Page 1

INSTALLATION INSTRUCTIONS

Instrucciones de instalación

Installationsanleitung

Instruções de Instalação

Istruzioni di installazione

Installatie-instructies

Instructions d´installation

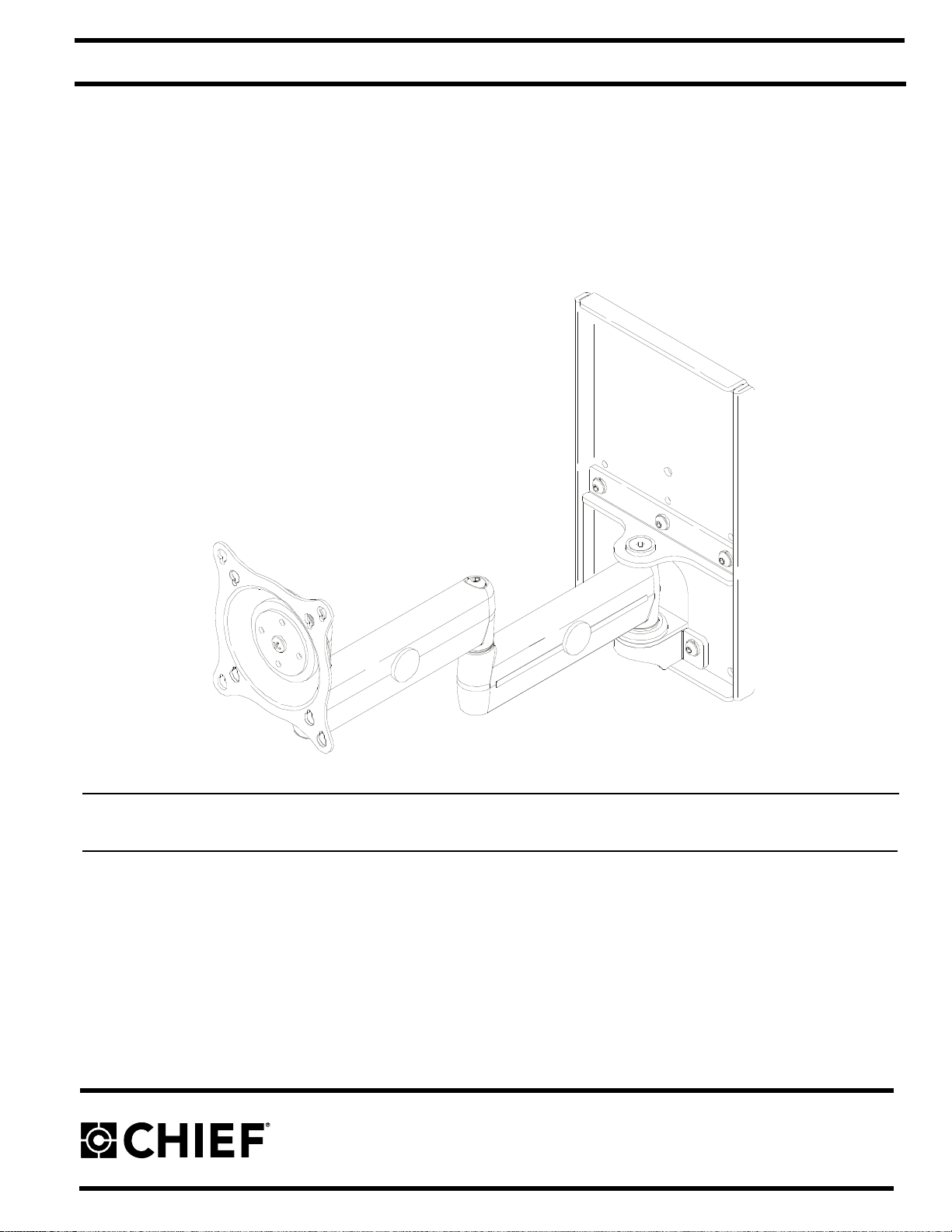

Small Flat Panel Steel Stud Wall Mount

Spanish Product Description

German Product Description

Portuguese Product Description

Italian Product Description

Dutch Product Description

French Product Description

FWDSK110

Page 2

FWDSK110 Installation Instructions

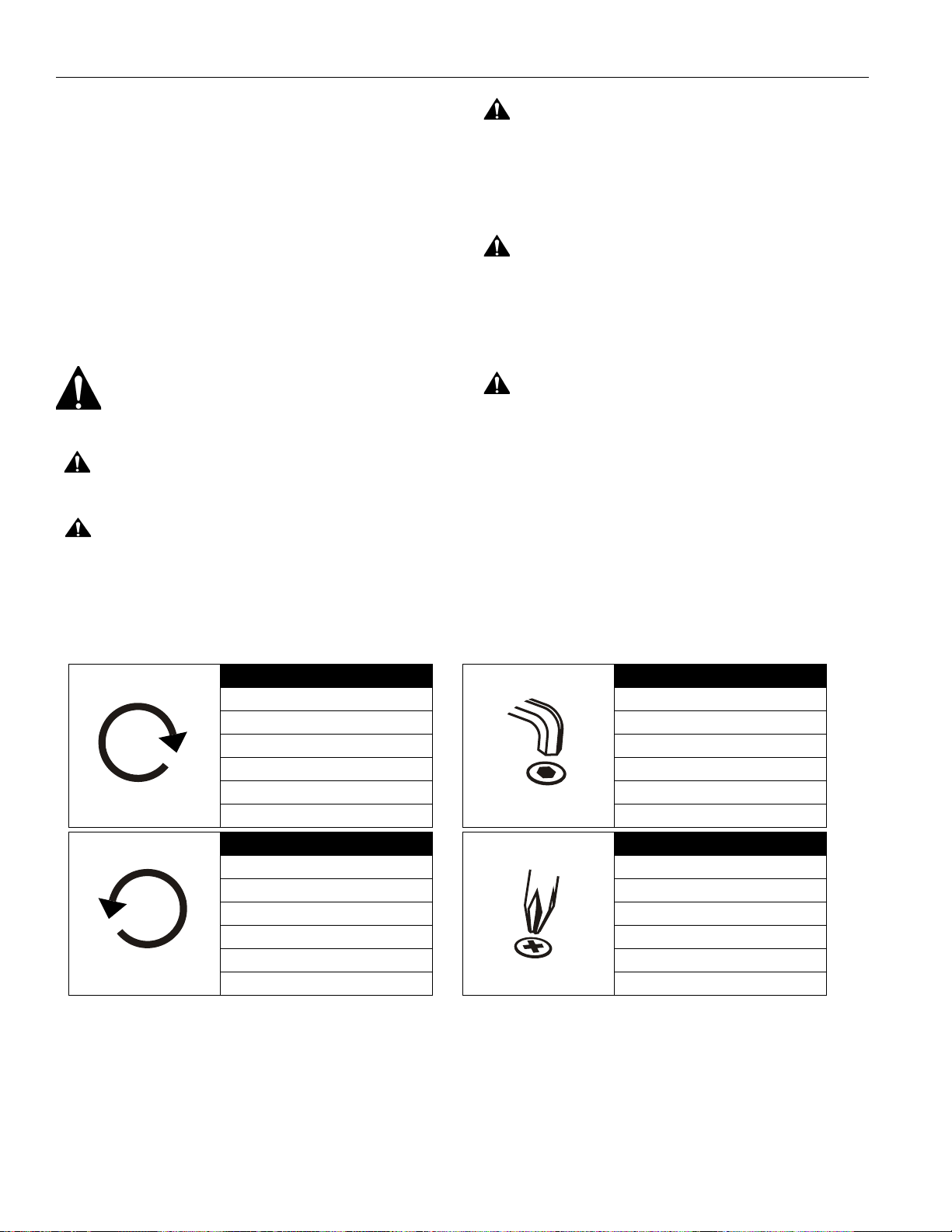

Tighten Fastener

Apretar elemento de fijación

Befestigungsteil festziehen

Apertar fixador

Serrare il fissaggio

Bevestiging vastdraaien

Serrez les fixations

Loosen Fastener

Aflojar elemento de fijación

Befestigungsteil lösen

Desapertar fixador

Allentare il fissaggio

Bevestiging losdraaien

Desserrez les fixations

Hex-Head Wrench

Llave de cabeza hexagonal

Sechskantschlüssel

Chave de cabeça sextavada

Chiave esagonale

Zeskantsleutel

Clé à tête hexagonale

Phillips Screwdriver

Destornillador Phillips

Kreuzschlitzschraubendreher

Chave de fendas Phillips

Cacciavite a stella

Kruiskopschroevendraaier

Tournevis à pointe cruciforme

DISCLAIMER

CSAV, Inc., and its affiliated corporations and subsidiaries

(collectively, "CSAV"), intend to make this manual accurate and

complete. However, CSAV makes no claim that the information

contained herein covers all details, conditions or variations, nor

does it provide for every possible contingency in connection

with the installation or use of this product. The information

contained in this document is subject to change without notice

or obligation of any kind. CSAV makes no representation of

warranty, expressed or implied, regarding the information

contained herein. CSAV assumes no responsibility for

accuracy, completeness or sufficiency of the information

contained in this document.

