China HBTV-3201HD Schematic

SERVICE MANUAL

Order No.: TV0904S003V0

COLOR TV

Model No. : HBTV-3201HD

CHASSIS: Mstar 6U89

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does

not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product. Products

powered b electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the

product deal with in this service information by anyone else could result in serious injury or death.

1

CONTENTS

Table of contents………………..................…………………………….2

1. General Information

1-1. General Guidelines...…………………………………………………..4

1-2. Important notice………………………………………………………...4

1-3. How to read this Service Manual……………………………………..5

…………...............…………………………..4

2. Specifications……………………………………………....................6

3. Location of Controls and Components

3-1.Board Location……………………………………………………………..7

3-1-1. L32R1 Board Location ……………………………………………………..7

3-2. Main Board……………………………………………………………7

3-2-1. Function Description……………………………………………………..8

3-2-2. Connector definition……………………………………………………..8

3-3. Power Board……………………………………………………………9

...........................7

3-3-1. Connector definition……………………………………………………9

3-3-2. Function Description……………………………………………………9

3-4. LCD Panel…………………………………………… …………… ……10

3-4-1. Connector definition……………………………………………………10

3-4-2. Function Description……………………………………………………11

4. Disassemble and Assemble

4-1 L32R1………………………………………………………………….…11

4-1-1 Remove the Pedestal………………………………………………….…12

4-1-2 Remove the Back Cover……………………………………………….…12

4-1-3 Remove the Main board……………………………………………….…12

4-1-4 Remove the power module…………………………………………….…12

4-1-5 Remove the speaker………………………………………………….…13

4-1-6 Remove the remote control……………………………………………. 13

…………………...........………….11

4-1-7 Remove the Keypad Assembly……………………………………….… 13

5. Installation Instructions ………..................………………..…..14

2

6. Operation Instructions

…………………………........................19

6-1 Front Panel Controls …………………………………………….........19

6-2 Rear Panel Controls ……………...……………………………..........19

6-3 Setting up your Remote Controller....................................................20

7. Electrical Parts

............................................................................20

7-1. Circuit diagram ...............................................................................20

7-2 .Wiring Connection Diagram...........................................................31

8. Measurements and Adjustments

.......................................31

8-1. Service Mode ..................................................................................31

8-1-1.How to enter into Service Mode

8-1-2.How to exit…

8-1-3. The default of Factory Mode Menu

.....................................................................................31

............................................................31

...............................................31

9. Trouble Shooting

9-1. Simple check ...............................................................................32

......................................................................32

9-2. Main board failure check ..............................................33

9-3. Pannel failure ...............................................................................34

3

1. General Information

1-1 General Guidelines

When servicing, observe the original lead dress. If a short circuit is found, replace all parts which

have been overheated or damaged by the short circuit.

After servicing, see to it that all the protective devices such as insulation barriers, insulation papers

shields are properly installed.

After servicing, make the following leakage current checks to prevent the customer from being

exposed to shock hazards.

1) Leakage Current Cold Check

2) Leakage Current Hot Check

3)Prevention of Electro Static Discharge(ESD)to Electrostatically Sensitive

1-2 Important notice

1-2-1. Follow the regulations and warnings

Most important thing is to list up the potential hazard or risk for the service personnel to open the

units and disassemble the units. For example, we need to describe properly how to avoid the

possibility to get electrical shock from the live power supply or charged electrical parts (even the

power is off).

This symbol indicates that high voltage is present inside. It is dangerous to

make any king of contact with any inside part of this product.

This symbol indicates that there are important operating and maintenance

instructions in the literture accompanying the appliance

1-2-2. Be careful to the electrical shock

To prevent damage which might result in electric shock or fire, do not expose this TV set to rain or

excessive moisture. This TV must not be exposed to dripping or splashing water, and objects

Filled with liquid, such as vases, must not be place on top of or above the TV

1-2-3. Electro static discharge (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such

Components commonly are called Electrostatically Sensitive (ES) Devices. The following

tech-niquesshouldbeusedtohelpreducetheincidenceofcomponentdamagecausedbyelectro

Static discharge (ESD).

1-2-4. About lead free solder (PbF)

This product is manufactured using lead-free solder as a part of a movement within the consum-er

products industry at large to be environmentally responsible. Lead-free solder must be used in the

servicing and repair of this product.

1-2-5. Use the genewing parts (specified parts)

Special parts which have purposes of fire retardant (resistors),high-quality sound (capacitors), low

noise(resistors), etc. are used.

