Page 1

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

1

MECHANISM OF 2.0NA ENGINE

CONTENT

CHAPTER 1 ENGINE PARAMETER AND SPECIAL MAINTENANCE TOOLS....2

SECTION 1 TECHNOLOGY DATA INSTRUCTION................................................2

SECTION 2 SPECIAL TOOLS...................................................................................5

SECTION 3 ENGINE NUMBER POSITION.............................................................6

SECTION 4 COLLATING METHOD OF ENGINE TIMING.....................................7

CHAPTER 2 ENGINE BODY........................................................................................9

SECTION 1 WHEEL TRAIN......................................................................................9

SECTION 2 CYLINDER HEAD..............................................................................14

SECTION 3 SHORT ENGINE..................................................................................26

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 2

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

2

CHAPTER 1 ENGINE PARAMETER AND SPECIAL MAINTENANCE TOOLS

SECTION 1 TECHNOLOGY DATA INSTRUCTION

ENGINE CHARACTER

Engine Model SQR481H

Engine Type

4-Cylinder, Water Cooled, In-line Double

Overhead Camshaft, 16 Valve,

Controllable Burning Rate, Variable Valve

Timing

Cylinder Diameter(mm) 83.5

Piston Stroke (mm) 90

Displacement (L) 1.971

Compression Ratio 10

Rated Power(Kw) 95

Rev at Rated Power(r/min) 5500

Max. Torque(N●M) 180

Rev at Max. Torque(r/mim) 4000

Minimum Fuel Consumption Rate(g/Kw.h)

301

Cylinder Pressure(Bar) 10±0.2

Fuel Pressure(Bar) 4

Low Idle Speed

(800±50r/min)

High Idle Speed

(2000r/min)

Engine Oil

Pressure(Bar)

High Speed

(4000r/min)

High Pressure Circuit 2--3

A/C Circuit

Pressure(Bar)

Low Pressure Circuit 12---16

Pressure Relief Valve

(Release Pressure to

Outside)

88±14.5

Expansion Tank

Cap(kpa)

Vacuum Valve(Lead Air

into Tank)

-10~~~~-2

Start Working

Temperature

87 Thermostat

Working

Temperature(℃)

Full Working

Temperature

104

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 3

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

3

TECHNOLOGY DATA INSTRUCTION

Item Standard Value

Intake cam 37.15

Cam Height

Exhaust cam 37.05

Intake cam

Camshaft Diameter

Exhaust cam

Intake cam 0.15--0.20

Camshaft

Axial clearance of Camshaft

Exhaust cam 0.15--0.20

Plane Degree of Lower Surface 0.04

Whole Height 140±0.41

Cylinder

Head

Surface Grind Limit* Total Grinding Quantity of

Cylinder Block and Head

Intake Valve 0.3±0.15

Fringe Thickness on Top of Valve

Exhaust Valve 0.3±0.15

Intake Valve 5.98±0.008

Valve Stem Diameter

Exhaust Valve 5.96±0.008

Intake Valve

Seal Bandwidth

Exhaust Valve

Intake Valve 0.02

Gap Between Valve Stem And Guide

Exhaust Valve 0.04

Intake Valve 65°

Tilt Angle

Exhaust Valve 68°

Intake Valve 107.998

Valve

Height

Exhaust Valve 106.318

Free Height 47.7

Working Tension in Advance/ Working Height Kg /mm

620N/32mm

Valve

Spring

Vertical Degree

Valve Guide Length 38±0.25

Valve

Guide

Inside Diameter 5.4±0.1

24

040.0

053.0−−

24

040.0

053.0−−

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 4

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

4

Outer Diameter

Pressure Height 16±0.3

Protruding Part of Valve Stem 47.5

Piston Piston Skirt Diameter 83.46±0.009

1st Ring 0.04--0.08

Side Clearance

2

n

d

Ring

0.01--0.025

1st Ring

0.2--0.4

End Play

2nd Ring

0.4--0.6

1st Ring

2nd Ring

Piston

Ring

Height

Oil Ring

1st Ring

2nd Ring

Ring

Groove

Height/ Depth

Oil Ring

2.5

Diameter

Length 60

Piston Pin

Diameter of Piston Pin Hole

Axial Clearance 0.076--0.265

Radical Clearance -0.0375

Coaxial Degree 0.05

Cylindricity 0.008

Crankshaft Mainshaft Diameter

Roundness

0.005

Cylindricity

Crankshaft

Connecting Rod Journal Diameter

Roundness

Whole Height 218±0.05

Cylinder Hole Roundness / Straightness Accuracy 0.008 / 0.01

Cylinder

Upper Surface Planeness 0.04

Radial Clearance of Connecting Rod Bearing 0.016--0.051

Connectin

g Rod

Axial Clearance of Big End 0.15--0.4

11

051.0

040.0++

2.1

05.0

03.0++

5.1

04.0

02.0++

5.2

03.0

01.0++

21

0

005.0−

21

008.0

002.0

2.1

01.0

03.0−−

5.1

005.0

030.0−−

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 5

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

5

SECTION 2 SPECIAL TOOLS

Camshaft Timing Tool

Crankshaft Timing Tool

Flywheel Tool

Guide Sleeve of Crankshaft Oil

Seal

Guide Sleeve of Camshaft Oil

Seal

Hydraulic Hoist

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 6

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

6

Fuel Pressure Gauge

Cylinder Pressure Gauge: when measure the cylinder

pressure, firstly remove the spark plug, screw the pipe

end of instrument instead of it, and operate the engine by

starter, then take the maximum value in cylinder pressure

gauge as cylinder pressure.

SECTION 3 ENGINE NUMBER POSITION

Position of Engine Cylinder Block Number

Engine Oil Dipstick

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 7

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

7

SECTION 4 COLLATING METHOD OF ENGINE TIMING

1. Remove the upper cover of engine timing

belt.

2. Remove the lower cover of engine timing

belt.

3. Loosen the central bolt of timing belt

tension pulley and remove the timing

belt.

