Chesterton DualPac 2211 Installation Instructions Manual

DualPac™ 2211

Installation Instructions

EQUIPMENT PREPARATION

MECHANICAL PACKING

INSTALLATION INSTRUCTIONS

IMPORTANT: Follow all plant procedures and equipment

manufacturer safety practices throughout installation process.

Read all instructions prior to installation.

1. Remove old packing from stuffing box. Stuffing box should

be free of any old packing residue, solids and corrosion left

from the process.

2. Inspect pump sleeve. Sleeve should be in good condition

and free of excessive wear, corrosion or pitting for optimum

packing service life.

3. Clean the packing gland and gland follower. Remove burrs,

corrosion or any residual material which would impede

insertion into the stuffing box.

4. Calculate the packing cross section:

a. Measure the shaft sleeve diameter (or locate and

measure a packing mandrel, an old packing sleeve or

a piece of wood the same diameter as the shaft sleeve).

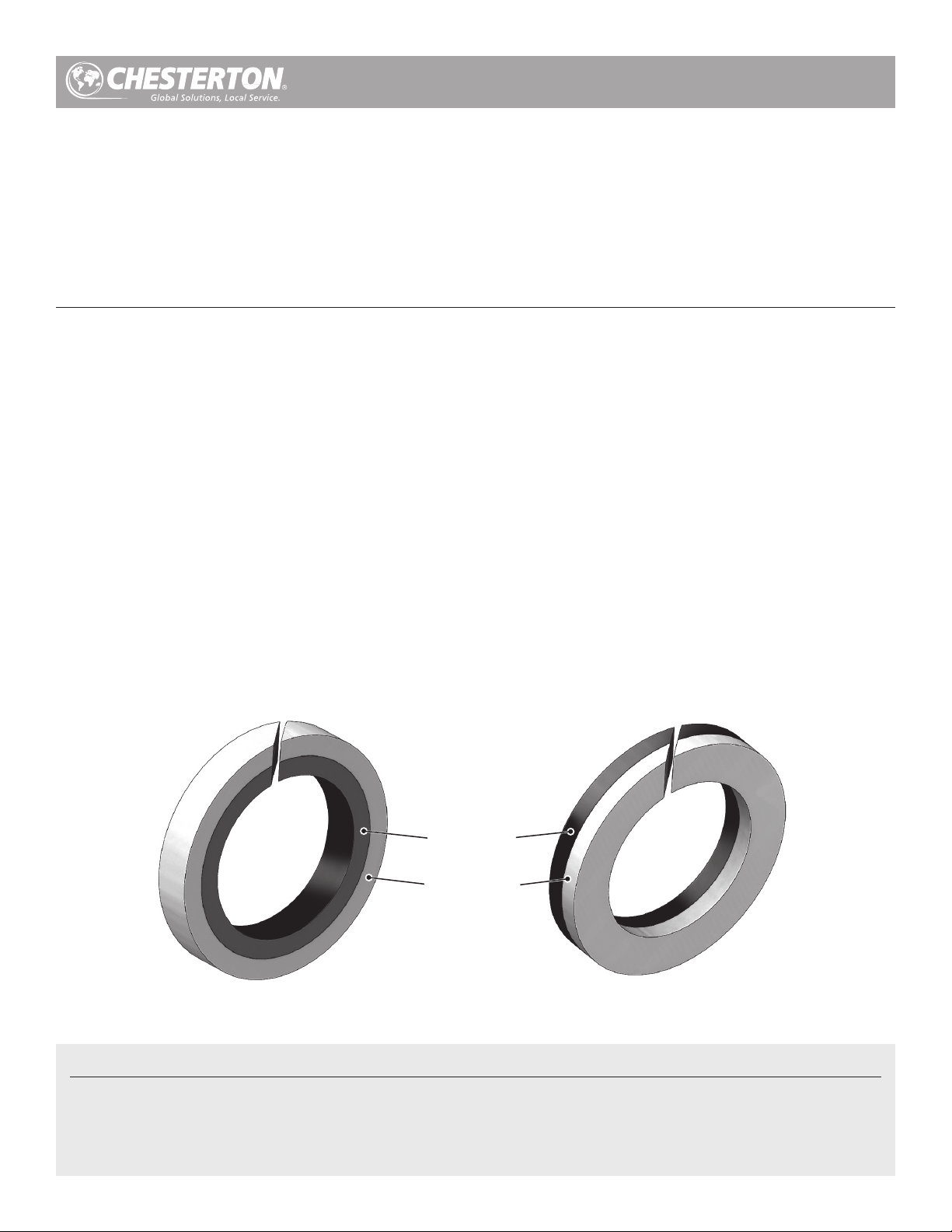

Figure 1 – Primary Sealer (SHOWN WITH Black ePTFE SEALING SHAFT) Figure 2 – End Ring

b. Measure the stuffing box bore.

c. Cross section = (Bore ID – Stem OD) ÷ 2.

5. Wrap the packing around the packing mandrel and mark at

one complete ring.

6. Remove packing from mandrel.

7. Before cutting rings determine which style packing you

want facing the shaft, then cut rings using a 45° skive cut.

8. Each ring should be cut with the arrangement required for

each application. Typical arrangement would be (3) primary

sealer rings (shown in Figure 1 with Black ePTFE facing the

shaft), (1) top end ring, and (1) bottom end ring (shown in

Figure 2).