When replacing any of components, be sure to use only manufacture's specified parts shown in

the parts list.

Safety Component

● Components identified by mark have special characteristics important for safety.

4

1-2-6. Safety Check after Repairment

Confirm that the screws ,parts and wiring which were removed in order to service are put in the

original positions, or whether there are the portions which are deteriorated around the serviced

places serviced or not. Check the insulation between the antenna terminal or external metal and

the AC cord plug blades. And be sure the safety of that.

Insuration Test

1. Unplug the plug from the AC outlet.

2. Remove the antenna terminal on TV and turn on the TV.

3. Insulation resistance between the cord plug terminals and the eternal exposure metal

should be more than M ohm by using the 500V insulation resistance meter

4. If the insulation resistance is less than M ohm, the inspection repair should be required.

If you have not the 500V insulation resistance meter, use a Tester.

External exposure metal: Antenna terminal Headphone jack

1-2-7. Ordering Spare Parts

Please include the following informations when you order parts. (Particularly the Version

letter)

1. Model number and Version letter

The model number can be found on the back of each product and the Version letter can

be found at the end of the serial number.

2. Part No. and Description

You can find them in your service manual.

1-2-8. Photo used in this manual

The illustration and photos used in this Manual may not base on the final design of products, which

may differ from your products in some way.

1-3. How to read this Service Manual

1-3-1. Using Icons

Icons are used to attract the attention of the reader to specific information. The meaning of each icon is

described in the table below:

Note:

A “note” provides information that is not indispensable, but may nevertheless be valuable to the

reader, such as tips and tricks.

Caution:

A “caution” is used when there is danger that the reader, through incorrect manipulation,

may damage equipment, loose data, get an unexpected result or has to restart(part of)

a procedure.

Warning:

A “warning” is used when there is danger of personal injury.

5

Reference:

A “reference” guides the reader to other places in this binder or in this manual, where

he/she will find additional information on a specific topic.

