Page 1

AIR CONDITIONER SYSTEM

AIR CONDITIONING SYSTEM OVERVIEW … … … … … … …… …… …… … U-2

REFILLING OF REFRIGERANT AND REFRIGERANT OIL … … … … … … … U-6

A/C SYSTEM COMPONENTS … … … … … … …… … … … … … …… ……… U-14

FAILURES AND SHOOTING ANALYSIS SHEET … … … … … … …… … … … U-20

PRECAUTIONS ON THE SECURITY OF A/C SYSTEM … … … … ……… …U-21

U-1

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 2

Evaporator

A/C Control System

Warm air radiator

Condenser

an

d Circuit

Compressor

AIR CONDITIONING SYSTEM OVERVIEW

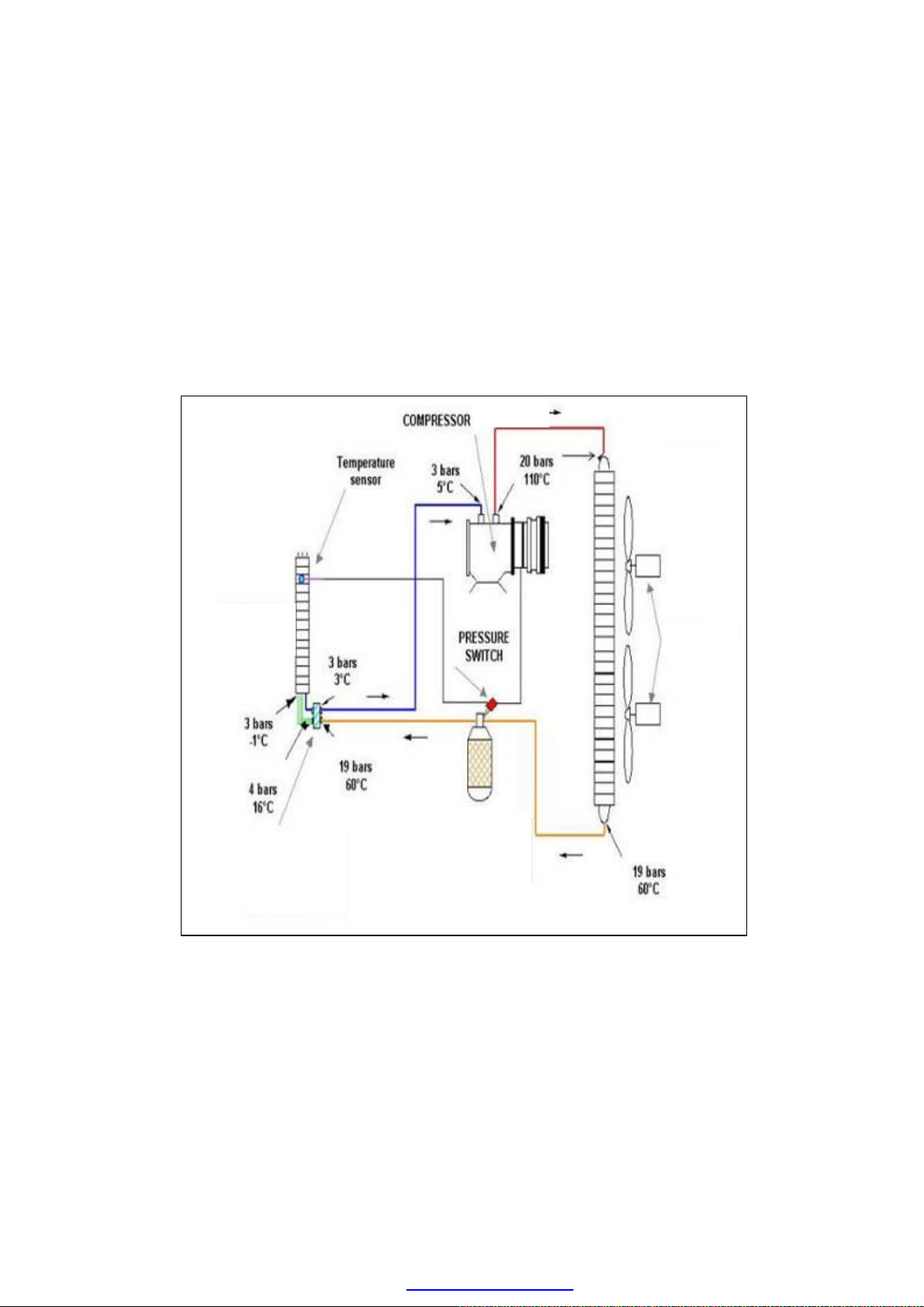

Based on its function, the Chery A15LHD air

conditioning unit may be divided into such five

basic components as the refrigeration system,

heating system, ventilation system, control system

and air purification system.

1. Refrigeration system It is available to cool

the air inside the vehicle based on the refrigeration

principle of vapor compression refrigerator. The

temperature of evaporator as the cold source is

lower than the dew-point temperature of air, so the

refrigeration system also play the role of

dehumidification and air purification. The

refrigeration system of Chery's electronic fuel

injection type engine adopts the coolant R134a. As

shown in the figure, the refrigeration system

mainly consist of the compressor, condenser,

expansion valve, evaporator and etc. In the

evaporator, the coolant fluid absorbs the heat from

the air inside vehicle and is gasified to the

low-pressure, low-temperature coolant vapor, and

then is inhaled into the compressor.

U-2

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 3

Condenser

Fan

The coolant vapor will be compressed by the compressor as the high-temperature,

high-pressure gas which enters into the condenser. In the condenser, the coolant is cooled by

the ambient air, and condensed into the fluid after emitting its heat outwards, then the

moisture content is filtered and removed from the fluid via the fluid reservoir. The

high-temperature, high-pressure coolant fluid is throttled down through the expansion valve

(installed in the inlet pipe of evaporator) to reduce its pressure and temperature, and then the

fluid enters into the evaporator. The low-temperature and low-pressure coolant fluid also

absorb the heat from the inside of vehicle, and gasifies again to the low-temperature and

low-pressure coolant vapor, and then is inhaled into the compressor. In such a manner, the

coolant cycles recurrently to make the indoor temperature of vehicle reduce. The pipelines

for coolant are shown in the figure below:

Compresso

Evaporator

Drying

Expansion

Valve

Bottle/Collector

2. Heating system It adopts the engine coolant as the heat source and introduces the

coolant into the radiator located at the compartment to heat the indoor air via the blower, and,

at the same time, it is also used to defrost and defog the front windscreen.Chery A15LHD’s

air conditioning unit adopts the reheating mixed type unit, the heating system of which is

used not only to individually heat the circulating air from the inside of vehicle or the fresh air

from the outside, but also to firstly cool these two kinds of airs and then heat the whole or

part to obtain the air temperature required. It is available to dehumidify the air, and also to

filter the air so as to get the clean air with desired humidity.

U-3

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 4

3. Ventilation system Apart from the cool and heat the air inside the vehicle, the

centrifugal blower is also used to change and ventilate the air inside the vehicle. The

ventilation system consists of the air filter, air inlet, air duct, vent and etc. The system

introduces the fresh air from the outside of vehicle into the inside while the ventilation and

discharge port extracts the vitiated air from the inside to the outside. Chery A15LHD adopts

the natural ventilation and forced ventilation. The open/close fresh air inlet is controlled by

the fresh/circulating air vacuum valve.

During the natural ventilation, the fresh air enters into the vehicle from the air inlet fixed

under the front windscreen (positive pressure area), and gets into the trunk from the seat belt

notch on the trunk cover, then passes across the vents (negative pressure area) on the body

rear skirt, trunk lining, rear side beam and finally discharges to the atmosphere. Due to the

movement of air in the rear body compartment, it plays a good role to defrost the rear

windows. In addition, the whole process is conducted without pressure, so the air changing

doesn’t create any noise and has nothing with the driving speed.

And during the forced ventilation, in case that the fresh air doesn’t pass through the heating

radiator (the mixed gate closed) after the air is pressurized by the blower, the air will enter

into the vehicle via all air ducts, and then discharge along the same route as that of natural

ventilation to the atmosphere.

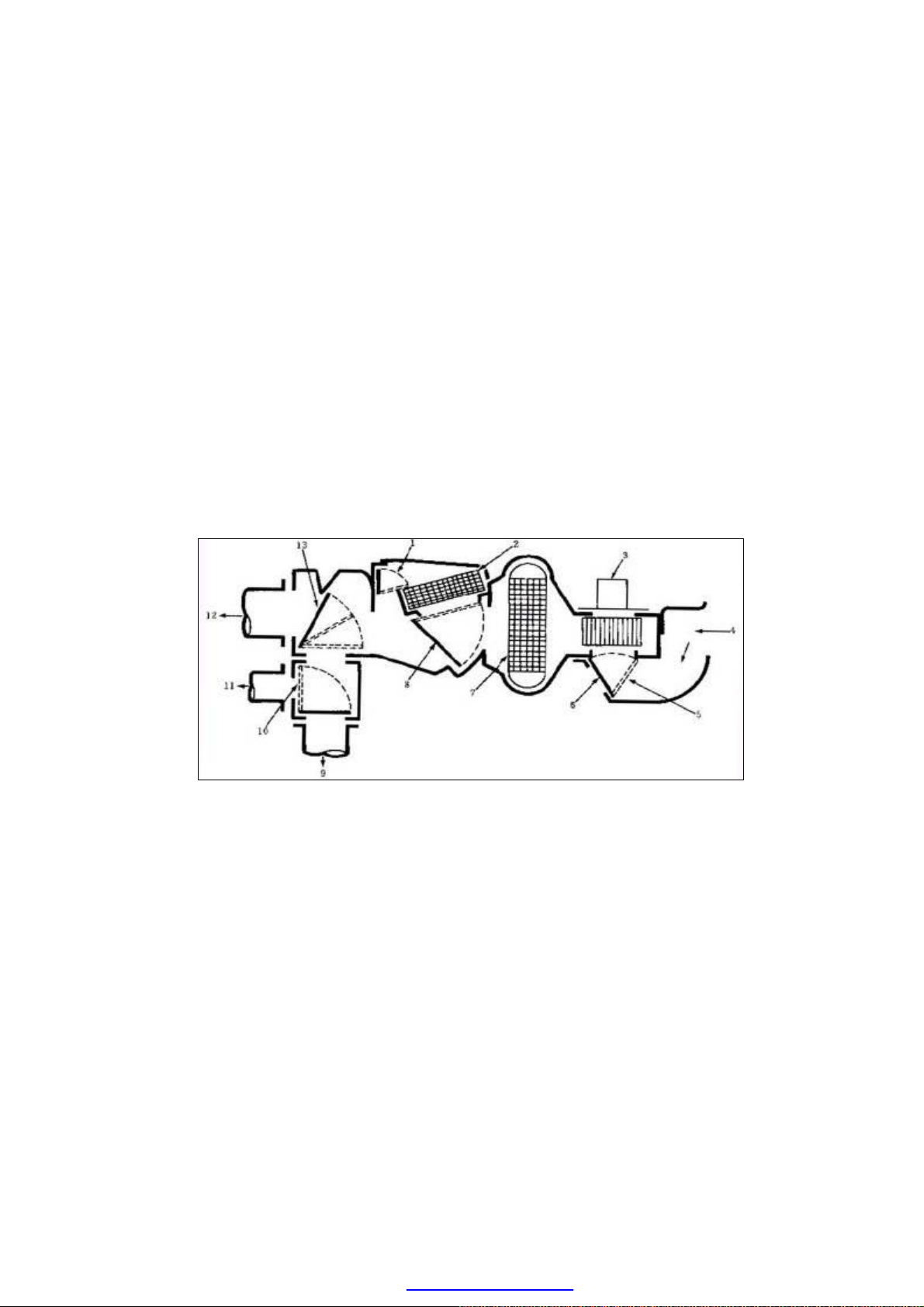

An individual type casing system with blower

1. Restrictor damper 5. Fresh/recirculated air door 9. To panel

2. Heater core 6. Recirculated air 10. A/C defrost damper

3. Blower motor 7. Evaporator core 11. To defroster

4. Fresh air 8. Air mix damper 12. To bottom outlet

U-4

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 5

Air-Conditioner Compressor

Air-Conditi

E

vaporator Assembly

on Harness

4. Control system The control system mainly consist of the electrical component, vacuum

hose and control mechanism. On one side, it is available to control the temperature and

pressure of refrigeration and heating system, and, on the other side, it is also used to control

the temperature of air inside the vehicle, the blowing rate and direction.

5. Air purification system The air purification system mainly indicates the dust filter,

which is used to filter the outside air inhaled, and continuously discharge the vitiated air

generated inside the vehicle to make the air inside the vehicle clean and hygienic.

