Page 1

CLUTCH

CLUTCH INTRODUCTION… … … … … … … … … … … … … … … … … … F-2

CLUTCH STRUCTURE … … ……………… … … … … … … … … … …F-2

OPERATING PRINCIPLE OF CLUTCH … … … … … … … … … … … …F-2

CLUTCH CABLE ASSEMBLY STRUCTURE … … … … … … … … … …F-3

ASSEMBLY AND ADJUSTMENT OF CLUTCH CABLE … … … … … … … …F-4

CLUTCH DISASSEMBLY …… … … … … … … … … … … … … … … … …F-5

CLUTCH OVERHAUL ………… … … … … … … … … … … … … … … … …F-6

CLUTCH INSTALLATION… … … … … … … … … … … … … … … … … …F-7

TROUBLE DIAGNOSIS………… … … … … … … … … … … … … … … … …F-8

F-1

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 2

CLUTCH INTRODUCTION

CLUTCH STRUCTURE

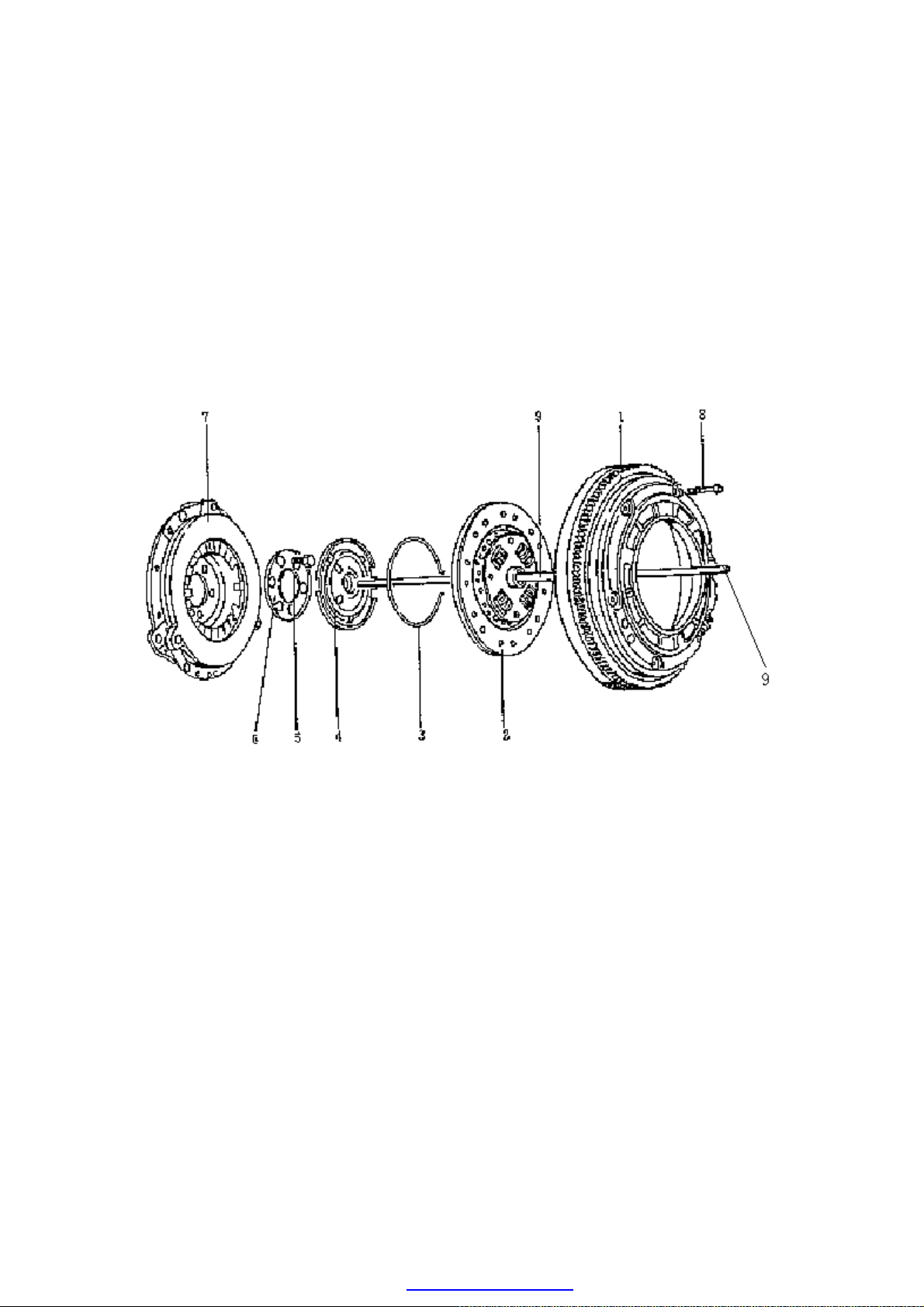

·As picture below, the clutch is dry diaphragm with single leaf. It consists of clutch driven

disk (2), release disk (4), intermediate disk (6), pressure plate (7) and flywheel (1).

·There are diaphragm springs in the pressure plate (7), which are fixed in the crankshaft by

intermediate disk (6) and bolt (5). Driven disk (2) is pressed on the flywheel (1) by

pressure plate (7), and bolt (8) is used to fix pressure plate (7) and flywheel (1) together;

the clutch pusher (9) is used to push separator disk (4) and then the separator disk (4) to

push the small end of diaphragm springs on pressure plate (7).

1.Flywheel 2.Driven Disk 3.Snap Ring 4.Release Disk 5.Bolt(M10)(110±5N.m)

6.Intermediate Disk 7.Pressure Plate 8.Bolt (23~25N.m) 9.Clutch Pusher

OPERATING PRINCIPLE OF CLUTCH

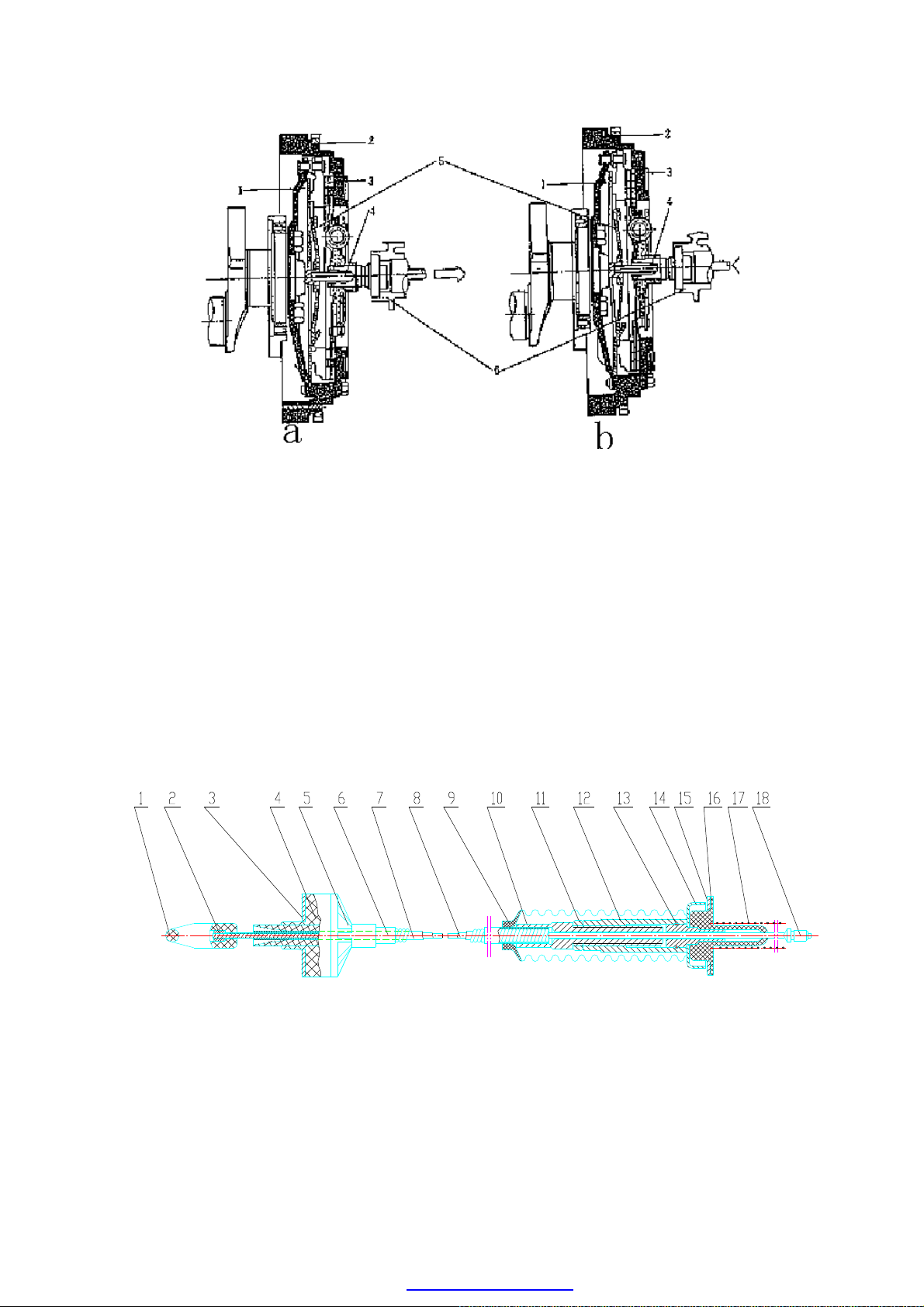

·As picture below, Picture a presents the connection status of clutch. When clutch pedal is

not treaded, the driven disk (3) is pressed on flywheel (2) by diaphragm spring (1). Driven

disk (3) and flywheel (2) are revolving synchronously, and the torque is transmitted to the

transmission-axle (6) by Separator disk (5) through driven disk (3).

·Picture b presents the disconnection state of clutch. When the clutch is treaded, pusher (4)

pushes separator disk (5) which presses the small end of diaphragm spring (1) to move the

big end of diaphragm spring (1) away from driven disk (3), so the pressure is disengaged

between driven disk (3) and flywheel (2) and the clearance is generated to cut off the

motive power of engine and pass the transmission.

F-2

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 3

in 6.Jacket

st Cover 10.Adjust Rod 11.Jam Nut 12.Adjust Bushing

a. Clutch Connection State b. Clutch Disconnection State

1.Diaphragm Spring 2.Flywheel 3.Driven Disk 4.Pusher

5.Seperator Disk 6.Transmission Axle

CLUTCH CABLE ASSEMBLY STRUCTURE

1.Clip 2.Cable Latch 3.Washer 4.Cable Cushion 5.Jacket Tie-

7.Inner Pipe 8.Cable 9.Du

13.Clip Ring 14.Retainer 15.Washer 16.Rubber Cushion 17.Gasket 18. Butt End

F-3

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 4

ASSEMBLY AND ADJUSTMENT OF CLUTCH CABLE

estern

Move direction of release

disk after driven disk wear

When driven disk wear down,

unscrew the nuts and adjust the

2~3mm free

travel

·Put dust cap up and screw jam nut (11) and

adjustment bushing (12) to the upper end

(make the adjustment travel L minimum)

so as to facilitate the assembly of clutch

cable.

·Coat a little lubricant on the assembly

fitting surface of clutch cable.

·Put clip (1) across the guiding cylinder of

clutch pedal on the front brattice to

connect the clutch pedal. Make sure that

washer (3) and end face of guiding

cylinder of clutch pedal are spliced.

·Make butt end (18) fixed by bracket after

across the slot in release arm of

transmission and rubber cushion through

the upper face of transmission.

·After the assembly, uplift the segregation

arm of transmission by hand and adjust the

adjustment bushing (12) down at the same

time, so the 2~3mm clearance for

segregation arm of transmission is

available; then tread the clutch pedal for 10

times to ensure the fitness of assembly and

readjust the adjustment bushing to

guarantee that the 2~3mm clearance for

segregation arm of transmission is

available (Remarks:For new clutch, the

adjustment travel L of driven disk cable

shall not be less than 18mm. See Pic.2).

·Carry out the driving examination for the

whole automobile. Clutch and gear shifting

operation shall be normal.

·Screw jam nut (11) down to close with

adjustment bushing (12), and then put

down dust cover (9).

L (adjustment travel)

Jam nut

Adjust

bushing

down

bushing to a proper position

Rubber cushion

Bracket

Transmission

release pusher

Picture 2 Sketch Map of W

Clutch Adjustment

F-4

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 5

CLUTCH DISASSEMBLY

·Disassemble the transmission.

·Unscrew 9 fixed bolts in flywheel

cornerwise and dismount the flywheel.

·Remove clutch plate.

·Pry out snap ring of release disk by

screwdriver and remove the release disk.

·Unscrew 6 connection bolts in clutch

pressure plate and output end of

crankshaft, and remove the clutch pressure

plate.

