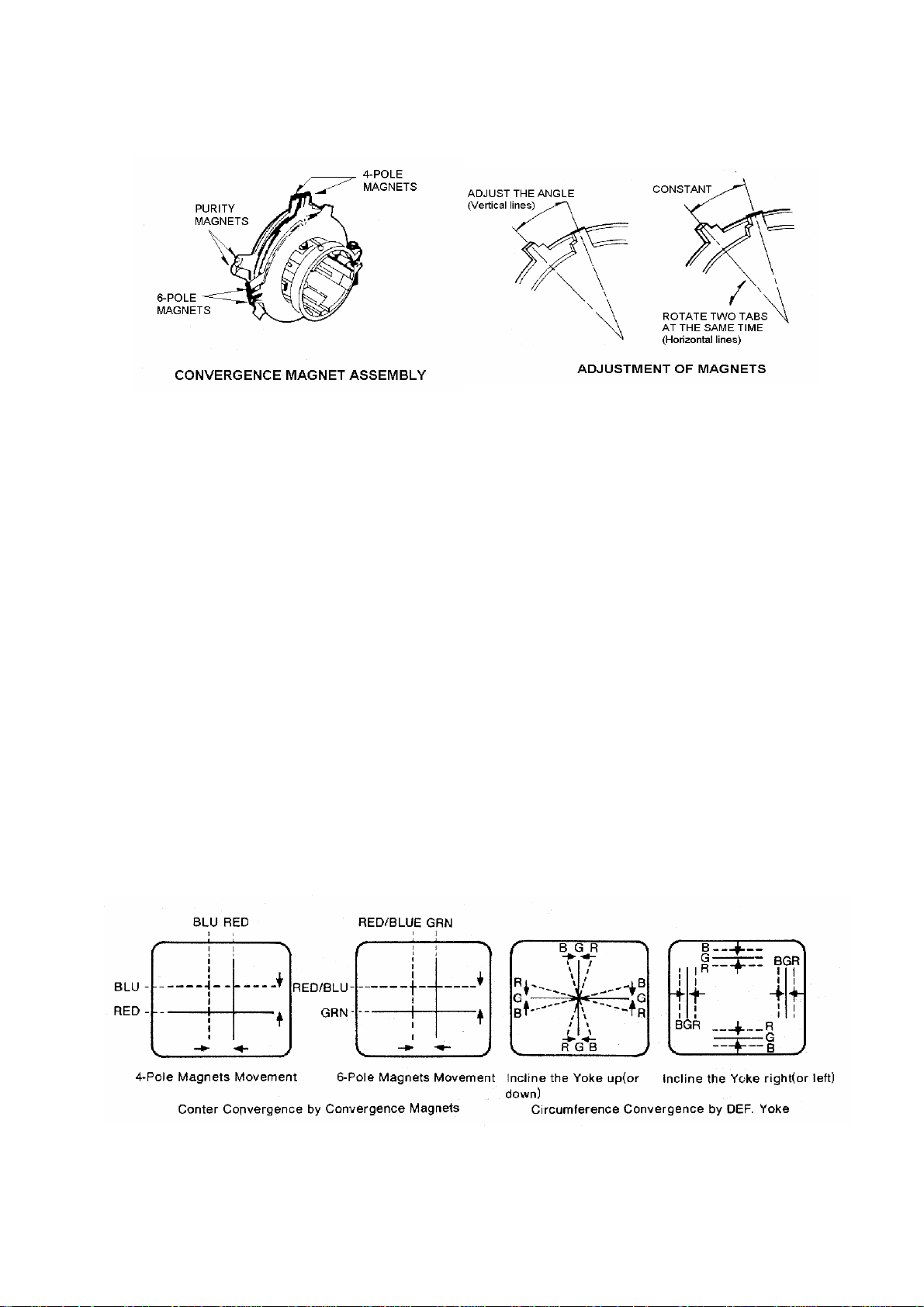

CONVERGENCE ADJUSTMENTS

NOTE : Before attempting any convergence adjustments, the receiver should be operate for at least

15 minutes.

