Chevrolet P20 (1961), K10 (1961), C20 (1961), K20 (1961), C30 (1961) Operator's Manual

...

1961

TRUC/(

.I

OPERATORS

GUIDE

www.carburetor-manual.com

Would you like some Free Manuals?

http://carburetor-manual.com/free-shop-manual-club-t-13.html

Also visit http://freeshopmanual.com for more Free Manuals

Also Visit my website for 7 FREE Download Manuals starting

with this one.

"The ABC's of Carburetion"

Click Here Now

file:///C|/Documents%20and%20Settings/Tim/Desktop/carburetor-manual-welcome/index.htm[4/25/2009 11:42:20 AM]

OPERATORS

MANUAL

FOR 1961

CHEVROLET

Light, Medium

and

Heavy

Duty

TRUCKS

This

operator's

and

owne

r's

manual

has

been

prepared to

furnish

information pertaining

to

the

driving,

care

and

lubri-

cation

of

Chevrolet

trucks

as

well

as

to

provide

tec

hni

cal

data

that

may

be

of

value

or

interest

to

truck

owners.

The

subject

contents

below

is a ready

reference

to

the

key

s

ubjects

and

will assist

in

finding

any

subject

covered

in

this

booklet.

An

index

is

provided

at

the

rear

of

this

booklet

to

cover

all

items described

and

give

their

respective

page

numbers.

All

inform

ation, illu strations, service procedures and speci-

fications

containe

d

in

this literature

are

based

on

the

latest

product

information

available

at

the

time

of

publication

approval. The

right

is rese

rved

to

make

changes

at

any

time

without

notice.

Subject Content.

Page

Preliminary Pointe

rs

. . . . . . 3

In struments

and

Controls.

Featur

es

17

Operating

Instructions

22

Maintenance . . . . . . . . . . .

40

Lubrication

Tec

hnic

al

Data

General

Information

Index

CHEVROLET

MOTOR

DIVISION

GENERAL

MOTORS CORPORATION

DETROIT 2,

MICHIGAN

S.cond Edition

Pc"t

Numbe r 3781607

Page

56

88

94

103

LITHO IN U,S.A.

OWNEU'S SEUVICE POLICY

Upon

delivery

of

your

new

Chevrolet

truck,

you

received

an

Owner

Service

Poli

cy

which

you

sho

uld

read

carefully.

Ke

ep this

policy

with your truck

during

the

warranty

period

as

it

serves

to introduce

the

Owner

to

any

Chevrolet

dealer.

PRELIMINARY

POINTERS

Proper

operation

of

this

vehicle

for

the

first few

hundred

miles

will

contribute

greatly

to

longer

life

and add

much

to

its

future performance and

economy

of

operation.

If

not

properly

maintained

and

wisely operated ,

your

truck

can

lose

much

of

its efficiency and

performance

which

it

is

capable

of

supplying

.

The

following

are

maintenance

hints and

driving

tips

to

aid

you

in

realizing

the

maximum

in efficiency and

economy

from

your

Chevrolet

truck:

•

It

is

recommended

that

the

maximum speed

be

confined

to

50

miles

per hour

for

the

first 500 miles.

•

Use

the

lowest

gear

ratio

available

when

starting

up

with

heavy

loads

and

climbing

grades

to

avoid

"over-taxing"

the

engine.

•

Avoid

driving for

extended

periods

at

anyone

constant

speed,

either

slow

or

fas

t.

• Avoid

full

throttle

starts

and

severe

application

. of

the

brake

s

in

stopping.

•

Continuous

driving

at

high

speeds

should

not

be

done

until

the

truck

has

been

driven

2000 miles.

•

Drive

at reasonable

lower

speeds

until

engine

has

warmed up.

•

Hill

and mountain

driving

requires

more

gasoline. A carbu-

retor adjusted for sea

level

driving be

comes

extremely

wasteful at

5000

feet

or

more

altitude.

•

The

engine

should

be

regularly

"tuned-up" so that

power

robbing

conditions,

which

may

develop

so

gradually

that

they

are

not

noticed,

may

be

found

and

corrected.

Faulty

spark plugs, for instance,

can

waste .as

much

as

one

gall

on

of

gasoline

in

every

ten.

•

Use

only

hign~st

qualit

y fuel.

Poor

quality gasoline,

whether

Regular

or

Premium, may

introduce

harmful

deposits

into

the

engine

.

•

Use

a good

grade

of

proper

viscos

ity

engine

oil.

Too

heavy

an oil

wastes

gasoline.

•

Have

the

air

cleaner

cleaned

and reoiled,

or

replaced ac-

cording to recommendation. A

dirty

air

cleaner

can

reduce

mileage

by

as

much

as

10

per

cent.

•

The

front

wheel

and

tire

assemblies

should

be

balanced

periodically

to

provide a more

comfortable

ride

and

prevent

improper tire wear.

Such

care in

operating

your

new

truck

will

assure

proper

mating-in

of

all

the

running

surfaces

of

the

moving

parts

of

the

engine,

transmission and

rear

axle

.

• 3 •

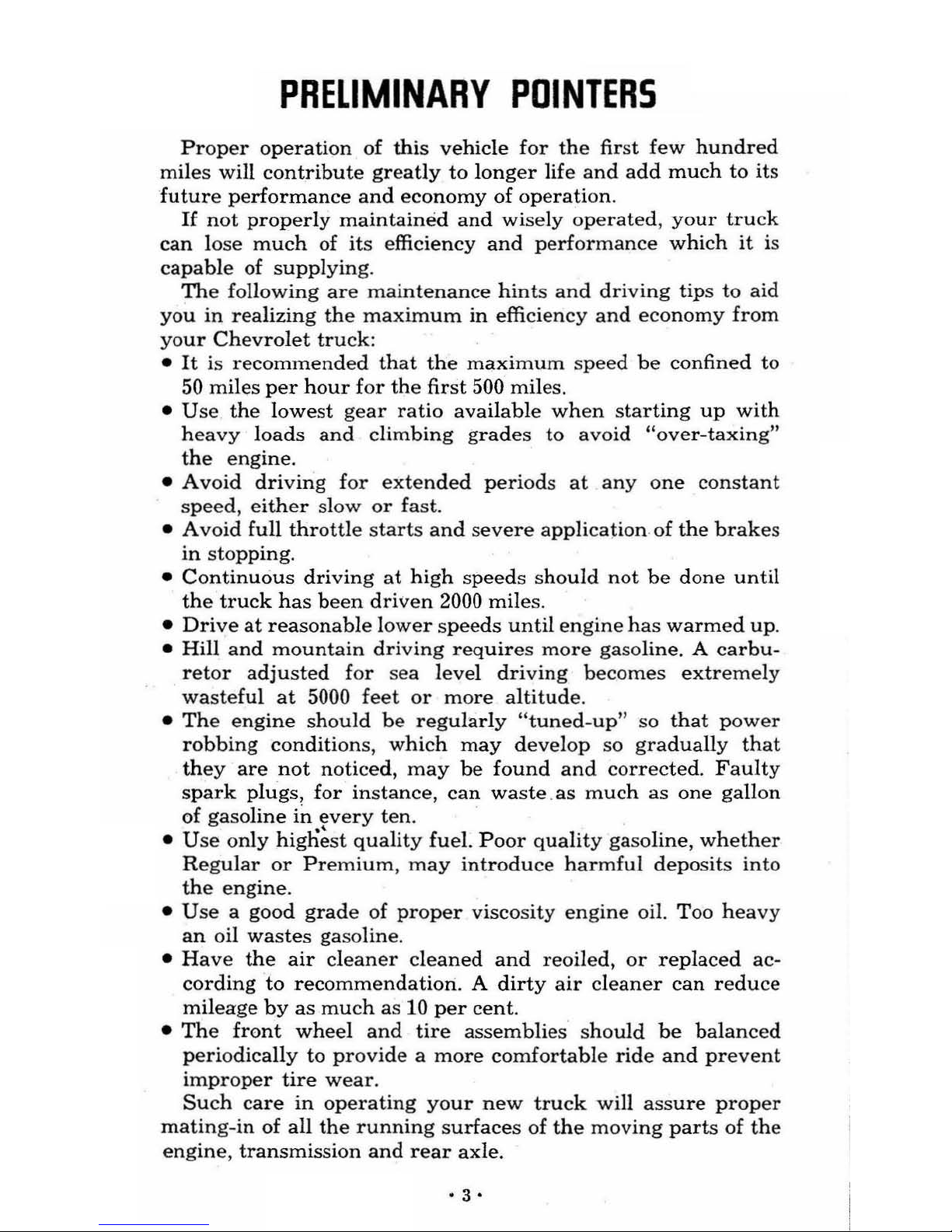

Fig.

I-/ns'rumen,

Cluster-

% -2

Ton

S'andard

Models

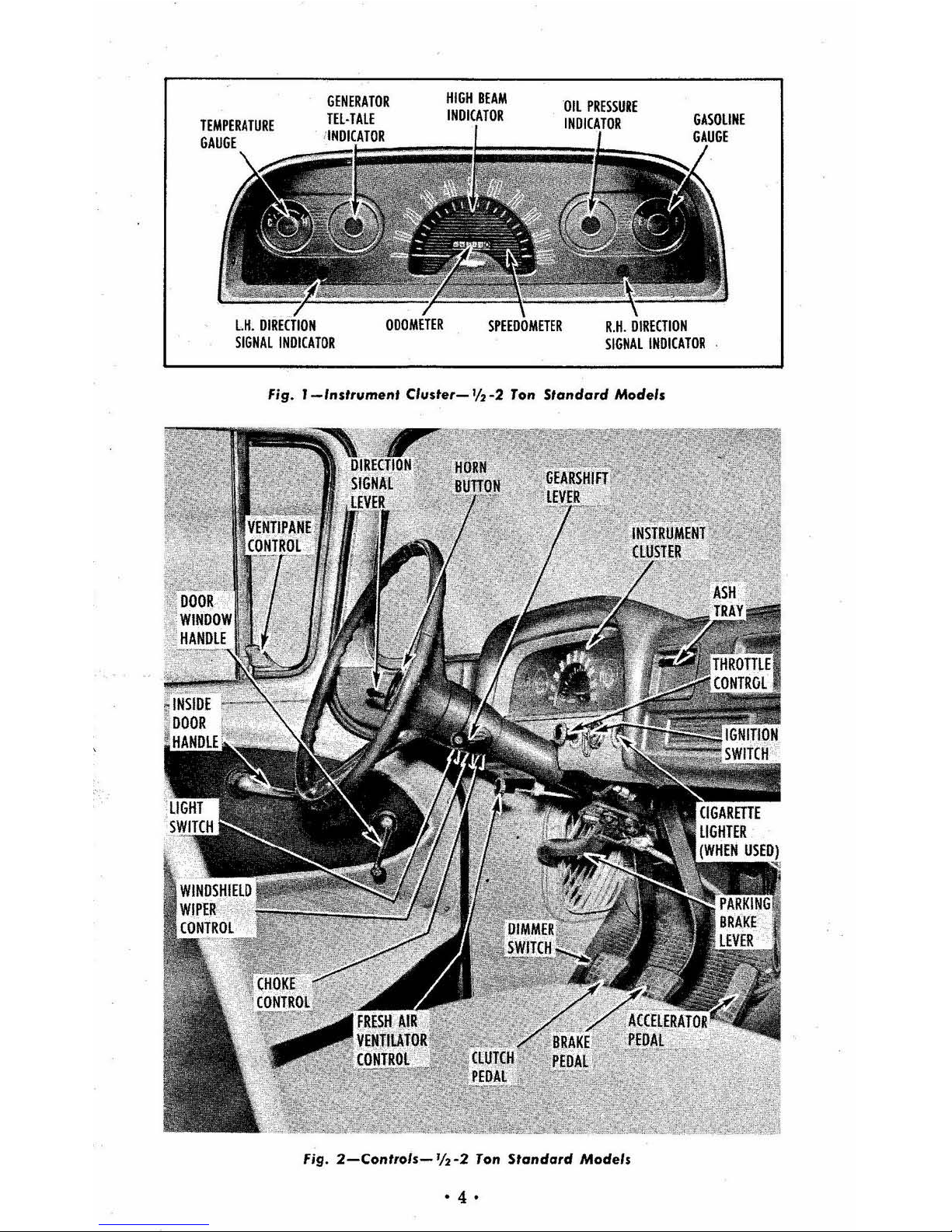

Fig.

2-Con,ro/s-'12-2

Ton

Standard

Models

• 4 •

INSTRUMENTS

AND

CONTROLS

The

type, location

and

operation

of

instruments

and

controls

vary

on

different

models

and

different

series

trucks.

There-

fore, regardless of past

experience

an

owner

or driver

may

have

had,

it

is

advisable

to famili

arize

yourself

with

the

instruments and contro ls and their

use

before driving this

new

truck.

As

severa

l different instrument groups and dash

panel assemblies are used,

the

paragraph concerning each

item

will desc

ribe the

operation

or

use

of

that

item

and

will

not

attempt

to

describe

location.

The location

of all

instru-

ments

and controls

will

be

shown

in various illustrations

on

the

following pages.

STANDARD

INSTRUMENTS

GASOLINE

GAUGE

The

gasoline

gauge

is

wired

through

the

ignition

switch

and

will only

indicate

the

amount

of.

fuel

in

the

tank

when

the

ignition

switch is

turned on.

As

this

gauge

utilizes a "balanced

needle"

for greater accuracy,

the

gauge

needle

will

not

neces-

sari

ly

return

to

the

empty

position

with

the

ignition

switch

off.

The

needle

may

stop in

the

center

of

the

gauge

.or go off

at

either

end

when

the

ignition switch is

turned

off.

TEMPERATURE

GAUGE

The

water

temperature

gauge

may

register

anyw

here

in

the

band

between

the

two

marks

("C" and

"H")

and

still indi-

cate normal operating temperatures.

As

this gauge utilizes a

"balanced

needle~'

for greater accuracy,

the

gauge

needle

will

not

necessarily return to

the

"cold" position

when

ignition is

turned

off.

The needle ,may

stay

in

the

center

of

the

gauge

or

go off

at

either

end

when

the

ignition switch is

turned

off.

AMMETER

OR

GENERATOR

TEL-TALE

LIGHT

The

ammeter

indicates

the

flow of

curren

t to

and· from

the

battery,

except

for

the

current

taken

by

the

sta

rting

motor

.

The

generator

tel-tale

light

indicates

generator

operation.

Normal

operation

is

with

the

light

off

or

for

the

ammeter

to

show

a positive

(+)

reading.

Refer

to

"Operating Instruc-

tions" for complete

gauge

(or

indicator) interpretation.

