Chicago Pneumatic CP861 Instruction Manual

CP861

Cut-O Tool

Model "K" & "L”

KF136502 Rev. G

Air Supply Requirements

1. Supply tool with 90 psig (6.2 bar) of clean, dry air. Higher pressure drastically

reduces tool life.

2. Connect tool to air line using pipe, hose and tting sizes shown in the diagram

on page 12.

3. Do not install a quick coupler directly into the tool throttle handle.

Lubrication

Use an air line lubricator with SAE #10 oil, adjusted to two drops per minute. If

an air line lubricator cannot be used, add air motor oil to the inlet once a day.

Noise & Vibration Declaration*

Sound pressure level 85 dB(A) in accordance with Pneurop 8N-1. For sound

power, add 10 dB(A).

Vibration value 3.3 m/s re. ISO 8662-1

Maintenance

1. Disassemble and inspect air motor every three months if the tool is used every

day. Replace damaged or worn parts.

2. High wear parts are underlined in the parts list.

*These declared values were obtained by laboratory type testing in compliance with the stated

standards and are not adequate for use in risk assessments. Values measured in individual work

places may be higher than the declared values. The actual exposure values and risk of harm

experienced by an individual user are unique and depend upon the way the user works, the

workpiece and the workstation design, as well as upon the exposure time and the physical condition

of the user. We, Chicago Pneumatic, cannot be held liable for the consequences of using the

declared values, instead of values reecting the actual exposure, in an individual risk assessment in

a work place situation over which we have no control.

2

To reduce risk of injury, everyone using, installing,

repairing, maintaining, changing accessories on, or

working near this tool must read and understand

these instructions before performing any such task.

We, Chicago Pneumatic Tool Company, 1800 Overview Road, Rock Hill, SC 29730 USA,

declare under our sole responsibility that the product to which this declaration relates, is in

conformity with the requirements of the Council Directive of June 1989 on the approximation

of the laws of the Member States relating to machinery (89/392/EEC).

Machine Name CP861 2-7/8" Cut-O Tool

Machine Type Power tool equipped for use with 3 in. diameter cutting wheels for metal

cutting - No other use is permitted

Serial No. Tools with No. 94200K, 01140L or higher

Technical Data

2.8 in. (73 mm) wheel capacity

Free speed 20,500 RPM

Air pressure 90 psi (6.2 bar)

Air consumption 17 cfm

Harmonized Standards Applied EN292

National Standards Applied ISO 8662-1, Pneurop 8N-1

Name and Position of Issuer W. A. LeNeveu, President, Chicago Pneumatic Tool

Company

Signature of Issuer

Place and Date of Issue Utica, NY 13501 USA, July 31, 1994

Limited Warranty: The "Products" of the Chicago Pneumatic Tool Company ("CP") are warranted to be

free from defects in material and workmanship for one year from the date of purchase. This Warranty

applies only to Products purchased new from CP or its authorized dealers. Of course, this Warranty

does not apply to products which have been abused, misused, modied, or repaired by someone other

than CP or its Authorized Service Representatives. If a CP Product proves defective in material or

workmanship within one year after purchase, return it to any CP Factory Service Center or Authorized

Service Center for CP tools, transportation prepaid, enclosing your name and address, adequate proof

of date of purchase, and a short description of the defect. CP will, at its option, repair or replace defective

Products free of charge. Repairs or replacements are warranted as described above for the remainder

of the original warranty period. CP's sole liability and your exclusive remedy under this Warranty is

limited to repair or replacement of the defective Product. (There Are No Other Warranties Expressed

Or Implied And CP Shall Not Be L

Any Other Damages, Costs Or Expenses Excepting Only The Cost Or Expense Of Repair Or

Replacement As Described Above.)

iable For Incidental, Consequential, Or Special Damages, Or

The goal of Chicago Pneumatic is to produce tools that help you work safely and

eciently. The most important safety device for this or any tool is YOU. Your

care and good judgment are the best protection against injury. All possible

hazards cannot be covered here, but we have tried to highlight some of the

important ones.

For Additional Safety Information Consult:

Your employer, union and/or trade association.

