Page 1

COLOR TELEVISION

SERVICE MANUAL

CHASSIS: - VE01

MODEL NO: - 1450KT, 2050KT, 2150KT

1

Page 2

CONTENTS

Safety Precautions------------------------------------------------------------------------ 3

Introduction----------------------------------------------------------------------------------- 3

1. SCART details------------------------------------------------------------------------------ 4

2. Micro-Controller and Small Signal function Æ TDA9351.------------------------ 5-8

3. Tuner------------------------------------------------------------------------------------------ 9

4. Video SwitchÆ HEF4052BP------------------------------------------------------------ 10

5. Sound Processor -ÆTDA9859--------------------------------------------------------- 10

6. Sound Output -ÆAN17821-------------------------------------------------------------- 10

7. Vertical Output Stage Æ STV9302A-------------------------------------------------- 10

8. Video Output Amplifier ------------------------------------------------------------------- 11

9. Power Supply------------------------------------------------------------------------------- 11

10. Memory IC Æ AT24C16---------------------------------------------------------------- 11

11. IC Description with Pin Details----------------------------------------------------- 12

11A. TDA9351------------------------------------------------------------------------- 12-18

11B. HEF4052BP--------------------------------------------------------------------- 18-19

11C. STV9302A----------------------------------------------------------------------- 19-20

11D. IC AT24C16--------------------------------------------------------------------- 20-21

11E. TDA9859------------------------------------------------------------------------- 21-23

11F. AN17821-------------------------------------------------------------------------- 24

11G.STR5Q0765----------------------------------------------------------------------- 24-25

11H. Video Amplifier Transistors--------------------------------------------------- 25-26

12. Alignment Procedures------------------------------------------------------------------ 26

12.A. Procedure to enter Service Mode------------------------------------------ 26

12.B. Procedure to enter Design Mode------------------------------------------- 26

12.C. White Balance Adjustment--------------------------------------------------- 27

12.D. Screen Adjustment------------------------------------------------------------- 27

12.E. Design and Service data adjustment-------------------------------------- 27-31

12.F. Manufacturing and alignment procedures-------------------------------- 32-42

13. Block Diagram-------------------------------------------------------------------------- 43

14. Circuit Diagram------------------------------------------------------------------------- 44

15. Track Side Layout--------------------------------------------------------------------- 45

2

Page 3

SAFETY PRECAUTIONS

• Do not change any module unless the set is switched off.

• The mains supply side of the SMPS transformer is live. Use an isolating transformer

• Servicing of the CTV set should only be carried out by qualified person.

• Components marked with warning symbol on circuit diagram are critical for safety and

must only be replaced with an identical component

• Power resistor and fusable resistors must be mounted in an identical manner to the

original component.

• Discharge the capacitors like Main Filter when working on these.

• Do not solder when the set is on.

• Do not connect any external device like Speakers etc. when the set is on.

• When any signals are to be connected/ disconnected switch off the set.

• Wear rubber shoes/non-conducting so that your body does not become a passage for

electric current.

INTRODUCTION:-

VE01 chassis is capable of driving 14”, 20”, 21”, 21”PF tubes at appropriate currents. This

chassis is capable of working in the PAL / SECAM / NTSC systems. The sound system is

capable of giving 1.5W r.m.s. output into a load 8E speaker. One page simple TELETEXT,

TOPTEXT and FASTEXT is provided. The chassis is equipped with 21 pin scart connector which

can accept via scart the SVHS format from VCRs.

The details of various sections with IC details and pin voltages are covered in this manual. The

alignment procedure in field and also at manufacturing line is also covered in detail. The block

diagram, circuit diagram and track side layout of VE01 chassis is also attached in this manual for

easy reference.

3

Page 4

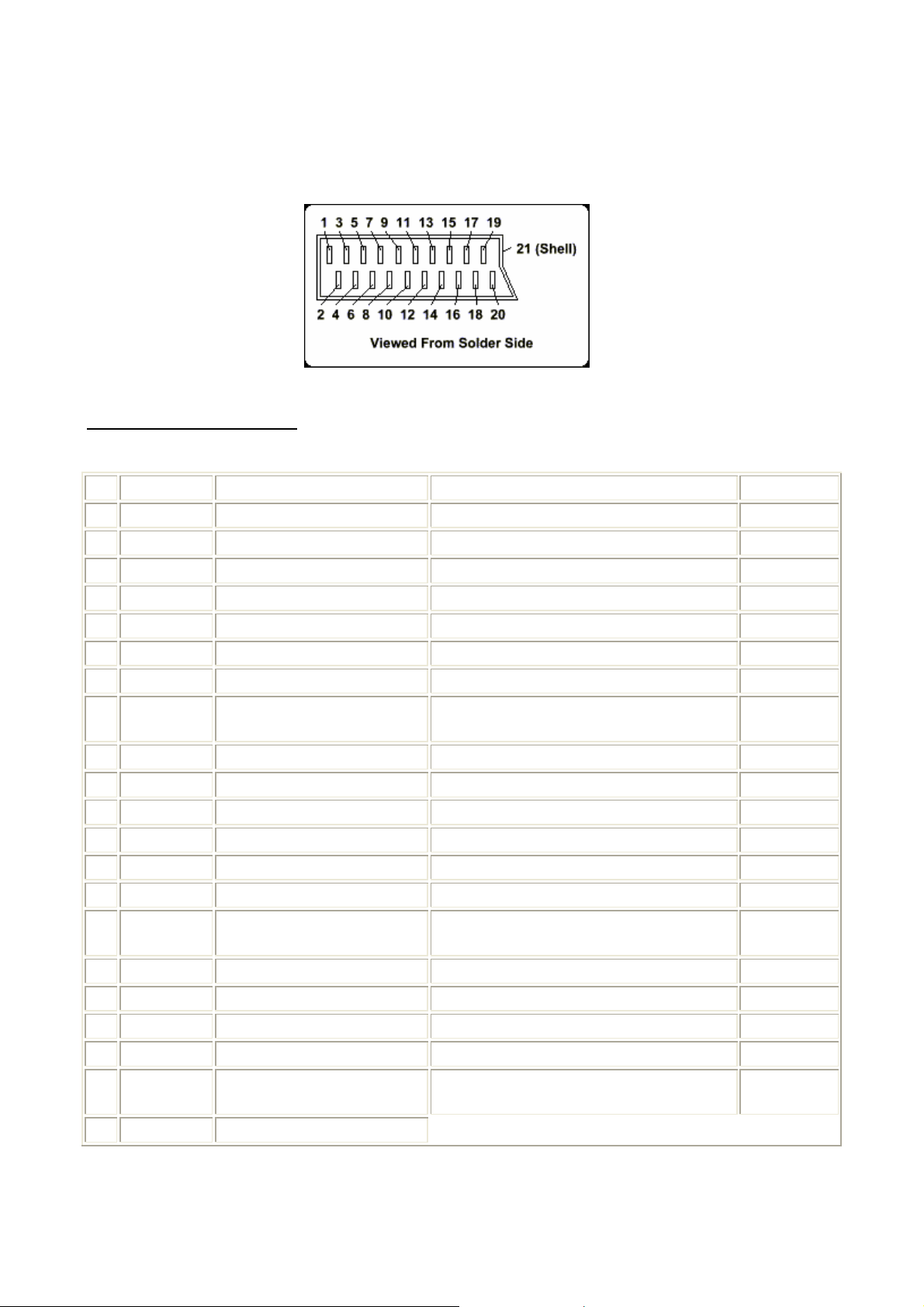

1. PERI- TV SOCKET (SCART)

PIN DETAILS OF SCART

Pin Name Description Signal Level Impedance

1 AOR Audio Out Right 0.5 V rms <1k ohm

2 AIR Audio In Right 0.5 V rms >10k ohm

3 AOL Audio Out Left + Mono 0.5 V rms <1k ohm

4 AGND Audio Ground

5 B GND RGB Blue Ground

6 AIL Audio In Left + Mono 0.5 V rms >10k ohm

7 B RGB Blue In 0.7 V 75 ohm

8 SWTCH Audio/RGB switch / 16:9

9 G GND RGB Green Ground

10 CLKOUT Data 2: Clockpulse Out Unavailable

11 G RGB Green In 0.7 V 75 ohm

12 DATA Data 1: Data Out Unavailable

13 R GND RGB Red Ground

0-2 V=TV, 5-8 V=WideScreen, 9.5-12

V=AV Mode

>10 kohm

14 DATAGND Data Ground

15 R

16 BLNK Blanking Signal 1-3 V=RGB, 0-0.4 V=Composite 75 ohm

17 VGND Composite Video Ground

18 BLNKGND Blanking Signal Ground

19 VOUT Composite Video Out 1 V 75 ohm

20 VIN

21 SHIELD Ground/Shield (Chassis)

RGB Red In /

Chrominance

Composite Video In /

Luminance

0.7 V (Chroma.: 0.3 V burst) 75 ohm

1 V 75 ohm

4

Page 5

2. MICRO CONTROLLER AND SMALL SIGNAL FUNCTION WITH TDA 9351

combination of microcontroller and chroma (Small Signal function). This IC performs all important

functions in TV receiver. The details of IC are bifurcated in two parts. Small Signal function and

microcontroller

:- This IC is a

2A:- SMALL SIGNAL FUNCTION:

2A.1: VISION IF AMPLIFIER: The vision IF amplifier can demodulate signals with positive and

negative modulation. The PLL demodulator is completely alignment-free. The VCO of the PLL

circuit is internal, and the frequency is fixed to the required value by using the clock frequency

of the Controller/ Teletext decoder as a reference. The setting of the various frequencies (38,

38.9, 45.75 and 58.75 MHz) can be made via the control bits IFA-IFC in sub address 27H.

Because of the internal VCO, the IF circuit has a high immunity to EMC interferences.

2A.2: VIDEO SWITCHES:

The selected CVBS signal can be supplied to pin 38, the IF video output. The selection

The video switch has one input for an external CVBS or Y/C signal.

between both signals is realized by means of the SVO bit in sub address 22H. The video ident

circuit can be connected to the incoming ‘internal’ video signal or to the selected signal. This

ident circuit is independent of the synchronisation and can be used to switch the time-constant

of the horizontal PLL depending on the presence of a video signal (via the VID bit). Because of

the availability of the Y/C input and the subcarrier output an external comb-filter can be applied.

In that case an external video switch (or comb-filter with integrated switch) must be used. The

subcarrier output is combined with a 3-level output switch (0 V, 4 V and 8 V). The output level

and the availability of the subcarrier signal is controlled by the CMB1 and CMB0 bits. The

output can be used to switch sound traps etc.

2A.3: SOUND CIRCUIT (QSS VERSION)

The sound IF amplifier is similar to the vision IF amplifier and has an external AGC decoupling

capacitor. The single reference QSS mixer is realised by a multiplier. In this multiplier the SIF

signal is converted to the intercarrier frequency by mixing it with the regenerated picture carrier

from the VCO. The mixer output signal is supplied to the output via a high-pass filter for

5

Page 6

attenuation of the residual video signals. With this system a high performance hi-fi stereo

sound processing can be achieved. The AM sound demodulator is realised by a multiplier. The

modulated sound IF signal is multiplied in phase with the limited SIF signal. The demodulator

output signal is supplied to the output via a low-pass filter for attenuation of the carrier

harmonics. The AM signal is supplied to the output (pin 44) via the volume control. It is possible

to get the AM output signal (not controlled on amplitude) on the QSS intercarrier output. The

selection is made by means of the AM bit in subaddress 29H. Another possibility is that pin 35

is transferred to external audio input pin and pin 32 to (non-controlled) AM output pin. This can

be realised by means of the setting the control bits CMB0 and CMB1 in subaddress 22H.