F-5

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 6

CLUTCH OVERHAUL

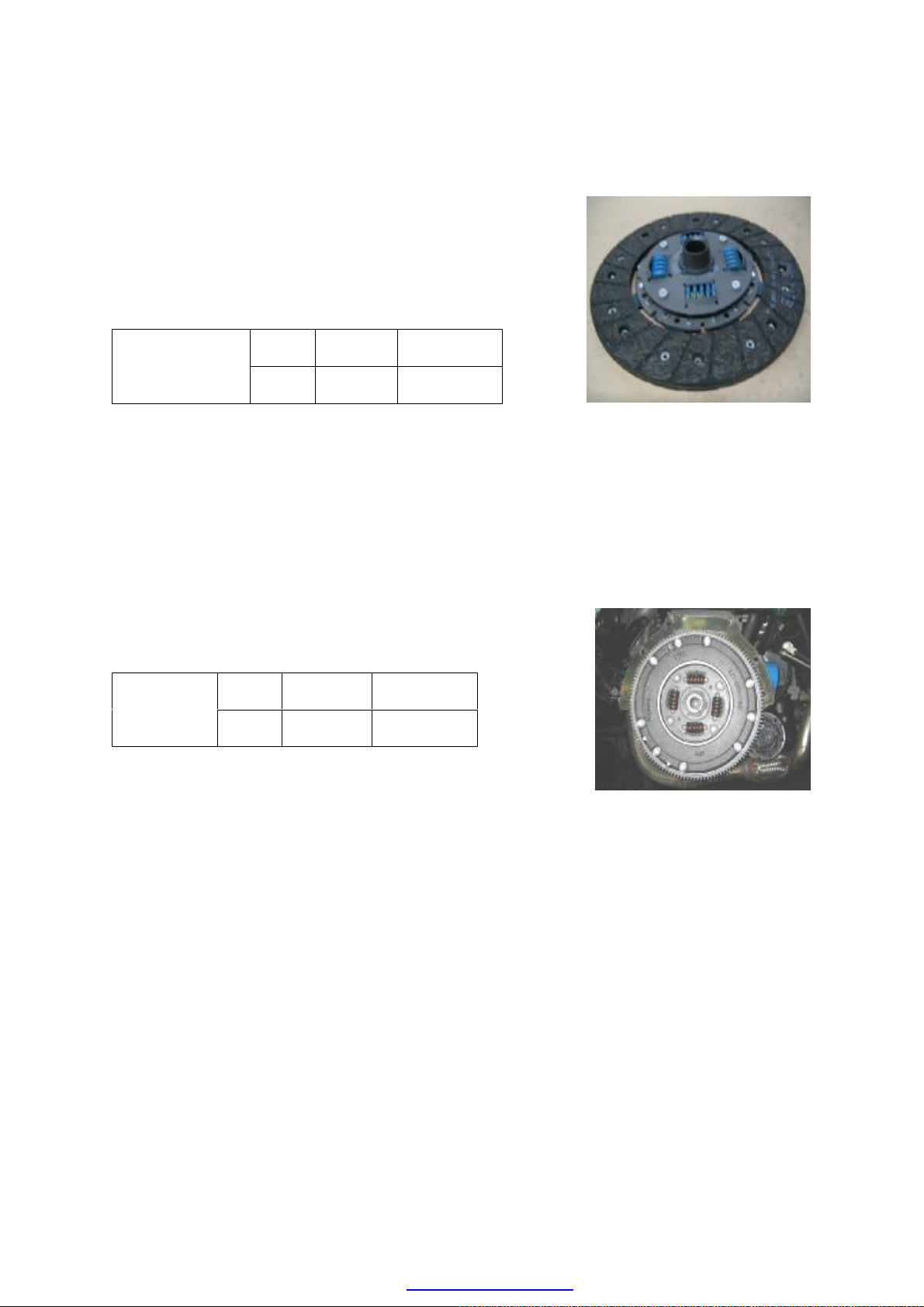

· Clutch friction disk: measure the dent depth of

rivet head, i.e. the distance between the rivet head

and the friction disk surface. In case it is found that

the depth reaches the using limit for any hole, the

friction disk shall be changed.

Standard value Maintenance

Rivet head

1.5mm

0.5mm

Dent depth

0.06in

0.02in

·Measure the clutch disc runout using a dial indicator.

If the runout is excessive, replace the clutch disc.

Runout 0.8mm max

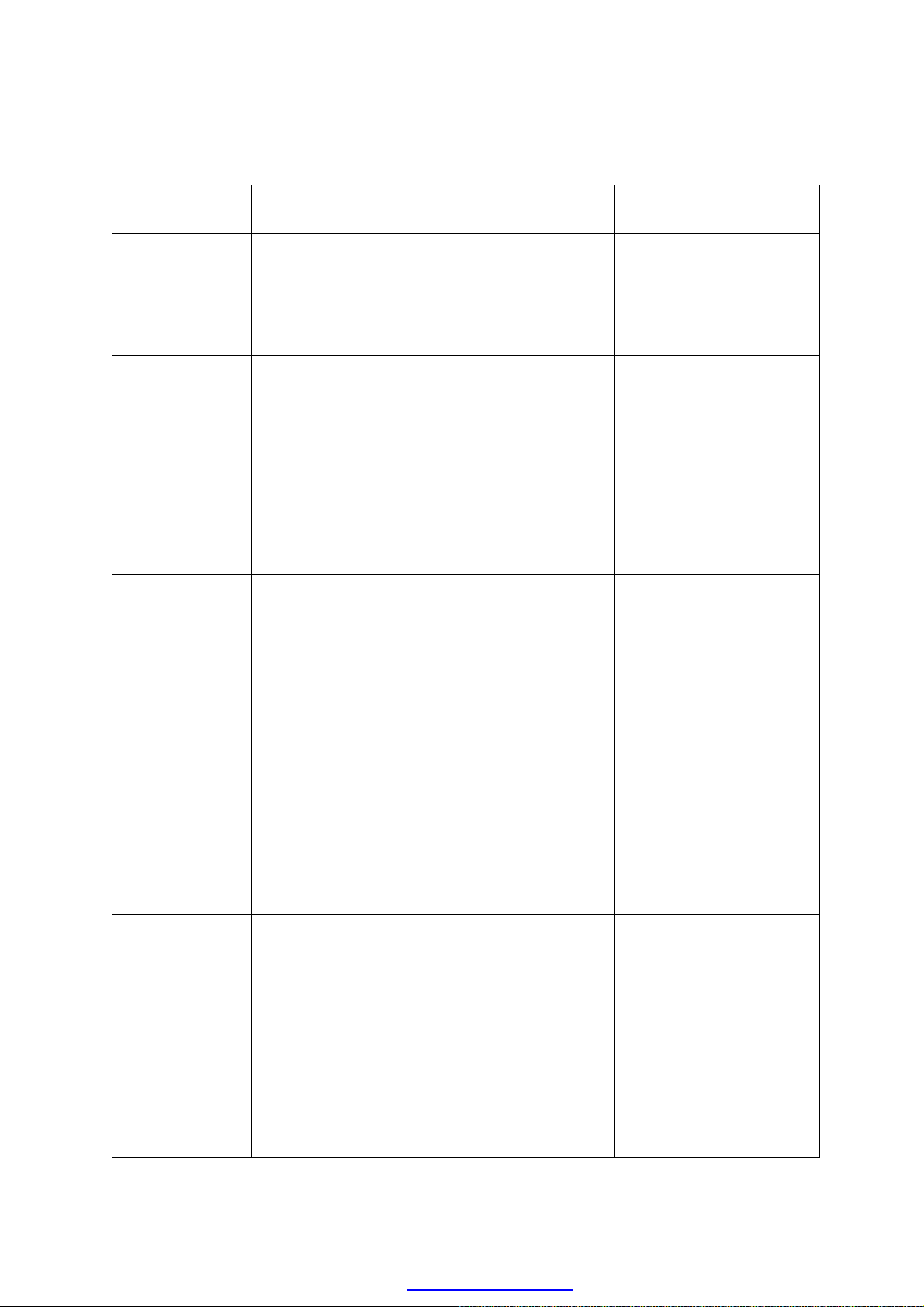

Clutch pressure plate:

·Examine whether the diaphragm spring has

abnormal wear or damage.

·Examine whether the pressure plate has wear or hot

point.

·In case of any abnormality, the pressure plate shall

be changed. The pressure plate shall not be

disassembled into two parts: diaphragm spring and

pressure plate.

·Measure the clutch pressure plate runout using a dial

indicator. If the runout is excessive, replace the

clutch disc.

Runout 0.25mm max

Flywheel:

·Examine whether the connection surface of friction

disk exists abnormal wear or hot point; the change

or maintenance shall be conducted if necessary.

·Measure the flatness of the flywheel with a straight

edge and a feeler gauge. If not as specified, replace

the clutch cover.

Maximum clearance 0.05mm

Service limit 0.15mm

F-6

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 7

CLUTCH INSTALLATION

Before the assembly, flywheel surfaces and pressure

plate shall be clear and dry.

——Assemble the pressure plate on the crankshaft

and screw up bolts in accordance with

prescribed moment.

Pressure plate

assembly bolt

Torque

—— Assemble release disk and fit on snap ring.

—— Assemble clutch disk.

—— Assemble flywheel.

——Screw up flywheel bolt uniformly according to

the diagonal line.

——Coat a thin layer of grease on the input axle

and then assemble the transmission with

engine.

N•m Kg-m 1b-ft

57-65 5.7-6.5 41.5-47.0

Flywheel

bolt

Torque

Remarks:

When put the input axle of transmission into the

clutch friction disk, the flywheel shall be revolved

until the input axle of transmission and spline

meshed.

N•m Kg-m 1b-ft

18-28 1.8-2.8 13.5-20.0

F-7

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 8

Trouble

symptom

Slip of clutch

Uncompleted

segregation of

clutch

Vibration of

clutch

Clutch noise

Non-separation of

clutch

TROUBLE DIAGNOSIS

Cause Treatment method

•Free travel (free play) of clutch pedal is wrong.

•Abrasion or oil stain for clutch friction disk.

•Distortion for friction disk 、 pressure plate or

flywheel surface.

•Diaphragm springs become weaker.

•Free travel of clutch pedal is wrong.

•Diaphragm springs become weaker or abrasion for

stabber fingertip.

•Rust for input axle spline.

•Mutilation or abrasion for input axle spline of

transmission.

•Excessive nodding action for clutch friction disk

assembly.

•Abrasion or oil stain for clutch friction disk.

•Brighten of clutch friction disk (to become

glassiness).

•Oil stain for clutch friction disk.

•Bad skid of segregation bearing on the bearing

sleeve of transmission.

•Shimmy of clutch friction disk assembly or bad

connection of friction disk.

•Vibration reduction torsion springs of clutch

friction disk assembly become weaker.

•Loose of rivet of clutch friction disk.

•Distortion of pressure plate or flywheel surface.

•Loose of the binding bolt of flywheel or loose of

binding bolt of pressure plate assembly.

•Abrasion or mutilation for segregation bearing.

•Abrasion for front bearing of input axle.

•Abnormal noise for clutch friction disk.

•Crack for clutch friction disk.

•Abnormal noise for pressure plate and diaphragm

spring.

•Clutch friction disk has fat liquor.

•Serious wear of clutch friction disk.

•Rivet head is displayed in surface of disk.

•Torsion springs become weaker

Adjust free travel

Change friction disk

Change frication disk,

pressure plate or flywheel

Change clutch pressure plate

Adjust free travel

Change pressure plate

Lubricate

Change the input shaft

Change friction disk

Change friction disk

Repair or change friction

disk

Change friction disk

Lubricate

Change friction disk

Change friction disk

Change friction disk

Change pressure plate or

flywheel

Screw down

Change segregation bearing

Change input shaft bearing

Change friction disk

Change friction disk

Change pressure plate

Change friction disk

Change friction disk

Change friction disk

Change friction disk

F-8

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 9

COOLING SYSTEM

DESCRIPTION OF COOLING SYSTEM … … …… …… … …… …… … …… …C-2

COMPONENTS OF 480 ENGINE COOLING SYSTEM … … ……………………C-2

WORKING PRINCIPLE OF COOLING SYSTEM … … …… …… … …………C-2

PARAMETERS OF COOLING SYSTEM … … …… …… … …… …… … …… C-3

ENGINE COOLANT … … …… …… … …… …… … …… …… … …………… …C-3

COOLANT DISCHARGE … … …… …… … …… …… … ………………………C-3

COOLING SYSTEM CLEANING … … …… …… … …… …… … ……… …C-3

COOLANT FILLING … … …… …… … …… …… … …… …… … ……………C-4

COOLING SYSTEM CHECKUP …… …… ……… ……… ……… …… …… …C-5

COOLING SYSTEM MAINTENANCE WARNING … … …… …… … ……… …C-5

WARNING … … ………… ………… ………… ………… …… …… … …… …C-5

WATER PUMP … … …… …… … …… …… … …… … … … ………………………C-6

STRUCTURE … … …… …… … …… …… … …… …… … …… …… … …C-6

DISASSEMBLY/ASSEMBLY … … …… …… … …… …… … …… …… … …C-6

THERMOSTAT … … …… …… … …… …… … …… …… … …… …… … …… …C-7

DISASSEMBLY/ASSEMBLY … … …… …… … …… …… … …… …… … …C-7

WATER TEMPERATURE SENSOR … … …… …… … …… …… … ………… …C-9

DISASSEMBLY/ASSEMBLY … … …… …… … …… …… … …… …… … …C-9

CHECKING … … …… …… … …… …… … …… …… … …… …… … …… C-9

COOLING FAN … … …… …… … …… …… … …… …… … …… …… … …… C-9

DISASSEMBLY/ASSEMBLY … … …… …… … …… …… … …… …… … …C-9

GUIDELINE FOR DISASSEMBLY … … …… …… … …… …… … ……… …C-10

EXPANSION RESERVOIR … … …… …… … …… …… … …… …… … …… …C-11

DISASSEMBLY/ASSEMBLY … … …… …… … …… …… … …… …… … …C-11

ASSEMBLY OF RADIATOR …… …… …… … ……… …… … …… …… … …… C-12

DISASSEMBLY/ASSEMBLY … … …… …… … …… …… … …… …… … …C-12

C-1

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 10

COOLING SYSTEM

Hose

Thermostat Chassis and

Hose Hose Hose Hose

Radiato

DESCRIPTION OF COOLING SYSTEM

COMPONENTS OF 480 ENGINE COOLING SYSTEM

Engine cooling system is used to cool engine to

prevent the engine from overheating, ensuring the

normal operation of engine. It is composed of the

timing belt-driven water pump, transverse radiator,

water tank, water pipe, thermostat, temperature control

switch of electrically-driven fan and water temperature

sensor.

WORKING PRINCIPLE OF COOLING SYSTEM

When the temperature of engine coolant is

relatively low, the thermostat shall turn it off, and the

coolant shall circulate and flow among the cylinder

block, water pump and warm air exchanger. This kind

of circulation is called small circulation.