US Department of Labor (OSHA); www.osha.gov; Council of the

European Communities europe.osha.eu.int

“Safety Code for Portable Air Tools” (ANSI B186.1) available from:

www.ansi.org

“Safety Requirements for Hand-Held Non-Electric Power Tools”

available from: European Committee for Standardization,

www.cenorm.be

Air Supply and Connection Hazards

Air under pressure can cause severe injury.

Always shut o air supply, drain hose of air pressure and disconnect

tool from air supply when not in use, before changing accessories or

when making repairs.

Never direct air at yourself or anyone else.

Whipping hoses can cause serious injury. Always check for damaged or

loose hoses and ttings.

Do not use quick disconnect couplings at tool. See instructions for

correct set-up.

Whenever universal twist couplings are used, lock pins must be

installed.

Do not exceed maximum air pressure of 90 psi/6.2 bar or as stated on

tool nameplate.

Projectile Hazards

Always wear impact-resistant eye and face protection when involved

with or near the operation, repair or maintenance of the tool or changing

accessories on the tool.

Be sure all others in the area are wearing impact-resistant eye and face

protection.

Even small projectiles can injure eyes and cause blindness.

Operating Hazards

Always shut o air supply, relieve hose of air pressure and disconnect

tool from air supply when changing accessories.

Cutting with these tools will create sharp edges. Wear gloves to protect

hands.

Avoid direct contact with accessory and work surface during and after

work.

Cutting edges and saw blades can become hot during use. Do not

touch.

Never force the tool to cut faster or through heavier gauge material than

rated capacity.

To prevent damage to the tool and accessory, accessory must be held

rmly against work surface while cutting.

Workplace Hazards

Slip/Trip/Fall is a major cause of serious injury or death. Be aware of

excess hose left on the walking or work surface.

High sound levels can cause permanent hearing loss. Use hearing

protection as recommended by your employer or OSHA regulation (see

29 CFR part 1910).

Maintain a balanced body position and secure footing.

Repetitive work motions, awkward positions and exposure to vibration

can be harmful to hands and arms. If numbness, tingling, pain or

whitening of the skin occurs, stop using tool and consult a physician.

Avoid inhaling dust or handling debris from the work process which can

be harmful to your health. Use dust extraction and wear respiratory

protective equipment when working with materials which produce

airborne particles.

Proceed with care in unfamiliar surroundings. Be aware of potential

hazards created by your work activity.

Some dust created by power sanding, sawing, grinding, drilling and

other construction activities contains chemicals known to the State of

California to cause cancer and birth defects or other reproductive harm.

Some examples of these chemicals are:

- Lead from lead based paints

- Crystalline silica bricks and cement and other masonry products

- And Arsenic and chromium from chemically-treated rubber

Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemicals: work in a

well ventilated area, and work with approved safety equipment, such as

dust masks that are specially designed to lter out microscopic particles.

Additional Safety Topics

This tool and its accessories must not be modied.

This tool is not intended for use in an explosive atmosphere and is not

insulated for contact with electric power sources.

Operators and maintenance personnel must be capable of handling the

power of the tool and performing the job task.

