Chery SQR372 Service Manual

SQR7080 Service Manual 372 Engine Mechanical System

1

SQR372 Engine

Service Manual

Chery Automobile Co., Ltd.

Forewords

In order to help the technical servicing personnel to have correct understanding and good command of the

cute Chery Model SQR7080 vehicle, and to master the skills for fast repairs and rational maintenance, a

special edition of the “Chery QQ Technical Service Manual—372 Engine Mechanics Division” is

compiled and published.

This Manual gives a detailed description on the dismounting, installation, checks and tests, adjustments

and diagnoses, technical standards and specifications for adjustments and diagnoses of various parts and

components as well as subsystems of Chery QQ 372 engines. This Manual is published by Chery

Automobile Co., Ltd.

Any parts or sections of this Manual shall not be copied or duplicated in whatever form or by whatever

approach without the written authorization of the publisher.

The right of interpreting the Manual belongs to the Service Department of Chery Automobile Co. Ltd

Editors

March of 2004

3、Special tools for maintenance:

S

Outer appearance Code and Name Purpose

Auxiliary devices for engine

dismounting and checks

Engine dismounting and check stand

Clockwise belt wheel wrench

Mounting onto engine

dismounting and check

stand

Dismounting and

installing engine

Camshaft clockwise

belt wheel dismounting

Chery Automobile Co., Ltd

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080 Service Manual 372 Engine Mechanical System

2

Spring bush pulling and removing

device

Installing crankshaft

oil seal

S

Valve locking block removal device

Auxiliary tools

Dismounting and

installation of valve

spring locks

Flying wheel fixture

Dismounting and

installation of

crankshaft

T

Valve guiding pipe punch

Removing and

installation of valve

guiding pipe

Shaft oil seal replacer

Oil seal stand screw driver

Outer appearance Code and Name Purpose

Crankshaft belt wheel fixture

Remove and install

crankshaft belt wheel

Remove and install

Wrench

camshaft slave gear

wheel

Replace valve spacing

adjust washer

Chery Automobile Co., Ltd

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080 Service Manual 372 Engine Mechanical System

3

Measuring

tools

Tool Piston ring dismounting device

Oils

Clearance gauge, calipers, Micrometer, ruler, centesimal meter, cylinder gauge ,

pressure meter, torque wrench

Engine lubricating oil, bond

Chapter 2 Timing Belt Service

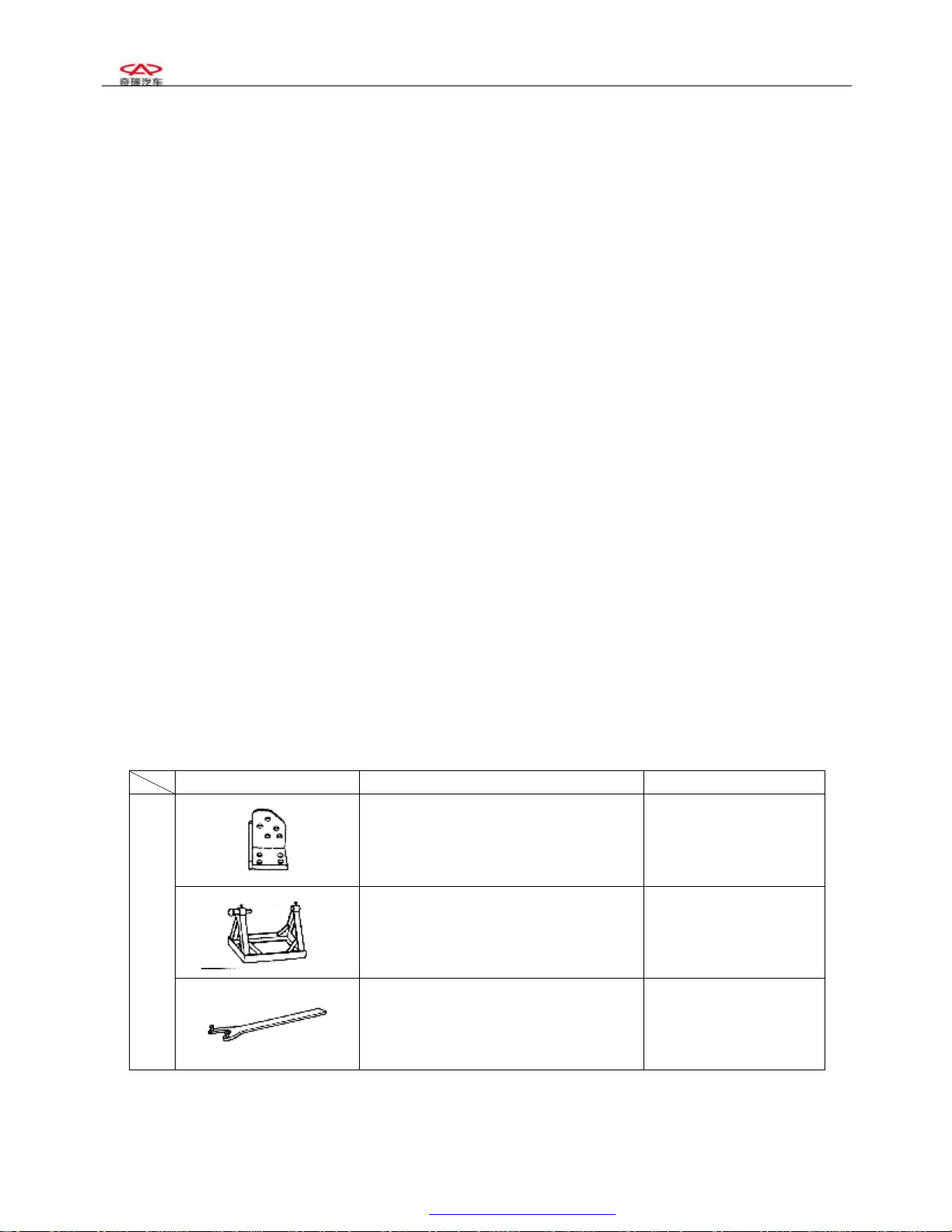

1. Configuration diagram

Water pump pulley assembly

wrench

1 Water pump pulley

2 Timing belt cover

3 Timing belt

4 Torsion shock absorber

5 Timing pulley damper

6 Tensioner

7 Crankshaft timing pulley

water pump Assembly

Chery Automobile Co., Ltd

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿ www.fineprint.com.cn

※ :Non-reusable part

Unit:N·m(kg·cm)

