Page 1

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

TFT LCD Tentative Specification

MODEL NO.: M236H7- L01

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

Customer:

Approved by:

Note:

1 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Versio n 0.0

www.panelook.com

Page 2

Global LCD Panel Exchange Center

D

www.panelook.com

oc No.:

Issued Date: 12, Apr, 2010

Model No.: M236H7-L01

Tentative

- CONTENTS –

-

REVISION HISTORY ------------------------------------------------------- 3

1. GENERAL DESCRIPTION ------------------------------------------------------- 4

1.1 OVERVIEW

1.2 FEATURES

1.3 APPLICATION

1.4 GENERAL SPECIFICATIONS

1.5 MECHANICAL SPECIFICATIONS

2. ABSOLUTE MAXIMUM RATINGS ------------------------------------------------------- 5

2.1 ABSOLUTE RATINGS OF ENVIRONMENT

2.2 ELECTRICAL ABSOLUTE RATINGS

2.2.1 TFT LCD MODULE

2.2.2 BACKLIGHT UNIT

2.2.3 OPTICAL TOUCH UNIT

3. ELECTRICAL CHARACTERISTICS ------------------------------------------------------- 7

3.1 TFT LCD MODULE

3.2 BACKLIGHT UNIT

3.3 OPTICAL TOUCH UNIT

4. BLOCK DIAGRAM ------------------------------------------------------- 12

4.1 TFT LCD MODULE

4.2 BACKLIGHT UNIT

4.3 OPTICAL TOUCH UNIT

5. INPUT TERMINAL PIN ASSIGNMENT ------------------------------------------------------- 13

5.1 TFT LCD MODULE

5.2 LVDS DATA MAPPING TABLE

5.3 BACKLIGHT UNIT

5.4 OPTICAL TOUCH UNIT

5.5 COLOR DATA INPUT ASSIGNMENT

6. INTERFACE TIMING ------------------------------------------------------- 16

6.1 INPUT SIGNAL TIMING SPECIFICATIONS

6.2 POWER ON/OFF SEQUENCE

7. OPTICAL CHARACTERISTICS ------------------------------------------------------- 19

7.1 TEST CONDITIONS

7.2 OPTICAL SPECIFICATIONS

8. PACKING ------------------------------------------------------- 22

8.1 PACKING SPECIFICATIONS

8.2 PACKING METHOD

9. DEFINITION OF LABELS ------------------------------------------------------- 24

10. PRECAUTIONS ------------------------------------------------------- 27

11.1 ASSEMBLY AND HANDLING PRECAUTIONS

11.2 SAFETY PRECAUTIONS

11.3 SAFETY STANDARDS

11.4 STORAGE

11.5 OPERATION CONDITION GUIDE

11.6 OTHER

11. MECHANICAL CHARACTERISTICS ------------------------------------------------------- 29

2 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Versio n 0.0

www.panelook.com

Page 3

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

REVISION HISTORY

Version Date Section Description

Ver. 0.0

12, Apr, 10

- M236H7-L01 Tentative Specification was first issued.

3 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 4

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

1. GENERAL DESCRIPTION

1.1 OVERVIEW

M236H7-L01 is a 23.6” TFT Liquid Crystal Display touch module which embedded Optical Touch unit

with W7 logo certification. The light source of the module is 2 CCFL Backlight unit and interface is 30 pins

2ch-LVDS which supports 1920 x 1080 Full HD mode and can display up to 16.7M colors. The inverter

module for Backlight is not built in.

1.2 FEATURES

- Extra-wide viewing angle

- High contrast ratio

- Fast response time

- Full HD (1920 x 1080 pixels) resolution

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

- DE (Data Enable) only mode

- LVDS (Low Voltage Differential Signaling) interface

- RoHS compliance

- Touch function “Plug and Play”