2A.4: FM DEMODULATOR AND AUDIO AMPLIFIER (MONO VERSIONS):-

demodulator is realised as narrow-band PLL with external loop filter, which provides the

necessary selectivity without using an external band-pass filter. To obtain a good selectivity a

linear phase detector and constant input signal amplitude are required. For this reason the

intercarrier signal is internally supplied to the demodulator via a gain controlled amplifier and

AGC circuit. The nominal frequency of the demodulator is tuned to the required frequency

(4.5/5.5/6.0/6.5 MHz) by means of a calibration circuit which uses the clock frequency of the

Controller/Teletext decoder as a reference. The setting to the wanted frequency is realised by

means of the control bits FMA and FMB in control byte 29H. When required an external sound

band-pass filter can be inserted in front of the narrow-band PLL. In that case pin 32 has to be

switched to sound IF input by means of the bits SIF (subaddress 21H) and CMB0/CMB1

(subaddress 22H). When the sound IF input is selected the subcarrier output or AVL function

are not available. From the output status bytes it can be read whether the PLL frequency is

inside or outside the window and whether the PLL is in lock or not. With this information it is

possible to make an automatic search system for the incoming sound frequency. This can be

The FM

realised by means of a software loop which switches the demodulator to the various

frequencies and then select the frequency on which a lock condition has been found. The

deemphasis output signal amplitude is independent of the TV standard and has the same value

for a frequency deviation of 25 kHz at the 4.5 MHz standard and for a deviation of 50 Khz for

the other standards. The audio control circuit contains an audio switch and volume control. In

the mono intercarrier sound versions, the Automatic Volume Levelling (AVL) function can be

activated. The pin to which the external capacitor has to be connected depends on the IC

version. For the 90 degree types the capacitor is connected to the EW output pin (pin 20). For

6

Page 7

the 110 degree types a choice must be made between the AVL function and a sub-carrier

output for comb filter applications. This choice is made via the CBM0 and CMB1bits (in

subaddress 22H). When the AVL is active it automatically stabilises the audio output signal to a

certain level. The signal on the deemphasis pin (28) can be supplied to the SCART connector

via a buffer stage. It is also possible to use this pin as additional audio input. In that case the

internal signal must, of course, be switched off. This can be realised by means of the sound

mute bit (SM in subaddress 29H). When the IF circuit is switched to positive modulation the

internal signal on the deemphasis pin is automatically muted. The audio switch is controlled by

means of the INA/INB bits in subaddress 22H. It is, however, also possible to overrule the

audio switch position by means of the ADS and ADX bits (subaddresses 28H and 21H

respectively).

2A.5: SYNCHRONISATION CIRCUIT :-

and vertical sync pulses and a data-slicing circuit which extracts the digital teletext data from

the analog signal. The horizontal drive signal is obtained from an internal VCO which is running

at a frequency of 25 MHz. This oscillator is stabilised to this frequency by using a 12 MHz

signal coming from the reference oscillator of the micro controller/Teletext decoder. The

horizontal drive is switched on and off via the soft start/stop procedure. This function is realised

by means of variation of the T ON of the horizontal drive pulses. In addition the horizontal drive

circuit has a ‘low-power start-up’ function. The vertical synchronisation is realised by means of

a divider circuit. The vertical ramp generator needs an external resistor and capacitor. For the

vertical drive a differential output current is available. The outputs must be DC coupled to the

vertical output stage. In the types which are intended for 90 degree picture tubes the following

geometry parameters can be adjusted:

• Horizontal shift

• Vertical amplitude

• Vertical slope

The IC contains separator circuits for the horizontal

• S-correction

• Vertical shift

The types which are intended to be used in combination with 110 degree picture tubes have an

East-West control circuit in stead of the AVL function.

7

Page 8

The additional controls for these types are:

• EW width

• EW parabola width

• EW upper and lower corner parabola correction

• EW trapezium correction

• Vertical zoom

2A.6: CHROMA AND LUMINANCE PROCESSING: -

(including the SECAM cloche filter) are realised by means of gyrators and are tuned to the right

frequency by comparing the tuning frequency with the reference frequency of the colour

decoder. The luminance delay line and the delay cells for the peaking circuit are also realised

with gyrators. The circuit contains a black stretcher function which corrects the black level for

incoming signals which have a difference between the black level and the blanking level.

2A.7: COLOUR DECODER :-

PAL/NTSC decoder does not need external reference crystals but has an internal clock

generator which is stabilised to the required frequency by using the 12 MHz clock signal from

the reference oscillator of the micro controller/Teletext decoder. Under bad-signal conditions

(e.g. VCR-playback in feature mode), it may occur that the colour killer is activated although

the colour PLL is still in lock. When this killing action is not wanted it is possible to overrule the

colour killer by forcing the colour decoder to the required standard and to activate the FCO-bit

(Forced Colour On) in subaddress 21H. The Automatic Colour Limiting (ACL) circuit

The IC can decode PAL, NTSC and SECAM signals. The

The chroma band-pass and trap circuits

(switchable via the ACL bit in subaddress 20H) prevents that over saturation occurs when

signals with a high chroma-to-burst ratio are received. The ACL circuit is designed such that it

only reduces the chroma signal and not the burst signal. This has the advantage that the colour

sensitivity is not affected by this function. The SECAM decoder contains an auto-calibrating

PLL demodulator which has two references, viz: the divided 12 MHz reference frequency

(obtained from the microcontroller) which is used to tune the PLL to the desired free-running

frequency and the bandgap reference to obtain the correct absolute value of the output signal.

The VCO of the PLL is calibrated during each vertical blanking period, when the IC is in search

or SECAM mode. The base-band delay line (TDA 4665 function) is integrated. This delay line

8

Page 9

is also active during NTSC to obtain a good suppression of cross colour effects. The

demodulated colour difference signals are internally supplied to the delay line.

RGB OUTPUT CIRCUIT AND BLACK-CURRENT STABILIZATION : In the RGB control

2A.8:

circuit the signal is controlled on contrast, brightness and saturation. The ICs have a linear

input for external RGB signals. It is possible to use this input for the insertion of YUV signals.

Switching between RGB and YUV can be realised via the YUV-bit in subaddress 2BH. The

signals for OSD and text are internally supplied to the control circuit. The output signal has an

amplitude of about 2 Volts black-to-white at nominal input signals and nominal settings of the

various controls. To obtain an accurate biasing of the picture tube the ‘Continuous Cathode

Calibration’ system has been included in these ICs. A black level offset can be made with

respect to the level which is generated by the black current stabilization system. In this way

different colour temperatures can be obtained for the bright and the dark part of the picture.

The black current stabilization system checks the output level of the 3 channels and indicates

whether the black level of the highest output is in a certain window (WBC-bit) or below or

above this window (HBC-bit). This indication can be read from the status byte 01 and can be

used for automatic adjustment of the Vg2 voltage during the production of the TV receiver.

During switch-off of the TV receiver a fixed beam current is generated by the black current

control circuit. This current ensures that the picture tube capacitance is discharged. During the

switch-off period the vertical deflection is placed in an overscan position so that the discharge

is not visible on the screen.

2B. - MICROCONTROLLER WITH TELETEX DECODER: -

with embedded microcontroller is a control system designed for TV sets with analogue picture

and sound control. The system also offers an on screen display (OSD) and IR remote control of

all functions.

3. TUNER: tuning is based on frequency synthesis tunning.

GDC Tuner EWT 5F3T1 is controlled by I2C bus through IC TDA 9361.The

The integrated teletex decoder

9

Page 10

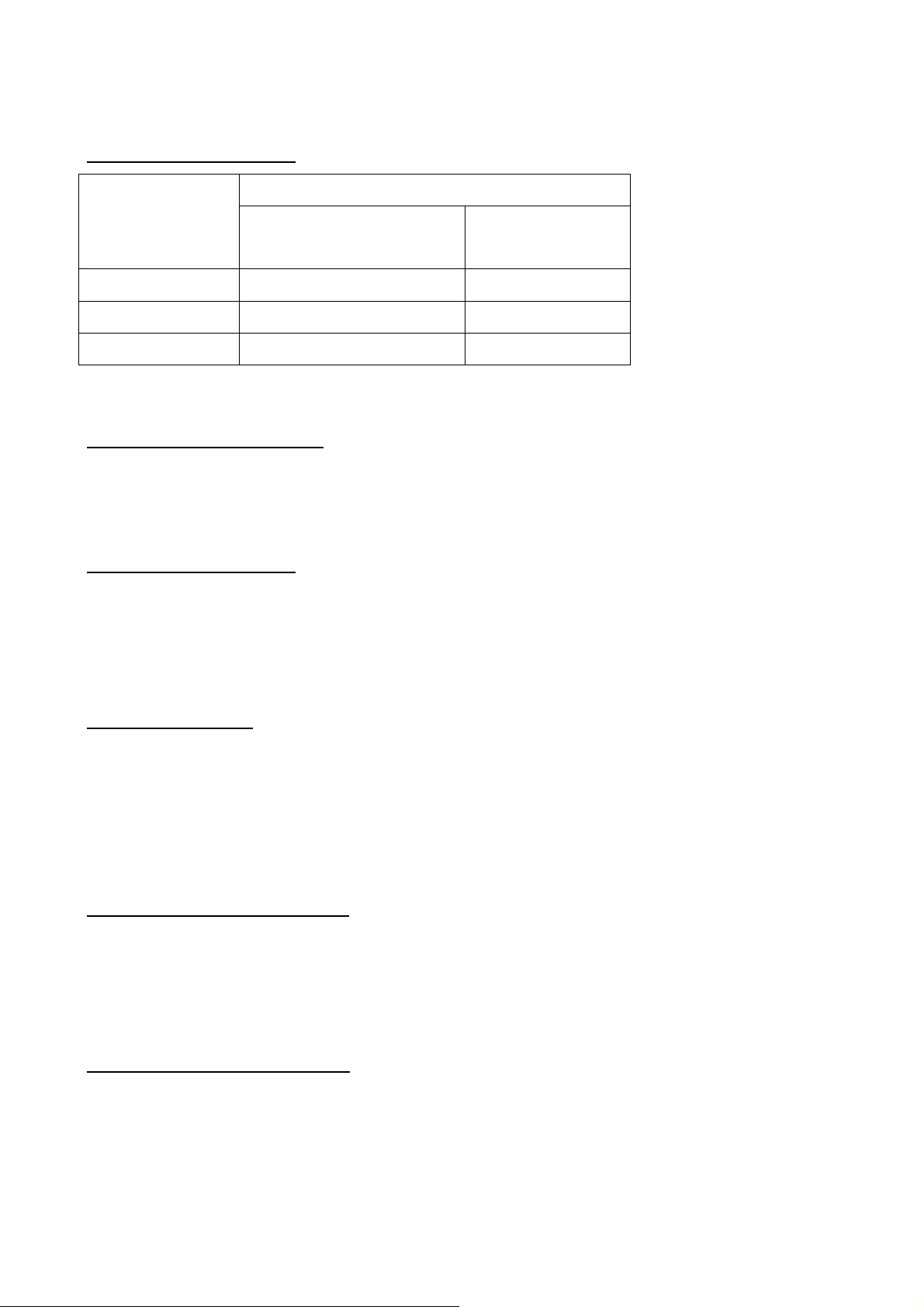

CHANNEL COVERAGE :

BAND

CHANEL RANGE

LOW BAND E2- S9 48.25 – 161.25

MID BAND S10 – S41 168.25 – 463.25

HIGH BAND E21 – E69 471.25 – 855.25

4. VIDEO SWITCH BU 4052

main function of this device is to accept an AV input from SCART, external AV and switch the

required output at pin no Z which is applied to small signal processing IC.

