Page 1

16” ELECTRIC Chain Saw

®

WITH BRAKE

Model 02810

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at: http://www.harborfreight.com

Copyright© 2002 by Harbor F reight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor F reight Tools.

For technical questions, please call 1-800-444-3353.

Page 2

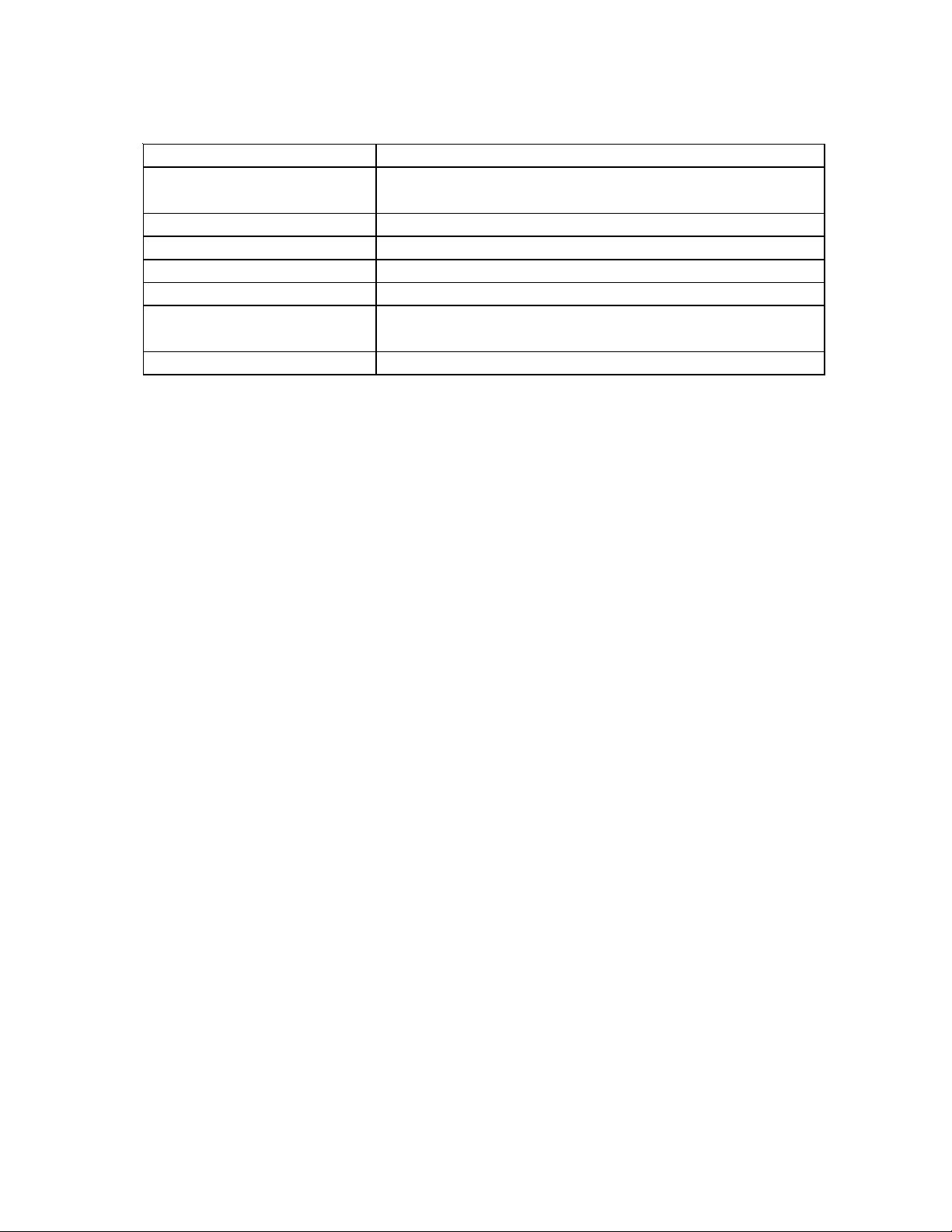

PRODUCT SPECIFICATIONS

Item Description

Electrical Requirements 2 HP / 120 V / 60 Hz / 13.2 Peak Amps,

7.8 No Load Amps / 1600 Watt

Cutter Bar Size 16”

Brake Stop Electromagnetic Stop Within .15 Sec. After Shutoff

Chain Type #91VG “Oregon

Oiler System Automatic

Chain Guide Rail

Dimensions

Weight 11 Pounds

16-1/8” Long x 2-1/2” Wide x 5/32” Thick

®

Chain”

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions,

assembly, operating, inspection, maintenance and cleaning

procedures, parts list and assembly diagram. Keep your invoice

with this manual. Write the invoice number on the inside of the front

cover. Keep this manual and invoice in a safe and dry place for

future reference.