For professional use only

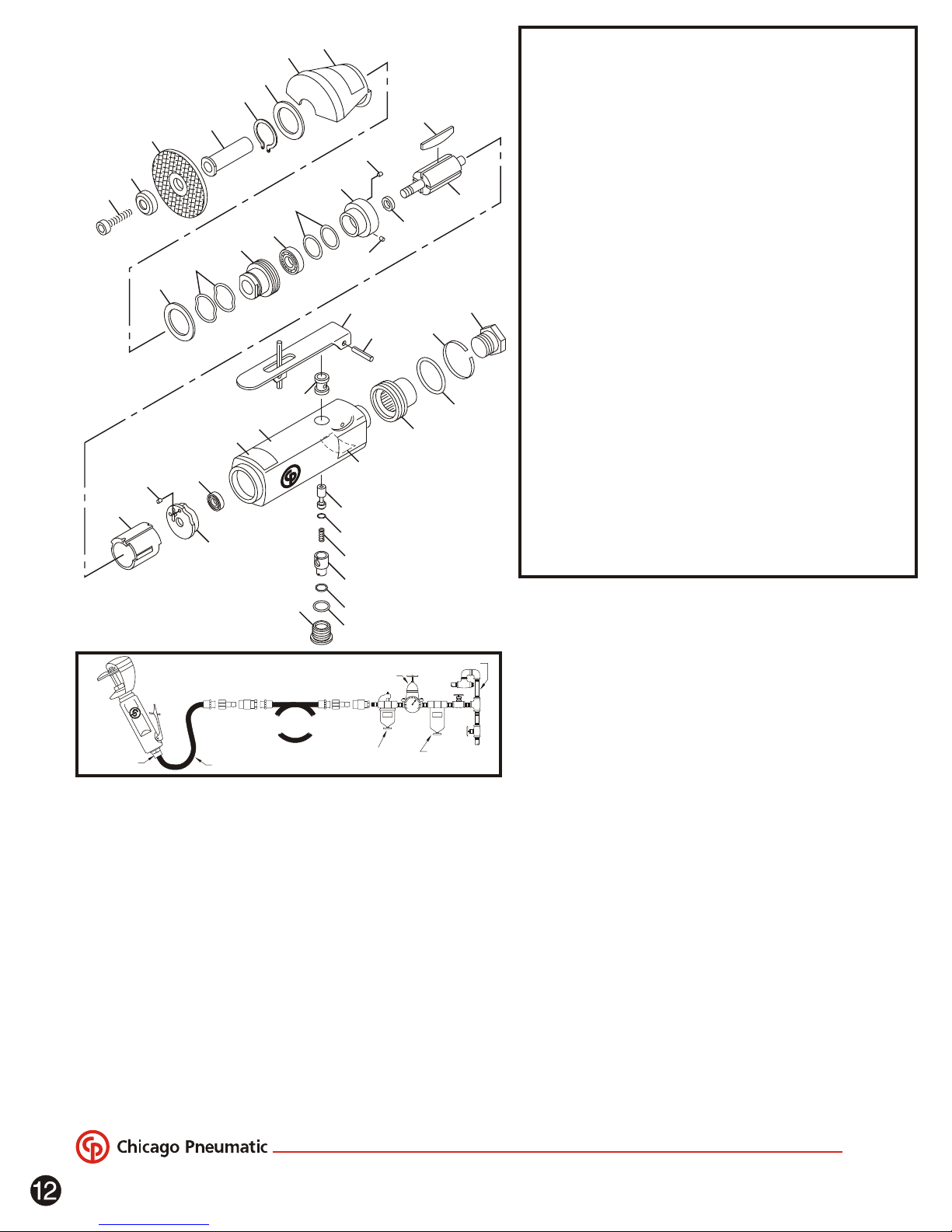

CP8 61

C ut-O To ol

136

138

142

105

59

60

107

143

106

105

116

119

62

59

65

70

67

104

63

71

14

140

15

9

32

144

54

145

139

61

146

141

5

58

7

3

Index

No.

3

5

7

9

14

15

19

20

32

54

58

59

60

61

62

63

65

67

70

71

104

105

106

107

116

119

125

127

136

138

139

140

141

142

143

144

145

146

Part

No. Description

KF124504

KF124505

C100129

KF124507

C138731

C114089

A043001

KF124511

KF136521

S039709

KF125474

KF127209

KF125477

KF124517

KF138243

KF124519

KF125473

C120326

KF124522

KF127208

KF136289

KF136291

KF136295

KF136294

KF136293

KF136290

CA157943

KF124528

P083071

CA155312

KF136292

CA157944

KF125475

KF125476

P092536

KF136505

KF136246

KF136500

CA144813

CA157797

8940158447

Spring-Throttle Valve

Valve-Throttle

O-Ring

Bushing-Throttle Valve

Lever - Throttle (Lock-O)

Pin-Roll

O-Ring

Plug-Throttle Valve

Housing-Motor (Incl: Index No's 9 & 146)

Bearing Ball

Plate-Rear End

(Includes:Index No. 59)

Pin-Roll

Liner

Rotor

Blade-Rotor Set (4)

Collar-Rotor

Plate- Front End

(Includes; Index Nos. 59 & 71)

Bearing-Ball

Shim (As Required)

Pin-Roll

Nut-Clamp

Spacer-Guard

Guard-Wheel

Washer-Wave

Ring-Ext. Retaining

Spindle-Wheel (Model K)

Spindle-Wheel (Model L)

Regulator-Air

O-Ring

Wheel-Cutting 2-7/8 in. (5 Pack)

Washer-Wheel (Model K)

Washer-Wheel (Model L)

Sleeve-Exhaust

Ring Snap

O-Ring

Screw-Hex Head Cap

Wrench-Spindle (Not Shown)

Decal-Caution

Decal-Warning

Decal-Guard Warning

Inlet Bushing

No.