4. Draw out the high voltage ignition cable.

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 8

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

8

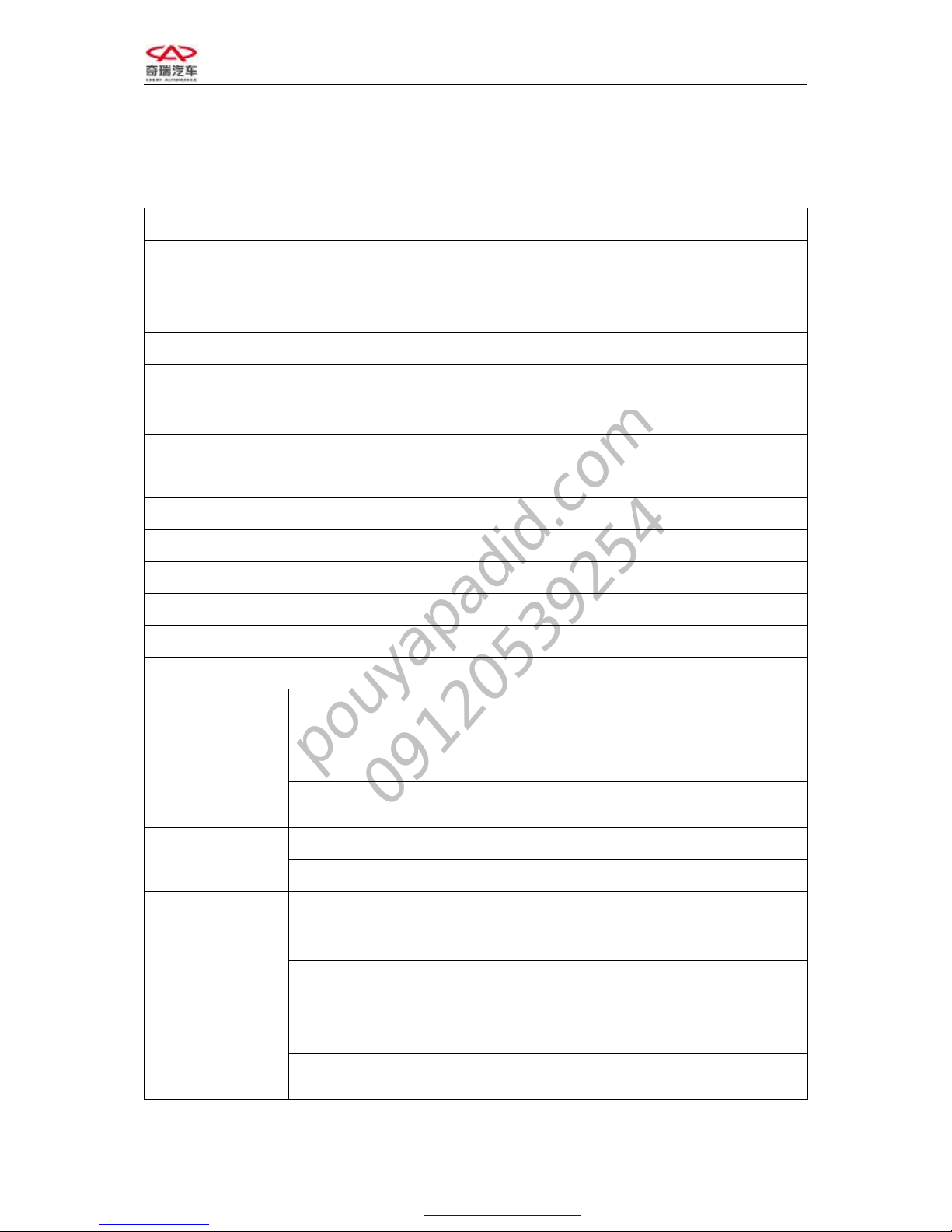

5. Loosen the bolt of valve cover and

remove the valve cover.