GENERAL SAFETY WARNINGS AND PRECAUTIONS

1. KEEP WORK AREA CLEAN AND DRY. Cluttered, damp, or wet work areas

invite injuries.

2. KEEP CHILDREN AWAY FROM WORK AREA. Do not allow children to handle

this product.

3. STORE IDLE EQUIPMENT. When not in use, tools and equipment should be

stored in a dry location to inhibit rust. Always lock up tools and equipment, and

keep out of reach of children.

4. DO NOT USE THIS PRODUCT IF UNDER THE INFLUENCE OF ALCOHOL OR

DRUGS. Read warning labels on prescriptions to determine if your judgement or

reflexes are impaired while taking drugs. If there is any doubt, do not attempt to

use this product.

5. USE EYE AND HEARING PROTECTION. Wear ANSI approved safety impact

eye goggles, full face shield and ANSI approved hearing protection (plugs or

muffs) during use. ANSI approved safety impact eye goggles and hearing protection are available from Harbor Freight Tools.

Page 2SKU 02810 For technical questions, please call 1-800-444-3353.

Page 3

6. DRESS SAFELY. Do not wear loose clothing or jewelry, as they can become

caught in moving parts. Wear a protective hair cov ering to pre vent long hair from

becoming caught in moving parts. Wear close fitting clothing and steel toed

shoes.

7. DO NOT OVERREACH. K eep proper footing and balance at all times to prevent

tripping, falling, back injury, etcetera.

8. INDUSTRIAL APPLICATIONS MUST FOLLOW OSHA REQUIREMENTS.

9. STAY ALERT. W atch what you are doing at all times. Use common sense. Do

not use this product when you are tired or distracted from the job at hand.

10. CHECK FOR DAMAGED PARTS. Before using this product, carefully check that

it will operate properly and perform its intended function. Check for damaged

parts and any other conditions that may affect the operation of this product. Replace or repair damaged or worn parts immediately.

11. REPLACEMENT PARTS AND ACCESSORIES: When ser vicing, use only

identical replacement parts. Only use accessories intended for use with this

product. Approved accessories are available from Harbor F reight Tools.

12. MAINT AIN THIS PRODUCT WITH CARE. Keep this product clean and dry for

better and safer performance.

13. MAINTENANCE: For y our safety , service and maintenance should be performed

regularly by a qualified technician.

14. USE THE RIGHT TOOL FOR THE JOB. Do not attempt to force a small tool or

attachment to do the work of a larger industrial tool. There are certain applications for which this tool was designed. It will do the job better and more safely at

the rate for which it was intended. Do not modify this tool, and do not use this tool

for a purpose for which it was not intended.

15. WARNING: The warnings, precautions, and instructions discussed in this manual

cannot cover all possib le conditions and situations that may occur. The operator

must understand that common sense and caution are factors, which cannot be

built into this product, but must be supplied b y the oper ator.

16. WARNING: Take caution as some woods contain preservatives such as copper

chromium arsenate (CCA) which can be toxic. When cutting these materials extra

care should be taken to avoid inhalation and minimize skin contact.

Page 3SKU 02810 For technical questions, please call 1-800-444-3353.

Page 4

SPECIFIC PRODUCT WARNINGS AND PRECAUTIONS

1. MAINTAIN A SAFE WORKING ENVIRONMENT . Make sure the work area is well

lit. Make sure there is adequate surrounding workspace. Always keep the work

area free of obstructions, tree limbs, vegetation, and other debris. Do not use the

Chain Saw in areas near flammable chemicals, dusts, and vapors. Do not use the

Chain Saw in a damp or wet location.

2. DO NOT USE THE CHAIN SAW WITH ADULTS, CHILDREN, AND PETS IN

CLOSE PRO XIMITY.

3. ALWAYS HOLD THE CHAIN SAW FIRMLY WITH BOTH HANDS UNTIL THE

ROTATING CHAIN (57) COMPLETELY STOPS. MAKE SURE TO STAND IN A

STABLE, BALANCED POSITION WHEN USING THE CHAIN SAW. Avoid awk-

ward postures.

