Chef's Choice Ceramic + Steel 700 Instructions Manual

MODEL 700

INSTRUCTIONS

Ceramic + Steel Diamond Hone®

Knife Sharpener

Read these instructions before use.

It is essential that you follow these

instructions to achieve optimum results.

© 2017 EdgeCraft Corp.

HUGB

2

IMPORTANT SAFEGUARDS

When using electrical appliances, basic safety precautions should always be

followed including the following:

1. Read all instructions. Every user should read this manual.

2. To protect against electrical hazards, do not immerse the Chef’sChoice

®

Ceramic + Steel Model 700 sharpener in water or other liquid.

3. Make sure that only clean knife blades are inserted in Chef’sChoice

®

Ceramic + Steel

Model 700.

4. Disconnect the appliance from its power source when not in use, before cleaning, during

service and when replacing parts.

5. Avoid contacting moving parts.

6. Do not operate any appliance with a damaged cord or plug or after the appliance

malfunctions, or is dropped or damaged in any manner.

U.S. customers: You can return your sharpener to EdgeCraft’s factory for service where

the cost of repair or electrical or mechanical adjustment can be estimated. When the

electrical cord on this appliance is damaged, it must be replaced by the Chef’sChoice

®

distributor or other qualified service to avoid the danger of electrical shock.

Outside U.S.: Please return your sharpener to your local distributor where the cost of repair

or electrical or mechanical adjustment can be estimated. If the supply cord of this appliance is damaged, it must be replaced by a repair facility appointed by the manufacturer

because special tools are required. Please consult your Chef’sChoice

®

distributor.

7. CAUTION! This appliance may be fitted with a polarized power plug (one blade is wider

than the other). To reduce the risk of electric shock, this plug will fit in a polarized outlet

only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not

fit, contact a qualified electrician. Do not modify the plug in anyway.

8. The use of attachments not recommended or sold by EdgeCraft Corporation may cause

fire, electric shock or injury.

9. The Chef’sChoice

®

Ceramic + Steel Model 700 is designed to sharpen Ceramic and Steel

knives. Do not attempt to sharpen scissors, ax blades or any blade that does not fit freely

in the slots.

10. Do not let the cord hang over edge of table or counter or touch hot surfaces.

11. When in the “ON” position (Red flash on switch is exposed when “ON”), the

Chef’sChoice

®

sharpener should always be on a stable countertop or table.

12. WARNING: KNIVES PROPERLY SHARPENED ON YOUR Chef’sChoice

®

Ceramic + Steel

Model 700 WILL BE SHARPER THAN YOU EXPECT. TO AVOID INJURY, USE AND HANDLE

THEM WITH EXTREME CARE. DO NOT CUT TOWARD ANY PART OF YOUR FINGERS, HAND

OR BODY. DO NOT RUN FINGER ALONG EDGE. STORE IN A SAFE MANNER.

13. Do not use outdoors.

14. Appliance is not intended to be used or cleaned by children or persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge of the

hazards involved.

15. Do not use honing oils, water or any other lubricant with the Chef’sChoice

®

Ceramic + Steel Model 700.

16. For household use only.

17.

SAVE THESE INSTRUCTIONS.

3

YOU MADE

AN EXCELLENT

CHOICE

Congratulations! As an owner of the highly versatile Chef’sChoice®

Ceramic + Steel Model 700 you will appreciate how easy it is to

maintain all of your Ceramic and Steel knives in factory sharp

condition. A highly precise guide system is provided to position

each style knife automatically at the optimum sharpening angle as

customized diamond abrasive disks quickly restore a fresh edge.The

edge is then polished and finished with the Chef’sChoice

®

revolutionary

polishing disks to astonishingly sharpness. You will appreciate the

joy of effortless cutting and the unmatched presentation of each

flawless slice.

The Chef’sChoice

®

Ceramic + Steel Model 700 is designed to

sharpen your Ceramic and Steel knives to primary edge facets of 15

degrees (30 degrees total included edge angle) matching or exceeding

the factory sharpness and edge quality of the highest quality Ceramic

and Steel knives.

Uniquely the Chef’sChoice

®

Ceramic + Steel Model 700 is designed

to create a precise 15º primary angle on the blade followed by a second

small microbevel along that edge facet that adds significant strength,

sharpness and durability to that already very sharp edge.

Thus you will realize the extra advantages in sharpness and durability

that has made the Chef’sChoice

®

Ceramic + Steel Model 700 the

choice for the professional chef, worldwide.

We strongly encourage you to read the following sections

that detail optimum sharpening procedures for each style

blade. Enjoy!