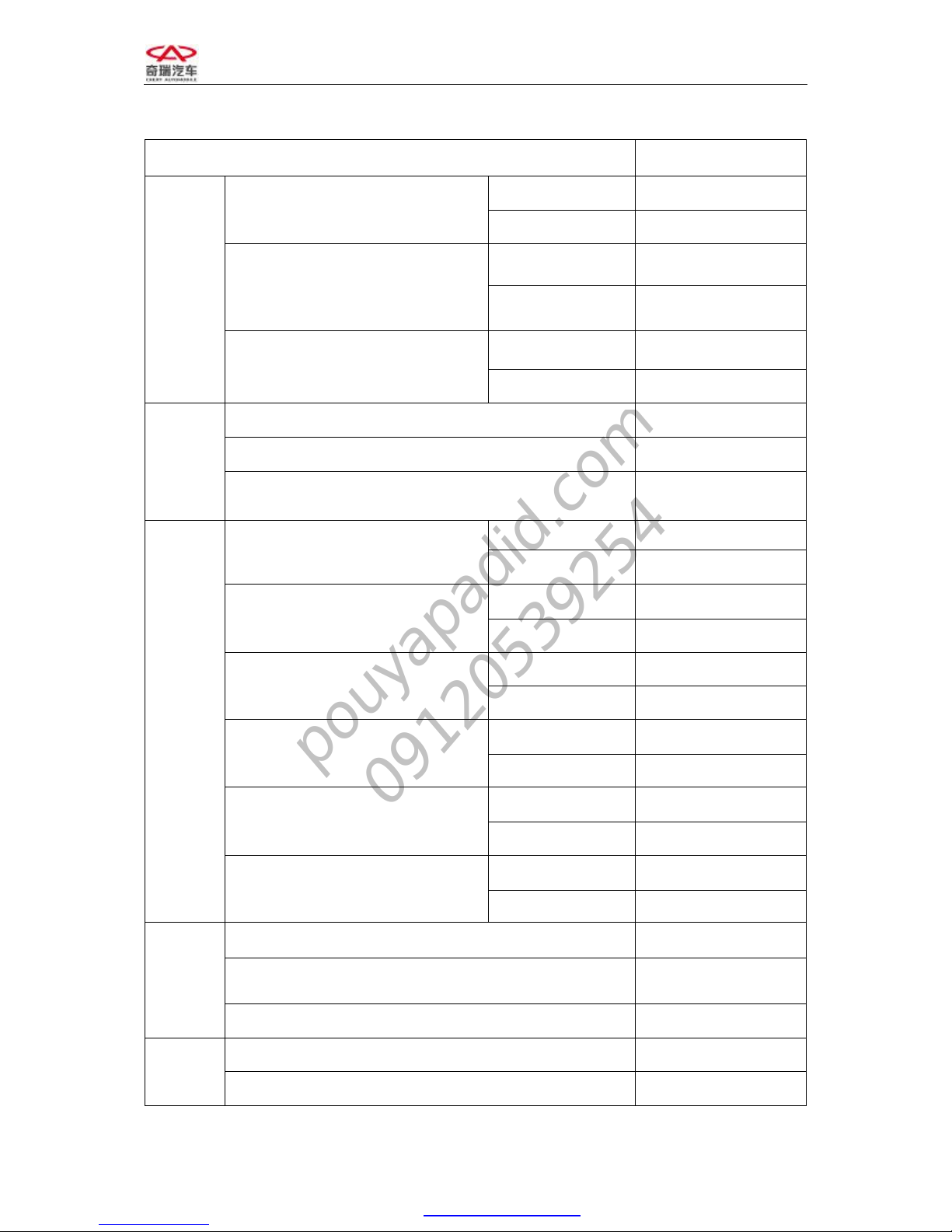

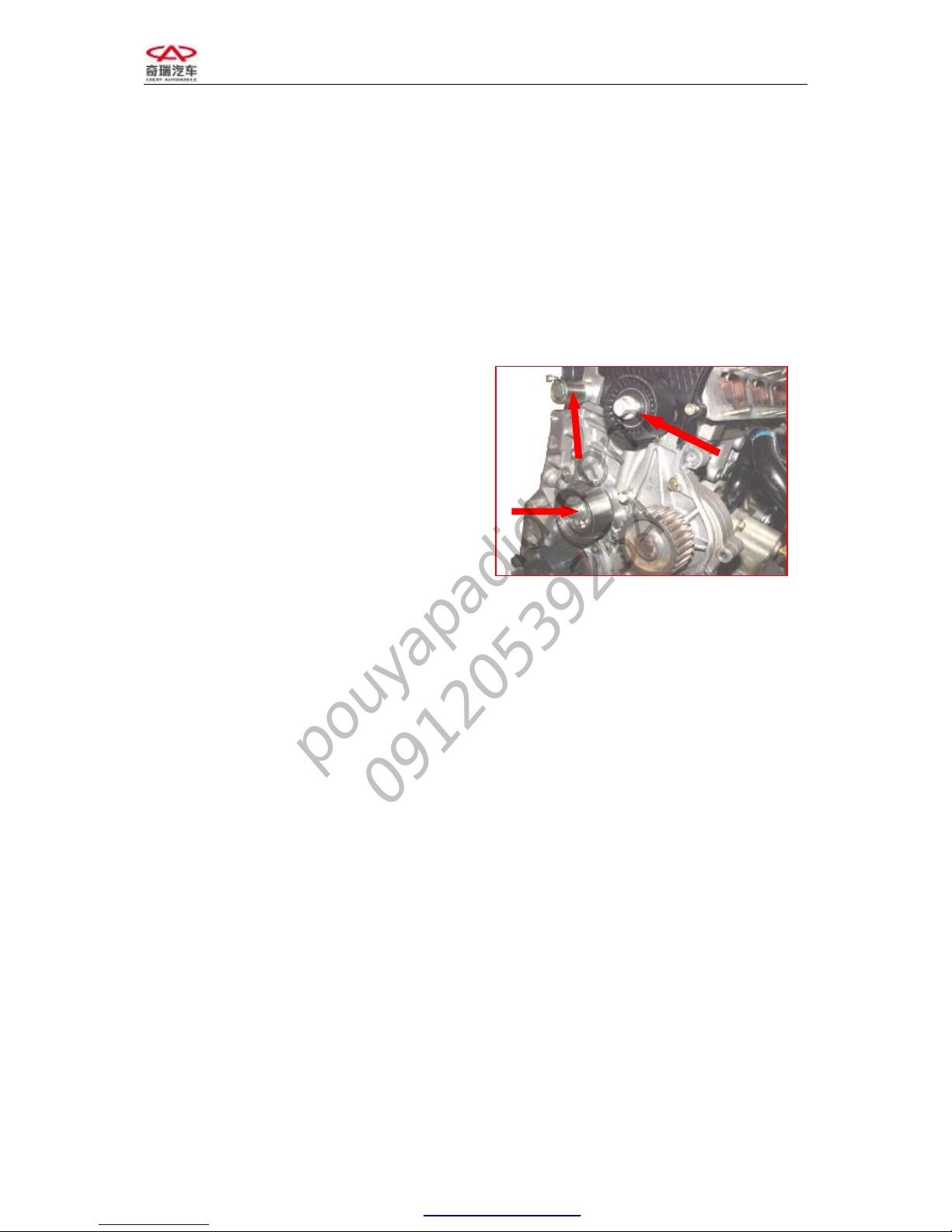

6. Rotate the camshaft in order to clip the

camshaft tool into the slot at the end of

camshaft.

7. Loosen the bolts of air intake and exhaust

camshaft tension pulleys with torque

wrench.

Note: It is not to remove but loosen.

8. Revolving the crankshaft, you may rotate

in the crankshaft tool so as to it cannot

move in both direction.

Note: Do it with patience and carefulness lest

the crankshaft should be broken.

Camshaft Tool

Crankshaft Tool

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 9

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

9

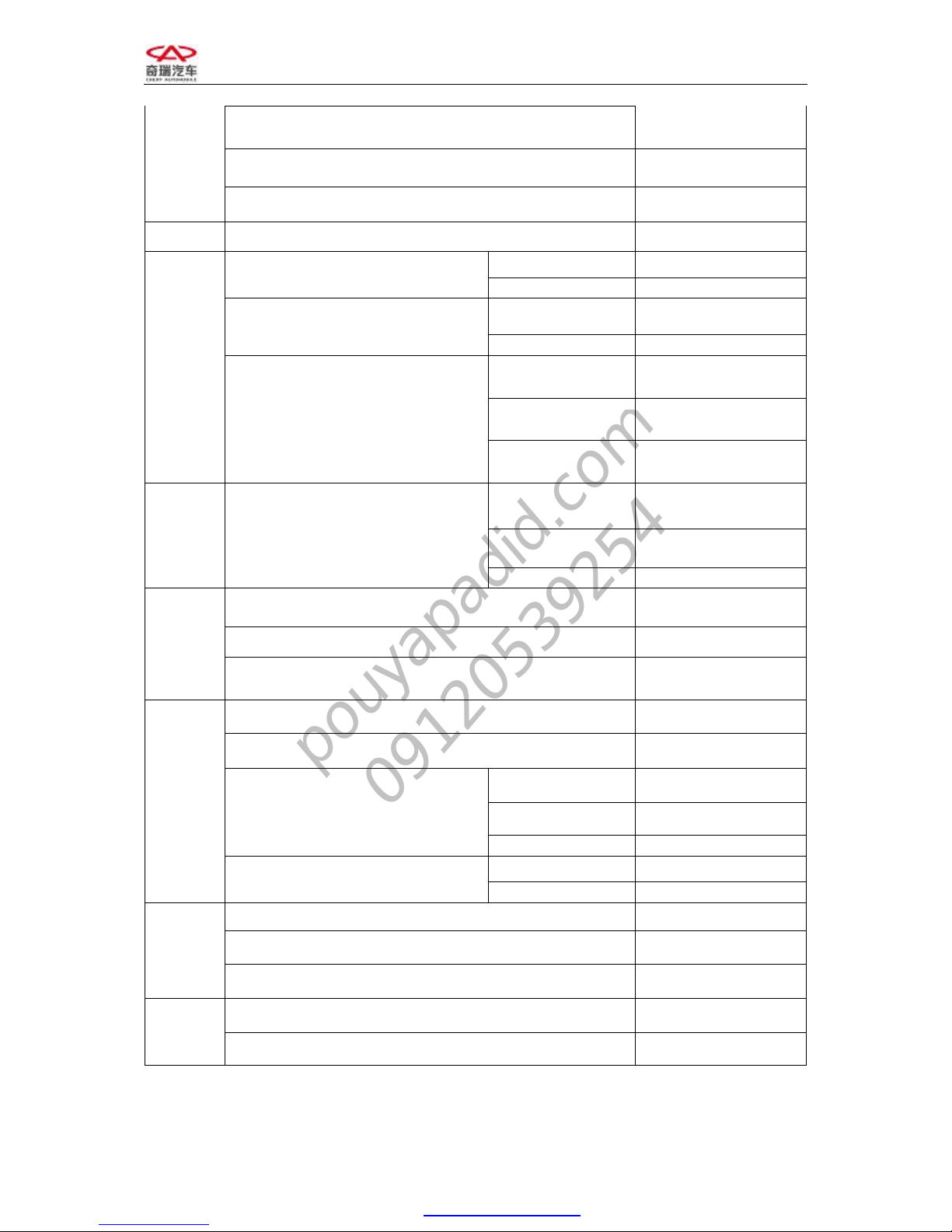

9. Mount the timing belt and rotate tension

pulley with Allen wrench in order to

tension the belt and make the finger of

tensioner point to the middle of U slot

opening. Fasten the bolt of tension pulley,

the fastening bolts of air intake and

exhaust camshaft tension pulleys and

camshaft.

Torque: 120±5Nm.