·5·

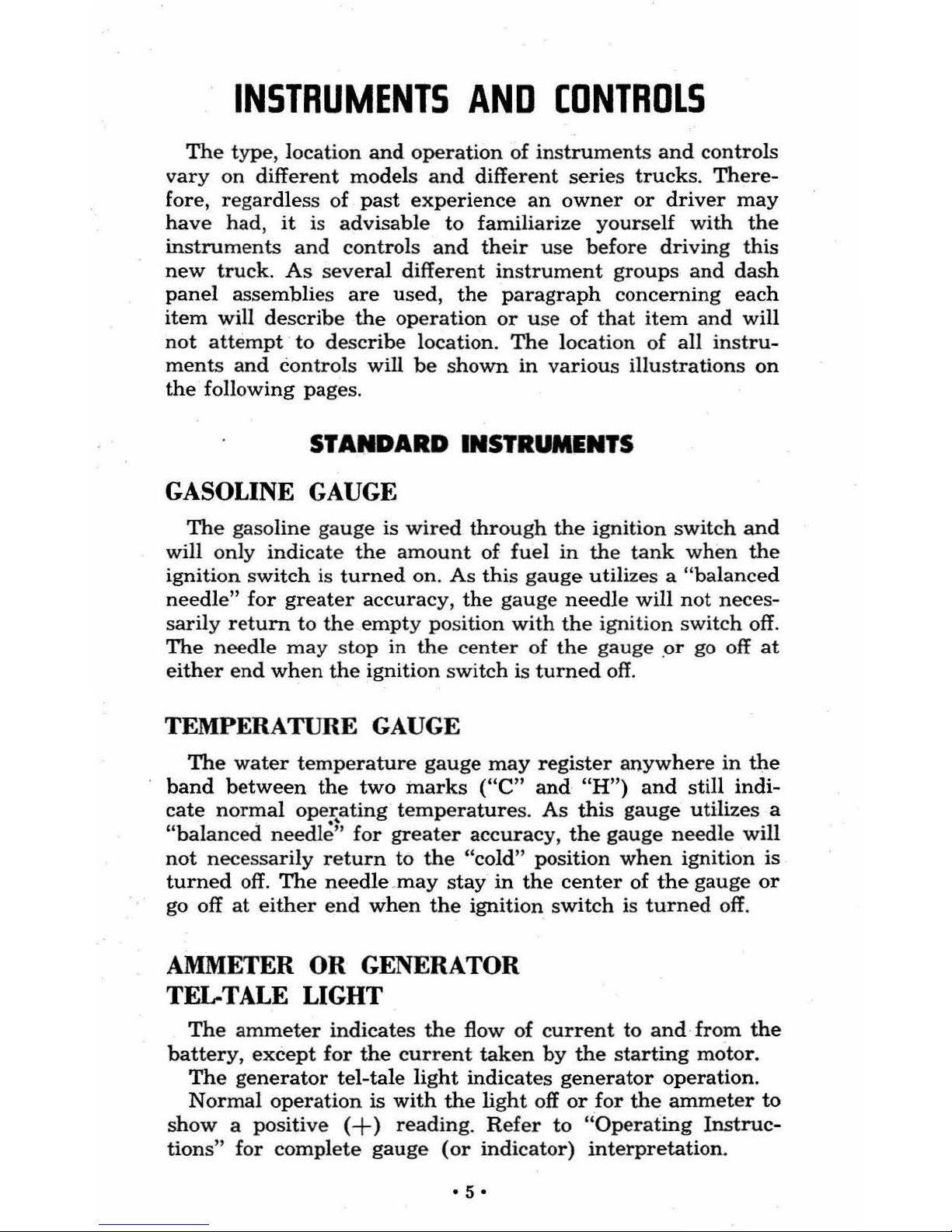

Fig.

3_lnslrumen'

(Iusf.,·2

'12

Ton

Standard

Models

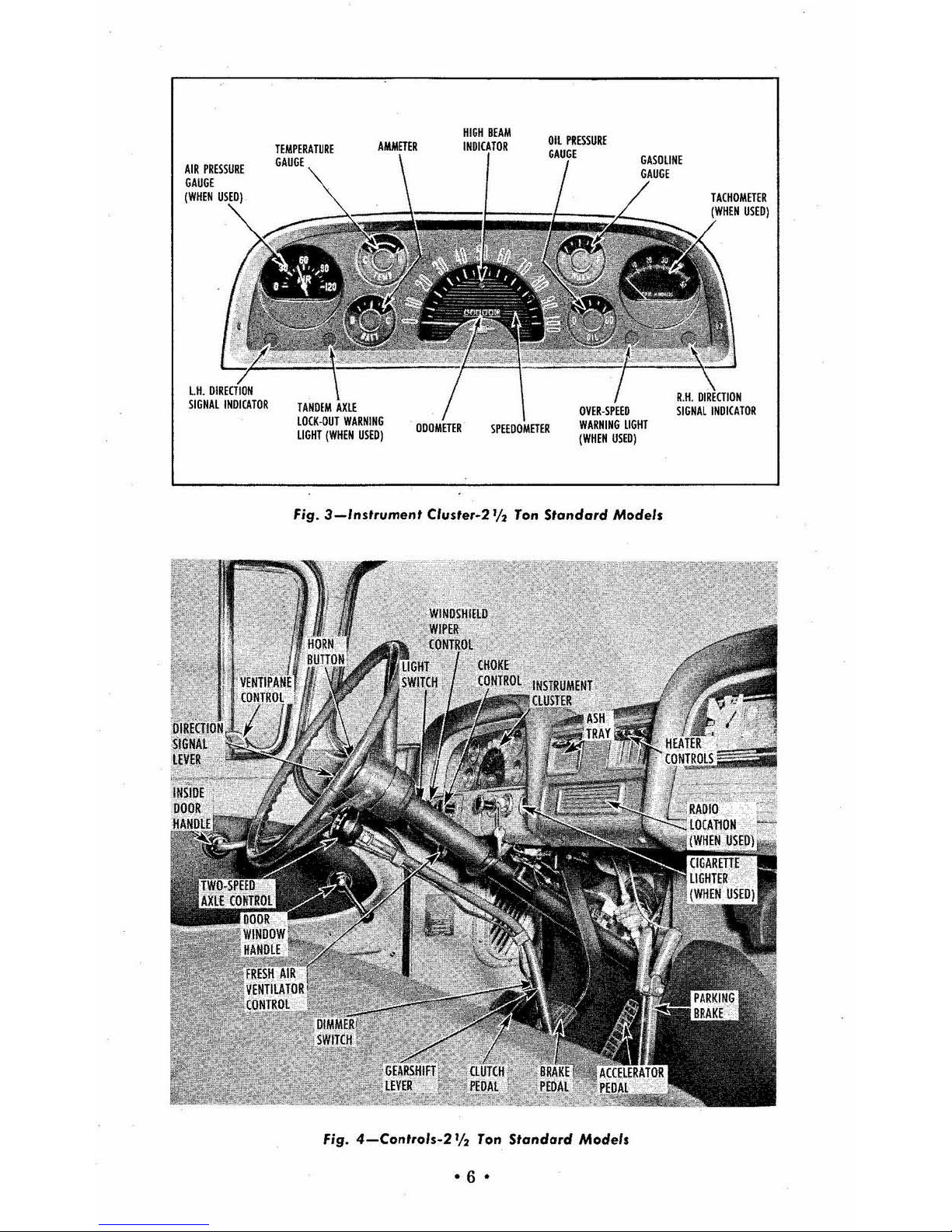

Fig.

4-(on',oh.2'12

Ton

Standard

Modell

·6

•

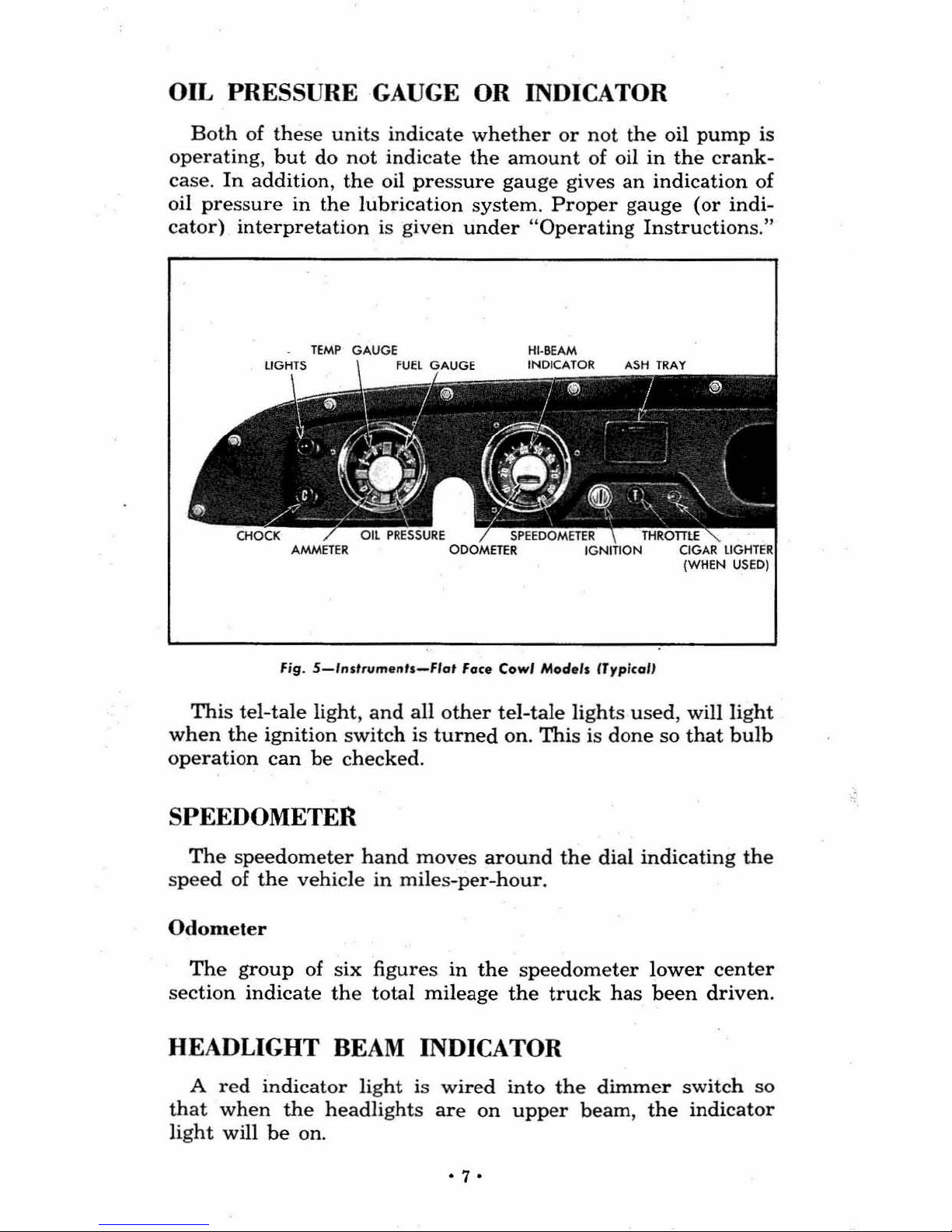

OIL PRESSURE

GAUGE

OR INDICATOR

Both

of

the

se units indica

te

whether

or

not

the

oil

pump

is

operating,

but

do

not

indicate

the

amount

of

oil

in

the

crank-

case. In addition,

the

oil pr

ess

ure

gauge

giv

es

an

indication

of

oil

pressure

in the lubri cat

ion

system. Proper

gauge

(or indi-

cator) int erpretation is giv

en

under

"Op

era

ting

Instructions,"

Fig .

5-lnstrum.nls-FIG'

Fac.

Cowl

Mod.,s

(Typico"

This tel-tale

light, and all

other

tel-tale

lights use d, will lig

ht

when

the

ignition switch is

turned

on.

Thi

s is d

one

so

that

bulb

op

eration

can

be

checked.

SPEEDOMETER

Th

e spee

domet

er ha

nd moves

around

the

dial

indicating

the

speed

of

the vehicle

in

miles-per-hour.

Odometer

The group

of

six

figur

es

in

the speedometer

lower

cent

er

secti

on

indicate the

tot

al mileage

the

truck has

been

driv

en.

HEADLIGHT

BEAM

INDICATOR

A red

indicator

light

is

wired into

the

dimmer

switch

so

th

at

when the headlights

are

on

upper beam,

the

indicator

li

ght

will

be

on.

·7·

OVER

SPEED

WARNING LIGHT

As

standard

equipment

on

seve

ral

larger

series

trucks

and

optional

equipment

on

certain others, a

red

light

warns

of

ex-

cessive

engine

speed on

overrun

on

VB

engines. As a

check

to

be

cert

ain

that

the

bu

lb

works,

this light

is

so

wired

that

it

turns on at

the

instant the ignition switch is turned on and

go

es off

after

the

engine has

started.

OPTIONAL INSTRUMENTS

AIR PRESSURE. GAUGE

This

gauge

is used

to

indicate

the

air

pressure

in

the

full

air

brake

system

or

the air

over

hydraulic

system.

Do

not

--a

ttempt

to

oper

ate

the vehicle

unle

ss

pressure

has

built

up

to

60 p

si

or

more.

Low

Pressure Indicator

A warning buzze

r,

mount

ed

und

er

the

dash

operates

when

air

pressure

in the bra

ke

system falls below

60

psi.

When

first

starting

the

vehicl

e,

the warn

ing buzzer will sound

until

pres-

sure has

built up.

Wh

en

the

desired

pressure has

been reached,

the

buz

zer

will s

hut

off.

If

the

buzzer oper

ates

under

normal

drivin

g,

bring

the vehicle to a contr

oll ed

stop

and

locate and

correct trouble

before

proceeding.

NOTE: Do not operate vehicle w hile buzz

er

is

operating as brakes

are not in

proper

operat-

ing condition.

TACHOMETER

Th

e tacho

meter

(when

installed)

indicates engine speed in

revolutions per

minute.

The sca

le reads

10, 20, 30, etc. By

add-

ing

two

zeroes

after

the

reading,

the

indicat

ed

engine spee

d

will become

1000 , 2000, 3000, etc.

Transmission shifting

range

is

indi

cated by two markers factory set at 25 & 40, w

hich

can

be

a

djustin

g a

long

the

periph

ery

of

the gage

to

indicate

the

opti

-

mum

range for

any

particular vehicle.

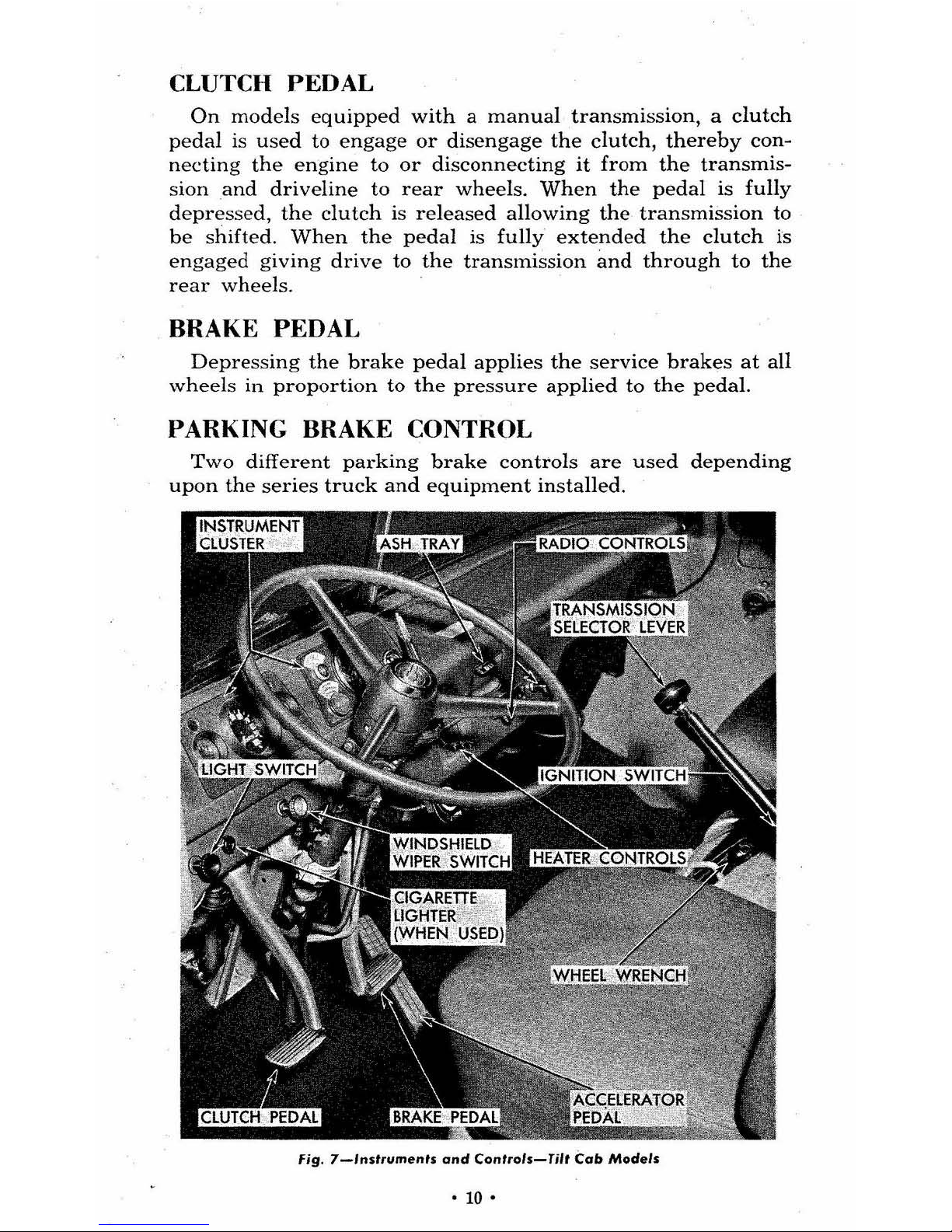

VACUUM GAUGE

This gauge

(when

installed)

indicates

engine vac

uum.

