Chesterton TwinHybrid 4400H Installation, Operation And Rebuild Instructions

INSTALLATION, OPERATION and

REBUILD INSTRUCTIONS

4400H TwinHybrid™

Gas Seal

Installation, Operation and Rebuild Instructions

TABLE OF CONTENTS

1.0 Cautions ................................................................... 2

2.0 Transport and Storage .......................................... 2

3.0 Description ............................................................... 2

3.1 Parts Identification ..........................................................2

3.2 Operating Parameters .....................................................3

3.3 Standard Materials .........................................................3

3.4 Intended Use ..................................................................3

3.5 Dimensional Data ..................................................... 4 - 5

Seal Data Reference

(Insert seal and equipment data here for future reference)

ITEM #

SEAL

(Example: 4400H – 50 mm SSC/CB/FKM/S)

4.0 Preparation for Installation ................................... 6

4.1 Equipment .....................................................................6

4.2 4400H TwinHybrid™ Gas Seal ........................................6

5.0 Seal Installation ....................................................... 7

6.0 Commissioning/Equipment Start-up ................. 8

7.0 Decommissioning/Equipment Shut Down ....... 8

8.0 Spare Parts .............................................................. 8

9.0 Seal Maintenance and Repair ..................... 8 - 11

9.1 4400H Trouble Shooting .................................................8

9.2 4400H TwinHybrid™ Gas Seal Rebuild Instructions .. 9 - 11

INSTALLATION DATE

1.0 CAUTIONS

These instructions are general in nature. It is assumed

that the installer is familiar with seals and certainly with

the requirements of their plant for the successful use of

mechanical seals. If in doubt, get assistance from someone

in the plant who is familiar with seals or delay the installation

until a seal representative is available. All necessary auxiliary

arrangements for successful operation (heating, cooling,

flushing) as well as safety devices must be employed. These

decisions are to be made by the user. The decision to use this

seal or any other Chesterton seal in a particular service is the

customer’s responsibility.

2.0 TRANSPORT AND STORAGE

Transport and store seals in their original packaging.

Mechanical seals contain components that may be subject to

alteration and ageing. It is therefore important to observe the

following conditions for storage:

