Chevrolet 19244108, Performance 19244099, Performance LS9 Specifications

ALL INFORMATION WITHIN ABOVE BORDER TO BE PRINTED EXACTLY AS SHOWN ON 8 1/2 x 11

LS9 Crate Engine IR 31JA14

TITLE PART NO.

19244108

DATE AUTHREVISION

SHEET OF

1 17

LS9 Crate Engine (19244099) Specications

Specications Part Number 19244108

Thank you for choosing Chevrolet Performance as your high performance source. Chevrolet Performance is committed to providing

proven, innovative performance technology that is truly.... more than just power. Chevrolet Performance parts are engineered,

developed and tested to exceed your expectations for t and function. Please refer to our catalog for the Chevrolet Performance

Authorized Center nearest you or visit our website at www.chevroletperformance.com.

This publication provides general information on components and procedures which may be useful when installing or servicing

an LS9 Crate engine. Please read this entire publication before starting work.

This LS9 Crate engine is assembled using brand new, premium quality components. Due to the wide range of engine applications,

if you are retrotting a previous application, you may encounter installation differences between the LS9 crate engine assembly

and the previous engine. These differences may require modications or additional components not included with the LS9 engine,

including cooling, fuel, electrical, and exhaust systems. Some fabrication work may be required.

It is not the intent of these specications to replace the comprehensive and detailed service practices explained in the GM service

manuals. Reference a service manual for a 2010 - 2013 Chevrolet Corvette (LS9) for any additional information not included in this

specication.

For information about warranty coverage, please contact your local Chevrolet Performance dealer.

Observe all safety precautions and warnings in the service manuals when installing this LS9 crate engine in any vehicle. Wear eye

protection and appropriate protective clothing. When working under or around the vehicle support it securely with jackstands. Use

only the proper tools. Exercise extreme caution when working with ammable, corrosive, and hazardous liquids and materials. Some

procedures require special equipment and skills. If you do not have the appropriate training, expertise, and tools to perform any part

of this conversion safely, this work should be done by a professional.

Legal and Emissions Information

This publication is intended to provide information about the LS9 crate engine and related components. This manual also

describes procedures and modications that may be useful during the installation of an LS9 crate engine. It is not intended

to replace the comprehensive service manuals and parts catalogs which cover General Motors engines and components.

Rather, it is designed to provide supplemental information in areas of interest to “do-it-yourself” enthusiasts and mechanics.

This publication pertains to engines and vehicles which are used off the public highways except where specically noted

otherwise. Federal law restricts the removal of any part of a federally required emission control system on motor vehicles.

Further, many states have enacted laws which prohibit tampering with or modifying any required emission or noise control

system. Vehicles which are not operated on public highways are generally exempt from most regulations, as are some

special interest and pre-emission vehicles. The reader is strongly urged to check all applicable local and state laws.

Many of the parts described or listed in this manual are merchandised for off-highway application only, and are tagged with

the “Special Parts Notice” reproduced here:

Special Parts Notice

This part has been specically designed for Off-Highway application only. Since the installation of this part may either impair

your vehicle’s emission control performance or be uncertied under current Motor Vehicle Safety Standards, it should not be

installed in a vehicle used on any street or highway. Additionally, any such application could adversely affect the warranty

coverage of such an on-street or highway vehicle.

The information contained in this publication is presented without any warranty. All the risk for its use is entirely assumed by the user.

Specic component design, mechanical procedures, and the qualications of individual readers are beyond the control of the publisher,

and therefore the publisher disclaims all liability incurred in connection with the use of the information provided in this publication.

Chevrolet, the Chevrolet Bow Tie Emblem, General Motors, and GM are all registered trademarks of the General Motors Corporation.

Chevy is a trademark of the General Motors Company.

ALL INFORMATION WITHIN ABOVE BORDER TO BE PRINTED EXACTLY AS SHOWN ON 8 1/2 x 11

LS9 Crate Engine IR 31JA14

TITLE PART NO.

19244108

DATE AUTHREVISION

SHEET OF

2 17

driveability and a smooth idle. Under this system, fuel pressure

of 87 psi is delivered at high RPM (above 5200 RPM) and

high throttle operation to provide adequate fuel ow. Pressure

of 60 psi below 1500 RPM for best idle stability and quality.