- Dual touch; Gesture supported

- W7 logo certification

1.3 APPLICATION

- TFT LCD Monitor, AIO Computers

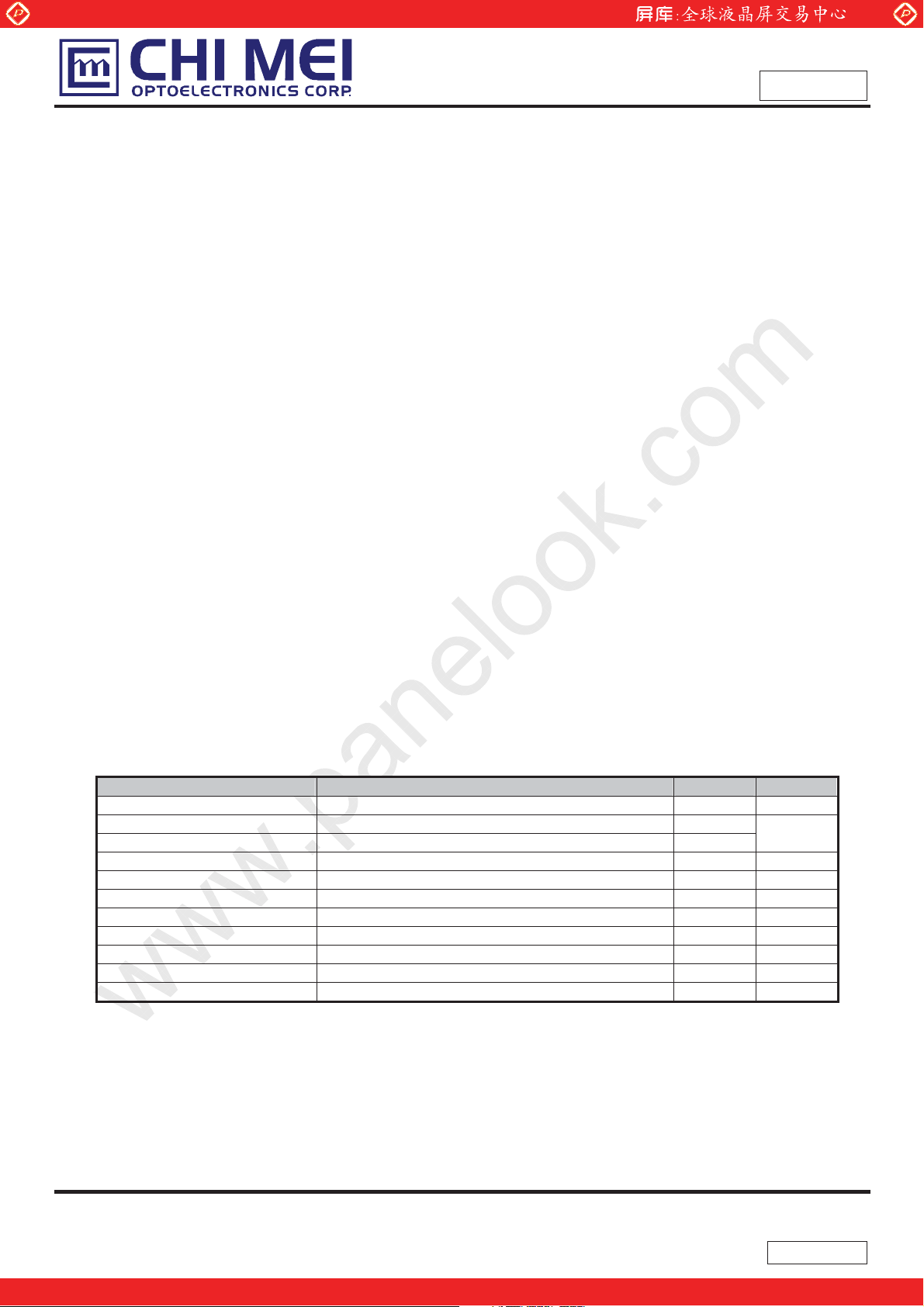

1.4 GENERAL SPECIFICATIONS

Item Specification Unit Note

Diagonal size 23.547 inch -

Active Area 521.28 (H) x 293.22 (V) mm

Bezel Opening Area 530.28 (H) x 302.22 (V) mm

Driver Element a-Si TFT active matrix - -

Pixel Number 1920 x R.G.B. x 1080 pixel -

Pixel Pitch 0.2715 (H) x 0.2715 (V) mm -

Pixel Arrangement RGB vertical stripe - -

Display Colors 16.7M color -

Transmissive Mode Normally White - -

Glass Surface Treatment 7H hard

Module Power Consumption 21.7 Watt (2)

(1)

4 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 5

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

1.5 MECHANICAL SPECIFICATIONS

Item Min. Typ. Max. Unit Note

Horizontal(H) 544.3 544.8 545.3 mm

Module Size

Note (1) Please refer to the attached drawings for more information of front and back outline dimensions.

Note (2) Please refer to sec.3.1 & 3.2 for more information of power consumption.

Vertical(V) 320.0 320.5 321.0 mm

Depth(D) 20 20.5 21 mm

Weight - 3295 3395 g -

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

(1)

5 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 6

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

2. ABSOLUTE MAXIMUM RATINGS

2.1 ABSOLUTE RATINGS OF ENVIRONMENT

TBD

2.2 ELECTRICAL ABSOLUTE RATINGS

2.2.1 TFT LCD MODULE

Item Symbol

Power Supply Voltage Vcc -0.3 +6.0 V (1)

Logic Input Voltage Vlogic -0.3 +3.6 V

2.2.2 BACKLIGHT UNIT

Item Symbol

Lamp Voltage VL - 2.5K V

Lamp Current IL 3.0 8.0 mA

Lamp Frequency FL 40 80 KHz

Note (1) Permanent damage to the device may occur if maximum values are exceeded. Function

www.panelook.com

Value

Min. Max.

Value

Min. Max.

Model No.: M236H7-L01

Tentative

Unit Note

Unit Note

(1), (2)

RMS

RMS

(1), (2)

oc No.:

operation should be restricted to the conditions described under Normal Operating Conditions.

Note (2) Specified values are for lamp (Refer to 3.2 for further information).

2.2.3 OPTICAL TOUCH UNIT

Item Symbol

USB Voltage V

4.75 5.25 V

USB

Min. Max.

Value

Unit Note

6 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 7

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

3. ELECTRICAL CHARACTERISTICS

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

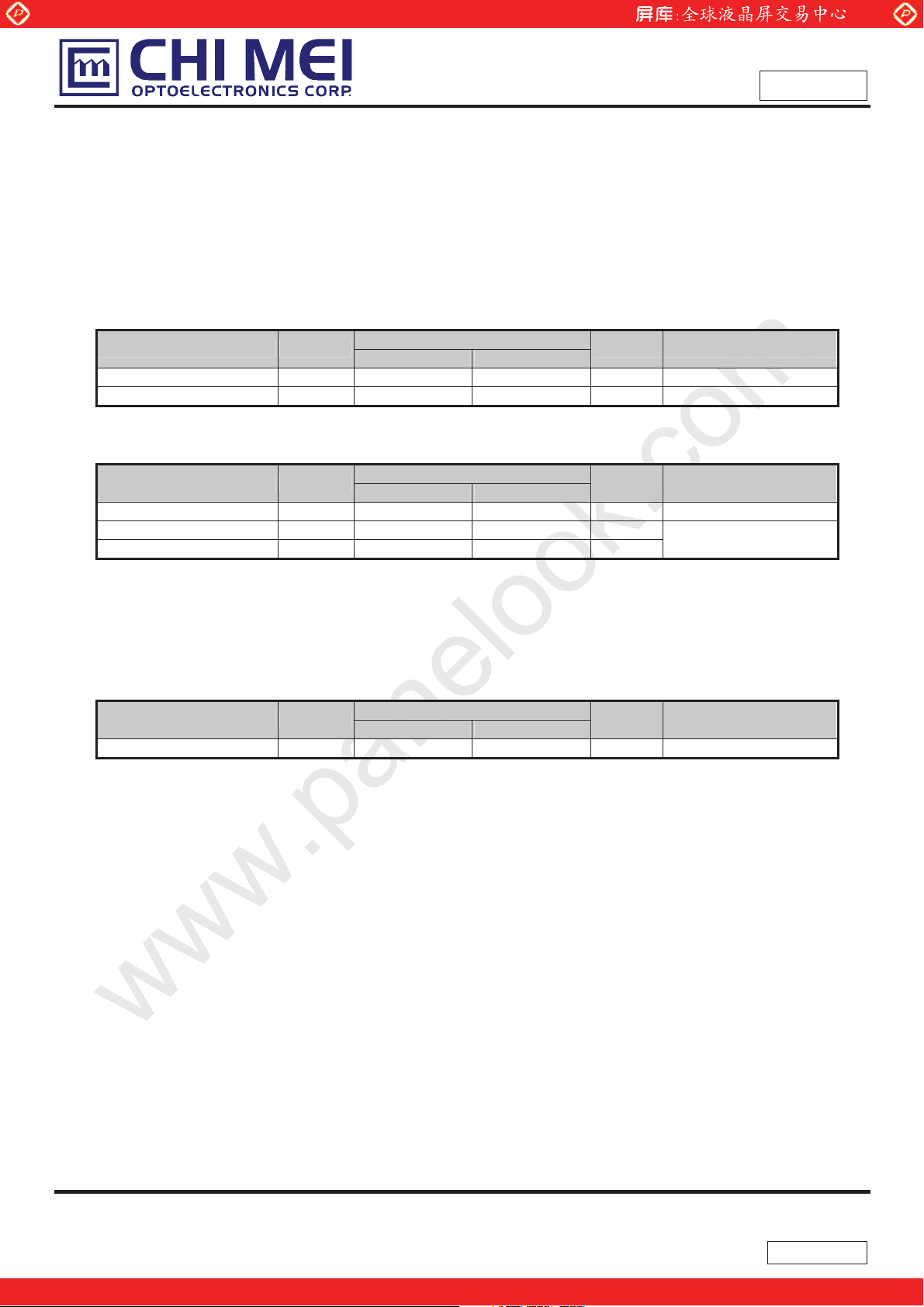

3.1 TFT LCD MODULE

Parameter Symbol

Ta = 25 ± 2 ºC

Min. Typ. Max.