5. SOUND PROCESSOR

The TDA 9859 selects signal from Three Stereo Sources or Six Mono Sources and out put

can be given to scart. The sound processor is I2C bus controlled and all settings of bus are

: TDA 9859 is designed to perform demodulation of FM TV sound.

OFF AIR CHANELS

FREQUENCY

: The HEF4052 is a dual four channel analog multiplexer. The

( IN MHZ)

stored in sub address register.

6. SOUND OUTPUT

It is supplied by 13 volts from the 13 volt DC coming from a separate winding in the SMPS

transformer. An out power of 1.5 Watt can be delivered into an 8 Ohm Load. This IC is also

having a feature of auto volume controller. Similarly stand by signal coming from

microcontroller is used to disable the sound out put from speaker.

7. VERTICLE OUTPUT STAGE

for 90 degree and 110 degree deflection systems . One supply voltage for the scan is

required. The drive voltage is amplified by an amplifier. The supply voltage of this IC is 15

Volts.

8. VIDEO OUTPUT AMPLIFIER

output amplifier section. IC TDA6107 or transistorized circuit can be used for video signal

: - IC AN17821 is used as the AF out amplifier for the Stereo application.

:- The STV 9302 is a vertical deflection circuit can be used

: The RBG output signal from TDA 9351 is applied to video

amplification and to be applied to cathodes of CRT for generation of R, G, and B colors. If IC

10

Page 11

is used, then internal amplifiers are used to amplify the video signal. The transistorized

amplifier can be designed by using transistor circuit in which 9 transistors are used. Chassis

VE01 consist of transistorized video amplifier circuit.

9. POWER SUPPLY

SMPS transformer controlled by STR 0765, which is designed for deriving, controlling and

protecting switiching transistor of SMPS. The transformer produces 110 volts for FBT, 13 Volt

for audio O/p IC, 33 Volts for tuner and 5 and 8 Volts regulated voltages through IC TA7805

and TA7808.

10. MEMORY IC

EEPROM organized as 128 pages X 16 bytes. This is compatible with I2C standards, two

wire serial interface which uses a bi directional data bus and serial clock.

: The DC Voltages required at various part of the chassis are applied by

: The 24C16 is a 16 Kilo Bit electrically erasable programmable memory.

11

Page 12

11. IC DISCRIPTION AND PIN DETAILS

• TDA 9351Æ TV Signal processor- Teletex decoder with embedded microcontroller

• HEF 4052BP-Æ Video Switch

• STV 9302-Æ Vertical Deflection Output

• 24C16-Æ Memory IC

• TDA 9859-Æ Sound Processor

• AN 17821-Æ Sound Output

• KA 5Q0765-Æ STR

• Video amplifier.

11A. TDA 9351:-

microcontroller and US Closed Caption decoder. The IC is used in television receivers with

90degree and 110 degree picture tubes. The ICs have supply voltages of 8 V and 3.3 V and

they are mounted in S-DIP envelope with 64 pins. This IC is having higher degree of

integration because delay line with adjustable delay time, PAL / SECAM / NTSC decoder has

been integrated. In addition to this some special features like Continuous Cathode

Calibration’, white point and black level offset, AVL are added in this version. As this is a

combination of microcontroller and TV signal processor, the features of IC are divided in two

sections

TV Signal processor Important Features

• Internal (switchable) time-constant for the IF-AGC circuit.

• A choice can be made between versions with mono intercarrier sound FM

demodulator and versions with QSS IF amplifier.

• The mono intercarrier sound versions have a selective FM-PLL demodulator which

This IC is the functions of a TV signal processor together with a

can be switched to the different FM sound frequencies (4.5/5.5/6.0/6.5 MHz).The

quality of this system is such that the external band-pass filters can be omitted.

• Source selection between ‘internal’ CVBS and external CVBS or Y/C signals

• Integrated chrominance trap circuit

• Integrated luminance delay line with adjustable delay time

• Asymmetrical ‘delay line type’ peaking in the luminance channel

• Black stretching for non-standard luminance signals

12

Page 13

• Integrated chroma band-pass filter with switchable centre frequency

• Only one reference (12 MHz) crystal required for the microcontroller, Teletext- and the

colour decoder

• PAL/NTSC or multi-standard colour decoder with automatic search system

• Internal base-band delay line

• RGB control circuit with ‘Continuous Cathode Calibration’, white point and black level

offset adjustment so that the colour temperature of the dark and the light parts of the

screen can be chosen independently.

• Linear RGB or YUV input with fast blanking for external RGB/YUV sources. The

Text/OSD signals are internally supplied from the microcontroller/Teletext decoder

• Contrast reduction possibility during mixed-mode of OSD and Text signals

• Horizontal synchronization with two control loops and alignment-free horizontal

oscillator

• Vertical count-down circuit

• Vertical driver optimized for DC-coupled vertical output stages

• Horizontal and vertical geometry processing

• Horizontal and vertical zoom function for 16 : 9 applications

• Horizontal parallelogram and bow correction for large screen picture tubes

Special Features of micro Controller

• 80C51 microcontroller core standard instruction set and timing

• 1 microsecond machine cycle

• 32 - 128Kx8-bit late programmed ROM

• 3 - 12Kx8-bit Auxiliary RAM (shared with Display and Acquisition)

• Auxiliary RAM page pointer

• 16-bit Data pointer

• IDLE and Power Down (PD) mode

• 14 bits PWM for Voltage Synthesis Tuning

• 8-bit A/D converter

• 4 pins which can be programmed as general I/O pin, ADC input or PWM (6-bit) output

• Text memory for 1 or 10 pages

13

Page 14

• In the 10 page versions inventory of transmitted Teletext pages stored in the

Transmitted Page Table (TPT) and Subtitle Page Table (SPT)

• Data Capture for 525/625 line WST, VPS (PDC system A) and Wide Screen Signalling

(WSS) bit decoding

• Automatic selection between 525 WST/625 WST

• Automatic selection between 625 WST/VPS on line 16 of VBI

• Real-time capture and decoding for WST Teletext in Hardware, to enable optimized -

processor throughput

• Automatic detection of FASTEXT transmission

• Real-time packet 26 engine in Hardware for processing accented, G2 and G3

characters

• Signal quality detector for video and WST/VPS data types

• Comprehensive teletext language coverage

• Full Field and Vertical Blanking Interval (VBI) data capture of WST data

Display Features

• Teletext and Enhanced OSD modes

• Single/Double/Quadruple Width and Height for characters

• Scrolling of display region

• Variable flash rate controlled by software

• Enhanced display features including over lining, underlining and italics

• Soft colours using CLUT with 4096 colour palette

• Globally selectable scan lines per row (9/10/13/16) and character matrix [12x10,

12x13, 12x16 (VxH)]

• Fringing (Shadow) selectable from N-S-E-W direction

• Fringe colour selectable

• Meshing of defined area

• 32 software redefinable On-Screen display characters

14

Page 15

PINNING: TDA 9351

Pin No Description Value

1. Stand By Stand by Low Level: 0

High Level : 3.31V

2. SCL Clock Signal Output Low level : 0V

High Level : 3.31V

3. SDA Data Out put Low Level : 0V

High Level : 3.31V

4.TUNING Tunning ( Not connected) 4 V

5. NTSC SW / AC TEST NTSC switch , AC Test 0V

6. KEY Key Input ( Pannel ) Low Level : 3.36V

High level : 3.48V

7. VOL1 Volume 3.3 V

8. MUTE Mute Low level : 0V

High Level : 4.06

9. Vss C/P Digital Ground for

microcontroller

10. BAND1 Band 1 (not connected) 0V

11. BAND2 Band 2 ( Not Connected ) 0V

12. Vss A Analog ground of teletext

decoder and digital ground

for TV processor

13. SECPLL Secam PLL decoupler Low level : 0V

14. Vp2 Second supply voltage for

TV processor

15. DECDIG Decoupling digital supply

of TV processor

16.PHL2LF Phase II filter Low level : 0V

0V

0V

High level : 2.27

8V

Low level : 0V

High level : 4.98V

High level : 2.88V

17. PHL2LF Phase I filter Low level : 0V

High Level : 3V

15

Page 16

18. GND3 Ground for TV processor 0V

19. DECBG Band gap decoupling 3.97 V

20. AVL / EWD Automatic volume leveling

/ East west drive output

21. VDRB vertical drive B output 0.59V

22. VDRA vertical drive A output 0.61

23. IF1 IF input 1 1.85V

24. IF2 IF input 2 1.85V

25. IREF Reference current input 3.97V

26. VSC Vertical sawtooth capacitor Low level : 0V

27. TUNER AGC Tuner AGC output Low level : 0V

28. AUDDEM Audio de emphasis or SIF

input 1

29. DECSDEM / SIF2 Decoupling sound

demodulator or SIF input2

Low level : 0

High level : 2.61V

high level : 3.65V

high level : 3.93V

3.14V

2.23V

30. GND2 Ground 2 for TV processor 0V

31. SNDPLL / SIF AGC Narrow band PLL filter

/AGC sound IF

32. AVL / REF0 Automatic Volume

Levelling / sound IF input /

subcarrier reference

output /AM output

33. H OUT Horizontal output 0.53V

34. FBISO Flyback input/sandcastle

output

35. AUDEXT / QSSO External audio input /QSS

intercarrier out /AM audio

output (non controlled)

36. EHTO EHT/Over voltage

protection input

2.23V

0V

0.67V

3.64V

Low level : 0V

High Level : 1.6V

16

Page 17

37. PLL IF IF-PLL loop filter Low level : 0V

High Level : 2.35V

38. IFVO / SVO IF video output / selected

CVBS output

39. Vp1 Main supply voltage TV-

processor (+8 V)

40. CVBSINT Internal CVBS input 2VPP

41. GND1 Ground 1 for TV-processor 0V

42. CVBS / Y External CVBS/Y input Low level : 0V

43. CHROMA Chrominance input

(SVHS)

44. AUDOUT / AMOUT Audio output /AM audio

output (volume controlled)

45. INSSW2 2nd RGB / YUV insertion

input

46. R2 / VIN 2nd R input / V (R-Y) input 2.49V

3.27V

8V

High Level : 3.3V

Low level : 0V

High Level : 3.3V

3.31V

0V

47. G2 / YIN 2nd G input / Y input 2.49V

48. B2 / UIN 2nd B input / U (B-Y) input 2.49V

49. BCLIN Beam current limiter

input/V-guard input

50. BLANKING Black current input 3 V

51. ROUT Red output 2Vpp

52. GOUT Green output 2Vpp

53. BOUT Blue output 2Vpp

54. VddA Analog supply of Teletext

decoder and digital supply

of TV-processor

55. VpE OTP Programming

Voltage

56. VddC Digital supply to core 3.3V

57. OSCGND Oscillator ground supply 0V

1.95 V

3.3V

0V

17

Page 18

58. XTAL IN Crystal oscillator input 1.57V

59. XTAL OUT Crystal oscillator output 1.76V

60. RESET Reset 0V

61. VddP Digital supply to periphrery 3.3V

62. AV1 AV input from video

0.06V

switching IC (+3.3 V)

63. AV2 AV input from video

0.6V

switching IC (+3.3 V) input

64. IRIN IR Input 4.8V

11B. IC-BU4052

:- 16 Pin IC. This IC is used for video switching The HEF 4052B is a dual

four channel analog Multiplexer / De- Multiplexer with common channel; select Logic. Each

Multiplexer / De-Multiplexer has four independents inputs / out puts. (Yo to Y

) and a

3

common input / out put (Z) . The Common Channel Select Logic includes two address inputs

(A0 and A1) and an active low enable input INH. Both Multiplexer / De Multiplexer has four bi

directional analog switches, each with one side connected to an independent input / out put. .