Additionally, the fuel system must be capable of owing 75 gph

at 87 psi. It is critical that constant 75 gph of fuel at 87 psi

be available at high RPM / high throttle operating ranges or

performance and/or engine durability will be adversely affected.

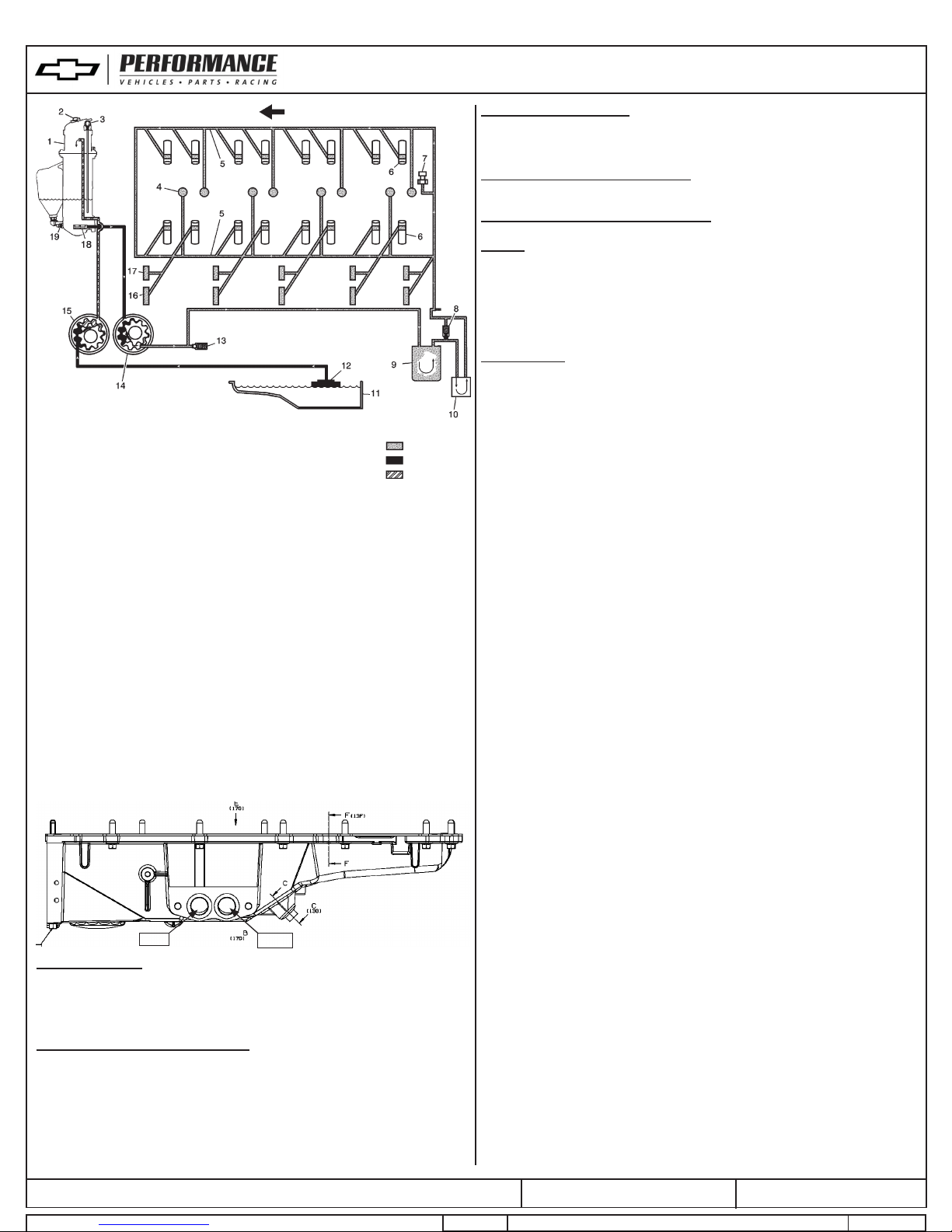

Oil System:

The LS9 Crate Engine is congured as a dry sump oiling

system (see diagram below). A remote oil tank and appropriate

oil lines are required for this type of installation (the production

Corvette oil tank is GM part number 12629421 and is shown

in the diagram). Chevrolet Performance p/n 25534412 is an

adapter kit to allow use of AN -12 hoses at the oil pan. Engine

lubrication is supplied by a gerotor type oil pump assembly.