SQR7080 Service Manual 372 Engine Mechanical System

4

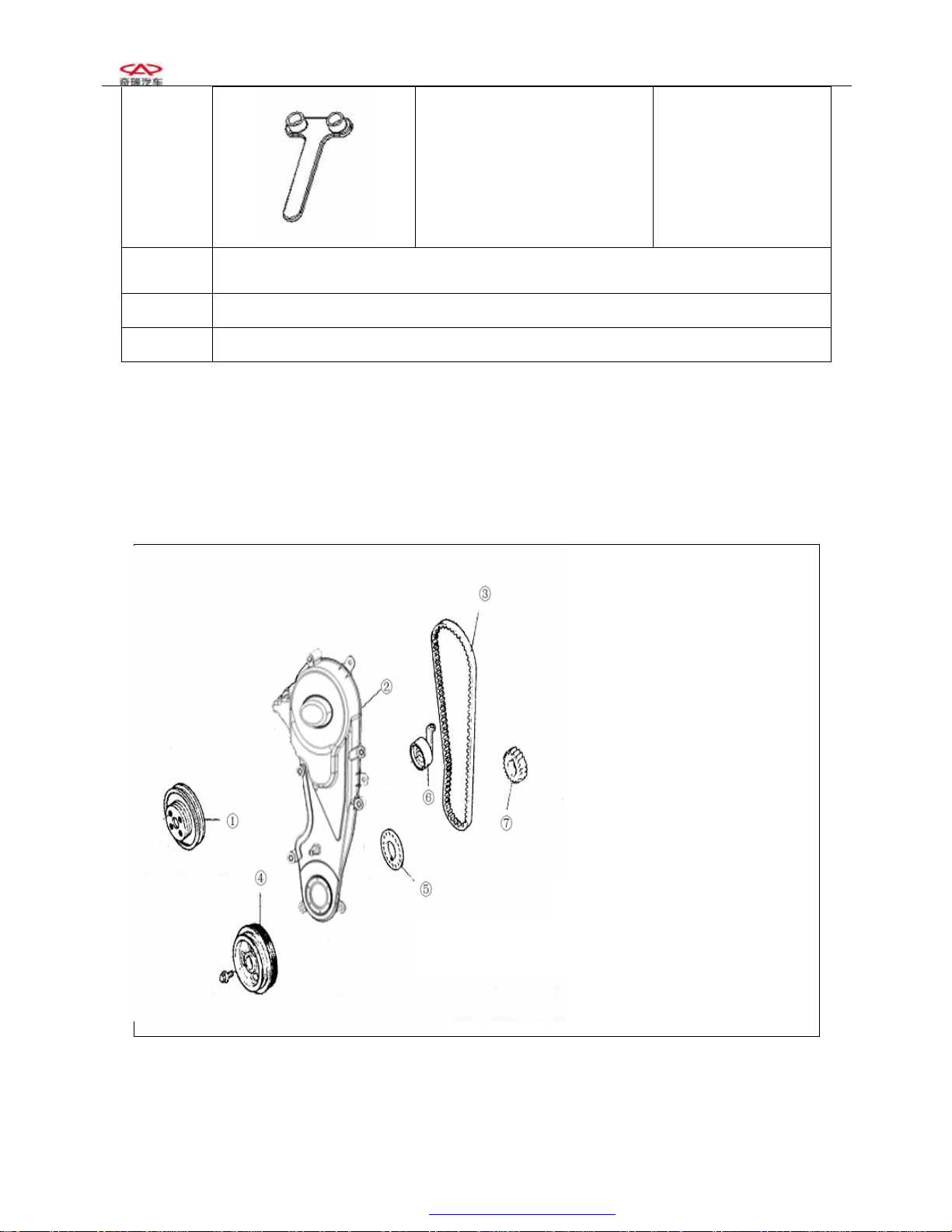

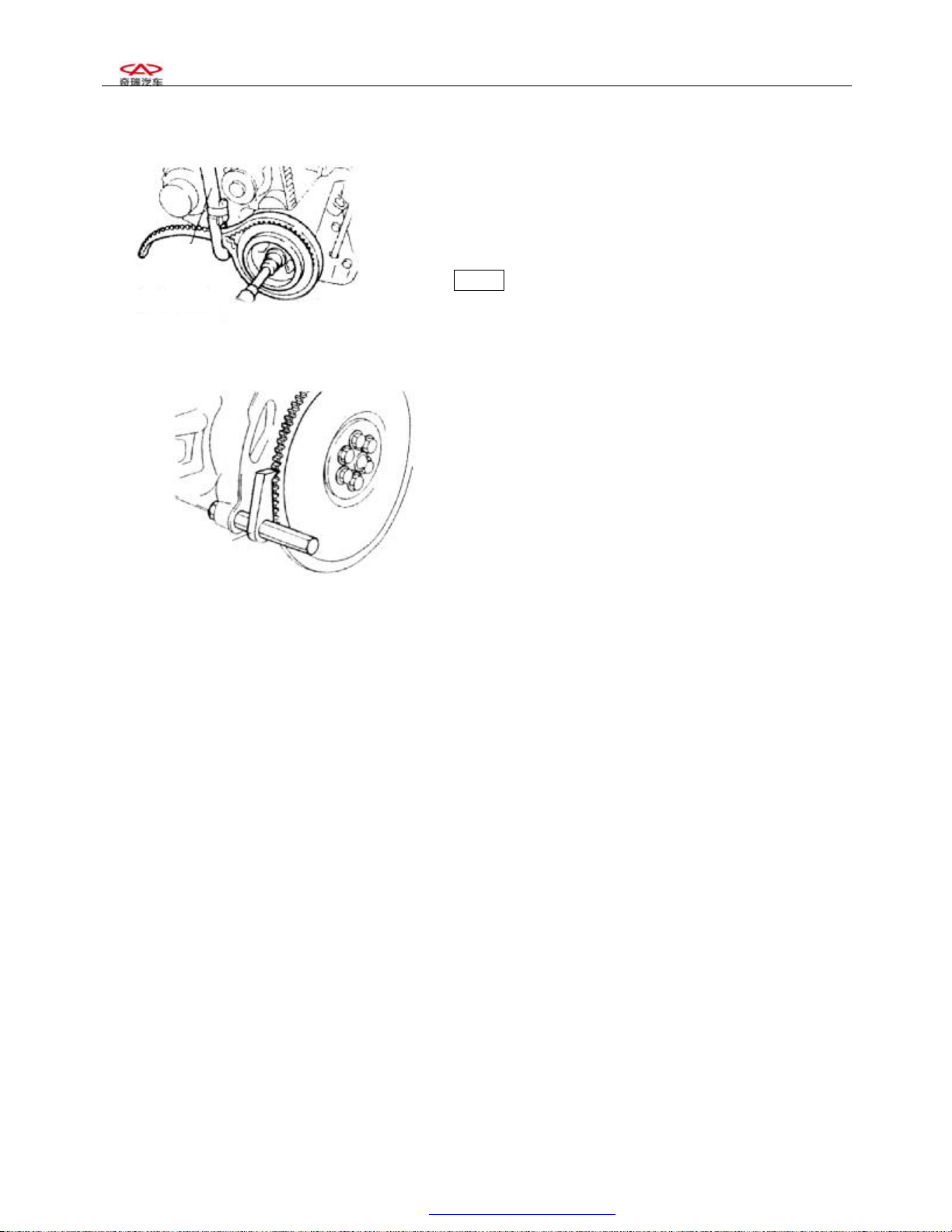

Remove torsional vibration damper.