When the temperature of engine coolant is

relatively high, the thermostat shall turn it on, the

coolant shall flow into the radiator, the electrically

-driven fan shall operate to lower down the temperature

of coolant. And then the coolant shall flow back to the

engine cylinder block. This kind of circulation is called

big circulation. As the big circulation operates, the

small circulation shall also play its role.

Warm Air/Heat Exchanger

Engine

Water Pump Inlet

Water Temperature Sensor

Cooling Water Pipe Assembly

Hose Assembly

Electrically-Driven Fan

Pressure Cap

Thermostat Assembly

Hose Assembly

Thermo-Switch

Expansion Tank

As the engine works under normal work

temperature the engine coolant shall expand. Under this

circumstance, the overflow valve installed on the

thermostat chassis shall turn it on, the coolant shall

flow into the expansion water tank through the

overflow pipe; and as the system cools down, the

coolant shall flow back to the water pump inlet from

the expansion reservoir.

The operation of electrically-driven fan is

controlled by the thermo-switch installed on the right

water chamber of radiator. When the contact points of

thermo-switch meet together, the electrically-driven fan

shall run. The water temperature sensor is fitted on the

back of cylinder head lying at the side of exhaust pipe.

C-2

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 11

PARAMETER OF COOLING SYSTEM

Cooling system Parameter

Total system capacity(L) 8

Coolant capacity

Fan

Water pump

Radiator

Thermostat

Thermo-switch

Coolant Discharge:

――To demount the pressure cap of expansion

reservoir;

Engine capacity(L) 3.3

Radiator capacity(L) 2.1

Expansion reservoir capacity(L) 0.4

Diameter: 280mm

Number of blades: 6

Operating voltage: 9-15V

Rotating speed Ι gear: high-speed engine 2000±200

Rotating speed II gear: high-speed engine 2800±200

Diameter of impeller: ф72mm

Transmission rate: 1.053:1

Opening pressure of the pressure cap: 160kPa

Front face area: 0.202m²

Heat abstraction area: 8.93m²

Opening temperature: 85º-89º

Full opening temperature: 99º-102º

Switch-on temperature gear95 Cº gear 102 CºⅠⅡ

Switch-off temperature gear≤84 Cº gear≤91 CºⅠⅡ

Operating voltage: 12V

ENGINE COOLANT

low-speed engine 1800±200

low-speed engine 2600±200

――To install a vessel under the radiator, demount

the radiator outlet hose under the radiator and

discharge the coolant.

Cooling System Cleaning:

――To discharge coolant, mount the radiator outlet

hose;

――To inject clean water up to the position of the

largest water surface of the expansion reservoir

from the expansion reservoir filler, and then close

the pressure cap;

――To start up engine to make it operate at idle speed,

C-3

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 12

preheat up to normal operating temperature, shut

――To check whether the pipeline is well connected

e cap; fill up coolant into the

expansion reservoir filler slowly. Since the

expansion reservoir is at the highest position in the

herefore, as the coolant level

rises, the air in the system shall be discharged into

and shall be discharged out

of the expansion reservoir by injecting coolant

――To continuously inject coolant up to the highest

nd then close the filler to prevent

――To start up the engine to make it operate at idle

speed and preheat up to normal operating

ns to run,

observe water thermometer and check if the engine

is at overheating condition. If the coolant level in

down and cool down;

――To discharge coolant;

――To repeat the abovC-mentioned steps until the

discharged water is the same as the clean water;

――To clean the cooling system according to the

following methods if the coolant is not correctly

used and replaced to meet the requirements in the

former utilization:

a. To discharge coolant;

b. To demount the radiator inlet hose, insert the main

water hose into the radiator filler until the outlet

water becomes clean;

c. In order to flush out the engine, you should connect

the main water hose with the water outlet of the

thermostat to clean the engine until the discharged

water flowing from the water pump inlet becomes

clean;

d. To repeat cleaning operations if the radiator is very

dirty, and connect the main water hose with the

radiator water outlet until the water flowing from

the radiator water outlet becomes clean.

Coolant Filling:

and fastened before injecting coolant;

――To open the pressur

cooling system. T

the expansion reservoir

slowly.

coolant level. A

coolant from spilling.

temperature. And until the fan begi

C-4

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 13

the expansion reservoir descends quickly, coolant

should be injected up to the highest position to cut

down the air circulation in the system.

if

――To open the pressure cap to check the coolant level, and

vel, start up the engine and

preheat it. Put the engine under idle speed

circumstance until the cooling fan runs, and check

if coolant leakage exists at various pipe joints. Shut

down the engine and wait for engine cooling. And

vel in the expansion

――To try best to prevent the coolant spilling from

――To shut the engine down to have it fully cooled(

possible, leave the engine alone for one night.);

inject coolant up to the highest position.

Cooling System Checkup:

――To check the coolant le

then check if the coolant le

reservoir is at normal condition.

scalding operator during checkup.

――To timely check if water flows into the engine oil

pan (the lubricating oil shall become milk white

after water flows) when no pipe leakage is found

and the expansion reservoir is short of coolant, and

timely stop water from flowing in when finding it.

COOLING SYSTEM MAINTENANCE WARNING

Warning:

·To try best not to move radiator cap or loose the radiator discharging plug when the engine

is under operation or the engine and radiator are at a very high temperature. Scorching

coolant may spill out, hurting the people and damaging the engine and cooling system.

·To shut down the engine until it cools down, and then carefully demount the radiator cap.

Meanwhile, wrap a large thick cloth onto the radiator cap, rotate it slowly to the position

of the first clip along the counter-clockwise direction and then release the pressure slowly.

·To use a cloth to push down the radiator cap, rotate and remove the radiator cap after the

operator ensures all the intensity of pressure has been released.

C-5

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 14

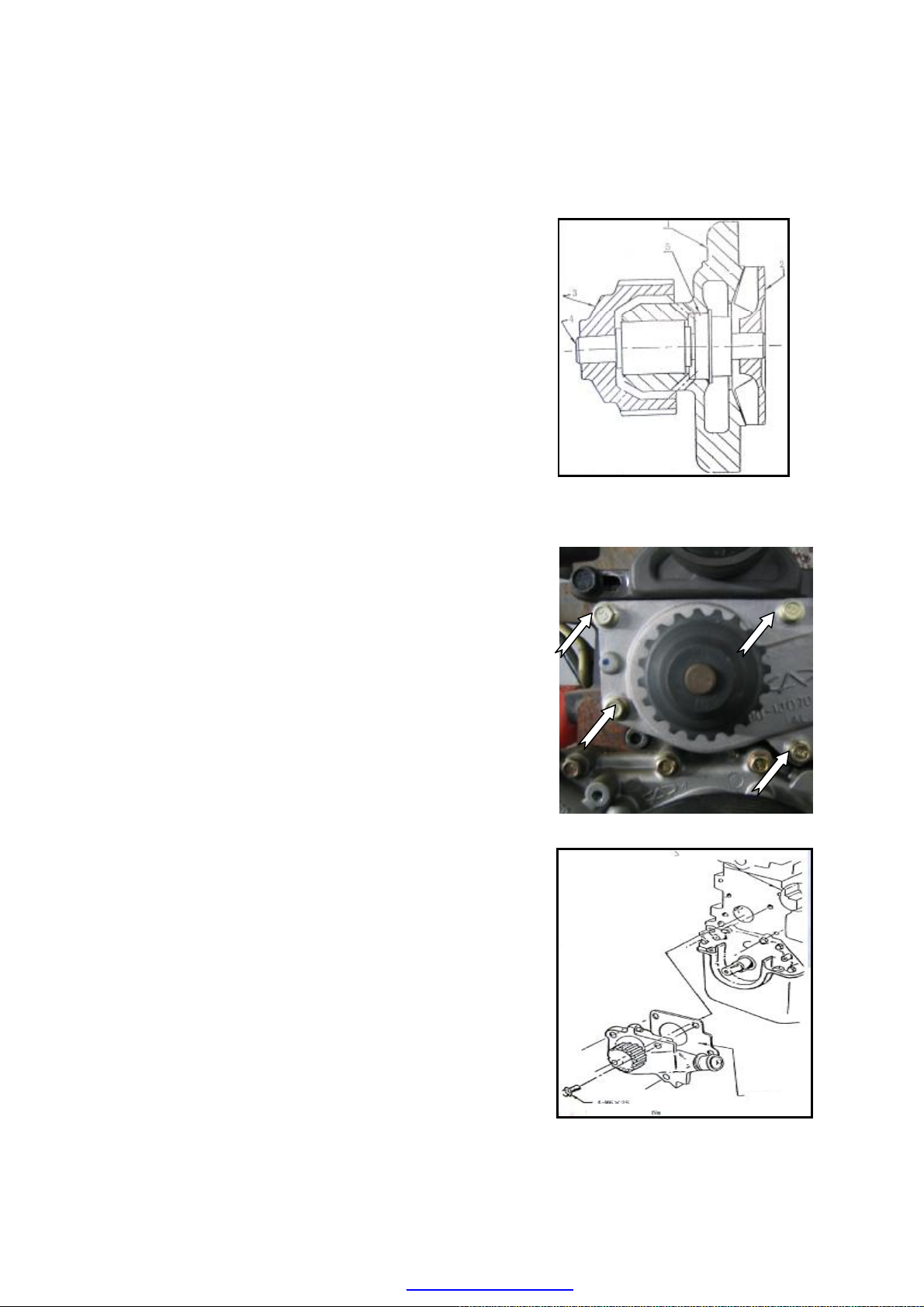

WATER PUMP

Structure:

To discharge engine coolant (refer to the coolant

4 bolts out of the front side of

To install the water pump assembly in the cylinder

block and screw up 4 fixing bolts by hand, and

The water pump impeller installed in the cylinder

Note: Because water pump assembly can not be

seal ring or bearing

Tightening Torque

Gasket

1—Water pump housing

2—Water pump impeller

3—Water pump gear

4—Water pump shaft bearing

5—Water pump seal (ceramics-lead)

Disassembly:

——To disconnect the negative terminal of battery;

——

discharge process);

——To disconnect poly V-belt and power pump belt;

——To demount timing shield;

——To unscrew and take

cylinder block.

——To demount the water pump assembly;

——To demount the water pump gasket.

Assembly:

——To install the new gasket on the water pump;

——

then screw up to 7.0—10.0Nm;

——

block should be able to rotate freely;

——To refill engine coolant;

——To check leakage occurrences of engine coolant.

repaired, it should be replaced when

is worn and torn.