( Yo to Y

) and the other side connected to common input / out put ( Z). For operation as a

3

digital multiplexer / demultiplexer VEE is connected to VSS (typically ground).

Application Information :

• Analog Multiplexing and De-Multiplexing.

• Digital Multiplexing and demultiplexing.

• Signal Gating

Pin no. Pin Description Voltage in Volts

1. Y0B (independent inputs/ Out

puts)

2. Y2B Y2/ out B (independent inputs

/ out puts)

18

PINNING: HEF 4052BP

( 1 Khz Colour Pattern)

0.50V

0.50V

Page 19

3. ZB ( Common input / outputs) 0.50V

4. Y3B (independent inputs / out

puts)

5. Y1B (independent inputs / out

puts)

6. INH ( enable input (active LOW) ) 0

7. VEE VEE 0

8. VSS VSS 0

9. A1 (address inputs) 0.21V

10. A0 ( address inputs) 0.21V

11. Y3A (independent inputs / out

puts)

12. Y0A (independent inputs / out

puts)

13. ZA ( Common input / outputs) 0

14. Y1A (independent inputs / out

0.50V

0.40 V

0.21V

0

0.20V

puts)

15. Y2A (independent inputs / out

puts)

16.

VDD

11C. STV 9302A (VERTICLE IC)

for T.V applications . This device supplied with upto 35 volts and provides upto 2 Vpp current

to derive the vertical deflection yoke.

Features:

• Power Amplifier.

• Fly Back generator

• Output Current upto 2 amp.

• Thermal Protection.

VDD 7.96V

: The STV 9302A is a vertical deflection booster designed

0.07V

19

Page 20

PINNING: STV 9302

Voltage in Volts

Pin no. Pin Description

( 1 Khz Colour Pattern)

1 INPUT(INVERTING) 0.59 V

2 SUPPLY VOLTAGE 14 V

3 FLY-BACK GENERATOR -11.43 V

4 Gnd or Negative supply -12.82 V

5 OUT PUT 0.33V

6 OUTPUT-STAGE SUPPLY 14.29 V

7 INPUT(NON INVERTING) 0.61 V

11D. IC-AT24C16: Features

:

This is a 16 Kilo Bite EEPROM with a wide operating range.

• Data EEPROM internally organized as 2048 bytes and 128 pages X 16 bytes.

• Low power C-MOS.

• Vcc = 2.7 – 5.5 Volt operation.

• Two wire serial interface bus, I

2

C- Bus Compatible.

• Filtered Inputs for Noise Suppression with Schmitt Trigger.

• Clock frequency upto 400 KHz.

• High Programming flexibility.

• High reliability

- Endurance 10

6

Cycles

- Data retention 40 Years.

- ESD protection 4000V on all pins.

• 8 Pin DIP/ DSO packages.

• Available for extended temperature ranges.

- Industrial -40

- Automotive -40

0

C to + 850C

0

C to + 1250C.

20

Page 21

PINNING :- 24C16

Pin

No

1 GND 0 V 0 V

2 GND 0 V 0 V

3 GND 0 V 0 V

4 GND 0 V 0 V

5 SDA. Serial Data Input 3.12 V 3.23 V

6 SCL. Serial clock 2.54 V 2.56 V

7 GND 0 V 0 V

8 VCC 5 V 5 V

11E. IC-TDA9859 (SOUND PROCESSOR) :

control facilities for the main and the scart channel of a T.V set. Due to extended switching

possibilities Signal from three stereo sources can be handled. This is plastic shrink dual in

Pin Description Stand-By

ON Condition Voltage

Voltage

- TDA 9859 sound processor provides the sound

( 1 Khz Colour Pattern)

line package 32 pin IC.

Features:

• I2 C bus control for all functions

• Multi Source Selector Switches.

• Six AF Inputs ( Three Stereo Sources or Six Mono Sources can be used as a input.)

• Each of the input signal can be switched to each of outputs.

• Out put for large speaker channels and pary –TV Connector scart,

• Stereo and pseudo stereo effects.

• Audio surround decoder can be added externally.

• To general purpose out put port.

21

Page 22

PINNING: TDA 9859

Pin no. Pin Pin Description Stand By Voltage

1 AV Left input Scart Input Left

Channel

2 P 1 Not connected Port -1 Input 0

3 MAIN Left Main Input Left

Channel

4 CSMO Smoothing Capacitor

of reference voltage

5 MAIN Right Main Input Right

Channel

6 VCC Supply Voltage Low Level : 0.02V

7 AUDIO OUT Right Scart Out put right

Channel

8 GND Ground 0

9 VO 2 Main Out put Right

Low Level : 0.32V

High Level : 3.8V

0 Low Level : 0V

High Level : 3.8V

Low Level : 0.02V

High Level : 8V

Low Level : 0V

High Level : 3.8V

High Level : 8V

Low Level : 0.05V

High Level : 3.8V

Low Level : 0.17V

Channel

10 VI 8 Input to Loud Speaker

Channel

11 CBR 1 Bass Capacitor

Connection-1 Right

Channel

12 CBR 2 Bass Capacitor

Connection-2 Right

Channel

13 Woofer out

Right( N.C)

14 CTR Treble Capacitor

15 MAIN OUT Right Loud Speaker Output

Woofer Out Right 0

Connection right CH.

Right Channel

High Level : 3.8V

Low Level : 0.16V

High Level : 3.8V

Low Level : 0.15V

High Level : 3.8V

Low Level : 0.14V

High Level : 3.8V

Low Level : 0V

High Level : 3.8V

Low Level : 0V

High Level : 3.8V

22

Page 23

16 SCL Serial Clock Input Low Level : 2.54V

High Level : 2.55V

17 SDA Serial Data Ip / Output Low Level : 3.10V

High Level : 3.27V

18 MAIN OUT Left Loud Speaker Out Put

Left Channel

19 CTL Treble Capacitor

Connection Left

Channel

20 Woff. Out Left ( N.C) Woofer Output Left 0

21 CBL 2 Bass Capacitor

Connection-1 Left CH

22 CBL 1 Bass Capacitor

Connection-2 Left CH.

23 VI 7 Input to Loud

Speaker Left Channel

24 VO 1 Main Output Left CH Low Level : 0.25V

25 GND 0

Low Level : 0V

High Level : 3.8V

Low Level : 0.10V

High Level : 3.8V

Low Level : 0.32V

High Level : 3.8V

Low Level : 0.29V

High Level : 3.8V

Low Level : 0.27V

High Level : 3.8V

High Level : 3.8V

26 AUDIO OUT Left Scart Output Left

Channel

27 CPS 2 Pseudo Stereo

Capacitor -2

28 AV 2 Left AV2 Left Low Level : 0.22V

29 CPS 1 Pseudo Stereo

Capacitor -1

30 AV 2 Right AV2 Right Low Level : 0.19V

31 P 2 (NC) Port-2 Output 0

32 AV1Right Scart Input Right Low Level : 0.18V

Low Level : 0.05V

High Level : 3.8V

Low Level : 0.23V

High Level : 3.8V

High Level : 3.8V

Low Level : 0.20V

High Level : 3.8V

High Level : 3.8V

High Level : 3.8V

23

Page 24

11F. SOUND OUTPUT IC: the IC AN178421 is used as the AF out amplifier for the Stereo

application. It is supplied by 13 volts from the 13 volt DC coming from a separate winding in

the SMPS transformer. An out power of 1.5 Watt can be delivered into an 8 Ohm Load.

PINNING:- AN17821

Pin No Description Voltage in Volts

1 VCC 13V

2 Channel 1 out put Low Level : 0V

High Level : 6.07V

3 Ground for channel out put 0V

4 Chanel out (-) Low Level : 0V

High Level : 6V

5 Standby Signal Input Low Level : 0V

High Level : 5V

6 Channel 1 input Low Level : 0V

High Level :1.44V

7 Ground 0V

8 Channel 2 input Low Level : 0V

High Level : 1.44V

9 Volume 2.8V

10 Channel 2 out put (-) Low Level :0V

High Level : 6V

11 Ground for channel 2 0V

12 Channel 2 out put Low Level : 0V

High Level : 6V

11G. STR 5Q0765

performance controller. This power switch consists of high voltage power sensitivity and

PWM controller IC. PWM Controller features integerated fixed oscillator under voltage

lock out, leading edge blanking, optimized gate turn off drivers, thermal shut down

protection, over voltage protection. It has a basic platform well suited for cost effective

:-The 5QO765RT is a power switch and an enhanced high

24

Page 25

design in CTV power supply. With this features it offers really safe and reliable power

management

Features :

• Quasi resonant convertor controller.

• Internal bus mode controller.

• Pulse by pulse current limiting.

• Over current latch protection.

• Over Voltage protection( V-Sink Min 11 Volt).

• Internal thermal Shut Down function.

• Under Voltage lock out.

• Internal High Voltage sensitivity

• Auto restart mode.

PINNING : STR 5Q0765

Pin No Description Voltage (in Volts)

1 Drain 300 V

2 Ground 0

3 VCC Low level: 12.59V

4 Feedback Low level : 0.3 V

5 SYNC Low Level : 0.74V

11. VIDEO AMPLIFIER STAGE

signal received from TDA9351. The R,G,B output from TDA9351 is applied to base of

B911,B921 and B931 and push pull amplifier is used to amplify this signal further and applied

:- Transistorised amplifier circuit is used to amplify the R,G,B

High level: 40V

High level: 6.9V

High Level :11V

to cathode of CRT. Voltage details of 9 transistors used in video amplifier section are as

follows.

25

Page 26

Transistor Base Voltage Collector Voltage Emitter Voltage

B931 3.95 V 88.9V 3.35V

B911 3.98V 87.1V 3.38V

B921 4V 86.1V 3.42V

V923 86V 6.8V 86.4V

V932 88.7V 170.4V 89V

V912 86.9V 175.2V 87.3V

V913 87.1V 6.82V 87.4V

V933 88.7V 6.83V 89V

V922 85.9V 175V 86.2V

12. VE01 CHASSIS MANUAL ALIGNMENT PROCEDURE

In order

to enter in service menu and design menu following procedure needs to be followed.

• 12A. Procedure to enter in service mode

1) Press Menu Key on Remote Handset.

2) Press 6483 on remote handset.

3) M – appears on the Screen.

4) Press 1234, set will enter into Service Mode.

5) To Change the value of parameter press Volume + / Volume – Key, To move from one

parameter to another press Channel + / Channel – Key on Remote Handset.

6) Press Stand By Key on remote handset to come out of Service Mode.

• 12B. Procedure to Enter Into Design Mode

1) Press Menu Key on Remote Handset.