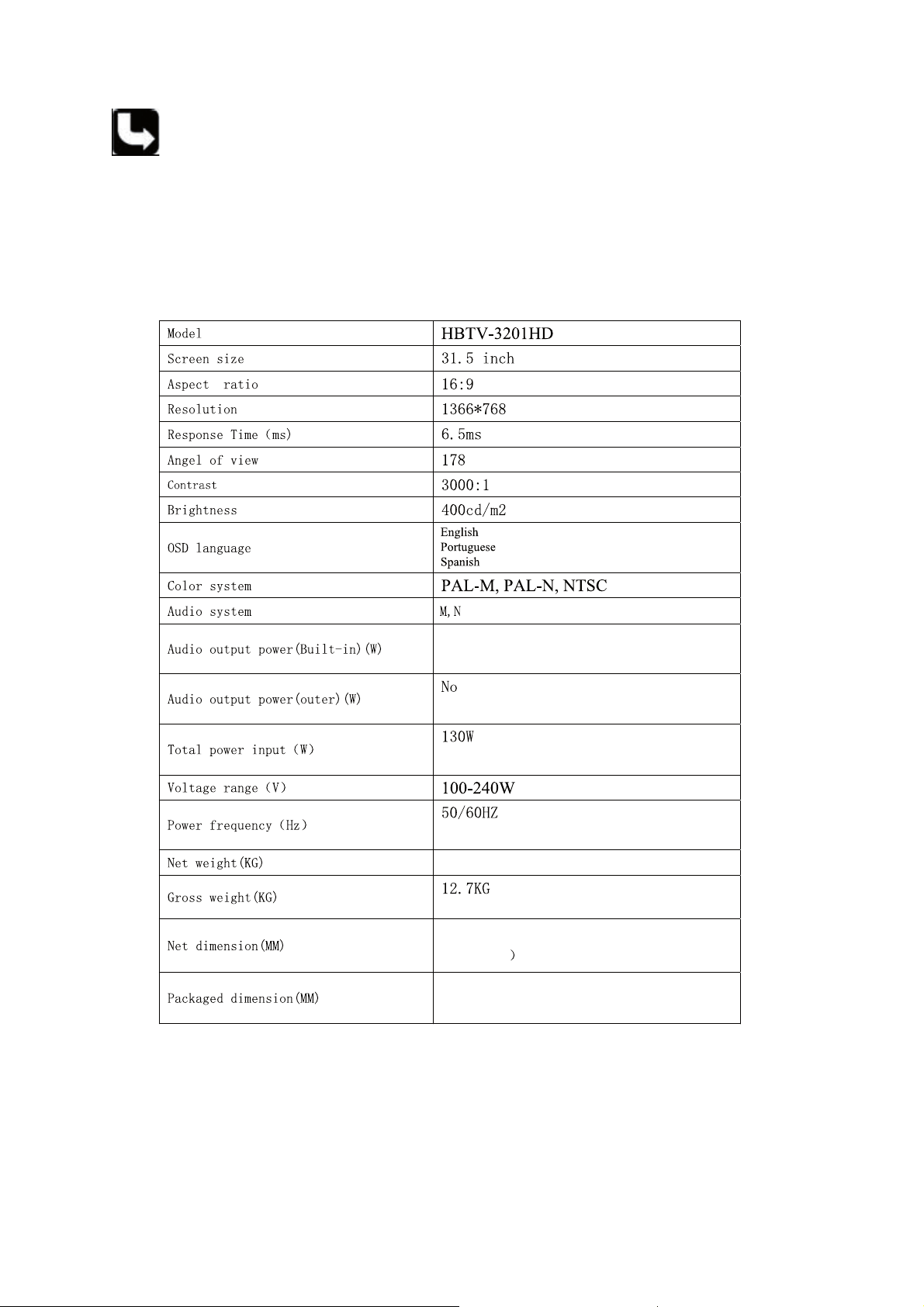

2. Specifications

10.2KG(withstand)