WARNING:

follow all instructions can result in serious personal injury,

damage to equipment, or voiding of factory warranty! It is the

installer’s responsibility to make sure all components are

properly assembled and installed using the instructions

provided.

WARNING:

for the installation of this kit can result in serious personal

injury or damage to equipment! It is the installer’s

responsibility to make sure the structure to which this kit is

attached can support five times the combined weight of all

equipment.

Failure to read, thoroughly understand, and

Failure to provide adequate structural strength

IMPORTANT WARNINGS AND

CAUTIONS!

WARNING:

serious injury or death if you do not follow the instructions.

CAUTION:

damage or destruction of equipment if you do not follow the

corresponding instructions.

A WARNING alerts you to the possibility of

A CAUTION alerts you to the possibility of

LEGEND

WARNING:

serious personal injury or damage to equipment! It is the

installer’s responsibility to make sure the combined weight of

all components attached to this accessory does not exceed

40 lbs (18.1 kg).

Exceeding the weight capacity can result in

2

Page 3

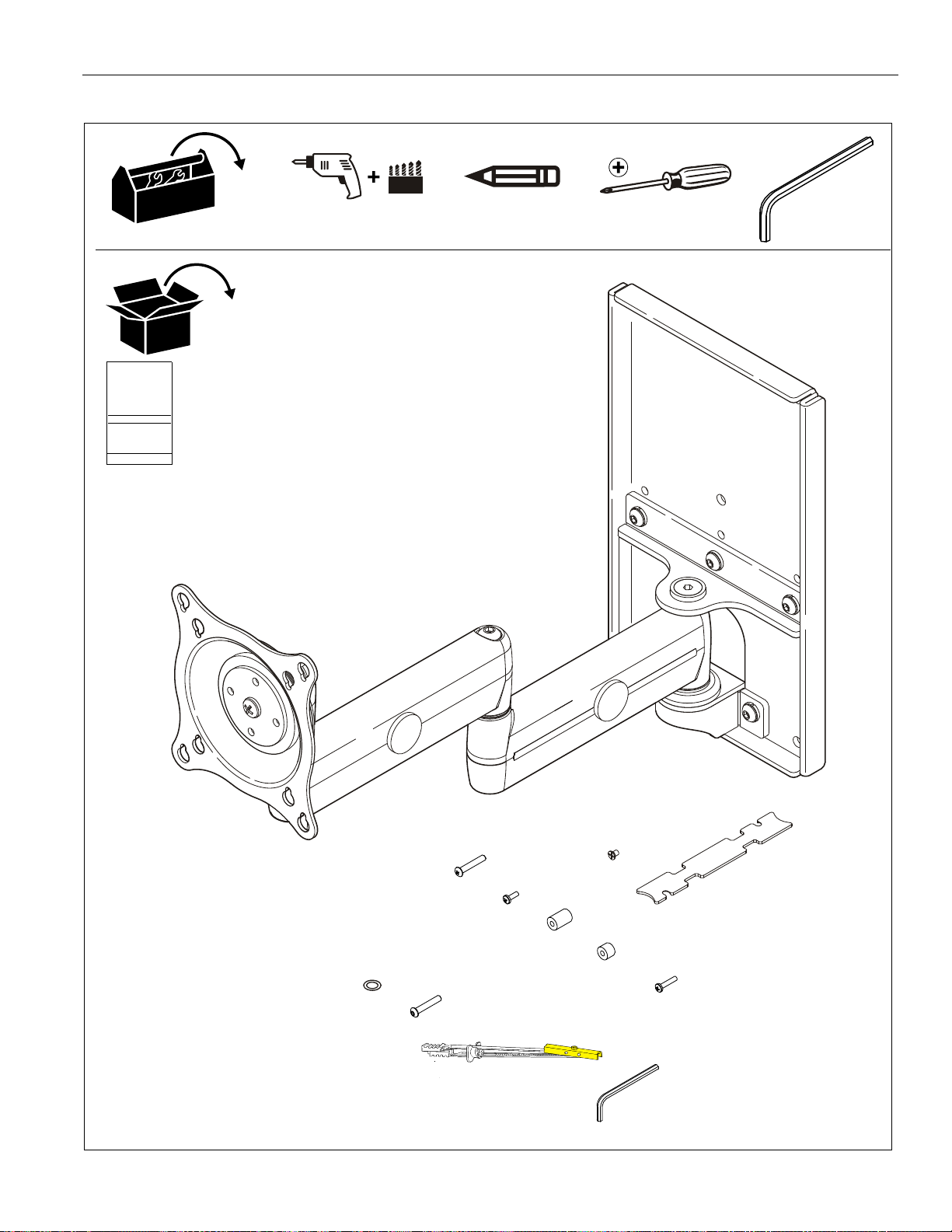

Installation Instructions FWDSK110

T

O

G

G

L

E

R

Ă

x1

I/M

A (1)