C-6

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 15

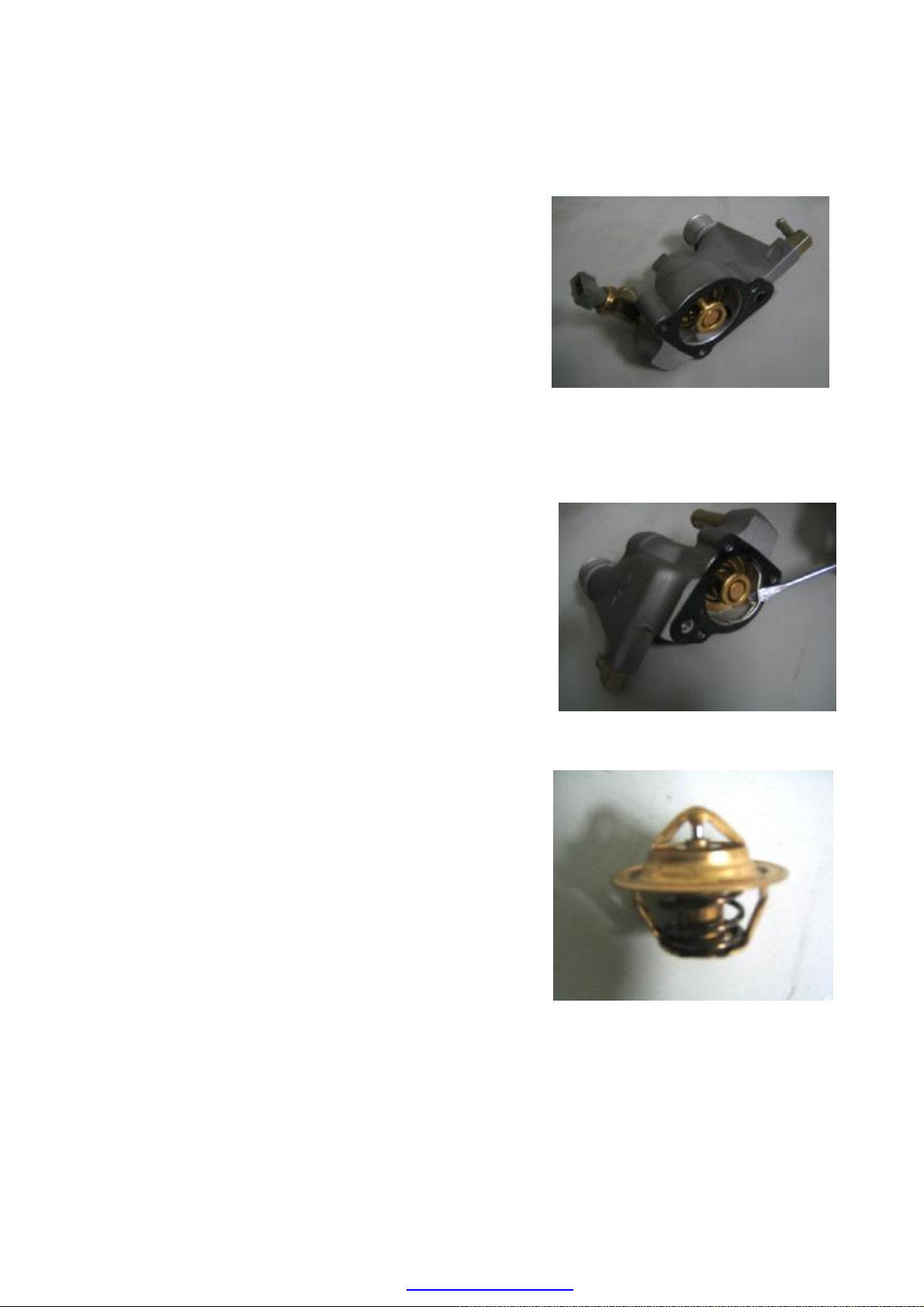

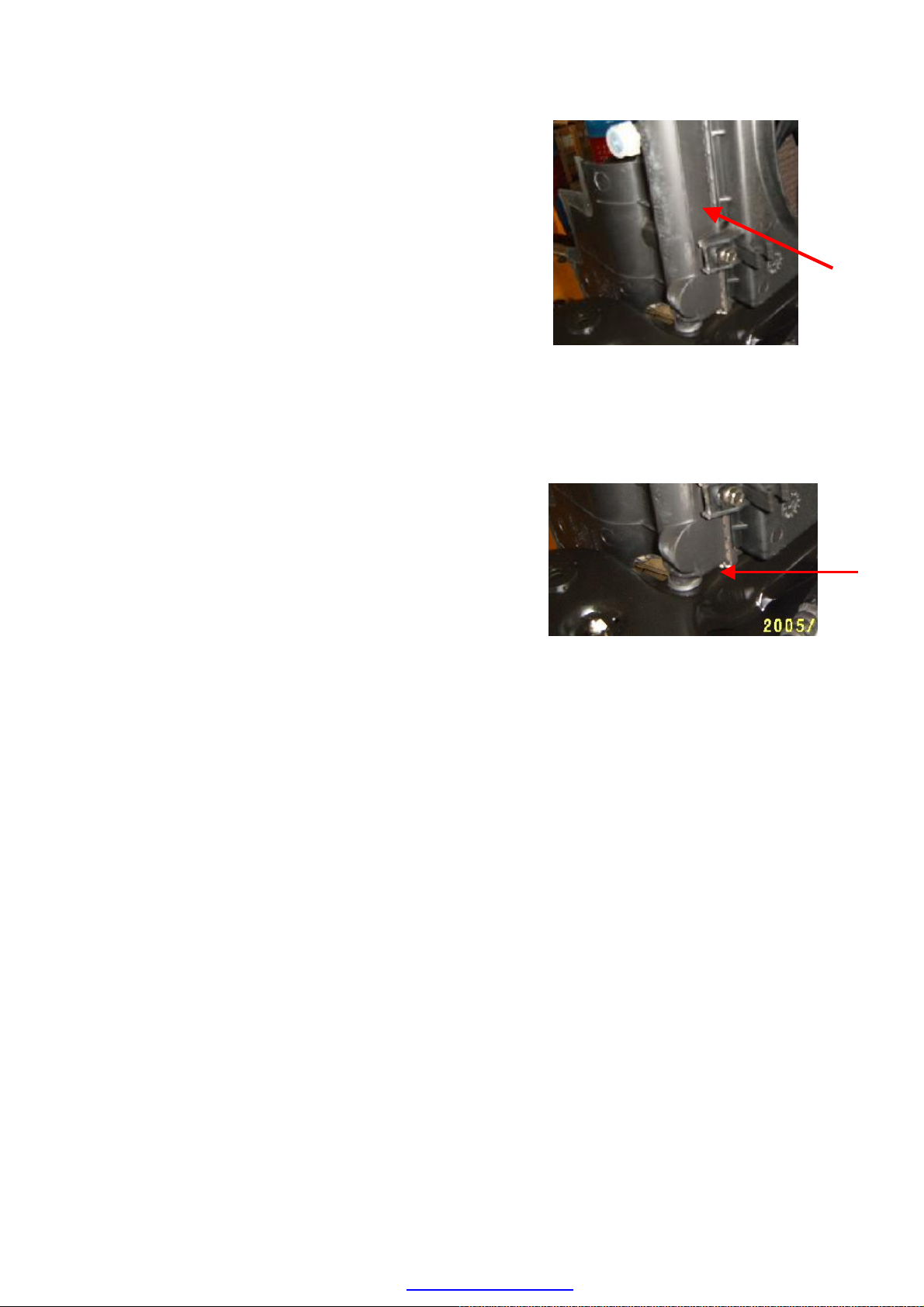

THERMOSTAT

To unscrew 3 M6×40 bolts and then demount the

To demount thermostat chassis and thermostat

To pry out the spring clamps by using chisel or

Disassembly:

——

bolts;

——

assembly.

——

screwdriver.

——To take the thermostat out;

——To clean up the thermostat;

C-7

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 16

——To take the seal ring

out, and replace it if it being

To demount the gasket from the thermostat chassis.

To measure the thermostat opening temperature

worn and torn.

——

(To replace with new gasket if it is worn and

torn, and allow no repeated use.)

——

under hot water.

Assembly:

——To clamp the thermostat and then put the gasket

into the thermostat aperture.

——To install thermostat (the side with spring facing

outward).

——To embed spring clamp to ensure the clip within

the thermostat chassis slot;

——To mount new gasket onto thermostat chassis;

——To mount the thermostat chassis and thermostat

assembly into the aperture at the rear side of engine

cylinder head, and screw up the bolt by hand to

9—12N.m.

C-8

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 17

WATER TEMPERATURE SENSOR

Disassembly:

——To demount water temperature sensor (at the

exhaust pipe flank and under the lifting eye).

Assembly:

——To apply Letai 243 glue on the screw thread,

screw up the bolt to 7.0—10.0Nm before

installation.

Checking:

Water temperature sensor is a negative temperature coefficient sensor, which is composed of

a thermal resistor. The resistance value of the resistor shall decrease as the engine temperature

rises. The variation is detailed in the following table:

Temperature (°C) Resistance Value (Ω)

-20 29,125

-10 16,660

0 9,790

+20 3,748

+25 3,000

+60 747

+80 377

+100 204

+120 117

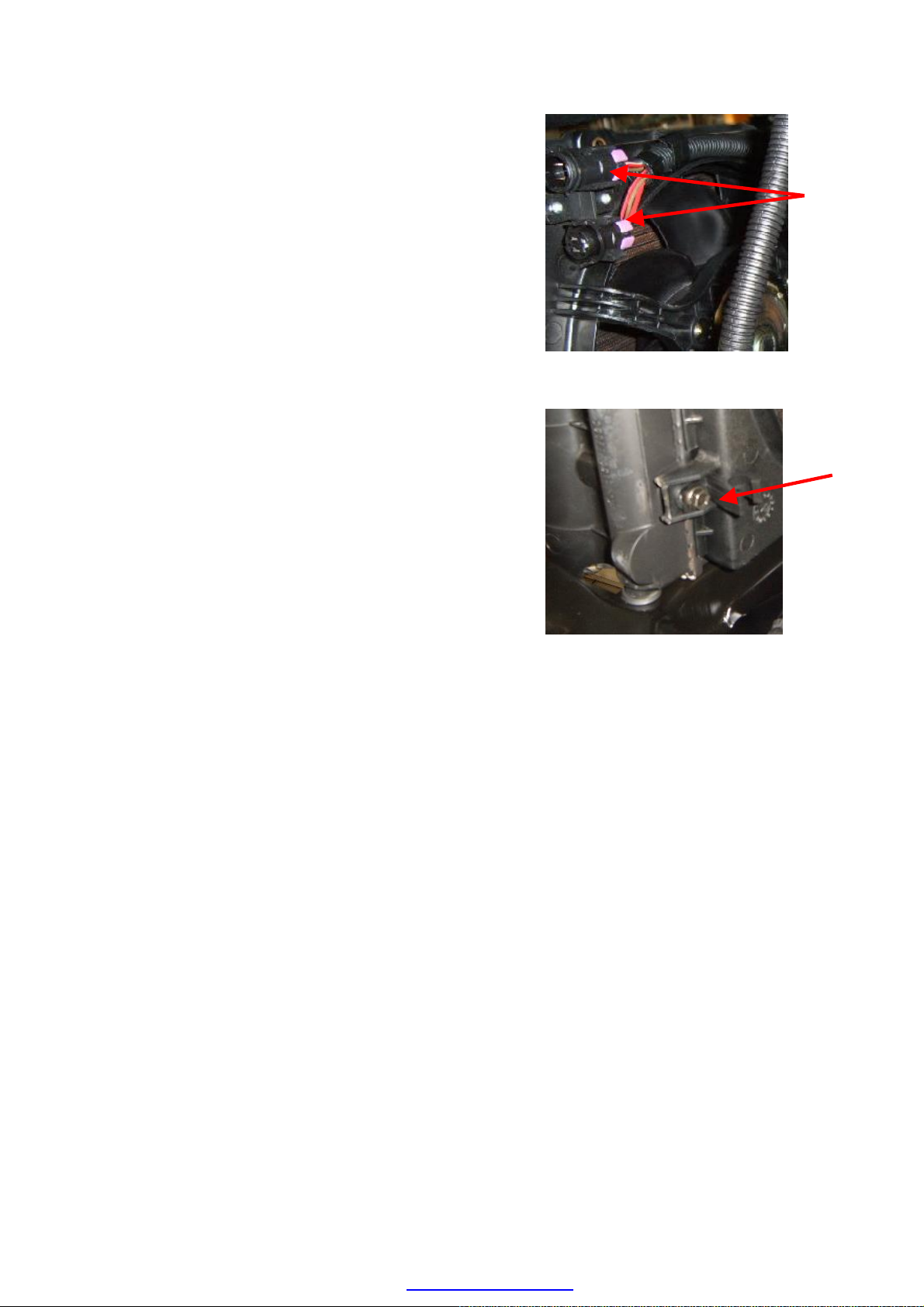

COOLING FAN

Disassembly:

——To disconnect the negative terminal of battery;

C-9

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 18

——To demount the matching plug of the cooling fan.

tapping screw from

p the engine and check if the cooling fan

During the disassembly process, you should pay

more attention not to pull A/C pipe to a large extent,

——To remove the fastening self-

the cooling fan.

——To take the cooling fan out.

Assembly:

——To assemble the cooling fan according to the

disassembly order (the tightening torque of

self-tapping screw is 1.8~2.2Nm)

——To start u

is under normal operation.

Guideline For Disassembly:

——

otherwise the A/C pipe shall crack and deform.

C-10

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 19

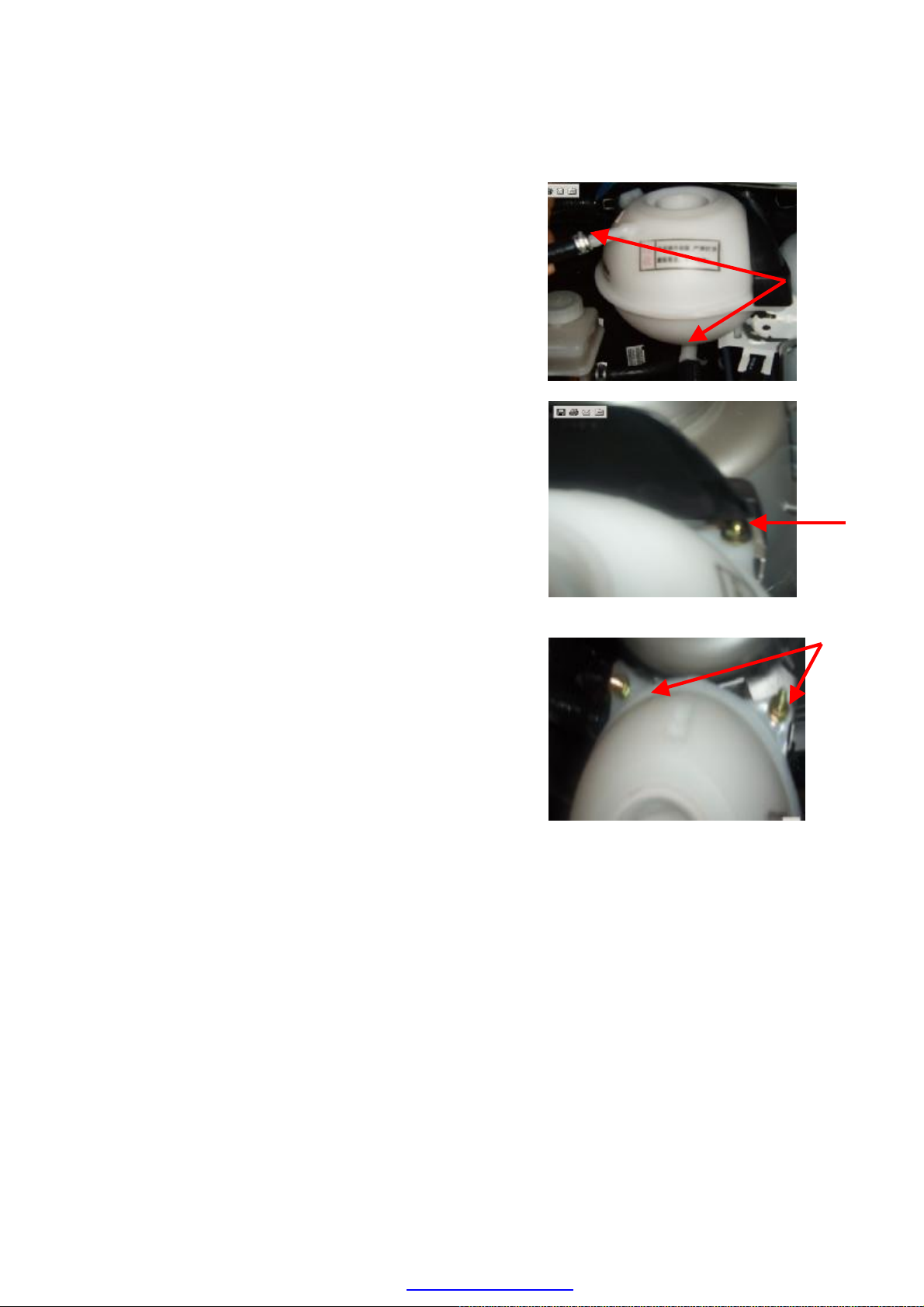

EXPANSION RESERVOIR

Disassembly:

——To demount the water pipe connecting with the

expansion reservoir.

——To pry out the protecting hood of expansion

reservoir by using a screw drive.

——To demount the fastening bolts of the expansion

reservoir by using M10 sleeve.