796*233*582

(with stand

870*267*657

6

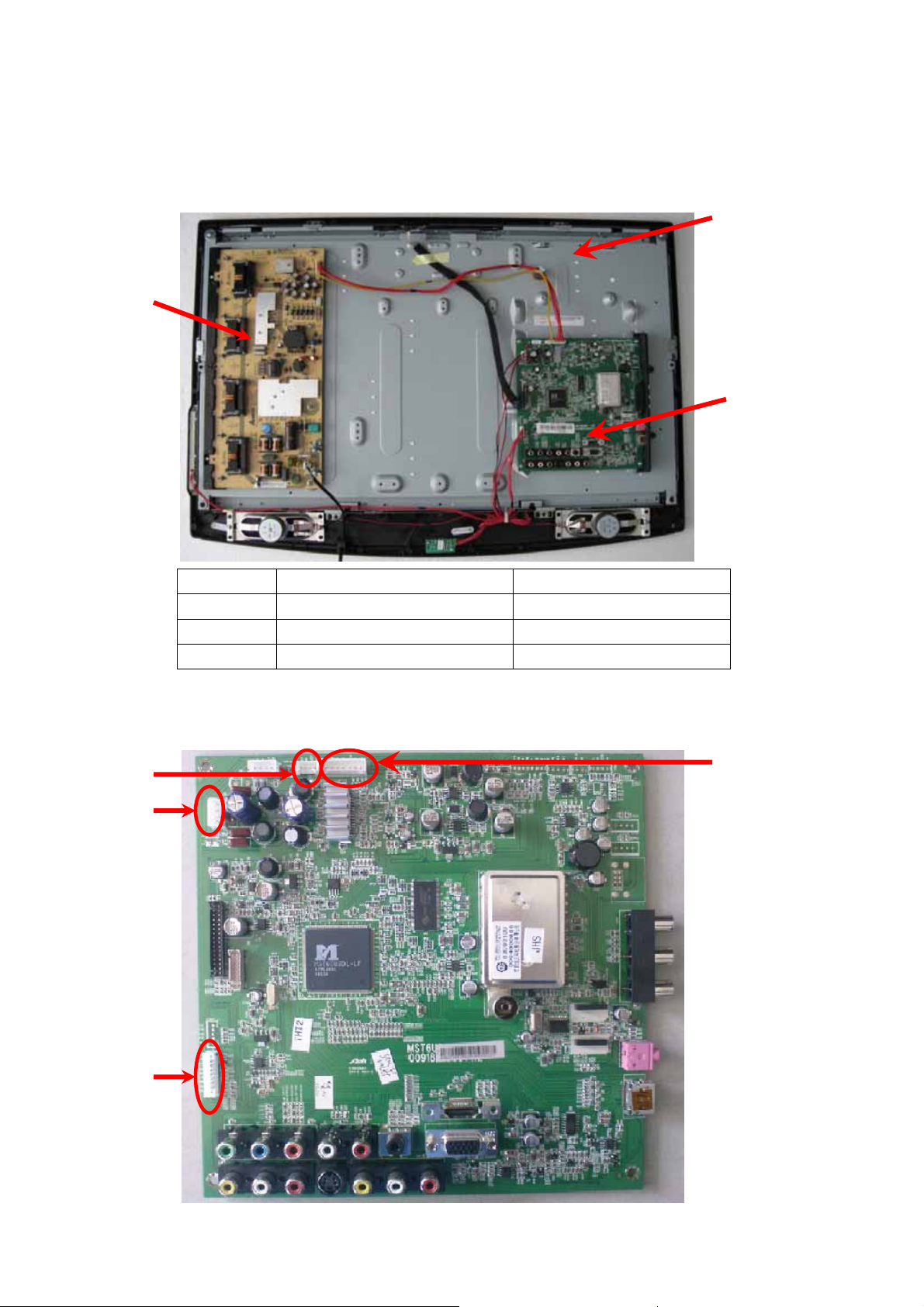

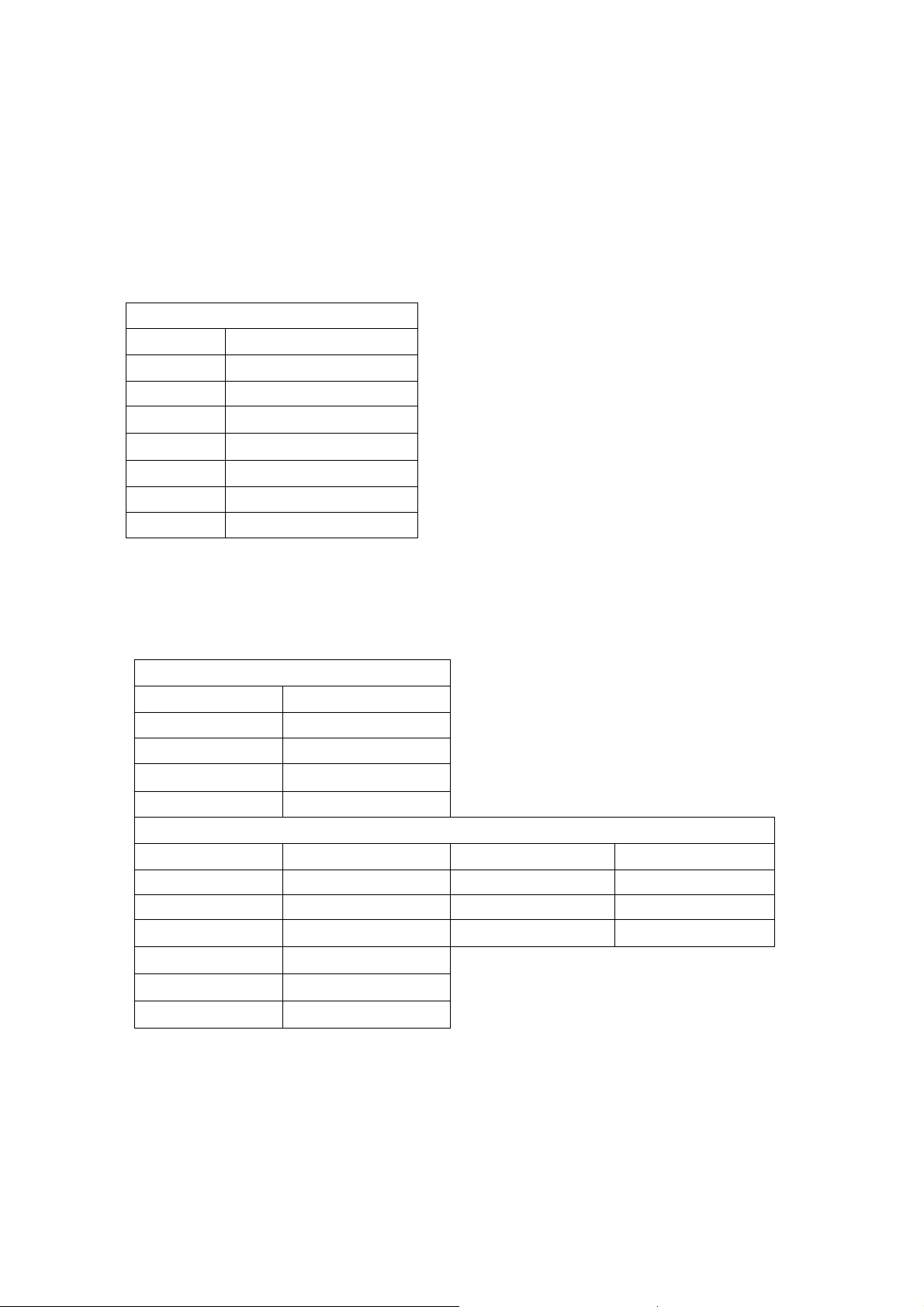

3. Location of Controls and Components

3-1 Board Location

3-1-1

B

L32H8 Board Location

A

C

No. Parts number Description

A Board 0094001236DA LCD PANEL

B Board 0094001274A Power Supply

C Board DZ0UQ0E0102M Mainboard Assembly

3-2 Main Board

CON2

CON17

CN5

CON28

7

3-2-1 Function Description:

Main Board:

Process signal which incept from exterior equipment,then translate into signal that panel can

display.

3-2-2 Connector definition

Main board connector

Power connectors (CON28)

CON28

Pin number Signal name

1 STN

2 GND

3 5VSTB

4 GND

5 GND

6 12VA

7 12VA

Notes:

CON28-Pin6.7 :The power for the mainboard when system power on.

CON28-Pin3 :The power for the mainboard when system standby.

CON28-Pin1 : System power on/standby, System board will use this pin to control system power.

Control connectors (CON2,CN5)

CON2

Pin number Signal name

1 ADJ

2 ON/OFF

3 GND

4 5V

Pin number Signal name Pin number Signal name

1 5VSTB 7 GND

2 GND 8 KEY1

3 LED-B 9 KEY2

4 LED-R

5 5VSTB

6 IRIN

Notes:

CON2-Pin3,4 : N/A

CON2-Pin2 : The control pin for the backlight.

CON2-Pin1 : The adjust pin for the backlight.

CN5-Pin6 : The pin for the remote.

CN5-Pin8,9 : The pin for the key.

Signal connectors (CON17)