Remove water pump pulley.

Remove the water pump pulley according to the

illustration.

图 29

Remove it with screwdriver and wrench according to

the illustration.

Remove torsional vibration damper

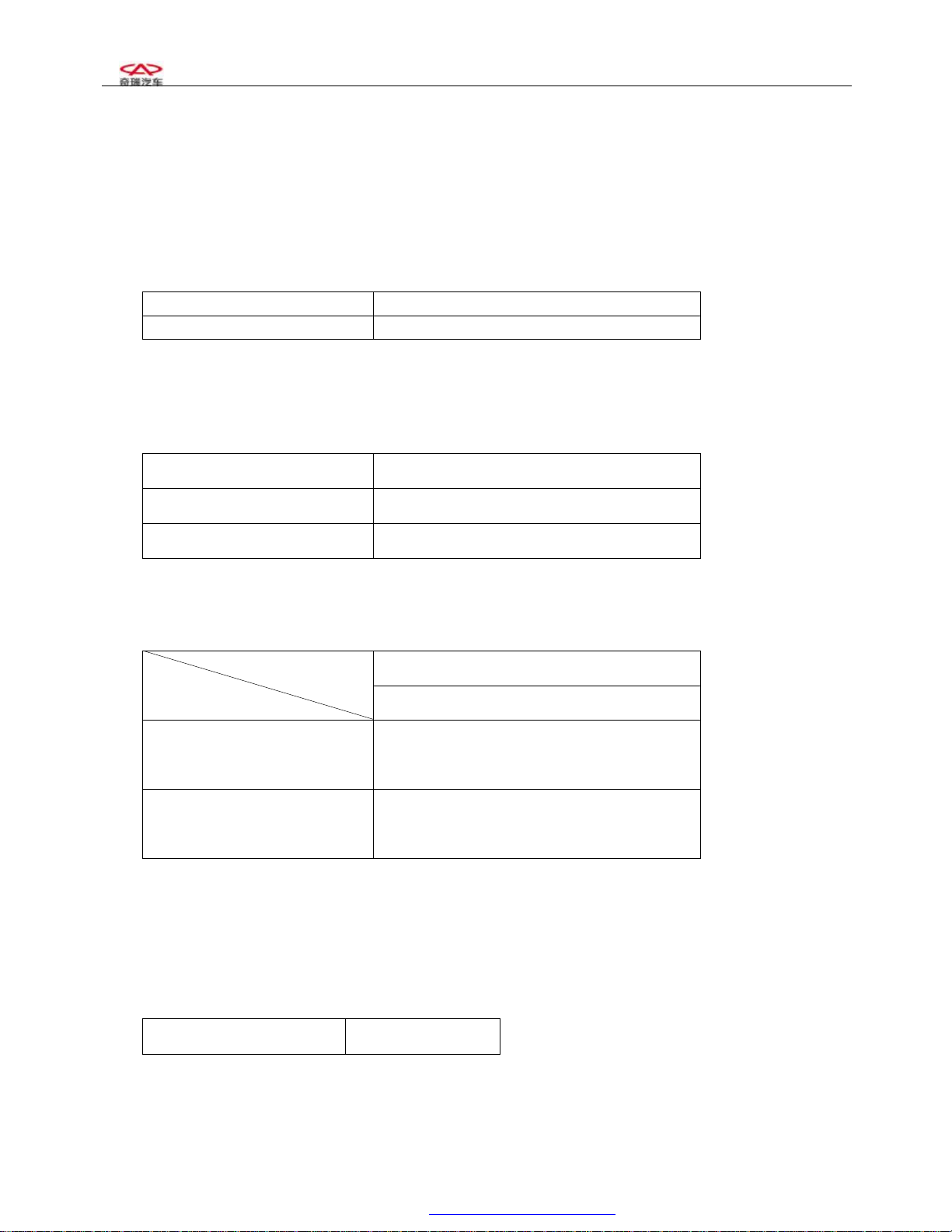

(1) Fix the flywheel and prevent the gear ring from

rotating.

SST

(2) Remove bolt of torsional vibration damper.