The oil pump assembly consists of 2 pump housings, 2 separate

gear sets, and 1 pressure relief valve. The front or forward gear

set is the secondary pump (15). The rear or rearward gear set

is the primary pump (14). The pump assembly is mounted at

the front of the engine and driven directly by the crankshaft

sprocket. The primary pump (14) gears rotate and draw oil from

the engine oil tank (3) through the oil tank screen (18). The oil

is pressurized as it passes through the primary pump and is

sent through the engine block lower oil gallery. Contained within

the primary pump is a pressure relief valve (13) that maintains

oil pressure within a specied range. Pressurized oil is directed

through the engine block lower oil gallery to the full ow oil

lter (10) where harmful contaminants are removed. A bypass

valve is incorporated into the oil lter, which permits oil ow in

the event the lter becomes restricted. Oil exits the oil lter and

is then directed to the external oil cooler (1). A bypass valve (9)

is incorporated into the oil cooler assembly in the event oil ow

within the cooler is restricted. Oil returns from the oil cooler and

is directed to the upper main oil galleries (6). Oil from the left

upper oil gallery is directed to the crankshaft bearings (16),

valve lifters 1, 3, 5, and 7, camshaft bearings (17), and piston

oil nozzles 1, 3, 5, and 7. Oil from the right upper oil gallery is

directed to the valve lifters 2, 4, 6, and 8 and piston oil nozzles

2, 4, 6, and 8. The piston oil nozzle assemblies are designed to

provide oil to the bottom side of the piston for cooling purposes.

The piston oil nozzles have an internal check ball that is held

in the normally closed position by the spring until system oil

pressure exceeds 20.7 kPa (43.5 psi). Oil exits the valve lifters

and is then pumped through the pushrods to lubricate the valve

rocker arms and valve stems. Oil returns to the oil pan (11),

where the secondary pump (15) draws oil through a oil pump

screen (12). The secondary pump (15) returns oil to the engine

oil tank (3). Incorporated within the engine oil tank assembly

are the oil level indicator (4), oil ll cap (5), oil temperature

sensor (2), positive crankcase ventilation (PCV) fresh air port,

and a serviceable oil pump screen (18). The engine oil pressure

sensor (8) is located at the top rear of the engine assembly.

Package contents:

Item Description Quantity

GM Part

Number

1 Engine Assembly 1 19244099

2 Engine Instructions 1 19244108

3 Pump Intercooler 1 20945282

Technical Information and Operational Requirements:

Supercharger/Intercooler System:

The LS9 Roots-type supercharger is a positive displacement

pump that consists of 2 counter-rotating rotors installed into

the lower intake manifold housing. The rotors are designed with

4 lobes and a helical twist. The rotors of the supercharger are

designed to run at a minimal clearance, not in contact with each

other or the housing and are timed to each other by a pair of

precision spur gears which are pressed onto the rotor shafts.

The rotors are supported at each end by self-lubricating nonserviceable bearings. The drive belt pulley is pressed onto

the input shaft. The input shaft is coupled to the rotor shaft. Both

the belt pulley and torsional isolator are also non-serviceable.

The cover assembly has an integrated intercooler.

The intercooler uses conventional coolant and must be

separate from the engine cooling system. The intercooler

assembly includes the cover, two charge air coolers/heat

exchangers, a water manifold assembly, two service bleed ports,

a factory coolant ll port, and a variety of sensors to monitor

air temperature and pressure. The water manifold, located at

the front of cover transfers coolant to the cover via four internal

transfer tubes. The transfer tubes and water manifold are sealed

with O-rings and press-in-place seals. Coolant enters the inlet

port of the water manifold assembly, is directed into and through

the two charge air coolers/heat exchangers, and exits back

into the water manifold. Coolant then exits the water manifold

outlet port.

An intercooler cooling system is required to ensure that heat

can be removed from the coolant. The system must include

appropriately sized lines, radiator, and pump (Provided

pump ows a minimum 5.5 gallons per minute ow rate

recommended) to ensure the coolant temperature remains in

an acceptable range, especially during high boost operating

ranges (i.e. heavy accelerations, high throttle positions,

etc). For optimal performance, it is recommended that

the coolant temperature be kept below 95 degrees F at

the intercooler inlet. It is critical that this temperature be

kept below 175 degrees F for safe engine operation. Use of

production components is recommended whenever possible,

a list of these parts is included below.