CN5

8

CON17

Pin number Signal name

1 L +

2 L -

3 R -

4 R +

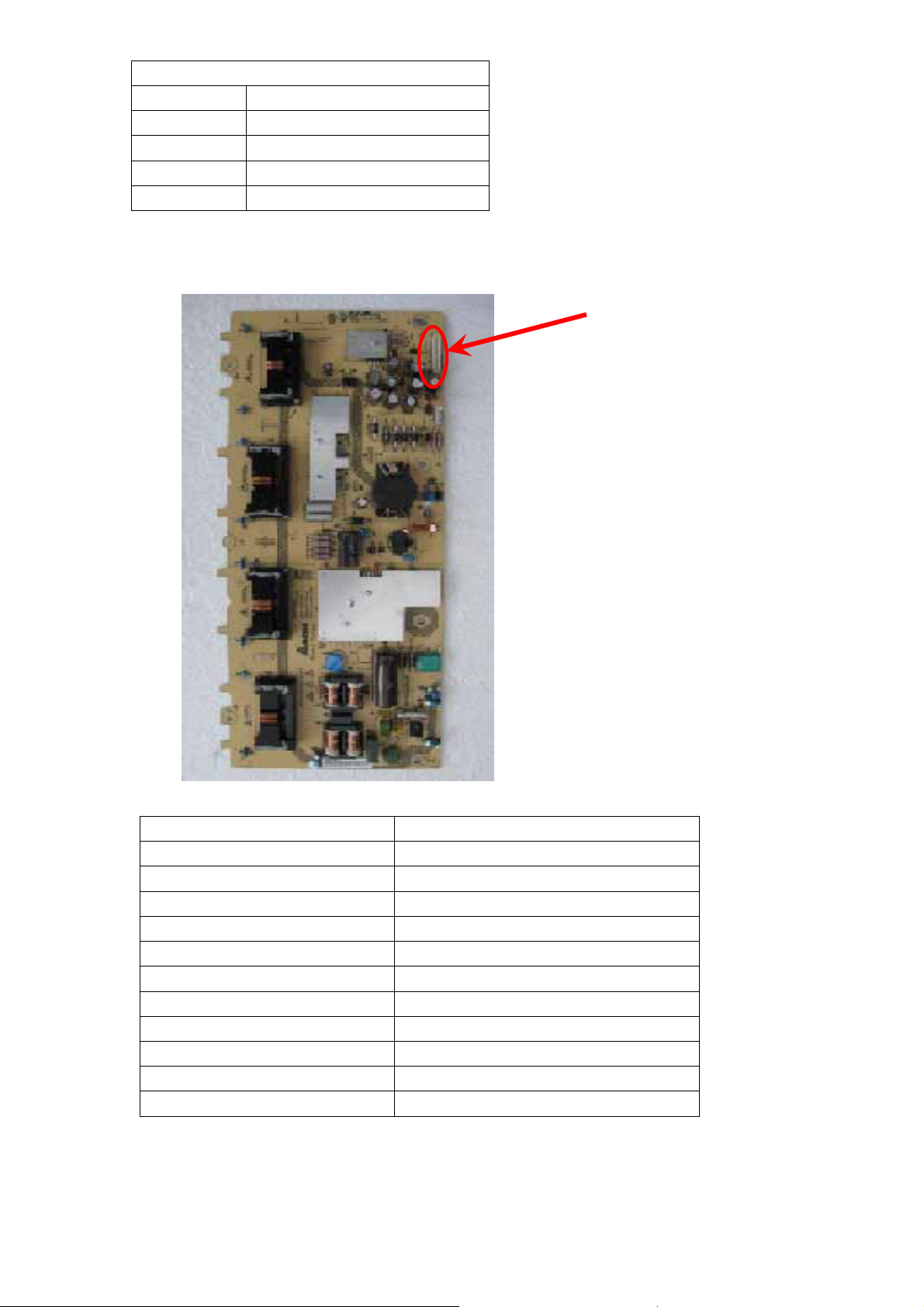

3-3. Power Board

3-3-1 Connector definition

CN2

CN2

PIN NUMBER DESIGNATION

1 12V

2 12V

3 GND

4 GND

5 5VSTB

6 GND

7 STN

8 SEL

9 V-IPWM

10 BL-ON

11 V-EPWM

3-3-2 Function Description:

Supply power for Main board and Panel

9

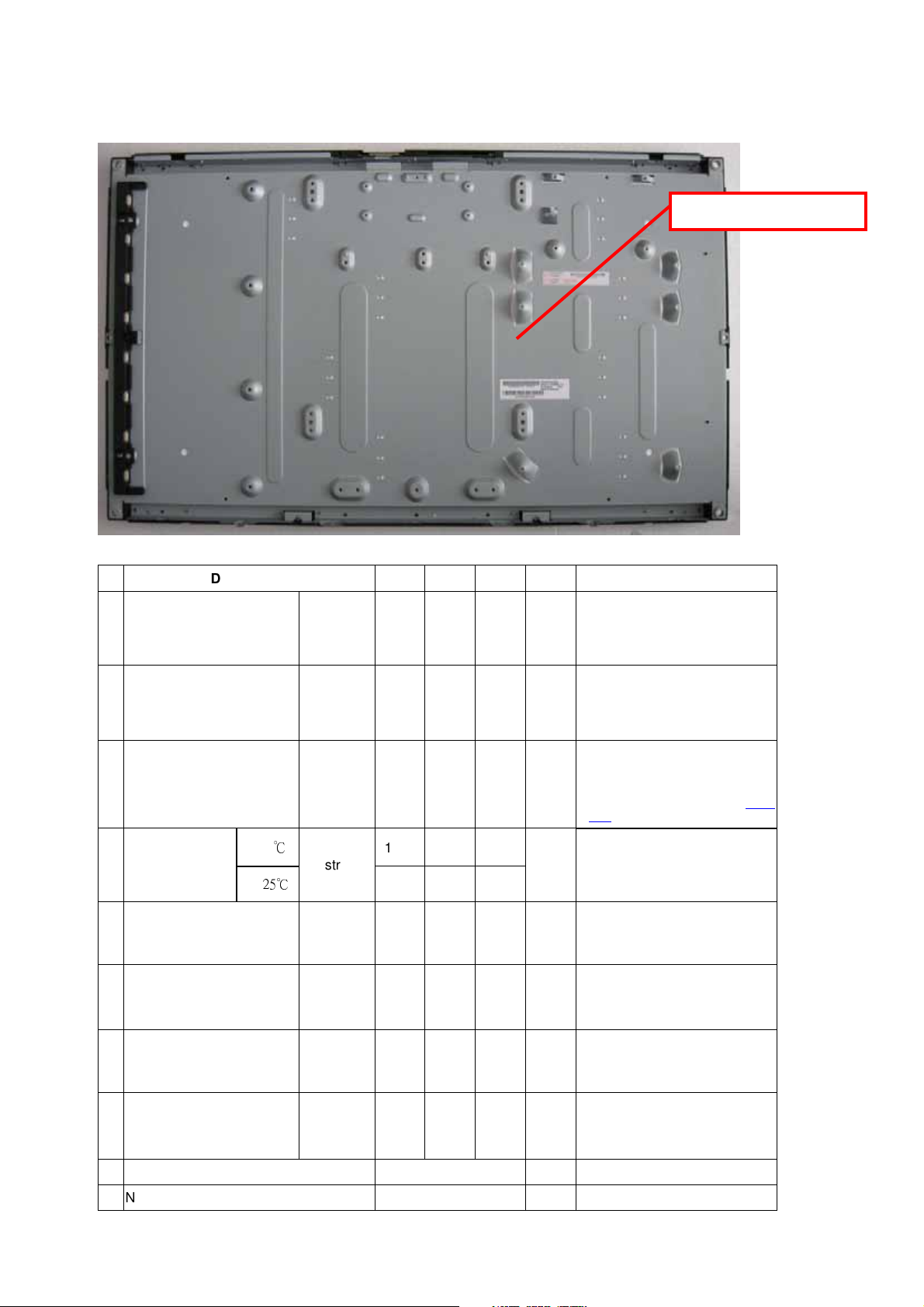

3-4. LCD Panel

ensure

3-4-1 Connector definition

BACKLIGHT CONNECTOR PIN CONFIGURATION :

Description Min Typ Max Unit

1 Operating Voltage Vo 639 710 781 Vrms

2 Operating Current Io 12 12.5 13 mArms

3 BL Total Power Dissipation PBL 76

78

80 Watt

AU(T315XW02 VP)

Condition/Note

1. Dimming range is set 100%

2. Base on lamp specification, for each

lamp need to be applied at least

minimum operating voltage to ensure

each lamp can be normally worked!

1. Dimming range is set 100%

2. Base on lamp specification, for each

lamp need to be applied at least

minimum operating current to ensure

each lamp can be normally worked!

1. Dimming range is set 100%.

2. In order to get typical light out, the

backlight need to be applied typical

power.

3. Input power of JIG BD is about 78 W

(typ) by AUO measure!

At 0

℃

4 Striking Voltage

At

25℃

Vstrike

5 Striking Time Ts 1000

1500 1650

1350 1500

- 1500 msec

Vrms

6 Operating Frequency fo kHz

PWM Operating Frequency F_PWM 120 180 240 Hz

7

PWM Dimming Duty Ratio D_PWM

8

20

9 Lamp Type U type

100

-

%

10 Number of Lamps 4 pcs

10

1. Base on lamp specification, to

each lamp can be normally ignited,

need to apply at least minimum

striking voltage to each lamp

1. To ensure each lamp can be normally

ignited, each lamp need to be applied

at least minimum striking voltage

during minimum striking time.

1. Operating frequency is set by

customer.

2. Need to double confirm display

quality.(*)

1. PWM frequency is set by customer.

2. Need to double confirm display

quality.(*)

Note 1. Dimming range

Note 2.

Note 3. Duty ratio definition.