Power Supply Voltage Vcc 4.5 5.0 5.5 V -

Ripple Voltage VRP - - 300 mV -

Power on Rush Current I

Power Supply Current

Power Consumption P

RUSH

White - 0.55 0.67 A (3)

Black - 1.5 1.9 A (3)

Vertical Stripe

LCD

- - 3 A (2)

- 1.18 1.43 A (3)

7.5 9.5 Watt (4)

LVDS differential input voltage Vid 200 - 600 mV (5)

LVDS common input voltage Vic - 1.2 - V

Logic High Input Voltage VIH 2.64 - 3.6 V

Logic Low Input Voltage VIL -0.3 - 0.66 V

Note (1) The module should be always operated within above ranges.

Note (2) Power on rush current measurement conditions:

+5.0V

Q1 2SK1475

R1

47K

(High to Low)

(Control Signal)

SW

+12V

R2

1K

47K

VR1

C1

1uF

0.01uF

Q2

2SK1470

C2

Value

FUSE

C3

1uF

Unit Note

Vcc

(LCD Module Input)

Vcc rising time is 470μs

Vcc

0.9Vcc

0.1Vcc

GND

470μs

7 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 8

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

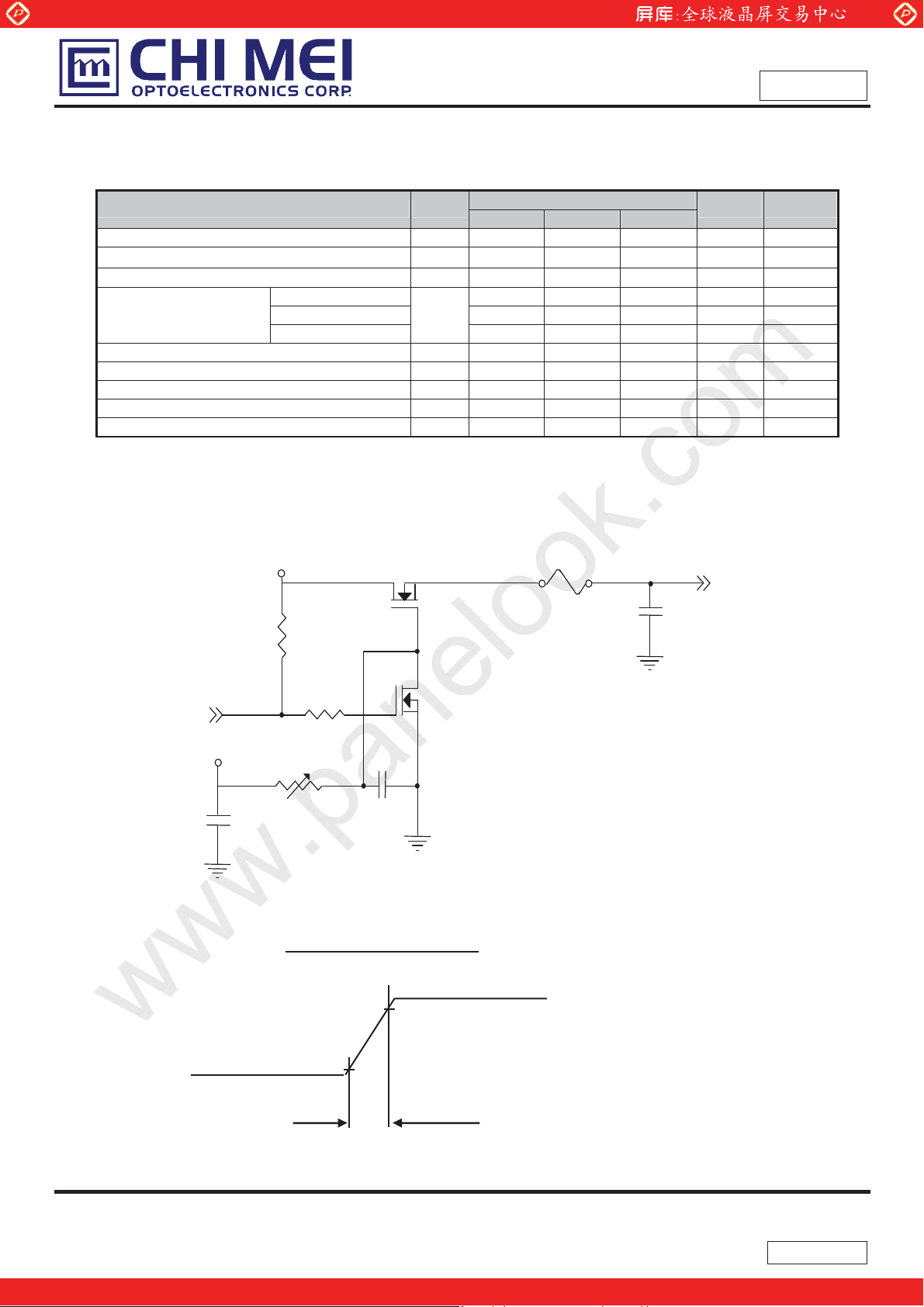

Note (3) The specified power supply current is under the conditions at Vcc = 5.0 V, Ta = 25 ± 2 ºC, Fr = 60

Hz, whereas a power dissipation check pattern below is displayed.

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

a. White Pattern

Active Area

c. Vertical Stripe Pattern

b. Black Pattern

Active Area

R

G

R

B

G

R

B

G

R R

G

B

B

B

B

R

R

R

G

G

G

G

B

B

B

B

R

R

Note (4) The power consumption is specified at the pattern with the maximum current.

Note (5) VID waveform condition

Active Area

8 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 9

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

3.1.2 Vcc Power Dip Condition:

Vcc

4.0V

4.5V

Td

Dip condition:

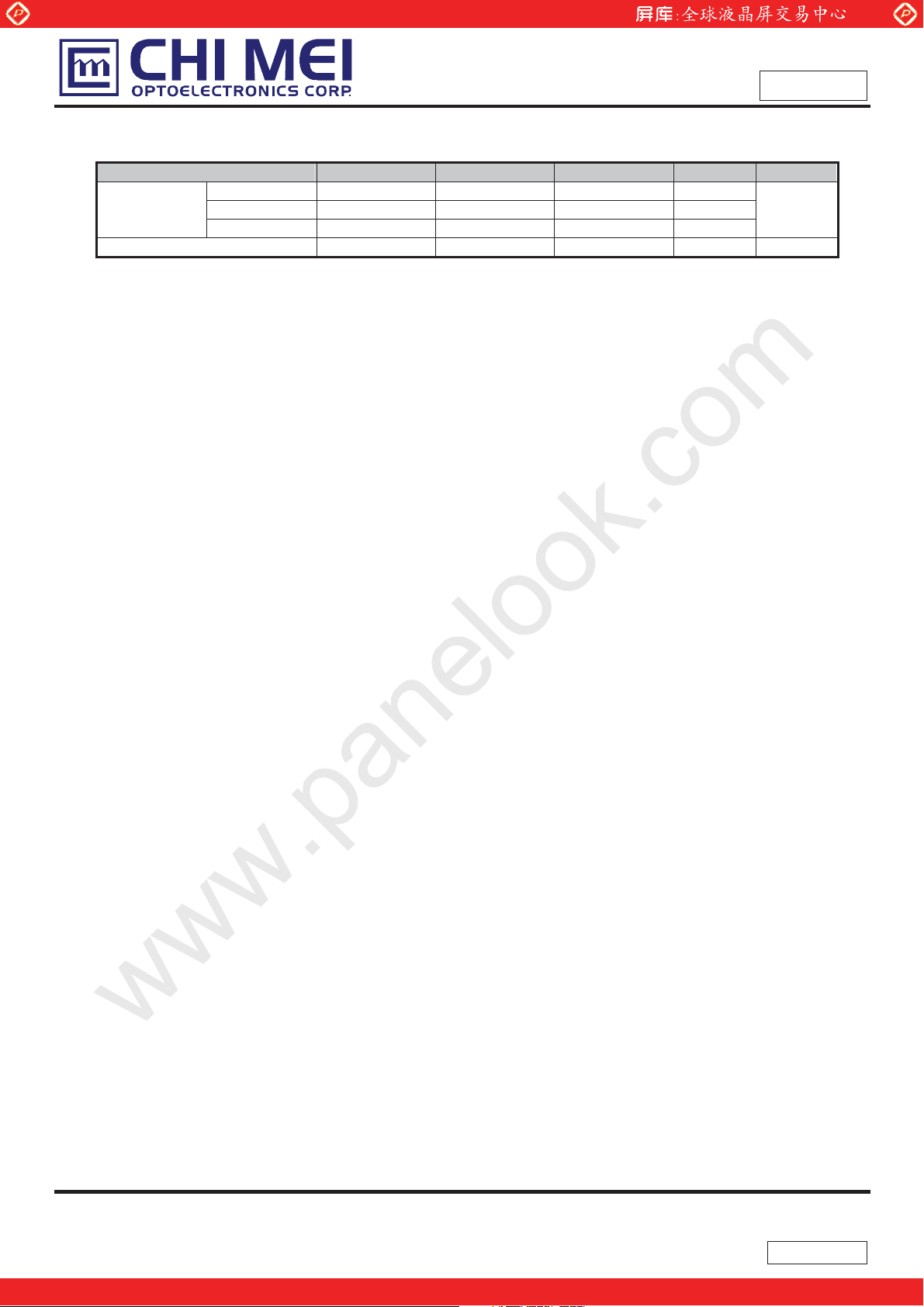

3.2 BACKLIGHT UNIT

Parameter Symbol

Lamp Input Voltage VL 819 910 1001 V

Lamp Current IL 3.0 7.5 8.0 mA

Lamp Turn On Voltage VS

Operating Frequency FL 40 80 KHz (3)

Lamp Life Time LBL 50000 Hrs (5), IL = 7.5mA

Power Consumption PL 12.285 13.65 15.015 W (4), IL = 7.5 mA

Min. Typ. Max.

1880(0 )к V

1480 (25 )

msTdVVccV 20,5.40.4 ≤≤≤

Value

к

Ta = 25 ± 2 ºC

Unit Note

IL = 7.5 mA

RMS

RMS

(2)

RMS

V

(2)

RMS

(1)

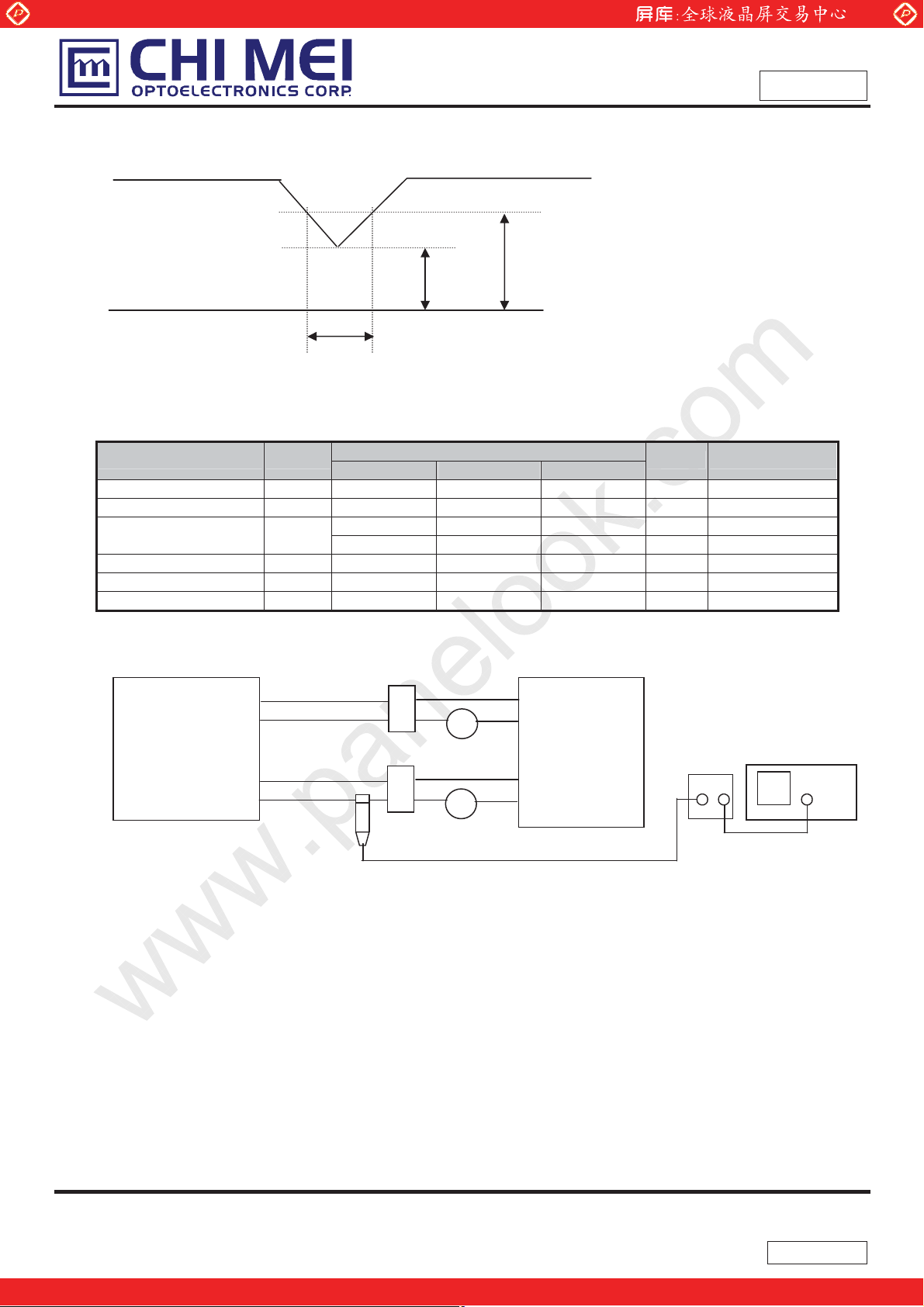

Note (1) Lamp current is measured by current amplify & oscilloscope as shown below:

Ta = 25 ± 2 ºC

Note (2) The voltage that must be larger than Vs should be applied to the lamp for more than 1 second

after startup. Otherwise, the lamp may not be turned on normally. It is the value output voltage

of NF circuit.