U-5

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 6

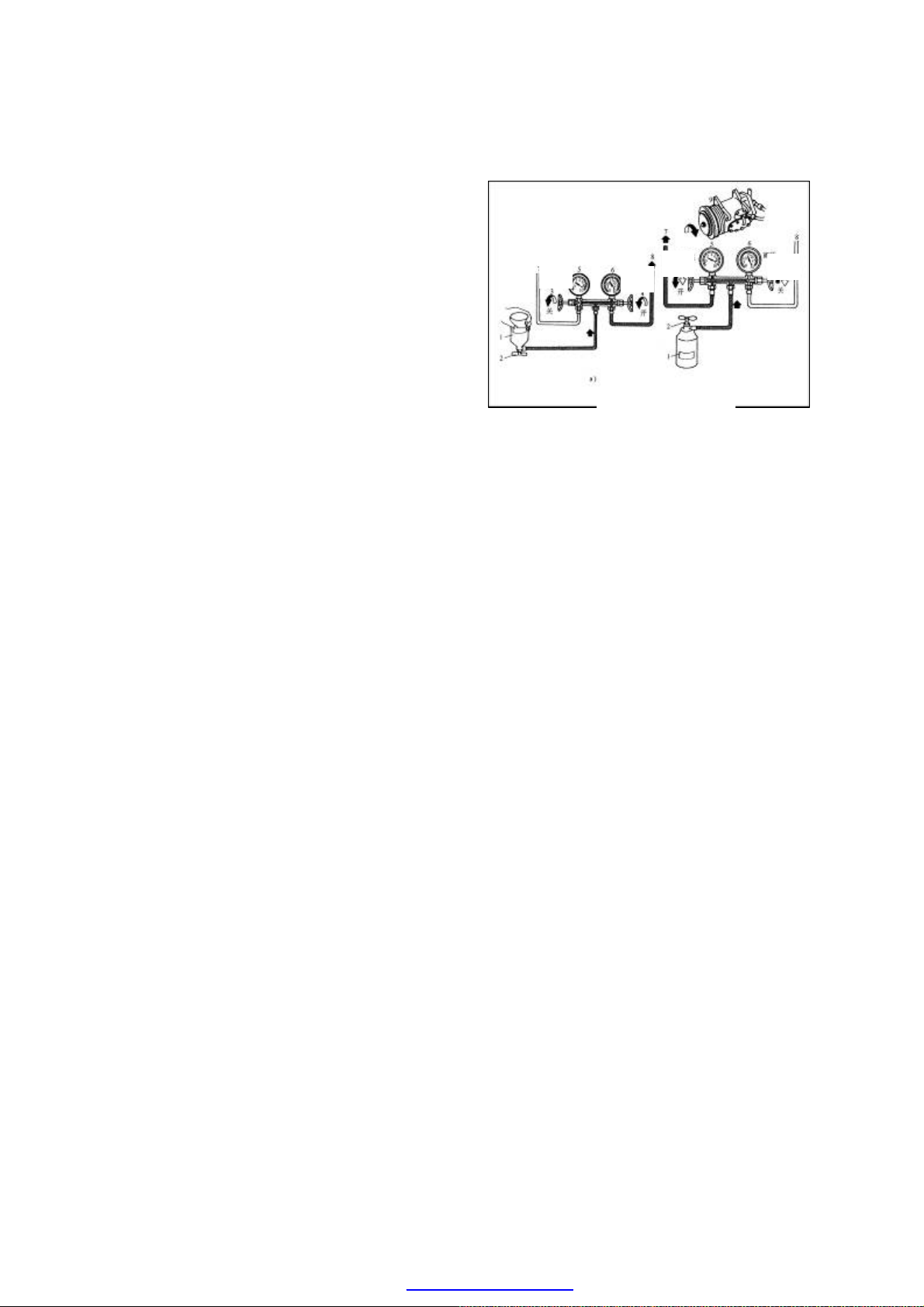

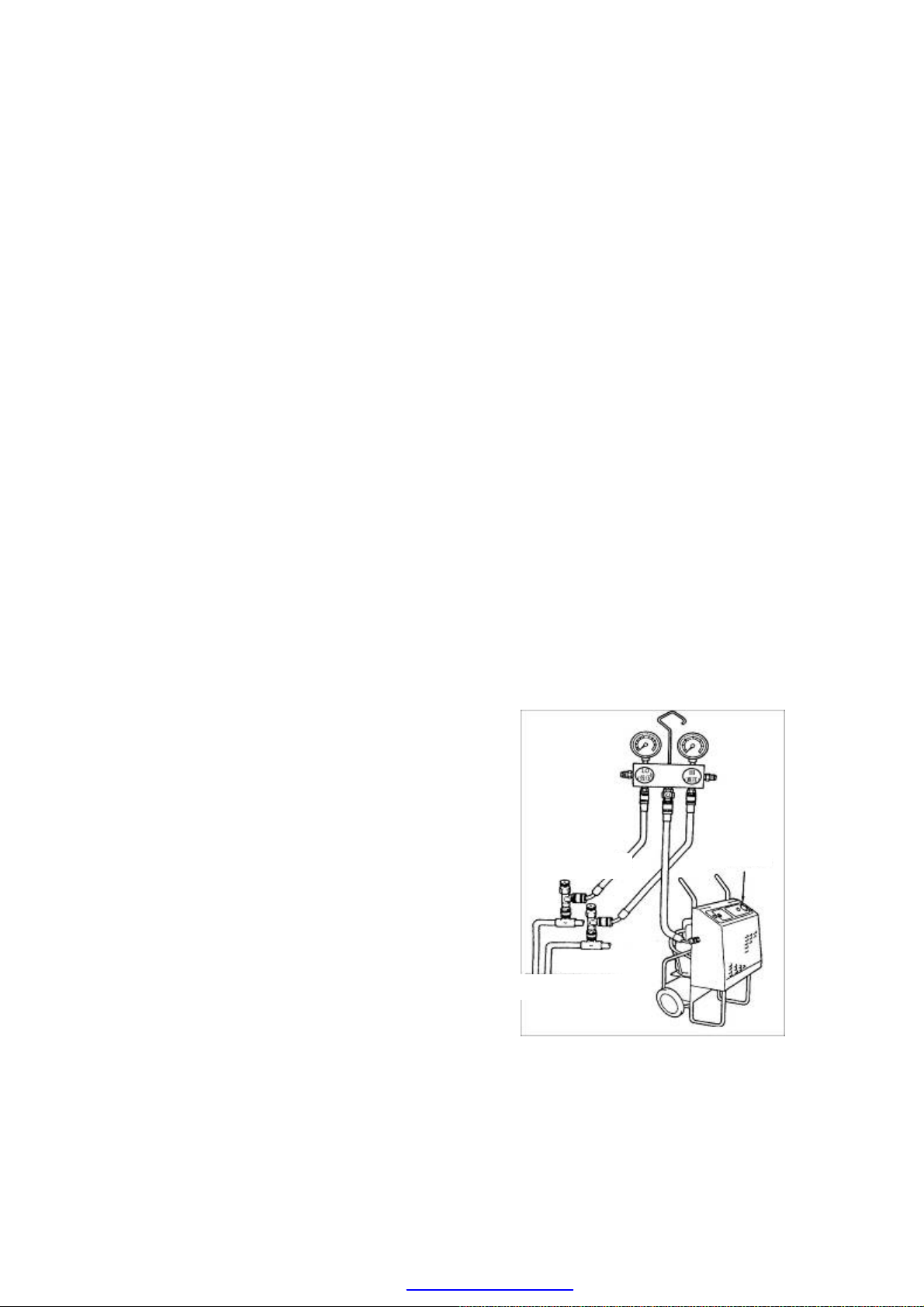

REFILLING OF REFRIGERANT AND REFRIGERANT OIL

Caution:

· If there are some moist materials or other

foreign materials circulating in the

refrigeration system, the cooling

performance of the refrigeration system will

considerably decrease and generate the

abnormal noise. So, after any refrigeration

and circulation part is removed, the

openings shall be immediately plugged to

avoid the entrance of moist materials or

other foreign materials.

· If the service reservoir is used to refill the

refrigerant, it is very dangerous to open the

valve located at engine high pressure side.

During the operation, the pressure inside the

service reservoir will rise, which may cause

the explosion of the reservoir, what’s more,

the metal fragment from explosion and the

refrigerant sputtered will be serious harmful

to the operators. Thus, it is recommended to

pay more attention to the close of the

high-pressure-side valve during the course

of engine operation.

Low

Low

pressur

Charging the refrigerant

1-Refrigerant tank

2-Unlock valve

3-Low-pressure manual valve

4-High-pressure manual valve

5-Low-pressure gauge

6-High-pressure gauge

7-Connect to low-pressure service valve hose

8-Connect to high-pressure service valve hose

9-A/C compressor

High

pressur

pressur

High

pressur

Caution:

· Take care not to exceed the starndard

value(s) specified in the technical

specification during refilling the refrigerant

into the refrigeration system. If exceeding

the standard values, it will considerably

reduce the efficiency of the A/C system, and

even damage the refrigerant recirculation

parts.

· In accordance with the regulation, the

refrigerant shall be refilled from the

high-pressure side at all time. If it is refilled

from the low-pressure side, the valve leaf of

A/C compressor will loosen and give off the

abnormal noise.

U-6

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 7

1. Precautions for Refrigerant Concerned

(1) To avoid the refrigerant contacting with

your skin, wear rubber gloves and safety

goggles while handling the refrigerant.

(2) Handle the refrigerant concerned at a well

ventilated location. Since the refrigerant is

a colorless gas at room temperature and its

density is greater than that of air, the

refrigerant will deposit in the maintenance

location, which may easily cause the

maintenance personnel choked.

(3) Do not allow the refrigerant to contact with

fire. Otherwise it may generate the toxic

gas.

(4) The O-ring can be applied once only.

(5) Chery model-A15LHD adopts the

refrigerant R134a which cannot be

interchanged with R12. Also compressor

oils cannot be mixed. During the course of

handling, any tool that has touched certain

kind of refrigerant must not touch any other

kind of refrigerant.

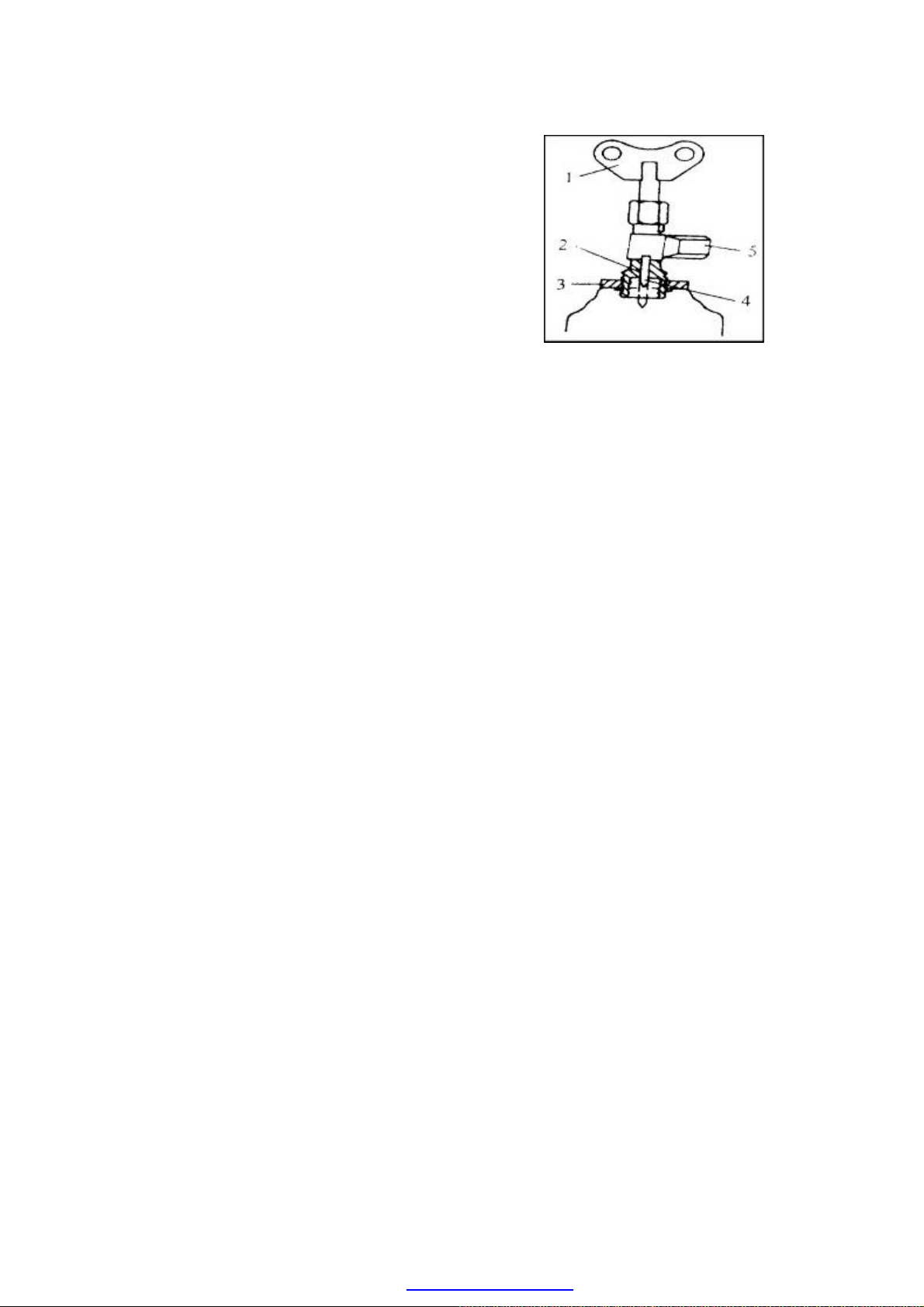

Refrigerant Tank Unlock Valve

1-Butterfly Handle

2-Refrigerant Tank Refilling Valve

3-Plate-shaped Nut

4- Needle Valve

5-Refilling Valve Joint

2. Method to Refill Refrigerant

If the 400g tanked refrigerant is required, a

refrigerant tank unlock valve shall be applied

(shown in the figure). The operation

procedures are as follows:

(1) Before the unlock valve is installed on the

refrigerant tank, turn the butterfly handle 1

in the counterclockwise direction till the

needle valve returns back completely.

(2) Turn the plate-shaped nut 3 in the

counterclockwise direction to lift it up to

the highest position, and then tighten the

valve and the dummy club at the center of

refrigerant tank.

(3) Install the intermediate filling hose of

manifold pressure gauge on the joint 5, and

then turn the plate-shaped nut in the

U-7

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 8

RECEIVER

SEVICE VALVE

clockwise direction and tighten it by hand

as possible.

(4) Turn the butterfly handle 1 in the

clockwise direction to make the valve

needle 4 in its front end punch a small hole

in the dummy club of refrigerant tank.

(5) Turn the butterfly handle 1 in the

counterclockwise direction, which the

refrigerant will flow into the manifold

pressure gauge along the charging hose.

(6) Then turn the butterfly handle 1 in the

clockwise direction to the lowest position,

and it can close down the refrigerant tank

again. However, do not detach the unlock

valve, otherwise the refrigerant inside the

tank will leak out.

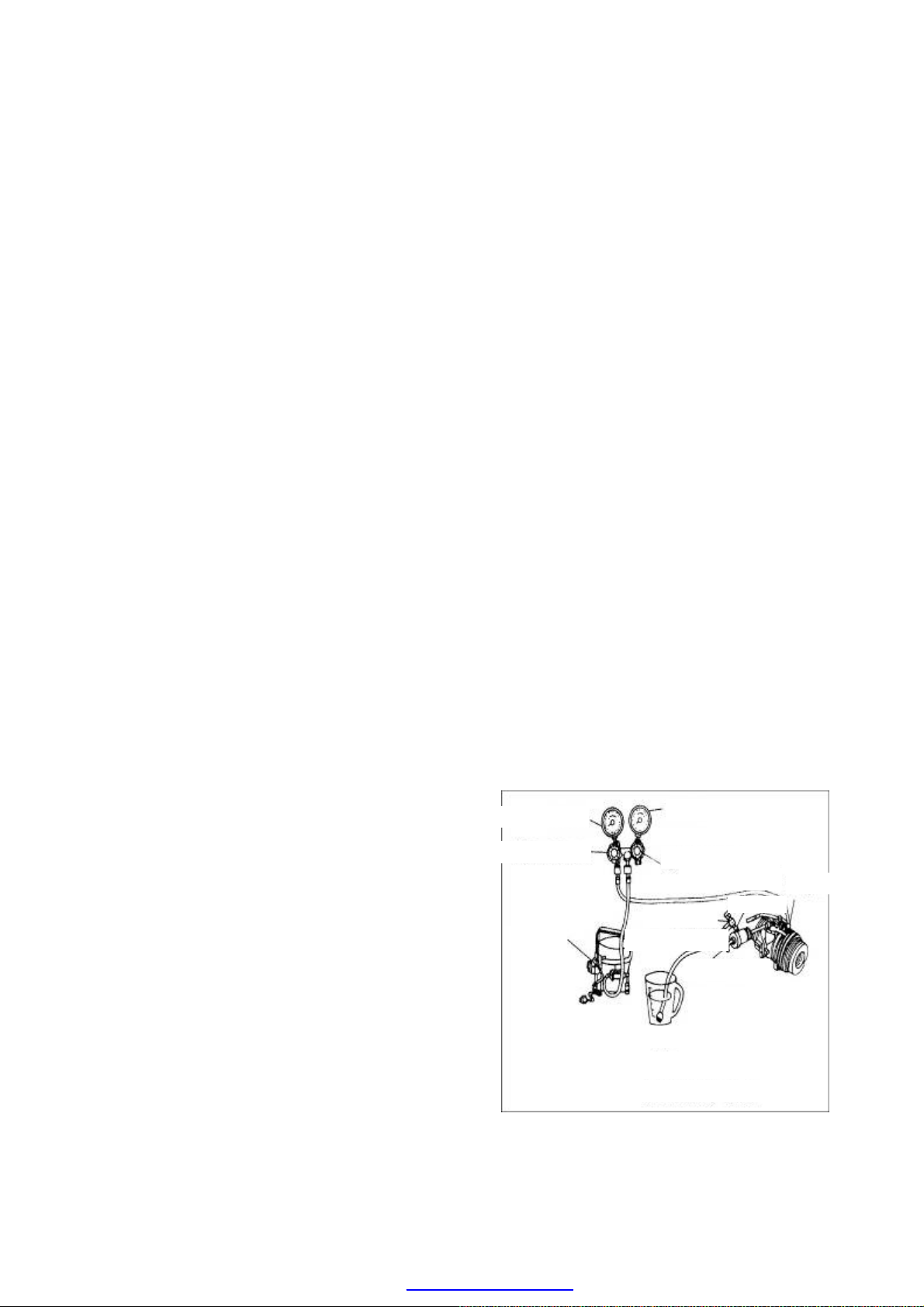

3. Refrigerant Refilling Procedures

(1) Connect the manifold pressure gauge to

the refrigerant tank, shown in the picture

below.

(2) Unscrew the handle of unlock valve 2 in

the counterclockwise direction to enable

the refrigerant to enter the intermediate

charging hose. In this case, do not open the

handle valves in the both sides.

(3) Unscrew the nuts of intermediate hose of

manifold pressure gauge, and then tighten

the nuts of intermediate hose after the air

inside the intermediate hose are drained

when you see the white refrigerant gas

overflow and heard the “fizzle” sound.

(4) Turn on the high-pressure manual valve 4,

shown in the figure below, stand the

refrigerant tank 1 upside down so as to let

the refrigerant in liquid-state charge into

the refrigeration system. In this case, do

not switch on the A/C unit to prevent the

refrigerant from returning back to the tank.

U-8

LOW-PRESSURE

SEVICE VALVE

HIGH-PRESSURE

REFRIGERATION DEVICE

RECYCLING

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 9

200 g or more refrigerants shall be charged

every time, and turn the compressor

several times by hand after the completion

of charging.

(5) Turn off the high-pressure manual valve 4,

shown in the figure below, and turn on the

low-pressure manual valve 3 to let the

refrigerant in gas-state charge into the

refrigeration system. The refrigerant

charged from the low-pressure manual

valve must be gas-state. If it is liquid state,

the liquid hammer phenomenon may

appear to damage the compressor. Turn off

the low-pressure manual valve when the

reading of low-pressure gauge reaches

2.8X105 Pa.

Refrigerant Refilling

Regulated amount:R134a,850±25g

4. Leak Check of Refrigeration System

Three effective methods can be used to check

the air tightness of refrigeration system: check

with electronic leak detector, soap solution and

halogen leak detector.