Fuel System:

The production LS9 application operates with a variable fuel

pressure system to allow for best performance and driveability.

By varying the fuel pressure over the operating range,

the required high RPM / high throttle fuel ow can be achieved

while still providing the ability to maintain excellent mid-range

ALL INFORMATION WITHIN ABOVE BORDER TO BE PRINTED EXACTLY AS SHOWN ON 8 1/2 x 11

LS9 Crate Engine IR 31JA14

TITLE PART NO.

19244108

DATE AUTHREVISION

SHEET OF

3 17

Engine Control System

An engine control system is required to operate the LS9 Crate

Engine. Check with your Chevrolet Performance dealer or

www.chevroletperformance.com for the Chevrolet Performance

control system #19299462.

Additional parts that are needed:

Starter

The LS9 crate engine does not include a starter. GM part

number 89017847 is matched to this application and is

recommended. See your Chevrolet Performance dealer

for details.

Air Induction

A high-quality, high-ow/low restriction air lter/cleaner should

be used to protect the engine. Additionally, your engine control

system may have recommendations for air cleaners and intake

systems for best performance. Chevrolet Performance universal

induction kit 19301246 is available.

Start-up and Break-in Procedures

Safety rst. If the vehicle is on the ground, be sure

the emergency brake is set, the wheels are chocked and

the car cannot fall into gear. Verify everything is installed

properly and nothing was missed.

1. This engine assembly needs to be lled with oil. After

installing the engine, ensure the oil system has been lled

with the appropriate motor oil to the recommended oil ll

level. The LS9 crate engine requires a special oil meeting

GM Standard GM4718M (this will be specied on the oil

label). Dexos 1 is one such recommended oil. Other oils

meeting this standard may be identied as synthetic.

However, not all synthetic oils will meet this GM standard.

Look for and use only an oil that meets GM Standard

GM4718M. If using GM12629421 oil tank, make sure

that the oil level falls within the cross hatched area on

the dipstick once the oil is warm. Also check and ll as

required any other necessary uids such as coolant, power

steering uid, etc.

