Chicago Electric 3223 User Manual 2

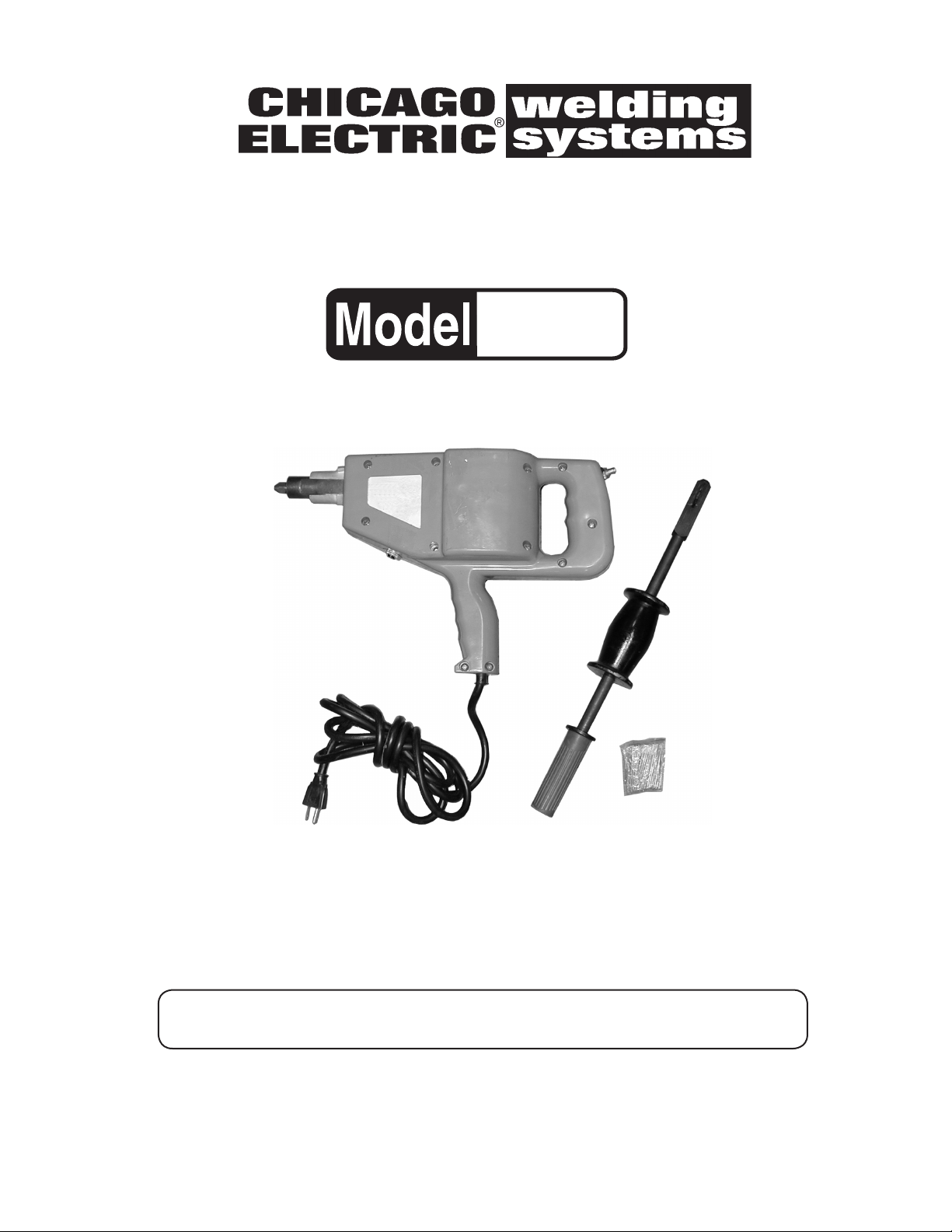

STUD WELDER DENT REPAIR KIT

Distributed exclusively by

Harbor Freight Tools

®

.

03223

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

TO PREVENT SERIOUS INJURY, READ AND UNDERSTAND

ALL WARNINGS AND INSTRUCTIONS BEFORE USE.