Req'd.

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

125

20

127

19

1/2" (12mm)

90

130

0

CA048360 (1/2")

NPT

1/4"NPT

Air Supply Diagram

1/2" (12mm)

3/8" (10mm)

CA048362 (1/2")

CA048361 (1/2")

NPT

NPT

FOR DETAILED INFORMATION ABOUT CHICAGO PNEUMATIC AIR TOOLS AND EQUIPMENT CONTACT:

HEADQUARTERS LOCATION

UNITED STATES

Chicago Pneumatic Tool

Company

Automotive Division

1800 Overview Drive

Rock Hill, SC 29730

Telephone: 1-803-817-7000

1-800-367-2442 (USA only)

Fax: 1-800-228-9096

AUSTRALIA

Atlas Copco Tools Australia

3 Bessemer Street

Blacktown • Australia

Telephone: 02-621-9482

Fax: 02-671-5915

BELGIQUE

Chicago Pneumatic Rep. Oce

Avenue Sluysmans 10-4030

Liege • Belgium

Tel/Fax: 04-343 8150

BRASIL

Chicago Pneumatic Brasil

Av. Mascote 159 V. Sta. Catarina

04363-000

Sao Paulo/SP • Brasil

Telefone: (011) 562-7314

Fax: (011) 563-9208

CANADA

Chicago Pneumatic Tool Co.

Automotive Division

1800 Overview Drive

Rock Hill, SC 29730

Telephone: 1-803-817-7000

Fax: 1-800-228-9096

CENTRAL AMERICA

Contact Chicago Pneumatic/USA

for names of CP Authorized

Distributors in this area

GERMANY

Desoutter GMBH

Paul-Friedlander-Str

65203 Wiesbaden • Germany

Telephone: 49-0611-270120/22

FAX: 49-0611-270140

INDIA

Consolidated Pneumatic Tool

Company (India) Ltd.

301/302, L.B. Shastri Marg

P.O. Box 7761

Mulund, Bombay 400 080 • India

Phone: 91-22-564-0011

Fax: 91-22-564-7687

Telex: 1171990 CPT I N

ITALY

Desoutter Italiana S.R.L.

Viale Della Repubblica, 65

20035 Lisson (Milano)

MEXICO

Chicago Pneumatic Tool

Company Mexico

San Francisco #223

Valle Dorado, Tlalnepantla

C.P. 54020 • Mexico

Telephone: 525-378-0754

FAX: 525-378-0753

SOUTH AFRICA

Chicago Pneumatic Tool

Company, S.A.

20 Anvil Road

PO Box 105

Is ando , T rans vaa l

1600

South Africa

Phone: 011-9746761

Fax: 011-974-2324

SOUTH AMERICA

Contact Chicago Pneumatic/USA

for names of CP Authorized

Distributors in this area

SOUTHEAST ASIA

Chicago Pneumatic Tool

Company Regional Oce

P.O. Box 1516

Unit 2103 - Citimark

28 Yuen Shun Circuit

Shatin

New Territories, Hong Kong

Telephone: (8522) 3570963

FAX: 852-763-1875

SWEDEN

Chicago Pneumatic

Distributor Markets

Sickla Industriväg 7

S-131 34 Nacka • Sweden

Telephone: 46 8743 9329

Fax: 46-8743 9427

UNITED KINGDOM

Chicago Pneumatic

Tool Company, Ltd.

P.O. Box 241

Eaton Road

Hemel Hempstead, Herts HP2 7DR

England

Domestic: 01442-847703/06

Export: 01442-232420/17

FAX: 01442-2847723

Visit our websit e:

http: \\w ww.c hicagopneumatic.c om

PRINTED IN JAPAN

Loading...

Loading...