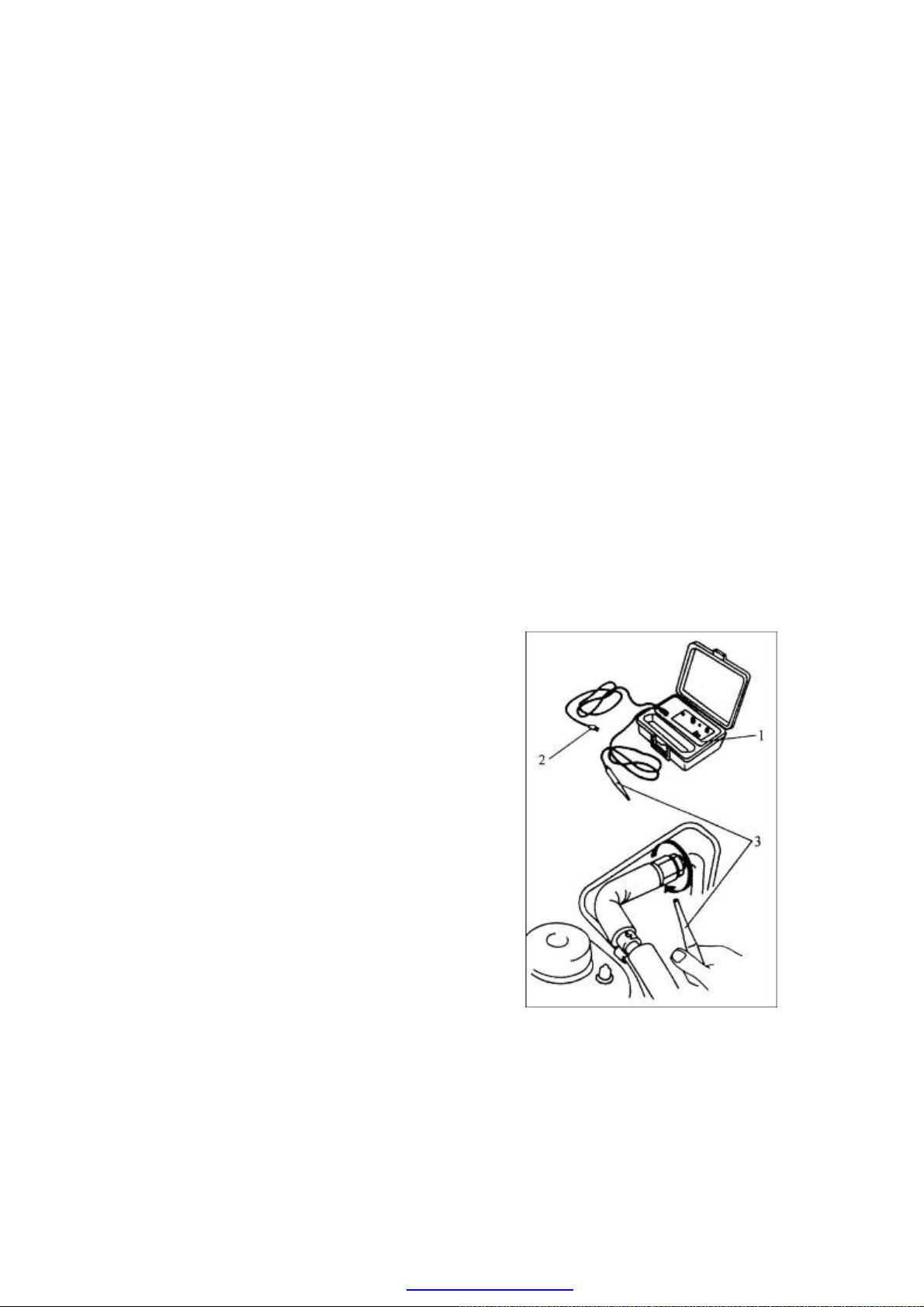

1) Check with Electronic Leak Detector

As shown in the figure, connect the power

supply connector 2 of electronic leak detector

1 to the power supply, and move probe 3

slowly (30 mm/s), which should be placed 3

mm away from the check point. And if any

alarming sound is emitted, it means there is a

leak phenomenon occurred at that place.

2)Check with Soap Solution

Apply the soap solution to the possible leak

position. Observe whether air bubbles appear.

If there are air bubbles, it indicates a leaking

accident occurs.

3)Check with Halogen Leak Detector

The inspection procedure is described below:

(1) Check the liquid propane capacity in the

1. Electronic leak detector.

2. Power supply connector.

3. Probe

If the leakage occurs at the joints

of refrigeration pipes, the relevant

O-rings shall be replaced.

U-9

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 10

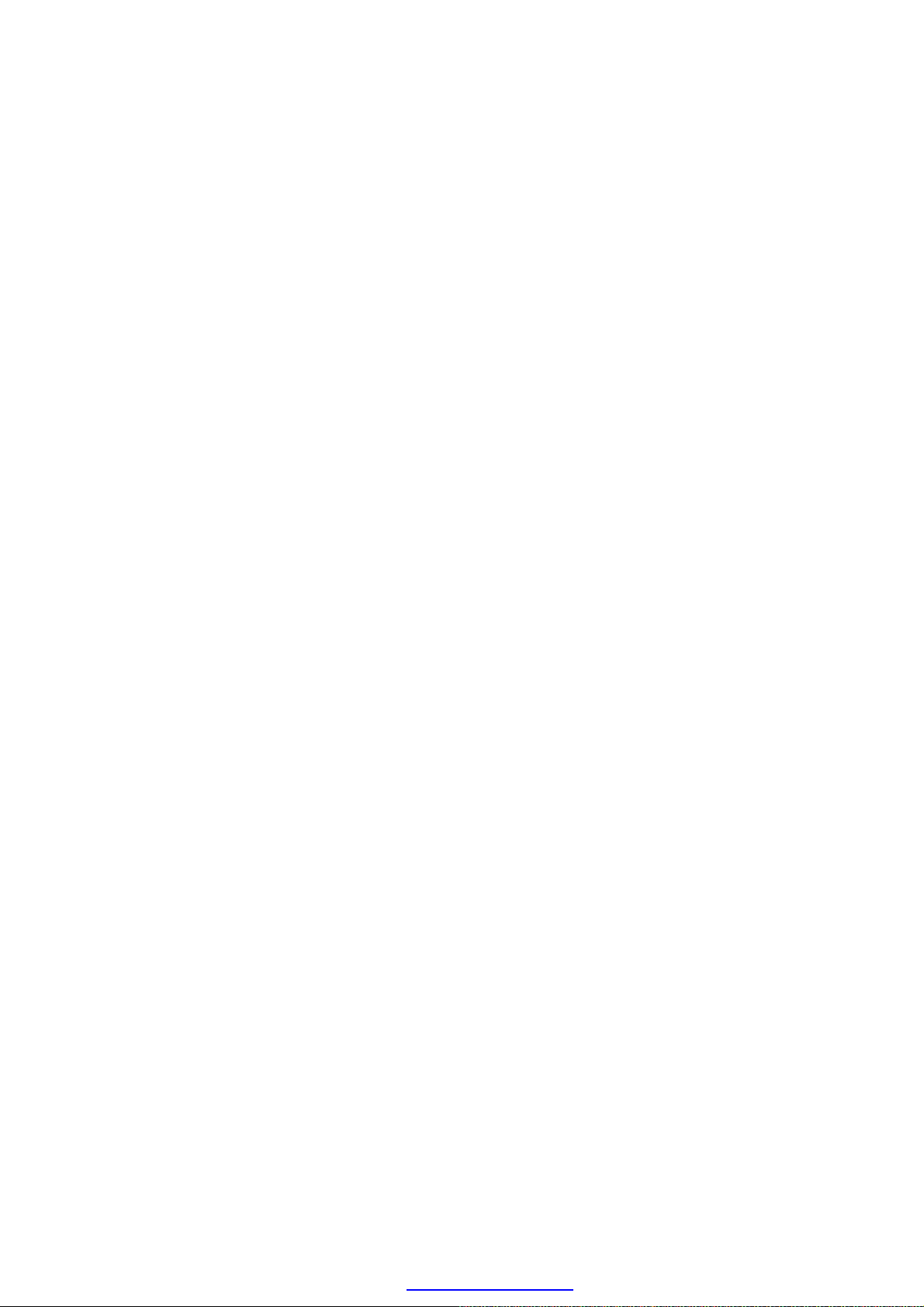

Vacuumizing and Charging the Refrigeration Oil

reservoir.

(2) Tighten the propane reservoir 16 to the

leak detector.

(3) Insert a lighting match into lighting device

9, and then slowly turn the adjusting

handle 14 in the counterclockwise

direction till the torch is lit.

(4) Adjust the flame to smallest. The smaller

the flame, the more sensitive to the leak of

refrigerant.

(5)Move suck pipe 3 to the possible leak

position.

(6) Observe the change of flame color. The

flame has no color if there is no leakage.

The flame is tint green if there is very

small leakage or be blue if there is

relatively big leakage, and it will become

purple if there is too much leakage.

5. Methods of Refrigerant Oil Charging

There are two methods for refrigerant oil

charging: direct charging method and vacuum

inhaling method.

1)Direct charging

Remove the oil charging plug 1, and charge

the specified model of refrigerant oil.

2)Vacuum inhaling

Vacuumize the refrigeration system to 30psi,

and then start to charge the refrigerant oil, the

procedures of which are as follows:

(1) Turn off the high-pressure manual valve,

and turn off the auxiliary valve.

(2) Remove the high-pressure side hose from

the manifold pressure gauge, and insert

the hose into the oil cup.

(3) Turn off the auxiliary valve to inhale the

refrigerant oil into the refrigeration system

from the oil cup.

Low-pressure gauge

Low-pressure manual valve

Vacuum pump

High-pressure gauge

High-pressure manual valve

Low-pressure side hose

auxiliary valve

High-pressure side hose

High-pressure pipe

Oil cup

Air return

Air exhaust

(4) When the refrigeration oils in the cup are

nearly evacuated, immediately turn off the

U-10

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 11

auxiliary valve so as to prevent the air

from being inhaled into the system.

(5) Connect the high-pressure side hose joint

to the manifold pressure gauge, turn on the

high-pressure manual valve, and start up

the vacuum pump to vacuumize the

high-pressure side hose. And turn on the

auxiliary valve to vacuumize for the

system to 30psi, and then vacuumize 15

min again so as to remove the air entering

into the system together with the oils. In

this case, the refrigeration oils are in the

high-pressure side, and the oils will return

back to the compressor after the operation

of the system.

3)Type & amount of refrigerant oil charged

Regulated amount: SP10 type, 150ml.

It is unnecessary to charge the refrigerant oil

into the newly-mounted A/C system, and it is

required to complement some refrigerant oil

only when a certain part is needed to repair or

when the vehicle is driven to a specified

mileage.

The amount of implementing oil required

when replacing parts is as follows: Evaporator

and condenser: 30ml. Drier: 20ml. and pipe:

10ml.

U-11

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 12

6. Methods of Refrigerant Vacuumizing

It is difficult to pump out the water from the

refrigeration system when vacuumizing. But

the vacuumizing can reduce the fluidization

point of water after the vacuum is generated in

the refrigeration system, which enables the

water to boil at the lower temperature, and

pump out it in the form of steam from the

system.

Conduct the leak check firstly before

vacuumizing. If vacuumizing without the leak

check, it is difficult to find out the leaking

position after vaccumizing when there is a

certain leakage phenomenon.

The purpose of vacuumizing is to further check

the air tightness of the refrigeration system

under the vacuum condition, and prepare for

the system’s refrigerant charging. Its

procedures are as follows:

(1) Connect the high-pressure gauge hose to

the high-pressure service valve joint of

refrigerant tank, shown in the figure below,

connect the low-pressure gauge hose to the

low-pressure service valve joints on the

pipe from the evaporator to the A/C

compressor, and connect the intermediate

hose to the interface of vacuum pump.

(2) Turn on the high- and low-pressure valves

of manifold pressure gauge, and start up

the vacuum gauge.

(3) The vacuum pump works for at least 15

min to make the vacuum reading of

low-pressure gauge below 30psi . If the

vacuum reading can’t be obtained, turn off

the manual valves at the high- and

low-pressure sides, stop vacuumizing, and

check the leaking position.

(4) Turn off the valves, and the gauge needle

doesn’t return back within 10 min, which it

is called the vacuum leakage check method.

If the vacuum down, it shows that there is a

leaking position which can be found out by

using a leakage detector.

(5) If the gauge needle doesn’t considerably

1- Connect to low-pressure service valve hose

2- Connect to high-pressure service valve hose

3-Low-pressure gauge

4-High-pressure gauge

5-Low-pressure manual valve

6-High-pressure manual valve

7-Vacuum pump

Low

pressu

On

On

Vacuumizing

High

pressure

On

U-12

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 13

return back within 10 min, it indicates that

the system is normal and the refrigerant can

be charged into the system.

(6) Restart the vacuum pump, and turn on the

low-pressure valve of the manifold

pressure gauge to continuously vacuumize

15 min. Then, turn off the low-pressure

valve to stop vacuumizing, and prepare for

charging the refrigerant.

7. Refrigerant Recycling Equipment Operation Guide

Recycle the refrigerant from the

refrigeration device

When the refrigerant is removed from the

OIL BOTTLE

refrigeration device under the following

conditions, a recycling receiver shall be

applied to recycle the refrigerant.

Before the components on the refrigerant pipe

are replaced.

DRAINED

OIL

QUANTITY

When moisture or air enters into the

refrigerant pipe.

When excessive refrigerants are charged into

the system.

WARNING:

(1) When the recycling receiver is required, take care to operate it according to the

requirements of device manufacturer's instructions.

(2) After the completion of recycling work, measure the level of compressor oil recycled so

that the same quantity of oils are added to the refrigeration device in the future.

Operation guide for refrigerant recycling receiver

1. Install the manifold pressure gauge kit on the service valve.

2. Recycle the refrigerant from the refrigeration device.

(a) Connect the intermediate hose to the recycling receiver.

(b) Operate the recycling receiver.

(c) Open the manual high- and low-pressure valves on the refrigeration pressure gauge kit.

1. After the completion of recycling work, turn off the recycling receiver.

2. Remove the manifold pressure gauge kit from the service valve.

U-13

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 14

A/C SYSTEM COMPONENTS

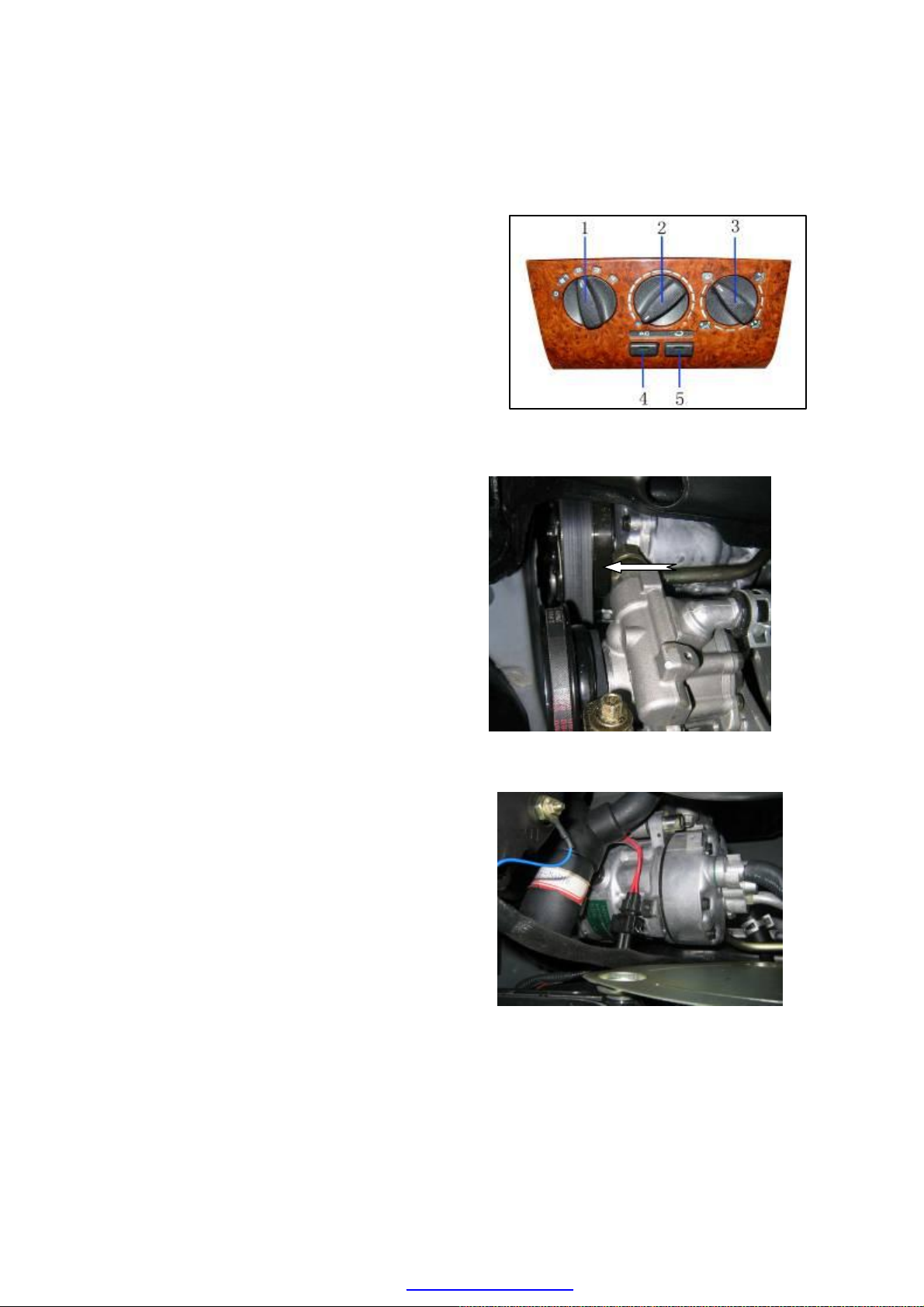

1. Function description of A/C control panel

(1) Blower switch

(2) Temperature control switch

(3) Air-flow distribution switch

(4) A/C ON/OFF

(5) Internal circulation switch

2. Removal/Installation of A/C compressor

(1) Drain off the coolant (see the coolant

recycling procedure)

(2) Loosen the drive belt, and remove it

(3) Remove the air filter and generator

(4) Remove the refrigerator pipes, and pull out

the electromagnetic clutch connector

(5) Remove the two bolts (M10*110) (with

tightening torque of 45±5N·m) used to

secure the compressor and its support.