3.0 DESCRIPTION

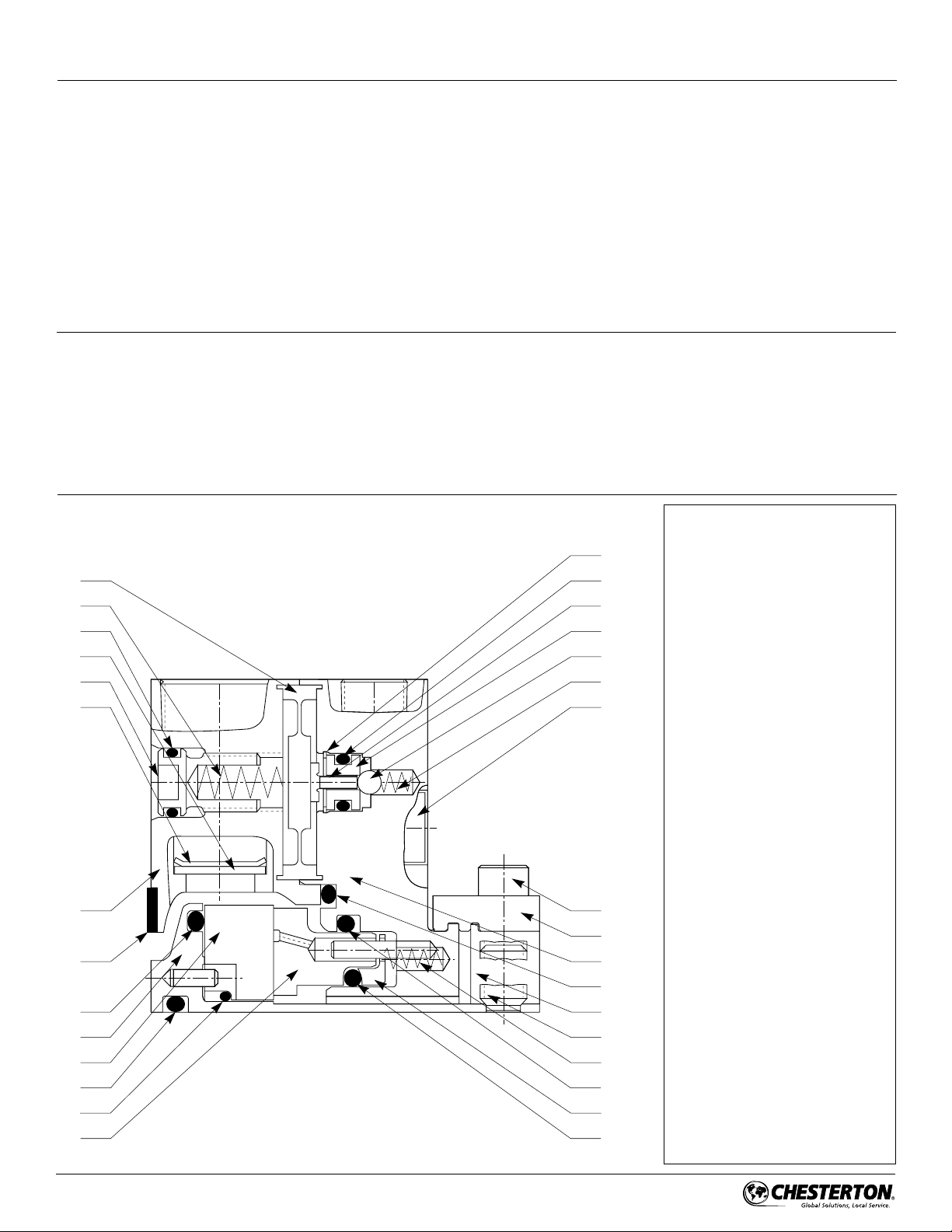

3.1 Parts Identification

Figure 1

20

19

18

35

17

36

6

3

4

1

5

2

28, 31-34, 37 (not shown in this view

7

8

)

Do not touch the mechanical seal for any reason while it is

operating. Lockout or uncouple the driver prior to personal

contact with the seal. Do not touch the mechanical seal

while it is in contact with hot or cold fluids. Ensure that all

the mechanical seal materials are compatible with the

process fluid. This will prevent possible personal injury.

• Dust free environment

• Moderately ventilated at room temperature

• Avoid exposure to direct sunlight and heat.

• For elastomers, storage conditions according to ISO 2230

should be observed.

KEY

1 – Sleeve Assembly

22

23

21

24

25

26

29

16

15

9

10

14

27

30

11

13

12

2 – Shaft O-Ring

3 – Gasket

4 – Rotary O-Ring

5 – Rotary Seal Ring

6 – Adapter

7 – Rotary Cushion O-Ring

8 – Stationary Seal Ring

9 – Gland

10 – Inter Gland O-Ring

11 – OD Stationary O-Ring

12 – ID Stationary O-Ring

13 – Pusher Plate

14 – Lock Ring

15 – Centering Clip

16 – Socket Head Cap Screw

17 – Adjusting Screw

18 – Screw O-Ring

19 – Inboard Spring

20 – Diaphragm

21 – Actuator

22 – Snap Ring

23 – Seat O-Ring

24 – Seat

25 – Ball

26 – Outboard Spring

27 – Dog Point Set Screw

28 – Cup Point Set Screw

29 – Gland Screws

30 – Spring

31 – 1/4" Pipe Plug

32 – 1/8" Pipe Plug

33 – 3/8" Pipe Plug

34 – Cap Plug

35 – Filter Disk

36 – Retaining Clip

37 – Support Gasket

2

3.0 DESCRIPTION cont.

3.2 Operating Parameters*

Speed Limits:

25 m/s (5000 fpm) Maximum

1,3 m/s (250 fpm) Minimum

Pressure Limits:

710 Torr (28" Hg) to 20 bar g (300 psig)

25 mm – 65 mm (1.000" -2.625")

510 Torr (20" Hg) to 17 bar g (250 psig)

70 mm – 90 mm (2.750" – 3.625")

Temperature Limits:

To 260°C (500°F) Maximum (elastomers)

* Consult Chesterton Mechanical Seal Application Engineering for higher

operating conditions.

3.3 Standard Materials

Faces :

Carbon Stationary Seal Ring

Sintered Silicon Carbide Rotary Seal Ring

Elestomers:

FKM, EPDM, FEPM, FFKM

Metal Parts:

316SS body

Alloy C-276 springs and drive pins

Hardened set screws (standard)

3.4 Intended Use

The mechanical seal is specifically designed for the intended

application and is to be operated within the operating

parameters as specified. For use beyond the intended

application and/or outside the operating parameters, consult

Chesterton Mechanical Seal Application Engineering to confirm

the suitability of the mechanical seal prior to putting the

mechanical seal in operation.