Note (3) The lamp frequency may produce interference with horizontal synchronization frequency from the

display, which might cause line flow on the display. In order to avoid interference, the lamp

HV (Pink)

LV (White)

HV (Blue)

LV (Black)

Current

Probe

1

2

1

2

A

A

Measure equipment:

Current Amplify: Tektronix TCPA300

Current probe: Tektronix TCP312

Oscilloscope: TDS3054B

Current

Amplify

Oscilloscope

frequency should be detached from the horizontal synchronization frequency and its harmonics as

far as possible.

9 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 10

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

Note (4) PL = IL × VL × 2

Note (5) The lifetime of lamp can be defined as the time in which it continues to operate under the condition

Ta = 25 ±2

o

C and IL =7.5 mArms until one of the following events occurs:

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

(a) When the brightness becomes

(b) When the effective ignition length becomes

(The effective ignition length is a scope that luminance is over 80% of that at the center point.)

Note (6) The waveform of the voltage output of inverter must be area-symmetric and the design of the

inverter must have specifications for the modularized lamp. The performance of the Backlight,

such as lifetime or brightness, is greatly influenced by the characteristics of the DC-AC inverter for

the lamp. All the parameters of an inverter should be carefully designed to avoid producing too

much current leakage from high voltage output of the inverter. When designing or ordering the

inverter please make sure that a poor lighting caused by the mismatch of the Backlight and the

inverter (miss-lighting, flicker, etc.) never occurs. If the above situation is confirmed, the module

should be operated in the same manners when it is installed in your instrument.

The output of the inverter must have symmetrical (negative and positive) voltage waveform and

symmetrical current waveform (Unsymmetrical ratio is less than 10%). Please do not use the inverter

which has unsymmetrical voltage and unsymmetrical current and spike wave. Lamp frequency may

produce interface with horizontal synchronous frequency and as a result this may cause beat on the

display. Therefore lamp frequency shall be as away possible from the horizontal synchronous

Љ

50% of its original value.

Љ

80% of its original value.

frequency and from its harmonics in order to prevent interference.

Requirements for a system inverter design, which is intended to have a better display performance, a

better power efficiency and a more reliable lamp. It shall help increase the lamp lifetime and reduce

its leakage current.

a. The asymmetry rate of the inverter waveform should be 10% below;

b. The distortion rate of the waveform should be within √2 ± 10%;

c. The ideal sine wave form shall be symmetric in positive and negative polarities.

* Asymmetry rate:

I p

I

-p

| I

* Distortion rate

I

– I –p | / I

p

(or I –p) / I

p

rms

rms

* 100%

10 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 11

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

3.3 OPTICAL TOUCH UNIT

Parameter Symbol

USB Voltage V

USB Current I

Power Consumption P

Note(1) Depend on operating mode

4.75 5 5.25 V

USB

65 - 110 mA (1)

USB

0.33 - 0.55 W (1)

USB

Value

Min. Typ. Max.

Unit Note

11 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 12

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

4. BLOCK DIAGRAM

4.1 TFT LCD MODULE

RXO0(+/-)

RXO1(+/-)

RXO2(+/-)

RXO3(+/-)

RXOC(+/-)

RXE0(+/-)

RXE1(+/-)

RXE2(+/-)

RXE3(+/-)

RXEC(+/-)

NC

Vcc

GND

INPUT CONNECTOR

VL

LAMP CONNECTOR

(YEONHO 35001HS-02L)

www.panelook.com

LVDS INPUT /

TIMING CONTROLLER

DC/DC CONVERTER &

REFERENCE VOLTAGE

oc No.:

Model No.: M236H7-L01

Tentative

SCAN DRIVER IC

TFT LCD PANEL

(1920x3x1080)

DATA DRIVER IC

BACKLIGHT UNIT

V

USB

4.2 BACKLIGHT UNIT

USB CONNECTOR

(ACES 85204-05001)

OPTICAL TOUCH SCREEN

1 HV(Pink)

2 LV(White)

1 HV(Blue)

2 LV(Black)

12 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 13

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

4.3 OPTICAL TOUCH UNIT

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

13 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 14

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

5. INPUT TERMINAL PIN ASSIGNMENT

5.1 TFT LCD MODULE

Pin Name Description

1 RXO0- Negative LVDS differential data input. Channel O0 (odd)

2 RXO0+ Positive LVDS differential data input. Channel O0 (odd)

3 RXO1- Negative LVDS differential data input. Channel O1 (odd)

4 RXO1+ Positive LVDS differential data input. Channel O1 (odd)

5 RXO2- Negative LVDS differential data input. Channel O2 (odd)

6 RXO2+ Positive LVDS differential data input. Channel O2 (odd)

7 GND Ground

8 RXOC- Negative LVDS differential clock input. (odd)

9 RXOC+ Positive LVDS differential clock input. (odd)

10 RXO3- Negative LVDS differential data input. Channel O3(odd)

11 RXO3+ Positive LVDS differential data input. Channel O3 (odd)

12 RXE0- Negative LVDS differential data input. Channel E0 (even)

13 RXE0+ Positive LVDS differential data input. Channel E0 (even)

14 GND Ground

15 RXE1- Negative LVDS differential data input. Channel E1 (even)

16 RXE1+ Positive LVDS differential data input. Channel E1 (even)

17 GND Ground

18 RXE2- Negative LVDS differential data input. Channel E2 (even)

19 RXE2+ Positive LVDS differential data input. Channel E2 (even)

20 RXEC- Negative LVDS differential clock input. (even)

21 RXEC+ Positive LVDS differential clock input. (even)

22 RXE3- Negative LVDS differential data input. Channel E3 (even)

23 RXE3+ Positive LVDS differential data input. Channel E3 (even)

24 GND Ground

25 NC For LCD internal use only. Do not connect.

26 NC

27 NC

28 Vcc +5.0V power supply

29 Vcc +5.0V power supply

30 Vcc +5.0V power supply

For LCD internal use only. Do not connect.

For LCD internal use only. Do not connect.

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

Note (1) Connector Part No.: FI-XB30SL-HF10 (JAE) or 187066-30091 (P-TWO)

Note (2) Mating Wire Cable Connector Part No.: FI-X30H(JAE) or FI-X30HL(JAE)

Note (3) Mating FFC Cable Connector Part No.: 217007-013001 (P-TWO) or JF05X030-1 (JAE)

Note (4) The first pixel is odd.

Note (5) Input signal of even and odd clock should be the same timing.