Chery Automobile Co., Ltd

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿ www.fineprint.com.cn

SQR7080 Service Manual 372 Engine Mechanical System

5

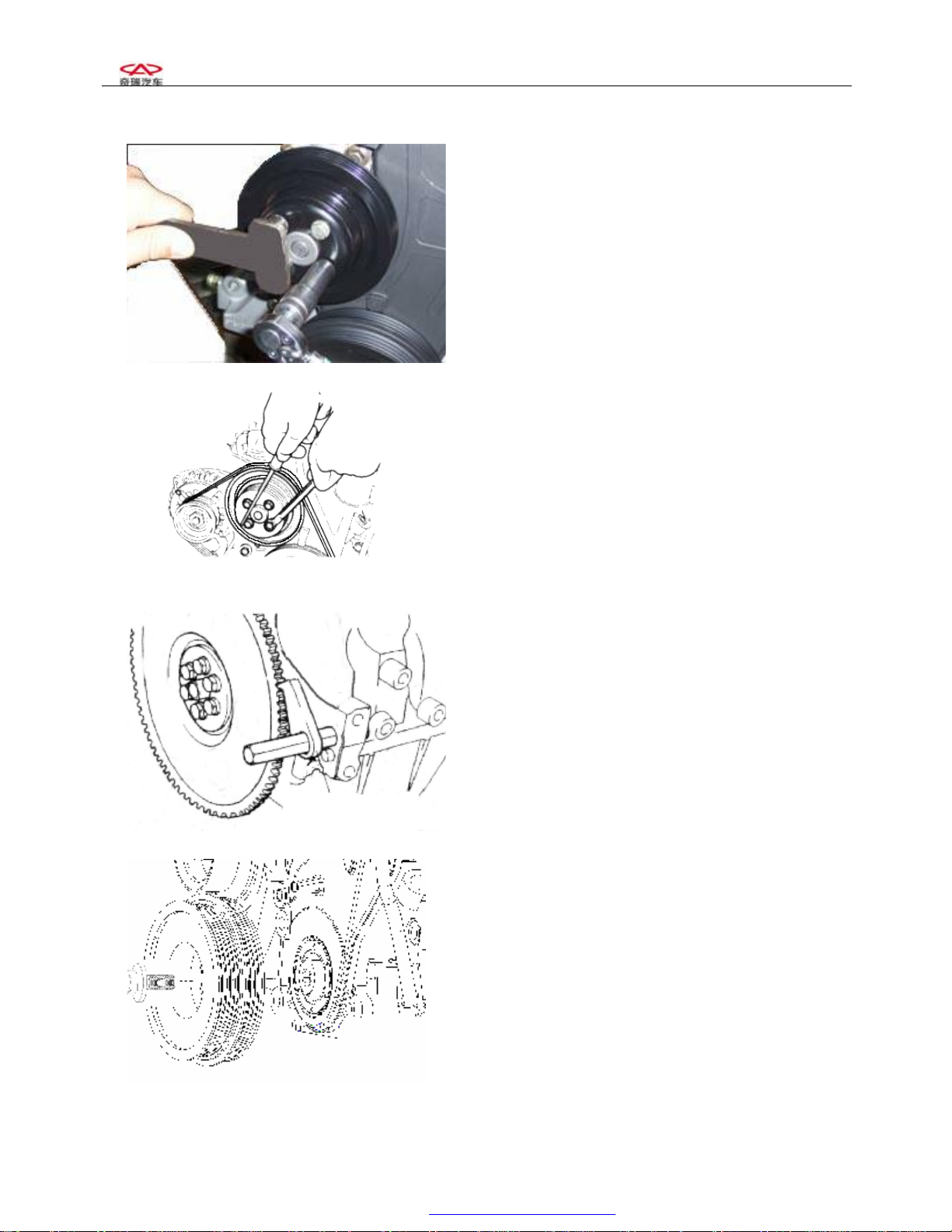

Remove timing cover cap

Torque: 6±1N.m

Remove timing pulley damper

Timing mark

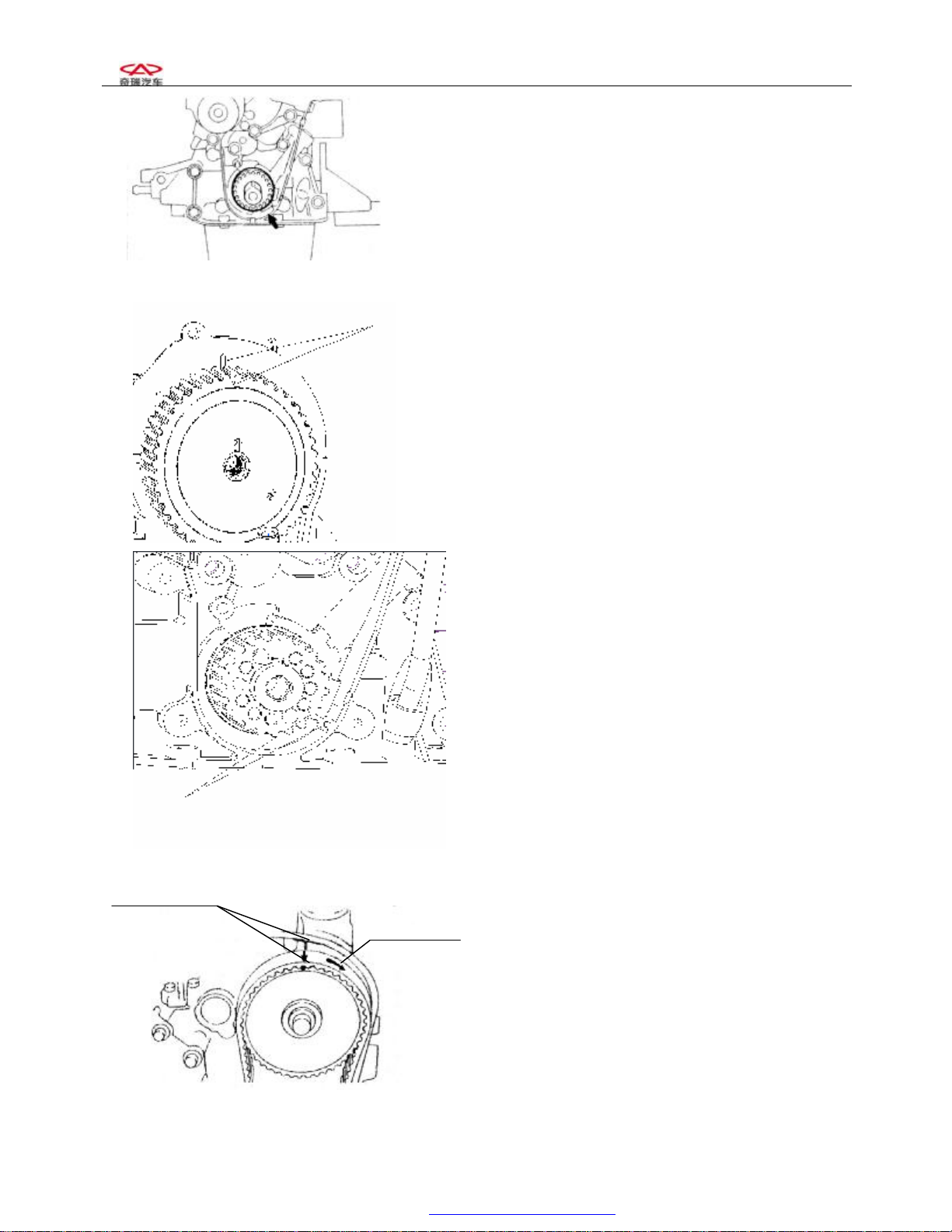

Remove the tensioner

Do“mark”

Clockwise

(1)Carry out the operation at the upper thrust point

of compression of the first cylinder piston

(2) After removing the timing cover cap, turn the bolt

and rotate the timing gear clockwise with wrench,

align timing mark of camshaft timing gear with the

cam mark of camshaft cover cap;

Attention: You can rotate the engine clockwise only,

after installing the pulley;

Before removal, make a arrow mark on the position of

timing mark, assemble according to original state.

(3) Make sure that the crankshaft timing pulley wheel

mark is aligned with the mark of the oil pump.

Timing mark

(4) Remove the tensioner bolt, and take off the

tensioner

Chery Automobile Co., Ltd

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080 Service Manual 372 Engine Mechanical System

6

Remove the timing belt.