(6) Install it in the reverse order of removal

Compressor Position and Related

Performance Parameters:

Chery A15LHD with the electronic fuel

injection type engine adopts the SD7V16 type

compressor, the performance parameters of

which are shown in the table below.

U-14

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 15

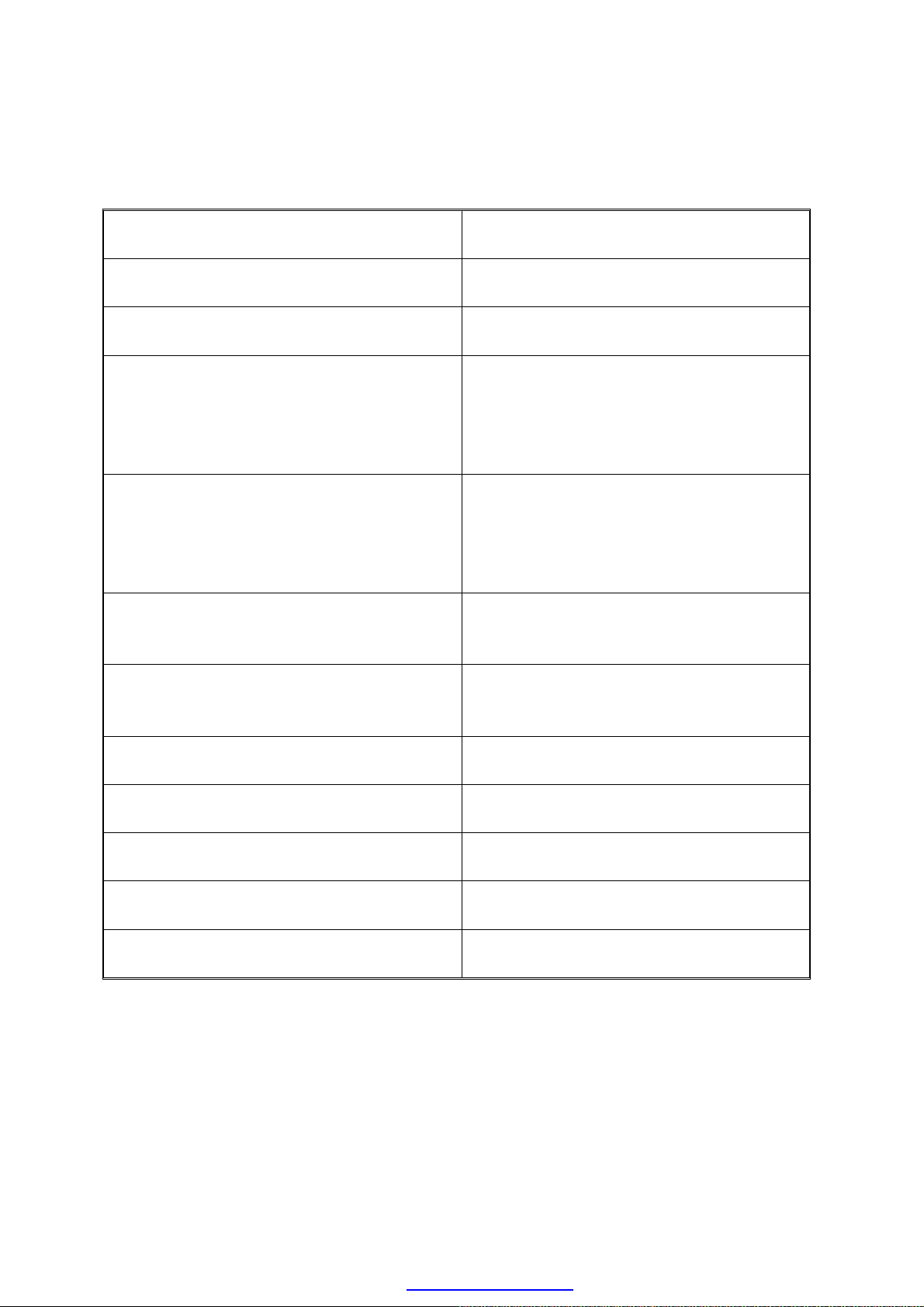

Swash Plate

Number of cylinders 7

Cylinder diameter (mm) 29.3

Travel (mm)

max

min

Displacement (cm³/r)

max

min

Allowable maximum instantaneous speed

34.2

2.2

161.3

10.4

8000

(r/min)

allowable maximum continuous speed

7000

(r/min)

Coolant R134a

Refrigerant oil (cm3) 115±15

Electromagnetic clutch mass (kg) 2.2

Rated voltage (V) 12

Rated power (W) 48

U-15

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 16

The compressor is driven by engine crankshaft pulley via the M belt. When the shift lever

on the A/C control mechanism is shifted to the refrigeration position, the electromagnetic

clutch of A/C compressor engages, and the compressor pulley make the main shaft and

swash plate rotate and then pull the rocking plate to swing. The swinging of the rocking

plate pushes the piston to move, which creates the air pumping effect to compress the

low-temperature and low-pressure air-state coolant into the high-temperature and

high-pressure air-state coolant.

The motion parts of compressor are lubricated using the sputtered refrigerant oil and the oil

in coolant. During the operation of compressor, due to the rotation and swing of the swash

plate, the refrigerant oil will be sputtered to anywhere. In addition, due to the intersolubility

of coolant and oil, when the coolant flows into the compressor, it also carries a part of

refrigerant oil which is available to lubricate the motion parts inside the compressor.

ADJUSTMENT OF ELECTROMAGNETIC CLUTCH

1. Use a thickness gauge to measure the clearance between the platen and A/C compressor

pulley.

2. Check whether the clearance is in the range specified by the technical specification.

• If it is found that the result doesn’t conform to the requirement of technical specification,

remove the platen, and use one or several shims to adjust the clearance.

Clearance:

0.6mm±0.2mm

3. Removal/Inspection of condenser

(1). Drain off the coolant from the system (see the

coolant recycling procedure)

(2). Remove the front bumper and headlamp crossbeam

assy.

(3). Remove the fluid reservoir and the refrigeration

pipes connecting to the condenser.

Check the condenser:

(1) Check the crack, damage or oily fluid leakage.

·Replace the condenser if any failure above occurs.

(2) Check whether the fender position is blocked by dust

or not.

·Clean it if blocked.

(3) Check the bent condition of fender position.

·Use a flat headed screwdriver to straighten the fender

U-16

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 17

position if the bent is found.

Installation of Condenser

(1) Use some self-tapping screws to secure the

condenser and radiator, and assemble the related

screw bush and spacer, with the tightening torque

of 6±0.6N·m;

(2) Use the bolts (M6) and spacer to secure the

condenser support on the front crossbeam, with the

tightening torque of 1.5±0.15N·m;

(3) Assemble the integrated condenser-radiator into the

related fixing holes;

(4) Use spacer, shim block and two nuts to fasten the

condenser and front crossbeam, where the tightening

torque of nut is 1.5±0.15N·m.

The condenser is designated to cool the coolant vapor

discharged from the compressor and condense the vapor

to make it give off its heat and become to the coolant

fluild.

Chery A15LHD adopts the serpentine condenser, as

shown in the figure. The condenser is secured with

engine radiator in a row, and there is an axial fan, which

is driven by a DC motor, behind them to forcedly cool

the condenser and radiator.

Introduction to the fluid reservoir:

Removal/Installation (see the Removal of Condenser)

Chery A15LHD’s fluid reservoir is located under the

condenser (i.e., the outlet of condenser), the structure of

which is shown in the figure.

In fact, the fluid reservoir is a pressure container used to

store the coolant, and it is available to delivery the

fluid-state coolant to the expansion valve at a specified

flow rate. The filter screen of fluid reservoir is applied to

filter the all kinds of foreign materials from the coolant.

The drying agent silicon oxide with powerful water

absorptivity is filled in the drying unit, which is used to

absorb the water content in the coolant. In addition, a

fusible plug is also installed on the reservoir. If the poor

heat emission of condenser or other causes result the

rapid rise of temperature and pressure of the

U-17

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 18

refrigeration system, the fusible plug will metal so as to

drain off the high-temperature and high-pressure coolant

when the temperature and pressure inside the reservoir

reach the specified value, which protects the

refrigeration system.

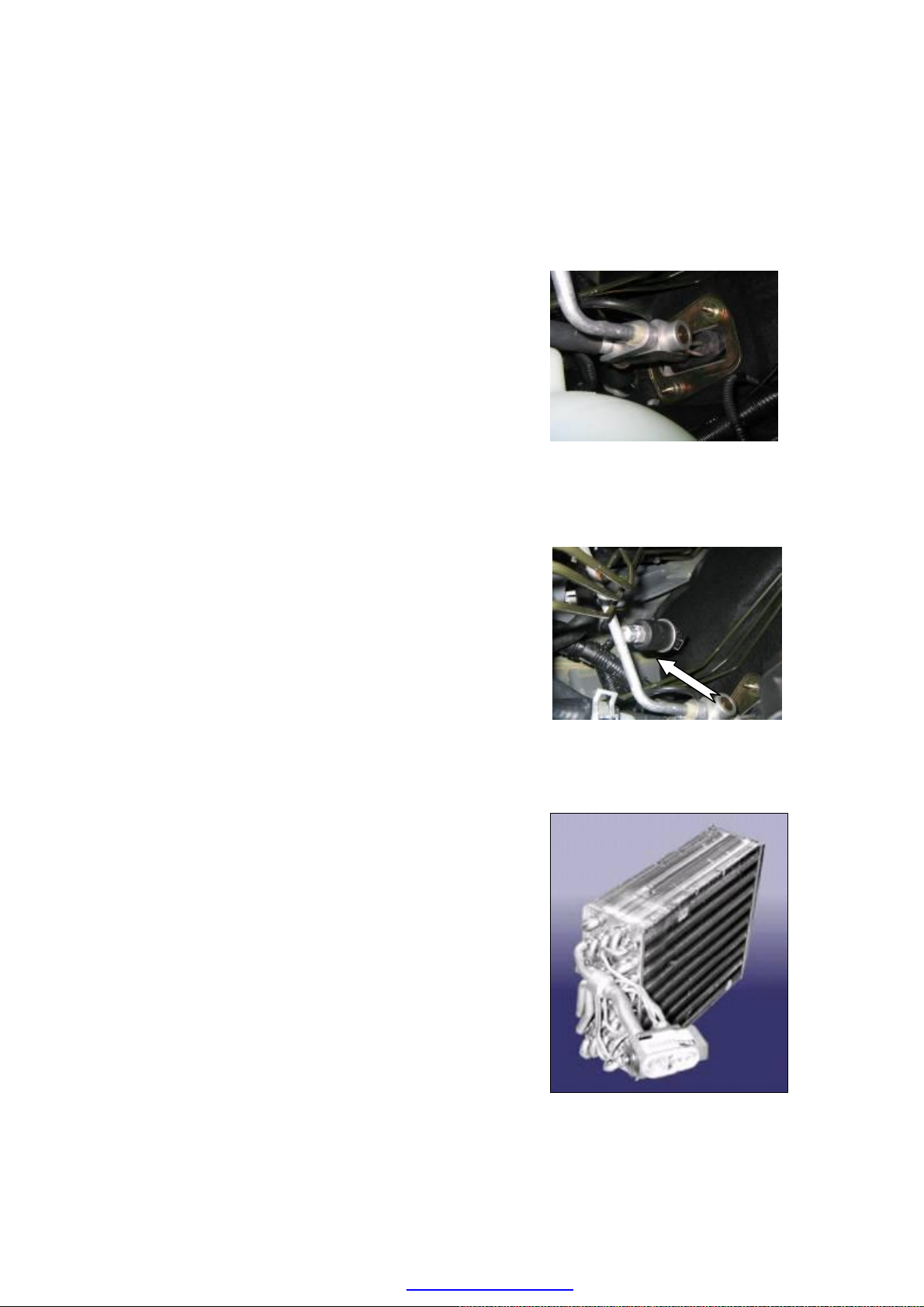

4. Introduction to the expansion valve and pressure

switch

1) Expansion valve

Chery A15LHD adopts the traditional thermo-expansion

valve, as shown in the figure, fixed on the inlet/outlet

pipes of evaporator.

The temperature sensor inside the expansion valve

adjust the opening of ball valve in accordance with the

temperature of coolant located at the evaporator outlet,

the purpose of which is to control the flow rate of

coolant.

2) Pressure switch

Chery A15LHD’s A/C pressure switch adopts the

dual-pressure (high and low pressures) and four-wire

pressure switch which is installed on the high pressure

pipe located at the front end of expansion valve, with 50

PSI or more of low-pressure CLOSE operation and

220 PSI or more of high-pressure CLOSE operation

5. Removal/Installation and inspection of evaporator

(1) Drain off the coolant from the system (see the

coolant recycling procedure)

(2) Remove the expansion valve

(3) Remove the instrument panel (see the

Disassembly/Assembly of Instrument Panel)

(4) Remove the control panel trim plate, and 4

self-tapping screws used to secure the control panel

and console. (tightening torque of 1.5±0.2N·m)

(5) Remove 1 bolt (M8*25) and 4 nuts secured with the

steering crossbeam and front side respectively

(tightening torque of 3.5±0.2N·m) from the fixed

evaporator.

(6) Remove the four bolts from the evaporator.

Inspection of evaporator:

U-18

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 19

(1) Check the crack, damage or oily fluid leakage.

·Replace the evaporation unit if any failure above

occurs.

(2) Check the bent of fender.

·Use a flat headed screwdriver to straighten it if a bent

is found.

The Chery A15LHD adopts the tube-fin type evaporator

which is installed in the air conditioning unit assy. under

the instrument panel.

The function of evaporator is opposite to that of

condenser. After expanded in the expansion valve, the

coolant fluid absorbs the heat inside the vehicle from the

evaporator, and evaporates to the coolant gas, then

enters into the compressor to circulate.

Introduction to the evaporator temperature sensor

(thermostat):

The evaporator temperature sensor used by the Chery

A15LHD is the heat-sensitive tube mechanical type

temperature regulator, which is closed when the working

temperature is adjusted to 4 or more while ℃

disconnected when adjusted to 4 or below. Its ℃

installation position is just under the evaporator, as

shown in the figure.

The tightening parameters of A/C pipe fasteners

Inner hexagonal head bolt (M10) secured in the

compressor: 30N•m;

Inner hexagonal head bolt (M6) secured in the

expansion valve: 7N•m;

To connect with condenser inlet pipe and tighten the

nuts: 32 N•m;

To connect with condenser outlet pipe and tighten the

nuts: 11.9 to 13 N•m;

U-19

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 20

FAILURES AND SHOOTING ANALYSIS SHEET

1. Precautions on A/C system installation

(1) For the pipes fixed using the fixing nuts, two

wrenches must be applied to ensure that the

pipes don't deform or break;

(2) Do not use the compressed air to clean the pipes,

and the nitrogen or coolant gas is available;

(3) Correctly assemble it, and check the tightening

torque of all connections as required;

(4) Check all parts to ensure that they aren’t damaged

and all adjacent parts don’t interfere each other;

(5) Conduct the leakage test to ensure there is no

leakage in the A/C system.

U-20

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 21

PRECAUTIONS ON THE SECURITY OF A/C SYSTEM

Coolant treatment

1. The operator shall pay more attention to prevent the coolant fluid from spraying into

your eye or on your skin because the fluid-state coolant is very dangerous. Only one drop

of coolant will cause your skin to be damaged partially if it drops up the skin of the skin.

You must put on your grooves and protective goggles. When the coolant sprays into your

eye or on your skin

(a) Use the cold water to clean those parts

(b) Do not wipe your eye or skin

(c) Immediately get to a hospital to have a professional personnel treat it.

It is recommended to use such equipment as the recovered, recycling, or reused equipment. If

there is any emergency system failure, it is recommended that the equipment is placed on a

ventilation treatment site before the implementation of the equipment maintenance service.

2. Do not dispose the coolant located at a closed place or near fire. If the coolant gas contacts

with sparks or the similar heat source (such as: cigarette or heater), it will generate the toxic

gas.