14 / 30

Version 0.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

5.2 LVDS DATA MAPPING TABLE

LVDS Channel O0

LVDS Channel O1

LVDS Channel O2

LVDS Channel O3

LVDS Channel E0

LVDS Channel E1

LVDS Channel E2

LVDS Channel E3

LVDS output D7 D6 D4 D3 D2 D1 D0

Data order OG0 OR5 OR4 OR3 OR2 OR1 OR0

LVDS output D18 D15 D14 D13 D12 D9 D8

Data order OB1 OB0 OG5 OG4 OG3 OG2 OG1

LVDS output D26 D25 D24 D22 D21 D20 D19

Data order DE NA NA OB5 OB4 OB3 OB2

LVDS output D23 D17 D16 D11 D10 D5 D27

Data order NA OB7 OB6 OG7 OG6 OR7 OR6

LVDS output D7 D6 D4 D3 D2 D1 D0

Data order EG0 ER5 ER4 ER3 ER2 ER1 ER0

LVDS output D18 D15 D14 D13 D12 D9 D8

Data order EB1 EB0 EG5 EG4 EG3 EG2 EG1

LVDS output D26 D25 D24 D22 D21 D20 D19

Data order DE NA NA EB5 EB4 EB3 EB2

LVDS output D23 D17 D16 D11 D10 D5 D27

Data order NA EB7 EB6 EG7 EG6 ER7 ER6

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

5.3 BACKLIGHT UNIT

Pin Symbol Description Remark

1-1 HV High Voltage Pink

1-2 LV Low Voltage White

2-3 HV High Voltage Blue

2-4 LV Low Voltage Black

Note (1) Connector Part No.: YEONHO 35001HS-02L or equivalent

Note (2) User’s connector Part No.: YEONHO 35001WR-02L or equivalent

5.4 OPTICAL TOUCH UNIT

Pin Name Description

1 V

2 D- Data 3 D+ Data +

4 GND Ground

5 Shield GND Shielding Ground

Note (1) Connector Part No.: ACES 85204-05001 (5 pin) or equivalent

USB Voltage, +5.0V power supply

USB

Pin 1 define

Rear side of panel module

15 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 16

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

5.5 COLOR DATA INPUT ASSIGNMENT

The brightness of each primary color (red, green and blue) is based on the 8-bit gray scale data input

for the color. The higher the binary input, the brighter the color. The table below provides the assignment

of color versus data input.

Color

R7 R6 R5 R4 R3 R2 R1 R0 G7 G6 G5 G4 G3 G2 G1 G0 B7 B6 B5 B4 B3 B2 B1 B0

Basic

Colors

Gray

Scale

Of

Red

Black

Green

Cyan

Magenta

Yellow

White

Red(0) / Dark

Red(1)

Red(2)

Red(253)

Red(254)

Red(255)

Red

Blue

0

0

1

1

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

:

:

:

:

:

:

1

1

1

1

1

1

www.panelook.com

Model No.: M236H7-L01

Data Signal

Red Green Blue

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

1

1

1

1

0

1

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

Tentative

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

0

0

0

1

1

1

0

0

0

0

:

:

0

0

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

oc No.:

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

0

0

0

1

1

1

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

Green(0) / Dark

Gray

Scale

Of

Green

Gray

Scale

Of

Blue

Note (1) 0: Low Level Voltage, 1: High Level Voltage

Green(1)

Green(2)

Green(253)

Green(254)

Green(255)

Blue(0) / Dark

Blue(1)

Blue(2)

Blue(253)

Blue(254)

Blue(255)

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

1

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

1

1

1

1

1

1

0

1

0

0

1

1

1

1

1

1

1

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

1

0

0

:

:

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

1

1

1

1

1

1

0

0

0

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

1

1

1

1

1

1

0

0

0

0

0

0

0

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

1

:

:

:

:

:

:

1

1

0

1

0

1

1

1

1

16 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 17

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

6. INTERFACE TIMING

6.1 INPUT SIGNAL TIMING SPECIFICATIONS

The input signal timing specifications are shown as the following table and timing diagram.

Signal Item Symbol Min. Typ. Max. Unit Note

Frequency Fc 58.54 74.25 98 MHz Period Tc - 13.47 - ns

Input cycle to

cycle jitter

Spread

spectrum

LVDS Clock

LVDS Data

Vertical Active Display Term

Horizontal Active Display Term

Note: Because this module is operated by DE only mode, Hsync and Vsync input signals are ignored.

modulation

range

Spread

spectrum

modulation

frequency

High Time Tch - 4/7 - Tc Low Time Tcl - 3/7 - Tc Setup Time Tlvs 600 - - ps

Hold Time Tlvh 600 - - ps

Frame Rate Fr 50 60 75 Hz Tv=Tvd+Tvb

Total Tv 1115 1125 1136 Th Display Tvd 1080 1080 1080 Th Blank Tvb 35 45 56 Th Total Th 1050 1100 1150 Tc Th=Thd+Thb

Display Thd 960 960 960 Tc Blank Thb 90

www.panelook.com

-0.02*Tc - 0.02*Tc ns (1)

T

rcl

clkin_mod

F

F

0.98*Fc - 1.02*Fc MHz

- - 200 KHz

SSM

140

oc No.:

Model No.: M236H7-L01

Tentative

(2)

(3)