D (4)

G (4)

C (2)

E (4)

(3/16")

B (4)

J (3)

F (4)

K (3)

H (4)

M (1)

(M4 x 12)

L (3)

(1/2" x 3/4")

(1/4"-20 x 1 3/4")

1/2" (Ø13mm)

(3/16")

(M4 x 20)

(M4 x 20)

(1/4")

(1/2" x 3/8")

(1/4"-20 SNAPTOGGLE BB)

TOOLS REQUIRED FOR INSTALLATION AND PARTS

3

Page 4

FWDSK110 Installation Instructions

Drywall

1/2" minimum

Drywall Thickness

Display Mount Installation Location

FRONT

(Both Sides of Stud)

(Must be centered on stud)

There must be a minimum of

1 7/8" (48mm) clearance

inside wall

Steel Stud (2 x 4 / 25ga minimum)

Stud type and structural strength must conform to the North American

Specification for the Design of Cold-Formed Steel Structural Members.

If back side of wall is unfinished, drywall must be installed

to a minimum of one stud left and right of the stud(s)

being used to install the mount. Drywall must be

secured to studs with screws 12" on center

[362 S 125 18, C-Shaped, S-Stud Section]

Site Requirements

WARNING:

OR DAMAGE TO EQUIPMENT! The figure below identifies the minimum reguirements for installation of display mounts onto a

steel stud structure. If the structure or its components do not meet these requirements contact the mount manufacturer for specific

instructions before attempting installation. It should also be noted that no other equipment should be mounted to the same stud.

IMPROPER INSTALLATION CAN LEAD TO EQUIPMENT FALLING CAUSING SERIOUS PERSONAL INJURY

4

Figure 1

Page 5

Installation Instructions FWDSK110

1/2" (Ø13mm) x3

Mounting holes

centered on

studs

5

(A) x1

(L) x3

Drywall

Plastic Straps

Plastic Cap

Steel Stud

Drywall

Anchor Metal Channel

SIDE VIEW

(M) x3

Mount Installation

After determining the site meets the installation requirements:

1. Identify desired mounting location on wall.

2. Using a stud finder or similar method locate studs.

3. Align mounting holes in mount with studs making sure

mounting holes are centered on studs. (See Figure 2)

4. Mark location of three mounting holes on wall.

5. Drill three 1/2" (Ø13mm) holes. (See Figure 2)

Figure 3

7. Holding plastic straps on anchor (L), pull anchor away

from wall until channel rests flush behind wall making

sure anchor channel is positioned vertically on stud as

show in figues below. (See Figure 4)

8. Slide plastic cap on anchor (L) towards wall until

flange of cap is flush with wall. (See Figure 4)

Figure 2

6. Hold metal channel on anchor (L) flat alongside

plastic straps and slide channel through hole.

(See Figure 3)

Figure 4

9. Snap off plastic straps on anchor at wall by pushing

side to side, snapping off straps level with flange of

plastic cap. (See Figure 5)

10. Repeat steps 6 through 9 for each mounting hole.

5

Page 6

FWDSK110 Installation Instructions

Plastic Straps

Steel Stud

Drywall

Anchor Metal Channel

Plastic Cap

SIDE VIEW

Steel Stud

Drywall

Anchor Metal Channel

Display Mount

SIDE VIEW

(K) x 3

(J) x 3

(A) x 1

(E) x 2

Centris Bracket

Display Installation

The mounting holes on the back of your display will either be

flush with the back surface, or recessed into the back surface.

Refer to the applicable installation procedure.

Flush Mount Display

Figure 5

11. Place mount over anchors and align mounting holes

in display mount with holes in anchors. (See Figure 6)

12. Place flat washer (J) onto Phillips pan head screws

(K).

13. Insert Phillips pan head screws (K) with flat washer (J)

through mounting hole in display mount and into

anchor (L) and tighten until flush against mount. DO

NOT overtighten!

WARNING:

EQUIPMENT FALLING CAUSING SERIOUS PERSONAL

INJURY OR DAMAGE TO EQUIPMENT! Overtightening of

mounting hardware can damage the steel studs. DO NOT

overtighten mounting hardware!