2) Press 6483 on remote handset.

3) M – appears on the Screen.

4) Press 5 on remote handset.

5) Press Lock key on remote handset, set will enter into Design Mode.

26

Page 27

6) To Change the value of parameter press Volume + / Volume – Key, To move from one

parameter to another press Channel + / Channel – Key on Remote Handset.

7) Press “Stand-By” Key to come out of Design Mode.

• 12C. White Balance Adjustment

1) Select R,G, B cut off parameter in Menu 3 of service mode and adjust these

parameters. Standard settings of these parameters are RD=32, GD=32, BD=32

2) Select the RGB drive parameters RB, GB in menu 3 and adjust this parameter.

Default setting of these parameter is RB= 32, GB=32.

3) Select Sub brightness parameter SB in menu 3 and adjust to get proper white balance.

The default value of SB=40.

• 12D. Screen Adjustment :-

1) Select parameter SC in menu 3 of service mode .

2) Increase the value of SC by using channel up key so that thin white line will be visible

on the screen

3) Adjust the screen intensity by varying screen pot of fbt using insulated screw driver

until a thin horizontal line is just visible.

:- ( In Field)

(In Field)

. OTHER SERVICE MODE ADJUSTMENTS: - can be done by entering into service

12E

mode by applying the suggested procedure and setting the default value mentioned below.

Few cases defaults values can be changed in a small variation for customer satisfaction.

SERVICE PRAMETERS: MENU 1

Parameter Variation Default Setting Remarks

V SLOPE 0-63 31 for 50Hz & 36 for 60Hz For adjusting picture vertical center

V SHIFT 0-63 41 for 50Hz & 36 for 60Hz For shifting picture vertical position

V SIZE 0-63 31 for 50Hz & 36 for 60Hz For adjusting Vertical amplitude

V SC 0-63 10 for 50Hz & 10 for 60Hz For adjusting Vertical S-Correction

H SHIFT 0-63 38 for 50Hz & 37 for 60Hz For adjusting picture H position

PROG NO. 1.

27

Page 28

SERVICE PRAMETERS: MENU 2

Parameter Variation Default Setting Remarks

AGC 0-63 28 For RF AGC adjustment

Search Speed 0-3 0

SERVICE PRAMETERS: MENU 3

Parameter Variation Default Setting Remarks

BT 0-100 75

CT 0-100 50

SC 3 Screen variation.

RB 0-63 32 R drive.

GB 0-63 32 G Drive

RD 0-63 32 R cut off

GD 0-63 32 G cut off

BD 0-63 32 B cut off

SB 0-63 42 Sub brightness

SERVICE PRAMETERS: MENU 4

Parameter Variation Default Setting Remarks

OSD.V.POS 0-63 16 for 50Hz & 8 for 60Hz To adjust OSD Vertical position

OSD.H.POS 0-63 27 for 50Hz & 24 for 60Hz To adjust OSD horizontal position

DESIGN PRAMETERS: MENU 0

Parameter Variation Default Setting

SUB CONTRAST 0-63 63

SUB COLOR 0-63 63

SUB SHARPNESS 0-63 63

SUB TINT 0-63 31

FS-VL-H 0-255 0

FS-VL-L 0-255 0

FS-VH-H 0-255 0

FS-VH-L 0-255 0

RGB.HSH.OFFSET 0-15 6

28

Page 29

DESIGN PRAMETERS: MENU 5

Parameter Variation Default Setting

PP Mode Std / dynamic / mild

Brightness 0-100 75 / 75 / 75

Contrast 0-100 75 / 100 / 50

Color 0-100 50 / 50 / 50

Sharpness 0-100 50 / 50 / 50

SC Brightness 0-63 20

Cool BD Offset 0-32 10

Warm RD Offset 0-32 10

YD PAL 0-15 8

YD NTSC 0-15 8

YD SECAM 0-15 8

YD AV PAL 0-15 8

YD AV NTSC 0-15 8

YD AV SECAM 0-15 8

DESIGN PRAMETERS: MENU 6

Parameter Variation Default Setting

OSO 0-1 1

AGC SPEED 0-3 1

FFI 0-1 0

FSL 0-1 0

FMWS 0-1 0

HP2 0-1 0

RPO 0-1 1

NTSC MATRIX JAPAN / U.S USA

VOL PIN OPEN DRAIN/ PUSH

PULL

VIDEO OUT IF / CVBS IF

OPEN DRAIN

29

Page 30

DESIGN PRAMETERS: MENU 7

Parameter Variation Default Setting

IF 38.9 / 38 / 58.75/ 45.75 38.9MHZ

DK OFF / ON ON

I OFF / ON ON

BG OFF / ON ON

M OFF / ON OFF

SIF PRIORITY DK/ I/ M/ BG BG

AV2 OFF/ ON OFF

SVHS OFF/ON ON

YUV OFF/ON OFF

EURO AV OFF/ON ON

S CURVE P1 0-70 20

S CURVE V1 0-75 40

S CURVE P2 0-100 70

S CURVE V2 0-100 75

DESIGN PRAMETERS: MENU 8

Parameter Variation Default Setting

CATHOD LEVEL 0-15 4

UOC VOLUME OFF / ON OFF

FM ATT 0-63 50

TDA 9874 AVL 0-3 1

TDA 9874 CAIN 0-30 15

DUAL OUT OFF / ON OFF

AUTO SOUND OFF / ON ON

HEADPHONE 0-3 0

TRU BASS 0-1 0

DEFAULT LANG 0-17 0

LANG OPT FRENCH / RUSSIAN / RU FRENCH

LANG SW ON / OFF ON

30

Page 31

DESIGN PRAMETERS: MENU 9

Parameter Variation Default Setting

BAND MODE 0-2 1

START ON 0-2 1

ON DELAY 6-15 10

LOGO OFF / ON OFF

NVM LOGO OFF / ON OFF

TXT BRIGHTNESS 0-63 20

SPANISH BIT OFF / ON OFF

NOT 0 OFF / ON ON

NOT 1 OFF / ON ON

NOT 2 OFF / ON ON

NOT 3 OFF / ON ON

NOT 4 OFF / ON ON

ZOOM V63 V56

WIDE V0 V2

31

Page 32

SpeakerBLOCK DIAGRAM

Key

Tuner

IR

Audio Processor

TDA 9859

Memory

AT24C16

Micro Processor (UOC IC )

TDA 9351

FRONT

Audio Output

AN17821

SWITCH IC

HEF4052BP

Video Amplifier

SCART

CRT

SMPS

AV

110VDC

28V

13V

8V

5V

Horizontal

O/P driver

Vertical output

STV 9302A

Horizontal

O/P TR.

FBT

Page 33

V

r

.

V

r

V

r

C

VE01 CHASSIS ALLIGNMENT PROCEDURE ON MANUFACTURING LINE

E

T

PRODUCT : CT

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS CUTTER

1 110006308 TIE,CABLE,PLASTIC,2.5X100mm 2

1 WRAP THE SPEAKER CONNECTOR TO TIE CABLE METAL SLEEVE AT SPEAKER FITTING SCREW.

2 TIE THE SPEAKER CONNECTOR TO RIGHT SIDE PORTION OF DEGAUSSING COIL SUCH THAT IT WOULD NOT

HANG OVER THE CHASSIS.

3 TIE THE DEGUASSING COIL CONNECTOR TO DEGAUSSING COIL.

4 CUT THE EXCESS LENGTH OF ALL THE TIES.

DO NOT LEAVE ANY CUT PORTION OF TIE ON THE CHASSIS

PRODUCT : CT

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS SERVICE REMOTE

1 TV SET 1

1 BEFORE SWITCHING ON THE TV SET , CHECK THAT CHASSIS DOCKING AND HARNESING HAVE DONE PROPERLY OR NOT.

2 CHECK THAT DEGAUSSING CONNECTOR HAS CONNECTED.

3 CONNECT RF SIGNAL TO TUNER.

4 SWITCH ON THE TV SET AND ADJUST THE 'SCREEN' AND 'FOCUS' POT OF FBT FOR CLEAR PICTURE.

5 CHECK THAT POWER ON LED IS GLOWING WITH NORMAL INTENSITY.

6 CHECK POWER ON/OFF SWITCH OPERATION BY SWITCHING THE SWITCH ON/OFF TWO TO THREE TIMES.

7 CHECK FOR THE PROBLEMS LIKE CPT GAP, SWITCH OFF SPOT, STRAY EMISSION ,ETC.

8 SELECT CHANNEL "EU 2CH" AND CHECK THAT 'SUB BRIGHTNESS' PATTERN HAS APPEARED .

9 CHECK FOR CHANNEL TUNNING, ELSE TUNE THE PROGRAMS USING "AUTO SEARCH" IN SEARCH MENU.

10 CHECK THE VOLUME VARIATION FROM ZERO TO MAXIMUM. OBSERVE THAT VARIATION IS NOT INTERMITANT. IT SHOULD BE

11 CHECK THE OPERATION OF CH UP/ CH DN/ VOL UP/ VOL DN/ MENU KEYS .

12 CHECK THAT THESE KEYS ARE NOT HARD TO OPERATE.

13 CHECK THE TV SET ASTHETICALLY

PRODUCT : CT

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS DIGITAL PANEL METER

1 TV SET 1 ALIGNER

2 REMOTE CHECKED BY

1 SWITCH ON THE SET.

2 CONNECT THE RF CORD TO TUNER.

3 SELECT THE 'STANDARD' MODE OF PICTURE CONTROL.

4 CONNECT THE DPM POSITIVE PROBE TO CATHODE OF DIODE "VD631" .

( DPM NEGATIVE PROBE IS INTERNALLY CONNECTED TO CHASSIS GROUND)

5 ROTATE THE PRESET "VR 631" USING ALIGNER TO SET +B VOLTAGE + 115V +/- 0.5V D

STAGE: HARNESING AT F-A LIN

STAGE: SWITCH ON

STAGE: +B VOLTAGE ALIGNMEN

PCB/ASSY :F.A. Roadsta

PCB/ASSY : Roadsta

PCB/ASSY :F.A. Roadsta

SHEET : 1 OF 1

SHEET : 1 OF 1

SHEET : 1 OF 1

1

Page 34

PRODUCT : CT

V

A

r

N

.

V

r

V

E

r

T

STAGE: SCREEN ADJUSTMEN

PCB/ASSY :F

Roadsta

SHEET : 1 OF 1

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS SERVICE REMOTE

1 TV SET 1 FEVIBONAD

2 INSULATED SCREW CHECKED BY

3 DRIVER

NOTE : WARM UP THE TV SET FOR AT LEAST 20 MINUTES ( DURING SOAKING AREA)

1 SELECT DIGITAL / RETMA / LION HEAD PATTERN ,

2 PRESS "MENU+6483" KEYS SEQUENCE TO ACCESS THE MANUFACTURING MODE.

3 PRESS KEY '3' TO APPEAR 'SERVICE MENU 3' ON SCREEN.

4 SELECT PARAMETER "SC " BY PRESSING CHANNEL UP/DN KEY .

5 PRESS 'VOL UP' KEY THEN A THIN HORIZONTAL LINE WILL BE DISPLAYED ON SCREEN.

6 ADJUST THE SCREEN INTENSITY BY VARYING SCREEN POT OF FBT USING INSULATED SCREW DRIVER UNTIL A THIN HORIZO

LINE IS JUST VISIBLE.