——To pull out the plug of liquid level sensor.

——To take the expansion reservoir out.

C-11

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 20

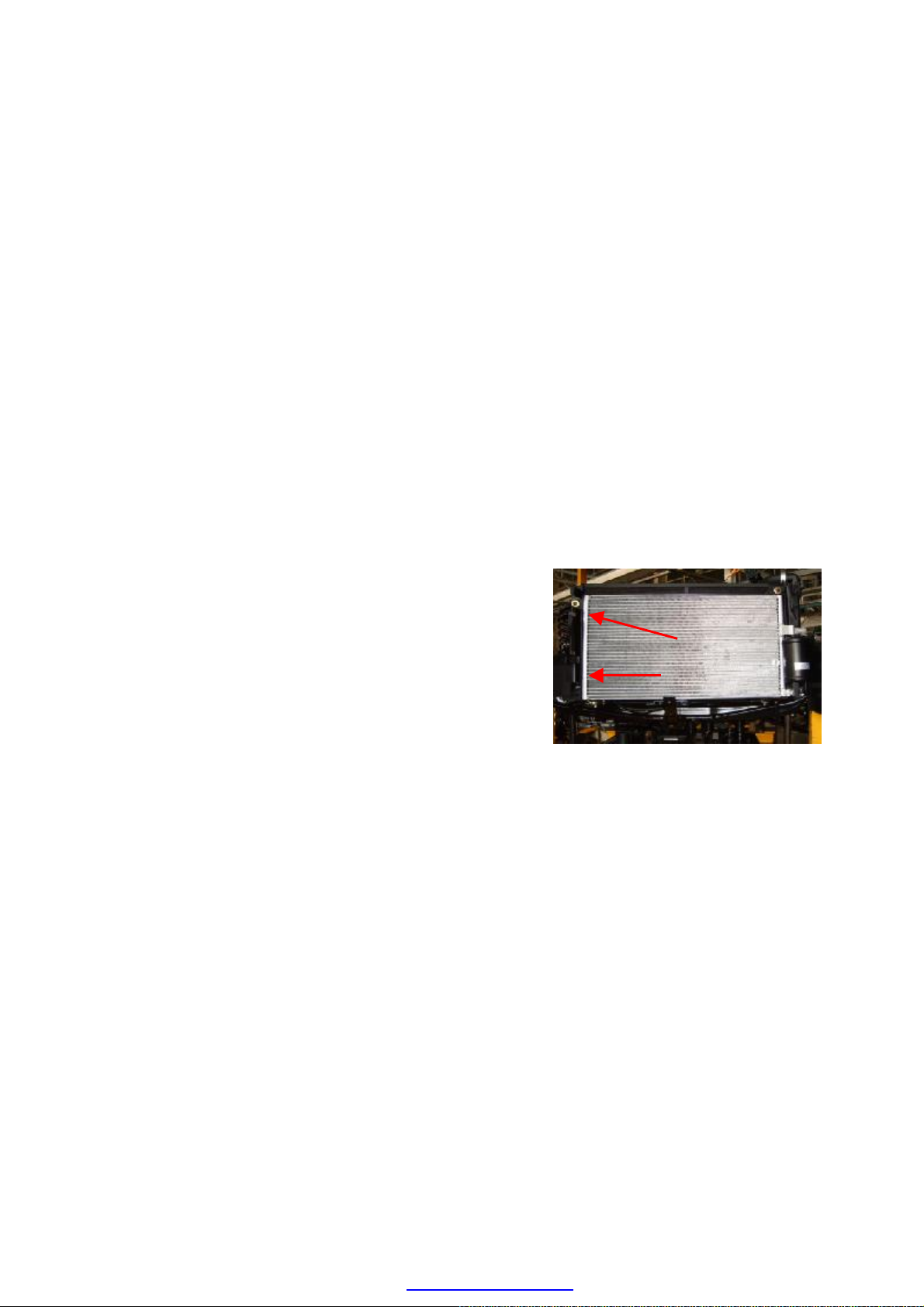

To demount the left and right wind boards by M10

Assembly:

——To assemble the expansion reservoir according to

the order opposite to the disassembly order(the

tightening torque of self-tapping screw is

4.0~5.0Nm).

——To refill coolant.

ASSEMBLY OF RADIATOR

Disassembly:

——To discharge coolant (refer to the coolant discharge

process)

——To demount the cooling fan (refer to the

disassembly process of the cooling fan).

——

sleeve.

——To take out the radiator.

C-12

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 21

——To take out the radiator

Assembly:

——To assemble the radiator according to the order

opposite of the disassembly order.

——To install the 2 wind boards onto the radiator by

using self-tapping screws with their tightening

torque of 6~7Nm.

——To install the radiator onto the front transom and

put it straightly towards the positioning hole.

——To install the left and right tensioned plates of the

radiator, and tighten the bolts of the plates with

tightening torque of 5±1Nm.

C-13

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 22

ENGINE ELECTRONIC SYSTEM

INPUT / OUTPUT COMPONENTS OF CONTROL SYSTEM … …… … … … …E-2

WORKING MODULE TABLE OF FUEL INJECTION / IGNITION SYSTEM …E-3

WORKING PRINCIPLE … …… … … … …… …… … … … …… …… … …E-4

ELECTRICAL CONTROL UNIT …… …… … … … …… …… … …………E-5

WORKING PRINCIPLE OF ELECTRONIC FUEL INJECTION CONTROL AND

ACTUATORS …………………………………………………………………………E-7

BASIC PRINCIPLE OF MALFUNCTION DIAGNOSIS FOR ELECTRONIC FUEL

INJECTION SYSTEM ………………………………………………………………E-21

DETAILED TABLE OF MALFUNTION DIAGNOSTIC CODE …………………E-24

PROCEDURES FOR FAULT DIAGNOSIS ACCORDING TO THE SYMPTOMS OF

THE ENGINE …… …… …… … …… …… …… …… …… …… …… ……E-62

SAFETY PRECAUTIONS OF SYSTEM MAINTENANCE ………………………E-88

SAFETY PRE CAUT IONS IN DI AGOSIS AND M AINTENANCE OF T HE

GASOLINE INJECTION ELECTRONIC CONTROL SYSTEM …………………E-88

SAFETY MEASURES ……………………………………………………………E-89

E-1

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 23

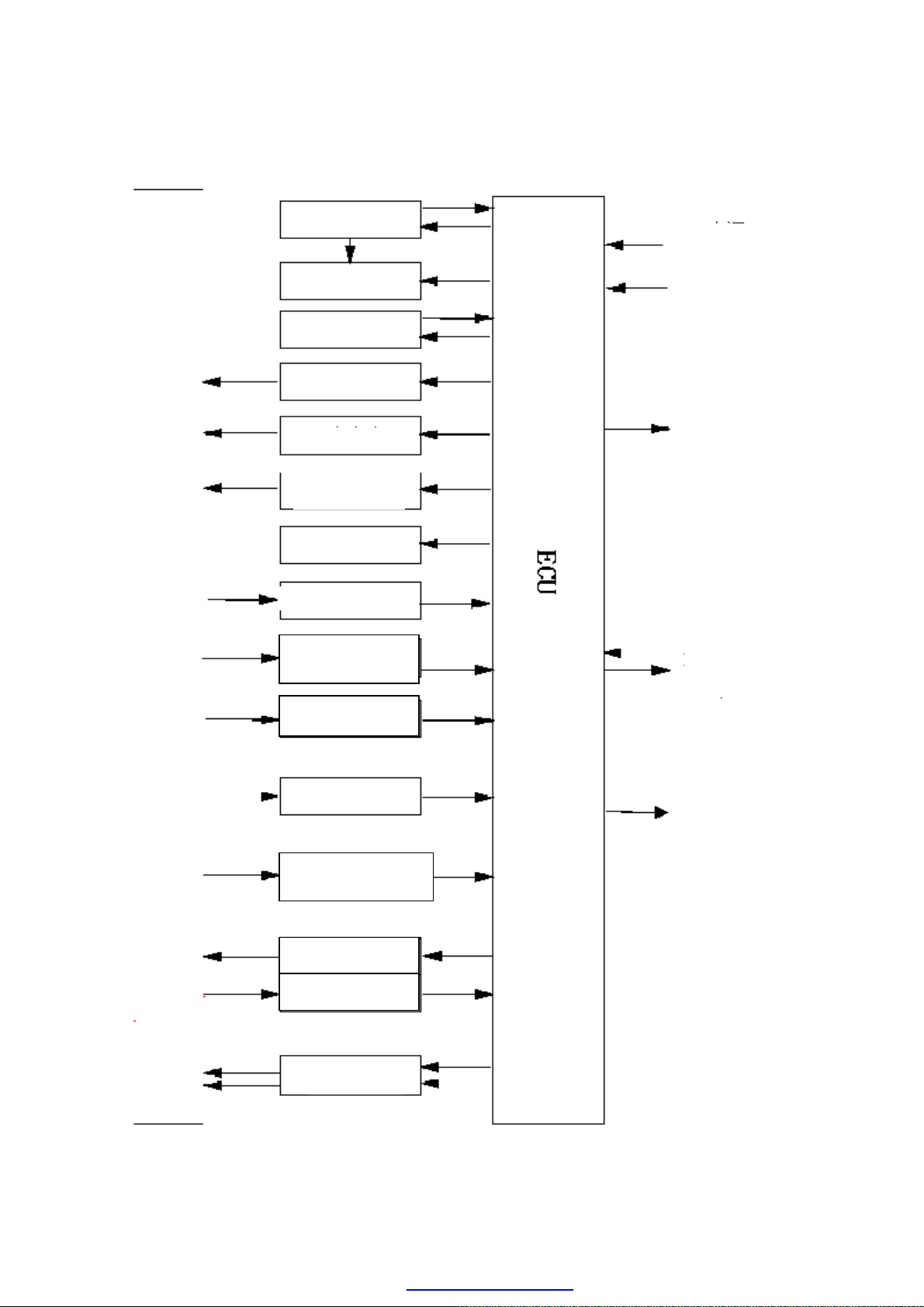

INPUT / OUTPUT COMPONENTS OF CONTROL SYSTEM

19

18

Diagnostic

connector

1 Engine ECU 11 Fuel injector

2 Air pressure / temperature sensor 12 Oxygen sensor (heater)

3 Engine speed sensor for top dead center 13 Fuel pump

4 Throttle valve position sensor 14 Carbon canister solenoid valve

5 Knock sensor 15 Two step speed fan controller

6 Coolant temperature sensor 16 Compressor relay control

7

Oxygen sensor (λ signal)

17 Idling speed step motor

8 Air condition request 18 Diagnostic connection

9 Ignition coil and spark plugs 19 Relay

10 Instrument panel

E-2

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 24

WORKING MODULE TABLE FOR FUEL INJECTION / IGNITION

Fuel pump

A/C relay

Fuel injector

Carbon canister

Throttle valve

position sensor

Air pressure /

Power supply

Cooling temperature

SYSTEM

Power supply relay

(Power supply +12V)

Power supply

(15/54)

Idling speed step motor

Malfunction

indicator

Ignition coil

ENGINE

Engine

solenoid valve

Coolant temperature sensor

Line K

temperature sensor

Knock sensor

·

overheat alarm light

·Decoder alarm light

TDC/rotate speed sensor

Oxygen sensor heater

Heated Oxygen sensor heater

·R.P.M. meter

Fan relay

E-3

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 25

WORKING PRINCIPLE

This system is capable of controlling the actual tested air-fuel ratio under all engine speeds to

stay close to the equivalent proportion of the chemical reaction, so as to protect the catalyst

package and subsequently reduce the discharge of pollution. The oxygen sensor analyses the

oxygen content of the discharge gas using real-time principle and makes it possible for the

ECU to control the amount of injecting fuel to correct the air-fuel ratio. The fuel with a

pressure of about 3.5 bars is directly injected into the air intake manifold near the throttle

valve.

The fuel injectors of all cylinders are utilizing a sequential phase angle control method

according to the intake sequence and the opening time of the air intake valves; the injection

destinations are stored in the ECU map, and can vary autonomously according to the engine

speeds and intake air pressures. The application of sensors in the system is a basic strategy

used to correct the engine under all operating conditions. The system is implementing an

induction type of electrical discharge ignition, where the power source module in the ECU

controls the ignition timing. The ignition advance angle is calculated according to the engine

compression ratio and intake air volume. The idling speed is maintained at stable condition

through controlling the opening of the branch-connection pipe by a step motor and also

through the changing of the ignition points.

Other than capable of obtaining the input signals and controlling the output components, the

system has also equipped with various other functions. These functions include the following:

- When self-diagnose that the sensor is faulty, adopt the restoration strategic control.

- Restoration of the self-regulating mixed concentration engine and variances in spare parts.

- Exchange data with the diagnostic tester.

The idling speed of the engine and the amount of CO in the air discharged must not be

manually adjusted.

E-4

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 26

ELECTRONIC CONTROL UNIT

The ECU is located on the left of engine firewall. The ECU handles various signals from the

sensors and controls the actuator so as to achieve the best possible operating condition. Many

extra functions are added as compared with the previous model. While by the usage of a

custom-made circuit board that can achieve many special functions, the integrated functions

are enhanced so that the structure has considerably reduced in size and become much more

compact.

The hard wares in the ECU are as follows:

-16 bit CPU single chip

- 8KB RAM (2KB IRAM + 6KB ERAM)

- 2MB FLASH EPROM (12V programming voltage)

- 2KB SERIAL EEPROM

- 16 CHANNELS 10 MODULES/NO. (A/D) CONVERTER

- 4PWM OUTPUT

- CAN MODULE (CAN2.0B)

The ECU software structure is divided into two parts for data processing:

-The “Application” part obtained the measurement of engineering parameter through sensors

to calculate the control parameters of the fuel injectors, ignition coils and idling speed step

motor for controlling the engine starting.

-The “Basic” part is collecting the data from the sensors and converts it into engineering data.