4. DO NOT USE THE CHAIN SAW IF THE CHAIN (57) IS DULL.

5. BE AW ARE OF THE DIRECTION OF THE RO T ATION OF THE CHAIN (57). Chain

must move in the direction shown in Figure C, page 7.

6. ALWAYS BE PREPARED FOR THE POSSIBILITY OF CHAIN SAW KICKBACK.

Kickback is a sharp, quic k, upw ard mov ement of the Chain Sa w when it is running.

This usually occurs when the upper/front quarter of the Guide Bar (52) binds with

the piece of wood being cut. In the event of a significant kickback, the Chain Safety

Brake may be automatically triggered, instantly stopping the rotating Chain (57)

and turning off the Chain Saw . The rotating chain ma y also be stopped by manually

pushing the Chain Safety Brake forward.

7. ALWAYS CARRY THE CHAIN SAW BY ITS HANDLE (47) WITH THE CHAIN

(57) POINTING BA CKW ARDS AND THE CHAIN SA W A SAFE DIST ANCE FROM

Y OUR BODY. NEVER CARRY THE CHAIN SAW BY ITS ELECTRIC CORD (23).

KEEP HANDS AND FINGERS WELL AW AY FROM THE ON/OFF TRIGGER (25B)

WHILE CARRYING THE CHAIN SAW.

8. MAKE SURE THE WOOD BEING CUT DOES NOT CONTAIN FOREIGN BODIES SUCH AS NAILS, SPIKES, ST ONES, ETC. DO NO T A TTEMPT TO CUT ANY

OTHER MATERIALS OTHER THAN WOOD.

9. DO NOT AB USE THE ELECTRIC CORD. Do not use the Electric Cord (23) to pull

its Plug from a power outlet or extension cord. Keep the Electric Cord away from

heat, water, oil, shar p edges, and moving par ts. Do not route the Electric Cord

where it can be walked on or tripped over.

10. KEEP ALL SAFETY GUARDS IN PLACE, IN PROPER ADJUSTMENT, AND IN

PROPER ALIGNMENT.

Page 4SKU 02810 For technical questions, please call 1-800-444-3353.

Page 5

11. IF AN EXTENSION CORD (not included) IS USED, MAKE SURE TO USE ONLY

(

)

UL APPROVED, OUTDOOR, CORDS HAVING THE CORRECT GAUGE AND

LENGTH. (See Figure A.)

REQUIRED MINIMUM EXTENSION CORD GAUGE – 120 VOLT

NAMEPLATE

AMPERES

At Full Load

0 - 25

Feet

0 - 5 16 16 16 12 12

5.1 - 8 16 16 14 10 -

8.1 - 12 14 14 12 - -

12.1 - 15 12 12 10 - -

15.1 - 20 10 10 10 - -

EXTENSION CORD LENGTH

25 - 50

Feet

50 -100

Feet

100 – 150

Feet

150– 200

Feet

FIGURE A

12. REDUCE THE RISK OF ACCIDENTAL STAR TING. Make sure the On/Off Trigger

(25b) is in the “OFF” position before plugging the Electric Cord into a grounded, 120

Volt, electrical outlet.

13. NEVER pass hands or legs directly under the Chain (57) when cutting wood. Always keep hands and legs a safe distance away from the rotating Chain.

14. PRIOR TO STARTING THE CHAIN SAW, MAKE SURE ALL ADJUSTING KEYS

AND WRENCHES ARE REMOVED FROM THE TOOL.

15. ALLOW THE CHAIN (57) TO ROTATE UP TO FULL SPEED BEFORE FEEDING

IT INTO WOOD. When turning off the Chain Saw, allow the Chain to slow and stop

on its own. Do not press against the Chain to stop it.

16. FEED THE CHAIN (57) GRADUALLY INTO THE MATERIAL BEING CUT. Do not

force the Chain Saw to remove material faster than it was designed to cut.

17. NEVER ATTEMPT TO REMOVE MATERIAL STUCK IN THE MOVING PARTS

OF THE CHAIN SAW WHILE IT IS PLUGGED IN AND RUNNING. TURN OFF

THE CHAIN SA W IF THE CHAIN (57) NEEDS TO BE BACKED OUT OF AN UNCOMPLETED CUT.