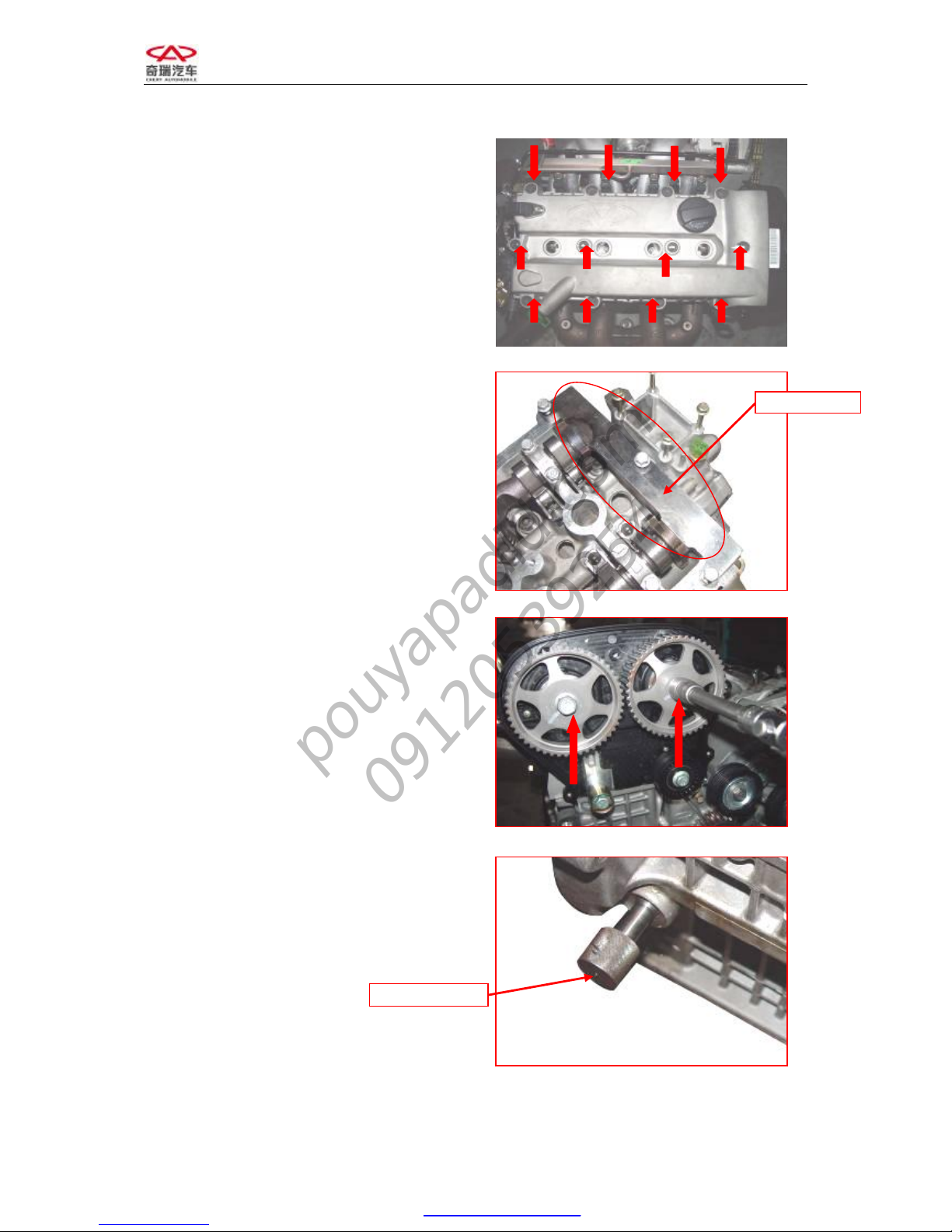

10. Remove the special timing tool, and

mount the valve cover, the high voltage

ignition cable and the timing belt cover.

CHAPTER 2 ENGINE BODY

SECTION 1 WHEEL TRAIN

I. STRUCTURAL DIAGRAM

Part Name Torque value Nm Re-screw angle

1

Bolt– Lower Part Of Timing

Front Cover

8+3

2

Bolt– Upper Part Of Timing Front

Cover

8+3

3

Bolt– Upper Part Of Timing Front

Cover

8+3

4

Lower Part Of Timing Front

Cover

5

Upper Part Of Timing Front

Cover

6

Washer- Lower Part Of Timing

Front Cover

7 Bolt- Crankshaft Timing Gear 130+10 65+5

8 Washer- Crankshaft Timing Gear

9 Crankshaft Timing Gear

10 Timing Belt

11 Water Pump

12 Bolt- Timing Gear Rear Cover 5+1.5

13 Timing Gear Rear Cover

14 Camshaft Timing Gear

15 Bolt- Camshaft Timing Gear 120+5

16 Bolt- Timing Tensioner 27+2.7

17 Timing Tensioner

18 Bolt- Timing Idler wheel 40+5

19 Timing Idler wheel

20 Contact Idler wheel

21 Bolt- Contact Idler wheel 40+5

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 10

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

10

II. MAINTENANCE

1. Replace upper and lower covers of timing

belt

1.1 Needed tools and auxiliary materials

Allen wrench, 10#, 13# sleeve, ratchet wheel

and ratchet rod.

1.2 Removal

1) Loosen the five bolts on the upper cover

with Allen wrench.

2) Remove the upper cover of timing belt.

3) Clip the flywheel with flywheel tool.

4) Remove the crankshaft pulley with 13#

sleeve.

Flywheel Tool

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 11

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

11

5) Remove the 5 bolts on the lower cover

of timing belt with 10# sleeve, ratchet

wheel and ratchet rod.

6) Remove the lower cover.

1.3 Inspection

Observe the timing cover and the timing belt.

Replace the timing belt cover or adjust the

position of timing belt if any trail from crack

or friction is found.

1.4 Installation

The installing steps are reverse to those for

removal.

Note: Install the lower cover first and then

install the upper one.

2. Replace timing belt

2.1 Needed tools and auxiliary materials

Allen wrench, 10#, 13# sleeve, ratchet wheel

and ratchet rod.

2.2 Removal

1) Remove the upper and lower covers of

timing belt (see “replace covers of

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 12

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

12

timing belt” for details).

2) Loosen the central bolt of tension pulley

and remove the timing belt.

2.3 Inspection

Check the timing belt carefully; replace the

parts if any following situation occurs.

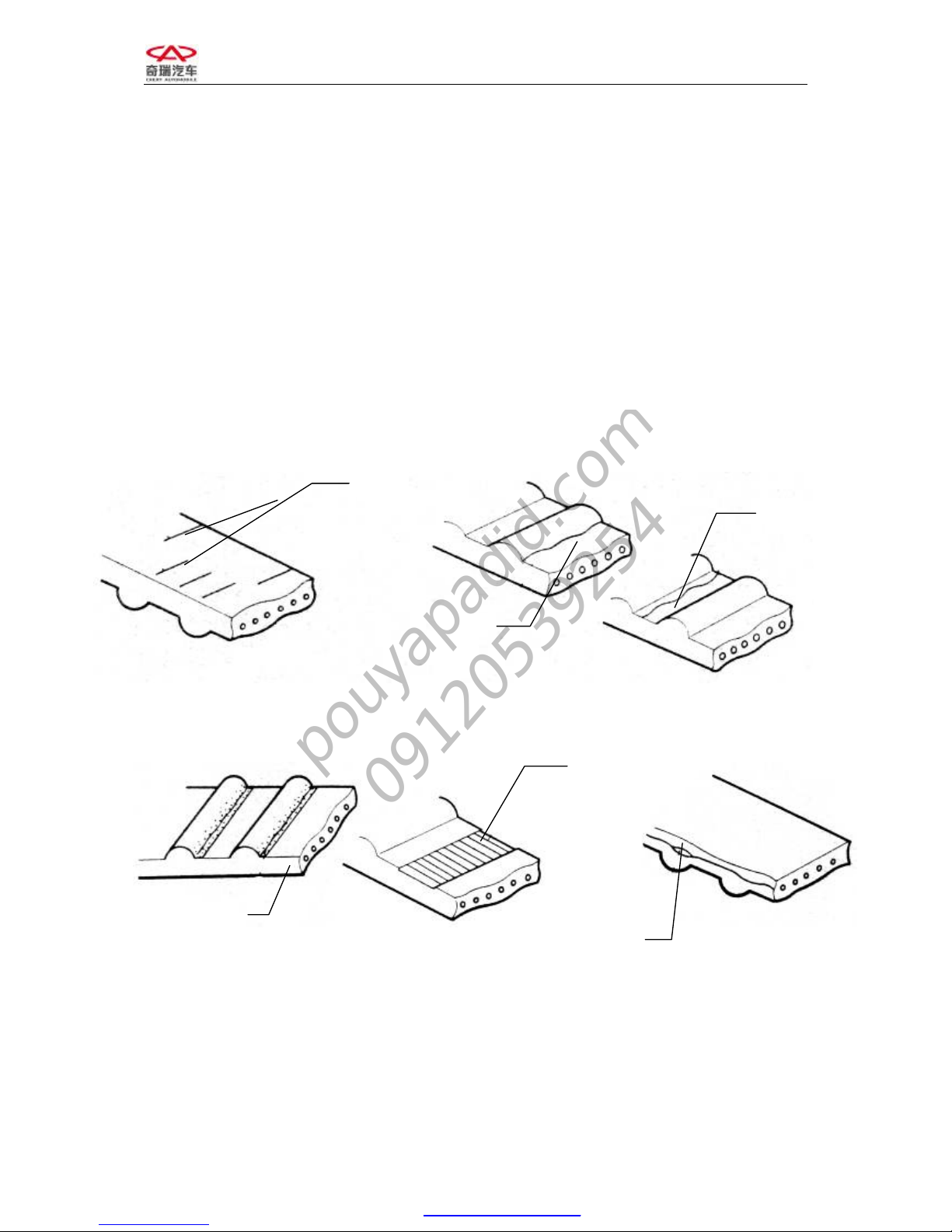

(1) Chap of back-side rubber

(2) Chap of dedendum, chap of separated

cord fabric.