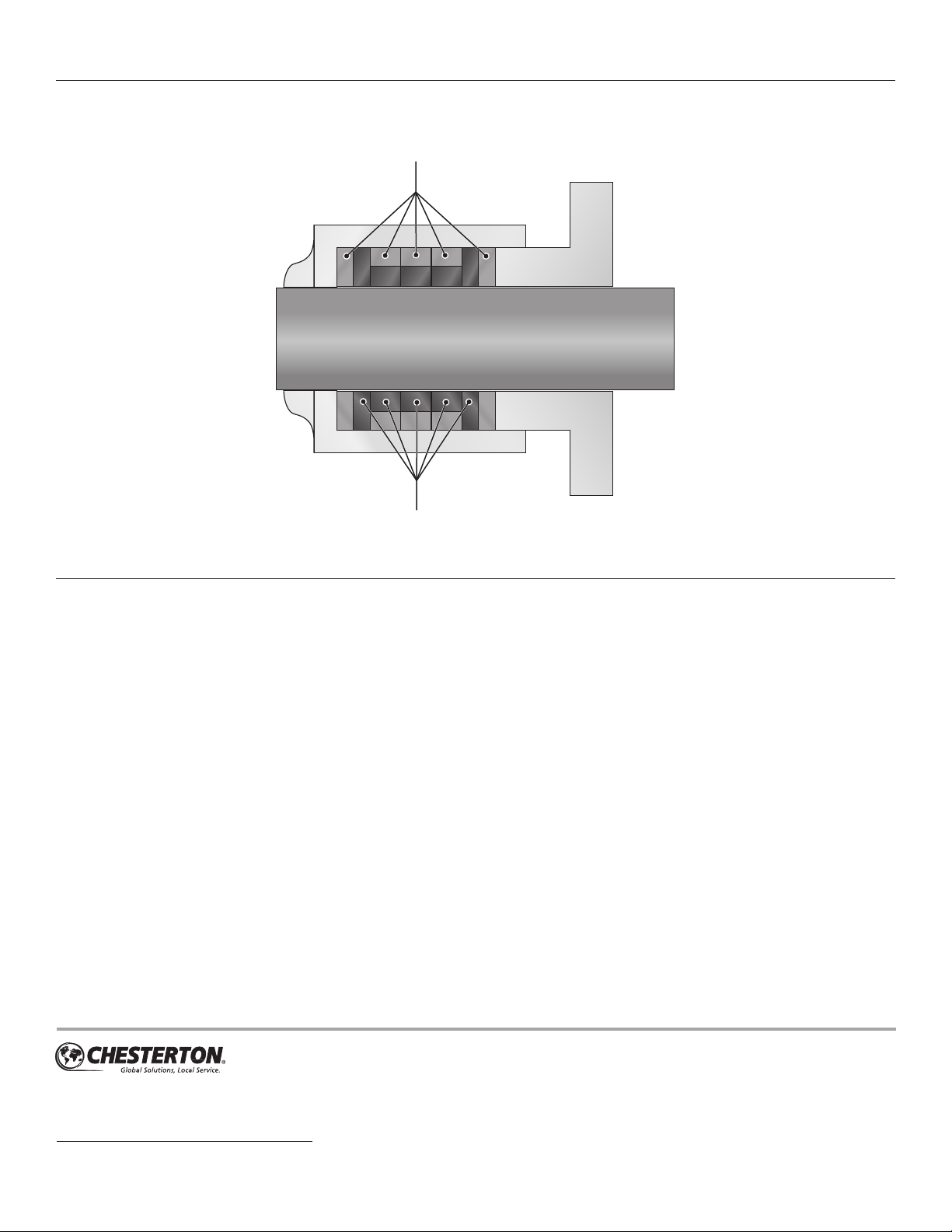

(See Figure 3 for stuffing box arrangement)

Additional rings may be required to pack the stuffing box. After

each ring is cut wrap them around mandrel to check fit before

proceeding to installation.

Black ePTFE

Yellow Aramid

CAUTIONS

These instructions are general in nature. It is assumed that the installer

is familiar with mechanical packing and with the plant requirements for

the successful use of mechanical packing. If in doubt, get assistance

from someone in the plant that is familiar with the product, or delay the

installation until a packing representative is available.

All necessary auxiliary arrangements for successful operation

(heating, cooling, flushing) as well as safety devices must be

employed. These decisions are to be made by the user.

The decision to use this or any other Chesterton product in

a particular service is the customer’s responsibility.

DUALPAC™ 2211 INSTALLATION INSTRUCTIONS

Figure 3 – Primary Sealer (SHOWN WITH 3 PRIMARY SEALER RINGS AND 2 END RINGS)

Yellow Aramid

Black ePTFE

INSTALLATION

9. Install each ring of packing by inserting it into the stuffing

box and, using the packing gland, pushing it in as far as

the packing gland will allow.

10. Stagger all ring joints 90°, at a minimum.

11. Use a Chesterton 176 tamping tool to firmly seat each ring

in the bottom of the stuffing box.