7 PRESS "VOL DN" KEY TO APPEAR ORIGINAL PATTERN.

8 APPLY THE FEVIBOND ON "SCREEN" POT. OF FBT

PRODUCT : CT

STAGE: FOCUS AND CONVERGENCE PCB/ASSY : F.A. Roadsta

SHEET : 1 OF 1

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS SERVICE REMOTE

1 TV SET 1 GLUE

2 PNUE. SCREW DRIVER CHECKED BY

3

FEVIBONAD

INSULATED SCREW APPROVED BY

DRIVER

TIGHTENING TORQUE OF SCREW DRIVER- 10 TO 15 kg.cm and TV SET IS FACING TOWARDS EAST.

FOCUS ADJUSTMENT :-

1 SELECT LION HEAD PATTERN.( EU 5CH) . CHOOSE SELECTABLE PICTURE MODE "STANDARD".

2 ADJUST THE FOCUS KNOB ON FBT USING INSULATED SCREW DRIVER , SO THAT '30' AT THE DIAGONAL CENTRE ON LION HEA

WILL GET AS SHARP AS POSSIBLE.

THIS SYMBOL INDICATES THE LOCATION OF FOCUS ADJUSTMENT CHECK ON SCREEN.

CONVERGENCE ADJUSTMENT :-

1 SWITCH OVER TO CROSS HATCH PATTERN.

2 BY TURNING THE 4 POLE MAGNET, MATCH THE RED AND BLUE LINES AT THE CENTRE. SHIFT THE RED AND BLUE LINE

OVER THE GREEN LINE BY USING 6 POLE MAGNET.

3 TIGHTEN THE CPM LOCK. BE CAREFUL NOT TO MOVE THE OTHER RINGS/MAGNETS AT THIS TIME.

4 CHECK AND ADJUST THE PICTURE FOR TILT.ADJUST THE TILT BY ADJUSTING THE YOKE.

5 APPLY GLUE ON BOTH SCREEN AND FOCUS KNOB OF FBT AFTER ADJUSTMENT OF FOCUS.

THIS HORIZONTAL

LINE MATCHING

WITH EXPOSURE

THIS HORIZONTAL

LINE MATCHING WITH

EXPOSURE POINTS

POINTS

EXPOSURE POINTS

ON THE SCREEN

EXPOSURE POINTS

ON THE SCREEN

FOR TFT CPT MODELS: TILT=0 mm TILT CHECK

FOR CONVENTIONAL CPT MODELS: TILT=2 mm FOCUS CHECK

NOTE: DO NOT TOUCH TO ANY PART OF FBT.

PRODUCT : CT

STAGE: CONVERGENC

PCB/ASSY : F.A. Roadsta

SHEET : 1 OF 2

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS SERVICE REMOTE

1 TV SET

CONVERGENCE ADJUSTMENTS

NOTE : Before attempting any convergence adjustments, the

receiver should be operated for at leat fifteen minutes.

CENTER CONVERGENCE ADJUSTMENT :

1.Select the Cross-hatch pattern (EU 4CH) .

2.Set the brightness and contrast for well defined

pattern.

3. Adjust two tabs of the 4-Pole magnets to change the

angle between them . ( See fig.-01 & 02) and

superimpose red and blue vertical lines in the center

area of picture screen.

4.Turn the both tabs at the same time keeping the angle

constant to superimpose red and blue horizontal

lines at the center of the screen. (See fig-04 & 02)

5.Adjust two tabs of 6-Pole magnets to superimpose

red/blue line and green one .Adjusting the angle

affects the vertical lines and rotating both magnets

affects the horizontal lines.

6.Repeat adjustments 3,4,5 keeping in mind red, green

and blue movement , because 4-Pole Magnets and 6Pole Magnets have mutual interaction and make line

CIRCUMFERENCE CONVERGENCE ADJUSTMENT:

1. Loosen the clamping screw of deflection yoke slightly to allow the

yoke to tilt.

2.Temporarily put a wedge as shown in fig1. ( Do not remove cover

paper on adhesive part of the wedge.)

3.Tilt front of the deflection yoke up or down to obtain better

convergence in circumference (see fig.3). Push the mounted

wedge in to the space between picture tube and the yoke, to fix

the yoke temporarily.

4.Put other wedge in to bottom space and remove the cover paper to

stick.

5.Tilt front of the yoke right or left to obtain better convergence in

circumference. (see fig.3)

6.Keep the yoke position and put another wedge in either upper

space. Remove cover paper and stick the wedge on picture tube to

fix the yoke.

7.Detach the temporarily mounted wedge and put it in another upper

space.Stick it on picture tube to fix the yoke.

8.After fixing three wedges , recheck overall convergence. Tighten

the screw firmly to fix the yoke and check the yoke is firm.

9.stick three adhesive tapes on wedges as shown in fig.o.

2

Page 35

V

r

T

Convergence

magnets of

CPM Assy

Convergence Adjustment: 2 OF 2 PREPARED BY

Screw to

Tighten CPM

CHECKED BY

Assy

APPROVED BY

FIG-01

FIG-02

FIG-03

PRODUCT : CT

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS SERVICE REMOTE

1 TV SET 1

SELECT RETMA PATTERN (EU 5CH).

PRESS "MENU+6483" KEYS SEQUENCE TO ACCESS THE MANUFACTURING MODE. THEN PRESS HOTKEY "1".

TO ACCESS 'SERVICE MENU-1'.

1 .HORIZONTAL CENTERING: H-SHIFT

2 VERTICAL LINERITY ADJUSTMENT: V-SLOPE

3 VERTICAL RASTER SHIFT: V-SHIFT

4 VERTICAL HEIGHT** V-SIZE

5 VERTICAL SCROLL V-SC

STAGE: GEOMETRIC ALIGNMEN

SELECT PARAMETER "H-SHIFT" BY USING CHANNEL DOWN KEY.

ADJUST "H-SHIFT" VALUE BY USING VOLUME UP/DN KEYS SUCH THAT THE PATTERN

IS LOCATED HORIZONTALLY AT CENTRE.

SELECT "V-SLOPE" & ADJUST IT BY VOLUME UP/DN KEY TO ADJUST CENTRE DOTTED LINE OF RETMA

PATTERN TO THE TOP EDGE OF BLACK HALF PATTERN ( i.e. EXACTLY THE TOP HALF PORTION OF

RETMA PATTERN IS VISIBLE).

SELECT "V-SHIFT" AND ADJUST IT SUCH THAT PATTERN WILL APPEAR AT MECHANICAL

CENTRE OF THE PICTURE TUBE.

SELECT "V-SIZE" AND ADJUST IT SUCH THAT HEIGHT OF THE LION HEAD PATTERN BECOMES ' 9 - 9'.

ACCEPTABLE RANGE IS 8.9 TO 9.1. ( REFER FIG- )

SELECT "V-SC" AND ADJUST IT SUCH THAT BIG CIRCLE WILL LOOK PERFECT CIRCLE.

PCB/ASSY :F.A. Roadsta

FIG-04

SHEET : 1 OF 1

USE "STAND BY" KEY TO QUIT THE MANUFACTURING/SERVICE MODE.

3

Page 36

PRODUCT : CT

V

r

V

T

T

T

E

S

S

S

R

R

OW

STAGE: OSD ALIGNMEN

PCB/ASSY :F.A. Roadsta

SHEET : 1 OF 1

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS SERVICE REMOTE

1 TV SET 1

PRESS "MENU+6483" KEYS SEQUENCE TO ACCESS THE MANUFACTURING MODE. THEN PRESS HOTKEY "1".

SELECT RETMA PATTERN (EU 5CH).

OSD DISPLAY ADJUSTMENT ** VERTICAL AND HORIZONTAL *** OSDH AND OSDV

SELECT SERVICE MENU -4 BY PRESSING HOTKEY "4"..

A BIG RECTANGLE WILL APPEAR ON SCREEN.

1 SELECT "OSD V-POS" BY CH.DN KEY. AND ADJUST DOTTED RECTANGLE AT THE VERTICAL CENTRE OF SCREEN.

2 SELECT "OSD H-POS" BY CH.DN KEY. AND ADJUST DOTTED RECTANGLE AT THE HORIZONTAL CENTRE OF SCREEN.

USE "STAND BY" KEY TO QUIT THE MANUFACTURING/SERVICE MODE.

OSD ALIGNMENT ON NTSC PATTERN:

2 SELECT COLOUR BAR+CIRCLE PATTERN ( NTSC SYSTEM )

SELECT PARAMETER "OSD V-POS " & "OSD H-POS" BY CHANNEL UP/ DN KEYS . ADJUST THE PARAMETER VALUES SUCH

THAT A BIG DOTTED RECTANGLE SHOULD BE SYMMETRICALLY LOCATED ON RETMA PATTERN.

PRODUCT : CT

STAGE: WHITE BALANCE ADJUSTMEN

PCB/ASSY : F.A. CHASSIS : ALL SHEET : 1 OF 1

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS SERVICE REMOTE

1 TV SET 1

INTRODUCTION TO WHITE BALANCE ADJUSTMENT WINDOW

GREEN AND BLUE CUT OFF

STATUS BAR

MODEL

SELECTION

WIND

GREEN AND

BLUE DRIVE

TATUS BAR

SUB

CONTRAST

STATUS BA

CURRENT

STATUS

SUB

BRIGHTNESS

STATUS BA

WHITE BALANCE

THIS INDICATES WHI

BALANCE CONDITION

"NG" OR "GOOD"

TOLERANCE OF

TARGET VALUES

TARGET VALUES OF

WHITE BALANC

4

Page 37

PRODUCT : CT

V

r

O

S

P

S

S

E

9

V

r

K

V

r

4

K

E

T

R

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS SERVICE REMOTE

1 TV SET 1

NOTE : WARM UP THE TV SET FOR AT LEAST 20 MINUTES ( DURING SOAKING AREA)

ENSURE "TONE" IN SETTINGS MENU IS "NORMAL" AND SELECTABLE PICTURE MODE IS "STANDARD"..

1 ENSURE THAT THE MODEL NAME DISPLAYED IN 'MODEL INFORMATION WINDOW' IS CORRECT.

2 TV SET WILL STOP IN FRONT OF CAMERA SENSOR ,CONNECT WHITE BALANCE SIGNAL FROM WHITE BALANCE TESTER.

TO TUNER INPUT OF SET.

3 AUTO DEGAUSSING WILL START.OBSERVE THAT , WHILE DEGAUSSING ,MONITOR DISPLAY WILL

APPEAR VIBRATING.AFTER DEGAUSSING , SENSOR WILL COME FORWARD TILL IT JUST TOUCHES TO SCREEN.

4 ENSURE THAT THE SET POSITION IS SUCH THAT SCREEN WILL BE IN FRONT OF SENSOR.AS WELL AS NEAR TO IT.

TAKE CARE THAT NO OSD WILL BE IN FRONT OF SENSOR SO THAT IT WILL NOT GET SENSED BY SENSOR WHILE TESTING

AND ADJUSTMENT OF WHITE BALANCE.

5 PRESS "MENU+6483" KEY AND HOTKEY "3" , SELECT SERVICE PARAMETERS FOR RGB CUTOFF

7 ADJUSTMENT & ADJUST IT BY VOL. UP/ VOL. DN KEYS. IF NEEDED ADJUST THE VALUES FOR PARAMETERS OF RGB DRIVES

6 IF NECESSARY, ADJUST THE 'SUB BRIGHTNESS' VALUE BY SELECTING APPROPREATE SERVICE PARAMETER.

7 THE ADJUSTMENTS ARE MUTUALLY INTERDEPENDENT SO ADJUST ALL ABOVE MENTIONED PARAMETERS TILL THE RED BL

BAR COMES AT CENTRE AND "NG" DISPLAY TURNS IN TO "GOOD" .