(3) Wearing, gear missing and incomplete

gear of cord fabric.

(4) Abnormal wearing of belt flank.

Replace the belt as any following situation occurs, even though abrasion cannot be found

directly.

1) The water pump leaks water out, and requires continuing infusion.

2) If the belt is spotted with much oil stains, and the rubber may be damaged due to

expansion, you should replace the belt.

Chap

Chap

Wearing

Abnormal Wearing

Gear Missing

Belt Core Desquamation

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 13

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

13

2.4 Installation

The installing steps are reverse to those for

removal.

Note: Do engine timing.

3. Replace idler wheel, tensioner and

contact belt pulley

3.1 Needed tools and auxiliary materials

Allen wrench, 10#, 13# and 15# sleeve,

ratchet wheel and ratchet rod.

3.2 Removal

1) Remove the timing belt (see “replace

timing belt” for details).

2) Remove idler wheel, tension pulley and

contact belt pulley.

3.3 Inspection

1) Check from appearance

Check idler wheel, tension pulley and contact

belt pulley carefully for any damages, such as

sunken trace and sliding damage etc.

2) Check performance

Revolve tension pulley, idler wheel and

contact belt pulley respectively to insure that

they can run freely without stagnancy.

Replace it with the spare part if any above

problem is found.

3.4 Installation

1) The installing steps of tension pulley,

idler wheel and contact belt pulley are

reverse to those for removal.

2) Mount the timing belt and collate engine

timing.

3) Mount other parts.

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 14

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

14

SECTION 2 CYLINDER HEAD

I. STRUCTURAL DIAGRAM

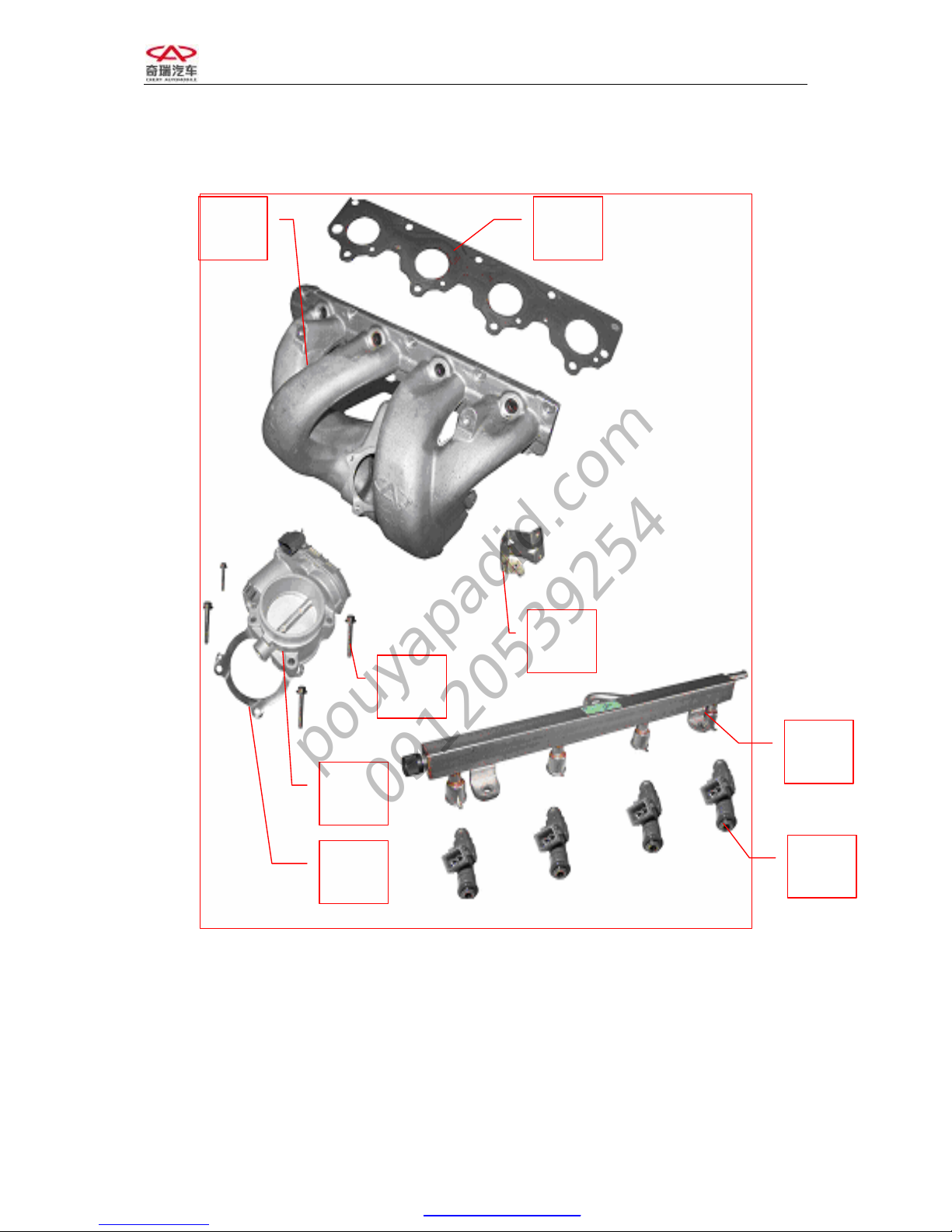

1. Gasket—Intake Manifold

2. Intake Manifold Assembly

3. Hexagonal Flange Bolt

4. Throttle Valve Body Assembly

5. Gasket—Throttle Valve Body Assembly

6. Oil injector Assembly

7. Fuel Distribution Pipe Assembly

8. Bracket

4

7

6

2 1

3

5

8

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 15

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

15

1. Intake Valve

2. Valve Oil Seal

3. Valve Spring Seat

4. Valve Spring

5. Valve Spring Retainer

6. Keeper

7. Exhaust Valve

8. Intake Camshaft Assembly

9. Bearing Cap Assembly

10. Control Valve-Camshaft Phaser Assembly

11. First Bearing Cap Assembly

12. Front Camshaft Oil Seal

13. Exhaust Camshaft Assembly

14. Rocker Arm Assembly

15. Hydraulic Tappet Assembly

16. Stud Bolt (9 Bars)

17. Cylinder Head Gasket

18. Temperature Sensor

19. Engine Hanger

20. Cylinder Head Bolt

21. Cylinder Head Assembly

11

15

14

13

8 9 10

17

7

18

1

5

4

3

2

6

12

16

19

20

21

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 16

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

16

II. MAINTENANCE

2.1 Replace intake manifold, delivery pipe

and oil injector

2.1.1 Needed tools and auxiliary materials

Ratchet wheel, ratchet rod, 10# sleeve and

crosshead screwdriver

2.1.2 Process of removal

1) Put the ignition key at the OFF position.

2) Loosen the plug of oil injector.

3) Remove the connecting bolt between

engine oil dipstick and intake manifold.

4) Remove the clamp between intake hose

and throttle valve body.

5) Remove the connecting bolt of throttle

valve body, and take out throttle valve

body.

Note: Because this throttle valve body is

electronic, do not force the middle vanes

turning manually or with other objects.

6) Loosen the joint of oil intake pipe.

7) Remove the fastening nut of intake

manifold and take out the intake

manifold.

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 17

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

17

2.1.3 Installation steps

The installing steps are reverse to those for

removal.

2.2 Replace camshaft, bearing bushings,

valve and valve oil seal.

2.2.1 Needed tools and auxiliary materials

Special tools for valve oil seal, engine

transmission oil, a set of sleeve tools, an

adjustable spanner, special tools for timing

and a set of Allen wrenches

2.2.2 Removal

1) Remove the dynamo belt (see “removal

of dynamo belt” for details).

2) Remove the timing belt (see

“replacement of engine timing belt and

timing calibration” for details).

3) Remove the cover of engine valve

chamber.

4) Clamp the timing special tool into

camshaft slot and fasten the bolt.