190

Tc -

INPUT SIGNAL TIMING DIAGRAM

DE

Th

DCLK

C

T

DE

DATA

Thb

T

hd

17 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 18

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

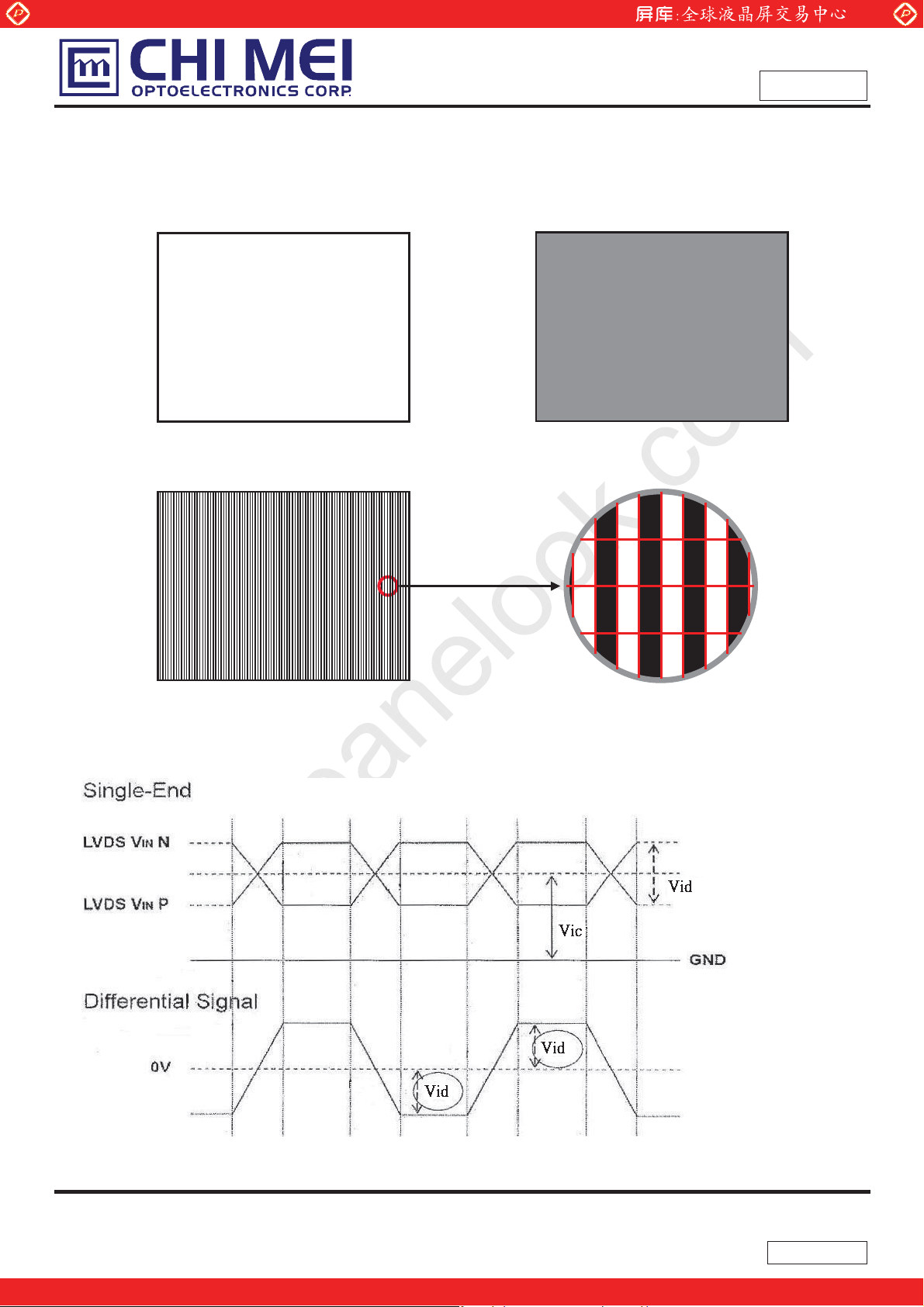

Note (1) The input clock cycle-to-cycle jitter is defined as below figures. Trcl = I T1 – TI

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

T1

Note (2) The SSCG (Spread spectrum clock generator) is defined as below figures.

T2

Note (3) The LVDS timing diagram and setup/hold time is defined and showing as the following figures.

LVDS RECEIVER INTERFACE TIMING DIAGRAM

Tc

RXCLK+/-

RXn+/-

Tlvs

Tlvh

18 / 30

Version 0.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

D

pply

g

p

Issued Date: 12, Apr, 2010

6.2 POWER ON/OFF SEQUENCE

To prevent a latch-up or DC operation of LCD module, the power on/off sequence should be as the

diagram below.

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

- Power Su

for LCD, Vcc

- Interface Si

(LVDS Signal of

Transmitter), V

- Power for Lam

Timing Specifications:

0.5< t1

0 < t2

0 < t3

nal

t4

t5

I

Љ

Љ

Љ

Њ

Њ

0V

0V

10 msec

50 msec

50 msec

500 msec

450 msec

10%

90%

t1

90%

10%

t7

t3 t2

Valid Data

t6 t5

50% 50%

ON OFF OFF

t4

10%

t6

Њ

90 msec

5< t7

Љ

100 msec

Note:

(1) The supply voltage of the external system for the module input should be the same as the definition of Vcc.

(2) Apply the lamp voltage within the LCD operation range. When the backlight turns on before the LCD

operation of the LCD turns off before the backlight turns off, the display may momentarily become abnormal

screen.

(3) In case of VCC = off level, please keep the level of input signals on the low or keep a high impedance.

(4) T4 should be measured after the module has been fully discharged between power off and on period.

(5) Interface signal shall not be kept at high impedance when the power is on.

(6) CMO won’t take any responsibility for the products which are damaged by the customers not following the

Power Sequence.

(7) There might be slight electronic noise when LCD is turned off (even backlight unit is also off). To avoid this

symptom, we suggest "Vcc falling timing" to follow "t7 spec".

19 / 30

Version 0.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

7. OPTICAL CHARACTERISTICS

7.1 TEST CONDITIONS

Item Symbol Value Unit

Ambient Temperature Ta 25±2

Ambient Humidity Ha 50±10 %RH

Supply Voltage VCC 7.0 V

Input Signal According to typical value in "3. ELECTRICAL CHARACTERISTICS"

Lamp Current IL 7.5±0.5 mA

Inverter Operating Frequency FL 55±5 KHz

Inverter Logah MIT70070.50

7.2 OPTICAL SPECIFICATIONS

The relative measurement methods of optical characteristics are shown in 7.2. The following items

should be measured under the test conditions described in 7.1 and stable environment shown in Note (5).

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

o

C

Item Symbol Condition Min. Typ. Max. Unit Note

Red

Color

Green

Chromaticity

(CIE 1931)

Blue

White

Center Luminance of White

(Center of Screen)

Contrast Ratio CR

Response Time

White Variation

Viewing Angle

Viewing Angle

Horizontal

Vertical

Horizontal

Vertical

Rx

Ry

Gx

Gy

Bx

By

Wx

Wy

L

C

=0°, θY =0°

θ

x

CS-1000T

Typ -

0.03

200 230 - cd/m2(4), (5)

0.648

0.332

0.275

0.610

0.150

0.075

0.313

0.329

Typ +

0.03

- (1), (5)

800 1000 - - (2), (5)

TR - 1.3 2.2

T

F

δW θ

+

θ

+θx-

x

+

+θY-

θ

Y

+

θ

+θx-

x

+

θ

+θY-

Y

θ

=0°, θY =0°

x

=0°, θY =0°

x

Њ

10

CR

Њ

CR

5

- 3.7 5.8

- - 1.33 - (5), (6)

150 170 -140 160 -160

150

178 -170

--

ms (3)

Deg. (1), (5)

Deg. (1), (5)

20 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 21

Global LCD Panel Exchange Center

D

y

y

y

Issued Date: 12, Apr, 2010

Note (1) Definition of Viewing Angle (θx, θy):

www.panelook.com

Normal

oc No.:

Model No.: M236H7-L01

Tentative

θX- = 90º

6 o’clock

θ

-

= 90º

x-

y-

Note (2) Definition of Contrast Ratio (CR):

The contrast ratio can be calculated by the following expression.

Contrast Ratio (CR) = L255 / L0

L255: Luminance of gray level 255

L0: Luminance of gray level 0

θx = θ

= 0º

θy- θy+

θx−

θx+

12 o’clock direction

y+

θ

+

= 90º

x+

θX+ = 90º

CR = CR (5)

CR (X) is corresponding to the Contrast Ratio of the point X at Figure in Note (6).

Note (3) Definition of Response Time (T

100%

90%

Optical

Response

Gray Level 255

10%

0%

, TF):

R

Gray Level 255

Gray Level 0

T

T

R

F

66.67ms 66.67ms

21 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 22

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

Note (4) Definition of Luminance of White (LC):

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

Measure the luminance of gray level 255 at center point

LC = L (5)

L (x) is corresponding to the luminance of the point X at Figure in Note (6).

Note (5) Measurement Setup:

The LCD module should be stabilized at given temperature for 40 minutes to avoid abrupt

temperature change during measuring. In order to stabilize the luminance, the measurement

should be executed after lighting Backlight for 40 minutes in a windless room.

LCD Module

LCD Panel

USB2000

Center of the Screen

CS-1000T

Light Shield Room

(Ambient Luminance < 2 lux)

Note (6) Definition of White Variation (δW): Measure the luminance of gray level 255 at 9 points

δW = Maximum [L (1) ~ L (9)] / Minimum [L (1) ~ L (9)]

D/10 D/2

Horizontal Line

D

D/10

W/10

1 3

2

W

W/2

4

5

6

Vertical Line

W/10

7

8

9

: Test Point

X

X=1 to 9

Active Area

22 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 23

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

8. PACKAGING

8.1 PACKING SPECIFICATIONS

(1) 7 LCD modules / 1 Box

(2) Box dimensions: 620(L) X 348(W) X 430(H) mm

(3) Weight: approximately: 27kg ( 7 modules per box)

8.2 PACKING METHOD

(1) Carton Packing should have no failure in the following reliability test items.