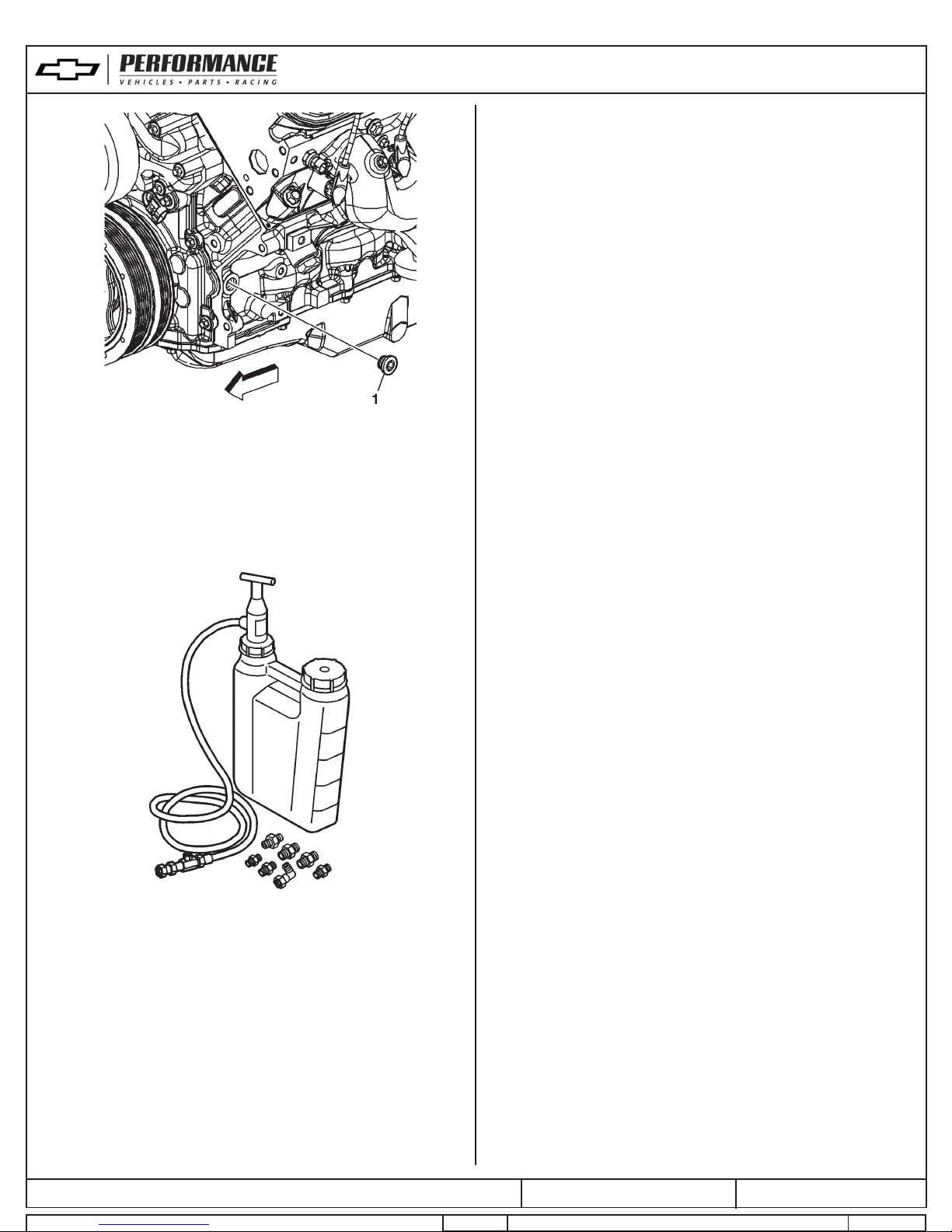

2. This engine MUST be primed with oil before starting.

The use of Kent-Moore engine preluber kit J45299 is

the preferred process for priming.

Note: A constant and continuous ow of clean engine oil is

required in order to properly prime the engine. Be sure to

use approved engine oil, as specied.

Main Pressure

Suction

Return to Oil Tank

1. Engine Oil Tank 11. Oil Pan Sump

2. Oil Fill Cap 12. Oil Pump Screen

3. Oil Level Indicator 13.

Pressure Relief Valve –

Oil Pump

4. Piston Oil Nozzle 14. Oil Pump – Primary

5.

Upper Main Oil

Galleries

15. Oil Pump – Secondary

6. Valve Lifters 16. Crankshaft Bearings

7. Oil Pressure Sensor 17. Camshaft Bearings

8.

Bypass Valve – Oil

Cooler

18. Oil Tank Screen

9. Oil Filter 19. Oil Temperature Sensor

10. Engine Oil Cooler

Accessory Drive

The LS9 Crate Engine requires an accessory drive system.

Chevrolet Performance kit #19243524 includes all of

the LS9 Corvette accessory drive components, see

www.chevrolet performance.com for list of individual

components.

Oil Out

Oil In

ALL INFORMATION WITHIN ABOVE BORDER TO BE PRINTED EXACTLY AS SHOWN ON 8 1/2 x 11

LS9 Crate Engine IR 31JA14

TITLE PART NO.

19244108

DATE AUTHREVISION

SHEET OF

4 17

6. Pump the handle on the J45299 preluber in order to ow

a minimum of 1-1.9 liters (1-2 quarts) engine oil. Observe

the ow of engine oil through the exible hose and into

the engine assembly. The engine will be primed after

a small amount of pressure change is seen on the in car

oil pressure gauge while pumping J45299.

7. Close the valve and remove the exible hose and adapter

from the engine.

8. Apply approved thread sealer and Install the oil gallery plug

to the engine and tighten to 60 N•m (44 lb ft).

Top-off the engine oil tank to the proper level.

3. Once the engine control system has been disconnected, crank

the engine using the starter for 10 seconds and check for oil

pressure. If no pressure is indicated, wait 30 seconds and crank

again for 10 seconds. Repeat this process until oil pressure is

indicated on the gauge.

4. Reconnect the engine control system. Start the engine and

listen for any unusual noises. If no unusual noises are noted, run

the engine at approximately 1000 RPM until normal operating

temperature is reached.

5. When possible, you should always allow the engine to warm

up prior to driving. It is a good practice to allow the oil sump

and water temperature to reach 180°F before towing heavy

loads or performing hard acceleration runs.

6. The engine should be driven at varying loads and conditions

for the rst 30 miles or one hour without wide open throttle

(WOT) or sustained high RPM accelerations.

7. Run ve or six medium throttle (50%) accelerations to about

4000 RPM and back to idle (0% throttle) in gear.

8. Run two or three hard throttle (WOT 100%) accelerations to

about 4000 RPM and back to idle (0% throttle) in gear.