Camshaft Tool

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 18

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

18

5) Dismantle the belt pulley of air intake

and exhaust camshafts with torque

wrench.

6) Remove the back cover of timing belt.

7) Dismantle the bearing caps of air intake

and exhaust camshaft respectively and

put them down in the sequence.

Note: The second, third, fourth and fifth

camshaft bearing caps are marked with I1, I2,

I3, I4 (E1, E2, E3, E4), which stands for the

corresponding bearing cap of 1, 2, 3, 4

cylinder respectively. (“I” refers to intake

camshaft, “E” refers to exhaust camshaft).

Torque:

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 19

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

19

See the following picture for removal sequence of intake and exhaust camshaft-bearing caps:

8) Take out the camshaft and the hydraulic tappet.

9) Remove the valve spring with special tools. (Picture is unavailable)

10) Remove the used valve oil seal with special tools. (Picture is unavailable)

2.2.3 Inspection

1) Check the valve spring.

Measure the free length, the verticality and

the length under special pressure with caliper.

Standard

Value(mm)

Free length 47.7

Length of

620N

32

Replace with the new valve spring if the

measured value exceeds the limit value.

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 20

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

20

2) Check camshaft

Measure the camshaft diameter with

micrometer caliper.

Standard Value

(mm)

Limit Value

(mm)

Diameter ¢24

-0.053

-0.040

Replace with the new camshaft if the

measured value exceeds the limit value.

3) Examine camshaft

Measure the high of cam with micrometer

caliper.

Standard Value

(mm)

limit value

(mm)

Intake

Cam

37.15

Exhaust

Cam

37.05

Replace with the new camshaft if the

measured value exceeds the limit value.

4) Examine diameter of valve stem

a: Measure the diameter of valve stem with

micrometer caliper.

See the picture for measuring points: they are

26, 52, and 78 mm from measure positions to

bottom of valve.

Valve

Guide

External Diameter

Of Valve Stem

Internal Diameter

Of Valve Guide

Measuring Point

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 21

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

21

b: Use internal micrometer guage to

measure the internal diameter of valve

guide and the measuring point is a

quartering point of guide.

c: Calculate the difference of measured

value and the clearance.

Replace the valve or the guide if the value

exceeds the limit value.

d: Examine the contact bandwidth of

valve.

e: Check the valve seat insert.

Standard

Value

IN ¢5.98±0.008

Outer Diameter

of Valve stem

(mm)

EX ¢5.96±0.008

IN

¢5.4±0.1 Inner Diameter

of Valve guide

(mm)

EX ¢5.4±0.1

IN

0.02 Clearance

(mm)

EX

0.04

IN

0.3±0.15

Thickness of

Valve Top

(mm)

EX

0.3±0.15

IN

1.158 Seal Bandwidth

(mm)

EX

1.306

Measuring Point

Contact Position (Should be

the Center of Slope)

Edge

Thickness

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 22

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

22

f: Examine the protruding capacity of

valve stem.

And Examine the protruding high of valve

stem with vernier caliper.(See picture)

Standard Value( mm)

Protruding Capacity

Of Intake Valve

stem

47.5

Protruding Capacity

Of Exhaust Valve

stem

47.5

5) Examine the axial clearance of camshaft.

Replace the camshaft if the value of axial

clearance exceeds the normal value.

Standard Value

Intake camshaft 0.015—0.02

Exhaust camshaft 0.015—0.02

6) Examine the planeness of cylinder

a: Clear the lower surface of cylinder head.

b: With the help of ruler and feeler gauge,

check whether the lower surface of

cylinder head is warped.(Measure it in

the sequence of A, C, D, E, F, G in the

picture)

Standard

Value

Cylinder head planeness

0.04

Top of Valve

Stem

Protruding High of Valve S

tem

Seat of Valve

Spring

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 23

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

23

C: Revise it if the planeness exceeds, and

replace when it exceeds the limit value.

The permitted maximum abrading thickness

between cylinder block and cylinder head is:

2.2.3 Installation

The installing steps are reverse to those for

removal.

Note:

1) Dismantle valve springs into groups.

The 1st and 4th cylinders are in one

group and the 2nd and 3rd ones are in

the other group. Then put the piston to

the upper point of 1st and 4th cylinders

in order to dismantle the valve spring of

1st and 4th cylinders, replace their valve

oil seal and mount the spring

immediately. And put the piston to the

upper point of 2nd and 3rd cylinders in

order to replace the other valve oil seal.

Those steps prevent from that the valve

falls into cylinder and the unanticipated

trouble occurs.

2) Wipe the engine transmission oil on the

opening of oil seal when mounting the

valve oil seal.

3) Fasten the cylinder bolt as the following

process.

A: Smear some oil on the top and root of

bolt.

B: Fasten to 40±5NM in sequence.

C: Fasten 90±5 degree clockwise.

D: Fasten 90±5 degree clockwise.

2.3 Replace thermostat

2.3.1 Structural diagram

8 4 1 5 9

7 3 2 6 10

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 24

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

24

2.3.2 Needed tools and auxiliary materials

Hatch clamp,10# sleeve, ratchet wheel and wrench

2.3.3 Removal

1) Loosen the clamp of thermostat water exhaust pipe with hatch clamp to release the

coolant.

Note: Do it after the temperature decreased to prevent scald.

2) Remove the 4 bolts of thermostat cover with 10# sleeve wrench.

3) Take out the thermostat.

2.3.4 Inspection

Put the thermostat in the boiling water and use it with thermometer. Then observe the

temperatures when the thermostat is turning on and fully opened.

Temperature value

Regular unlocking temperature 87℃

fully opened temperature 104℃

Replace the new thermostat if the measured value is abnormal.

2.3.5 Installation

The installing steps are reverse to those for removal.

Note: Fill in the engine coolant with fixed quantity after installation.

1

2

3

4

5

6

1. Pad—Thermostat Seat

2. Thermostat Seat

3. Hexagonal Flange Bolt

4. Thermostat Assembly

5. Hexagonal Flange Bolt

6. Cover—Thermostat Seat

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 25

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

25

SECTION III SHORT ENGINE

I. STRUCTURE DIAGRAM

1. Piston

2. Connecting Rod Upper Bearing

3. Timing Hole Plug

4. Connecting Rod Lower Bearing

5. Pad

6. Bolt

7. Oil Filter

8. Oil Cooler

9. Oil Filter Seat

10. Connecting Rod Bolt

11. Connecting Rod Bearing Cap

12. Oil Pump

13. Bolt

14. Gasket

15. Crankshaft Timing belt pulley

16. Gasket

17. Bolt

18. Crankshaft Pulley

19. Bolt

20. Bolt

21. Coolant pump

22. Coolant Pump Gasket

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 26

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

26

23. Crankshaft Main Bearing Bolt

24. Frame Bolt

25. Frame

26. O-Type Ring

27. Crankshaft

28. Cylinder Block

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 27

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

27

II. MAINTENANCE

1. Replace oil pan

1.1 Needed tools and auxiliary materials

10# open end wrench, 10#, 15# and 17#

sleeve, ratchet wheel and ratchet rod, Le Tai

5901 Glue, engine oil

1.2 Process of Replacement

1.2.1 Process of removal

1) Loosen the oil discharge bolt of oil pan

to discharge the engine oil.

Note: Engine oil should be stored in special

container. And Pay attention to environment

protection.

2) Remove the fastening bolt of oil pan

with 10# open end wrench and 10#

sleeve.(18 bars of M7×25, 3 bars of

M7×40,4 bars of M7×95)

3) Remove the connecting bolt (2 bars,

black) between oil pan and transmission

housing with 17# sleeve wrench.

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 28

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

28

4) Remove the connecting bolt between the

oil return pipe of PVC valve and the oil

pan with 15# sleeve wrench.

5) Tap the edge of oil pan with rubber

pestle, and then remove the oil pan.

Note: Pay attention to safety because the oil

pan might fall down when being tapped.

6) Clean the engine frame with

right-angled tool to get rid of old Le Tai

glue.