CENTER CONVERGENCE ADJUSTMENT

1. Receiver crosshatch pattern with a color bar signal generator.

2. Adjust the BRIGHTNESS and CONTRAST Controls for well defined pattern.

3. Adjust two tabs of the 4-Pole Magnets to change the angle between them (See figure 3) and

superimpose red and blue vertical lines in the center area of the picture screen.

4. Turn both tabs at the same time keep in their angles constant to superimpose red and blue

horizontal lines at the center of the screen. (See figure 4.)

5. Adjust two tabs of 6-Pole Magnets to superimpose red/blue line with green one. Adjusting the

angle affects the vertical lines and rotating both magnets affects the horizontal lines

6. Repeat adjustment 3, 4, 5 Keeping in mind red, green and blue moment, because 4-Pole Magnets

and 6-Pole Magnets interact and make dot movement complex.

FIG 3 FIG 4

Page 8

8

CIRCUMFERENCE CONVERGENCE ADJUSTMENT

NOTE : This adjustment requires Rubber Wedge Kit.

1. Loosen the clamping screw of deflection yoke to allow the yoke to tilt.

2. Place a wedge as shown in figure (1) temporarily.

(Do not remove cover paper on adhesive part of the wedge.)

3. Tilt fron t of the deflection yoke up or down to obtain better convergence in circumference.(See

figure 4) Push the mounted wedge into the space between picture tube and the yoke to hold the

yoke temporarily.

4. Place other wedge into bottom space and remove the cover paper to stick.

5. Tilt front of the yoke right or left to obtain better convergence in circumference.(See figure 4).

6. Hold the yoke position and put another wedge in either upper space. Remove cover paper and

stick the wedges, recheck overall convergence.

7. Detach the temporarily mounted wedge and put it in another upper space. Stick it on picture tube

to fix the yoke.

8. After placing three wedges, recheck overall convergence. Tighten the screw firmly to hold the

yoke tightly in place.

9. Stick 3 adhesive tapes on wedges as shown in figure 1.

CHASSIS ADJUSTMENT MANUAL

How to enter the service the service mode using the user remote control

Push buttons of remote control in sequences as follows

‘DISPLAY’-‘MUTE’-‘SLEEP’-‘FUSSY’

1.HEAT RUN(AUTO POWER ON MODE) : F4

- It need in assembly line during heat run that protect to auto power off after no

signal 15 minutes and

auto power on for input power of sets on/off by line condition which

sometimes line power connection of palette with main power line would be

badly contacted by shaking during the sets through on assembly lines.

- Heat run function is operated by pressing the F4 key.

- To cancel this function press the F4 key one more or power on/off.

- It must be canceled before final output.

Page 9

1.HEAT RUN(AUTO POWER ON MODE) : F4

9

- It need in assembly line during heat run that protect to auto power off after no signal 15 minutes and auto power on for input

power of sets on/off by line condition which sometimes line power connection of palette with main power line would be badly

contacted by shaking during the sets through on assembly lines.

- Heat run function is operated by pressing the F4 key.

- To cancel this function press the F4 key one more or power on/off.

- It must be canceled before final output.

-

2. GEOMETRY ADJUSTMENT (F2)

If press “F2”key, The 2 adjustment modes are toggled that “GEOMETRY” and “PINCUSHION”mode.

2-1. V-SIZE

- Select the V-SIZE by pressing CH UP/DOWN key

- Adjust the V-SIZE by pressing VOL UP/DOWN key for approximately one-half inch over scan at top and bottom

of picture screen.

2-2. V-CENTER

-.For receive PAL-N (50Hz) RETMA pattern, press the “ CH “ key on the remote control

- Select the V-CENTER by pressing CH UP/DOWN key.

- Adjust V-CENTER so that the circle of Retma signal may be centered in the verical direction..