SERVICE PARAMETERS:-

RGB CUTOFF'

UOC/VX05T/ PI

RDC RD RD R CUT RDC y= 292+/- 5

GDC GD GD G CUT GDC FOR LOW BEAM Y=15

BDC BD BD B CUT BDC FOR HIGH BEAM Y=113

RGB DRIVE

GDRV GB GB GDRV GDRV FOR TOSHIBA BRAND

BDRV RB RB BDRV BDRV X= 260

SUB BRIGHTNES

SBRT

USE "STAND BY" KEY TO QUIT THE MANUFACTURING/SERVICE MOD

PRODUCT : CT

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS REMOTE

1 TV SET 1

1 CONNECT THE RF SIGNAL CORD TO TUNER.

2 CHECK FOR VOLUME VARIATION FROM ZERO TO MAX. (FOR CH-02 & CH-05) SOUND SHOULD BE DISTORTION

FREE AT MAX. VOLUME LEVEL.

3 CHECK FOR HISSING SOUND , DISTORTED SOUND PROBLEMS..

4 CHECK SOUND MUTE, AVL.

5 BANG THE CHASSIS FOR LOOSE CONTACT .

6 REMOVE THE RF SIGNAL CORD FROM TUNER.

7 FOR DETAILS, PLEASE REFER USERS GUIDE BOO

PRODUCT : CT

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS

1 TV SET 1 SERVICE REMOTE

2 EXT. DEGAUSSING COIL CHECKED BY

1 CONNECT RF SIGNAL CORD TO TUNER .

2 SELECT CHANNEL "EU 5CH" .CHECK FOR GEOMETRICAL ALIGNMENTS, DISPLAY ALIGNMENTS,(HEIGHT & WIDTH SHOULD BE

HEAD PATTERN.)

LION HEAD PATTERN SHOULD LOOK LINEAR AND SYMMETRICAL .

3 CHECK FOR FOCUS ADJUSTMENT AT DIAGONAL CENTRE OF PICTURE TUBE. '30' DIGITS ON LION HEAD

PATTERN SHOULD BE SHARP VISIBLE.

4 PRESS "ZOOM' KEY ON REMOTE TO SELECT "ZOOM' MODE AND CHECK THAT HEIGHT OF THE RETMA PATTERN IS

SELECT "WIDE" MODE AND CHECK THAT PATTERN HEIGHT IS 75% OF THE SCREEN.

5 SELECT CROSS HATCH PATTERN (EU 4CH) AND CHECK FOR CONVERGENCE QUALITY. HORIZONTAL AND VERTICAL LINES

SHOULD BE WHITE.

6 CHECK FOR SUB BRIGHTNESS ON CHANNEL ( EU 2CH).. SUB BRIGHTNESS SHOULD BE SUCH THAT 5 & 1/2 BARS ON

SUB BRIGHTNESS PATTERN WITH PICTURE MODE "STANDARD" ARE VISIBLE .

IF REQUIRED ADJUST PARAMETER "SB" IN SERVICE MENU-HOTKEY-3 FOR SPECIFIED SUB BRIGHTNESS ALIGNMENT.

7 CHECK THAT OSD DISPLAY IS NOT CUTTING ON COLOUR BAR+CIRCLE PATTERN WHEN 'ZOOM' MODE IS SELECTED.

8 CHECK FOR P-CONTROL- CONTRAST,BRIGHTNESS,COLOUR ,SHARPNESS.

9 CHECK FOR ALL BANDS TUNING WITH THEIR RESPECTIVE SOUND.

10 CHECK FOR WHITE BALANCE, TILT ALIGNMENT.& COLOUR PATCH.

11 CHECK FOR SELECTABLE PICTURE MODES AS STANDARD,DYNAMIC, MILD , USER.

12 CHECK CPT RELATED PROBLEMS (SCRATCH/CONVERGENCE-DYNAMIC&STATIC / YOKE TILT,CPT GAP OR TILT).

13 CHECK FOR RASTER COLLAPSE DURING SWITCH OFF, CHECK FOR THE PROBLEMS SUCH AS DAMPING

BAR, BLOOMING, RETRACE LINES, STRAY EMISSION ETC.

1

FOR DETAILS, PLEASE REFER USERS GUIDE BOO

USE "STAND BY" KEY TO QUIT THE MANUFACTURING/SERVICE MOD

STAGE: WHITE BALANCE ADJUSTMEN

OC POC/ROADSTAR TSB2 VX04T X= 275+/- 5

BRTSUB-BRI BRTS BRTC FOR LOW BEAM Y= 5

STAGE: SOUND Q.C.-1 PCB/ASSY :F.A. Roadsta

STAGE: PICTURE Q.C.-1 PCB/ASSY :F.A. Roadsta

PCB/ASSY : F.A. Roadsta

WHITE BALANCE METE

DSPM2129

CR

CG

CB

WG

WB

SB

SHEET : 2 OF 2

SPECIFICATIONS:

FOR ALL OTHER BRANDS

y= 271

FOR HIGH BEAM Y= 9

SHEET : 1 OF 1

SHEET : 1 OF 1

5

Page 38

PRODUCT : CT

V

G

V

S

V

G

r

V

S

r

V

G

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS

1 TV SET 1 REMOTE

TELETEXT CHECKING:

1 OBSERVE THAT "P100 (INDEX PAGE OF TELETEXT) HAS APPEARED. PRESS "TXT/MIX" KEY AGAIN AND OBSERVE THAT THE TE

2 PAGE HAS SUPERIMPOSED ON THE COLOUR BAR PATTERN. SELECT PAGE "P102" BY USING PROGRAM UP KEY AND OBSER

3 THAT " *** LARGE CHARACTERS *** " PAGE HAS APPEARED. . PRESS "TV/AV" KEY TO QUIT FROM TELETEXT MODE.

4 SELECT SETTINGS MENU AND CHECK THAT TXT=EAST/WEST " FUNCTION.

5 PRESS "SUB CODE " KEY ON REMOTE & CHECK "DK/I/BG" OPTION

PRODUCT : CT

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS

1 TV SET 1 REMOTE

2 HV METER CHECKED BY

3 HAND GLOVES

4 BALUN

NTSC CHECK:

1 SELECT COLOUR BAR+CIRCLE PATTERN.

2 SELECT COLOUR SYSTEM=NTSC IN 'SETTINGS ' MENU.

3 SELECT TINT OPTION IN PICTURE MENU. AND VARY ITS VALUE .

4 WHILE TINT VARIATION ,CHECK THAT RED COLOUR IS CHANGING.

5 IF FOUND ANY ABNORMALITY IN CHECKING , PLEASE REJECT THE SET.

H.V. TEST

1 REMOVE THE MAINS CORD FROM PALLET AND INSERT IT IN HV SOCKET.(SPECIALLY PROVIDED)

2 SNAP SPECIAL BALUN INTO TUNER POINT.

3 TOUCH THE HV TERMINAL TO BALUN POINT.

4 PRESS THE TEST /ENABLE BUTTON ON HV TESTER,IF BUZZER OPERATES FOR UNSPECIFIED TIME THEN REJECT THE SET.

5 REMOVE MAINS CORD FROM SOCKET AND INSERT IN PALLET SOCKET.

6 RELEASE THE SET FOR NEXT STAGE.

AFTER CHECKING, MAKE "M-MODE" ON BY PRESSING "SERVICE KEY+DEMO KEY".

SETTING PARAMETER: 1.1KV, 3mA, FOR 3 SEC.

PRODUCT : CT

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS NTSC PATTERN

1 TV SET 1 GENERATOR

3 SERVICE REMOTE

4 FOR NTSC ALIGNMENTS

1 SELECT NTSC PATTERN .( COLOR BAR+CIRCLE PATTERN )

2 PRESS "MENU+6483" KEYS SEQUENCE TO ACCESS THE MANUFACTURING MODE. THEN PRESS HOTKEY "1" TO ENABLE MENU-1.

1 .HORIZONTAL CENTERING: H-SHIFT

2 VERTICAL LINERITY ADJUSTMENT: V-SLOPE

STAGE: TELETEXT CHECKIN

SELECT COLOUR BAR PATTERN. PRESS "TXT/MIX" KEY ON REMOTE

STAGE: NTSC / H.V. CHECKIN

STAGE: NTSC ALIGNMENT

SELECT PARAMETER "H-SHIFT" BY USING CHANNEL DOWN KEY.

ADJUST "H-SHIFT" VALUE BY USING VOLUME UP/DN KEYS SUCH THAT THE PATTERN

IS LOCATED HORIZONTALLY AT CENTRE.

SELECT "V-SLOPE" & ADJUST IT BY VOLUME UP/DN KEY SUCH THAT EXACTLY THE TOP HALF PORTION OF

RETMA PATTERN IS VISIBLE.

PCB/ASSY :F.A. CHASSIS :ROA SHEET : 1 OF 1

PCB/ASSY :F.A. Roadsta

PCB/ASSY :F.A. Roadsta

SHEET : 1 OF 1

SHEET : 1 OF 1

3 VERTICAL RASTER SHIFT: V-SHIFT

4 VERTICAL HEIGHT** V-SIZE

5 VERTICAL SCROLL V-SC

PRODUCT : CT

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS REMOTE H-SET

1 TV SET 1 MONITOR av out SET

2 AV CORDS CHECKED BY

3 monitor av in tv set

CONNECT THE RF SIGNAL CORD TO TUNNER. SELECT CHANNEL "EU 2CH".

AV IN CHECKING 1 KEEP MONITOR SET IN TV MODE AND 'TESTING TV SET' IN 'EURO AV' MODE BY USING "TV/AV" KEY ON REMOTE.

2 CHANNEL "EU 2CH" IS SELECTED IN MONITOR TV SET.

3 CONNECT "VIDEO OUT" AND "AUDIO OUT" CORD OF MONITOR SET TO "VIDEO IN " AND "AUDIO IN" JACKS OF TESTING TV SET

4 LISTEN FOR NORMAL SOUND AND PICTURE OF CHANNEL "EU 2CH" PRESENT IN THE "TESTING TV SET" .

5 CHECK THE AUDIO FOR BOTH THE AUDIO IN JACKS.

AV OUT CHECKING:1 KEEP MONITOR SET IN 'AV' MODE AND 'TESTING TV SET' IN 'TV' MODE BY USING "TV/AV" KEY ON REMOTE.

2 SELECT SUB BRIGHTNESS PATTERN (EU 2CH) ON TESTING TV SET.

3 CONNECT "VIDEO IN" AND "AUDIO IN" CORD OF MONITOR SET TO "VIDEO OUT " AND "AUDIO OUT" JACKS OF TESTING TV SET

4 LISTEN FOR NORMAL SOUND AND PICTURE OF CHANNEL "EU 2CH" PRESENT IN THE "MONITOR TV SET" .

5 REMOVE THE AV CORDS AFTER TESTING.

CHECK "CD PLAY=ON/OFF" FUNCTION IN SOUND MENU

SELECT "V-SHIFT" AND ADJUST IT SUCH THAT PATTERN WILL APPEAR AT MECHANICAL

CENTRE OF THE PICTURE TUBE.