9. Change the oil and lter. Replace the oil per the specication

in step 1, and replace the lter with a new UPF48R AC Delco

oil lter. Inspect the oil and the oil lter for any foreign particles

to ensure that the engine is functioning properly.

10. Drive the next 500 miles (12 to 15 engine hours) under normal

conditions. Do not run the engine at its maximum rated engine

speed. Also, do not expose the engine to extended periods

of high load.

11. Change the oil and lter. Again, inspect the oil and oil lter for

any foreign particles to ensure that the engine is functioning

properly.

1. Remove the engine oil lter, and ll with clean engine oil.

2. Install the oil lter and tighten.

3. Locate and remove the engine block left front oil gallery

plug (1).

4. Install the M16 x 1.5 adapter P/N 509375 J 45299 Engine

Preluber.

5. Install the exible hose to the adapter and open the valve.

ALL INFORMATION WITHIN ABOVE BORDER TO BE PRINTED EXACTLY AS SHOWN ON 8 1/2 x 11

LS9 Crate Engine IR 31JA14

TITLE PART NO.

19244108

DATE AUTHREVISION

SHEET OF

5 17

LS9 Engine Specications

Type ................................................. 6.2L Gen IV Small Block V8

Displacement ..................................................... 376 cubic inches

Bore x Stroke .............................................4.065 inch x 3.62 inch

Compression ........................................................................9.1:1

Supercharger Boost Ratio ..................................................10.5:1

Block ..................Cast aluminum, six bolt cross-bolted main caps

Cylinder Head ................................Cast aluminum rectangle port

Valve Diameter (Intake/Exhaust) ............................ 2.16”/1.59”

Chamber Volume .................................................................. 68cc

Crankshaft ............................... Forged Steel, internally balanced

Connecting Rods ................................................Forged Titanium

Pistons ..............................................................Forged aluminum

Camshaft ...................................................Hydraulic roller tappet

Lift ................................................... 562” intake, .558” exhaust

Duration .............. 211° intake, 230° exhaust @.050” tappet lift

Rocker Arm Ratio ................................................................1.7:1

Oil Pressure (Minimum, with hot oil) ............ 6 psig @ 1000 RPM

. ..............................................................18 psig @ 2000 RPM

. ..............................................................24 psig @ 4000 RPM

Recommended Oil ............5w30 Dexos 1 motor oil or equivalent

................... (must meet GM4718M specication, which will be

.......................................................... specied on the oil label)

Oil Filter .................................... AC Delco Part Number UPF48R

Fuel........................................... Premium unleaded - 92 (R+M/2)

Maximum Engine Speed .............................................6600 RPM

Spark Plugs ........................................................... GM 12571165

................................................................... AC Delco # 41-104

Spark Plug Gap .....................................................................040”

Firing Order ......................................................... 1-8-7-2-6-5-4-3

Information may vary with application. All specications listed

are based on the latest production information available at

the time of printing.

ALL INFORMATION WITHIN ABOVE BORDER TO BE PRINTED EXACTLY AS SHOWN ON 8 1/2 x 11

LS9 Crate Engine IR 31JA14

TITLE PART NO.

19244108

DATE AUTHREVISION

SHEET OF

6 17

Caractéristiques techniques du moteur en caisse LS9 (19244099)

Numéro de pièce des caractéristiques techniques 19244108

Nous vous remercions d'avoir choisi Chevrolet Performance comme source de haute performance. Chevrolet Performance s'est

engagée à offrir une technologie de rendement éprouvée et novatrice qui est réellement... beaucoup plus que de la puissance.

Les pièces de Chevrolet Performance ont été conçues, élaborées et mises à l'essai de manière à dépasser vos attentes de réglage

précis et de fonction. Veuillez vous reporter à notre catalogue pour connaître le centre Chevrolet Performance autorisé le plus près

de chez vous ou visitez notre site Web à www.chevroletperformance.com.

La présente publication offre de l'information d'ordre général sur les composants et les procédures pouvant s'avérer utile lors de

l'installation ou de l'entretien du moteur en caisse LS9. Veuillez lire en entier la présente publication avant de commencer

à travailler.