2-3.V-OFFSET

-.For receive NTSC-M or PAL-M (60Hz) RETMA pattern, press the “ CH “ key on the remote control

- Select the V-OFFSET by pressing CH UP/DOWN key.

- Adjust V-OFFSET so that the circle of Retma signal may be centered in the verical direction..

-.By this adjustment, we can compensate the difference of vertical center according to reception signal which is

50Hz or 60Hz.

2-4. H-CENTER

- Select the H-CENTER by pressing CH UP/DOWN key.

- Adjust the H-CENTER by pressing VOL UP/DOWN key to be coincident with screen center and mechanical center.

2-5. V-LIN.

-.Adjust vertical linearity by pressing VOL UP/DOWN key.

3.PIN CUSHION ADJUSTMENT(F2)

3-1. H.WIDTH

- For receive RETMA pattern, press the “ CH “ key on the remote control.

- Select the H-WIDTH by pressing CH UP/DOWN key.

- Adjust the H-WIDTH by pressing VOL UP/DOWN key so that the left and right side of picture may position an

interval of 4-BAR and 5 BAR.

3-2. PINCUSHION

9

Page 10

- For receive CROSS HATCH pattern,press the “CH”key on the remocon.

10

- Select the PINSHION by pressing CH UP/DOWN key.

-. When the vertical lines of the left and right side are distorted, adjust the PINSHION by pressing VOL UP/DOWN key.

so hat the vertical lines may be straight.

3-3. PIN. TILT

- For receive CROSS HATCH pattern,press the “CH”key on the remocon.

- Select the PIN.TILT by pressing CH UP/DOWN key.

-.When the screen shape is not rectangular but trapezoid, adjust the PIN.TILT by pressing VOL UP/DOWN key.

to correct the unbalanced shape.

3-4.PIN.TOP & PIN.BOT.

- For receive CROSS HATCH pattern,press the “CH”key on the remocon.

- Select the PIN.TOP or PIN.BOT by pressing CH UP/DOWN key.

-. When the vertical lines of theTOP or BOTTOM side are not straight but distorted, adjust PIN.TOP &PIN.BOT.

by pressing VOL UP/DOWN key to correct the unbalanced TOP or BOTTOM vertical lines.

.

3-5.PIN.COR.SW.

-.It is no need to adjust, set this data “1”

-.Check if the top and bottom side of the vertical lines are straight .

3-6.H.WIDTH COMP.

-.It is no need to adjust, set this data “6”

-.Check if the H.Width is the same according to the reception of low beam and High beam signal.

4.. SCREEN ADJUSTMENT(F3)

- Receive the video no signal.

- Select the SERVICE mode by pressing CH UP/DOWN key.

- Make the horizontal line by pressing VOL UP/DOWN key.

- Adjust the SCREEN , till horizontal line is just disappeared.

5. WH ITE BALANCE ADJUSTMENT.(F3)

- Receive a black and white pattern or white balance adjusting pattern.

- Before attempting white balance adjustment, the receiver should be operate for at least 15minites.

- Check the all of position to the reference value (nominal center)

- The reference color of the measurement equipment set to G.

- Adjust the R DC,G DC, G DC at bias mode.

- Adjust the R DRV,B DRV at drive mode.

5-1. WHITE BALANCE ADJUSTMENT FOR DVD MODE .(F1)

Page 11

-.This procedure is need to compensate the W/Balance difference between “TV/VIDEO/S-VHS”mode and

11

“DVD” mode.

1) Input the “GREY SCALE PATTERN” signal to both “VIDEO1 or 2” and “DVD” input jack

2) Select “DVD” input mode by pressing TV/VIDEO button.

3) Select the “B-Y DC LEVEL” or “R-Y DC LEVEL” mode by pressing CH UP/DOWN key in FACTORY1 mode.

4) Change both “B-Y DC LEVEL” and “R-Y DC LEVEL” data in order to get the same W/Balance value as that

Of VIDEO mode.

6 . SUB BRIGHT ADJUSTMENT.

6-1 METHOD 1

- Receive the RETMA PATTERN.

