Chicago Electric 90282 User Manual

UTILITY WINCH - 2000 LBS.UTILITY WINCH - 2000 LBS.

UTILITY WINCH - 2000 LBS.

UTILITY WINCH - 2000 LBS.UTILITY WINCH - 2000 LBS.

90282

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright © 2003 by Harbor Freight Tools®. All rights reser ved. No portion of

this manual or any artwork contained herein may be reproduced in any shape

or form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

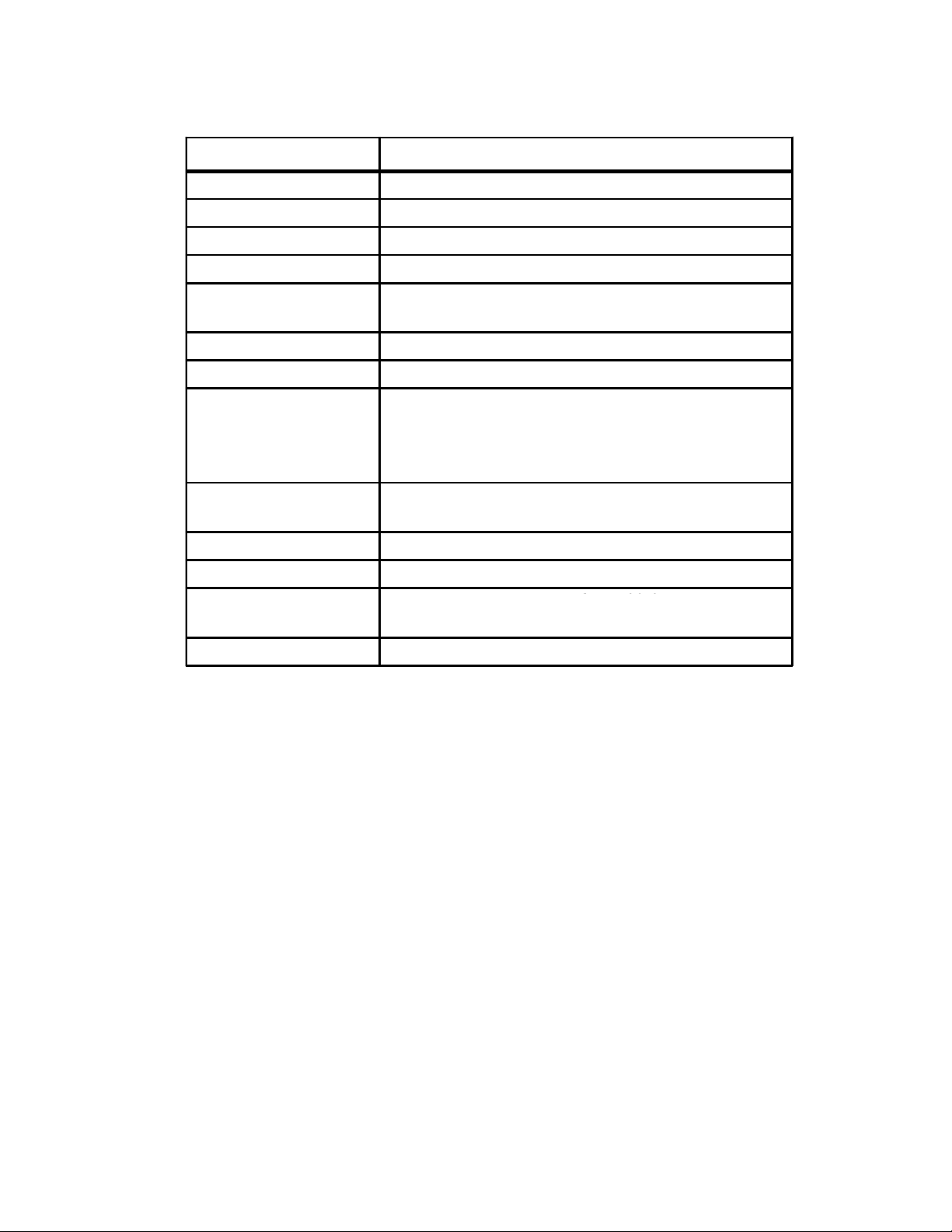

Specifications

ITEM DESCRIPT ION

Capacity 2,000 lbs.

Cable 49 feet (L) x 5/32 inches (dia.)

Drum Size 1-1/4 (dia.) x 2-7/8 (L) inches

Hook 4 (L) x 5/8 inch opening; spr ing loaded latch

Base Plate Size

Motor Power 12 VDC

Gear Reduction Rat io 153:1

Cable Speed

Control Cable

Clutch Free- spooling pull-out clutch release

Overall Dimensions 11-3/8 (L) x 4-1/2 (D) x 4-1/4 (H) inches

Power Cabl es

Weight 13.9 lbs.

5-1/4 (L) x 4 (W) x 4-1/4 (H) inches;

2 mounting holes: 5/16 (dia.) inch

, Amperage at Maximum Load = 100

10.5 feet per minute (500 lb. load); 10 amp

7.5 feet per minute (1000 lb. load); 40 amps

5.9 feet per minute (1500 lb. l oad); 60 amps

4.2 feet per minute (2000 lb. l oad); 90 amps

8-1/2 feet, handheld pistol grip with pushbutton

switches marked IN and OUT

Switch-to-motor: 51" (L) feet with lugs

Switch-to-battery: 68" (L) feet with lugs

with lugs

- #12 A WG

with lugs

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to

reduce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted. Do not use electrically

powered tools in the presence of flammable gases or liquids.

Page 2SKU 90282

REV 04/04

3. Keep children awa y . Children must never be allowed in the work area. Do not let

them handle machines, tools, or extension cords.

4. Store idle equipment. When not in use , tools must be stored in a dry location to

inhibit rust. Always lock up tools and keep out of reach of children.

5. Use the right tool for the job. Do not attempt to force a small tool or attachment to

do the work of a larger industrial tool. There are certain applications for which this tool

was designed. It will do the job better and more safely at the rate for which it was

intended. Do not modify this tool and do not use this tool for a purpose for which it

was not intended.

6. Dress properly. Do not wear loose clothing or jewelry as they can be caught in

moving parts. Protective, electrically non-conductive clothes and non-skid footwear

are recommended when working. Wear restrictive hair covering to contain long hair.

7. Do not overreach. Keep proper footing and balance at all times. Do not reach over

or across running machines.

8. Maintain tools with care. Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories. Inspect

tool cords periodically and, if damaged, have them repaired by an authorized

technician.

9. Disconnect power. Unplug tool when not in use.

10. Remove adjusting keys and wrenches. Check that keys and adjusting wrenches

are removed from the tool or machine work surface before turning on.

11. Avoid unintentional starting. Be sure the switch is in the Off position when not in

use and before connecting power.

12. Stay alert. Watch what you are doing, use common sense. Do not operate any tool

when you are tired.

13. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting fixtures; and any other condition that may affect proper operation. Any

part that is damaged should be proper ly repaired or replaced by a qualified

technician. Do not use the tool if any switch does not turn On and Off properly.

14. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use accessories

intended for use with this tool. Approved accessories are available from Harbor

Freight Tools.

15. Do not operate tool if under the influence of alcohol or drugs. Read warning

labels if taking prescription medicine to determine if your judgment or reflexes are

impaired while taking drugs. If there is any doubt, do not operate the tool.

16. Maintenance. For your safety, service and maintenance should be performed

regularly by a qualified technician.

Page 3SKU 90282

Loading...

Loading...