L'assemblage de ce moteur en caisse LS9 est effectué en utilisant des composants neufs de première qualité. Compte tenu de

la vaste gamme d'applications de moteurs, si l'on pose en après-vente une application antérieure, il se peut que l'on constate

des différences de pose entre le moteur en caisse LS9 actuel et la version précédente. Ces différences peuvent nécessiter des

modications ou des composants supplémentaires qui ne sont pas compris avec le moteur LS9, y compris les systèmes de

refroidissement, électrique et d'échappement, ainsi que le circuit d'alimentation. II se peut qu'une certaine fabrication soit requise.

Ces caractéristiques techniques ne sont pas destinées à remplacer les pratiques d'entretien complètes et détaillées expliquées

dans les manuels d'atelier GM. Se reporter au manuel de réparation de la Chevrolet Corvette 2010-2013 (LS9) pour de plus amples

renseignements non inclus dans les présentes caractéristiques techniques.

Pour obtenir de l'information sur l'étendue de la garantie, prière de communiquer avec le concessionnaire Chevrolet Performance local.

Observer toutes les précautions et tous les avertissements en matière de sécurité présentés dans les manuels de réparation

au moment de poser ce moteur en caisse LS9 dans n'importe quel véhicule. Porter un protecteur pour la vue et des vêtements

de protection appropriés. Lorsqu'on travaille sous ou autour d'un véhicule, le soutenir solidement à l'aide de chandelles. Utiliser

seulement les outils appropriés. Faire preuve d'extrême prudence lorsqu'on travaille avec des liquides ou des matériaux

inammables, corrosifs ou dangereux. Certaines procédures nécessitent l'utilisation d'un équipement spécial et des habiletés

particulières. Si vous ne possédez pas la formation, l'expertise et les outils nécessaires pour effectuer toute partie de cette

conversion en toute sécurité, ce travail devrait être réalisé par un professionnel.

Information juridique et relative aux émissions

La présente publication a pour objet d'offrir des renseignements sur le moteur en caisse LS9 et les composants connexes.

Ce guide décrit également les procédures et les modications pouvant s'avérer utiles lors de l'installation d'un moteur en

caisse LS9. Ces renseignements ne sont pas destinés à remplacer les manuels de réparation complets et les catalogues

de pièces en matière de moteurs et de composants de la General Motors. Plutôt, ce guide a été conçu pour offrir des

renseignements supplémentaires sur les matières pouvant intéresser les «bricoleurs» et les mécaniciens.

Cette publication s'applique aux moteurs et aux véhicules qui sont utilisés hors des voies publiques, sauf indication

contraire expresse. Les règlements fédéraux restreignent la dépose des véhicules automobiles de toute partie d'un

système antipollution exigé par la loi fédérale. En outre, de nombreux États ont établi des lois qui interdisent le traquage

ou la modication de tout système antipollution ou antibruit exigé par la loi. En règle générale, les véhicules qui ne roulent

pas sur les voies publiques, tout comme certains véhicules d'intérêt spécial et pré-émissions, sont exempts de la plupart de

la réglementation. On suggère fortement au lecteur de consulter tous les règlements municipaux et provinciaux applicables.

Plusieurs des pièces qui sont décrites ou énumérées dans le présent ouvrage sont commercialisées à des ns hors

autoroute seulement et elles portent l'étiquette «Special Parts Notice» (avis sur les pièces spéciales) qui est reproduite ici.

Avis spécial sur les pièces

Cette pièce a été conçue spéciquement pour une application hors route seulement. Puisque la pose de cette pièce pourrait

nuire au rendement antipollution du véhicule ou donner lieu à son manque d'homologation en vertu des normes de sécurité

actuelles des véhicules automobiles, celle-ci ne doit pas être posée dans un véhicule qui sera utilisé sur une voie publique

ou une autoroute. En outre, une telle application pourrait donner lieu à l'annulation de la garantie d'un tel véhicule sur route

ou autoroute.

Les renseignements contenus dans cette publication sont présentés sans aucune garantie. Tout risque encouru pendant l'utilisation

de cette publication est entièrement assumé par l'utilisateur. La conception de composant spécial, les procédures mécaniques et les

qualications de chaque lecteur sont hors du contrôle de l'éditeur et c'est pourquoi il décline toute responsabilité afférente en lien avec

l'utilisation des renseignements fournis dans cette publication.

Chevrolet, l'emblème Chevrolet, General Motors et GM sont des marques déposées de General Motors. Chevy est une marque

de commerce de la General Motors Company.

French

Loading...

Loading...