[Caution] It is absolutely not allowed to use screw

driver or some other sharp-edged tools to remove the

belt.

Attention: Pay attention to the following points while

using timing belt:

- Don’t bend the belt even at a small angle,

otherwise it will result in rope fracture inside the

belt.

- - Service life of belt is short, don’t pollute the belt

with grease and water.

- You have no choice but rotate the engine

clockwise after installing the belt.

2.7 Remove the crankshaft timing gear

Chery Automobile Co., Ltd

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080 Service Manual 372 Engine Mechanical System

7

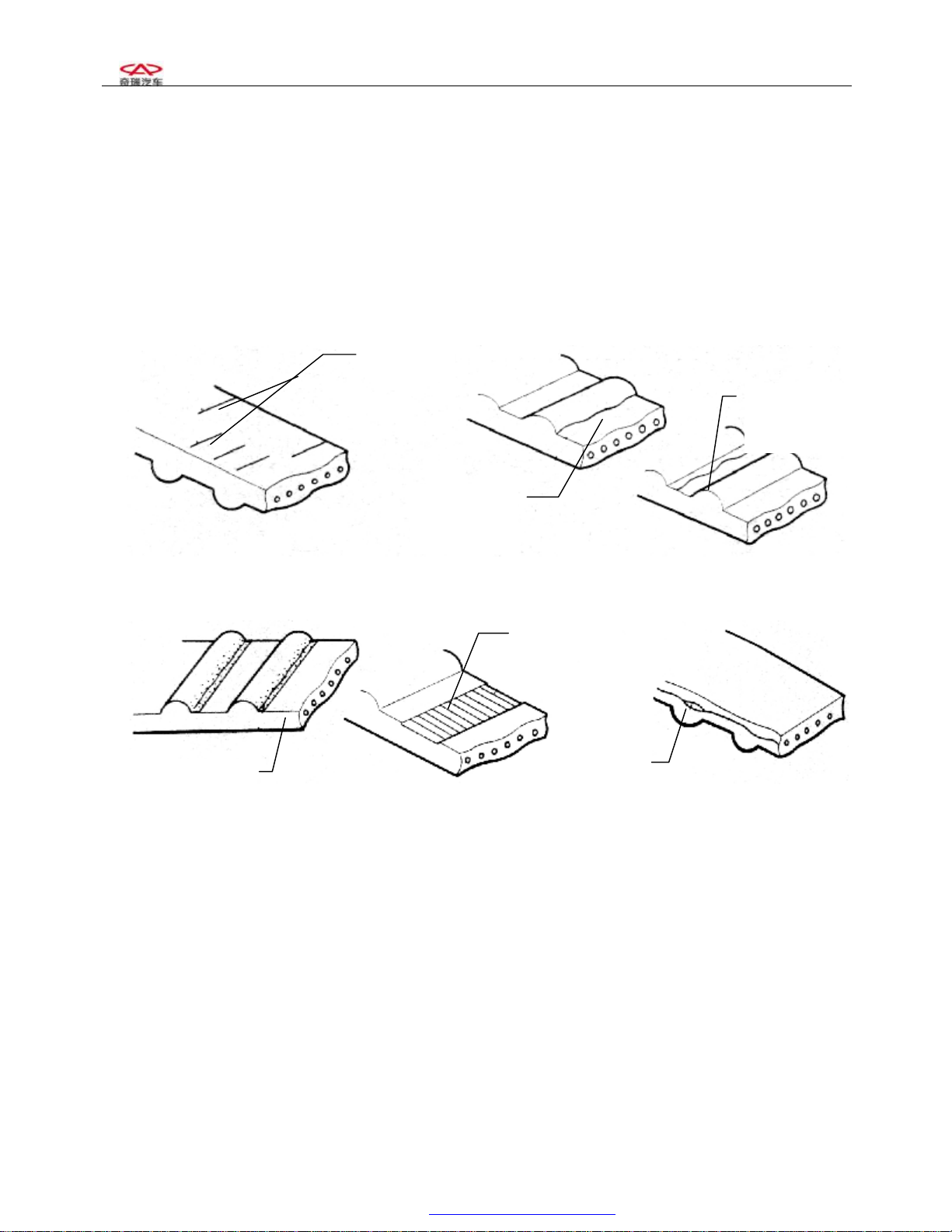

Tears and

MIS

3 Make careful and detailed checks on the timing belt. Replace with new parts if any of the

conditions shown in the figure occurs.

3.1Cracks on the back side rubber;

3.2Cracks of teeth roots, cracks clearing off the fabric lining layer;

3.3Tears and wears of fabric lining layer, missing rear teeth, broken teeth, etc.

Chap

wears

Chap

3.4 Abnormal tears and wears on belt sides

Abnormal

tears and wears

Drop-off

of belt core

Chery Automobile Co., Ltd

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿ www.fineprint.com.cn

SQR7080 Service Manual 372 Engine Mechanical System

8

3.5 Even if the damages on the outer appearance can not be confirmed, the belt should be replaced

under any of the following circumstances:

3.5.1If the water in the water pump is leaked, which makes it necessary to refill the water

continuously;

3.5.2 There are much oil stains on the belt, the belt should be replaced for the rubber will be damaged

when it is expanded;

3.6 Specifications and model of the timing belt

Part number 372-1007081

Belt wide 25.3mm

3.7 Timing belt tensioner

Turn the belt tensioner supporting stand bolts to see if there are any abnormal sound. Check to see if

there are any damages on the contacting surface of the belt.

Specifications and model of the timing belt tensioner

Part number

Wide

Outside diameter

372-1007030

27.0mm

φ50mm

3.8 Check to see if there are any damages on the outer appearance

Specifications and model of clockwise pulley

EF Model

Item

Diameter of camshaft timing

GL、ZL、GS、ZS

φ110.7

+0.1

-0.2

gear (mm)

Diameter of crankshaft timing

φ54.65

+0.7

-0.13

gear (mm)

3.9 Baffle of crankshaft timing gear

Check to see if there is any deformation

Standard size of crankshaft timing gear:

Wide 28.6mm

Chery Automobile Co., Ltd

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080 Service Manual 372 Engine Mechanical System

9

4. Installation

4.1 Installation of crankshaft timing gear

4.2 Installation of timing belt

Timing mark

4.2.1 On the upper thrust point of the first cylinder

compression

Place the camshaft timing gear around the front end of

the air exhaust camshaft so as to make the positioning

groove on the gear be aligned with the positioning pin

on the end surface of the camshaft. Then use screws to

fix the clockwise gear, with the torque of 100 ± 5N.m.