Note: Do not lacerate the frame surface.

1.2.2 Installation

1) Spread Le Tai 5910 glue on the

connection surfaces of frame and oil

pan, close the oil pan and fasten the

fastening bolt of oil pan.

Note: Spread glue to the inner of hole for

installing bolt on the oil pan!

2) Screw the bolt. Screw to combine

enough at first then to get specified

Torque.

See the diagram for screwing sequence.

Torque: 15±3NM

3) Infuse engine oil to specified capacity.

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 29

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

29

2 Replace the engine oil strainer

2.1 Needed tools and auxiliary materials

10# open end wrench, 10#, 15#, 17# sleeve,

ratchet wheel and ratchet rod, Le Tai 5901

Glue, engine oil

2.2 Process of replacement

2.2.1 Process of removal

1) Remove the oil pan.(See “replace oil

pan” for details)

2) Remove the connecting bolt between

engine oil strainer and frame with 10#

sleeve wrench.(total 8 bars)

3) Draw out the engine oil strainer

carefully.

2.2.2 Installation

1) Spin the nozzle of engine oil strainer

into the frame carefully.

2) Mount the 8 bolts for the strainer and

fasten them.

Note: the bolts should be mounted with Le

Tai 243 glue.

Torque: 8±3Nm

3) Install oil pan (See “installation of oil

pan” for details).

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 30

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

30

3 Replace the piston, piston ring, piston

pin and connecting rod bearing

3.1 Needed tools and auxiliary materials

10# open end wrench, 10#, 15#, 17# sleeve,

ratchet wheel and ratchet rod, Le Tai 5901

Glue, engine oil, torque wrench Special tools

for installing piston, feeler gauge, clearance

gauge, micrometer caliper

3.2 Process of replacement

3.2.1 Process of removal

1) Dismantle the timing belt (see

“dismantle the timing belt” in the

section of “replacement of engine

timing belt” for details).

2) Remove the oil pan(see REPLACE OIL

PAN for details.

3) Remove the cylinder head. (see

“removal of cylinder head” for details).

4) Dismantle the engine oil strainer (see

the “replacement of engine oil strainer”

for details).

5) Loosen the big bolt on connecting rod.

6) Remove the connecting rod bearing

lower cover.

Connecting Rod

Bearing Lower Cap

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 31

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

31

7) Uplift the connecting rod and the piston

with a wooden stem and then remove

the connecting rod and piston assembly.

8) Remove the piston ring.

9) Remove the retainer ring of piston pin

and draw out the piston pin.

Note: With large tension, the retainer ring

may hurt people in the process of removal.

3.2.2 Inspection

I. Check piston

1) Examine the diameter of piston.

Measure the diameter along the vertical

direction to piston pin and at the place 11mm

under piston skirt with micrometer caliper.

Cylinder No.

Standard Size

1 83.46±0.009

2 83.46±0.009

3 83.46±0.009

4 83.46±0.009

Replace with the new one if the part cannot

be worn and torn any longer.

Retainer Ring

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 32

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

32

2) Examine the clearance between piston

ring and ring groove.

a. Clean up the accumulated carbon in the

ring groove with piston ring.

b. Examine the clearance between piston

ring and ring groove with feeler gauge.

Reference Value(mm)

1st Ring

0.04--0.08

2nd Ring

0.01--0.025

Replace with the new one if the examined

clearance cannot be worn and torn any

longer.

3) Inspect the end clearance of piston ring.

a. Put the piston ring at the position 45mm

below the top surface of cylinder

aperture and push the piston ring into

cylinder with piston.

b. Measure the opening with feeler gauge.

Replace with the new piston if the examined

clearance exceeds the limit.

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 33

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

33

4) Inspect the diameter of piston pin and

piston pin hole.

a. As the following picture, measure the

piston pin position around with

micrometer caliper. And take the

maximum value as the diameter of

piston pin.

b. Measure the diameter of piston pin hole

around with micrometer guage for

inside diameter, as the following picture,

and take the minimum value as the

diameter of pin hole.

Replace with the new piston and pin if the

examined clearance exceeds the limit.

Standard

Size

Diameter of piston pin

21

0

005.0−

Diameter of piston pin

hole

21

008.0

002.0

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 34

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

34

5) Inspect the connecting rod journal and

connecting rod bearing

a. Examine the diameter of connecting rod

journal.

Measure the axle diameter of connecting rod

with micrometer caliper.

Rotate the crankshaft 90° and measure it

again.

Work out the Roundness and cylindricity

through twice measuring.

① Roundness=Max. diameter — Min.

diameter /2 as the picture, take the

vertical diameters on the same plane,

subtract the half of Minimum from the

Maximum to get roundness.

② cylindricity= Maximum bore -

Minimum bore/2 As the picture,

measure the bores of 3 planes along

both A direction and B direction

respectively. Get the maximum and the

minimum from 6 values, and then

subtract the half of Minimum from the

Maximum to get cylindricity;

b. Inspect the radial clearance of

connecting rod bearing

Inspect the radial clearance of connecting rod

bearing with clearance gauge. Clean up the

connecting rod journal and connecting rod

bearing. And put clearance gauge on the

journal, fasten bearing bushing and fasten the

bolt according to set torque.

Note: Do not rotate the crankshaft during the

process.

Standard Value

Diameter

9.47

0

016.0−

Roundness

——

Cylindricity

——

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 35

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

35

Loosen the connecting rod bolt, remove the

cap, and measure the maximum width of

pressed clearance gauge with the ruler on its

package to get the clearance value.

Replace with the new connecting rod bearing

if the examined clearance exceeds the limit.

Note: Use the same brand consistent with

assorting sign when you replace the bearing

bushing.

Standard

Value

Abrasion

Limit

Clearance 0.016—0.051

Selection of connecting rod bearing:

You may select the connecting rod bearing by

observing the sign on the first balance weight

at the front end of crankshaft.(see picture,

unavailable)

6) Inspect the planeness of cylinder block

surface.

a: Clean the upper surface of cylinder

block.

b: Check with ruler and feeler gauge

whether the surface of cylinder block is

warped. (Measure it in the sequence of

A, C, D, E, F, G in the picture)

C: Revise it if the warping amount is

excessive.

Replace with the new cylinder if it exceeds

the limit. The maximum for the sum of

permitted abrading thickness of cylinder

block and cylinder head is:

Standard Value

limit

value

warping

amount

0.04

Clearance Gauge of Plastic

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 36

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

36

7) Inspect cylinder

a: Inspect if the cylinder wall is scratched

or scored. If there are cylinder scoring

and scratching you need to hone cylinder

wall, replace cylinder liner or replace

cylinder block.

b: Examine the inner diameter and

cylindricity of cylinder with cylinder

gauge.

Standard value

Inner diameter 83.5

cylindricity 0.008

cylindricity= Maximum bore - Minimum

bore/2

As the picture, measure the bores of 3 planes

along both A direction and B direction

respectively. Get the maximum and the

minimum from 6 values, and then subtract the

half of Minimum from the Maximum to get

cylindricity;

3.2.3 Installation

1) Spread oil on the piston pin and in the

piston pin hole, connect the piston and

connecting rod with piston pin, and

mount the piston pin circlip.

2) Mount the piston ring. Mount the rings

on the piston in the sequence of oil ring

expander, upper and lower segments, 2nd

air ring and 1st air ring; Pay attention to

the direction of piston ring, the side with

“TOP” should be upward. The two

segments and expander are staggered.

The angle of expander connector points

to the top of piston, and the 1st ring and

2nd ring form 120° with the upper

expander.

12 mm

Center

Bottom

The Openings Of Rings Form

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 37

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

37

3) Mount the upper bearing of connecting

rod and the connecting rod together.

Note: the gap on bushing should be orderly

with that of connecting rod.

4) Spread the engine transmission oil in the

engine cylinder, clasp the piston ring

with special tool, tap the piston head

with wooden handle and encase the

piston connecting rod assembly.