- Select the NORMAL mode in the fuzzy.

- Select the SUB BRIGHT mode by pressing CH UP/DOWN key in FACTORY1 mode.

- Adjust the SUB BRIGHT value before disappeared black 20% level by pressing VOL UP/DOWN key.

6-2 METHOD 2

- Change Mode to VIDEO NO SIGNAL

- Select the NORMAL mode in the fuzzy key.

- Select the SUB BRIGHT mode by pressing CH UP/DOWN key in FACTORY1 mode.

- Adjust the SUB BRIGHT value till disappeared to back screen by pressing VOL UP/DOWN.

7. AGC ADJUSTMENT.(F1 key)

- Receive the RF color bar signal.

- Strength of input signal control 60dBu-63dBu.

- Measure the AGC voltage with scope at tuner AGC pin.

- Select the AGC point less tuner AGC voltage.

- Select the AGC AUTO mode, and then press the vol up/down key

- AGC is arranged automatically and then Confirmation of the strong signal.

8. FOCUS ADJUSTMENT

-.For receive RETMA pattern, press the “ CH “ KEY on the remote control.

-.Adjust the FOCUS VOLUME on the FBT and make the picture on the screen finest.

9. USER RESET.

- It be cleared all user control to initial for all output sets will be same user control condition.

-.It need after final inspection.