12. Repeat steps 9 through 11 until all rings are installed or

stuffing box is filled.

13. Install packing gland and gland follower; tighten gland bolts

to a snug load.

14. Back off on gland load and loosen gland bolts until gland

moves freely.

15. Finger-tighten bolts until gland is snug against packing.

16. Use a feeler gage to make sure that the gland is not touching the shaft (gland/shaft contact will generate excess heat

and cause equipment wear and/or damage).

17. Take-up gland nuts finger tight. Break in slowly. 100 to 200

drops per minute leakage at start, adjust (see note) until

leakage is approximately 20 to 60 drops per minute. Lower

leakage may be achieved depending on the application and

condition of the stuffing box.

NOTE: Adjust packing gland gradually one flat at a time, no

more than one adjustment every 15 minutes. Never permit

box to heat up. Be sure gland adjustments are applied

evenly.

DualPac is a registered trademark of A.W. Chesterton Company.

860 Salem Street

Groveland, MA 01834 USA

Telephone: 781- 438 -7000 Fax: 978-469- 6528

www.chesterton.com

© 2016 A.W. Chesterton Company.

® Registered trademark owned and licensed by

A.W. Chesterton Company in USA and other countries.

DISTRIBUTED BY:

FORM NO. EN36475 REV. 1 9/16

Chesterton ISO certificates available on www.chesterton.com/corporate/iso

Loading...

Loading...