Copyright © 2003 by Harbor Freight Tools®. All rights reserved. No portion of

this manual or any artwork contained herein may be reproduced in any shape

or form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353.

Cover Rev 06f, 07e

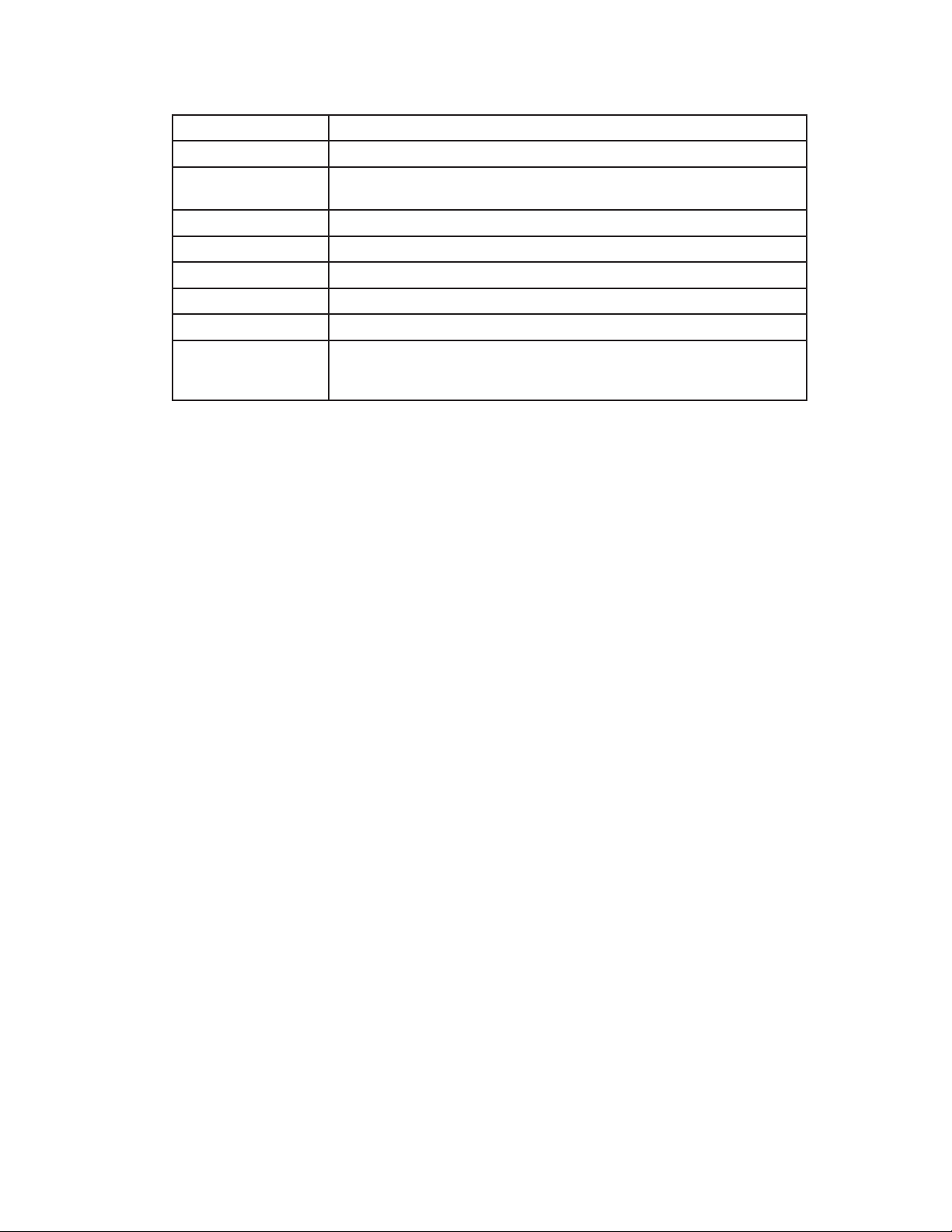

Specifications

Welding Process Resistance Weld

Power Requirement 120 V~, 60 Hz, ~40 A Peak

Recommended

Circuit

Switch Pushbutton, momentary

Circuit Breaker Pushbutton reset; Rating: 125/250 VAC, 60 Hz, 10 amp

Stud Weld Time 0.5 to 1.0 seconds

Line Cord 6 foot, 3-prong plug, UL listed

Weight 10.1 lb.