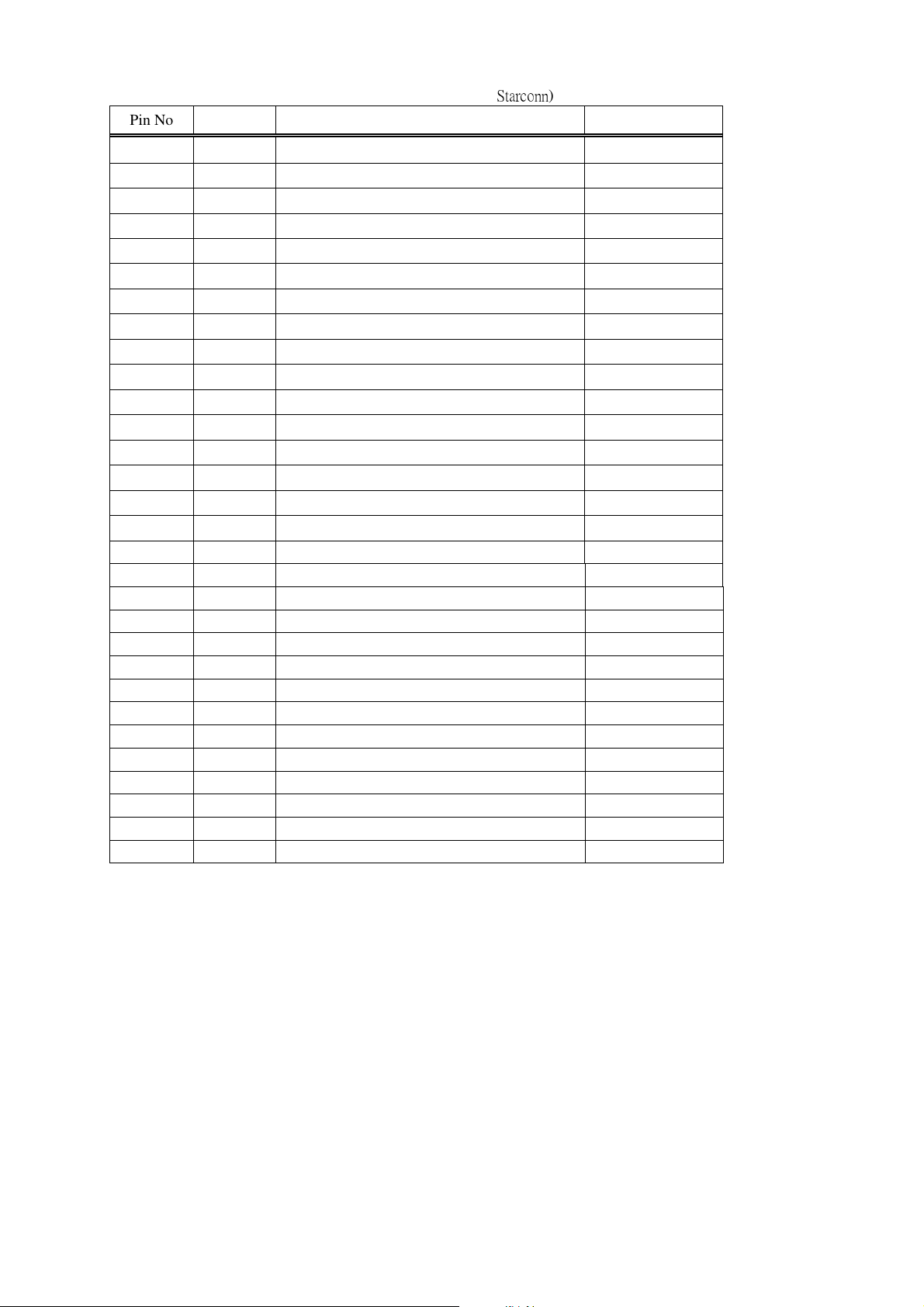

LVDS:

Connector on Panel: 093G30-B0001A-1 (Manufactured by

Pin No Symbol Description Default

1 VCC +12V, DC, Regulated

2 VCC +12V, DC, Regulated

3 VCC +12V, DC, Regulated

4 VCC +12V, DC, Regulated

5 GND Ground and Signal Return

6 GND Ground and Signal Return

7 GND Ground and Signal Return

8 GND Ground and Signal Return

9 LVDS Option Low/Open for Normal (NS), High for JEIDA NS mode

10 Reserved Open AUO internal test

11 GND Ground and Signal Return for LVDS

12 RIN0- LVDS Channel 0 negative

13 RIN0+ LVDS Channel 0 positive

14 GND Ground and Signal Return for LVDS

15 RIN1- LVDS Channel 1 negative

16 RIN1+ LVDS Channel 1 positive

17 GND Ground and Signal Return for LVDS

18 RIN2- LVDS Channel 2 negative

19 RIN2+ LVDS Channel 2 positive

20 GND Ground and Signal Return for LVDS

21 RCLK- LVDS Clock negative

22 RCLK+ LVDS Clock positive

23 GND Ground and Signal Return for LVDS

24 RIN3- LVDS Channel 3 negative

25 RIN3+ LVDS Channel 3 positive

26 GND Ground and Signal Return for LVDS

27 Reserved Open or High AUO internal test

28 Reserved Open or High AUO internal test

29 GND Ground and Signal Return

30 GND Ground and Signal Return

Starconn

)

3-4-2 Function Description:

Display the signal.

4. Disassemble and assemble

4-1. L32R1

11

Loading...

Loading...