Proper

interpretation

of

the

gauge

readings

will

indicate engine con-

dition , and

in

many

instan

ces show

the

way

to

more

economi-

cal operation.

• 8 •

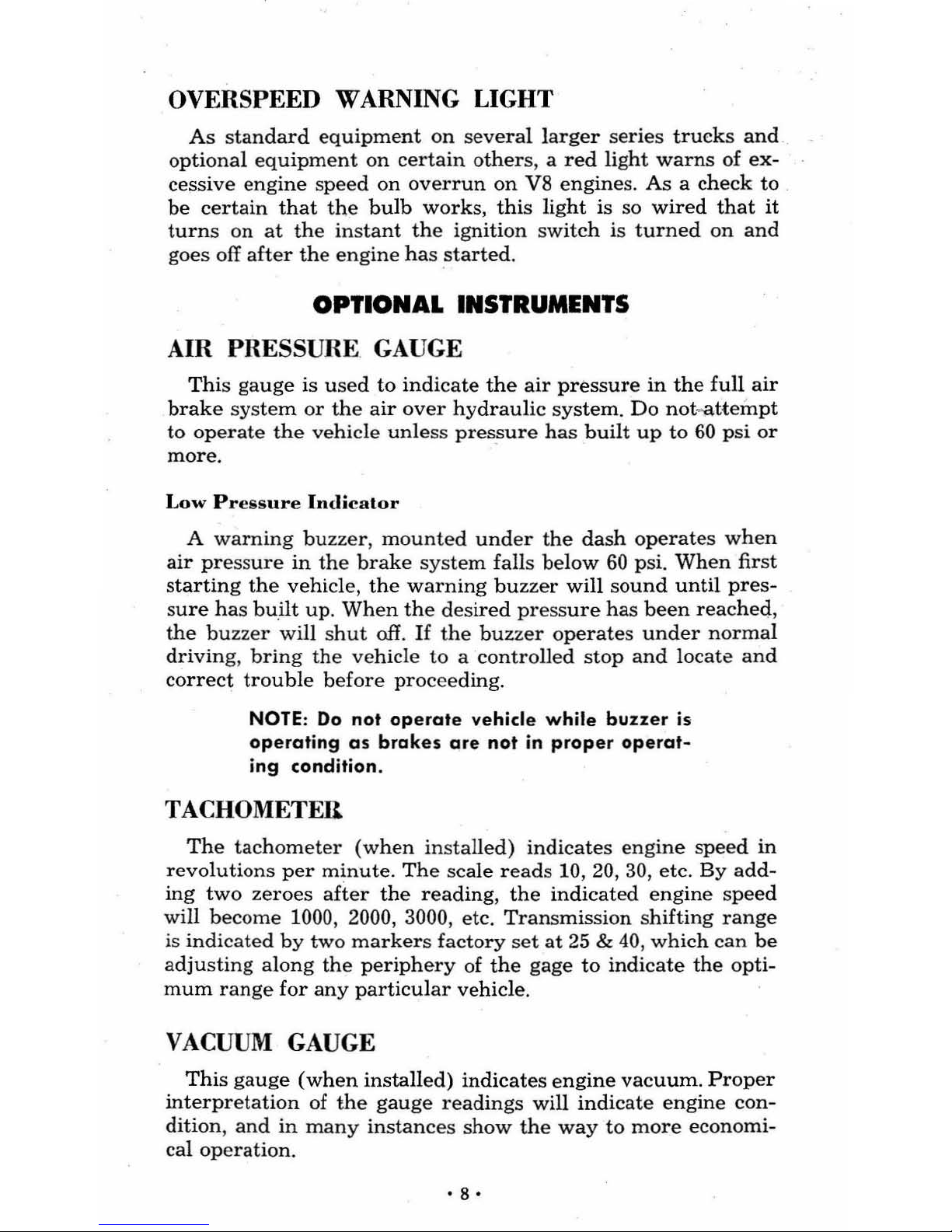

STANDARD CONTROLS

CHOKE CONTROL

The

carburetor

hand

choke

control

knob

is

used

to

close

or

partially

close

the

carburetor

choke

valve.

This

restricts

the

air

intake

and

produces a richer

fuel

mixture

for

starting,

while

at

the

same

time

opening

the

throttle by

means

of a fast

idle

link

on

the

carburetor

except

on

those models

equipped

with

an

updraft

carburetor.

HAND THROTTLE CONTROL

Pulling

out

on the

control

knob

opens

the

carburetor

throttle

to provide a

uniform

engine

speed

above

the

idle setting.

ACCELERATOR PEDAL

The

accelerator

pedal

is

used

to

open

and

close, as

required

,

the

carburetor

throttle

valve

to

vary

vehicle engine speed.

fig.

6-lnsfrumenh

Gnd

Controls-Forward

Conrrol Models (TyplcalJ

•

9'

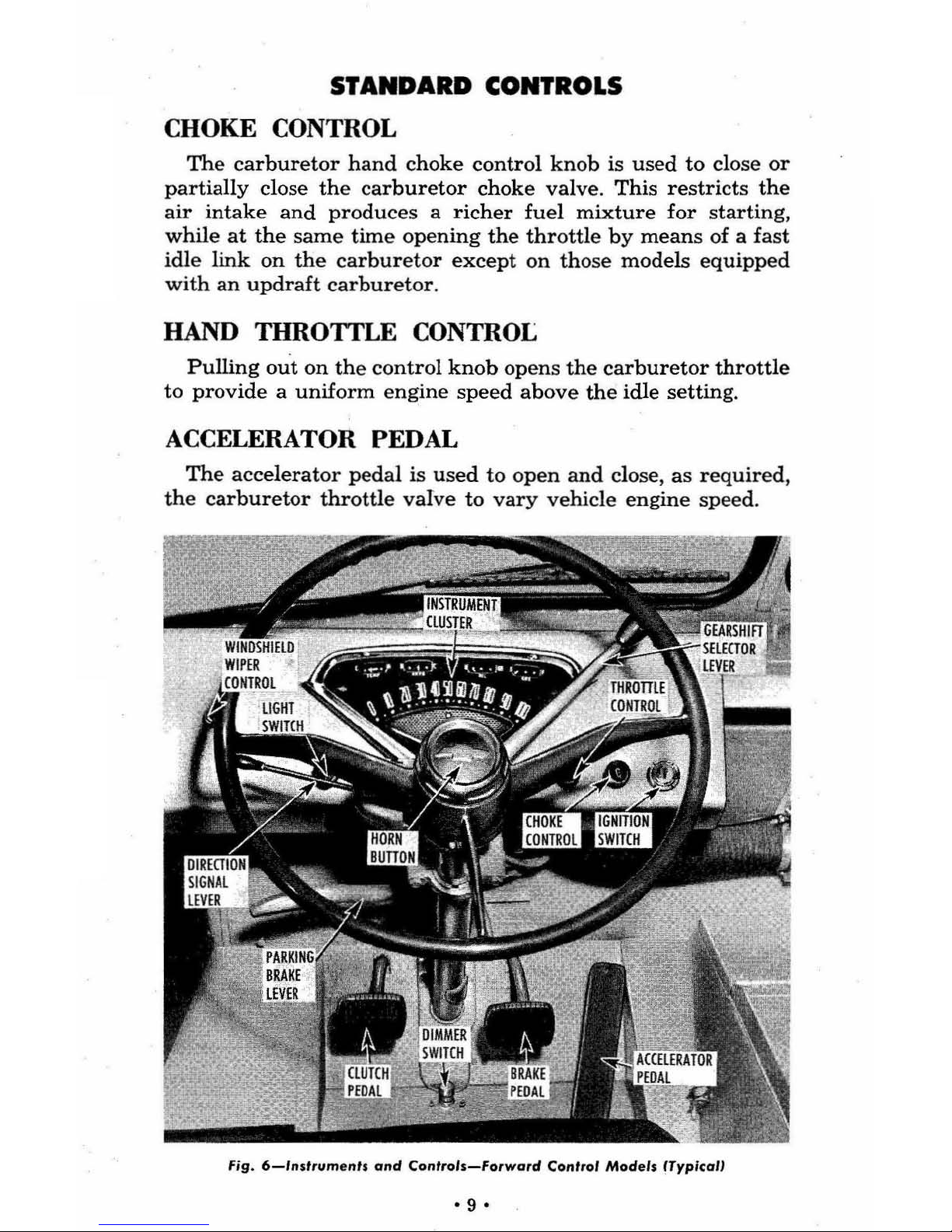

CLUTCH PEDAL

On

models

equipped

with a manual

transmission , a

clutch

pedal

is

used

to

engage

or

disengage

the

clutch,

thereby

con-

necting

the

engine

to

or

disconnecting

it from

the

transmis-

sion

and

driveline

to

rear

wheels.

When

the

pedal

is

fully

depressed,

the

clutch

is re

leased

allowing

the

transmission to

be

shifted.

When

the

pedal

is

fully

extended

the clutch

is

engaged giving

drive

to

the

transmission

and

through

to

the

re

ar

wheels.

BRAKE PEDAL

Depressing the

brake

pedal

applies

the

service

brakes

at

all

wheels

in

proportion

to

the

pressure

applied

to

the

pedal.

PARKING BRAKE CONTROL

Two

different

parking

brake

controls

are

used

depending

upon

the

series

truck

and

equipment

installed.

Fig.

7_lns'rumen's

and

Controls-Til,

Cab Models

.

10·

On

one

line

of trucks, a contr

ol l

ever exte

nding up from the

cen

ter section

of the fro

nt floor is used. By pulling st

raig

ht

back on

the lev

er, the pa

rking

brak

es

are

applied. To release

the bra

kes, s

queez.e the mova

ble

lever at the top of the contro

l

a

nd

at the same

time, push

forward.

CAUTION :

On

models

equipped

wifh

auxiliary

transmission, au

xilia ry transmission

must

be

in

gear

before applying

parking

brak

e.

The oth

er one used, is a trigger type l

eve

r mount

ed

to the

left of

the stee

ring co

lumn

und

er the instrument

panel.

To

a

pp

ly the brakes, pull back

on the l

eve

r. To release, squeeze

the "pistol

" ty

pe

tri

gger a

nd push forwa

rd.

GEA

HSHIFT LEVER

The gearshift contr

ol on

tru

cks e

quip

ped

wit

h 3-speed trans-

mi

ss

ion is loc

ated

on the s

teering column.

Thi

s co

ntr

ol is used

in the conve

ntional

HH" p

atte

rn

as explain

ed und

er "Operat-

in

g Instruction

s"

to sh

ift

the

tran

smissi

on

to the desir

ed ratio.

Th

e g

earshift

contro

l for vehicl

es with the 4- or 5-

spee

d

tr

ansmissio n is lo

cat

ed

in

the

center

sec

tion

of

the front floor

except

tilt

cab models

whi

ch

is locate

d betwee

n the fro

nt

seats

. The shifting

pattern

for

ea

ch transmission is shown on

top

of the con

tro

l lever knob.

S

ee HOperating

Ins

tru

cti

ons"

for t

he

spec

ific tran

smission

u

sed

.

Th

e c

ontro

l lev

er

for

vehi

-

cles equipped with

four

wheel

drive is m

oun

ted

next

to the

trans

mi

ssion c

ontrol lever.

This

control is used

to sel

ect

fig.

8-I

gn;,;on Switch fS·

'ar'

. r Cont

rol}

the diff

ere

nt

axle drives

.

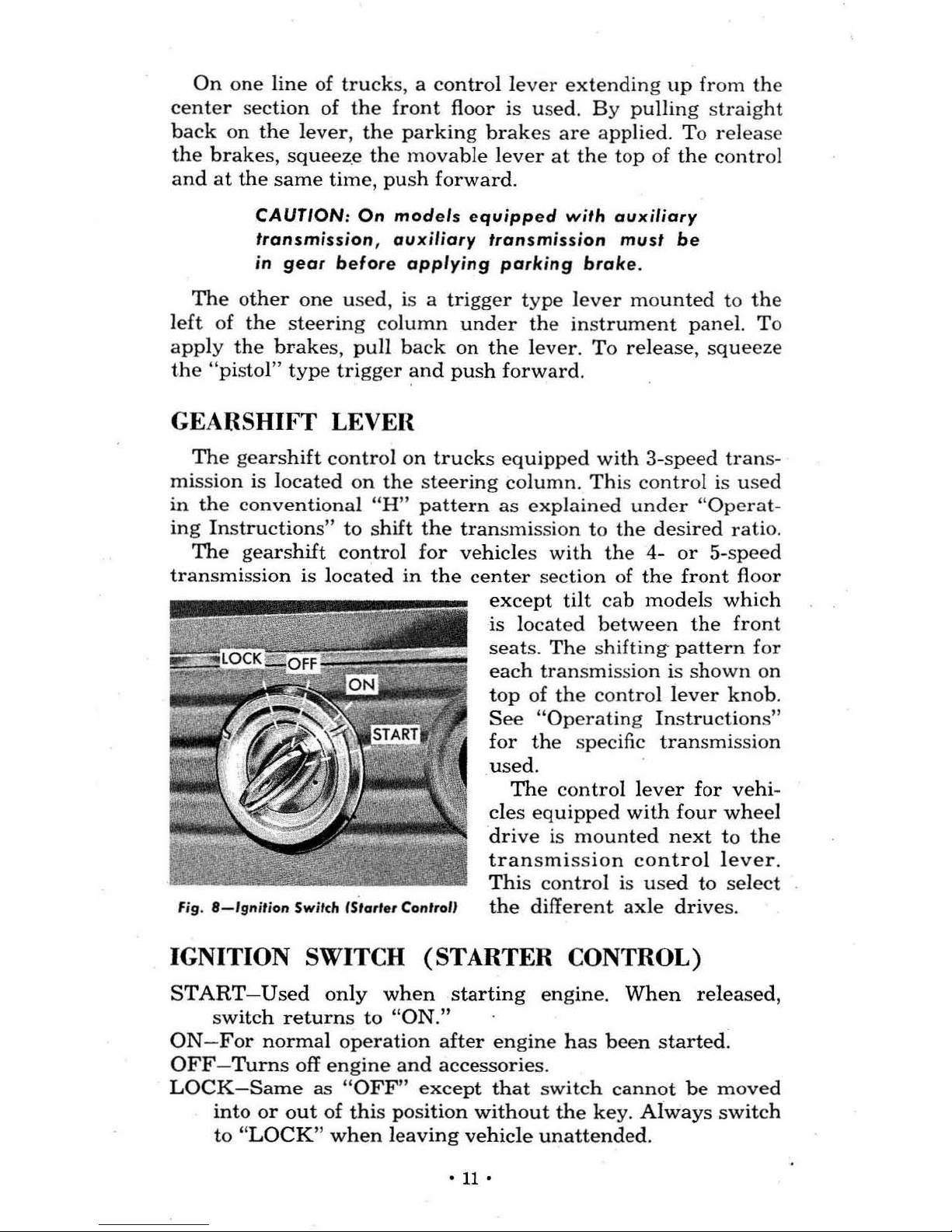

IGNITION S

WIT

CH (STARTER CONTROL)

ST

ART-Used

on

ly

when

starting

eng

ine. Wh

en

released

,

s

witch return

s to

"ON

."

ON

- For nor

ma

l operati

on

aft

er engine h

as bee

n s

tarted

.

OFF

- T

urn

s off engine and acc

ess

ori

es.

L

OCK-Same

as HOFF" except

that

switch cannot be moved

i

nto or out of

this position

without the k

ey. Always switch

to

"L

OCK" when lea

ving veh

icle

unattend

ed .

•

11

•

NOTE

: Key

cannot

be

removed from the

igni-

tion switch

when

in

"OFF" position thus

guarding

against

accidentally

leaving

switch

off

but

not

locked

. Key

must

be

removed

when

the switch is

in

"LOCK"

or "ON"

pos

i-

tion. The switch

may

then

be

moved

be-

tween

"OFF"

and

"ON" without the key .

WINDSHIELD WIPER SWITCH

Start

wiper

by

turning

knob

clockwise.