18. NEVER LEAVE THE CHAIN SAW UNATTENDED WHEN IT IS PLUGGED IN.

Tu rn off the Chain Saw, unplug it from its electrical power source, and wait until it

has completely stopped before leaving.

19. ALWA YS RELEASE THE ON/OFF TRIGGER (25B) TO ITS “OFF” POSITION, AND

UNPLUG THE CHAIN SAW FROM ITS ELECTRICAL SUPPLY SOURCE BEFORE PERFORMING ANY INSPECTION, MAINTENANCE, OR CLEANING

PROCEDURES.

20. IMPORTANT! TREE FELLING AND BRANCH TRIMMING IS A DANGEROUS

ACTIVITY. USE OF A CHAIN SAW REQ UIRES THAT Y OU BE IN GOOD PHYSICAL CONDITION, WITH GOOD BALANCE AND COORDINATION. If you are in

Page 5SKU 02810 For technical questions, please call 1-800-444-3353.

Page 6

any doubt about the safety issues in volved, have a qualified, certified, arborist/tree

surgeon do the work for you.

21. WARNING: Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities, contain chemicals known (to the State of California) to

cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are: lead from lead-based paints, crystalline silica from bricks and cement or other masonry products, arsenic and chromium from chemically treated

lumber. Your risk from these exposures v aries, depending on how often you do this

type of work. To reduce your exposure to these chemicals: w ork in a well ventilated

area, and work with approved safety equipment, such as those dust masks that are

specially designed to filter out microscopic particles. (California Health & Safety

Code § 25249.5,

22. WARNING: We recommend that people with pacemakers not use this tool. This

tool produces strong electromagnetic fields that can cause interference or failure of

the pacemaker. People with pacemakers should consult their physician(s) for advice.

et seq.

)

UNPACKING

When unpacking, check to make sure all the parts shown on the Parts List on page 11

are included. If any par ts are missing or broken, please call Harbor Freight Tools at the

number shown on the cover of this manual as soon as possible.

ASSEMBLY INSTRUCTIONS

NOTE: For additional references to the par ts listed in the following pages, refer to the

Assembly Diagram on page 12.

To Attach Or Replace The Chain Guide Rail And Chain:

1. WARNING: Mak e sure to turn the On/Off Trigger (25b) to its “OFF” position and unplug the Electric Cord (23) from its electrical outlet before performing this procedure.

2. Remove Screw (7) and Nylon Insert Nut (67) from the Chain Cover (46) with the

tools provided. Note the Blade Guide Pin (62) and Bolt (6) shown in Figure B. Make

sure the Guide Pin is positioned near the rear (left end) of the slot. Mak e certain that

the oil port is open and free of debris.

3. Place the Chain (57) around the rear of the Chain Gear (45), making certain that the

teeth along the top of the Chain point forward.

4. Place Guide Bar (52) with the center slot over the threaded end of the Bolt (66), and

fixed pin (molded into the Front Cover (42)), as in Figure C. The Blade Guide Pin

(62) goes into the lower hole in the blade. These steps may be easier with assistance.

REV 05/05

Page 6SKU 02810 For technical questions, please call 1-800-444-3353.

Page 7

FIGURE B

5. Replace the Chain Cover (46), and tighten the Nylon Insert Nut (67) so that the

Cover is snug, but not tight. (See Figure D, next page.)

6. Pull gently up on the tip of the Guide Bar (52), while turning the Blade Adjustment

Screw (61) clockwise (photo 005.) Because the saw is light in weight, this is easier

if someone holds the handle. Do not overtighten the Chain. There should only be

about 1/4” of space when the Chain is pulled upw ard at the center of the Guide Bar .

Lightly oil the entire Chain (57). (See Figure C.)

FIGURE C

7. When finished, tighten the Nylon Insert Nut (67) securely, and replace Screw (7).

Check the Chain tension after initial operation of the saw. It may need adjustment.

REV 05/05

Page 7SKU 02810 For technical questions, please call 1-800-444-3353.

Page 8

OIL FILL CAP (11)

ON/OFF TRIGGER (25b)

FIGURE D

CHAIN COVE R

(46)

To Check For Proper Chain Tension:

BLADE ADJUSTMENT

SCREW (61)

NUT

(67)

GUIDE BAR (52)

CHAIN (57)

1. The Chain (57) tension is proper when the Chain snaps back after being pulled 1/4”

awa y from the Guide Bar (52) with light force . There should be no sagging between

the Chain and Guide Bar underneath. When necessary, use a screwdriver to turn

the Adjustment Screw (61) clockwise to tighten, or counterclockwise to loosen, the

Chain (57). (See Figure D.)