3

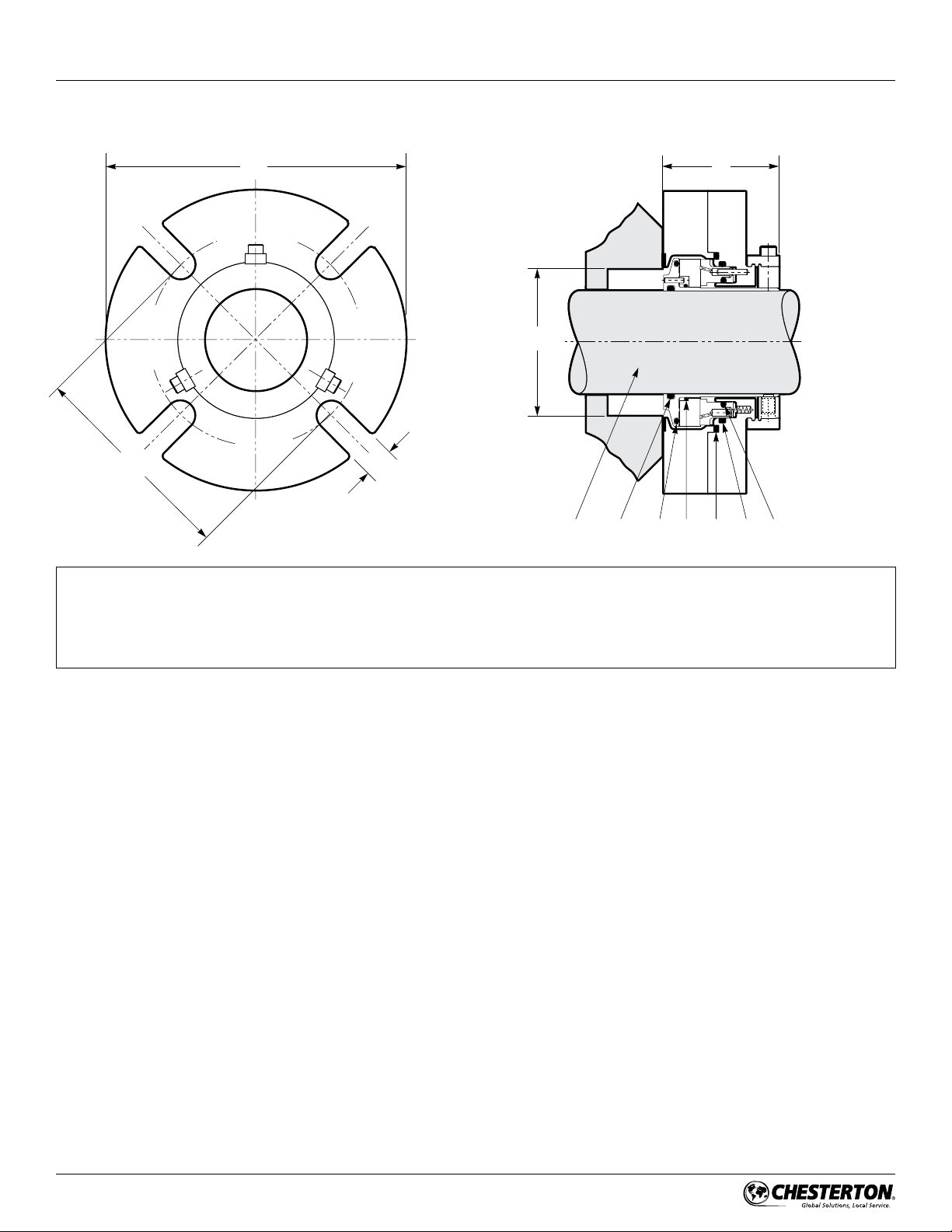

3.0 DESCRIPTION cont.

3.5 Dimensional Data (Drawings)

Figure 2

G MIN

KEY (chart)

A – Shaft Size

B – Maximum Gland Diameter

C – Stuffing Box Inside Diameter

F – Outboard Seal Length

B

C

H

TA

G – Maximum Bolt Circle by Bolt Size

H – Slot Width

T – Shaft O-Ring

U – Rotary Seal O-Ring

V – Rotary Cushion O-Ring

W – Stationary Seal O-Ring (outside diameter)

X – Stationary Seal O-Ring (inside diameter)

Y – Gland Adaqpter O-Ring

F

VU Y W

X

4

Loading...

Loading...