Test Item Test Conditions Note

ISTA STANDARD

Random, Frequency Range: TBD

Vibration

Dropping Test TBD Non Operation

Top & Bottom: TBD

Right & Left: TBD

Back & Forth: TBD

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

Non Operation

Figure 8-1 Packing method

23 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 24

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

For ocean shipping

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

Sea / Land Transportation (40ft HQ Container)

Film

Film

PE Sheet

PE Sheet

Corner Protector

(50*50*1000mm)

PP Belt

Carton label

Corne r Prot ector

(50*50*800mm)

Corner Protector

(50*50*1250mm)

Pallet

(1250*1050*143mm)

For air transport

Sea / Land Transportation (40ft Container)

PP Belt

Carton label

Film

Film

PE Sheet

PE Sheet

Corner Protector

(50*50*1000mm)

Figure 8-2 Packing method

Corner Protector

(50*50*800mm)

Corner Protector

(50*50*800mm)

Pallet

(1250*1050*143mm)

PE Sheet

Film

Corner Protector

(50*50*1000mm)

PP Belt

Carton label

Corner Protector

(50*50*1250mm)

Pallet

(1250*1050*143mm)

24 / 30

Figure 8-3 Packing method

Version 0.0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 25

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

9. DEFINITION OF LABELS

9.1 CMO MODULE LABEL

The barcode nameplate is pasted on each module as illustration, and its definitions are as following explanation.

(a) Model Name: M236H7-L01

(b) Revision: Rev. XX, for example: A0, A1… B1, B2… or C1, C2…etc.

(c) CMO barcode definition:

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

Serial ID: XX

Code Meaning Description

XX CMO internal use -

XX Revision Cover all the change

X CMO internal use -

XX CMO internal use -

YMD Year, month, day

L Product line # Line 1=1, Line 2=2, Line 3=3, …

NNNN Serial number Manufacturing sequence of product

(d) Customer’s barcode definition:

Serial ID: CM

Code Meaning Description

CM Supplier code CMO=CM

23H71 Model number M236H7-L01= 23H71

X Revision code Non ZBD: 1,2,~,8,9 / ZBD: A~Z

X Source driver IC code

X Gate driver IC code

-XX-X-XX-YMD-L-NNNN

Year: 0~9, 2001=1, 2002=2, 2003=3…2010=0, 2011=1, 2012=2…

Month: 1~12=1, 2, 3, ~, 9, A, B, C

Day: 1~31=1, 2, 3, ~, 9, A, B, C, ~, W, X, Y, exclude I, O, and U.

-23H71-X-X-X-XX-L-XX-L-YMD-NNNN

Century=1, CLL=2, Demos=3, Epson=4, Fujitsu=5, Himax=6, Hitachi=7, Hynix=8,

LDI=9, Matsushita=A, NEC=B, Novatec=C, OKI=D, Philips=E, Renasas=F,

Samsung=G, Sanyo=H, Sharp=I, TI=J, Topro=K, Toshiba=L, Windbond=M

XX Cell location Tainan Taiwan=TN, Ningbo China=CN

L Cell line #

XX Module location

L Module line #

YMD Year, month, day

NNNN Serial number By LCD supplier

1,2,~,9,A,B,~,Y,Z

Tainan, Taiwan=TN ; Ningbo China=NP

1,2,~,9,A,B,~,Y,Z

Year: 0~9, 2001=1, 2002=2, 2003=3…2010=0, 2011=1, 2012=2…

Month: 1~12=1, 2, 3, ~, 9, A, B, C

Day: 1~31=1, 2, 3, ~, 9, A, B, C, ~, T, U, V

25 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 26

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

(e) FAB ID(UL Factory ID):

Region Factory ID

TWCMO GEMN

NBCMO LEOO

NBCME CANO

NHCMO CAPG

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

26 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 27

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

www.panelook.com

Model No.: M236H7-L01

Tentative

10. PRECAUTIONS

10.1 ASSEMBLY AND HANDLING PRECAUTIONS

(1) Do not apply rough force such as bending or twisting to the module during assembly.

(2) To assemble or install module into user’s system can be only in clean working areas. The dust and oil

may cause electrical short or worsen the polarizer.

(3) It is not permitted to have pressure or impulse on the module because the LCD panel and Backlight will

be damaged.

(4) Always follow the correct power sequence when LCD module is connecting and operating. This can

prevent damage to the CMOS LSI chips during latch-up.

(5) Do not pull the I/F connector in or out while the module is operating.

(6) Do not disassemble the module.

(7) Use a soft dry cloth without chemicals for cleaning because the surface of polarizer is very soft and

oc No.:

easily scratched.

(8) It is dangerous that moisture comes into or contacts the LCD module because moisture may damage

LCD module when it is operating.

(9) High temperature or humidity may reduce the performance of module. Please store LCD module

within the specified storage conditions.

(10) When ambient temperature is lower than 10ºC, it may reduce display quality. For example, the

response time will become slow and the starting voltage of CCFL will be higher than that in room

temperature.

10.2 SAFETY PRECAUTIONS

(1) The startup voltage of Backlight is approximately 1000 Volts. It may cause electrical shock while

assembling with inverter. Do not disassemble the module or insert anything into the Backlight unit.

(2) If the liquid crystal material leaks from the panel, it should be kept away from the eyes or mouth. In

case of contacting with hands, skin or clothes, it has to be washed away thoroughly with soap.

(3) After the module’s end of life, it is not harmful in case of normal operation and storage.

10.3 SAFETY STANDARDS

The LCD module should be certified with safety regulations as follows:

(1) UL60950-1 or updated standard

(2) IEC60950-1 or updated standard

27 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 28

Global LCD Panel Exchange Center

D

Issued Date: 12, Apr, 2010

10.4. Storage

(1) Do not leave the module in high temperature and high humidity for a long time.

www.panelook.com

oc No.:

Model No.: M236H7-L01

Tentative

It is highly recommended to store the module with temperature from 0

And relative humidity of less than 70%

(2) Do not store the TFT-LCD module in direct sunlight.

(3) The module should be stored in dark place. Sunlight or fluorescent light is prohibited in storing.

к

to 35к

10.5. Operation condition guide

(1) The LCD product should be operated under normal condition.

Normal condition is defined as below:

Temperature: 20±15

Humidity: 65±20%

Display pattern: continually changing pattern (Not stationary)

(2) If the product will be used in extreme conditions such as high temperature, high humidity, high altitude,

display pattern or operation time etc…It is strongly recommended to contact CMO for application

engineering advice. Otherwise, its reliability and function may not be guaranteed.

к

10.6 OTHER

When fixed patterns are displayed for a long time, remnant image is likely to occur.

11. MECHANICAL CHARACTERISTICS

[Refer to the next 2 pages]

28 / 30

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Version 0.0

www.panelook.com

Page 29

www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Page 30

www.panelook.com

www.panelook.com

Global LCD Panel Exchange Center

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Loading...

Loading...