Full

counter

clock-

wise

position turns wiper off.

The

electric wiper

has

two posi-

tions-OFF

and

ON.

When

the

wipers

are

turned

off,

they

will

return

to

the

inner

end

of

the

wiper

cycle.

CAUTION:

In

icy

weather,

never

attempt

to

ope~ate

electric

wipers

if

blades

are frozen

to

the

windsh

ield. Free

the

blades

before

operation

01

wipers

.

Fig.

9-Lighring

Switch

DIMMER SWITCH

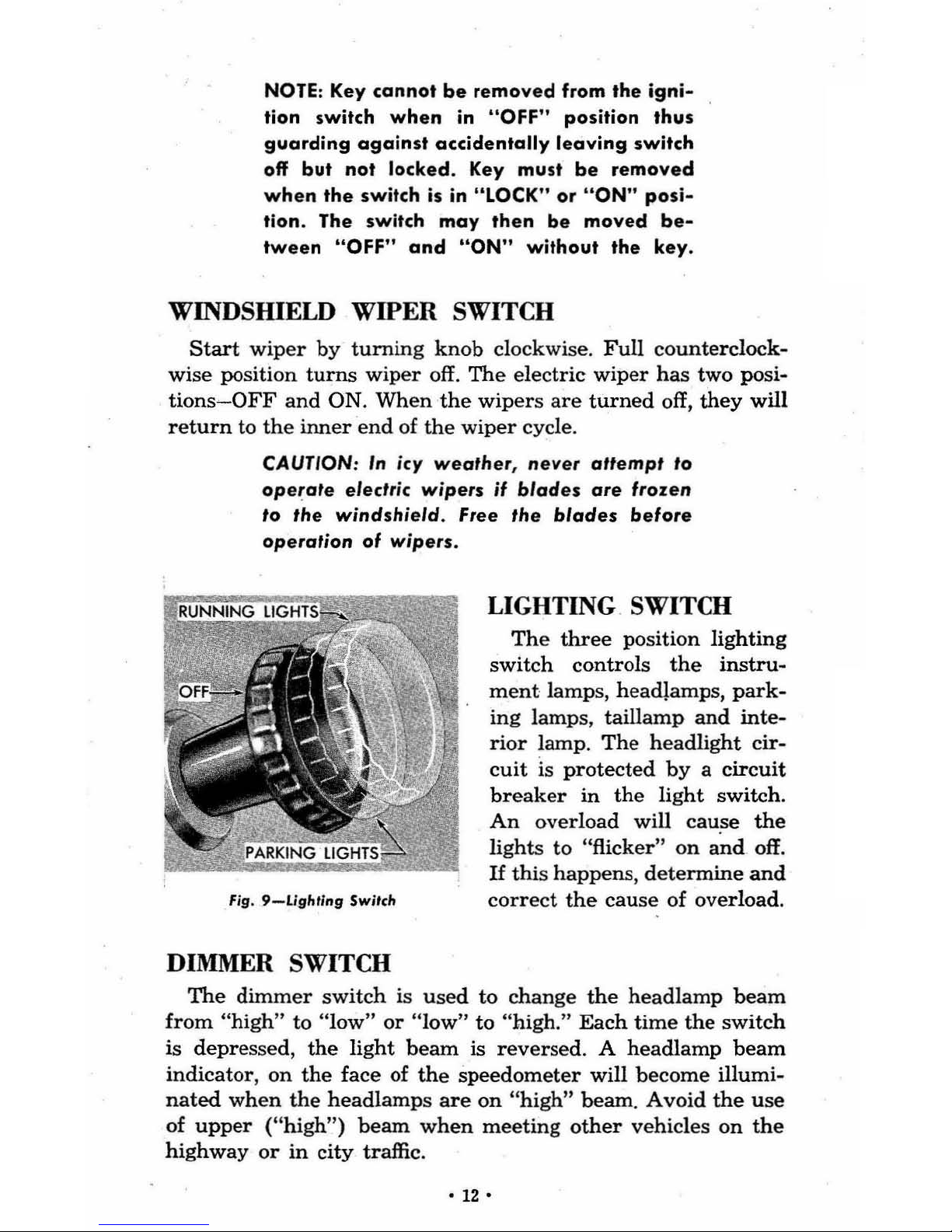

LIGHTING SWITCH

The

three

position lighting

switch controls

the

instru-

ment

lamps, headlamps,

park-

ing lamps , taillamp

and

inte-

rior

lamp.

Th

e headlight cir-

cuit

is

protected

by

a circuit

br

eaker

in the

light

switch.

An

overload will cause

the

lights

to

"flicker"

on

and

off.

If

this happens, determine

and

correct

the

cause

of

over

load.

The

dimmer

switch

is

used

to change

the

headlamp

beam

from "high" to "low" or "low" to "high." Each

time

the

switch

is depressed,

the

light

beam

is reversed. A

headlamp

beam

indicator,

on

the

face of

the

speedometer

will become illumi-

nated

when

the

headl

amps

are

on

"high"

beam. Avoid

the

use

of

upper

("high")

beam

when

meeting

other

vehicles on

the

highway

or

in

city

traffic.

•

12·

HORN BUTTON

The

horn

butt

on

is

conveniently

located at

the

center

of

the

steering

wheel.

Depressing

this

button

gro

unds

out

the

horn

circuit

causing

the

horns

to operate.

COWL

VENTILATOR CONTROL KNOBS

Two knobs

are used

to

open

and

close

the

dampers

in

the

vent

ilati

ng

system.

Pull

knob(s)

out

to a

dmit

outside

air,

push

knob(s)

in

to s

hut

off

air.

WINDOW REGULATORS AND HANDLES

The door

windows

are

opened

and

closed

by

turning

the

handles from

within

the

vehicle.

DOOR VENTIPANE AND HANDLES

The

se

are

operated

directly

by a turn down

catch

handle

. A

spring

loaded

friction device

in

the

ventilator

lower

pivot

holds

the

ventilator

open

to

any

position selected.

Rain

deflectors

are used over

the

ventipane

to

prevent

ent

ry

of

water.

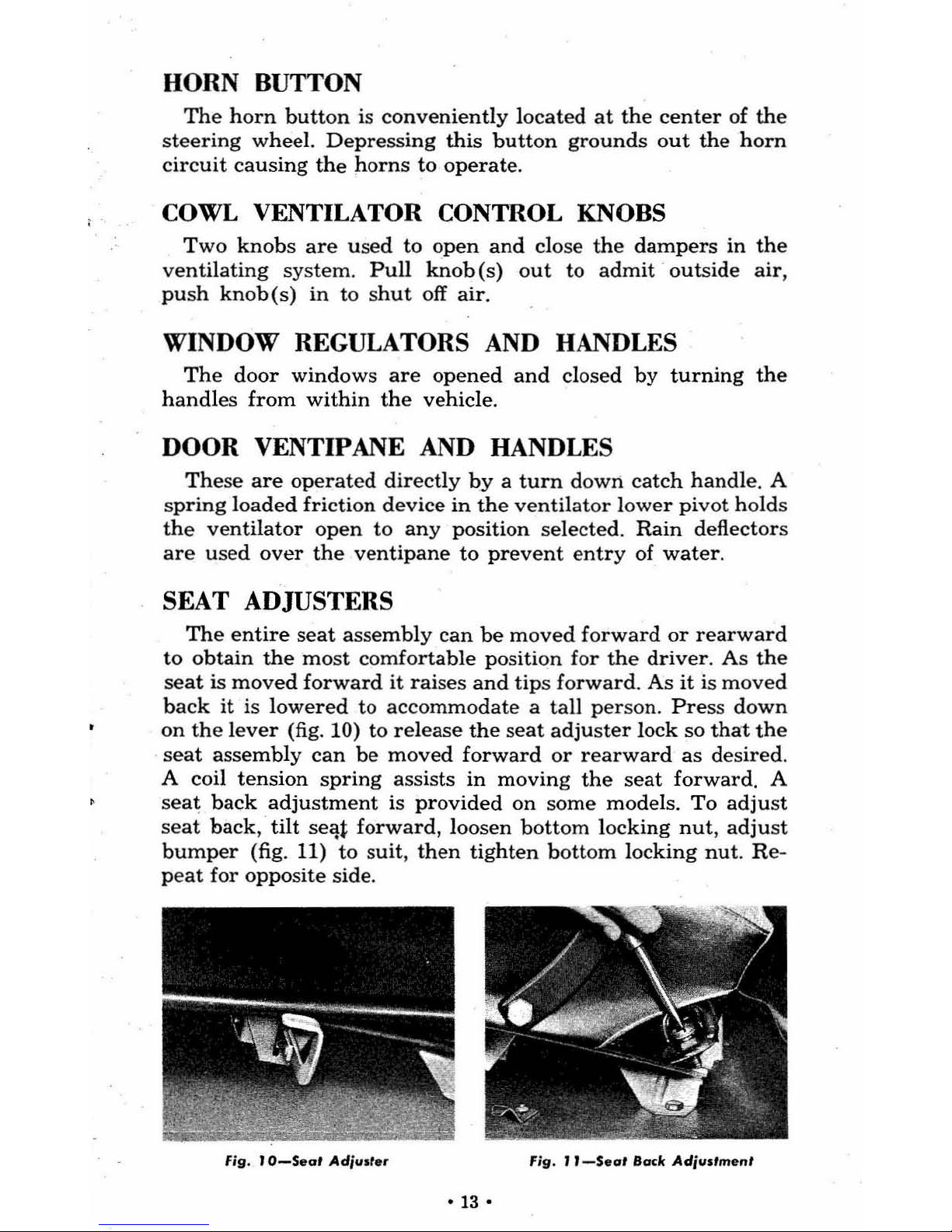

SEAT ADJUSTERS

The

entire

seat

assembly

can

be

moved

forward

or

rearward

to

obtain

the

most

comfortable

position

for

the

driv

er.

As

the

seat

is

moved

forward

it

raises

and tips forward.

As

it is

moved

back it is

lowered

to

accommodate a tall

person.

Press down

on the

lever

(fig. 10) to

relea

se

the

seat

adjuster

lock so

that

the

seat

ass

embly

can

be

moved

forward

or rearward as desired.

A coil

tension

spring

assists in m

oving

the seat forward. A

seat

back

adjustment

is

provided

on

some

models.

To

adjust

seat

back, tilt

se'lt

forward,

loo

sen

bottom

locking

nut, adjust

bumper

(fig. 11)

to

suit,

then

tighten

bott

om

locking

nut.

Re-

peat

for

opposite s

ide

.

Fig

. r

O-Seat

Ad;ust.r Fig. J

I-SuI

Back Ad;ustment

·13·

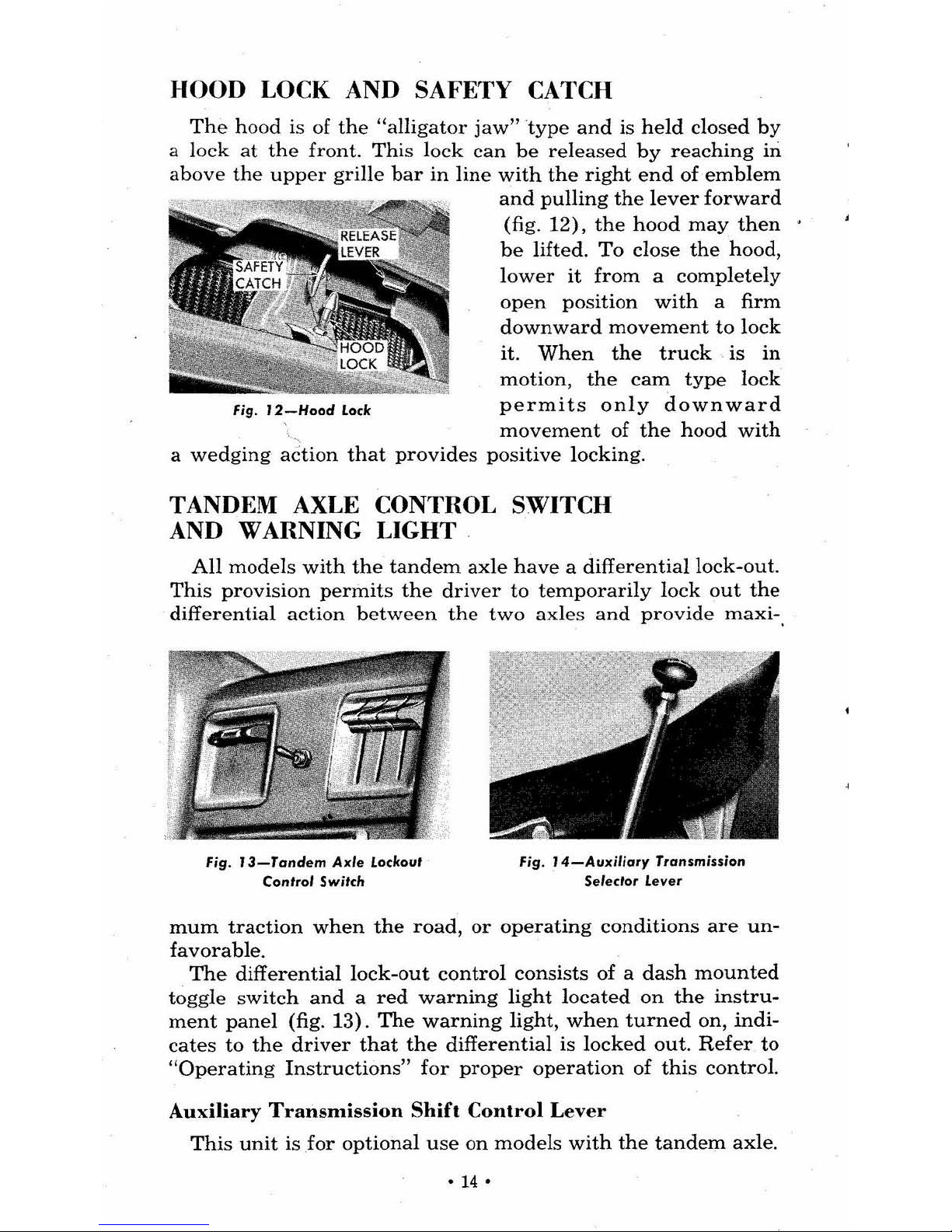

HOOD

LOCK

AND SAFETY CATCH

The

hood is of

the

"alligator

jaw"

type

and

is

held

closed

by

a lock

at

the

front.

This lock

can

be

released

by

reaching

in

above

the

upp

er

gri

lle

bar

in

line

with

the

right

end

of

emblem

and

pulling

the lever

forward

(fig. 12),

the

hood

may

then

be

lifted.

To

close

the

hood,

l

ower

it

from

a

completely

open

position with a firm

downward

movement

to

lock

it.

When

the

truck

is

in

motion,

the

cam

type

lock

Fig.

12-Hood

Lock

permits

only

downward

movement

of

the

hood

with

a

wedging

adtion

that

provides

positive

lock

ing.

TANDEM AXLE CONTROL SWITCH

AND WARNING LIGHT

All

models

with

the

tandem axle

have a differential lock-out.

This

provision

permits

the

driv

er

to

temporarily

lock

out

the

differential

action betw

een

the

two

axles

and

provide

maxi-,

Fig.

l3-Tandem

Axle

Lockout

Control Switch

Fig .

14-Auxiljory

Transmission

Selector Lever

mum

traction

when

the

road, or

operating

conditions

are

un-

favorable.

The

differential

lock-out

control

consists

of a

dash

mounted

toggle

switch

and a red

warning

light

located

on

the

instru-

ment

panel

(fig. 13).

The

warning

light,

when

turned

on,

indi-

cates

to

the

driver

that

the

differential

is locked

out.

Refer

to

"Operating

Instructions"

for

proper

operation

of

this

control.

Auxiliary

Transnlission

Shift

Control Lever

This unit

is

for

optional

use

on

models

with

the

tandem

axle

.

•

14

•

The

control for

this

unit

is

mounted

between

the

two

front

seats

(fig. 14).

The shift

pattern

is

shown

on

the

control

lever

knob.