Page 12

Page 13

LA769337X(X:J〜N)/LA769337FBTentative

13

LA76933 7X(X:J〜N)/LA76933 7FB

Pin Assignment

PIN FUNCTION PIN FUNCTION PIN FUNCTION PAD Name

内部結線

Internal connections

1 SIF Output 64 VIF Input1 BIP

2 VIF AGC 63 VIF Input2 PInt01 C_Sync PSYNC P33

3 SIF Input 62 IF Ground PInt02 CLOCK PCL P32

4 FM Filter 61 RF AGC Output PInt03 DATA PDA P31

60 Video Output

Output

6 Audio Output 59 AFT Filter PInt06 INT_B PB B

7 SIF APC Filter 58 APC Filter PInt07 INT_G PG G

8 IF Vcc 57 Black Level Det. Filter PInt08 INT_R PR R

Ext. Audio Input / VM

Output

10 ABL 55 Video/Vertical Vcc PInt11 ENABLE PENA P30

11 RGB Vcc 54 External Video Input PInt12 PDC PPDC PEIN

12 Red Output 53 Chroma APC Filter PInt13 CVBS PCVBS CVIN

56 Internal Video Input

fsc Output

PInt04 I PI I 5 FM Output / Selected Audio

PInt05 FS PFS BL

PInt09 HS PHS HS 9

PInt10 VS PVS VS

PInt14 CPU TST B PCPUB TSTB 13 Green Output 52 Selected Video Output or

PInt15 CPU TST G PCPUG TSTG

μCOM

14 Blue Output 51 Cr Input PInt16 CPU TST R PCPUR TSTR

15

16 V Ramp Osc. Capacitor 49 Cb Input PInt18 AFT PAFT AN3

17 Vertical Output 48 DVD-Y PInt19 VDD PVDD VDDi

18 VCO IREF 47 NC Pint20 4MHZ

19 Horizontal/BUS Vcc 46 YC-Y Pint21 R out PROUT

20 Horizontal AFC Filter 45 YC-C Pint22 B out PBOUT

21 Horizontal Output 44 Flyback Pulse Input Pint23 Vref PVREF

22 Video/Vertical/BUS Ground 43 CCD Vcc

23 P00/INT0 42 CPU Ground Pint25 R input PR_IN

24 P01/INT1 41 FIL

25 P02 40 RES

26 P03/INT3 39 P07/AN7

27 P14/PWM1 38 P06/AN6

28 P15/PWM2 37 P05/AN5

E/W Output

50 4.43MHz Crystal PInt17 Reset PRES RESi

P4M

Clock

Pint24 B input PB_IN

Pint26 Vcc*2 PVCC2

29 P17 36 P04/AN4

30 P16/PWM3 35 VDD

31 P12/SDA1 34 XT2

32 P13/SCK1 33 XT1

No.72

Page 14

LA42032

14

Block Diagram

Standby

Ri=

30kΩ

Input amplifier

IN1

2

MUTE

PRE

GND

6

V

CC/ground shorting protection circuit

Load shorting protection circuit

3

Thermal protection circuit

IN2

4

Ri=

30kΩ

Input amplifier

1

Ripple

Filter

Test Circuit

Ripple

Filter

1 2 3 4 5 6 7 8 9 10 11 12 13

C3

+

47μF

/16V

**

IN1

C1

4.7μF

/10V

PRE

GND

C2

4.7μF

/10V

15kΩ

* LA42032 employs the zero-bias type input circuit, with the input pin potential being nearly zero (about 0.01V).

Accordingly, the polarity must be determ ined accor ding t o the DC potential of a circuit connected to the previous stage

of LA42032.

R1

+5V

C4

10μF

/10V

LA42032

CC

V

Output amplifier

Output amplifier

C5

1000μF

/16V

++

CC

75

R

C8

0.1μF

R4

2.2Ω

+OUT1

12

11

-OUT1

PWR

10

GND

+OUT2

8

9

-OUT2

PWR

GNDIN2 STBY MUTE +OUT2 +OUT1 N.C.-OUT2 -OUT1V

R

L

C9

0.1μF

R5

2.2Ω

C7

0.1μF

R3

2.2Ω

L

C6

0.1μF

R2

2.2Ω

No.A0855-3/7

Page 15

15

Page 16

1116

N

16

DIAGRAM

BLOCK

LV

CONFIDENTIAL

DIP-36s

+

19202135

DATA

DATA

CLKVSS

22

+

L+R LPF

23

L-VROUT

2425262728293031

+

L-VRIN

L-OUTR-TC1HPFC

L-BC2

L-BC1

ST-2

+

L-DC

+

32

out

L Line

+

3334

Lch-C

+

+

Lch-A Lch-B

36

AGND

+

CONTROL

CONTROL

TONE CONT

DC

+

+

Matrix

-

TOTAL

Bypass

-

MUTE

Bypass

P Stereo

MONO-SW

SURROUND

ANALOG

Pseud

-

+

SURROUND

(AViSS)

SURROUND

P Stereo

Stereo

Bypass

+

-

+

MUTE

TOTAL

Matrix

TONE CONT

Bypass

DC

-

181716

1211

10987

6

5 151413

32 4

1

+

L+R VREF VDDVCC

+

R-VROUT

+

R-VRIN

R-OUT

R-BC2

R-BC1

R-TC1LPFC

ST-1

+

+

out

R Line

+

Rch-C R-DC

+

Rch-B

+

Rch-A

GND

+

+

Page 17

4.TROUBLE SHOOTING

17

NO POWER

Check fuse F801

OK NG

Check replace the

D812,D813,D814,D815

OK NG

Check the I501 #35

voltage (5V)

OK NG

Replace the F801

Check and replace the I804,I806,R820,

Q401 etc.

Check the I501 #19

Power on:5V

OK NG

Check the I501 #21

H. output waveform

OK NG

Check the Q401,Q402,

T401,T402

OK NG

OK

Check and replace

D810 diode

Check and replace the

Q803,Q804,D503

Replace I501

Replace Q401,Q402

Page 18

NO PICTURE(RASTER & SOUND OK)

18

Check whether the brightness & contrast are controllable or not?