4

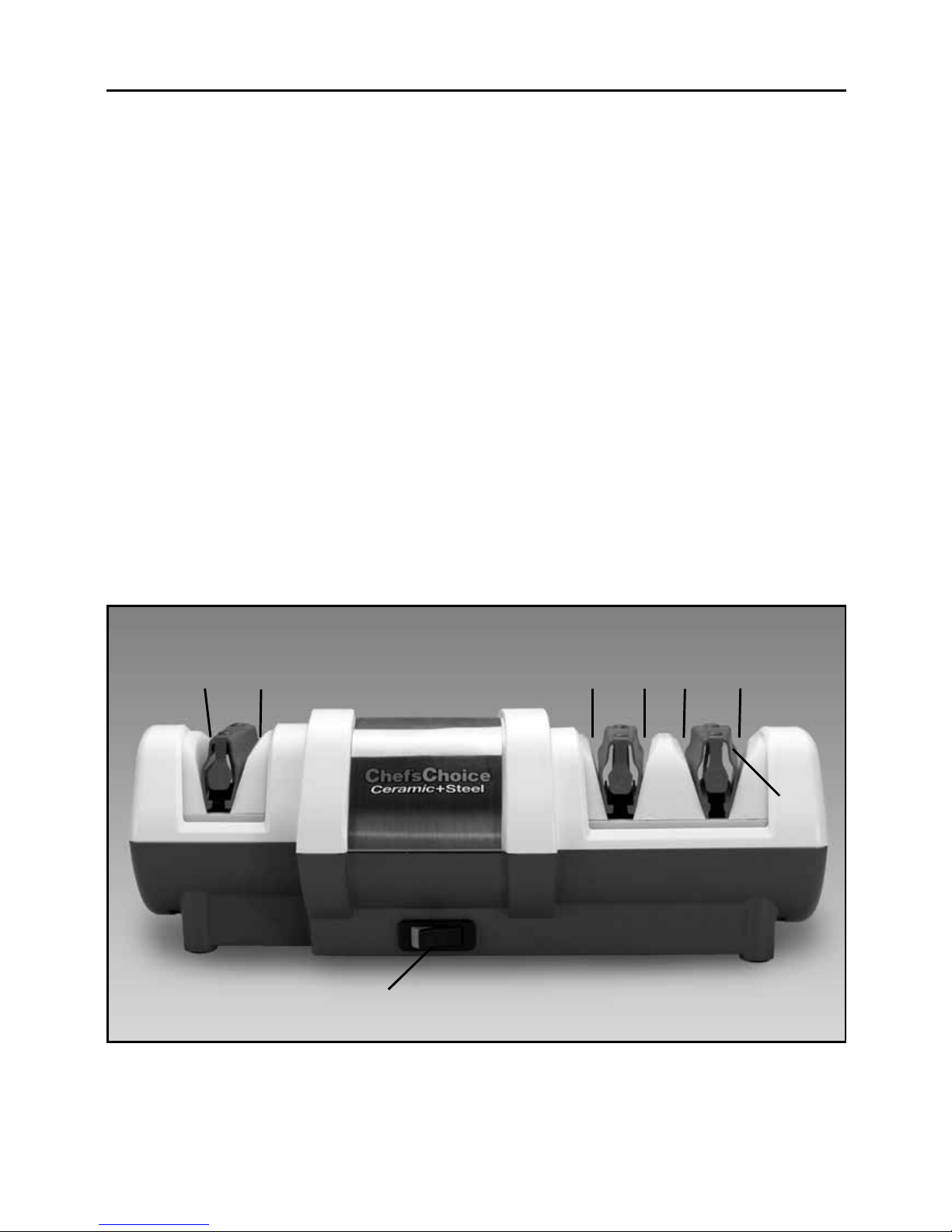

GETTING ACQUAINTED WITH THE MODEL 700 SHARPENER

The Model 700 (Figure 1) is a unique sharpener with Stage 1 Steel designed exclusively

to sharpen steel knives and the Stage 2 Ceramic designed primarily to sharpen Ceramic

Knives. Stage 3 Polish/Finish contains the proprietary Chef’sChoice

®

ultrafine diamond

abrasive disks designed for both ceramic and steel blades to create a microscopic bevel along

the edge and to polish it to astonishing sharpness.