OPTIONAL CONTROLS

TWO SPEED AXLE SWITCH

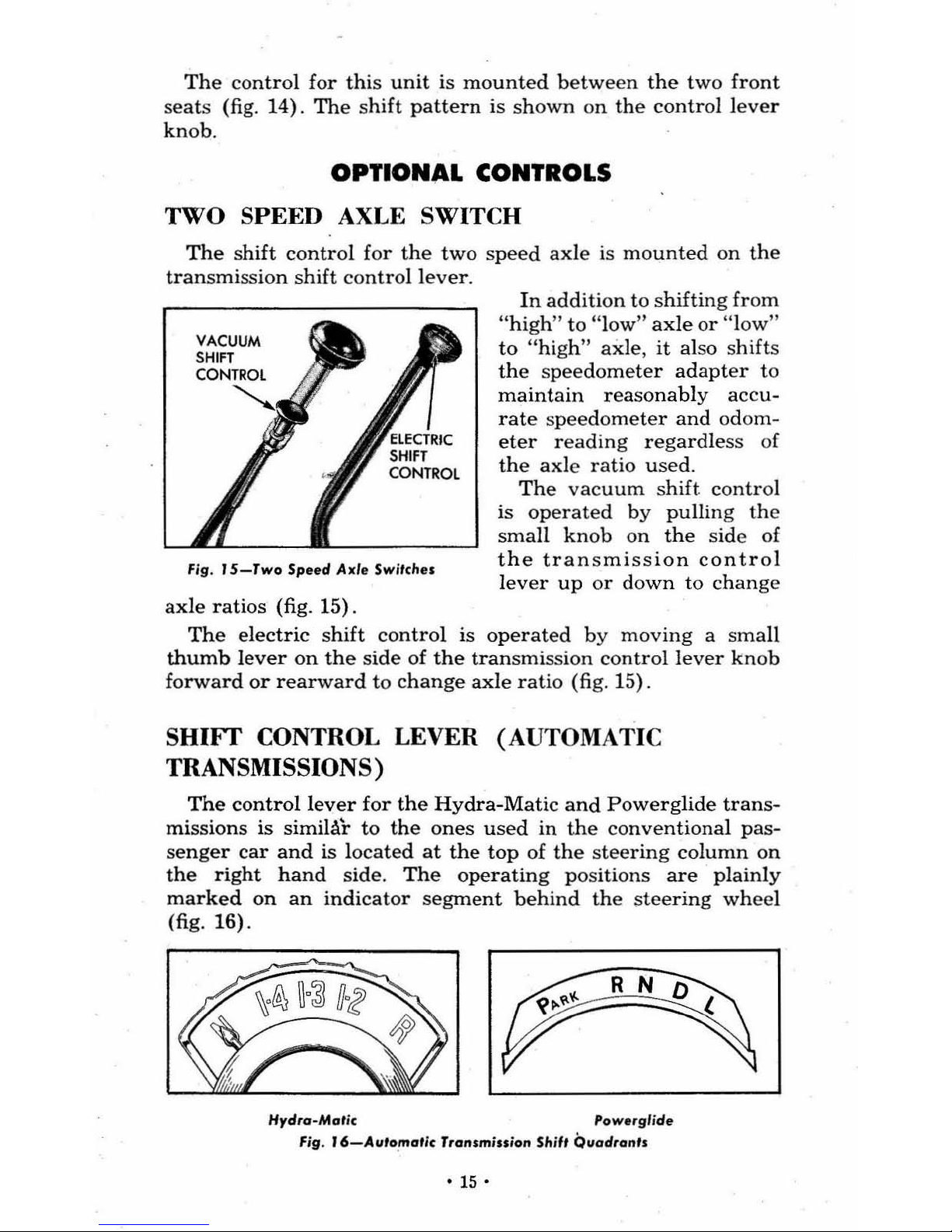

The

shift

control

for

the

two

speed

axle

is

mounted

on

the

transmission shift

control

lever.

Fig.

15-Two

Speed Axle Swi'che,

axle

ratios

(fig.

15).

In

addition

to

shifting

from

"high" to "low"

axle

or

"low"

to

"

high

'!

axle, it also shifts

the

spee

dometer

adapter

to

maintain reasonably accu-

rate

spee

dometer and odom-

eter

reading

regardle

ss

of

the

axle

ratio used.

The

vacuum shift

control

is

operated

by

pulling

the

small

knob

on

the

side

of

the

transmission

control

lever

up

or

down

to

change

The

electric

shift

control

is

operated

by

moving

a

small

thumb

lever

on

the

side

of

the

transmission control

lever

knob

forward

or

rearward

to

change

axle

ratio

(fig. 15).

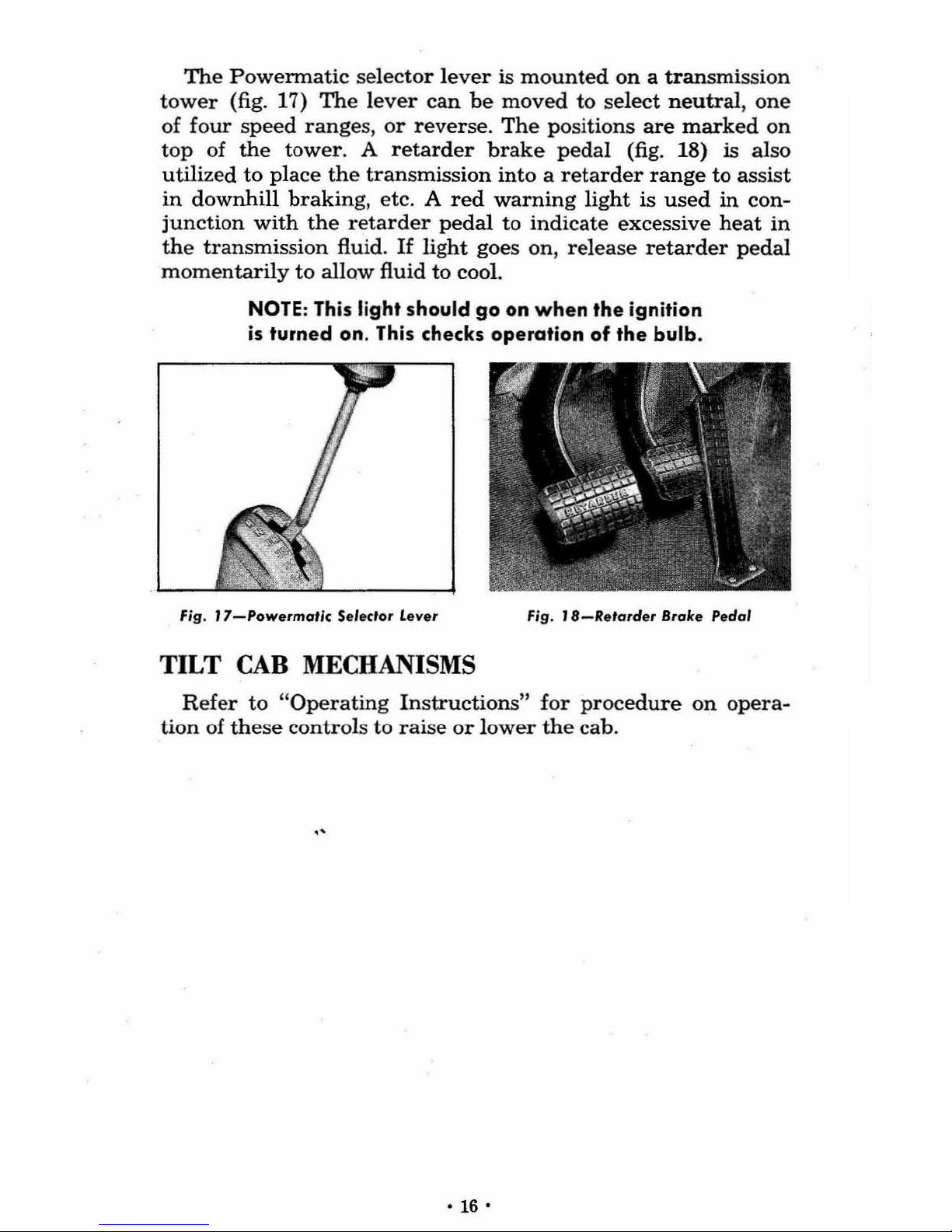

SHIFT CONTROL LEVER (AUTOMATIC

TRANSMISSIONS)

The

control

lever

for

the

Hydra-Matic

and

Powerglide

trans-

missions

is

simiI.fr to

the

ones

used

in

the conventional

pas-

senger

car

and

is

located

at

the

top

of

the

steering

column

on

the

right

hand

side. The operating

positions

are

plainly

marked

on

an

indicator

segment

behind

the

stee

ring

wheel

(fig. 16).

Hydro-MCJtic

Powe,glide

Fig

.

16-Auto

.maf;c Tronsmission Shiff Quodranls

•

15

•

The

Powermatic selector lever

is

mounted

on a transmission

tower

(fig. 17)

The

lever

can

be

moved

to select

neutral, one

of

four

speed

ranges

, or

reverse. The positions

are

marked

on

t

op

of the tower. A

retarder

brake

pedal

(fig. 18)

is

also

utili

zed to

place

the

transmission

int

o a

retarder

range

to

assist

in

downhill

braking

, etc. A

red

warning

light

is

used

in

con-

iu

nction

with

the

retarder

pedal

to indicate excessive

heat

in

the transmission

fluid.

If

light

goes on,

release

retarder

pedal

momentarily

to

allow fluid

to

cool.

NOTE:

This

light should go on

when

the ignition

is

turned

on

.

This

checks operation

of

the bulb.

Fig. J

7-Powermoric

$eleclor lever F

ig. J a-Re'arder

Bralce Pedal

TILT

CAB

MECHANISMS

R

efer

to

"Operating

Instructions"

for

procedure

on opera

-

tion of

these

controls

to rai

se

or lower the cab.

·

16·

FEATURES

STANDARD EQUIPMENT

ASH

TRAY

A

convenient

tilt

type

ash

tray

is located

in

the

center

area

of

the

instrument

panel.

The

tray

is

opened

by

pushing

it

for-

ward

at

the

bottom

and

pulling

it

out

at

top. To

remove

the

ash

tray

for

emptying, depress

the

circular

snuffer

at

top

of

tray

and

pull

out. To

replace

, h

ook

the

lower

inner

edge

of

tray

over

retaining rod, and

push

in at top.

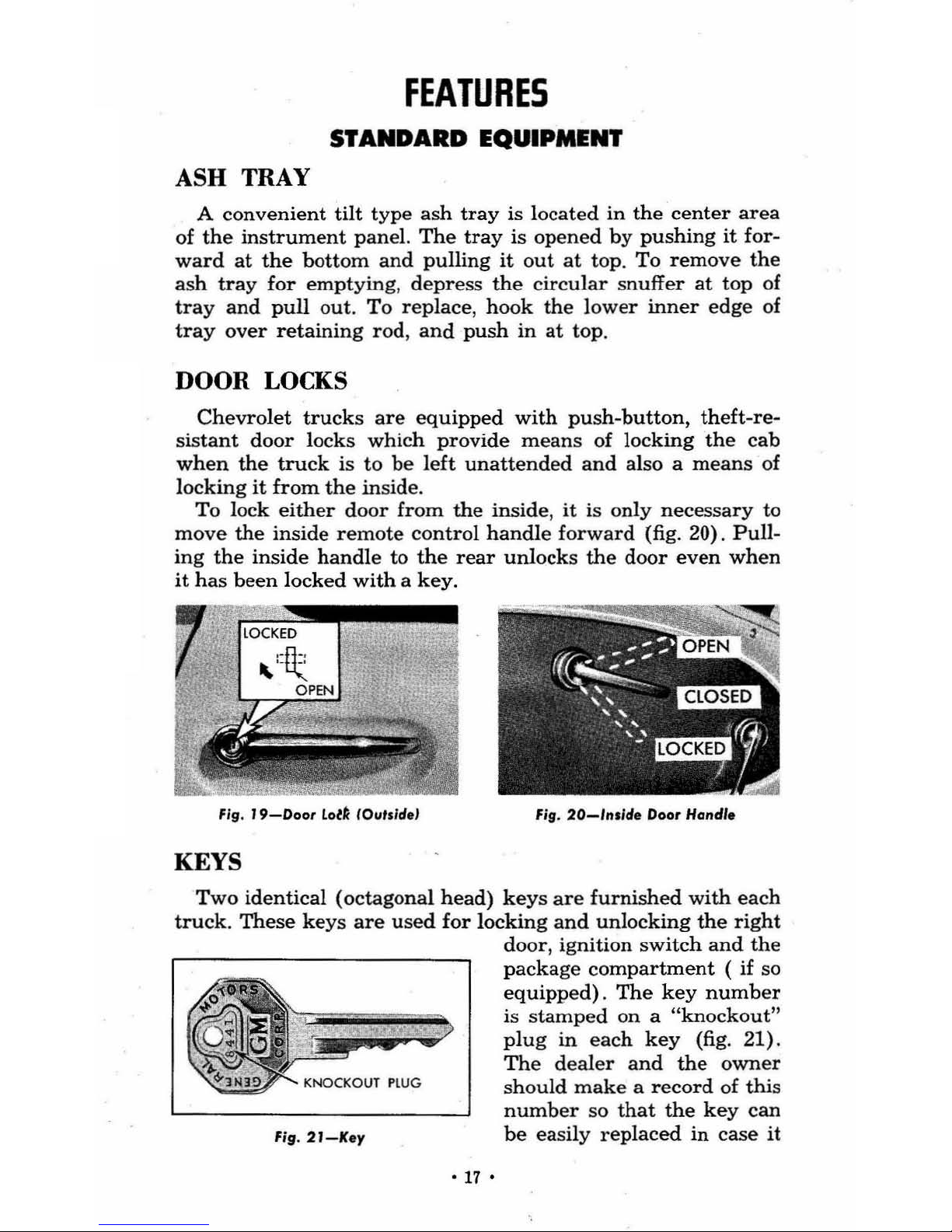

DOOR LOCKS

Chevrolet

trucks

are

equipped

with

push-button,

theft-re-

sistant

door

locks

which

provide

means

of

locking

the

cab

when

the

truck

is

to

be

left

unattended

and

also a

means

of

locking

it

from

the

inside.

To lock

either

door from

the

inside, it

is

only

necessary to

move

the

inside

remote

control

handle

forward

(fig. 20).

Pull-

ing

the

inside

handle

to

the

rear

unlocks

the

door

even

when

it

has

been

lock

ed

with

a key.

Fig

.

19-000'

LolA

lOuts/d.'

Fig.

20-lnslde

Door Handl.

KEYS

Two

identical (octagonal

head)

keys

are

furnished

with

each

truck.

These

keys

are

used

for

locking

and

unlocking

the

right

door, ignition switch and the

package

compartment

( if so

equipped). The

key

number

is

stamped

on

a "knockout"

plug

in

each

key

(fig. 21).

The

dealer

and

the

owner

should

make a record

of

this

number

so

that

the

key

can

Fig.21-K

ey

be

easily replaced in case

it

•

17

•

is l

ost, and

the

"knock

out"

plug should

be

removed

so that

unauthorized

persons cann

ot

obtain

the

key

number

and have

a

duplicate

made.

REAR VIEW MIRROR

An adjustable

rear

view mirr

or

is

mounted

on

the

forward

edge

of

the

left

door

at

the

belt line,

or

optiona

lly

mounted

(different

sty

le

mirror)

on

the

garnish

mo

lding

above

the

center

of

the wind

shield.

As

the

mirror

in

either

case

is swivel

mounted,

it

may

be

adjusted

to

suit

any

driver

(fig.

22).

Standard

Op

tion al

fig

.

22-II

.or

V

iew

Mirrors (Typical

'nstallot;on'

ACCESSORY OPERATION

Listed

below

are

severa

l o

ptional

accesso

ry

items

requirin

g

specific

instructions

for

their

use.