OK NG

Check the voltage of heater,

185V,9V(D904) on CRT board

OK NG

Check the ABL VOLTAGE

NG

OK

Check the video input waveform:

I501 #56(internal) or #54(external)

Check and replace

the R404,D401

Check the ABL

circuit:D504,C416

OK NG

Check the I501 B+(5V)

:#55(V/C/D B+)

OK NG

Check and replace the I401,Q804

Q803

OK

Check and replace the I102(sda

scl B+ etc.),SF101

Check and replace Q501

Replace the I501

Page 19

NO VERTICAL SCAN(one horizontal line raster)

19

Check the vertical drive

waveform of I501 #17

OK

NG

Check the vertical-input

waveform of I301 #1

OK

Check the 28V line of I301 #2

OK NG

Check the vertical-output

waveform of I301 #5

Check the 5V line of I501 #55

And replace the I501

Check and replace the R406,D403

OK NG

Check the connecting stage of

D.Y. wafer

Check and replace I301,R306

Page 20

NO SOUND(picture OK):AV STEREO

20

Check the waveform of IA01

#2#(

OK NG

TV audio)

Check the waveform of I601

#2 & #4(audio input)

OK

OK

OK NG

O

K G

Check the FM-output waveform

of I501 #5

Check the SIF waveform of I501

#1,#3(4.5MHz)

Check and replace I501

Check the mute pin of I601 #6

L:normal,H:

OK NG

Check the B+(12V) of I601 #7

OK NG

Check the speaker and speaker

connector

mute

Check and replace I501

Check and replace D808,R621

Page 21

NO SOUND(picture OK):RF STEREO mdel

21

Check the SIF waveform of IS01

#47

OK NG

Check the reset of IS01 #20:High

Check IS01 #7(scl),#8(sda)

OK

Check the B+ of IS01

#6,#16,#33,#46

OK NG

Check the audio R/L waveform

I601 #2,#4

OK NG

Check the mute and standby pin

I601 #5,#6

Check the SIF waveform of I501

#1(4.5MHz)

Check and replace I501

Check I501

Check and replace

D601,DS03,Q803,Q804

Check and replace IS01

OK NG

Check the B+of I601 #7

OK

Check the speaker and speaker

connector

Check and replace I501

Check and replace D808,R621

Page 22

21",29"BLOCK DIAGRAM

22

RF input

IR input

90V~250Vac

TUNER

33V

AC

I102

RF_AGC

I201

-

PREAMP

JAV01

-VIDEO1

JAV02

-VIDEO2

(OPTION)

JAV01

-AUDIO1

JAV01

-AUDIO2

(OPTION)

F801

FUSE

SF101

SAW

FILTER

EEPROM

LINE FILTER

I502

Key input

IR input

I103(LA7016)

(OPTION)

.VIDEO½ SW

IF input

D813~D816

(RECTIFIER

DIODE)

RF_AGC

I501(LA76933)

.CPU

.IF input

.VIDEO/CHROMA/DEFLECTION

.AUDIO PROCESSOR

.AUDIO/VIDEO SW

.VIDEO OUTPUT

.EW OUTPUT

MONO ONLY

AODIO IN

IA01(LV1116N)

(AV STEREO)

.AUDIO INPUT & SW

.AUDIO OUTPUT SW

.AUDIO VOLUME

CONTROL

I806

STR-W6754

EW DRIVE

5V

T801

SMPS TRANS

RGB OUTPUT

Q303

H.DRIVE

V.DRIVE

Q402

H.DRIVE

45V

I301(LA78045)

VERTICAL OUT

25V

IS01(MSP3425G)

(RF STEREO)

.STEREO/SAP DECODER

.AUDIO INPUT & SW

.AUDIO OUTPUT SW

.AUDIO VOLUME CONTROL

12V

R701

Q803

12V SW

123V

45V

12V

Q901~Q906

VIDEO AMP

R,L AUDIO

R,L AUDIO

STAND_BY 5V

SW 12V

TO FBT

TO H_DRIVE/33V

TO SOUND AMP

12V

Q401/T402

H.OUPUT

P401

D.Y.

I601(AUDIO AMP)

LA42032

180V

12V

CRT BOARD

SCREEN

FOCUS

T401

FBT

123V

H.V

ABL

R SPEAKER

L SPEAKER

HEATER

25V

11V

페이지 1

Page 23

23

Loading...

Loading...