Timing mark

Timing mark

Clockwise

4.2.2 Make sure that the punched mark on the

crankshaft clockwise pulley is aligned with the mark

of the oil pump.

4.2.3 Install timing pulley accordingly.

Chery Automobile Co., Ltd

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080 Service Manual 372 Engine Mechanical System

10

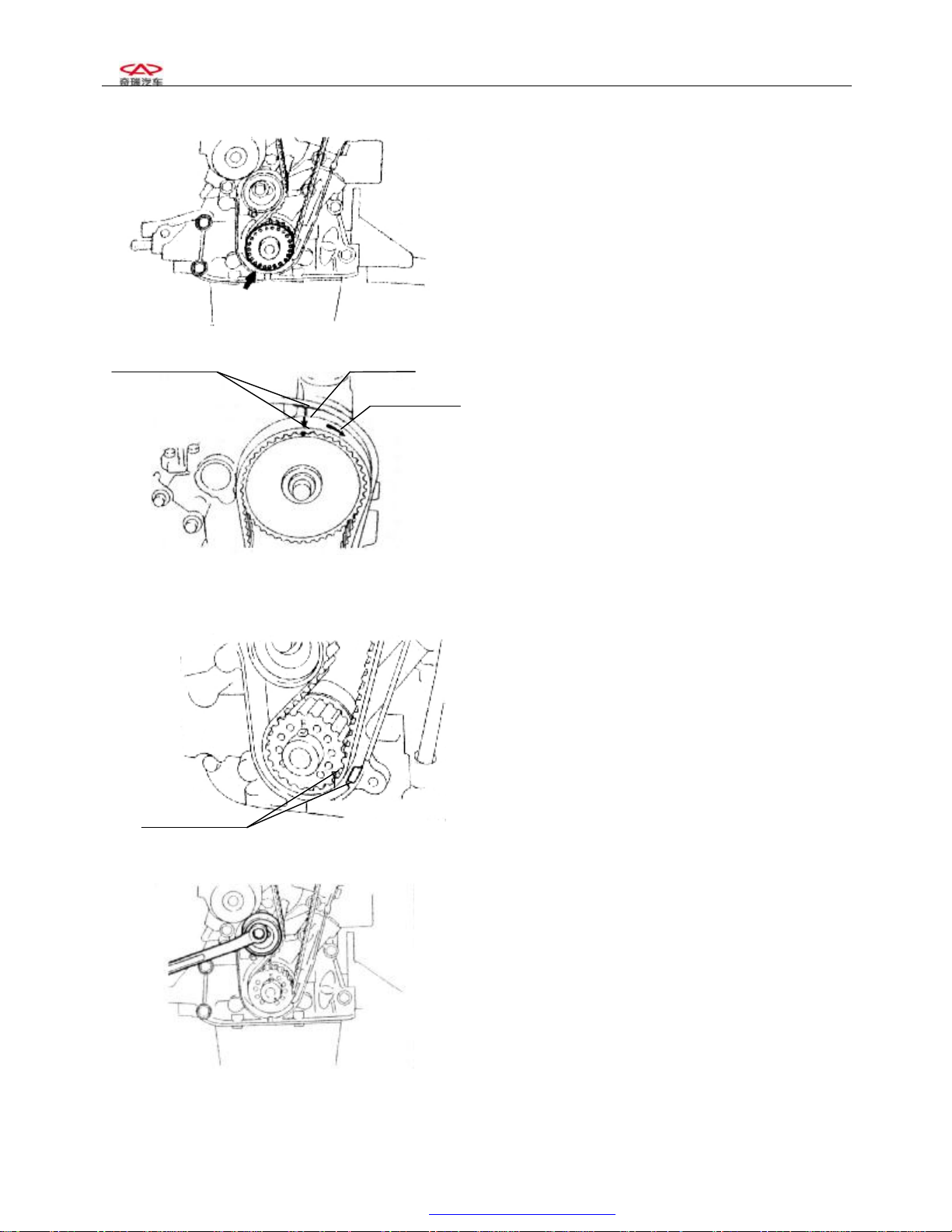

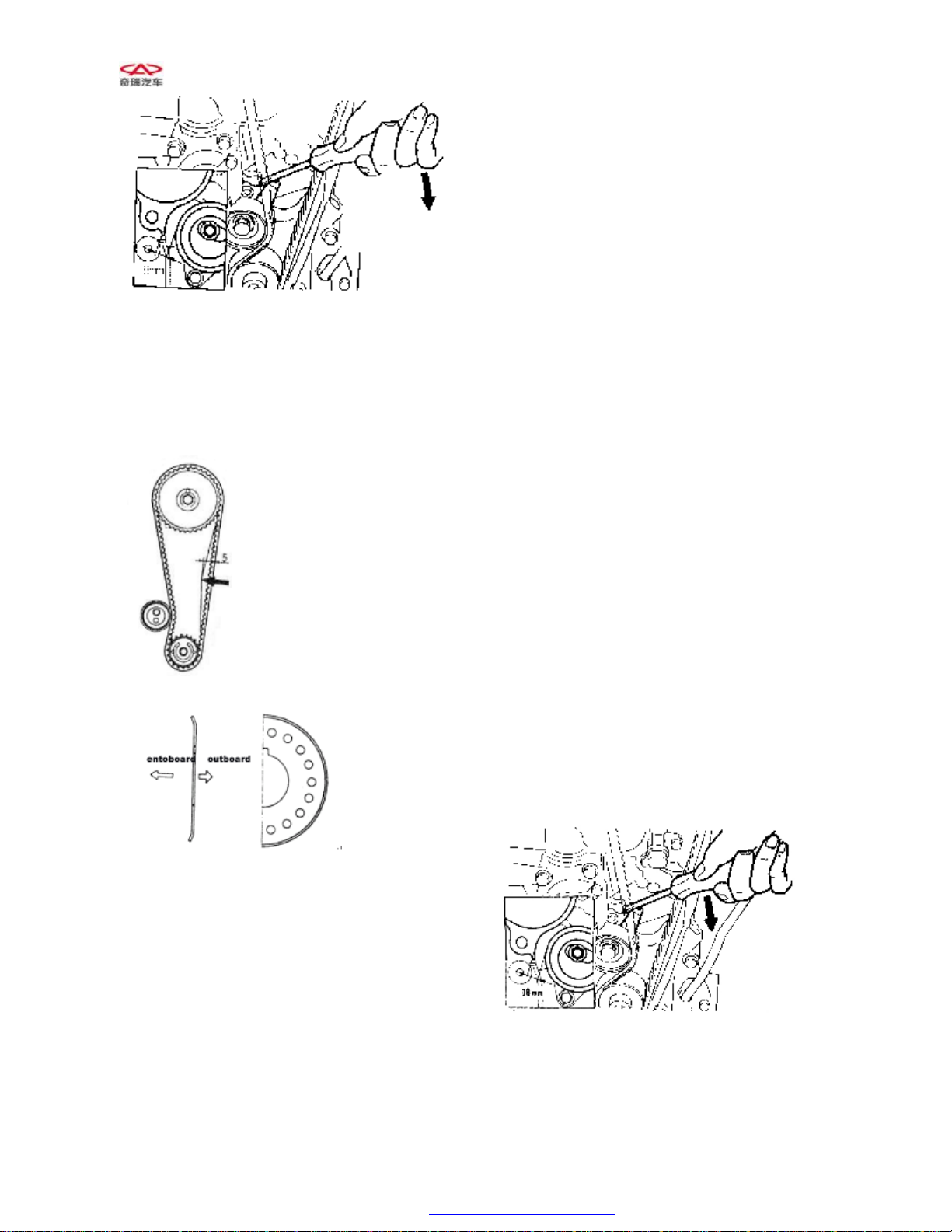

4.3 Install the tensioner

4.3.1 Adjust the tension of the timing belt

As shown in the figure, make the space between the ①

edge of the stretching wheel and the water pump case

arc to be about 8mm;

Tighten the bolt of the stretching wheel with a ②

torque of 25 ± 3N.m. Use a screwdriver to swing the

stretcher toward the right..

③ Turn the crankshaft for two circles towards the

engine rotating direction, so that the camshaft pulley

and the crankshaft pulley matches the clockwise marks

respectively.

④ Use hands to press down for about 5mm. The force

for pressing the clockwise belt is about: [Reference]

20~30 N

Notice: When the deflection of the timing belt fails to

meet the specifications, the key is to adjust the

above-mentioned stretcher fastening bolt by widening

the spacing.

Tighten the S/A fixing bolt of the stretcher with the

specified torque of 25 ± 3N.m

4 Install the baffle of the crankshaft timing pulley

[Attention] Install the baffle towards the direction