Storage of coolant

A6E851001039W02

1. The coolant shall be stored in the high-pressure resistance equipment, and take care to

slightly place the fluid reservoir to prevent the reservoir from being impacted by some sharp

materials. Heating the coolant fluid reservoir or taking it near the fire will make it explode,

and the metal fragment generated and the sputtered fluid-state coolant will cause the serious

injury to people. It is recommended to store the coolant under the environment of 400C

(1040F) below.

Safety Notices

1. Do not sit inside the vehicle which operates at the idle speed for a long time, and also do

not leave a child in the vehicle.

2. Switchover the air conditioner to the external circulation mode and inhale the fresh air

into the vehicle from the outside, and change the blower switch to the High-Speed

position when the engine has operated in an unclosed environment for a long time.

3. Avoid the open of luggage boot cover during driving because the gas emitted from the

engine may enter into the vehicle. If the boot cover must be opened, please close all

windows, and change the air conditioner to the external circulation mode to inhale the

fresh air into the vehicle from the outside.

4. Do not open the high-pressure valve of manifold pressure gauge during the operation of

compressor. If the high-pressure valve is opened, the coolant will flow in the reverse

direction and cause the fluid reservoir to be broken.

U-21

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 22

Coolant shortage treatment

·If it is found that there is the coolant shortage during checking the failure, it is

recommended to add the coolant. The reason is: there is the difference between the pressure

values indicated by the different pressure gauges, so it is difficult to add the coolant with

accurate quantity in accordance with the pressure reading. If the coolant added is excessive

or insufficient, it may cause a series of negative effects, such as: to damage the coolant

recycling parts, or, to reduce the refrigeration effect. Thus, if it is found that the coolant is

insufficient, it is recommended to completely drain off the coolant from the coolant

circulating pipes, and then add the specified quantity of coolant.

Compressor oil treatment

·For this model of vehicle, it is recommended to use the SP10 model compressor oil;

otherwise it may be available to regulate the compressor.

·Take care not to spray the compressor oil on the surface of the vehicle during the

maintenance operation. Thus, if this case occurs, immediately wipe and clean it, otherwise

the compressor oil will damage the paintwork on the surface of the vehicle.

·Engine oil shall absorb the moisture.

U-22

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 23

Relay

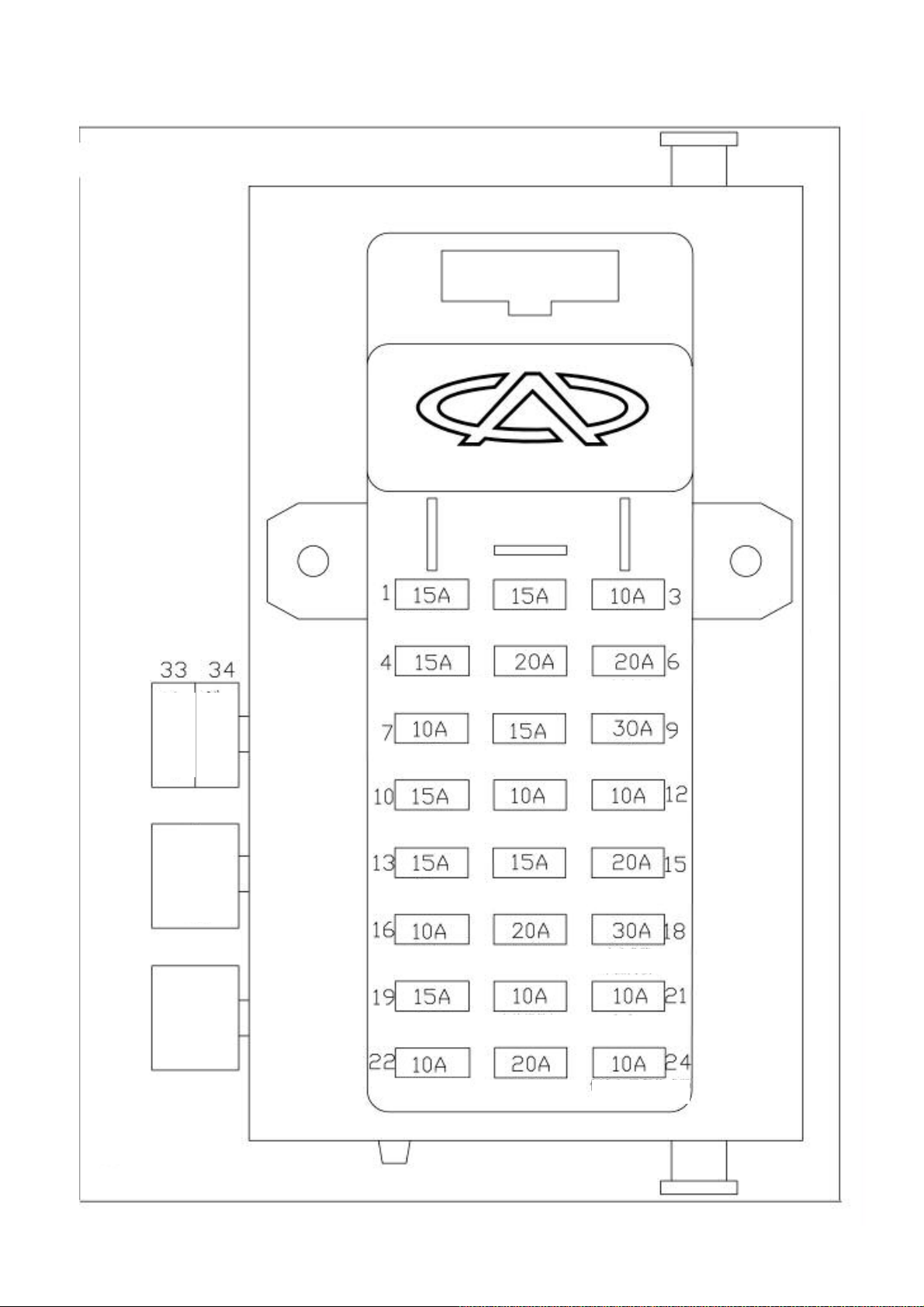

Layout Diagram Of Central Electrical Box

(Under The Steering Wheel)

A/C Clutch

ABS

Fuse

ABS

Fuse

Sunroof

,

Taxi

License Lamp

Ceiling Light

,

Trunk Lamp

,

Audio Equ ipment

Headlamp Switch

Rear W

indow Heating

Instr

ument

Wiper

A/C

Fog Lamp

Horn

Brake Lamp

Thermo

-

Sensitive Switch

Win do w R eg ul ato r

/Central Control Lock

Cigarette Lighter

Malfunction Alarm Lamp

Instrument

Back-Up Lamp

Mileage Sensor

Wiper Relay

Emergency

Alarm Relay

Burglar Alarm

Electric Rea rview Mirror

Page 24

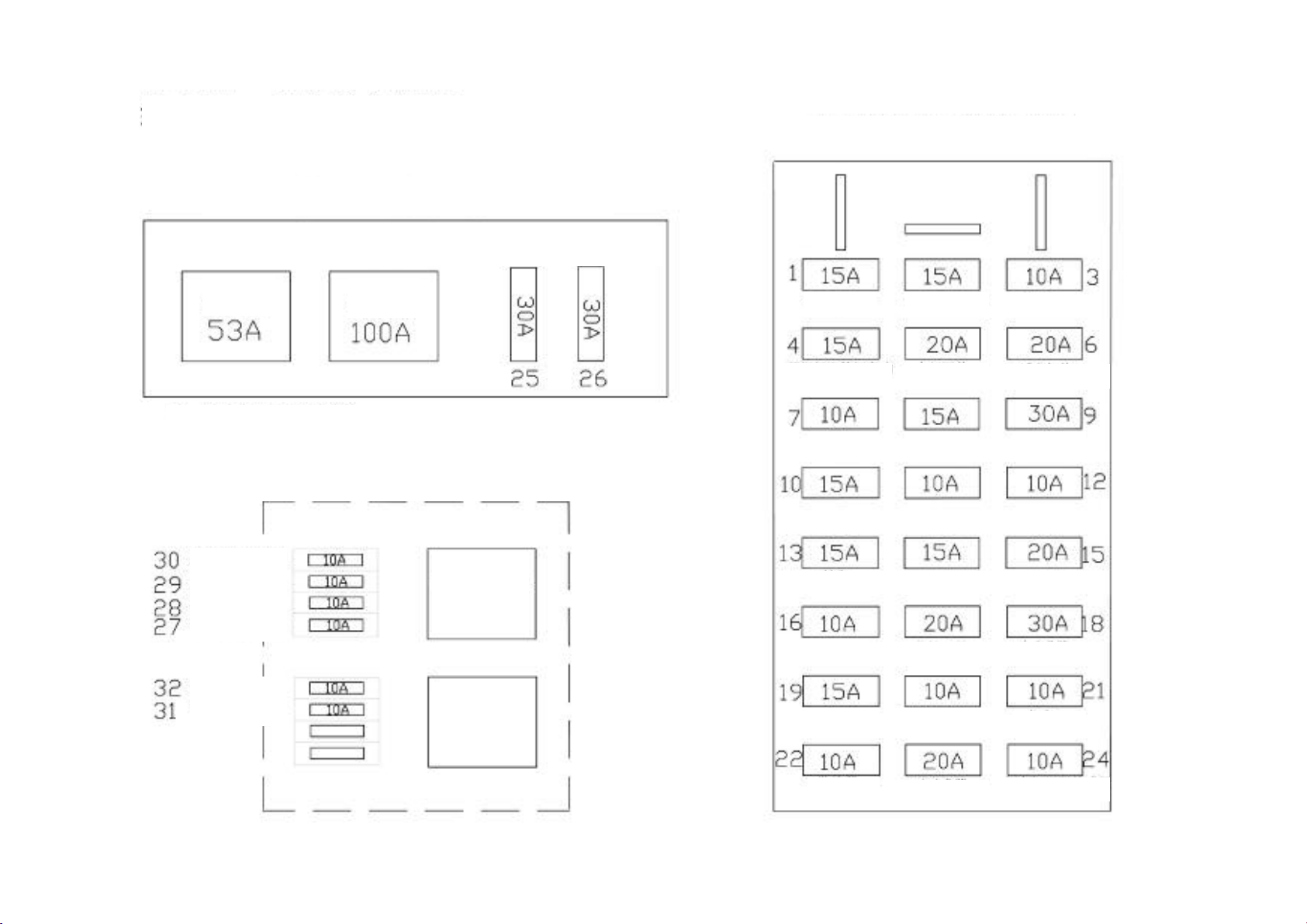

Fuse Layout Diagra

m Of Central Electrical Box

(Under The Steering Wheel)

A/C clutch

Sunroof, Taxi

License Lamp

Top LampTrunk Lamp

Fog Lamp

Window Regulator

Thermo

-

Sensitive Switch

Brake Lamp

Burglar Alarm

Window Regulation

Back-Up Lamp

mileage Sensor

Layout Diagram Of Relay

&

Fuse

Radiator Fan Control

(1)

Side Of Carwash Container

Low Speed

High

Speed

Low Speed

High

Sp

eed

Relay

Relay

Note: For Dual

-

Speed Fan, Use 50a Fuse For High Speed.

Layout Diagram (2)

Of Fuse In Relay Box

Right Of Front Engine Compartment

Fuse For Left High

Fuse For Left High

Fuse For Left

low

Fuse For

Right High

Fuse For Right

Fuse For

Right Low

Low And High

Beam Lamp

Position Light

Beam Lamp

Beam Lamp

Position Lamp

Beam Lamp

Beam Of

Headlamp

Relay

A/C

Relay

Audio Equipment

Instrument Wiper A/C

Horn

Cigarette Lighter Malfunction Alarm Lamp

Headlamp Switch

Rear Window Heating

Instrument

Page 25

Page 26

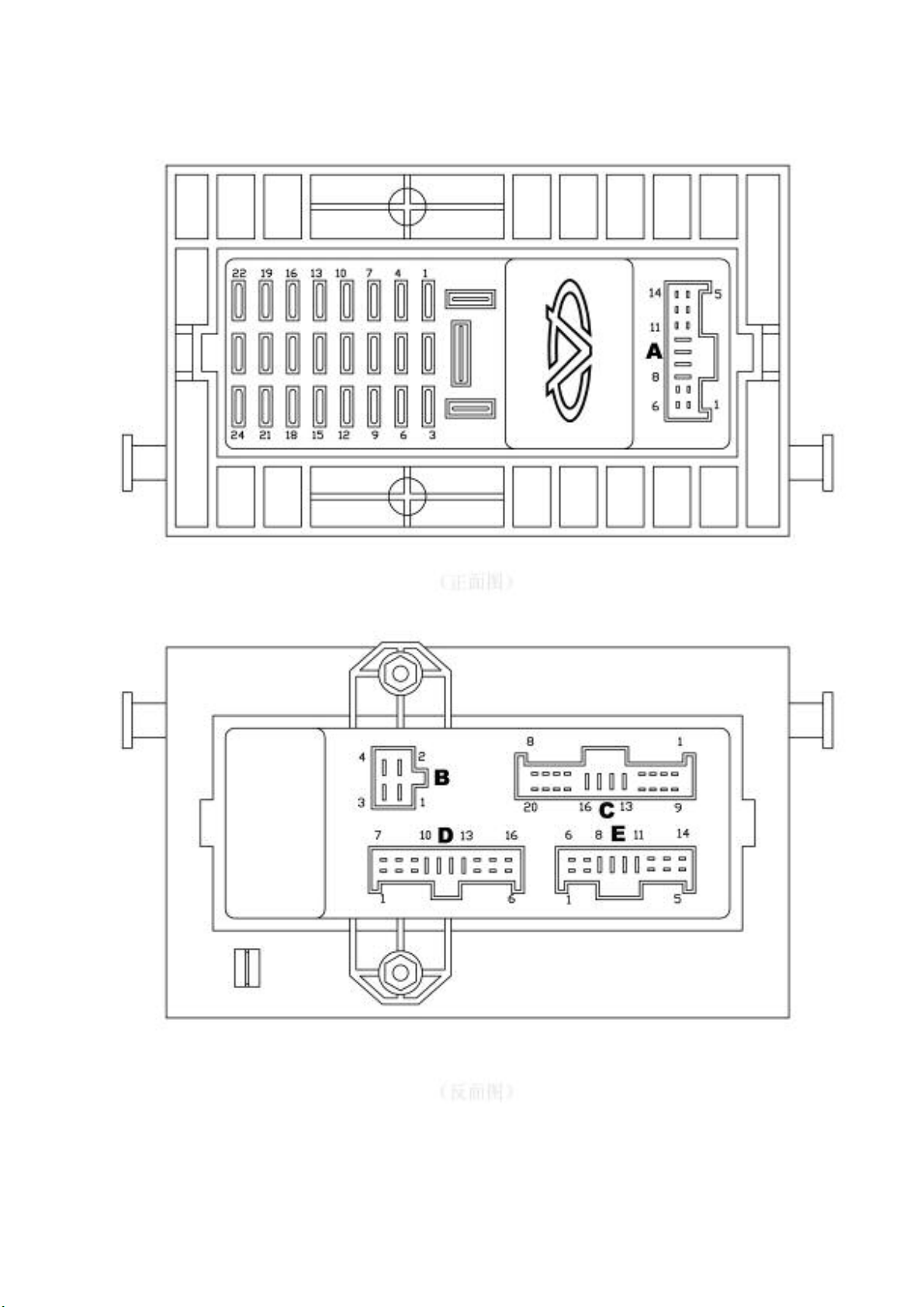

CODE AND FUNCTION DESCRIPTION OF THE INSERTING PART

AND CONTACT IN THE CENTRAL ELECTRICAL BOX

Code of

inserting part

A

01. Sunroof, Taximeter (+15)

02. A/C signal input of ECU

03. ——

04. Trunk lamp, radio, taxi mark light

05. ——

06. ——

07. ——

08. ——

09. Rear window preheating switch, rearview mirror defroster

switch

10. ——

11. Light switch, interior illuminator, power supply for ABS

diagnosis (+15)

12. ——

13. Positive grid of power supply for combined instrument (+15)

14. Brake switch

Function of contact of inserting part Circuit serial No.

——

138

——

247

——

——

——

——

134

——

132

——

114

192

01. ——

B

C

02. ——

03. ——

04. ——

01. Horn switch

02. Fog lamp relay (Positive)

03. Fog lamp switch

04. Horn relay signal (30)

05. Dual-tone horn

06. Wiper motor (Positive)

07. Instrument panel indicator light, switch illuminator,

adjustable resistor of light switch

08. Back-up lamp switch

09. ——

10. ——

11. ——

12. Fog lamp relay (negative)

13. ——

14. ——

15. Thermo-sensitive switch, A/C high voltage switch

16. Positive grid of power supply for central electrical box (+30)

——

——

——

51

142

219

220

140

141

154

209

83

152

——

——

215

——

——

47

6

Page 27

CODE AND FUNCTION DESCRIPTION OF THE INSERTING PART

AND CONTACT IN THE CENTRAL ELECTRICAL BOX

Code of

inserting part

Function of contact point of inserting part Circuit serial No.