IMPROPER INSTALLATION CAN LEAD TO

WARNING:

EQUIPMENT FALLING CAUSING SERIOUS PERSONAL

INJURY OR DAMAGE TO EQUIPMENT! Using screws of

improper size may damage your display! Proper screws will

easily and completely thread into display mounting holes.

WARNING:

EQUIPMENT FALLING CAUSING SERIOUS PERSONAL

INJURY OR DAMAGE TO EQUIPMENT! Inadequate thread

engagement in display may cause display to fall! Back out

screws ONLY as necessary to allow installation of Centris

bracket!

1. Ensure Centris bracket is able to swivel and tilt easily, yet

still be tight enough to hold display in desired position.

Adjust as required before proceeding.

See "ADJUSTMENTS" for detail.

IMPROPER INSTALLATION CAN LEAD TO

IMPROPER INSTALLATION CAN LEAD TO

2. Using Phillips screwdriver, carefully install two screws

(E) into the upper mounting holes on the display.

Thread screws completely into display, then back out

3 complete turns. (See Figure 7)

3. Pick up and align display so that screws (E) (installed

on the back of the display in the previous step) fit into

the mounting holes on the Centris bracket; rotate the

bracket as required (See Figure 7). Lower the display

into place.

6

Figure 6

Figure 7

4. Using Phillips screwdriver, install two remaining

screws (E) through the lower mounting holes in

Centris bracket and into display.

5. Tighten all four screws (E). Do not overtighten!

6. Proceed to "CABLE MANAGEMENT."

RECESSED MOUNTING HOLES

1. Ensure Centris bracket is able to swivel and tilt easily, yet

still be tight enough to hold display in desired position.

Adjust as required before proceeding.

See "ADJUSTMENT" for detail.

Page 7

Installation Instructions FWDSK110

(A) x 1

(D or H) x4

(F or G) x 4

Centris Bracket

(E) x 4

Cable Path

(typical)

(C) x 2

Adjustment Screws

Adjustment Screw

Phillips Screwdriver

2. Carefully place display face down on protective

surface.

3. Determine depth of recessed mounting holes relative

to back surface of display (against which Centris head

will contact). (See Figure 8)

4. Select proper length spacer and screw.

(See Figure 8)

NOTE: All spacers used should be the same length. If

the recess depths result in multiple spacer

lengths, then select the longer spacer.

5. Place the four selected spacers over each of the

mount holes on the back of the display.

6. Pick up and orient the mount (A) so that the mounting

holes in the Centris bracket are aligned with the holes

in the spacers; rotate the bracket as required. (See

Figure 8)

Figure 9:

ADJUSTMENTS

Swing Arm

PIVOT / SWING

1. Using 3/16" hex key, slightly loosen or tighten the

adjustment screw(s) as necessary (See Figure 10).

WARNING:

EQUIPMENT FALLING CAUSING SERIOUS PERSONAL

INJURY OR DAMAGE TO EQUIPMENT! Using screws of

improper size may damage your display! Proper screws will

easily and completely thread into display mounting holes.

7. Using Phillips screwdriver, install fo u r scr e ws (D o r H)

8. Tighten all four screws. Do not overtighten!

CABLE MANAGEMENT

1. Attach all cables to display.

CAUTION:

movement of display, and that cables will not be pinched by

installation of cover (C) or screws (E).

2. Carefully insert cables in cavity located in lower

3. Using Phillips screwdriver, install cover (10) with two

Figure 8

IMPROPER INSTALLATION CAN LEAD TO

through the mounting holes in Centris bracket,

through the spacers (F or G), and into the display.

(See Figure 8)

Ensure that adequate cable slack exists for

portion of mount arm (See Figure 9).

screws (20). (See Figure 9)

Figure 10

Centris Head

1. If previously attached, disconnect cables from display, then

remove display.

2. Using Phillips screwdriver, slightly loosen or tighten

the adjustment screw as necessary (See Figure 11).

Figure 11

7

Page 8

FWDSK110 Installation Instructions

8832-000218 RevC

©2007 Chief Manufacturing

www.chiefmfg.com

08/07

USA/International A 8401 Eagle Creek Parkway, Savage, MN 55378

P 800.582.6480 / 952.894.6280

F 877.894.6918 / 952.894.6918

Europe A Fellenoord 130 5611 ZB EINDHOVEN, The Netherlands

P +31 40 2668620

F +31 (0) 40 2668615

Asia Pacific A Room 30I, Block D, Lily YinDu International Building

LuoGang, BuJi Town, Shenzhen, CHINA. Post Code: 518112

P +86-755-8996 9226 ; 8996 9236 ; 8996 9220

F +86-755-8996 9217

Loading...

Loading...