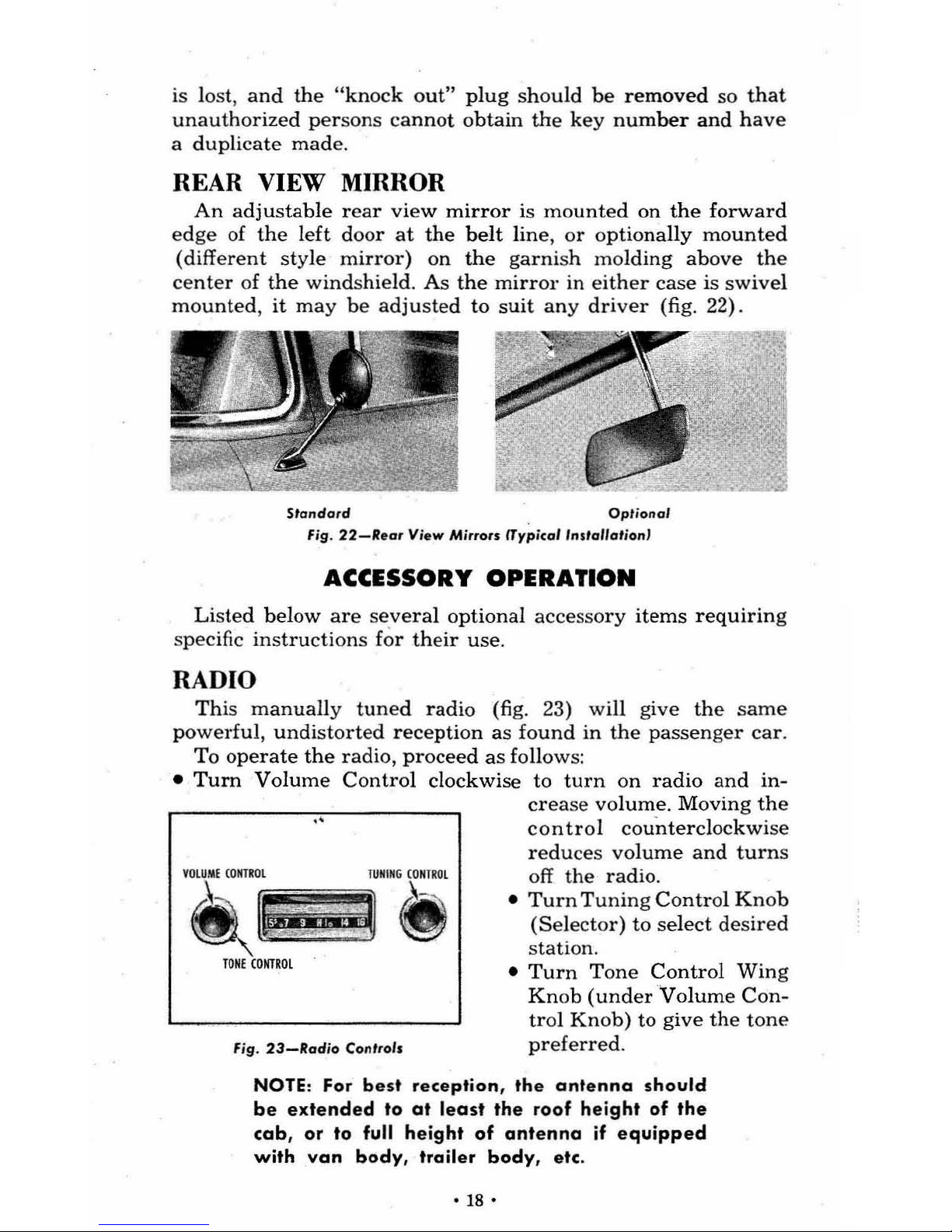

RADIO

This manually

tuned

radi

o (fig. 23) will

give

the

same

powerful,

unrli

storted

reception

as

found

in

the

passenger

car.

To

opera

te

the

radio,

proceed

as

follows:

•

Turn

Volume

Control

clockwise

to

turn

on

radio

and

in-

crease volum

e.

Moving the

contro

l

coun

tercl

ockwise

reduces volu

me

and

turns

'.;'

.,.

f'i

TONECOIiTROl

Fig .

23-lladio

Con trols

off

the

radio.

•

Turn Tuning

Control

Knob

(Selector)

to select

desired

station.

•

Turn

Tone

Control

Wing

Knob

(under

Volume Con

-

trol

Knob)

to

give

the

tone

preferred.

NOTE: For

best

reception,

the

antenna

should

be

extended

to

at

least

the

roof

height

of

the

cab, or

to full

height

of

antenna

if

equipped

with

van

body,

trailer

body,

etc .

• 18 •

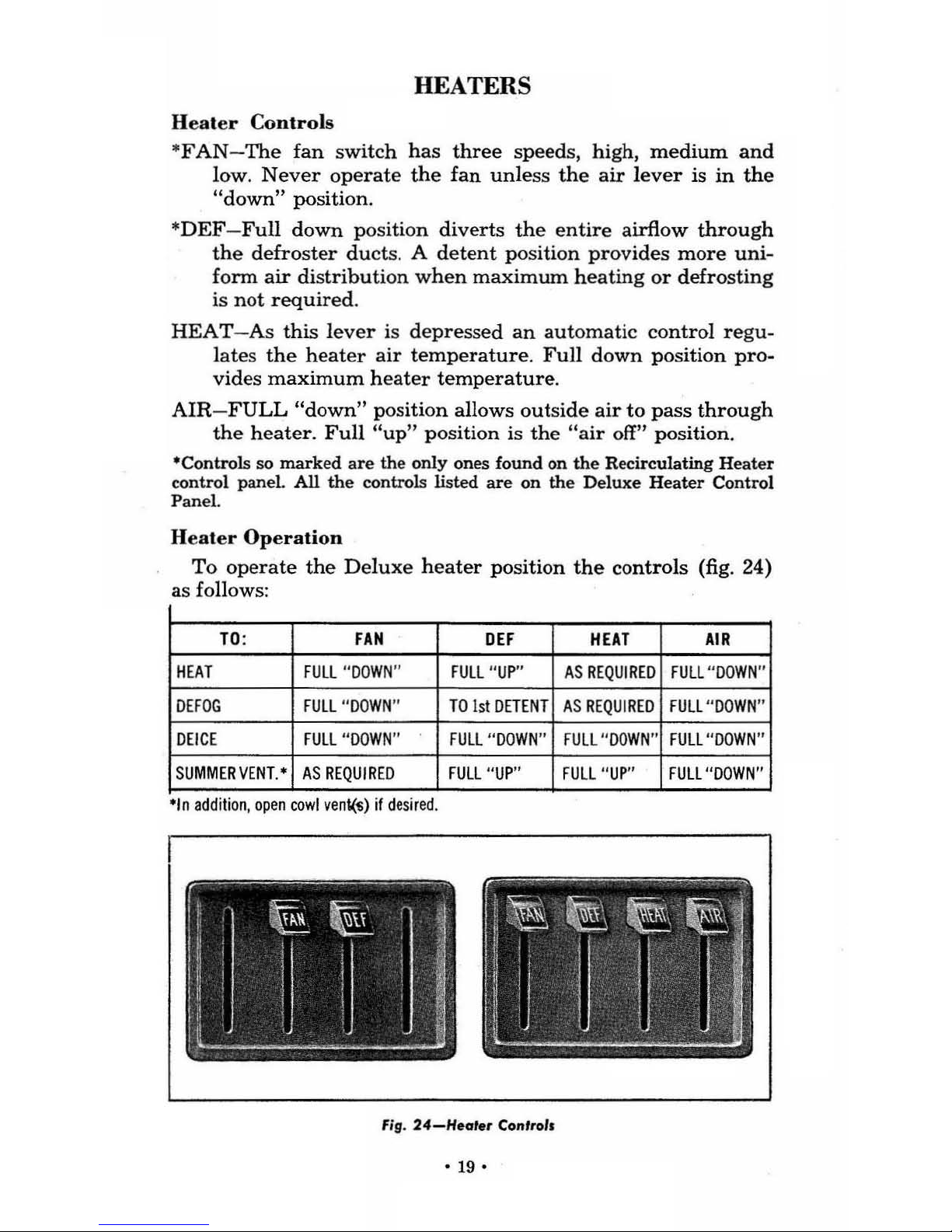

HEATERS

Heater

Con

trol

s

"

FAN

-The

fan

sw

itch

has

three

speeds, high,

medium

and

low.

Never

operate

the

fan

unless the

air

lever

is

in

the

"down" position.

"

DEF -Full

down

position

diverts the

entire

airflow

through

the

defroster

duct

s. A

detent

position provides

more

uni-

fonn

air distributi

on

when

maximum

heating or defrosting

is

not

required.

HEAT-As

this lever

is de

pre

ssed

an

automatic

control regu-

lates

the

heat

er

air

temperature.

Full

down

pos

ition

pro-

vides

maximum

heater temperature.

AIR-FULL

"down" pos ition allows

outside air to pass through

the

heater.

Full

"up" position is

the

"air off" position.

·Controls so marked are the only ones found on the Recirculating Heater

control paneL

All

the controls listed are on the

Deluxe

Heater Control

Pane

l.

Heater

Operation

To

operate

the

Del

uxe hea

ter

position

the

controls (fig. 24)

as

follows:

TO

:

FAN

OEF

HEAT

AIR

HEAT

FUll

"DOWN"

FUll "UP"

AS REQU

IRE

D

FUll "

DOWN

"

DEfOG

FUl

l "

DOWN"

TO

1st

DETENT

AS

REQUIRED

FUll "DDWN"

DEICE

FUll

"DOWN

" FUll "

DOWN

"

FUll

"DOW

N"

FUll

"DOWN"

SUMM

ER

VENT

.•

AS

REQUIRED

FUll

"UP"

FULL "UP"

FULL

"DOWN"

·'n

addi

tion, open

cowl

vent(ti)

If

desired.

Fig.

24-H.aler-

Can'r-als

·

19·

To

Operate

the

Recirculating

Heater

position

the

controls

(fig. 24) as follows:

TO:

FAN

DEF

HEAT

AS

REQUIRED

FUll

"UP"

DEFOG

FUll "

DOWN

"

TO

FI

RST

DETENT

DEICE

FUll "

DOWN"

FUll

"DOWN"

SUMMER

VENT'

AS

REQUIRED

FUll

"UP"

·In

addition,

open

cowl

vent(s)

if

desi

red

.

AIR CONDITIONING

The

Cool

Pack

Air

Conditioning

unit

operates

on 100%

recirculated

air

and

is

entirely

independent

of

the

heater

(fig. 25).

The

air

conditioning

and

heater

units

are

not

designed

to operate at

the

same time.

Fig.

25-CooI

-'oclc Air Conditioning

Contro' •

'J""t.

,.

~-

\ i.

b

''''

.'

~

.

.,..

"'t~

' .

fig.

26-Di,..ction

Signa'

lever

•

For

the

first

15

minutes

of operation,

rotate

the

FAN

knob

to

"high"

speed

and

the

COOLER

knob

to full cooling posi-

tion.

Then

readjust

fan

speed

and

cooling as

desired

.

•

Adjust

the

louvers

in

the

cooling

unit

to

direct

the

cooled

air

as

desired.

DIRECTION SIGNALS

The

direction signal lever, located

to

the

left of

the

steering

column

(fig. 26) allows a signal to

be

given

by

means

of

flashing lights

at

both

the

front

and

rear

of

the

vehicle. Move

the lever

"down" before turning left or

"up"

before turning

right.

The

lever

will

return

to

neutral

when

the

turn

is

completed.

SAFETY

HINT:

A Safety Hazard Switch is

avail-

able

as

an

optional

accessory

to

be

used

in

the direction

signal

circuit to flash the

signal

lights for emergency road stops .

•

20'

CIGARETfE LIGHTER

The

cigarette

lighter

is

located

on the

instrument

panel

face.

To

operate,

push

it in.

When

it

become

s heated,

it

automatically

"snap

s"

out

ready

for use.

WINDSHIELD WASHERS

To

operate

the

washer

s,

pre

ss

the

blltt

on

in the

center

of

the

wiper

control

knob.

Thi

s will send a strea

m of

water, or

other

cl

eaning

agent

onto

the

windshield.

Pressing

the

push

butt

on

also

causes

the

wiper knob

to

automati

cally

turn

to

the

"ON

"

po

sition,

and

the

wiper

will

operate

until

the

knob

is

manuall

y

returned

to

its "OFF" position .

Ke

ep

the

jar

under

the

hood

filled

at

all

time

s. G. M.

Wind-

shield

Washer

Solvent, added

to

the

water,

will

aid

in cuttin

g

road

film

and

grease

on

the

windshield.

Fill

jar

only

% full

with

G. M.

Windshield

Washer

Anti-Fre

eze solution

in

winter.

·21

•

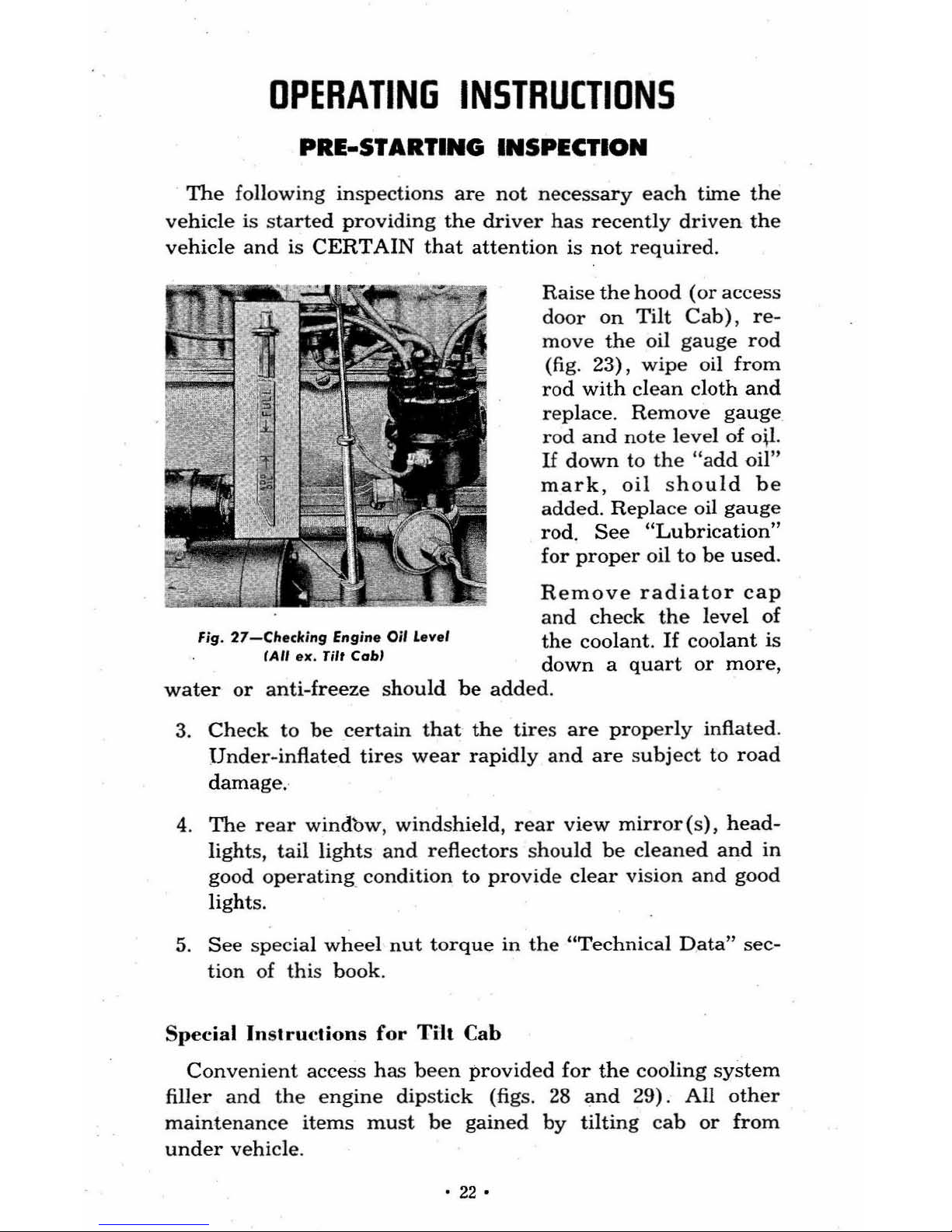

OPERATING

INSTRUCTIONS

PRE-STARTING

INSPECTION

The

following

inspections

are

not

necessary

each

time

the

vehicle

is

started providing

the

driver

has

recently

driven

the

vehicle

and

is

CERTAIN

that

attention

is

not

required.

Raise

the hood

(or

access

door

On

Tilt

Cab),

re-

move

the

oil

gauge

rod

(fig. 23),

wipe

oil

from

rod

with

clean

cloth

and

replace.