17. ——

C

D

18. Wiper intermittent relay

19. License lamp

20. Mileage meter sensor

01. ——

02. Cigarette lighter

03. Turn signal switch, headlamp regulation switch

04. ——

05. Positive grid of combined instrument (+15)

06. Sunroof, Taximeter (+30)

07. Grounding wire

08. ——

09. Rearview mirror switch, regulation module, shift lever box

(+15)

10. Ignition switch (+15)

11. Central lock controller, window regulator module (+30)

12. Ignition switch, wiper switch (+15)

13. Positive grid of power supply for central electrical box (+30)

14. ——

15. ——

16. ——

——

149

210

81

——

129

175

——

116

——

53

——

272

14

260

8

10

——

——

248

01. ——

02. ——

03. ——

04. A/C compressor electromagnetic clutch

05. ——

E

06. ——

07. ——

08. Positive grid of power supply for central electrical box

(+30).

09. Ignition switch (+15)

10. Light switch

11. ——

12. Horn relay

13. ——

14. ——

——

——

——

137

——

——

——

5

9

207

——

139

——

——

Page 28

Illustration Of This Circuit Diagram Book

Page 29

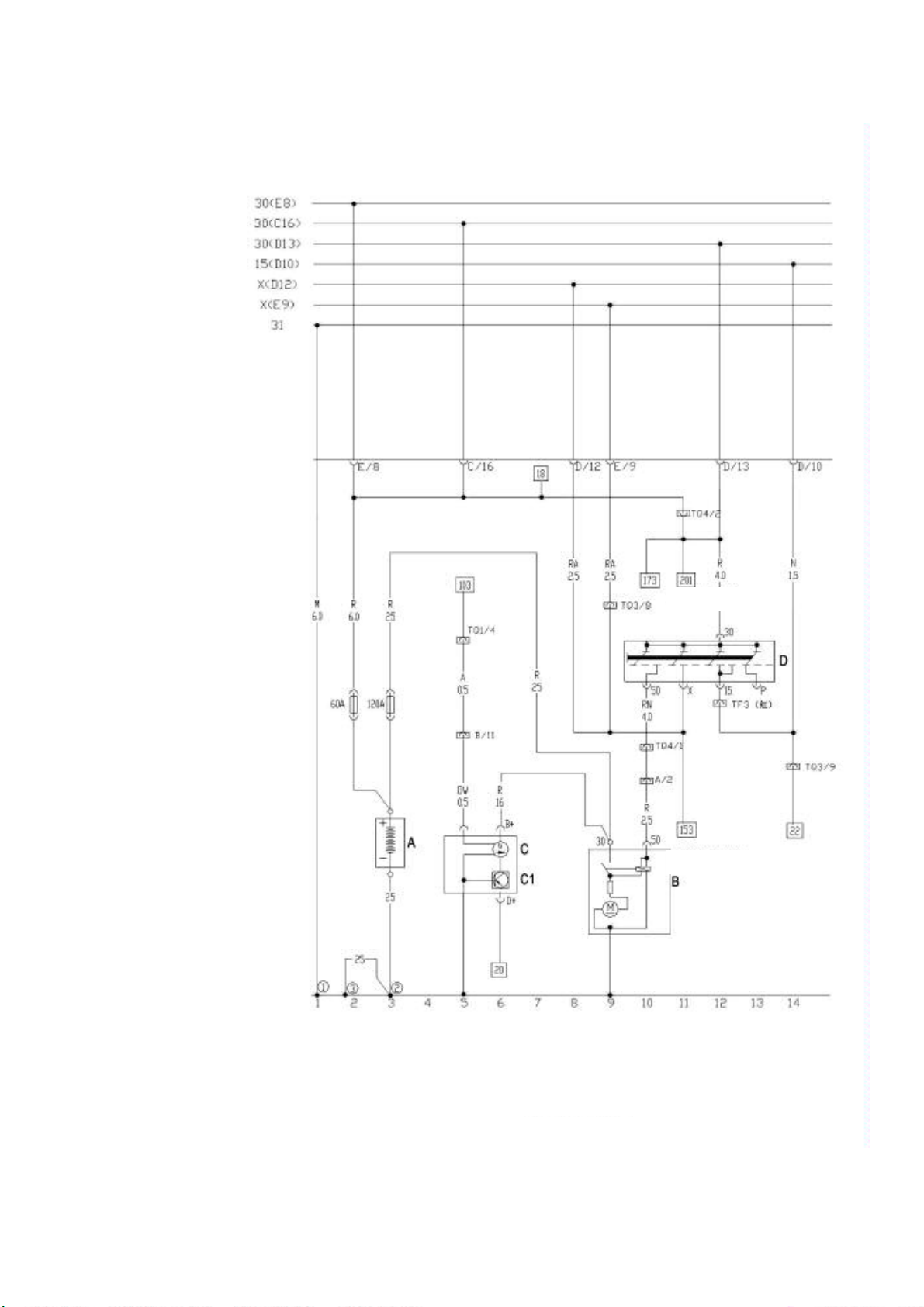

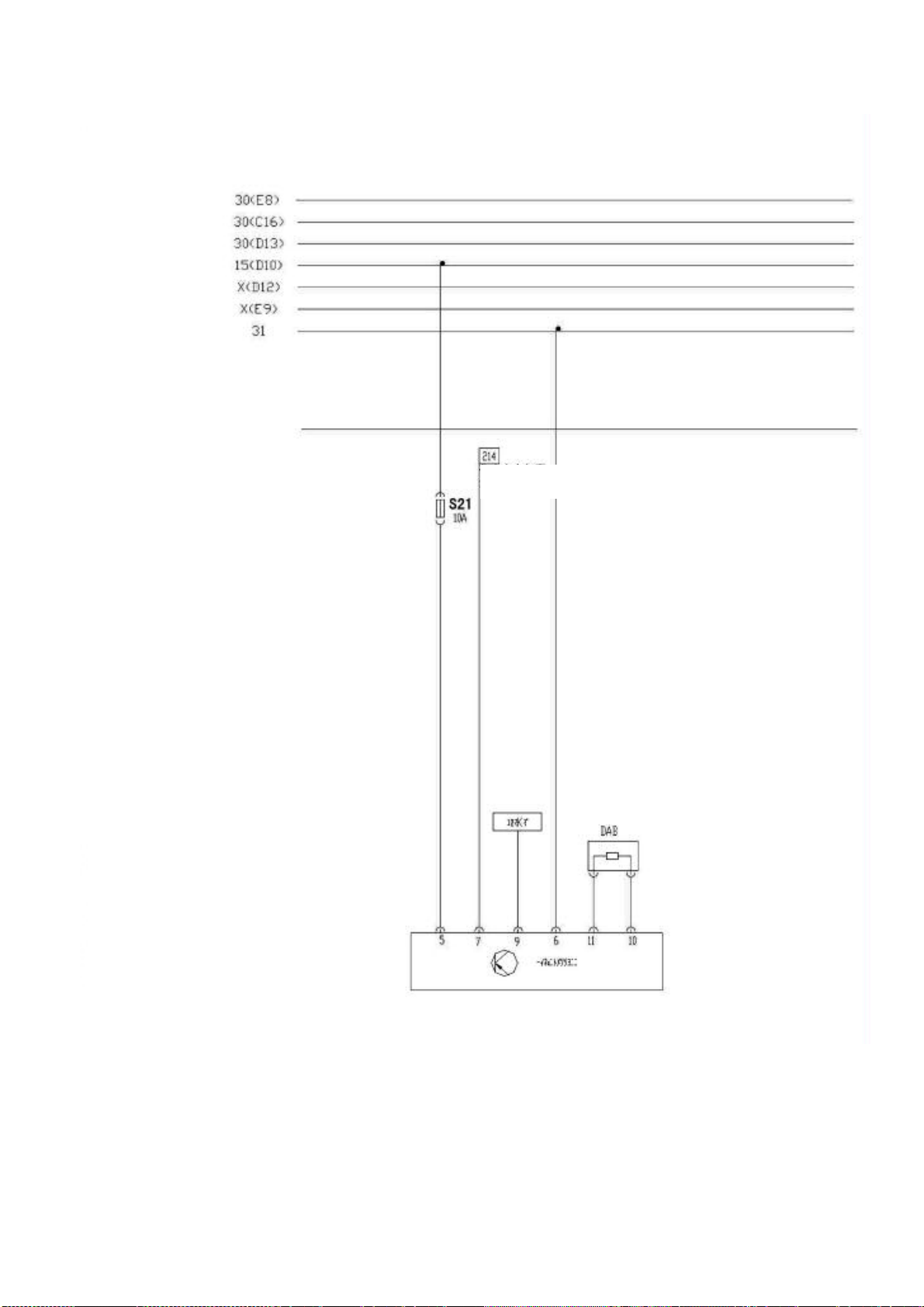

NOTES ON COMPILATION

1. The circuit code on the main circuit board of the central electrical box

30: No fuse, positive grid is connected directly from the battery;

15: No fuse, the positive grid is connect to the ignition switch;

X: No fuse, the positive grid is connect to the ignition switch, and cut off in the starting process.

31: Dummy ground wire, this wire maybe exist or not.

Example: 30(E8) indicates that the positive grid wire of No.30 in the central electrical box is directly output

from the battery and connected to the 8# pin of plug base E in the central electrical box, other symbols such as

30(C16), 15(D10), X(D12)…can be interpreted in the same way.

2. The segmentation of the main circuit board in the central electrical box

This segmentation of the main electrical circuit board includes fuses, relays and connectors.

3. Indicating the extension of the wire or circuit

The circumstances that the wire or circuit been extended are as follows:

——Located at right of the circuit diagram on previous page

——Located at left of the circuit diagram on next page

4. Symbol of the contact point (pin) on the main circuit board of central electrical box

Can be used as “help” in referring to the circuit diagram of main circuit board, example: E/8

indicates the 8thpin of the plug base E in the central electrical box.

5. Color of the wire and cross sectional area of the wire in square millimeters (color of the

wire may not match with the actual item, so the color indicated is only used for reference)

6. Symbol of connector

This symbol is usually marked on the component itself.

7. Name of the part or component (Description can be found at the bottom left in every page of

the electrical circuit diagram).

8. Number label for the extension of circuit or wire

The number in the square box indicates the corresponding circuit serial number with the extension

of the wire in the circuit.

9. Internal wire

For the purpose of searching internal circuit of the component. The circuit comprised of this wire

maybe exist or not.

10. Grounding point

Indicated by a numerical code enclosed in a circle, its connection points are indicated in every

electrical circuit diagram.

11. Circuit serial number

Used for searching components and connection points of the discontinuous wires.

12. Connection points used in the multi-socket plug base

Given the corresponding terminal number for the socket.

Page 30

Battery, Ac Generator, Ignition Switch, Starting Motor

Headlamp Switch

/8

Wiper Swit

N=

TQ4

Double

-

socket plug in connector

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

A Battery

B Starting Motor

C Ac Generator

C1 Voltage Regulation

D Ignition Switch

ch/2

!Grounding Point, ground bracket beside the central electrical box

" Car body connection point, close to the battery.

# Grounding point of the engine, located at the side of gearbox.

Page 31

MPI System (UAES)

N=

N1

N2

N01

Fuel Pump Relay

Master

Relay

Green

Blue

Brown

Charcoal

Valve

Oxygen

Sensor

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

S35 System Fuse

S36 Fuel Pump Fuse

S37 Ecu Fuse

A+ Positive Grid Of Battery

1~4 Cylinder Ignition Coils

2~3 Cylinder Ignition Coils

Q Spark Plug

-N04 Fuel Injector

G Fuel Level Sensor

G6 Fuel Pump

Canister

Solenoid

Page 32

To

Low

Speed Relay

Stepping Motor

Water Sensor

Air Intake Pressure /

Temperature Sensor

Throttle Position

Sen

sor

To High Speed Relay

To

Low

Speed Relay

To High Pressure Switch

To Headlamp Switch

To Air Blower Switch

To Odometer Sensor

Charcoal

Canister

Solenoid Valve

Oxygen

Sensor

Phase Angle

Sensor

Tachogenerator

Knock Sensor

Dia

gnosis Port

To Wate r

Tem pe rat ur e Me ter

Air Intake Manifold Ground

Ground Of Battery Negative Grid

Page 33

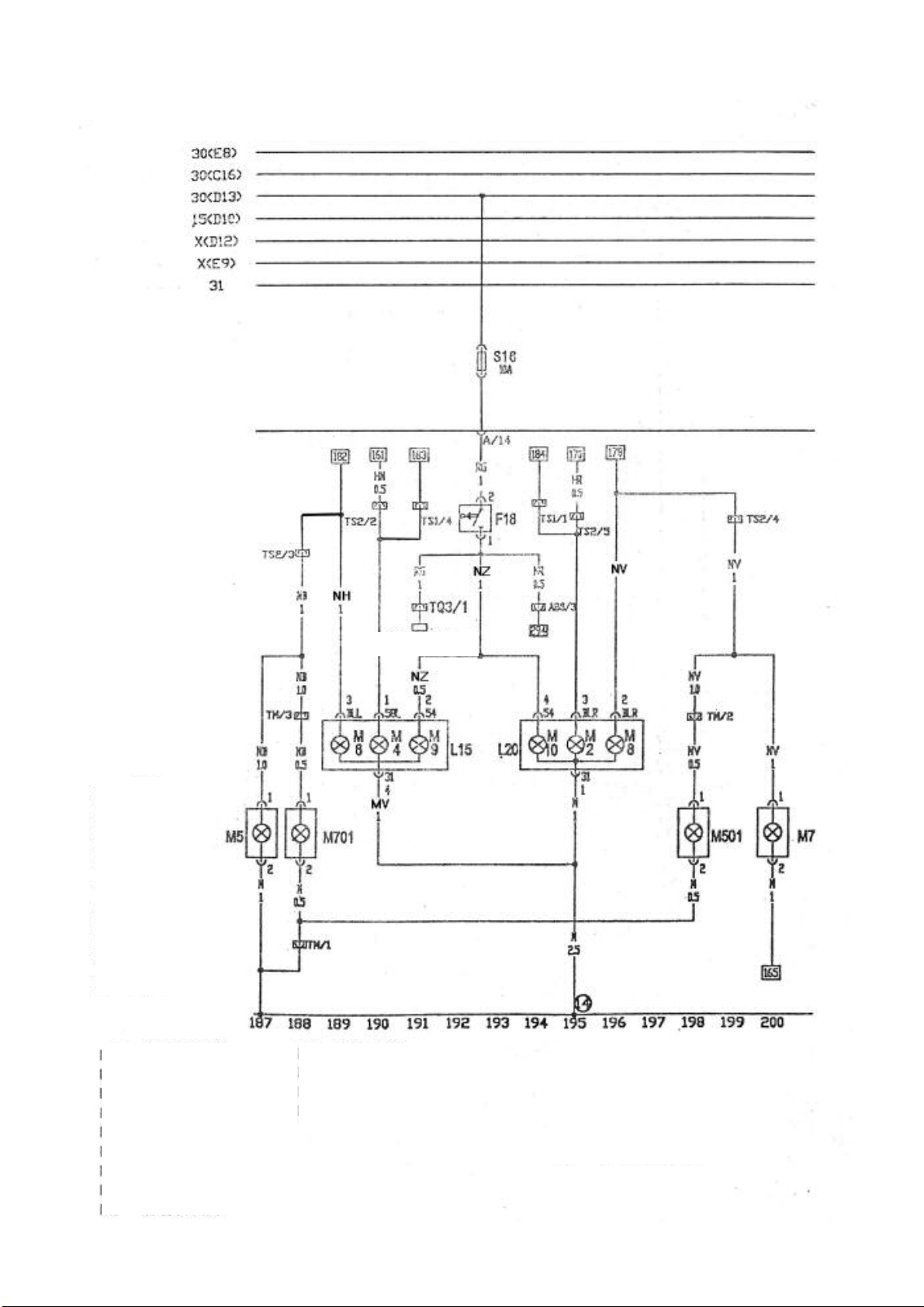

Air Conditioner, Operation Mechanism, Cooling System

N=

N

beside of

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

A+ Positive grid of battery

E9 Air blower switch

F18 Thermal-sensitive switch

23 Air blower serial regulation resistor

V2 Air blower

V7 Fan motor

J32 Grounding point, ground bracket

the central electrical box

J69 Cooling fan high speed relay

J70 Cooling fan low speed relay

J5 Air blower relay for air conditioner (in the electrical box)

J6 Rear window preheating relay (in the electrical box)

$ Grounding point, in the harness of the i protection sleeve

% Grounding point, ground bracket beside of the central electrical box

Page 34

A/C switch, Internal circulation solenoid valve

N=

N63 Internal circulation solenoid valve

High and low voltage switch

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

E35 A/C switch

E36 Internal circulation switch

K84 A/C operation illuminator

F38 External temperature switch

F23 High voltage switch

F73 Low voltage switch

&' Five-socket plug in connector

TK Main circuit grounding wire

Page 35

Oil pressure switch, Coolant temperature sensor,

Hand brake indicator light switch, Odometer sensor

N=

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

G2 Coolant temperature sensor

F22 Oil pressure switch (low voltage)