2. NOTE: A Chain (57) which is too taut leads to premature Chain and Guide Bar (52)

wear . A Chain which is too loose may jump out of the Guide Bar groove and damage the tool or cause personal injury. New chains typically lose tension initially

during use. When necessary, readjust the Chain tension by follo wing the directions

in Step # 1 of this section.

To Refill The A utomatic Chain Lubrication System:

1. The Chain Saw features an

automatic

Chain Lubrication System with a built-in Oil

Reservoir. Lubrication of the Chain (57) is carried out automatically while the Chain

Saw is running. The oil le vel should be chec ked bef ore each use of the Chain Saw.

2. To refill the Oil Reservoir, unscrew the Oil Fill Cap (11). Fill the Oil Reservoir with a

quality grade chain saw Chain Oil (SAE 30). When filling, avoid introducing dirt or

other foreign material into the Oil Reservoir. Then, retighten the Oil Fill Cap onto the

Oil Reservoir. (See Figure D.)

REV 05/05

Page 8SKU 02810 For technical questions, please call 1-800-444-3353.

Page 9

OPERATING INSTRUCTIONS

The Safety Brake:

1. The Saf ety Brak e is activated when the bac k of the operator’ s hand pushes against

the back of the Protect Plate (17). When activated, the Chain Saw will stop automatically, and the On/Off Trigger (25b) should be manually released. Ne xt, pull the

Protect Plate (17) back to its initial position in order to restart the Chain Saw .

NOTE: If the Protect Plate (17) is

not

pulled back to its initial position, the Chain Saw will

not operate. (See Figure E.)

2. To check for proper operation of the Safety Brake, disconnect the Chain Saw from

its electrical power outlet and push the Protect Plate (17) forward. Pull on the Chain

(57) with your hand protected by heavy wor k gloves. The Chain Saw should be

automatically locked in its “OFF” mode.

ON/OFF TRIGGER (25b)

ELECTRIC

CORD (23)

FIGURE E

PRO TECT PLA TE (17) HANDLE (47)

CHAIN (57)

CARBON BRUSH (4)

CARBON BRUSH HOLDER (5)

CARBON BRUSH HOUSING (6)

To Start The Chain Saw:

1. Make sure the On/Off Trigger (25b) is in its “OFF” position. (See Figure E.)

2. Plug the Electric Cord (23) into a grounded, 120 volt, electrical outlet.

(See Figure E.)

3. Use both hands to firmly grasp the handle portion of the Motor Housing Handle (1)

and Handle (47). (See Figure E.)

4. Bef ore starting the Chain Saw , mak e sure nothing is in contact with the Chain (57).

(See Figure E.)

5. Make sure the Protect Plate (17) is pulled back towards your body until it “clicks”

and locks in place. (See Figure E.)

6. To star t the Chain Saw, push the Safety Switch on the On/Off Trigger (25b) and

squeeze the On/Off Trigger . (See Figure E.)

7. Release the On/Off Trigger (25b) to stop the Chain Saw . WARNING: Firmly hold the

Chain Saw with both hands until the Chain Saw completely stops. (See Figure E.)

Page 9SKU 02810 For technical questions, please call 1-800-444-3353.

Page 10

INSPECTION, MAINTENANCE, AND CLEANING

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUF ACTURER AND/OR DISTRIBUT OR HAS PRO VIDED THE PARTS DIA GRAM IN THIS MANU AL AS A

REFERENCE T OOL ONL Y. NEITHER THE MANUF ACTURER NOR DISTRIBUT OR MAKES ANY REPRESENT ATION OR W ARRANTY OF ANY KIND T O THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REP AIRS TO

THE PRODUCT OR THAT HE OR SHE IS QUALIFIED T O REPLACE ANY P AR TS OF THE PRODUCT. IN F ACT , THE

MANUF ACTURER AND/OR DISTRIBUT OR EXPRESSLY ST ATES THA T ALL REPAIRS AND PAR TS REPLACEMENTS SHOULD BE UNDERT AKEN BY CER TIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER.

THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REP AIRS TO THE ORIGINAL

PRODUCT OR REPLACEMENT PARTS THERETO , OR ARISING OUT OF HIS OR HER INSTALLA TION OF RE-

PLACEMENT PARTS THERETO .