shown in the right figure.

Chery Automobile Co., Ltd

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿ www.fineprint.com.cn

SQR7080 Service Manual 372 Engine Mechanical System

11

5 Install the timing cover cap

torque :6±1N.m

6 Install the torsional vibration damper (use SST)

1)、 When there is not a flying wheel,

① Fix a part of the crankshaft pulley.

②Pay attention not to make the gear belt moving,

tighten the bolt according to the specified torque :

torque98.0±10N.m{10±1kgm}

2 )、 When there is a flying wheel,

① Fix the flywheel to prevent the tooth ring from

turning

② Then tighten bolt of torsional vibration damper.

Chery Automobile Co., Ltd

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿ www.fineprint.com.cn

SQR7080 Service Manual 372 Engine Mechanical System

12

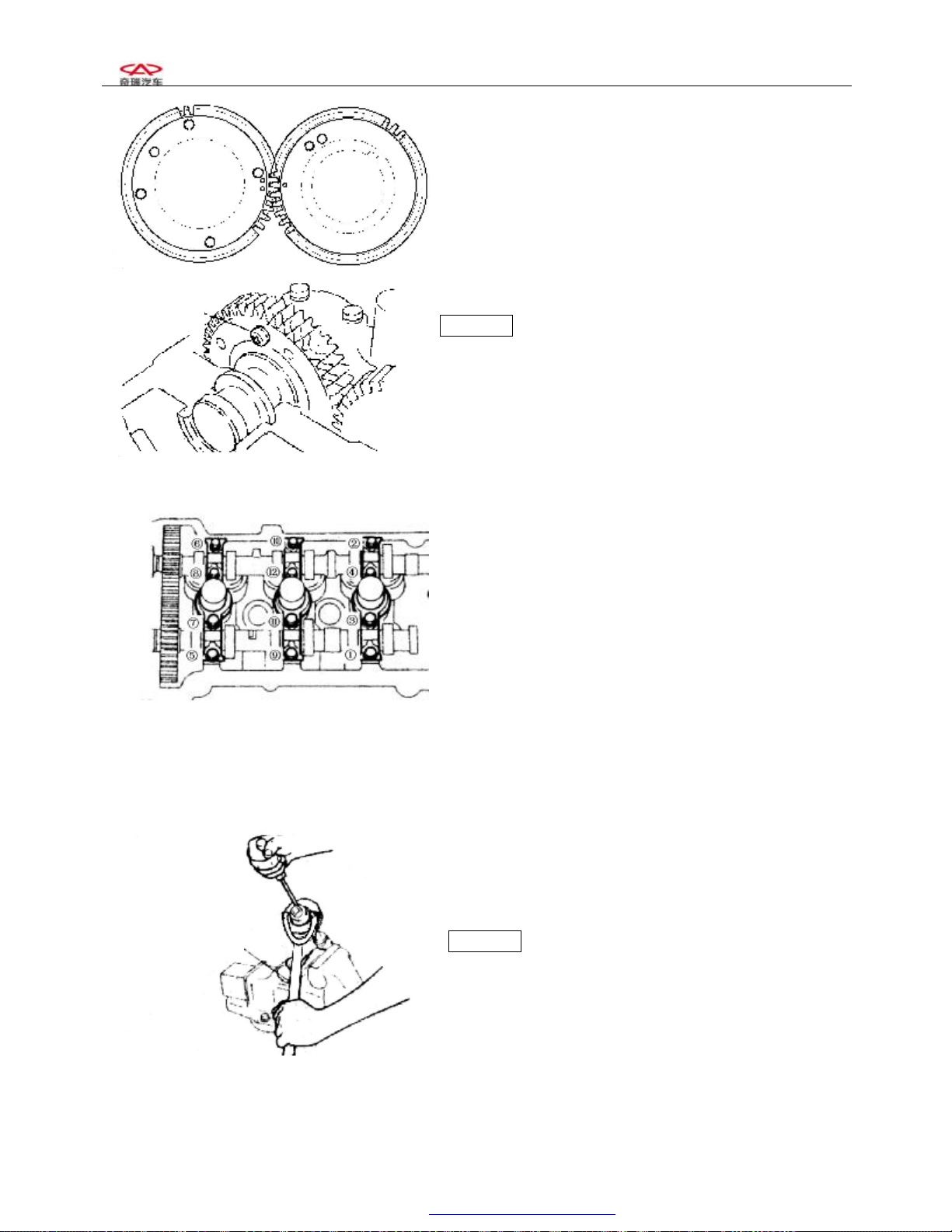

Chapter 3 Camshaft Service

3-1.Diagram ( Removal and installation order for timing belt)

(1) Valve cage cover

(2) Valve cage cover

gasket

(3) Camshaft timing

pulley

(4) Camshaft cover

(5) Circular plug

(6) Camshaft bearing

cap

(7) Exhaust camshaft,

(8) Intake camshaft,

(9) Oil seal

(10) Spring retainer

(11) Wave washer

(12) Intake camshaft

sub-gear

(13) Snap ring

(14) Lock nut

(15) Flange

Non-reusable part

3-2 Removal

Remove cylinder ①

head cover assembly

Remove the valve chamber cover cap bolt

from two sides to the centre symmetrically.