F9 Hand brake switch indicator light

F34 Brake oil level alarm switch

G40 Odometer sensor

()))*ounding point, engine cylinder block

+ Ground connection, in the headlamp harness

TQ1 Ten-socket plug in connector

F34 Ten-socket plug in connector TS2

Page 36

Radio and Six channel loudspeaker

N=

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

R Radio

R2 Front left loudspeaker

R3 Front Right loudspeaker

R4 Rear right loudspeaker

R5 Rear left loudspeaker

R6 Front left loudspeaker

R7 Front right loudspeaker

R1 Antenna

T8 8 socket plug in connector

T1 Single-socket plug in connector

Page 37

Instrument Panel And MFA

N=

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

F10 Multi-channel converter

F15 Stabilizer

G20 Fuel sensor

G25 Coolant temperature sensor

G30 Rpm sensor

G35 Preset level comparator

J114 Control unit

J119 Multi-function display

K1 Abs alarm light

K2 Left-turn signal lamp

K3 Right turn signal lamp

K4 Generator charging alarm light

K5 Engine self-inspection

indicator light

K6 Hand brake alarm light

Oil pressure alarm light

Engine over-temperature alarm light

Instrument panel illumination light

Instrument panel illumination light

Instrument panel illumination light

Instrument panel illumination light

Low beam lamp,position alarm light

K14 Single socket plug

in connector

K15 Fuel alarm light

Y1 Digital clock

T1 High beam alarm light

Page 38

Front Fog Lamp, Cigarette Lighter, A/C Panel Indicator Light

N=

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

A/C panel indictor light

Front right fog lamp

Front left fog lamp

Coolant level switch

Cigarette lighter indicator light

Cigarette lighter

, Grounding point, in the headlamp harness

Page 39

Compressor Magnetic Clutch, Dual-Tone Horn

N=

N25

Z1

Rear win

dow

heater

Rear Window Heating System

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

J1 Idle speed accelerating relay (in the electrical box)

J3 Dual-tone horn relay (in the electrical box)

L39 Rear window heating switch illuminator

K10 Rear window heating switch

E15 Rear window heating indicator lamp

Compressor magnetic clutch

H1(2) Dual-tone born

- Grounding connection point, in the harness of dual-tone horn

Page 40

Wiper, Washer, Horn Button

N=

V

5

Wa sh er

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

E22 Wiper switch

H Horn button

J31 Intermittent wiper relay

S5 Fuse 15A

V Wiper motor

Page 41

Front Headlamp, Light Relay, Front Position Light

N=

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

A+ Positive grid of battery

L1 Left high beam lamp

L2 Left low beam lamp

L3 Right low beam lamp

L4 Right high beam lamp

M1 Right position lamp

M3 Left position lamp

J55 Light relay

S27 Right high beam lamp fuse 10A

S28 Left low beam lamp fuse 10A

S29 Left position lamp fuse 10A

S30 left high beam lamp fuse 10A

S31 Right low beam lamp fuse 10A

S32 Right position lamp fuse 10A

. Grounding point, in the harness of headlamp

Page 42

Turn Signal Lamp Switch, Emergency Alarm Relay

N=

Parking Light Switch

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

E2 Tur n signal lamp switch

E3 Emergency alarm light switch

E4 Light changing and turn signal lamp switch

E19 Parking lamp switch

J2 Emergency alarm light relay

K6 Emergency alarm light

S17 Fuse 10A

Page 43

Tail Lamp, Stop Lamp, Side Lamp

N=

E

lectronic fuel i

njection

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l low

F18 Brake lamp switch

L15 Right tail lamp

L20 Left tail lamp

M2 Rear left position lamp

M4 Rear right position lamp

M5 Rear left turn signal lamp

M6 Front left turn signal lamp

M7 Front right turn signal lamp

M8 Rear right turn signal lamp

braking signal

M9 Left brake lamp

M10 Right brake lamp

M501 Right turn signal lamp

M701 Left turn signal lamp

S20 Fuse

S7 Fuse

S8 Fuse

T3 3-socket plug in connector

T1 Single-socket plug in connector

/ Grounded in the rear lamp

Page 44

Light Switch

N=

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

E1 Light switch

E20 Panel indicator light/adjustable

resistor for instrument illuminator

L9 Panel indicator light

S3 Fuse 10A

Page 45

Rear Fog Lamp, Backup Lamp

N=

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

E23 Front fog lamp switch

J4 Fog lamp relay (in the electrical box)

K17 Rear fog indication lamp

L1 Rear fog lamp

L40 Front and rear fog lamp switch illuminator

S10 Fuse 15A

S14 Fuse 10A

E24 Rear fog lamp switch

T3 Three-socket plug in connector

T3a Three-socket plug in connector

T2 Two-socket plug in connector

T1 Single-socket plug in connector

T1a Single-socket plug in connector

Page 46

Interior front and rear lamp, Trunk lamp, Door switch,

N=

License lamp, Shadow shield light

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

F2 Front left door switch

F3 Right front door switch

F5 Luggage boot light switch

F10 Rear right door switch

F11 Rear left door switch

TB Two -socket plug in connector

TD Four-socket plug in connector

TAa Tw o-socket plug in connector, left of luggage boot

W1 License lamp

W3 Trunk lamp

W4 Shadow shield light

W5 Delay on/off interior front ceiling light

X Interior rear ceiling light

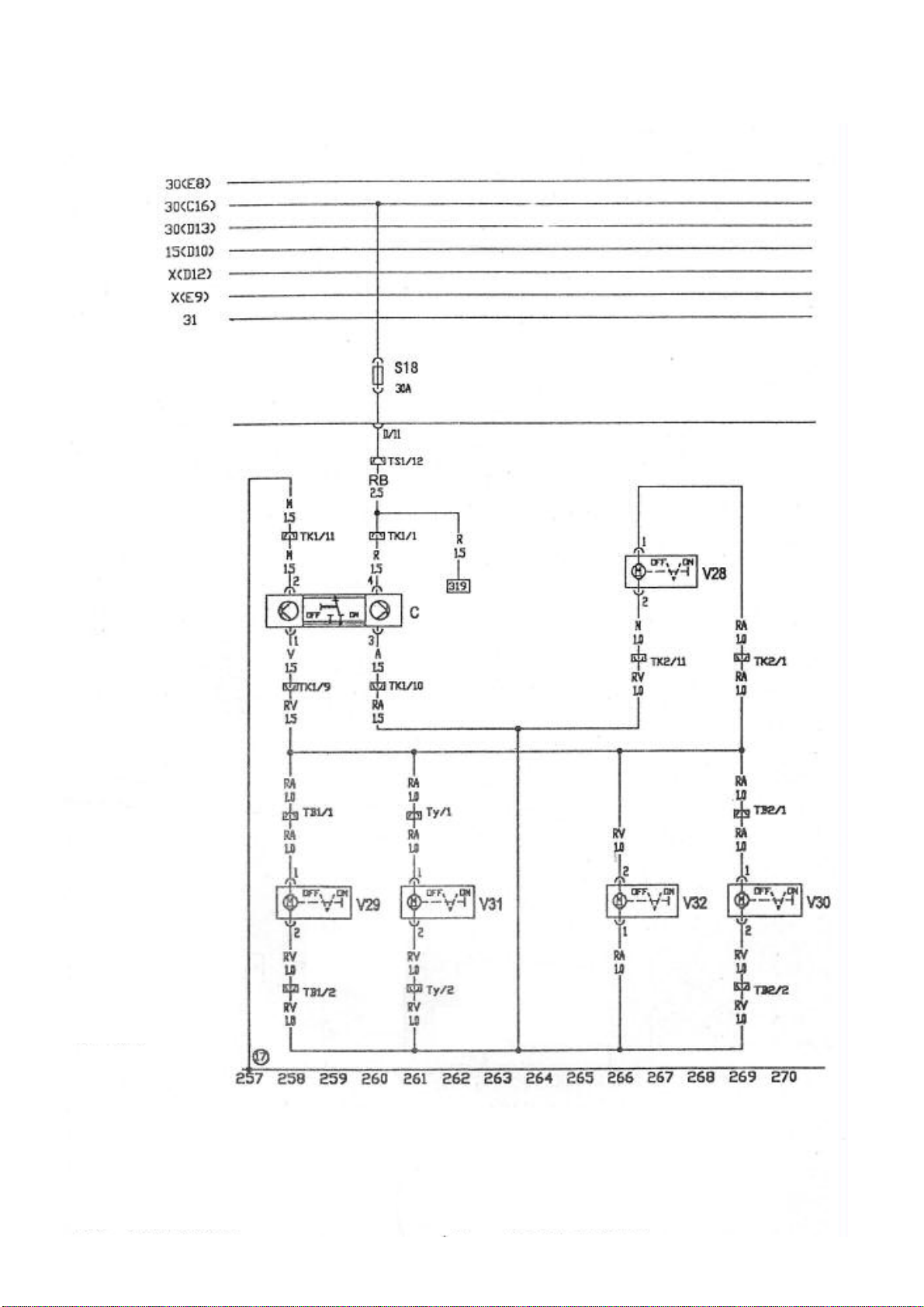

Page 47

Central Door Lock

N=

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

C Central lock controller (in the front left door)

V28 Front right door lock control motor

V29 Rear left door lock control motor

V30 Fuel tank lid control motor

V31 Trunk lock control motor

V32 Rear right door lock control motor

TB1 Four-socket plug in connector (left column B)

TB2 Four-socket plug in connector (right column B)

TK1 12-socket plug in connector (left column A)

TK2 12-socket plug in connector (right column A)

Ty Tw o-socket plug in connector (left column C)

0 Grounding point beside of the central electrical box

Page 48

Electrical Rearview Mirror

N=

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

F77 Rearview mirror switch

X1 Left adjustment

X2 Down regulation

Y1 Up regulation

Y2 Right regulation

V17 Left rearview mirror control motor

V25 Right rearview mirror control motor

Z4 Left rearview mirror defroster

Z5 Right rearview mirror defroster

TK1 12-socket plug in connector (left column A)

TK2 12-socket plug in connector (right column A)

TZ 2-socket plug in connector

(at the side of central electrical box)

Page 49

B=White,

N=

N55 ABS solenoid valve

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

J104 ABS controller

A Battery

VG4 ABS hydraulic pump

G44 Rear right wheel RPM sensor

G45 Front right wheel RPM sensor

G46 Rear left wheel RPM sensor

G47 Front left wheel RPM sensor

S33 Power supply fuse of ABS solenoid valve

S34 Power supply fuse of ABS hydraulic pump

TK Diagnostic port

1 Grounding point, ground bracket at the side of central electrical box

Page 50

Control Unit Of Electrical Window Regulator

B=White,

N=

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

G Win do w regulator module

E40 Front left window regulator switch

E81 Front right window regulator motor

V14 Motor of front right window regulator

V15 Motor of front left window regulator

2 At the side of central electrical box

TK1 12-socket plug in connector (right column b)

TK2 12-socket plug in connector (left column b)

Page 51

Control Switch Of Electrical Window Regulator

N=

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

E39 Rear window regulator lock switch

E52 Rear left door window regulator switch

E54 Rear right door window regulator switch

E53 Rear right door window regulator switch

E55 Rear left door window regulator switch

V26 Rear left door window regulator motor

V27 Rear right door window regulator motor

TA1 4 -socket plug in connector (right column b)

TA2 4 -socket plug in connector (left column b)

Page 52

Air Bag Control Module

N=

Malfunction alarm light

Instrument air bag

B=White,

Black,

R=Red,

M=Brown,

V=Green,

A=Blue,

H=Grey,

Z=Viole t,

G=Ye l lo w

Page 53

AXLE AND SUSPENSION SYSTEM

ALIGNMENT OF THE WHEEL … … … … … … …… … … … … … … … …M-2

BASIC INSPECTION BEFORE THE ALIGNMENT……………………… … …M-2

USUAL TROUBLE OF THE TIRE… … … … … …… … …… … … …… … …M-5

ALIGNMENT OF THE REAR WHEEL … … … … … … … ……… … … … … M-9

ALIGNMENT OF THE FRONT WHEEL… … … … … … ………… … ……M-10

FRONT SUSPENSION… … … … … … … … … …… … … … … … …… …M-13

REMOVAL AND INSTALLATION OF THE FRONT SUSPENSION………… …M-13

OVERHAUL OF THE FRONT SUSPENSION… … … … … … … ……… … …M-15

REMOVAL AND INSTALLATION OF THE FRONT WHEEL BEARING … … M-19

REAR SUSPENSION AND REAR AXLE… … … … … … … …… … …… … …M-22

REMOVAL / INSTALLATION OF THE REAR AXLE ASSY …… … … …… …M-22

REMOVAL / INSTALLATION OF THE REAR SHOCK ABSORBER ASSY … M-25

OVERHAUL OF THE FRONT AND REAR AXLE… … … … … … …… ……M-28

M-1

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 54

AXLE AND SUSPENSION SYSTEM

ALIGNMENT OF THE WHEEL

It is easy to understand that the theory of the four wheels alignment related to the definitions

and the functions of various angles. However, the corresponding theory can hardly be applied

to the four wheels alignment tester and chassis maintenance due to the chassis structure of the

vehicle body, which all the angles of the four wheels alignment bear on the mechanical

structure of the chassis. For examples:

--The camber will be changed as the toe-in varied. The wheels will be turned while

adjusting the toe-in, which results the camber changing. The larger the caster is, the

more the camber changed.

--The wheel setback will be changed as the caster adjusted. When the caster increases or

decreases, the upper fulcrum of the steering shaft can move forwards or backwards and

the lowest fulcrum of the steering shaft (tire) is also movable. The front wheel moves

forwards or backwards along with the caster increasing or decreasing so that the axle

setback will be altered. The turn plate must have the function of sliding forwards and

backwards in order to make the front wheel move forwards and backwards freely.

--The toe-in will be changed as the camber varied and vice versa. Various suspension

structures have different ways to adjust the camber. If the upper or lower fulcrum is

moved left or right, not only the camber but also the toe-in will be changed. As a result,

even if the camber is properly adjusted, the stable driving status cannot be achieved

because of the toe-in changing. Therefore, after eliminating of malfunction, another one

will appear.

--Changing the toe-in of the rear wheel influences that of each front wheels. The toe-in of

the rear wheel determines the thrust angle of the rear wheel. The method of thrust line

positioning is adopted to determine the toe-in of the front wheel in all the advanced four

wheels alignment testers.

Precaution: The front wheel must be adjusted first and then the rear wheel when

processing the four wheels alignment. The sequence of the rear wheel adjustment is the

camber first, the toe-in second and so on. And the sequence of the front wheel

adjustment is the caster first, the camber second, the toe-in third and so on.

BASIC INSPECTION BEFORE THE ALIGNMENT

Check the tire pressure, tire No. and rim No.

----Check the tire pressure and adjust it to the specified pressure

Tire inflation pressure kPa

Item Front wheel

No-load/half-load

200 220 350 420

Rear wheel Spare wheel Mini spare wheel

Full-load 210 260 420 420

M-2

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 55

----Rim and Tire

A15LHD wheel No.

Tire No. Rim No.

185/60 R14×82H 6J×14

Note:

The above tire-rim combination is suitable for the steel or aluminum alloy rim. Please

do not use rims and tires of other models which may lead to improper consequence.

Preaution: Be sure to consult the relevant instruction if non-standard tires or rims (such

as light weight alloy rims or wheels of winter tire)should be installed.

Positioning of the tire

Different working conditions between the front wheel and the rear wheel lead to the different

wear status, which depends mainly on the road condition, the driving custom and so on. The

front wheel wears faster than the rear one does. In order to prevent the tires from wearing in

different degrees and to prolong the service life of the tires, it is necessary to check and rotate

the tires, adjust the tire pressure, and examine the tightening degree of the wheel bolt at

interval of 5000km.

------ Utilization of the cold-resistant tire

If using the cold-resistant tire, all the four tires must be replaced at same time. Please do not

excess the top speed and must accord to the tire pressure limited by the tire manufacturer.

Precaution: Using the cold-resistant tire may affect the safety and the maneuverability

of the vehicle. Standard tires in same size and No. should be utilized. Do not use the

cold-resistant tire as long as the road condition is available.

------Snow chain

M-3

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 56

Adjusting the snow chain of the tire should accord to the type of the road condition.

Inspection must be applied before install the snow chain. Please refer to the instruction of the

snow chain manufacturer when install the snow chain on the tire. Please remove the wheel

house before install the snow chain which may score the wheel house. Install the snow chain

firmly on the front tire. It is not recommended to fix the snow chain on the rear wheel. The

snow chain should be retightened after 0.5~1.0km driving with it.

Precaution: Using the snow chain may affect the vehicle maneuverability, so the vehicle

speed should not excess 50km/h (30mph) or the speed limited by the snow chain

manufacturer(less than 50km/h). Please stop the car and tighten the snow chain

immediately when hearing collision between the snow chain and the vehicle body or the

chassis when using the snow chain. Abrupt turning, concussion and passing the

chuckhole, the vehicle locking and braking should be avoided. The instruction of the

snow chain manufacturer should be also complied. Improper utilization of the snow

chain will cause interference between the snow chain and the vehicle body.