Remove

gauge

rod

and

note

level

of oil.

If

down to the

lIadd

oil"

mark,

oil

sho

uld

be

added.

Replac

e oil

gauge

rod.

See

"Lubrication"

for

proper

oil

to

be

used.

Remove

radiator

cap

and

check

the

level

of

the

coolant.

If

coolant

is

Fig.

27-Cltecking

Engine

Oi'

L

eve

l

fAil

ex.

Tilt

Cahl

down

a quart or more,

water

or

anti-freeze

should

be

added

.

3.

Check

to

be

certain

that

the

tires

are

properly

inflated.

Under-inflated

tires

wear

rapidly

and

are subject

to

road

damage

.

4.

The

rear windbw, windshield, rear

view

mirror(s),

head-

light

s,

tail

lights

and

reflectors

sho

uld

be

cleaned

and

in

good operatinK condition to provide clear vision and good

lights.

5.

See

special

wheel

nut

torque

in

the

"Technical Data" sec-

tion

of

thi

s book.

Special Instruct

ions for

Tilt

Cab

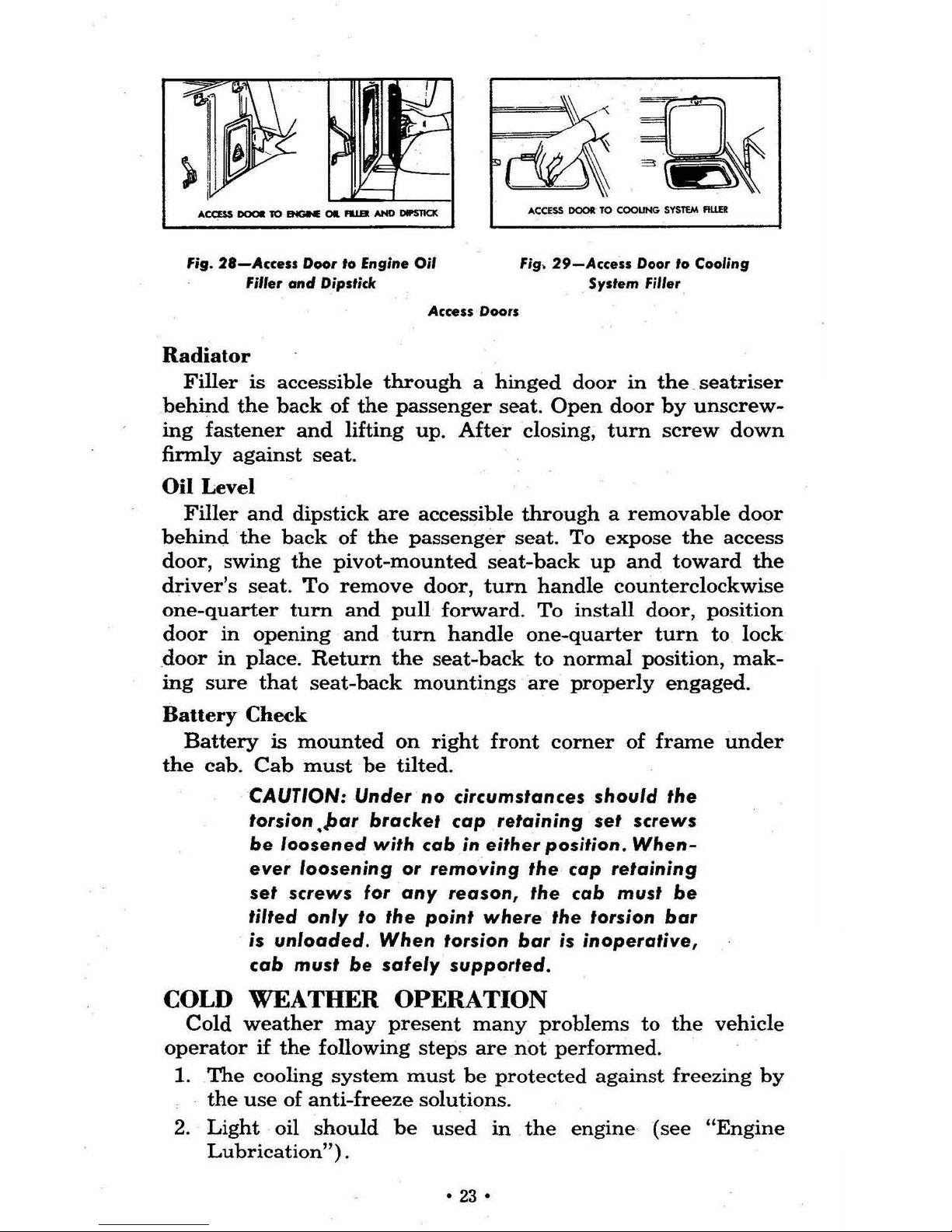

Convenient access has

been

provided for

the

cooling

system

filler

and

the

engine

dipstick

(figs.

28

and

29).

All

other

maintenan

ce

items

must

be

gained

by

tilting cab

or

from

under

vehicle.

• 22 •

fig. 2'-'\"

...

0001' to

Engin.

Oil

fm.r

and

Dipstick

Acwu

Doors

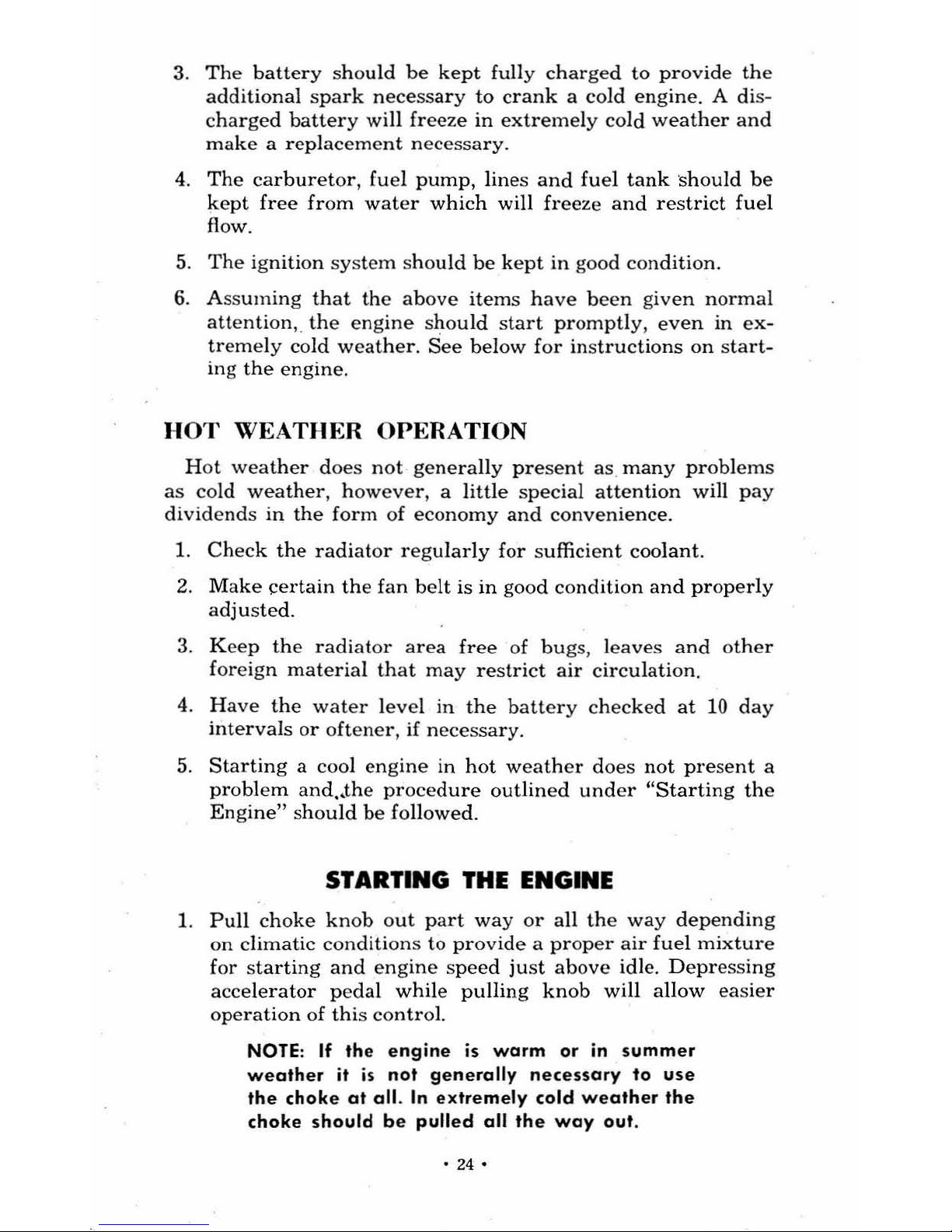

Radiator

fig.

29-Acc.u

Door

10

Cooling

.

Sy.t.m

Filler

Filler

is accessible

through a hinged

door

in

the. seatriser

behind

the

back

of

the

passenger

seat. Open

door

by

unscrew-

ing

fastener

and

lifting up.

After

closing,

turn

screw

down

finnly

against

seat.

Oil Level

Filler

and

dipstick

are

accessible

through a removable

door

behind

the

back

of

the

passenger

seat.

To

expose

the

access

door,

swing

the

pivot-mounted

seat-back

up

and

toward

the

driver's seat.

To

remove

door, turn handle counterclockwise

one-quarter

turn

and

pull

forward. To install door, position

door

in

opening

and

turn

handle

one-quarter

turn

to

lock

door

in

place.

Return

the

seat-back

to

normal

position,

mak-

ing

sure

that

seat-back

mountings

are

properly

engaged

.

Bauery

Check

Battery

is

mounted

on

right

front

corner

of

frame

under

the

cab.

Cab

must

be

tilted

.

CAUTION: Under

no

circumslances should Ihe

torsion .par bracket

cap

retaining

set

screws

be

loosened

with

cab

in

either position,

When-

ever

loosening

or

removing

the cap retaining

set

screws

for

any

reason,

the

cab must

be

IiIled only 10 Ihe poinl where Ihe lorsion bar

is

unloaded

. When torsion bar is

inoperative,

cab

musl

be

safely

supporled.

COLD

WEATHER

OPERATION

Cold

weather

may

present

many

problems

to

the

vehicle

operator

if

the

following

steps

are

not

performed

.

1.

The

cooling

system

must

be

protected

against

freezing

by

the

use

of

anti-freeze

solutions.

2.

Light

oil

should

be

used

in

the

engine

(see

"Engine

Lubrication") .

•

23

•

3.

The

battery

shou ld

be

kept

fully

charged

to

provide

the

additional

spark

necessary

to

crank a cold

engine. A dis-

charged

battery

will

freeze

in

extreme

ly cold

weather

and

make a replacement

necessa

ry.

4.

The

carburetor,

fuel

pump

, li

nes

and

fuel tank 'shou

ld

be

kept

free

from

water whi

ch will

freeze

and res

tri

ct

fuel

flow.

5.

The

ignition

system

should

be

kept

in

good

condition.

6.

Assuming that

the

above

items

have

been

given nor

mal

attention

•. the

engine

sJ:tou

ld

start

promptly,

even

in

ex-

treme

ly cold

weather.

See

below

for

instructions

on

slar

l-

ing

the

engine.

H

OT

WEA

TH

ER OPE

RATIO

N

Hot

weather

does

not

gene

rally pr

esent as,

many

problems

as

cold

weather,

however,

a

litt

le

special attention

wi

ll

pay

dividends

in

the form

of

economy

and

convenience

.

1.

Check

the

radiator

regularly

for

sufficient

cool

ant.

2.

Make

certa

in

the

fan

belt

is in

good

condition and

properly

adjusted.

3.

Keep

the

radiator

area free

of

bugs,

leaves

and

other

foreign

material

that

may

restrict

air

circulation.

4.

Have

the

water level in

the

battery

checked

at

10

day

intervals

or

oftener,

if

necessary

.

5.

Starting

a cool

engine

in

hot

weather

does not

present

a

problem

and.~the

procedure

ou

tli

ned

under

"Starting the

Engine"

shou

ld

be

foll

owed.

STARTING THE ENGINE

1.

Pu

ll

choke

knob

out

part

way

or

all

the

way

depending

on

climatic

conditions

to

provide a proper

air

fuel

mixture

for

starting

and

engine speed just

above

id le.

Depressing

accelerator

peda

l w

hile pu

lli

ng knob

will all

ow

easier

operation

of

this

control.

NOTE:

If

the e

ngin

e is

warm

or

in

summ

er

weath

er

it

is

not

ge ne

rally

ne

cessary

to

use

the

choke at

all

. In e xtre

mely

cold

weather

the

choke should

be

pulled

all

Ihe

way

oul

.

•

24

•

2.

Make certain

the

tran

smission

gear shift

or

selec

tor

lever

is

in

neutral.

(On aut

oma

tic

transmi

ssion

mode

ls,

engin

e

will

not start

unl

ess

tran

smissio

n is

in

neutra

l "N" posi-

tion.

Pow

er

glide

mode

ls

may

also

be start

ed

in

Park "P"

position.)

Depre

ss

the clutch

pedal

,

if

so equipped, to

re-

lieve

the load on the

transmission.

3.

Pla

ce ignition

key

in switch

and

turn

key

clockwi

se

to

"

ON" po

sition.

4.

Turn

the

ignition key

clockwis

e again

st

spring

ten

sion

to

crank e

ngine.

RELEASE

KEY

AS

SOON

AS

ENGINE

STARTS

:

If

engine

does not

start

in 5 to

10

seco

nds,

re-

l

ease key

and check

to

see

if a

bove ins

tructions

have

been

pe

rformed

correctly.

5. AS'soon

as

engine start

s,

push

choke knob

in

part

way

and

a

dju

st

throttle

for smoo

th

idle.

6.

Note

oil

gauge

(or

indicator)

and

ammeter

(or

generato

r

indicator)

readin

gs.

Ammeter

should show

charge

or lig

ht

s

hould

be

off

unl

ess

engine is

idlin

g slowly.

The

charging

rat

e s

hown

on

an

ammeter

with a fu

lly ch

arged

battery

may

be

so slig

ht that

the

needle

may

appear to rema

in

cen

ter

ed

on

the

gauge and

not

move away

from

the gau

ge

center

mark. Th

e oil gau

ge should

show

some

pressure

or

indicator lig

ht

sho

uld

go

out.

On

vehicles equIpped

wit

h

oil

pressure lig

ht

be

cer

tain

lig

ht

is off be

fore continu

ing,

if

st

ill on,

stop engine

and

determine fault.

On

vehicl

es

eq

uipped

with

an

oil

pre

ssu

re

gauge,

in

unusuall

y co

ld

weath

er

the

oil

gauge

needle

may

move

all

the

way over

to

"60."

If

so,

run the

engine

just

above

idling speed

until

th

e indicat.or h

and

drop

s to

around

the center

of

the

gauge

befo

re

dri",ing

vehicle. The

choke

knob

should

be

push

ed

in

all

the

way

as

soon

as

the

engine is sufficie

ntly

warmed

up.

CAUTION:

Excessive

use

of

the

choke

. will

provide

a

fuel-air

mixture

too

rich

to

burn.

Some

of

this

unburned

fuel

will

leak

post

the

pistons

and

dilute

the

engine

oil

. This

will

cause

improper

lubrication,

excessive

engine

wear

and

poor

performance

.

7.

Check

the

temperature

gauge

while

operating ve

hicl

e.

Norma} operating

range

is

betw

ee

n "e"

and

"H"

mark

s.

Hot

weather, long hard driving, or

prol

onged idling may

cause the nee

dle

to

be

in the high

ra

nge

of

the

gauge

.

•

25

•

However,

if

the

needle

moves

clear

to

the

"H"

hot

end

of

the

gauge,

stop

the

engine

until

the cau

se

of

overheating

is

determined.

A

hot

engine

is

eas

ily flooded and

may

start hard.

If

the

carburetor

is flooded,

proceed

as

follows:

a.

Tu

rn

on

ignition.

b.

Hold

accelerator

at

wide

open thr

ottle

position.

c.

DO

NOT pull

choke

knob

out.

d.

Engage starter

by

turning key

clockwise

against

spring

tension.

e.