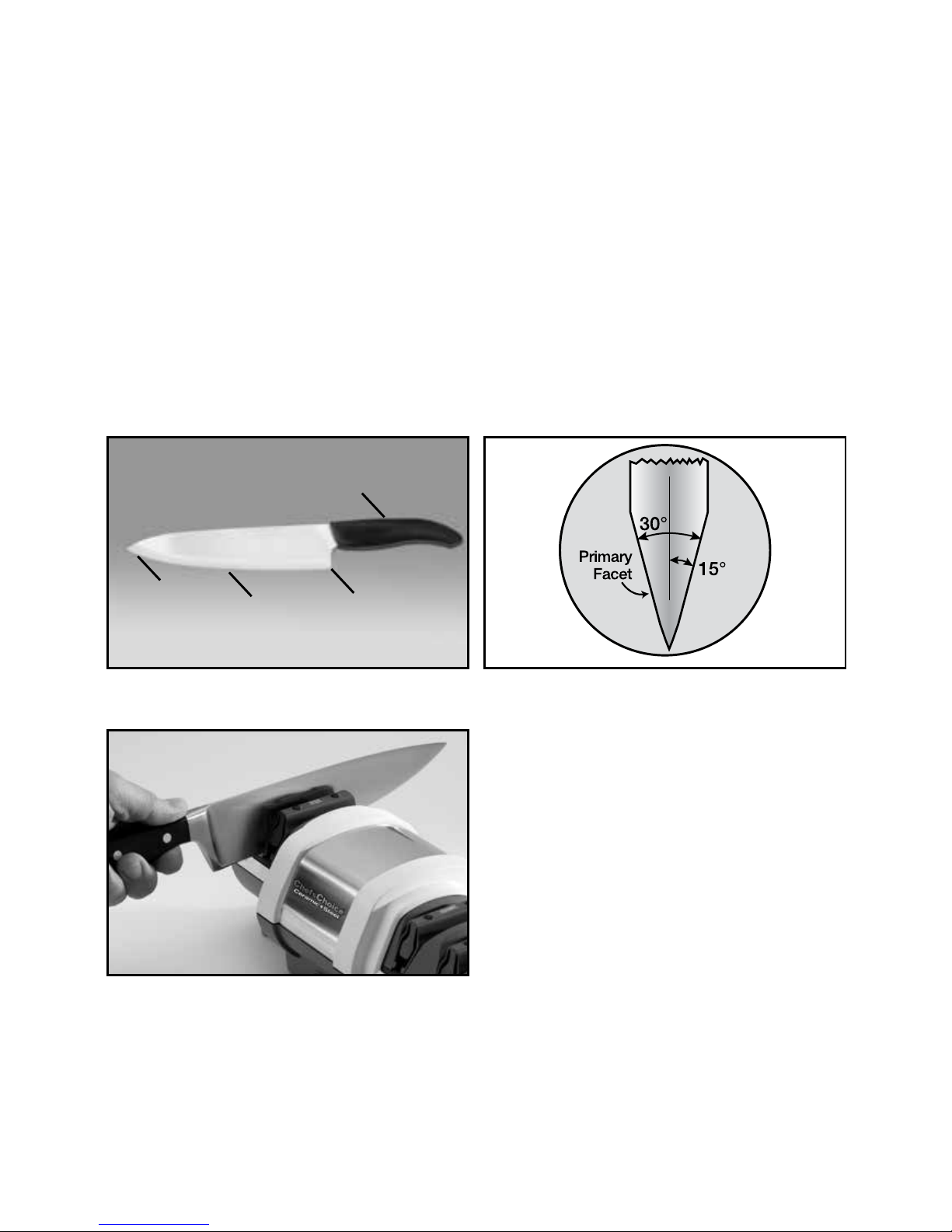

Steel knives are first sharpened at a nominal 15° (Figure 3) with fine diamond abrasives in the

Stage 1, followed by polishing with micro diamond abrasives in the Stage 3. Steel knives are

NOT sharpened in Stage 2 Ceramic.

Ceramic knives are first sharpened at a nominal 15° (Figure 3) with fine diamond abrasives in

Stage 2, and then polished and finished in Stage 3.

Special procedures for sharpening serrated blades are described beginning on page 11.

The Chef’sChoice

®

Ceramic + Steel Model 700 is equipped with a manually activated

diamond dressing system that can be used, when necessary, to remove any accumulated food

or sharpening debris from the surface of the ultrafine abrasive disks in Stage 3 Polish/Finish.

We strongly urge that you always thoroughly clean your knives before sharpening them. Unless

you are a heavy user of the sharpener, you will be able to sharpen for months or even a year

or more before you need to clean the Stage 3 disks. Only if you sense a distinct decrease in

polishing efficiency in the Stage 3 is there any need to use this convenient feature described

on page 11.