Note: the end of connecting rod with a point

should face the cylinder and consists with the

arrowhead on the top side of piston.

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 38

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

38

5) Mount the lower bearing of connecting

rod and the connecting rod cap together.

Then spread engine transmission oil.

Note: the gap on bushing should be orderly

with that of connecting rod.

6) Close the connecting rod cap and screw

down the bolt.

Torque: 25±3N•m, then screw 90°±5°

7) Examine the axial clearance of

connecting rod.

Examine the axial clearance with micrometer

guage or feeler gauge.

Standard Value(mm)

Clearance 0.15—0.50

8) Mount the engine oil strainer.

9) Mount the oil pan.

10) Mount the cylinder head.

11) Mount the timing belt during timing

adjusting.

4.Replace front oil seal of crankshaft

4.1 Needed tools and auxiliary materials

Ratchet wheel and ratchet rod, 13#, 15#, 17#,

22# sleeve, 13# open end wrench, allen

wrench, engine transmission oil and guide

sleeve of crankshaft oil seal

4.2 Process of Replacement

4.2.1 Process of Removal

1) Dismantle the timing belt (See

“replacing the timing belt” for details).

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 39

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

39

2) Engage the gear to 5th, then press the

brake with toes, Dismantle the

connecting bolt of timing belt pulley and

crankshaft with torque wrench. Remove

the timing belt.

Torque:130±10,then screw 65°±5°

3) Pry out the old oil seal with right-angled

screwdriver carefully.

Note: Be careful in dismantling the oil seal

not to damage the oil seal seat ring.

4.2.2 Installation

1) Clean the oil seal seat ring and spread

transmission oil on the seat ring

2) Spread transmission oil at the seal lip.

3) Enclose the guide sleeve of crankshaft

oil seal, special tool, with that oil seal.

4) Press the oil seal into oil seal seat ring

and knock it to right position with

hammer.

5. Replacement of oil pump

5.1 Needed tools and auxiliary materials

A set of big sleeves, a set of small sleeves

and a set of open end wrench

Guide Sleeve of Crankshaft Oil Seal

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 40

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

40

5.2 Process of Replacement

5.2.1 Process of Removal

1) Dismantle the timing belt (See “removal

of timing belt” for details).

2) Engage the gear to 5th, then press the

brake with toes, and remove the timing

belt pulley.

3) Dismantle the fastening bolt of oil pump

with 10# sleeve and take out the oil

pump. Torque:8+3NM

4) Pry out the oil seal.

5) Clean the seat ring of oil pump.

5.2.2 Installation

1) Spread oil on the gasket of oil pump.

2) Mount the oil pump in its seat ring.

Note: The bulge of oil pump should be put

downwards because the wrong position can

not make the bolt be screwed in.

3) Mount the oil seal.

4) Mount the other parts.

6. Replacement of crankshaft rear oil seal

6.1 Needed tools and auxiliary materials

A set of big sleeves, a right-angled

screwdriver, a small hoist and engine oil

6.2 Process of Removal

1) Suspend the engine assembly from

vehicle (See “suspending of engine

assembly” for details).

2) Remove the clutch pressure plate.

3) For removing the flywheel, lock the flywheel

with special tool and then screw off the

fastening bolt with sleeve wrench.

4) Pry the old oil seal with the right-angled

screwdriver.

Note: Do not damage the oil seal seat ring.

Fastening

Flywheel Tool

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 41

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

41

6.2 Installation

1) Clean the oil seal seat ring. Clean the oil

seal seat ring with clean oiled gauze.

2) Spread the oil at the lip of crankshaft

front oil seal.

Enclose the guide sleeve of crankshaft oil

seal, special tool, with that oil seal. Then

press it into oil seal seat ring.

3) Mount the flywheel and the clutch

pressure plate, and then mount the

engine on the vehicle.

Torque:25±5N.M, then screw 30°±5°.

7. Replace crankshaft and thrust washer

7.1 Needed tools and auxiliary materials

A set of open end wrenches, a set of sleeve

tools, a small hoist, Le Tai glue, Engine oil,

feeler gauge, feeler gauge, micrometer gauge.

7.2 Process of Removal

1) Suspend the engine assembly from

vehicle (See “suspending of engine

assembly” for details).

2) Drain out the engine oil.

3) Remove the timing belt (see “replace

timing belt” for details).

Guide Sleeve of Crankshaft Oil Seal

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 42

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

42

4) Dismantle the accessories, such as

dynamo, A/C compressor, power

steering pump and bracket.(See the

“replacement of engine accessory” for

details)

5) Dismantle the engine cylinder head

assembly. ( See the “replacement of

cylinder head” for details)

6) Dismantle the engine clutch pressure

plate, the flywheel and the timing belt

pulley.

7) Remove the oil pan and engine oil

strainer.(See the “replacement of oil pan

and strainer” for details.)

8) Remove the piston connecting rod

assemblies for 4 cylinders and Put them

in order.

Note: You’d better stick the number on each

piston connecting rod assembly to prevent

from wrong mounting.

9) Dismantle engine oil pump assembly.

10) Dismantle the frame assembly under

cylinder block and remove the

crankshaft and thrust washer.

7.3 Inspection

1) radial clearance of crankshaft

a): Clean the journal and bearing bushing.

b): Install crankshaft

c): Make the length of plastic clearance

gauge equal to the width of bearing.

Then put it on the journal paralleling the

axis.

Clearance Gauge

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 43

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

43

d): Mount the main bearing cap carefully

and screw down the bolt with

specified torque.

e): Dismantle the main bearing cap

carefully.

f): Measure the width at the most bread

part of pressed plastic line with ruler on

plastic clearance gauge package, then

get clearance value.

Standard Value

Clearance

-0.0035-0.034

Replace the new bearing bushing if the

measured clearance value exceeds the limit

value.

Note: Replace the whole group when

replacing bearing bushing.

Selecting method of main bearing bushing:

By observing the sign on cylinder (see the

picture), we could see 5 As which correspond

to bearing bushings respectively.

There two kinds of signs on this vehicle, A

and B, corresponding to two kinds bushing,

red one and blue one (the color can be

recognized on the new bushing but it is

possible unrecognized the color on the old

one.) A corresponds to red bushing, and B

corresponds to blue bushing.

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 44

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

44

2) Inspect the crankshaft axial clearance

Mount the crankshaft and measure its radical

clearance with micrometer guage.

Standard Value

Clearance 0.076—0.265

Replace the new thrust washer if the

measured value exceeds the limit value.

Standard thickness of thrust washer:

7.4 Installation

1) Clean the engine and spread the engine

transmission oil on the crankshaft

journal.

2) Mount the crankshaft correctly and then

mount the thrust washer.

3) Mount the cylinder frame and screw

down the crankshaft fastening bolt.

See the picture for the screwing sequence

Screwing way and Torque:

A: Pre-fasten the bolt according to the

sequence in the picture.

B: Screw the bolt as the sequence on the

picture to 45±5 N.m.

C: Screw 180±5°

4) Mount and screw down the bolt of

frame periphery.

Torque: 23N.m

5) Mount the engine oil strainer, oil pan,

crankshaft front and rear oil seal and oil

pump.

6) Mount the engine accessories, suspend

the engine assembly from vehicle and

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Page 45

CHERY A21 SERVICE MANUAL MECHANISM OF 2.0NALC ENGINE

45

mount the water pipe and insert electric

connector.

8 Replace coolant pump

8.1 Needed tools and auxiliary materials

A box sleeve wrench, a set of open end

wrench, allen wrench, coolant

8.2 Removal

1) Remove the engine timing belt.(see

“engine timing calibration” for details.)

2) Loosen the engine water exhaust pipe,

and exhaust coolant.

3) Removal the coolant pump.

8.3 Installation

The installing steps are reverse to those for

removal.

Infuse enough coolant after installation.

Note: Do not splash the coolant on the timing

belt and skin.

PDF created with pdfFactory Pro trial version www.pdffactory.com

pouyapadid.com

09120539254

Loading...

Loading...