After that it controls the actuator through the calculated parameter generated by the

“application” software, and manages the self-diagnostic programs of the various sensors and

actuators. In addition, it can also communicate with the externally connected diagnostic

tester through the use of “K” serial cable.

The operating system is capable of ensuring the accurate management of the matters related

with time (such as the management of definite and delay timing) and angles (related to the

engine rotation sequence). This type of management is integrated in the software and

calculated according to the precise priority to ensure the optimization management of the

engine even at its high-speed condition. This type of “modular structure” design allows the

possibility of achieving all kinds of flexibility control and in the mean time not tampering the

overall characteristic of the system.

The following data are transmitted into the ECU:

- Battery voltage

- Absolute pressure sensor in the air intake manifold

- Top dead center

- Throttle valve opening angle position

- Air intake temperature

E-5

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 27

- Engine coolant temperature

- Air conditioning operation

- Signal from oxygen sensor

- Knock sensor for the accelerator meter on top of the engine crankshaft housing

The air intake efficiency is obtained by calculating through the processing of absolute

pressure, air intake temperature, engine speed, throttle valve position and other signals, and

help to determine the air intake quantity of the cylinder. The inbuilt power supply module in

the ECU is controlling the following functions:

- To control the injected fuel quantity through the control of opening timing of the fuel

injector

- Idling speed step motor

- Ignition coils of the 4 high voltage outputs

- Check valve for recirculation the gaseous fuel on top of the air intake manifold (carbon

canister)

- Temporary turnoff of the air condition compressor

- Dual speed cooling fan for the engine

- Overheating alarm light in the coolant of the engine

- Malfunction alarm light

Other than these major functions, ECU also controls:

- All the self-diagnostic strategy related to input sensors and output actuators

- Wrong signals restoration strategy works on basically effective input signals

E-6

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 28

WORKING PRINCIPLE OF ELECTRONIC FUEL INJECTION

Manif

old absolute

pressure and intake air

temperature sensor

CONTROL AND ACTUATORS

※ Intake Pressure and Intake Air Temperature

Sensor

Purpose: detects manifold absolute pressure from

0.1~0.2bar and intake air temperature, provides engine

with load information.

Composition and principle: this sensor is composed

of two different sensors (i.e. manifold absolute

pressure sensor and intake temperature sensor), and is

installed above pressurizer.

Pressure-sensitive element inside intake pressure

sensor detects pressure signal on intake manifold for

injection pulse width control of EFI system. This

sensor also serves as the substitute of load signal

sensor.

Intake air temperature sensing element is a resistor

of negative temperature coefficient (NTC), which is

similar to water temperature sensor with resistance

value decreasing with the increasing of intake air

temperature. And engine ECU monitors the variation

of intake air temperature via a comparison circuit

inside.

TMAP

Failure diagnosis: The electronic device next to

intake pressure sensor detects sensor circuit troubles

such as open circuit, short circuit and sensor damages,

etc. In case ECU detects any sensor output signal that

goes beyond output characteristic curve, the sensor is

diagnosed as failed by ECU. For example: when

intake pressure is higher than upper limit or lower than

lower limit, ECU detects sensor failure (in case that

intake pressure is lower than lower limit when starting,

ECU is able to recognize the starting condition), and

the engine fault indicating lamp goes on. Under this

condition the engine works in failure mode.

Installation: to be installed on pressurizer.

Circuit diagram of manifold absolute

pressure and intake air temperature sensor

Pins:

1# is grounded (connecting ECU 17#);

2# outputs temperature signal

(connecting ECU 40#);

3# connects with standard 5V power

source (connecting ECU 33#);

4# outputs pressure signal (connecting

ECU 37#).

E-7

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 29

Troubleshooting: mainly check if there is short circuit

1 Seal ring

5 Ca

sing

Failure diagnosis:

or open circuit on the connection between 4 lines on

sensor and ECU.

If there is short circuit, open circuit or grounding

between sensor wire harnesses.

Sectional view of intake pressure and

intake air temperature sensor

2Stainless steel bushing 6 Pressure bracket

3 PCB 7 Welded joint

4 Sensing element 8 Bonded joint

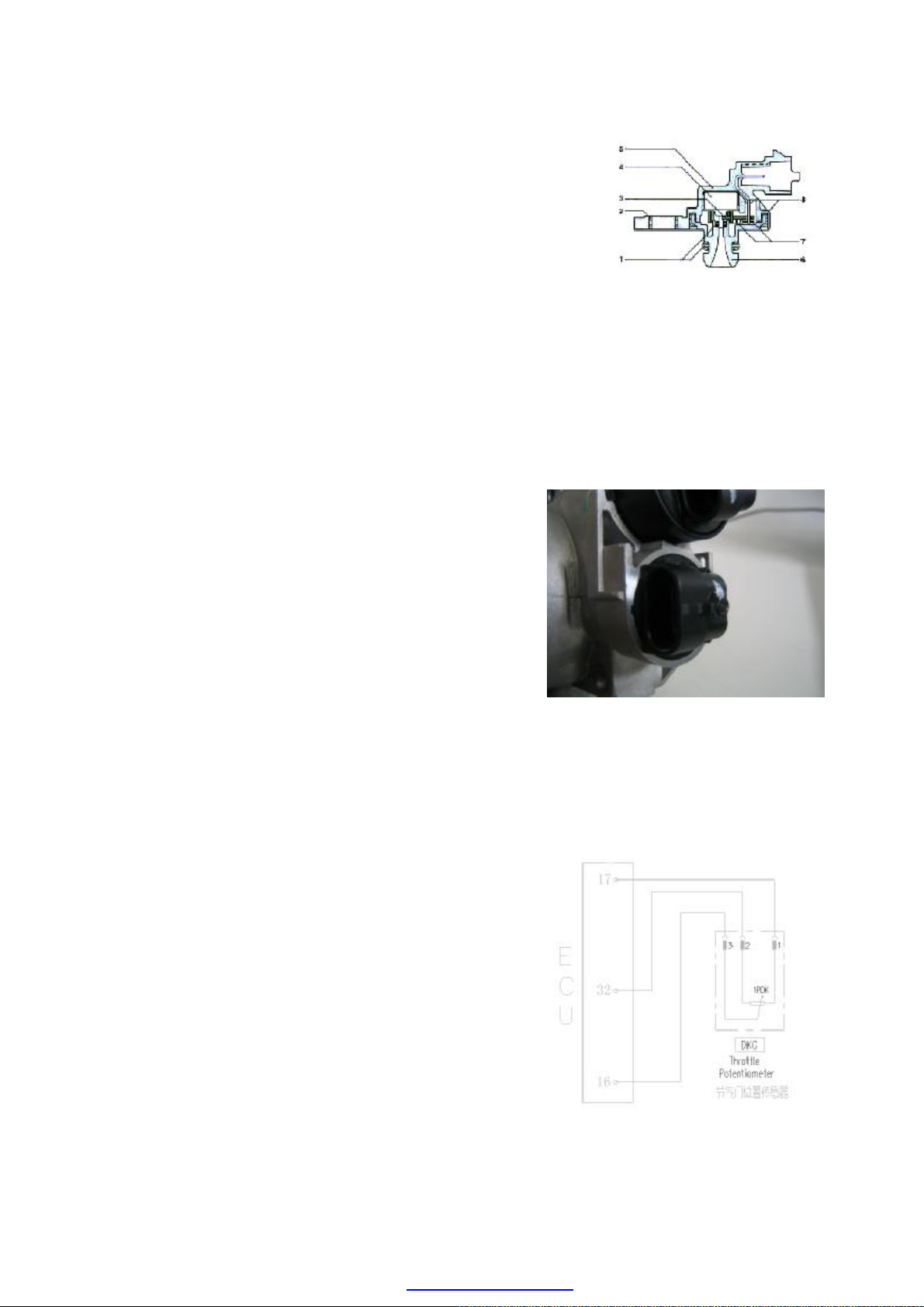

※Throttle Position Sensor

Purpose: this sensor is designed to provide ECU with

information of throttle angle. As per such information,

ECU obtains engine load information and operating

mode information (for instance: start-up, idle speed,

reverse, part load and full load) as well as acceleration

and deceleration information. This sensor is three-wire

style, and the throttle opening can be detected by ECU

via monitoring voltage variation.

Composition and principle: Consisting of two

compass sliding contact resistors and two sliding

contact arms, throttle position sensor is an angle

sensor that outputs linear signals. The axes of contact

arms are on the same axial line with throttle axis, with

5V power supply voltage US being applied to both

ends of each contact resistor. When throttle turns,

contact arms turn along with it and move on sliding

contact resisters, educing potential of contacts UP as

output voltage. This sensor is actually an angle

potentiometer.

Throttle Position Sensor

ECU monitors throttle angle, and

detects sensor failure when output signal exceeds

upper or lower limit, in which case engine will work in

failure mode, and fault indicating lamp will go on.

Installation: allowable tightening torque for fastening

screw is 1.5Nm-2.5Nm.

E-8

PDF created with pdfFactory Pro trial version www.pdffactory.com

Circuit diagram of throttle position sensor

Page 30

Pins:

1 sensor signal ground (ECU17#)

2 5V power (ECU32#)

3 sensor signal (ECU16#)

Troubleshooting: mainly check if there is short circuit

or open circuit on the connection between 3 lines on

sensor and ECU.

Check to see if there is short circuit, open circuit or

grounding between sensor wire harnesses.

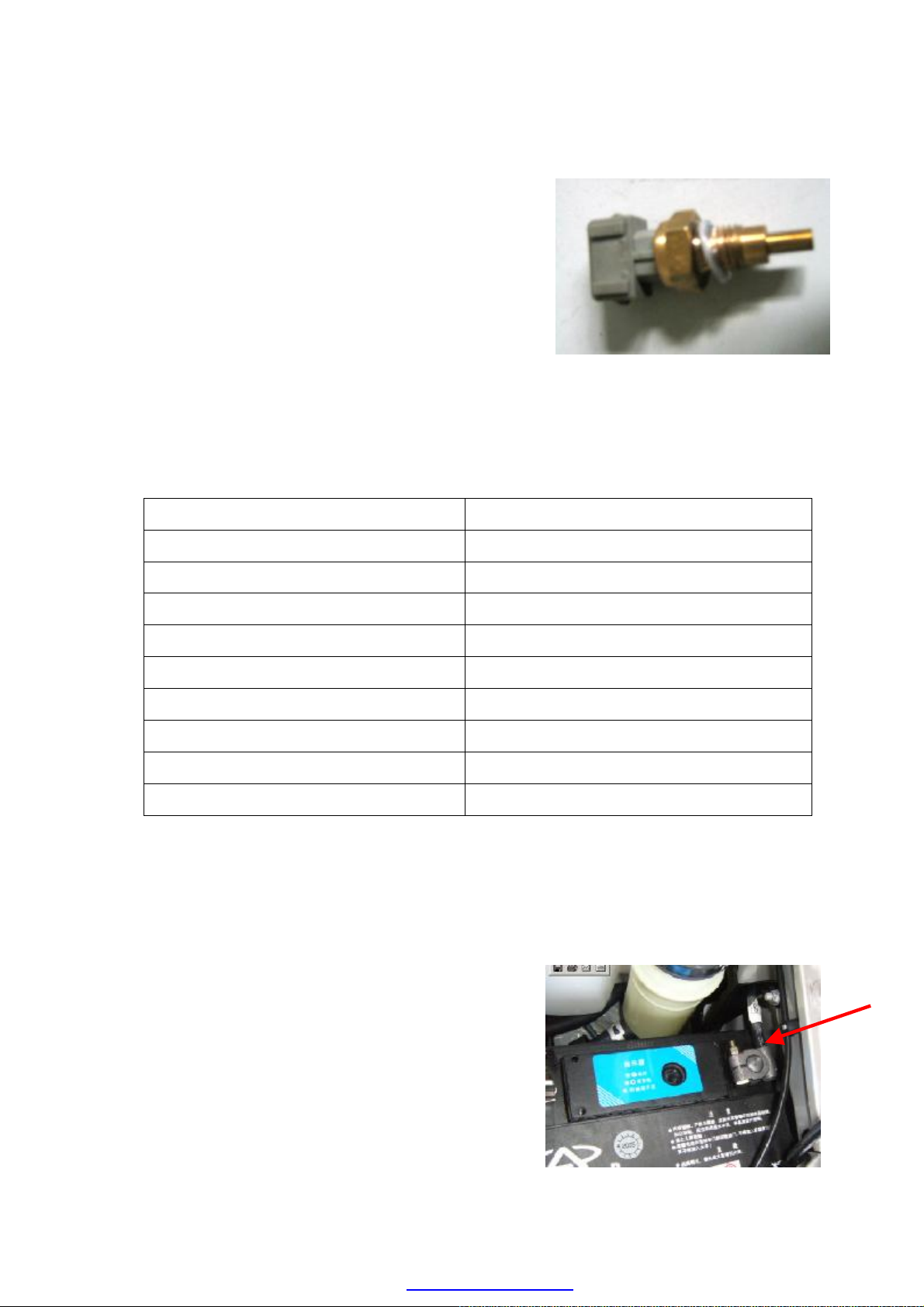

※Coolant Temperature Sensor TF-W

Purpose: this sensor is designed to provide coolant

temperature information. To provide engine ECU with

water temperature signal used for control of ignition

timing and fuel injection pulse width in startup, idle

speed and normal operation.

Composition and principle: this sensor is a

thermistor of negative temperature coefficient (NTC)

with resistance value decreasing with the increasing of

coolant temperature except linear relation. The said

thermistor is installed in a heat-conducting sleeve.

ECU monitors water temperature variation by

converting resistance value of thermistor into a

changing voltage through a bleeder circuit (inner

structure of ECU).

Failure diagnosis: When coolant temperature is

higher than allowed upper limit or lower than lower

limit, failure mark of the knock sensor is set, engine

fault indicating lamp goes on and engine works in

failure mode. In this case ECU controls ignition and

fuel injection according to set water temperature for

failure mode, at the same time the fan is running at

high-speed mode.