When

engine

starts,

release

starter,

and close

throttle

slowly.

NOTE

: Do

not

remove

the

radiator

cop

when

engine

is

excessively

hot,

do

not

put

water

in

an

overheated

engine,

and

do

not

run

en-

gine

when

indicator

is

above

"H."

OPERATING THE:

SYNCHROMESH TRANSMISSION

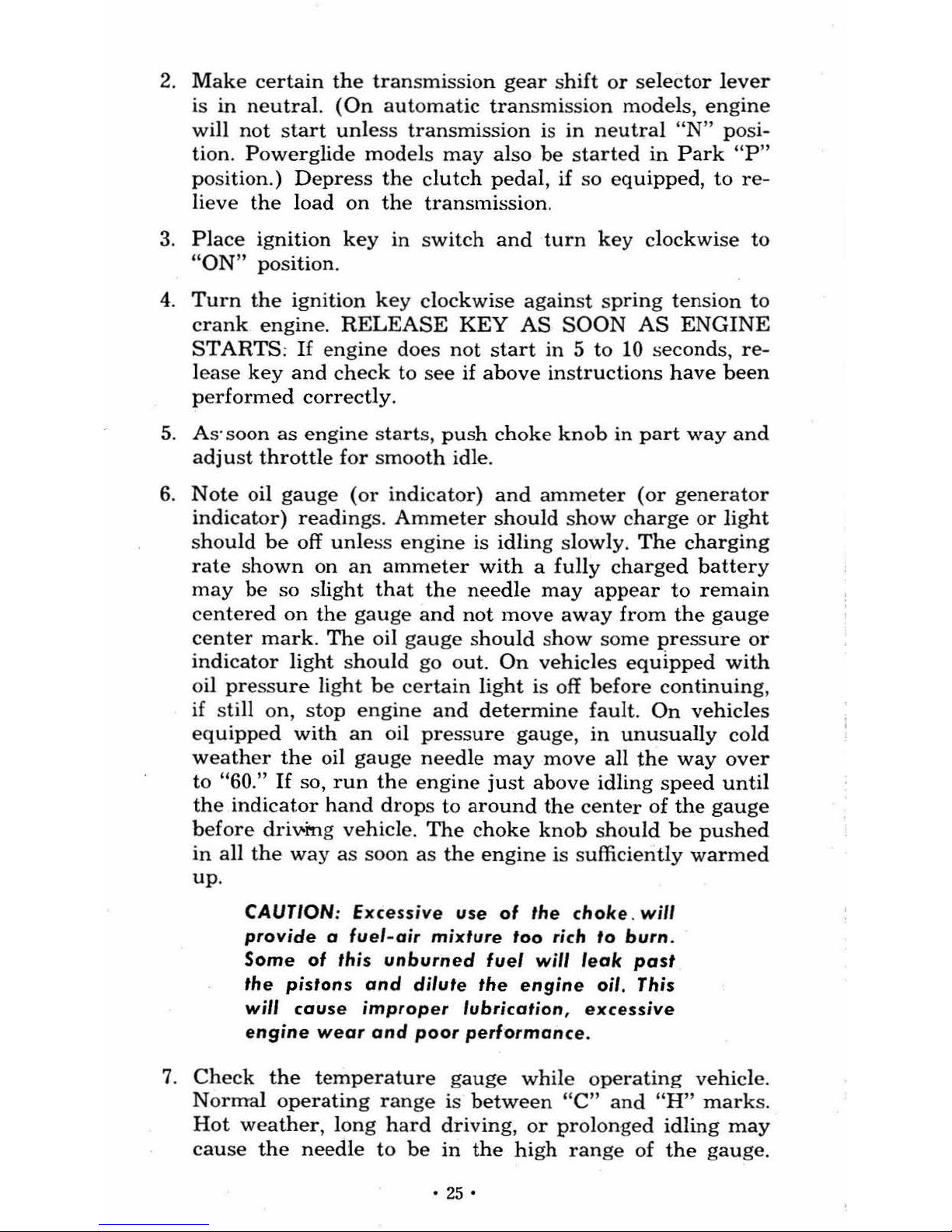

Three.Speed -The gear shi

ft

control

on

trucks

equipped with

this transmission

is

located

on

the

righ

t s

ide

of

the

stee

ring

column.

This transmission

uses

the

conventional "H"

shifting

pattern

as sh

own

in

Figure 30.

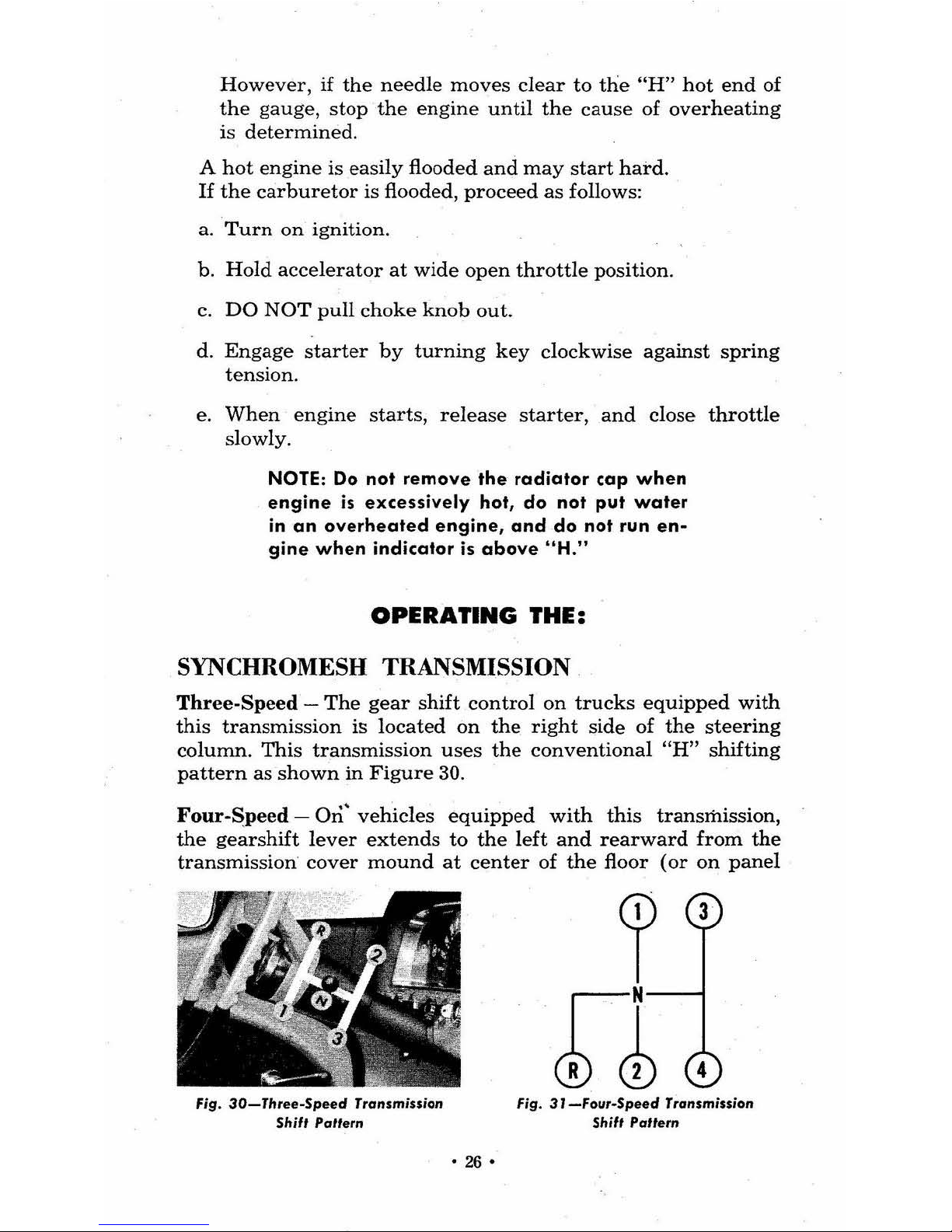

Four-S:peed

-

Ori~

vehicles

equip

ped

with

this

transmission,

the

gearshift lever

extends

to

the

left

and rearward from

the

transmission' cover

mound

at

center

of

the

floor

(or

on

panel

Fig.

30-Three-Speed

Transmission

ShUI

Paller"

•

26

•

?~

r~1

Fig.

3J-Four-Speed

Transmission

Shif,

Pallem

between

front

sea

ts

on

tilt

cab

mo

dels).

Thi

s l

ever

is used

to

s

hift

the

tran

smission

gears

to

the d

esire

d position.

Figure

31

sh

ows

the shifting pattern.

This

pattern

is

also sh

own

on the

co

ntrol lever knob.

Five-Speed -

When the vehicle

is

equipped

with

anyone

of

the

five-speed

transmi

ssions,

the shifting

pattern

is s

hown

on

the shift

control lever knob a

nd

in Figure

32. The

contro

l l

ever

is

in the same

position

as desc

rib

ed

above

under "four-speed."

NOTE: If

the

vehicle

is

equipped

with a two

speed

rear

axle,

refer

to

the

Two

Speed

Axle

instructions

later

in

this

section

.

tiJ

tfJ

r~l

~

~1

CLARK 0 .0 .

SPICER

0 .0.

NEW

PROCESS

CLARK

S

PICER

Fig.

32-Fiv

e·Spee

d Transmission Shiff PaUerns

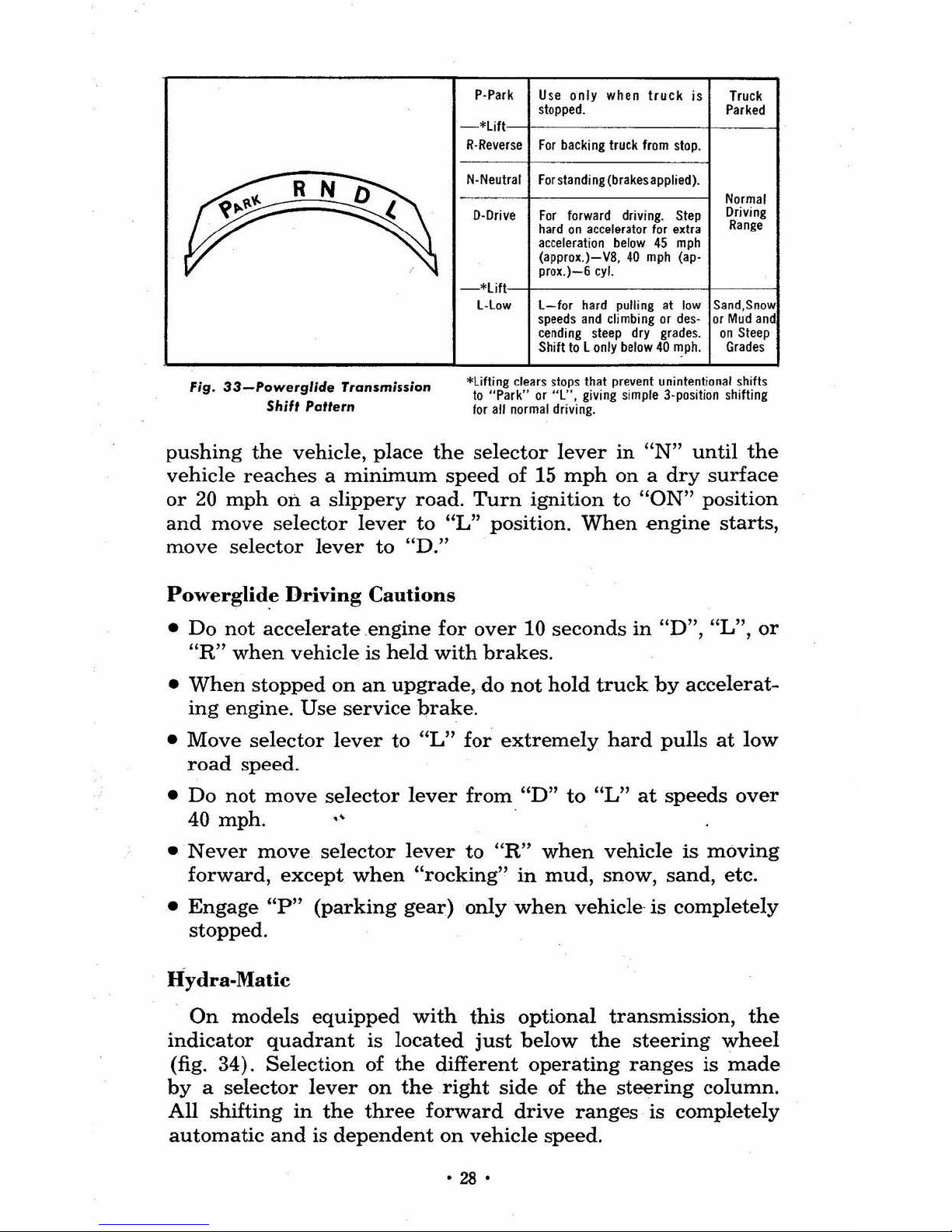

AUTOMATIC ·'fRANSMISSION

Pow

erg

lid

e

This optional

transmi

ssion

is a completely

aut

omatic u

nit

which

repla

ces

the

standard

clutch

and

transmis

sion.

Selectiv

e

control

is

obtained

through

the

selector

lever

which

is

located

On

the

right sid

e of

the

stee

rin

g co

lum

n.

The

diff~rent

ranges

are

indicated

on a quadrant

(fig.

33).

Towing

and

Pushing

Cautions-If

your

truck

must

be

towed,

place sel

ector

lever

in

"N"

pos

iti

on.

Do

not

exceed

30

miles

per hour.

If

the transmission

is

not

opera

ting p'roperly, the

propeller

sha

ft s

hould

be disco

nnect

ed from

the rear axle,

or

the

rear

wheels shou

ld

be

raised b

efore

any

towing

is

at-

tempte

d.

Should

it

ever

be

nece

ssary

to

start

the engine

by

• 27 •

Fig.

33-Powerglide

Transmission

Shift

Partern

P·Park Use

only

wilen truck is Tru

ck

stopped. Parked

R·Reverse

For

backing truck from stop.

N·Neulral Forslanding{brakesapplied).

D·Orive For forward driving. Stell

hard

on

accelerator

for

extra

accelerati

on

below

4S

mph

{allllro~.)-V8,

40

mph (ap·

Ilrox.)-6cyl.

Normal

Driving

Range

-*lift

-t

-------t---

---I

l·low

l-for

hard pulling at

low

Sand,Snow

speeds and climbing or des·

orMudand

cending steep dry grades.

on

Steep

Sh

ift

tolonlybelow40~ph

.

Grades

*liftingclears

slops Ihat prevent unintentional shifts

to

"Park" or

"l",

giving simple 3·position shifting

lor

all

normal driving.

pushing

the

vehicle,

place

the

selector

lever

in

"N"

until

the

vehicle

reaches a minimum

speed

of 15

mph

on a dry

surface

or

20

mph

on a slippery

road.

Turn

ignition

to

"ON"

position

and

move

selector

lever

to

"L"

position.

When

engine

starts,

move

selector

lever

to

"D."

Powerglid~

Driving

Cautions

•

Do

not

accelerate.engine

for

over

10

seconds

in

uD", "L", or

"R"

when

vehicle

is

held

with

brakes.

•

When

stopped

on

an

upgrade,

do

not

hold

truck

by

accelerat-

ing

engine.

Use

service

brake.

•

Move

selector

lever

to

"L"

for

extremely

hard

pulls

at

low

road

speed.

•

Do

not

move

selector

lever

from

"D"

to

ilL"

at

speeds

over

40

mph.

•

Never

move

selector

lever

to

"R"

when

vehicle

is

moving

forward,

except

when

"rocking"

in

mud,

snow,

sand,

etc.

•

Engage

up"

(parking

gear)

only

when

vehicle

is

completely

stopped.

Hydra-Malic

On

models

equipped

with

this

optional

transmission,

the

indicator

quadrant

is

located

just

below

the

steering

wheel

(fig.

34).

Selection

of

the

different

operating

ranges

is

made

by a selector

lever

on

the

right

side

of

the

steering

column.

All

shifting

in

the

three

forward

drive

ranges

is

completely

automatic

and

is

dependent

on

vehicle

speed,

•

28

•

Loading...

Loading...