Installation of the tire

----Make sure that the opening of the valve is slippery and no burrs before installing the tire

valve. Then apply glycerol onto the rubber surface of the tire valve or dip it briefly in the

glycerol. Pull or press the locating ring of the tire valve with special purpose tool at the

force of 200-400N in order to make it through the hole on the wheel, which means the

installation is finished. (Suds are permitted to replace the glycerol.)

----Wipe glycerol or suds round the bead before installing the tire, and please note at the

same time:

When there is a light point mark on the rim, please aim the uniformity test mark at the point.

When there is no light point mark on the rim, please aim the dynamic balance test mark at

the position of the tire valve.

When there is no light point mark on the rim and no dynamic balance test mark but the static

balance test mark on the tire, please aim the tire valve at the static balance test mark.

The instructions for the uniformity, dynamic balance and static balance test mark of the tire

should be offered by the production department or the supplier in written form.

----Inflate the tires according to the specified pressure strictly. Please do not excess 10% of

the rated pressure during inflating. The spare tire assy is assembled at the rated pressure

of 3.5atm and is separately stored with the four tires installed on the vehicle. Please check

and adjust the tire pressure before the four wheel alignment: front wheel 2.0±0.2atm,

rear wheel 2.1±0.2atm.

----Screw the valve cap after inflating the tire and undergo the dynamic balance test. Set the

proper weight balance block onto the inside and outside brims of the rim as required. The

M-4

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 57

final assy imbalance is expected to be less than 100g·cm, approximately equal to a 5g

balance block on the inside and outside brims of the rim.

Precaution: No more than one balance block with 70g weight at most is allowed to

set on each side of a wheel. Avoid over hitting on the balance block. If that happened,

replace it immediately. Do not reuse the replaced balance block.

----During installing the wheel and the tire assy, pre-screw the wheel bolt on the rim by hand

first, and then tighten the screws with the special purpose tools under the way of diagonal

method, (the tightening torque is 100±10N·m). No impact wrench is allowed in order to

avoid screwing too tight or loose. Do not use lubricating grease while installing the wheel

bolt. (The wheel bolt should be tightened to maintain the tightening torque after the initial

100km driving since the new installation of the wheel and tire assy. The check of the

tightening torque of the wheel bolt is one of the daily service items.)

----Decussating method is adopted to tighten the set nut. The tightening degrees should be

similar so that the wheels can turn freely. The wheel should stand on the ground during

the last tightening.

----Install the trim cover or place it as required. Clip trim cover should be installed into

through beating by hand or prying by rubber tools.

USUAL TROUBLES OF THE TIRE

Proper utilization of the tire

The tire is an important part of the wheel assy. Please pay attention to the following items

while using:

------The tire of the same manufacturer and the same No. should be used on the same vehicle.

------Do not install tires out of the specified types

------Make all the tires wear evenly. In order to remedy and lighten the uneven wear, besides

periodic checking and correcting the parameters of the wheel alignment, the rotation

should be also applied. The specific rotation way depends on the practical wearing status.

It is recommended to adopt the tire rotation at interval of 5000~8000km

Usual troubles of tires and trouble diagnosis

------Wear on shoulder of tire

The wear on shoulder of tire means the brim with burrs forming of the tire wears are more

badly than other parts. The theoretical reason for the wear on shoulder of tire is that the tire

rolls at the limit lateral runout angle.

Main reason: Frequently steering at high speed, improper adjusting the toe-in and the camber,

or often driving on the vaulted or zigzag road.

M-5

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 58

Maintenance: Adjusting the positioning angle of the front wheel

------Wear on center of tire

The wear on center of tire means the abnormal wear on the center surface of the tire. The

theoretical reason for this kind of wear is that the diameter elongation at the center of the tire

surface is larger than that on the shoulder of the tire.

Main reason: Overhigh tire pressure

Maintenance: Readjusting the tire pressure to make it within the range of the specified value.

------Serrated wear

The serrated wear means the wear on the surface of the tire strip in ladder shape. The

theoretical reason for this kind of wear is the uneven deformation of the tread pattern of the

tire contact patch.

Main reason: The toe-in and the camber are not conformed to the specified value

Maintenance: Adjusting the toe-in and the camber to make it within the specified value.

Checking the tire pressure is within the specified range.

------Initial severe wear somewhere on the tire

The initial severe wear is the severe wear on the tread pattern of tire contact patch due to the

wheel locking while emergent braking.

Main reason: Vehicle speed while emergent braking, road conditions, wheel load and the

braking intensity

Maintenance: Avoiding emergent braking and taking precautionary measure as early as

possible

------Nick and crack on the sidewall of tire

The main reason is the sharp things on the road or the little stones, nails and metal flakes

embedded into the tread slot.

------Initial wear on half round of the tire or wear in different places of the shoulders on

both sides

The main reason is the gyration part is in unbalanced state, or the tire and wheel are eccentric,

or the bearing is worn or loose and so on. The eccentricity or bend of the rim or the steering

knuckle may also cause the wear.

Troubleshooting Guide

Trouble Possible causes Solutions

Serious wear of tire

Tire noise Improper tire pressure Adjust

PDF created with pdfFactory Pro trial version www.pdffactory.com

Improper tire pressure Adjust

M-6

Page 59

Degradation of tire Replace

Road noise or

vehicle vibration

Up-and-down

shaking of steering

wheel

Circular vibration of

steering wheel

Insufficient tire pressure

Unbalance of tire

Deformation of rim or tire

Uneven wear of tire

Overbeating of tire and rim

Looseness of wheel nut

Unbalance of tire

Breach or wear of engine bearing

pad

Breach or wear of transmission

bracket rubber

Overbeating of tire and rim

Looseness of wheel bolt

Unbalance of tire

Uneven wear of tire

Insufficient tire pressure

Damage or wear of front wheel

bearing

Malfunction of steering system

Malfunction of suspension system

Adjust

Adjust

Repair or

Replace

--

Replace

Lock

Adjust

Replace

Replace

Replace

Lock

Adjust

--

Adjust

Replace

--

--

Improper tire pressure

Serious or uneven wear of tire

One side deflection

of steering wheel

Unstable running

PDF created with pdfFactory Pro trial version www.pdffactory.com

Malfunction of steering system

Malfunction of braking system

Malfunction of suspension system

Uneven tire pressure of both sides

Deformation of rim or tire

Looseness of wheel bolt

Malfunction of steering system

M-7

Adjust

--

--

--

--

Adjust

Repair or

Replace

Lock

Page 60

Malfunction of suspension system --

--

One side deflection

of braking

Heavily steering of

steering wheel

Improper

returnability of

steering wheel

Check whether the connection of the transmission rod of steering system is loose,

deformed, etc.

Check the status of the ball joint and the rubber bush of front and rear suspension

Check whether the shock absorber works normally

Uneven tire pressure of both sides

Malfunction of braking system

Insufficient tire pressure

Malfunction of steering system

Malfunction of suspension system

Insufficient tire pressure

Malfunction of steering system

Malfunction of suspension system

Adjust

--

Adjust

--

--

Adjust

--

--

------Check whether the shock absorber leaks grease

------Check whether the bush wears out

------Check whether the shock absorber is improper through shaking the vehicle body up and

down by pressing the foreside and the tail of the vehicle

Pre-check before wheel alignment

------Check the status of the tire inflation. Adjust to the recommended pressure if necessary.

------Check the clearance of the front wheel bearing. Adjust it if necessary.

------Check the flop of the vehicle and the tire.

------Check whether the ball joint and the steering linkage are too loose.

------Check the shock absorber by shaking the vehicle.

Note:

The vehicle must be on the level ground with no-load.

No-load: Full gasoline in the oil reservoir, engine coolant and the oil filled at the specified

level; the spare tire, jack and tools in the pointed position.

M-8

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 61

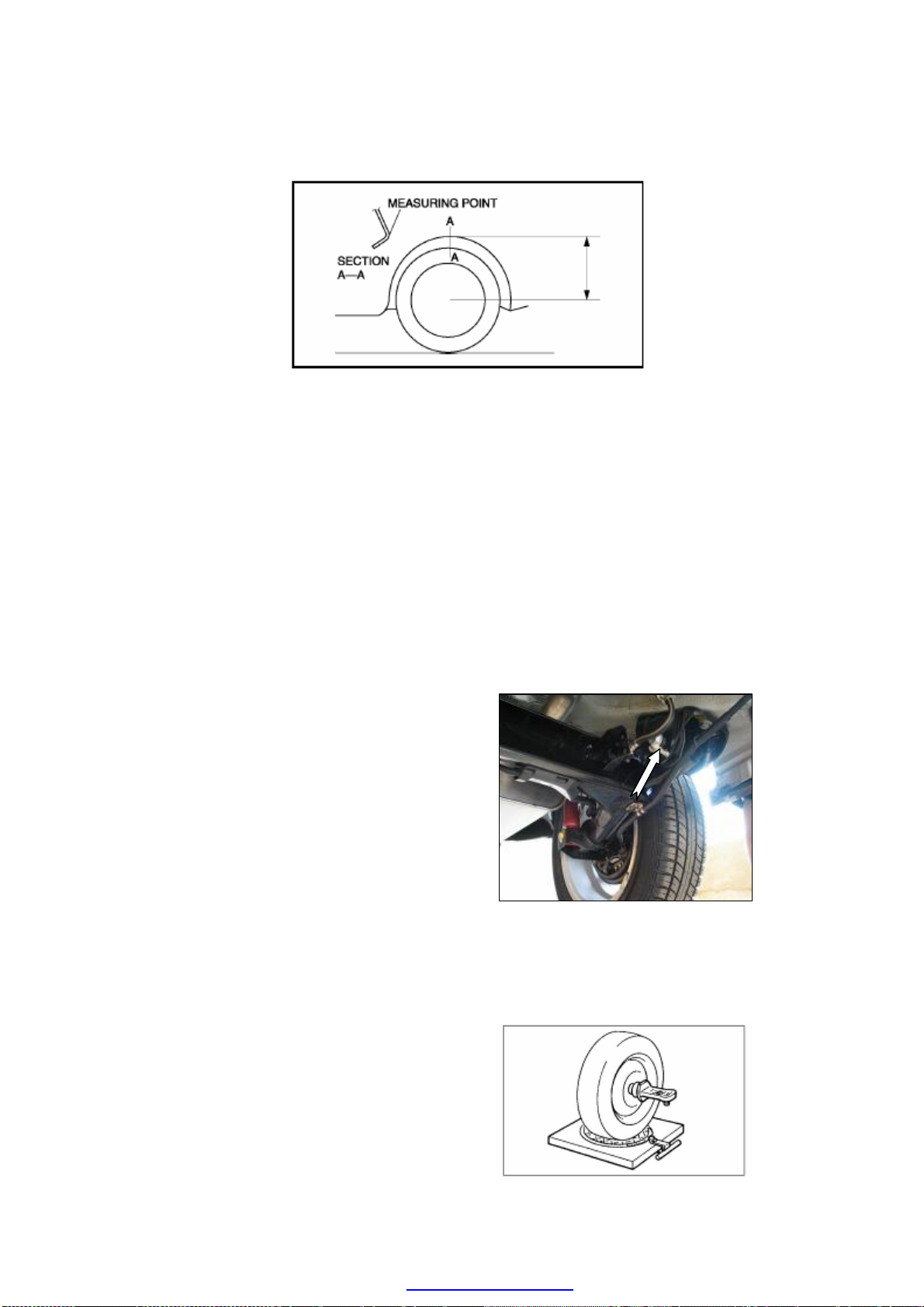

------Measure the height from the wheel center to the mudguard edge. The measured

rear wheel should be adjusted

difference from left and right should be not more than 10mm.

ALIGNMENT OF THE REAR WHEEL

It is recommended to utilize the four-wheel alignment tester with thrust line positioning

method on this type of chassis.

Note: thrust line positioning is defined as adjusting the front wheel toe-in based on the

rear wheel thrust line.

With the thrust line positioning, the adjustment of the rear wheel toe-in will influence the

single front wheel toe-in, so during four-wheel alignment, the

before the front wheel alignment.

Measure the vehicle height

------Rear measure point

From ground to the center of the joint bolt of

the rear axle and the body (as the arrow

shows)

Precaution: Check whether the height from

left and right are same before processing

the wheel alignment

------If there is a difference of the heights from

left and right, that means there are

damaged or deformed components of the

front and rear suspension.

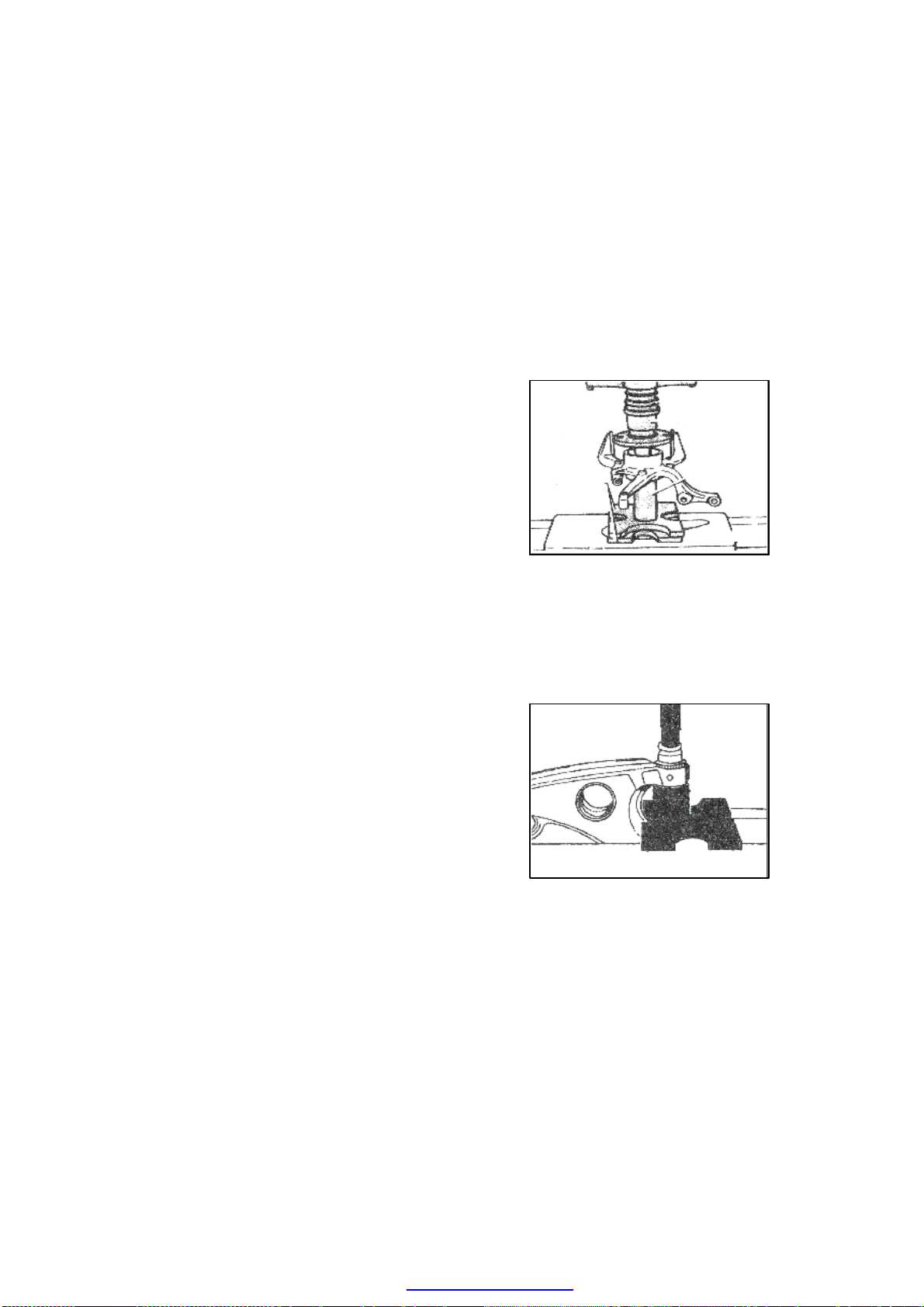

Install the wheel alignment tester on wheel

------Please refer to the specific instruction of

manufacturer for the wheel alignment

tester.

M-9

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 62

Check the caster

Inspection angle Value

Rear wheel caster -1°30′±10′

Note: The rear wheel caster cannot be adjusted. If there is abnormal wear on the tire of

the rear wheel, so check whether there are worn or deformed parts on the rear

suspension

Check the rear wheel toe-in

Car No. Chery A15LHD

Rear wheel toe-in 20′±10′

Note: The rear wheel toe-in out of standard range may lead to wear on shoulder of

tire on both sides. If the differences of the rear wheel toe-in both rear wheel are too

much, the vehicle running direction may be affected. Therefore the rear wheel toe-in

is a vital parameter of the alignment angles.

ALIGNMENT OF THE FRONT WHEEL

------Install the wheel alignment tester on the wheel

Please refer to the specific instruction of manufacturer.