Coolant Temperature Sensor

Limiting data: 2.5±5%KΩ

Installation hint: tightening torque is 15Nm in

maximum.

E-9

PDF created with pdfFactory Pro trial version www.pdffactory.com

Circuit diagram of Coolant

temperature sensor

Page 31

Hints: the vehicle is equipped with 2 water

Failure diagnosis:

1.K

nock

ing

iezoelectric

connection

temperature sensors, one is single-pin water

temperature sensor, providing the water temperature

gauge with water temperature signal; the other is

double-pin, providing the engine ECU with water

temperature signal.

Pins: this sensor has 3 pins, which can interchange for

use.

1 coolant temperature sensor signal (ECU 39#)

2 sensor signal ground (ECU 35#)

3 another line connects water temperature signal of

gauge.

Troubleshooting: mainly check if there is short circuit

or open circuit on the connection between 3 lines,

ECU and gauge on sensor.

If there is short circuit, open circuit or grounding

between sensor wire harnesses.

Line grounding or defect grounding is liable to cause

engine water temperature gauge to indicate excessive

temperature.

※Knock Sensor KS

Purpose: this sensor is designed to provide ECU with

engine knocking information so as to carry out

knocking control.

Composition and principle: knock sensor is a sort of

vibration acceleration sensor, which is fixed on engine

cylinder block. ECU controls engine ignition via

signals detected by pressure-sensing element.

ECU monitors on various sensors,

actuators, power amplification circuits and sensing

circuits. In case any of the following situations occurs,

failure mark of the knock sensor is set.

Knock sensor failure

Knocking control data processing circuit failure

block

2.Casing

3.P

ceramics

4.Contactor

5.Electric

KS with cable

Cylinder-detecting signal is unreliable

After failure mark of knock sensor being set, knocking

closed-loop control is shut down, reducing a safety

angle from the ignition advance angle stored in ECU.

When error frequency cuts down to below setting

E-10

PDF created with pdfFactory Pro trial version www.pdffactory.com

Circuit diagram of knock sensor

Page 32

value, failure mark restores.

Ox y g e n Se n s or

Circuit diagram

of Oxygen sensor

Installation hint: tightening torque is 20±5Nm.

Pins:

1 Knock sensor signal 1 (ECU19#)

2 Knock sensor signal 2 (ECU20#)

Troubleshooting: mainly check if there is short circuit

or open circuit on the connection between 2 lines on

sensor and corresponding ECU pins.

If gasket is added during installation; if tightening

torque is proper.

If there is stitching defect between sensor and cylinder,

or there is foreign matter between them.

※Oxygen Sensor

Purpose: this sensor is designed to provide the

information that if there is surplus oxygen after full

combustion of fuel, which is injected into engine

cylinder in the intake air. ECU, when applying this

information, can carry out fuel quantitative

closed-loop control so as to achieve utmost conversion

and purification of the three major toxic elements (HC,

CO and NOX) in the engine exhaust with the

application of three-way catalytic converter.

Composition and principle: the sensing element of

oxygen sensor is a porous ceramic pipe, the outer side

of pipe wall is surrounded by engine exhaust, while

inner side vents to atmosphere. According to inside

and outside oxygen concentration difference, sensor

figures out indirectly fuel injection pulse width, and

then transfers the information to ECU, and the ECU

controls the injection again.

The working voltage of oxygen sensor fluctuates

between 0.1-0.9V, 5-8 variations in 10 seconds is

required; if lower than such frequency value, it shows

that the sensor is aged, and needs replacement. The

said sensor is unrepairable.

Failure diagnosis: ECU monitors on various sensors,

actuators, power amplification circuits and sensing

circuits. In case any of the following situations occurs,

failure mark of the oxygen sensor is set.

Accumulator voltage is unreliable

E-11

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 33

Manifold absolute pressure signal is unreliable

Interior structure

of

oxygen sensor

Engine coolant temperature signal is unreliable.

Injector driver stage failure

After oxygen sensor failure mark is set, fuel

quantification closed-loop control is shut down, and

the primitive fuel injection time stored in ECU is used

to carry out fuel quantification.

Installation hints: the tightening torque of oxygen

sensor is 50-60Nm, a layer of rust preventive oil shall

be applied on oxygen sensor after replacing so as to

prevent from incapable removal in case of rust.

Troubleshooting: mainly check if the plug connection

of several wires on the sensor is in good condition, and

if there is short circuit or open circuit.

Generally, sensor damage is caused by plumbum and

phosphorus poisoning, so pay attention to fuel quality,

meanwhile excessive consumption of engine oil is

Oxygen sensor has a cable, the other end of which is

electric connection. The outside of sensor is wrapped

with asbestos fireproof covering.

There are 4 pins on the joint:

1# connecting with heating control (ECU1#);

2# connecting with heating power and main relay;

氧传感器内部构造图

3# connecting with sensor ground (ECU36#);

4# connecting with signal (+) (ECU18#).

※ Electronic Control Unit ECU

Purpose: ECU is the core of electronic engine control

system. Sensors sent various signals to ECU for

electric control, and then ECU controls operations of

fuel injector and ignition coil, etc. after internal

calculation, thus controlling working of engine.

Normal operation voltage: 9-16V

Composition: it has shielded casing and printed

circuit board, which integrates lots of electronic

control units for the control of EFI system.

E-12

ECU

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 34

Installation: to be fixed by the support of bracket

under pilot trench of front windshield. Pay attention to

waterproofing.

Functions:

Multipoint sequential injection

Controlling ignition

Idle speed control

Independent knocking control on cylinder-by-cylinder

basis (knock sensor KS-1);

Providing sensors with power supply: 5V/100mA

Adopting cylinder-detecting signal (Phase sensor PG1)

λclosed-loop control with self-adaptation

Controlling carbon canister control valve

Air conditioning switch

Engine-fault indicating lamp

Fuel quantitative correction

Engine speed signal output (TN signal)

Speed signal input

Failure self-diagnosis with flash code function

Accepting engine load signal

Troubleshooting: due to the fact that ECU (electric

control unit) has low failure rate, so generally it is not

advisable to replace ECU for troubleshooting on any

problem. Failure of components such as periphery

circuit and sensors shall be checked and solved firstly.

Do not replace ECU until all periphery components

are confirmed to be fault-free.

Description of pins of ECU:

Pin Connection point Type Pin Connection point Type

1 Heated oxygen sensor Output 42 A/C temperature sensor Input

2 Ignition coil 2 Output 43

3 Ignition ground wire Ground 44

4 45

5 Ignition coil 1 Output 46 Carbon canister Valve Output

Non-sustained power

supply

Non-sustained power

supply

Input

Input

E-13

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 35

6

7

8

9 50 Control of low speed fan Output

10 51 Electronic ground 2 Ground

11 52

12 Sustained power supply Input 53 Electronic ground 1 Ground

13 Ignition switch Input 54

14 The main relay Output 55

15 Engine rotary sensor A Input 56

16 Throttle position sensor Input 57 A/C compressor switch Input

17 Sensor ground 1 Ground 58

18 Oxygen sensor Input 59 Speed signal Input

19 Knock sensor A Input 60

20 Knock sensor B Input 61 Power ground 1 Ground

22 63

23 64

24 65

25 66

26 67

27

28 69 Fuel pump relay Output

29 Inspection light Output 70 A/C compressor relay Output

30 71 Diagnostic K wire I/O

31 72

32 5V power supply 2 Output 73

33 5V power supply 1 Output 74

34 Engine rotary sensor B Input 75 A/C switch Input

35 Sensor ground 3 Ground 76 Blaster switch Input

36

37

38 79 Phase angle sensor Input

39

40

41

Fuel injector 4 (the 2nd

cylinder)

Fuel injector 2 (the 3rd

cylinder)

Output of engine speed

signal

Fuel injector 1 (1

cylinder)

Sensor ground connector

2

Air intake pressure

sensor

Temperature sensor of

engine coolant

Temperature sensor of

air intake

Output 47

Output 48

Output 49

Output 68 Control of high speed fan Output

Ground 77 Headlight switch Input

Input 78

Input 80

Input 81

Fuel injector 3 (the 4th

cylinder)

Non-sustained power

supply

Phase angle sensor D of

step motor

Phase angle sensor A of

step motor

Phase angle sensor B of

step motor

Phase angle sensor C of

step motor

Power ground connector

2

Output

Input

Output

Output

Output

Output

Ground

E-14

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 36

Circuit diagram of the electrical fuel

※Electrical fuel pump

Function: Supply the fuel from the fuel tank to the

engine at required pressure and flow (vary from

individual system).

Structure and working principle: The electrical fuel

pump is comprised of direct current motor, vane pump

and end cover (integrated with non-return valve, release

valve and anti-electromagnetic interference elements).

The pump and the motor are mounted on the same shaft

and sealed in the same house. The pump and motor are

surrounded by the gasoline for cooling and lubrication.

The battery supplies power to the electrical fuel pump

through the fuel pump relay and the pump relay

switches on the circuit of the electrical fuel pump only

during start-up and operation of the engine. If the

engine stops running due to malfunction, the fuel pump

will stop operation automatically. The maximum

pressure at exit of the electrical fuel pump is

determined by the release valve within the range of

450-650 kPa. However the pressure of the whole fuel

system fluctuates along with fluctuation of the air

intake manifold pressure. The difference between the

system pressure and the air intake manifold pressure,

which normally is 350kPa, is determined by the fuel

pressure regulator.

Electrical fuel pump

Note: The temperature of fuel has a large impact on

performance of the fuel pump. When running under

high temperature for a long time, if the fuel temperature

is higher than a certain temperature, the pressure of the

fuel pump will be decreased rapidly. So please check

carefully whether the performance of the fuel pump

under high temperature is good if the engine fails to hot

start.

Pins: The electrical fuel pump has two pins connecting

to the fuel pump relay. Beside these 2 pins there are

marks of “+” and “-” on the shell of the fuel pump

respectively, which represent the positive and negative

grid.

The 70# pin of ECU controls the fuel pump relay.

E-15

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 37

Troubleshooting: The common malfunctions of the

fuel pump are representation of insufficient fuel

pressure, not pumping fuel and so on. It shall be

verified firstly in troubleshooting that the fuel pressure

is within rated range and the pipeline is leaked. In

addition both the positive and negative pressure of the

fuel tank will have impacts on the fuel system.

※Solenoid fuel injector

Function: The fuel injector supplies atomized fuel to

the engine through injecting the fuel within the required

time according to the demand from the ECU.

Structure and working principle: The ECU sends the

electrical pulse to the fuel injector coil for generate a

magnetic force. If the magnetic force is increased

enough to overcome the composite force of the release

spring pressure force, the gravity force of needle valve,

and the friction force, the needle valve will begin to

rise and the fuel injection will start. The maximum lift

range of the needle valve is no more than 0.1mm.

When the fuel injection pulse ends, the pressure force

of the release spring will make the needle valve close

again.

Notes on installation: Only the specific connector can

be used in the fixed fuel injector and shall not be

mixed.

For the convenience of installation it is recommended

that the upper O ring connected to the fuel distributor

pipe shall be coated with silica-free clean oil. Pay

attention not to make oil contaminate the inside of the

fuel injector and the injection hole.

Place the fuel injector in the fuel injector base in

vertical direction and fasten the injector on the base by

the clasp.

Note: As for the car not being used for a long time, it is

possible that such car can not start properly because the

coagulation of fuel in the fuel injector. Under such

circumstance verify carefully that the fuel injector is

coagulated.

Fault diagnosis: The electrical injection system of A15

RHD car can conduct fault diagnosis on the driving

stage of the fuel injector in stead of conducting fault

diagnosis on its self. If the driving stage of the fuel

injector is short or overloaded to the battery power

E-16

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 38

Idle actuator

with step motor

C

onnected

to the

Circuit diagram of the solenoid fuel injector

supply, short to ground or open, the malfunction flag

bit is set. The closed loop control of the oxygen sensor

and its memory precontrol are disabled, but the last

data stored in its memory is valid. After the

malfunction is fixed, the malfunction flag bit will be

reset.

Working pressure: 350 kPa

Resistance of the fuel injector: 11-16Ω

Pins: Each fuel injector has two pins. Of which the

one marked by “+” is connected to the 87# pin of

output terminal of the fuel pump relay; the other is

connected to the 27#, 6#, 7#, or 47# pin of the ECU

respectively.

Troubleshooting: The common malfunctions of the

fuel injector such as unsmooth fuel injection and

defective atomization are normally resulted due to long

term use of the engine. So the fuel injector shall be

cleaned periodically. The circuit short or open in the

internal coil of the fuel injector also will result

malfunction of the fuel injection system. Verify that the

system circuits are short or open.

87# pin of the

main relay

※ Idle actuator with step motor DLA

Function: The idle actuator with step motor is also

equipped with a bypass air intake duct. If the throttle is

closed air can enter the engine through such bypass

duct. The ECU can adjust the sectional area of the

bypass duct through this step motor, control the air

intake flow and in turn control the quantity of fuel

injection based on the air flow. The increase or

decrease of the engine rotary speed can be achieved

through increasing or decreasing the sectional area of

the bypass duct under idle speed, through which the

closed loop control of engine rotary speed under idle

speed is achieved eventually.

E-17

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 39

External appearance of

The step

motor

Circuit of the stepper of the idle

Structure and working principle: The step motor is a

micro-motor, which is comprised of steel stators

installed in a circle and a rotor. Each steel stator has a

coil. The rotor is permanent magnet and the center of

the magnet is a nut. All the coils of stators are always

on. If the current direction of any coil is changed, the

rotor will turn by an angle. If all coils of stators change

their currents directions in a proper order, a rotating

magnetic field will be generated and result in the

permanent magnet rotor rotating in designed direction.

Fault diagnosis: The ECU can detect the circuit short

and circuit open in the two coils of the idle step motor.

Upon the occurrence of such malfunction the engine

malfunction alarm light will be lit and the engine will

enter the malfunction operation mode.

Pins:

Pin A is connected to the 29# pin of ECU;

Pin B is connected to the 4# pin of ECU;

of the idle actuator

Pin C is connected to the 26# pin of ECU;

Pin D is connected to the 21# pin of ECU.