1. WARNING: Always turn the On/Off Trigger (25b) to its “OFF” position and unplug the

Electric Cord (23) from its electrical outlet before performing any inspection, maintenance, or cleaning. (See Figure E.)

2. BEFORE EACH USE, inspect the general condition of the Chain Saw. Check for

loose screws, misalignment or binding of moving par ts, cracked or broken par ts

(i.e., Chain, 57), damaged electrical wiring, and any other condition that may affect

its safe operation. If abnormal noise or vibration occurs, have the problem corrected

before further use.

3. UPON EVERY THREE HOURS OF USE, make sure the Chain (57) is adequately

lubricated and taut. If necessary, remove the Guide Bar (52) and Chain. Clean the

groove in the Guide Bar thoroughly and clean the Oil P ort in the F ront Cover (42) to

ensure that it is not block ed or obstructed, see Figure B. To maximize the life of the

Guide Bar, turn the Guide Bar ov er and then reinstall. (See Figures C and D.)

4. PERIODICALLY, remove the Carbon Brush Housing (6) to inspect the condition of

the Carbon Brush (4). If the Carbon Brush is simply dirty , you ma y carefully clean it

with a pencil eraser. The Carbon Brush has a wear limit marking on it. You may

safely use the Carbon Brush up to the wear limit. When it has worn up to the wear

limit, the Carbon Brush must be replaced. When replacing the Carbon Brush make

sure it fits neatly into its Carbon Brush Holder (5) and that the spring on the Carbon

Brush operates freely . Make sure the carbon portion of the Carbon Brush contacts

the Motor Armature (24). After inspection or replacement, replace the Carbon Brush

Housing. (See Figure E.)

Do not use damaged equipment.

5. TO CLEAN: Clean with a soft brush, cloth, or vacuum to remove debris from the

Cold Saw . If necessary , use a mild detergent or mild solv ent. Then, use a premium

quality, lightweight machine oil to lubricate all moving parts.

6. If cutting efficiency diminshes, the included round file may be used to sharpen the

teeth of the chain. The chain should also be sharpened professionally at least once

a year, depending on use.

Page 10SKU 02810 For technical questions, please call 1-800-444-3353.

Page 11

PARTS LIST

traPnoitpircseDyt'QtraPnoitpircseDyt'Q

1gnisuohrotoM123etalpekarB1

2revocraeR133kcolbekarB1

a381*2.4TSwercS0143tlebekarB1

b3rehsawtalF1153raegnoiniP1

4hsurbnobraC163dornoitcennoC1

5redlohhsurbnobraC173lanimreT1

6gnisuohhsurbnobraC183gnirpsnoisroT1

702*5TSwercS593hctiwS2

861*3TSwercS404806gniraeB1

903*5TSwercS214raeggiB1

01rotatS124revoctnorF1

11elttobliO13453*6MwercS1

31epipliO1446MtuN1

a411pmupliO154raegniahC1

b415.3.aidllableetS164revocniahC1

c41gnirpspmupliO174eldnahediS1

d41etalperusserppmupliO19453*5TSwercS1

e41dorlluppmupliO10522*5TSwercS1

f412pmupliO115gnisuoH1

5101*4MwercS225rabediuG1

61gnirpspotS145906gniraeB1

71etalptcetorP155gniraeB1

8152*5niP16522*5TSwercS1

91revoCgnidniW175niahC1

02806gniraeB1857*4niP1

12niprohcnaekarB195lanimretrebbuR2

22kcolekarB10661*4TSwercS1

32droccirtcelE11603*5MwercstnemtsujdaedalB1

42erutamrA126nipediugedalB1

a52dorpotsreggirT136rehsawgnirpS3

b52reggirT146rehsawtalF2

c52gnirpsreggirT15601MtuN1

72draugdroC16652*8MtlobxeH1

82roticapaC1768MtuntresninolyN1

9241*2.4TSwercS386revocediS1

03egarohcnadroC196gniRgniniateR1

REV 05/05

Page 11SKU 02810 For technical questions, please call 1-800-444-3353.

Page 12

ASSEMBLY DIAGRAM

NOTE: Some parts are listed and shown for illustration

purposes only, and are not available individually

as replacement parts.

REV 05/05

Page 12SKU 02810 For technical questions, please call 1-800-444-3353.

Loading...

Loading...