Accessories

20 A (dedicated)

- Bag: 100 each 2mm, 3mm, 4mm studs; steel with copper coating

- 2 lb. slide hammer dent puller

- One of each nozzle (2mm, 3mm, 4mm)

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to

reduce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

Keep work area clean1. . Cluttered areas invite injuries.

Observe work area conditions2. . Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted. Do not use electrically

powered tools in the presence of flammable gases or liquids.

Keep children away3. . Children must never be allowed in the work area. Do not let them

handle machines, tools, or extension cords.

Store idle equipment4. . When not in use, tools must be stored in a dry location to inhibit

rust. Always lock up tools and keep out of reach of children.

Use the right tool for the job5. . Do not attempt to force a small tool or attachment to

do the work of a larger industrial tool. There are certain applications for which this

tool was designed. It will do the job better and more safely at the rate for which it was

intended. Do not modify this tool and do not use this tool for a purpose for which it was

not intended.

Dress properly6. . Do not wear loose clothing or jewelry as they can be caught in

moving parts. Protective, electrically non-conductive clothes and non-skid footwear are

recommended when working. Wear restrictive hair covering to contain long hair.

Do not overreach7. . Keep proper footing and balance at all times. Do not reach over or

across running machines.

REV 04b, 04e, 07e

For technical questions, please call 1-800-444-3353.

Page 2SKU 3223

Use eye and ear protection8. . Always wear ANSI-approved impact safety goggles. Wear

a NIOSH-approved dust mask or respirator when working around metal, wood, and

chemical dusts and mists.

Maintain tools with care9. . Keep tools sharp and clean for better and safer performance.

Follow instructions for lubricating and changing accessories. Inspect tool cords periodically

and, if damaged, have them repaired by a qualified technician. The handles must be kept

clean, dry, and free from oil and grease at all times.

10. Disconnect power. Unplug tool when not in use.

11. Remove adjusting keys and wrenches. Check that keys and adjusting wrenches are

removed from the tool or machine work surface before plugging it in.

Avoid unintentional starting12. . Be sure the switch is in the Off position when not in use

and before plugging in. Do not carry any tool with your finger on the trigger, whether it

is plugged in or not.

Stay alert13. . Watch what you are doing, use common sense. Do not operate any tool

when you are tired.

Check for damaged parts14. . Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting fixtures; and any other condition that may affect proper operation. Any part

that is damaged should be properly repaired or replaced by a qualified technician. Do

not use the tool if any switch does not turn On and Off properly.

15. Guard against electric shock. Prevent body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerator enclosures.

16. Replacement parts and accessories. When servicing, use only identical replacement

parts. Use of any other parts will void the warranty. Only use accessories intended for

use with this tool. Approved accessories are available from Harbor Freight Tools.

17. Do not operate tool if under the influence of alcohol or drugs. Read warning labels

if taking prescription medicine to determine if your judgment or reflexes are impaired

while taking drugs. If there is any doubt, do not operate the tool.

18. Use proper size and type extension cord. If an extension cord is required, it must be

of the proper size and type to supply the correct current to the tool without heating up.

Otherwise, the extension cord could melt and catch fire, or cause electrical damage to

the tool. This tool requires use of an extension cord with up to 20 amps capability (up to

50 feet), with wire size rated at 10 AWG. Longer extension cords require larger size wire.

If you are using the tool outdoors, use an extension cord rated for outdoor use (signified

by “WA” on the jacket).

19. Maintenance. For your safety, service and maintenance should be performed regularly

by a qualified technician.

People with pacemakers should consult their physician(s) before use. 20.

Electromagnetic fields in close proximity to heart pacemaker could cause pacemaker

interference or pacemaker failure.

This Stud Welder requires the use of both hands when operating.21. This helps maintain

tool stability and keeps hands away from the working area of the tool.

For technical questions, please call 1-800-444-3353.

Page 3SKU 3223

Loading...

Loading...