Troubleshooting: Verify that the four circuits between

the step motor and the ECU are short or open. Verify

that the step motor is jammed. Verify that there is

circuit short or circuit open inside the step motor.

※ Ignition coil ZSK-ROV

Function: The ignition coil transforms the low voltage

of the primary winding into the high voltage of the

secondary winding. The spark plug generates the spark

through discharging and ignites the combustion gas

mixed with air and fuel.

Structure and working principle: The ignition coil is

comprised of the primary winding, the secondary

winding, the iron core, the shell and so on. If the

battery voltage applies on the primary winding, the

primary winding is charged. After the ECU cut off the

circuit of the primary winding the charging will be

stopped and the high voltage will be inducted in the

secondary winding.

Fault diagnosis: Because the ECU is not able to

conduct diagnosing for the ignition coil, there is no

diagnostic trouble code for the malfunction of the

ignition coil. Whether the ignition coil functions

properly can be judged only by inspecting the ignition

E-18

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 40

Circuit diagram of the igni

tion coil

87# main relay

coil resistance. The ignition coil produces quite a lot

heat under normal operation and the over temperature

of ignition coil will result in such malfunctions as

increase of the ignition coil’ s resistance, unstable

operation of the engine and engine stall.

Primary winding: 0.47 ohms

Secondary winding: 8 ohms

Pins:

1# pin of the primary winding is connected to the 5#

pin of ECU;

2# pin of the primary winding is connected to the 2#

pin of ECU;

3# and 4# pins are jointly connected to the positive grid

of power supply.

High voltage side: 1#, 2#, 3# and 4# pins are

connected respectively to the spark plug of the cylinder

with the same number through the distributor circuit.

Troubleshooting: Verify that there is circuit short or

circuit open in the coils.

Ignition coil with double spark

Verify that there is electrical leakage and crack on the

shell.

Verify that the electricity for ignition is not sufficient

due to coil ageing.

※Carbon canister control valve

Function: It is used to control the purge airflow of the

carbon canister. The carbon canister control valve is

controlled by the ECU through the pulse length and

frequency (i.e. duty ratio) based on the engine load.

The excessive accumulation of fuel vapor in the carbon

canister will result in fuel spill and environment

pollution, so the function of the solenoid valve of the

carbon canister is to open the valve at an appropriate

time so that the excessive fuel vapor can enter the air

intake pipe and participate in the combustion.

Structure and working principle: The carbon canister

is comprised of magnetic coil, armature, valve and

other elements. There is a filter screen at its inlet. The

airflow passing the carbon canister control valve is not

only relative to the duty ratio of the pulse which is sent

by the ECU to the carbon canister control valve, but

also relative to the pressure difference between the exit

and inlet of the carbon canister control valve. If there is

no pulse, the carbon canister control valve is closed.

E-19

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 41

Carbon canister control valve

Circuit diagram of the solenoid valve

of the charcoal canister

TEV

-2

The ECU can indirectly control the purge airflow

through controlling the charging time of the carbon

canister solenoid valve based on the signals provided

by various sensors of the engine.

Fault diagnosis: The ECU doesn’t have the function of

self-diagnosis for the carbon canister control valve, but

has the function of self-diagnosis for the driving stage

of control valve of carbon canister. If the driving state

of the control valve of carbon canister is short or

overloaded to the battery voltage, short to ground or

open, the basic memory of the closed loop control of

fuel quantity will be closed, the memory of idling air

demand quantity will be closed and the memory data at

that time is valid. The common malfunctions of engine

are unstable idling or excessive high idle speed under

the malfunction of the solenoid valve of carbon

canister.

Carbon canister control valve

Pins:

1# pin is connected to the 87# pin on output terminal of

the main relay;

2# pin is connected to the 46# pin of ECU.

Troubleshooting: The blockage and crack of the

carbon canister will result in the increase of air intake.

※ Steel fuel distribution pipe assembly

Function: Store and distribute the fuel and provide a

relative stable pressure for the fuel injection system so

as to achieve the uniform fuel supply pressure and

quantity for each cylinder and stable operation of

engine.

Structure: The fuel distribution pipe assembly is

comprised of fuel distribution pipe (KVS-S) and fuel

injector (EV).

Installation requirement: The connection of fuel pipe

and rubber hose shall be fastened by clamp. The model

of the selected clamp shall match to the rubber hose to

ensure the seal connection between the fuel pipe and

the rubber hose.

Fault diagnosis: There is seldom possibility for the

malfunction occurrence in the main fuel supply pipe.

Most of the malfunctions, which result in the leakage of

the fuel system, are caused by poor assembly, so proper

note shall be paid during installation that any used

O-oil seal shall not be used again and appropriate

lubricant is allowed to be painted during assembly.

E-20

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 42

BASIC PRINCIPLE OF FAULT DIAGNOSIS FOR ELECTRONIC

FUEL INJECTION SYSTEM

·RECORD OF MALFUNCTION INFORMATION

The electronic control unit consistently monitors the operations of sensors, actuators,

related circuits, malfunction alarm lights, voltage of battery and so on, even the

operation of the electronic control unit itself, as well as carries out the examination on

reliabilities of the signals output by the sensors, driving signals of actuators, and

internal signals (such as oxygen closed loop control, knock control, idle speed control,

battery voltage control and etc.). Once it is found that there is a malfunction in some

chain or some signal is not reliable, the electronic control unit will set the record of

malfunction information in the RAM of malfunction memory. The record of

malfunction information is stored as diagnostic trouble code and displayed in the

same order as the occurrence of the malfunctions.

Based on their frequency of occurrence, the malfunctions can be classified as “steady

state malfunction” and “random malfunction” (such as the malfunctions caused by

temporary circuit open of wiring harness or defective contact of connectors).

·MALFUNCTION STATUS

If the duration period of the identified malfunction exceeds its setting stabilizing time

at the first time, ECU will regard this malfunction as a stable malfunction and store it

in the memory of “steady state malfunctions”. If the malfunction disappears within its

setting stabilizing time, it will be stored as “random malfunction” or “non existence”.

If this malfunction is identified again, it will still be regarded as “random

malfunction”, but the “existence” of historic malfunction will not influence normal

operation of the engine.

·MALFUNCTION TYPES

Short to positive grid of power supply;

Short to ground;

Circuit open (if there is pull up resistance or pull down resistance in input stage, the

ECU will regard the malfunction of circuit open on input terminal as the malfunction

that the input terminal is short to power supply or to ground.);

Unreliable signals.

·FOUR TYPES OF MALFUNCTIONS

Maximum malfunction, the signal exceeds the upper limit of the rated range.

Minimum malfunction, the signal exceeds the lower limit of the rated range.

Signal malfunction, no signal.

E-21

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 43

Illogical malfunction, there is signal but the signal is not logical.

·LIMP DRIVE

If some detected important malfunctions last longer than the setting stabilizing time,

ECU will take proper software measures, for example, disable some control functions

including the oxygen sensor closed loop control and the like, replace some unreliable

data with the setting values and etc.. Therefore even the working condition of the

engine is quite bad at that time, but the car still can be driven. The objective of such

measures is to drive home or drive to service station limpingly so as to avoid the

embarrassment that the car has to be broken down on highway or in field. As soon as

the detected malfunction disappears, the normal data will be reused.

·MALFUNCTION ALARM

Some cars equipped with M7.9.7 system have the malfunction alarm light. If some

important components such as ECU, the air intake manifold absolute pressure sensor,

the throttle position sensor, the coolant temperature sensor, the knock sensor, the

oxygen sensor, the phase angle sensor, the fuel injector, two drive stages of idle

actuator with step motor, the carbon canister control valve, the cooling fan relay have

malfunctions, when the corresponding malfunction flag bit is set, ECU will send

alarm through the malfunction alarm light until this malfunction flag bit is reset.

·MALFUNCTION READOUT

The malfunction information record can be called from the electronic control unit

through the diagnostic tester, or be read through the flashing code. If the malfunction

is related to the function of fuel air mixing ratio regulator, the corresponding

malfunction information record can be read at least 4 minutes after the engine starts

running.

ISO 9141-2 Standard diagnostic connector

Connection to the diagnostic tester

This system adopts the “K” line communication protocol, and utilizes the ISO 9141-2

standard diagnostic connector (shown in the above figure). This standard diagnostic

connector is fixed on the wiring harness of the engine. The 4#, 7#, and 16# pins of the

standard connector are connected to the engine management system (EMS), the 4#

pin is connected to the ground wire of the car, the 7# pin is connected to the 71# pin

of ECU (i.e. the “K” line of engine data), the 16# pin is connected to the positive grid

of the battery.

E-22

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 44

The detailed procedures are:

Turn on the ignition switch, but not start up the engine, ground the 7# pin of ECU by

K wire for more than 2.5 seconds, then open the ground connection, after that the

coding light starts flashing.

After the K wire is grounded for more than 2.5 seconds the output of flashing code is

the value of P-CODE. For example, the flashing method of P0203 is: consecutive

flashes of 10 times-pause-consecutive flashes of 2 times-pause,-consecutive flashes of

10 times-pause-consecutive flashes of 3 times.

·CLEARING MALFUNCTION INFORMATION RECORD

After the malfunction is fixed, the malfunction information record in the memory

shall be cleared. Such malfunction information, which appeared at the time of ignition

but failed to be maintained to the end of stabilizing period, will not be recorded. If the

value Hz of frequency counter reaches 0, the malfunction information records in the

malfunction memory will be cleared automatically. The malfunction information

record will be cleared upon the demand of “clearing the malfunction memory”

through the diagnostic tester. The malfunction information records in the external

RAM can be cleared by disconnecting the connector of ECU or removing the wire of

the battery.

·TROUBLESHOOTING:

WE ONLY CAN KNOW THE ROUGH POSITion of the malfunction whose

malfunction information record is obtained through the above measures, and it doesn’t

mean that we have found out that malfunction exactly. Because any malfunction is

possibly caused by the damage of electric components (such as sensors, actuators or

ECU and the like), the circuit open, or the circuit short to ground or positive stud of

battery, even the mechanical malfunctions.

The malfunction is intrinsic and its appearance is various symptoms. After the

symptom is detected the diagnostic tester or the flashing code shall be used to search

the malfunction information record, and excluding corresponding malfunction based

on the malfunction information. And then carry out the troubleshooting based on the

symptom of the engine.

E-23

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 45

DETAILED TABLE OF DIAGNOSTIC TROUBLE CODES

Diagnostic trouble code: P0107 “Undervoltage in circuit of air intake pressure

sensor”

Item

No.

1

2

3

5

6

Operation procedure

Connect the diagnostic tester and adaptor,

and turn the ignition switch to “ON”

position.

Observe the “air intake pressure” in data

flow and verify that it is maintained at

101kPa (the exact value is determined by

the atmospheric pressure at that time).

Disconnect the connector of the air intake

pressure sensor on the wiring harness and

inspect with multimeter to verify that the

voltage between the 3# and 1# pins of the

connector is about 5V.

Verify that the circuits between the 17#,

33# and 37# pins of ECU and the 1#, 3#,

and 4# pins of the sensor connector are

short to ground.

Start up the engine, run at idle speed. Step

on the accelerator pedal slowly until the

nearly full opening, observe the “air intake

pressure” displayed on the diagnostic

tester and verify that the value is stable

without significant change; if step on the

accelerator pedal quickly until nearly full

opening, whether the value exceeds 90kPa

instantaneously.

Start up the engine, run at idle speed.

Observe the value of “Coolant

temperature” on the diagnostic tester to

verify that the indicated value is increased

along with the temperature increase of the

engine coolant.

Inspection

results

Follow-up

procedure

Proceed to next

step.

Yes Proceed to Step 5

No

Proceed to next

step.

Yes Proceed to Step 5

No

Proceed to next

step.

Repair or replace

Yes

the wiring

harness. 4

No

Yes

No

Yes

No

Proceed to next

step.

Refer to diagnosis

help.

Replace the

sensor.

Refer to diagnosis

help.

Replace the

sensor.

E-24

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 46

Diagnostic trouble code: P0118“Over temperature indicated by engine coolant

temperature sensor”

Item

No.

1

2

3

4

5

6

Operation procedure

Connect the diagnostic tester and

adaptor, and turn the ignition switch to

“ON” position.

Observe the “coolant temperature” in

data flow to verify that it matches to the

engine temperature (the exact value is

determined by the engine temperature at

that time).

Note: If the indicated value is

maintained at -40 at that time, there ℃

may be some open malfunction occurs

in the circuit.

Disconnect the connector of the coolant

temperature sensor on the wiring

harness, inspect with multimeter to

verify that the resistance between 1#

and 2# pins of the sensor matches to the

temperature (see the related part of this

maintenance manual for reference).

Disconnect the connector of the coolant

temperature sensor on the wiring

harness, inspect with multimeter to

verify that the voltage between 1# and

2# pins of this connector is about 5V.

Check whether the circuits between 39#

and 35# pins of ECU and the 1# and 2#

pins of the sensor connector are short to

ground.

Start up the engine, run at idle speed.

Observe the value of “Coolant

temperature” on the diagnostic tester to

verify that the indicated value is

increased along with the temperature

increase of the engine coolant.

Inspection

results

Follow-up procedure

Proceed to next step.

Yes Proceed to Step 6

No Proceed to next step.

Yes Proceed to next step.

No Replace the sensor.

Yes Proceed to Step 6

No Proceed to next step.

Yes

Repair or replace the

wiring harness.

No Proceed to next step.

Yes

Refer to diagnosis

help.

No Replace the sensor.

E-25

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 47

Diagnostic trouble code: P0122 “Undervoltage in circuit for throttle position

sensor”

Item

No.

1

2

3

4

5

6

Operation procedure

Connect the diagnostic tester and adaptor,

and turn the ignition switch to “ON”

position.

Observe the item of “throttle absolute

opening” in the data flow to verify that the

value is maintained within 4%-10% (the

exact value varies from individual auto

model.)