Remove ② valve chamber cover gasket

2 Routine check of valve

valve clearance standard:

Valve

clearance

3 Dismount the camshaft clockwise gear

Attention· You must prevent the camshaft from rotating.

Chery Automobile Co., Ltd

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿ www.fineprint.com.cn

IN 0.18±0.05

EX

0.25±0.05

SQR7080 Service Manual 372 Engine Mechanical System

13

Intake

Set bolt

4 Removal of camshaft cover cap and camshaft

bearing cover

(1) Align the marks on the camshaft gears as shown in

Exhaust

the right figure.

(2)Use bolt to position the master and slave gears on

the air inlet camshaft, as shown in the right figure.

Attention In order to eliminate the radial force, keep the

camshaft in the leveled position before dismounting it

(to avoid possible damages caused by excessive radial

forces)

(3)Remove the bolts in the sequence shown in the

right figure;

Remove the camshaft bearing cover

(4)Remove the spark plug

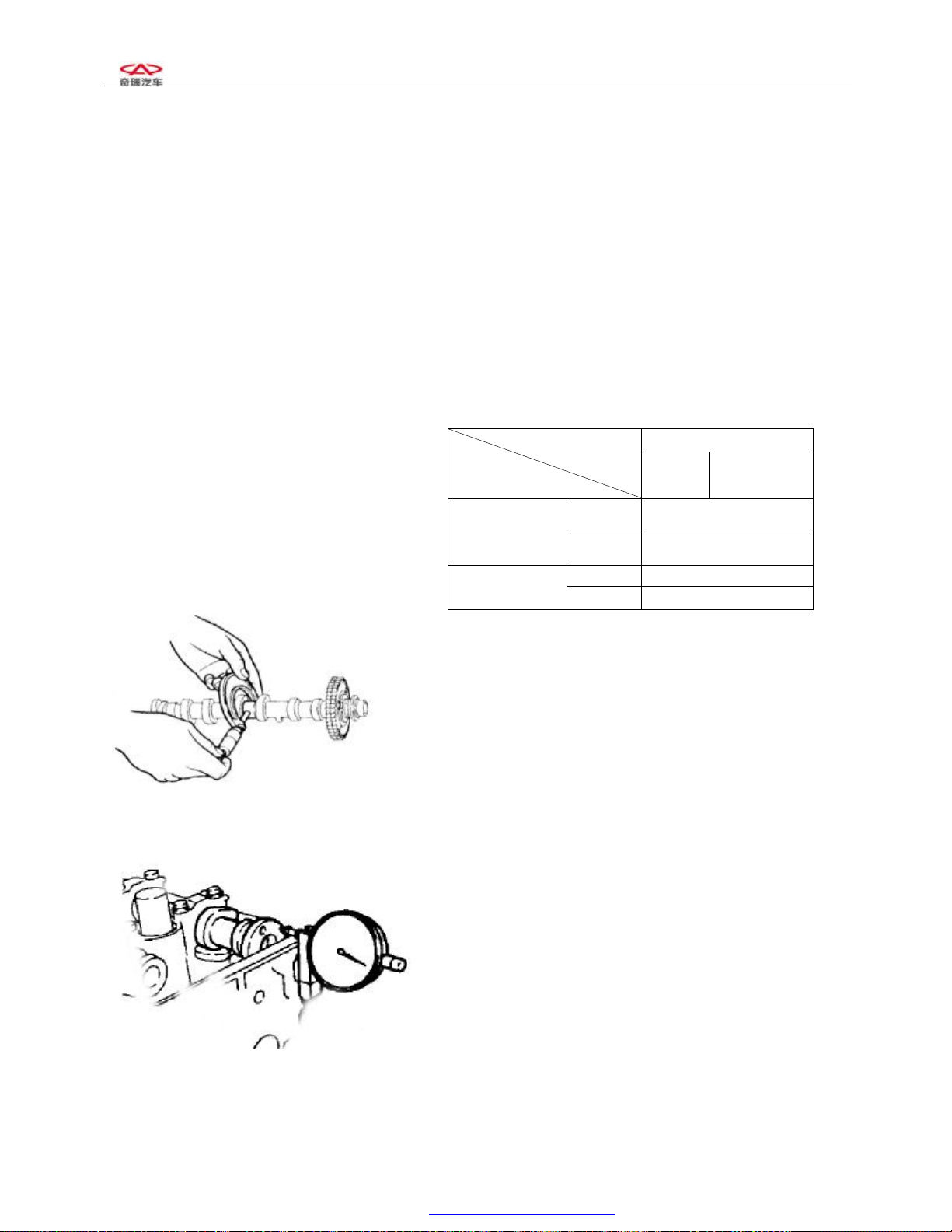

(5)Remove the camshaft slave gear. Use the special

tool as shown in the right figure.

SST

Clip the camshaft tightly, and turn the gear, to keep

the bite state of master and slave gear; remove the fixing

bolts of slave gear.

Attention Do not damage the surface of the camshaft.

Chery Automobile Co., Ltd

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080 Service Manual 372 Engine Mechanical System

14

IN φ22.9

(6) Use tensioning apparatus to remove the bearing use

elastic snap ring, remove wave washer and teethed ring.

3-3 Camshaft

1 Use the caliper to measure the height of the camshaft.

If it is below the specified limits, make proper

replacement.

Camshaft Unit:mm

EF

Item

Standard

Model

Limit

IN

EX

EX φ22.9

ZL、

RL

φ23.0

φ23.0

GL、GS、

ZS

-0.02

-0.02

-0.033

-0.033

2 Checks on camshaft axial clearance

(1)、 When the axial spacing is measured with a clipper

to be larger than the benchmark value, the camshaft is to

be replaced.

The air inlet camshaft axial clearance is 0.1~0.170mm。

The air exhaust camshaft axial spacing is 0.1 ~

0.173mm。

Limits for operation:0.18mm

3-4 Cleaning

1、Clear off the spark plug carbon accumulation with a

metal brush.

Chery Automobile Co., Ltd

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

Loading...

Loading...