SELECT "V-SIZE" AND ADJUST IT SUCH THAT HEIGHT OF THE LION HEAD PATTERN BECOMES ' 9 - 9'.

ACCEPTABLE RANGE IS 8.9 TO 9.1. ( REFER FIG- )

SELECT "V-SC" AND ADJUST IT SUCH THAT BIG CIRCLE WILL LOOK PERFECT CIRCLE

STAGE: AV CHECKIN

PCB/ASSY :F.A. Road Star SHEET : 1 OF 1

6

Page 39

PRODUCT : CT

V

2

Y

V

2

5

K

V

G

O

S

K

V

E

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS

1 TV SET 1 REMOTE

2 HAMMER CHECKED BY

1 CONNECT THE RF SIGNAL CORD TO TUNER.

2 CHECK FOR VOLUME VARIATION FROM ZERO TO MAX. (FOR CH-02 & CH-05) SOUND SHOULD BE DISTORTION

FREE AT MAX. VOLUME LEVEL.

3 CHECK FOR HISSING SOUND , DISTORTED SOUND PROBLEMS..

4 CHECK SOUND MUTE, AVL.

5 BANG THE CHASSIS FOR LOOSE CONTACT .

6 REMOVE THE RF SIGNAL CORD FROM TUNER.

7 FOR DETAILS, PLEASE REFER USERS GUIDE BOOK.

SHOCK TEST:

1 GENTLY HIT THE HAMMER ON TOP SIDE OF FRONT COVER. CHECK FOR ANY ABNORMALIT

PRODUCT : CT

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS

1 TV SET 1 SERVICE REMOTE

1 CONNECT RF SIGNAL CORD TO TUNER .

2 SELECT CHANNEL "EU 5CH" .CHECK FOR GEOMETRICAL ALIGNMENTS, DISPLAY ALIGNMENTS,(HEIGHT & WIDTH SHOULD BE

HEAD PATTERN.)

LION HEAD PATTERN SHOULD LOOK LINEAR AND SYMMETRICAL .

3 CHECK FOR FOCUS ADJUSTMENT AT DIAGONAL CENTRE OF PICTURE TUBE. '30' DIGITS ON LION HEAD

PATTERN SHOULD BE SHARP VISIBLE.

4 PRESS "ZOOM' KEY ON REMOTE TO SELECT "ZOOM' MODE AND CHECK THAT HEIGHT OF THE RETMA PATTERN IS

SELECT "WIDE" MODE AND CHECK THAT PATTERN HEIGHT IS 75% OF THE SCREEN.

5 SELECT CROSS HATCH PATTERN (EU 4CH) AND CHECK FOR CONVERGENCE QUALITY. HORIZONTAL AND VERTICAL LINES

SHOULD BE WHITE.

6 CHECK FOR SUB BRIGHTNESS ON CHANNEL ( EU 2CH).. SUB BRIGHTNESS SHOULD BE SUCH THAT 5 & 1/2 BARS ON

SUB BRIGHTNESS PATTERN WITH PICTURE MODE "STANDARD" ARE VISIBLE .

IF REQUIRED ADJUST PARAMETER "SBI" IN SERVICE MENU-HOTKEY-3 FOR SPECIFIED SUB BRIGHTNESS ALIGNMENT.

7 CHECK THAT OSD DISPLAY IS NOT CUTTING ON COLOUR BAR+CIRCLE PATTERN WHEN 'ZOOM' MODE IS SELECTED.

8 CHECK FOR P-CONTROL- CONTRAST,BRIGHTNESS,COLOUR ,SHARPNESS.

9 CHECK FOR ALL BANDS TUNING WITH THEIR RESPECTIVE SOUND.

10 CHECK FOR WHITE BALANCE, TILT ALIGNMENT.& COLOUR PATCH.

11 CHECK FOR SELECTABLE PICTURE MODES AS STANDARD,DYNAMIC, MILD , USER.

13 CHECK CPT RELATED PROBLEMS (SCRATCH/CONVERGENCE-DYNAMIC&STATIC / YOKE TILT,CPT GAP OR TILT).

14 CHECK FOR RASTER COLLAPSE DURING SWITCH OFF, CHECK FOR THE PROBLEMS SUCH AS DAMPING

BAR, BLOOMING, RETRACE LINES, STRAY EMISSION ETC.

1

FOR DETAILS, PLEASE REFER USERS GUIDE BOO

PRODUCT : CT

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS

1 TV SET 1 REMOTE

SWITCH ON THE SET.

SELECT FOLLOWING FUNCTIONS 1 SELECT "SETTINGS" MENU AND CHECK 'EURO AV' FOR 'Y/C, RGB, VIDEO' OPTIONS.

2 IN SETTINGS MENU - CHECK TONE=NORMAL, WARM, COOL.

3 CHECK 'BLACK STRETCH' IN SETTINGS MENU-BRIGHTNESS INCREASES WHEN BLACK STRETCH IS 'OFF'.

4 SELECT "TIMER" MENU AND CHECK THAT ON TIMER, OFF TIMER, REPEAT SETTINGS ARE AVAILABLE.

5 SELECT "SETTINGS--->LANGUAGE" MENU AND CHECK THAT 18 DIFFERENT LANGUAGES ARE AVAILABLE INCLUDING 'ENGLISH'.

6 IN SETTINGS MENU - CHECK BLUE SCREEN ON/OFF ( CHECK THIS FEATURE WITHOUT RF SIGNAL )

7 LOCK FUNCTION: PRESS "LOCK" KEY FOR 4 SECOND TO ACTIVATE LOCK FUNCTION . CHECK THAT LOCK MENU WITH DIFF. L

ARE AVAILABLE.

8 REVEAL & HOLD : PRESS "REVEAL" KEY , CHECK THAT TV SWITCHES TO ALL THE TUNNED PROGRAMS AND EURO AV MODE

AND STOPS AT THE PROGRAM TO WHICH "HOLD" KEY IS PRESSED.

9 FOR DETAILS , PLEASE REFER USER'S GUIDE BOO

PRODUCT : CT

RAW MATERIAL / CONSUMABLES : JIGS / FIXTURE INSTRUMENTS : PREPARED BY

SR N STOCK NO LOC DESCRIPTION QPS SERVICE REMOTE

1 TV SET 1

1 CHECK THE SET IN ALL ASPECTS.

2 PRESS "MENU+6483" KEYS SEQUENCE TO ACCESS THE MANUFACTURING MODE. THEN PRESS HOTKEY "2" TO ENABLE MENU-2.

3 SELECT "SHIPPING" OPTION AND PRESS VOL UP KEY.

4 AFTER SIPPING ,TV SET WILL SWITCH AGAIN.

5 MAKE THE MAINS 'POWER' SWITCH OFF.

USE "STAND BY" KEY TO QUIT THE MANUFACTURING/SERVICE MOD

STAGE: SOUND Q.C.-

STAGE: PICTURE Q.C.-

STAGE: FEATURE CHECKIN

STAGE: SHIPPING PCB/ASSY : F.A. RoadStar SHEET : 1 OF 1

PCB/ASSY :F.A. RoadStar SHEET : 1 OF 1

PCB/ASSY :F.A. RoadStar SHEET : 1 OF 1

PCB/ASSY :F.A. RoadStar SHEET : 1 OF 1

7

Page 40

VILEUR UOC STEREO SCH

2005.10.10

C710

0.1u

47u/16V

C202 0.01u

+

LM-01

C112

100u16V

C116

0.068u

C117

0.15u

C118

6800p

R112

12K

R113

100

+

C812

R815

5.6K

1

2

XS152

1

2

3

XS151

1

2

3

4

5

XS156

TDA9859

AV1 L

1

2 31

3

MAIN L

+

CSMO

4

MAIN R

5

6

VCC

AUDIO

7

OUT R

8

GND

VO2

9

VI8

10

11

CBR1

12

CBR2

WOOF

13

OUT R

14

CTR

MAIN

15

OUT R

16

SCL

R814

5.6K

N151

AN17821

Vcc

2

3

1

10u/16V

C152

+13V

0.01u

+

C151

R191

2.2K

10u/16V

C191

C334

1u

VD702

1N4148

+

+

R141

VD141

1N4148

10K

R340

100

2200u/25V

R192

8.2K

+

C153

1u

100u/16V

V141

2SA1015

R142

10K

V142

2SC1815

R338

330

10u/16V

R157

C141

270K

+

+8V

R143

22K

R404

1.5K

INV IN

1

C412

0.033u

R412

1.5K

R731

3.3K

+8V

R734

10K

+

C335

R339

110

+3.3V

+5V

N701

AT24C16

C703

XP2001

0.01u

8

+

R701 3.3K

R710 3.3K

R712 3.3K

C702

7

47u/16V

R709

SCL

6

100

R711

5

SDA

100

+3.3V

R724

10K

1.2K

2K

2.7K

12K

R733 3.3K

R723

47

R722

3.9K

12 Vss A

13

C301

0.22u

C303

C307

C309

2.2u

0.01u

L301

+8V

+ +

1u

10uH

R301 15K

0.22u

2200p

C306

4700p

R401 100

R402 100

1000p

C302

47u/16V

C304

C305

C308

4.7u

C401

1000p

C402

14

+

15

16

17

18

19

0.1u

20

+

C310

21

22

23

TO XP2001

SW705

SW704

SW703

SW702

SW701

P+

P-

V+

V-

MENU

1

2

XS701

FROM XS701

1 2

1

2

3

4

R729

R728

R727

R726

24

R403

25

39K

C403

26

0.1u

27

C207

0.022u

28

C311

3300p

29

+ +

C312

+ + +

2200u/25V

R632

R633

VR631

+26V

R634

2.4K

+13V

C647

C652

2200u/25V

C667

1000u/16V

TP91

51K

51K

B+ ADJ

20K

VD632

1N4148 VD652

C633

0.033u

10u/16V

30

C314

C313

4700p

31

820p

C315

4.7u

R302

2.7K

R633A

1.5K

R652

220

B+ +110V

R635

1K

R636

10K

K

R

A

V631

TL431LP

FROM XS231

+9V

R227

220

R223

C223

4.7K

R740 220

1000/1KV

TVR4J

TVR4J

!

!

N611

KA5Q0765

C617

33u

0.01u

C221

1000p

1

22

VD201

R201

MTZJ5C1

3.3K

R202

R204

270

47K

R203

C603

C605

L602

1000/1KV

LF-033

VD605

TVR4J

VD606

TVR4J

VD611

TVR4J

VD616

5V1HSC

R611

68K

R612

68K

C618

C619

0.1u

0.033u

4

5

3

+

R617

VD619

2.4K

HZ9A3

NAME

VALUE

IF

BT+31V

C201

+

BP+5V

C206

3.3u

L911

XS602

2

!

XS601XP601

1

!

2

AGC

1

SDA

SCL

AS

P10X180M

!

PS601

!

1000/1KV

680p/2KV

SW601

C615

t

A04

L611

LF-05

TPAGC

R602 1.8

L601

LF-033

C601

0.22u/AC275V

F601

T3.15AL/AC 250V

1

C616

R737 220

R221

1.5k

C607A

470p/AC 400V

VD603

5

!

VD604

R601

220K

!

2

R226

220

L221

0.75uH

V221

2SC1674C

R224

1.2K

+8V

!

+

C611

C610

2200p/1KV

220u/400V

PC817B/C

R229

VD613

RGP10J

VD615

1N4148

33

C706

10u/50V

N612

C225

0.01u

+

2

1

4