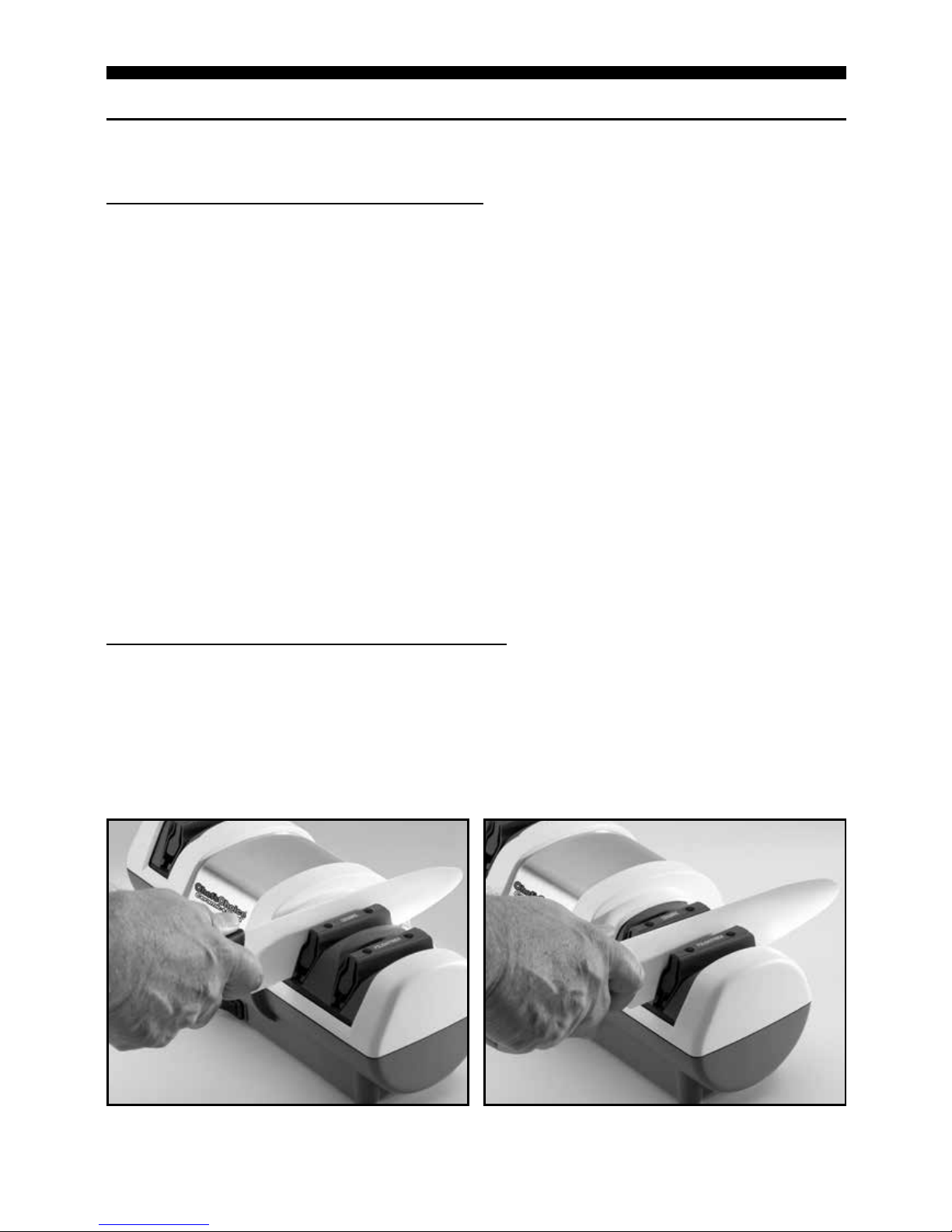

Figure 1. Chef’sChoice® Sharpener Model 700 designed to sharpen both steel and the ceramic knives.

On/Off

Switch

Knife

Holding

Spring

Guide

LeftLeft LeftRight Right Right

Ceramic Knife

Stage 2

Polish/Finishing

Stage 3

Steel Knife

Stage 1

5

Periodically, the swarf (metal and ceramic dust) created during sharpening needs to be cleaned

out. Please see “Cleaning the Sharpener” on page 13.

Never operate the sharpener from the back side. Use just enough downward pressure when

sharpening to ensure uniform and consistent contact of the blade edge with the abrasive disks

on each stroke (see Suggestions, page 12.) Additional pressure is unnecessary and will not

speed the sharpening process. Avoid excessive cutting into the plastic enclosure. Accidental

cutting into the enclosure however will not functionally impact operations of the sharpener or

damage the edge.

Try a practice pull through the sharpener with the power “OFF”. Insert a steel knife blade

smoothly into the left slot between the left angle guide of the Stage 1 (Figure 4) and the plastic

knife holding spring. Do not twist the knife. Move the blade down in the slot until you feel it

contact the diamond disk. Pull it towards you lifting the handle slightly as you approach the

tip. This practice pull will give you a feel for the spring tension. Remove the knife and read the

following instructions specific to the type of knife you will be sharpening.

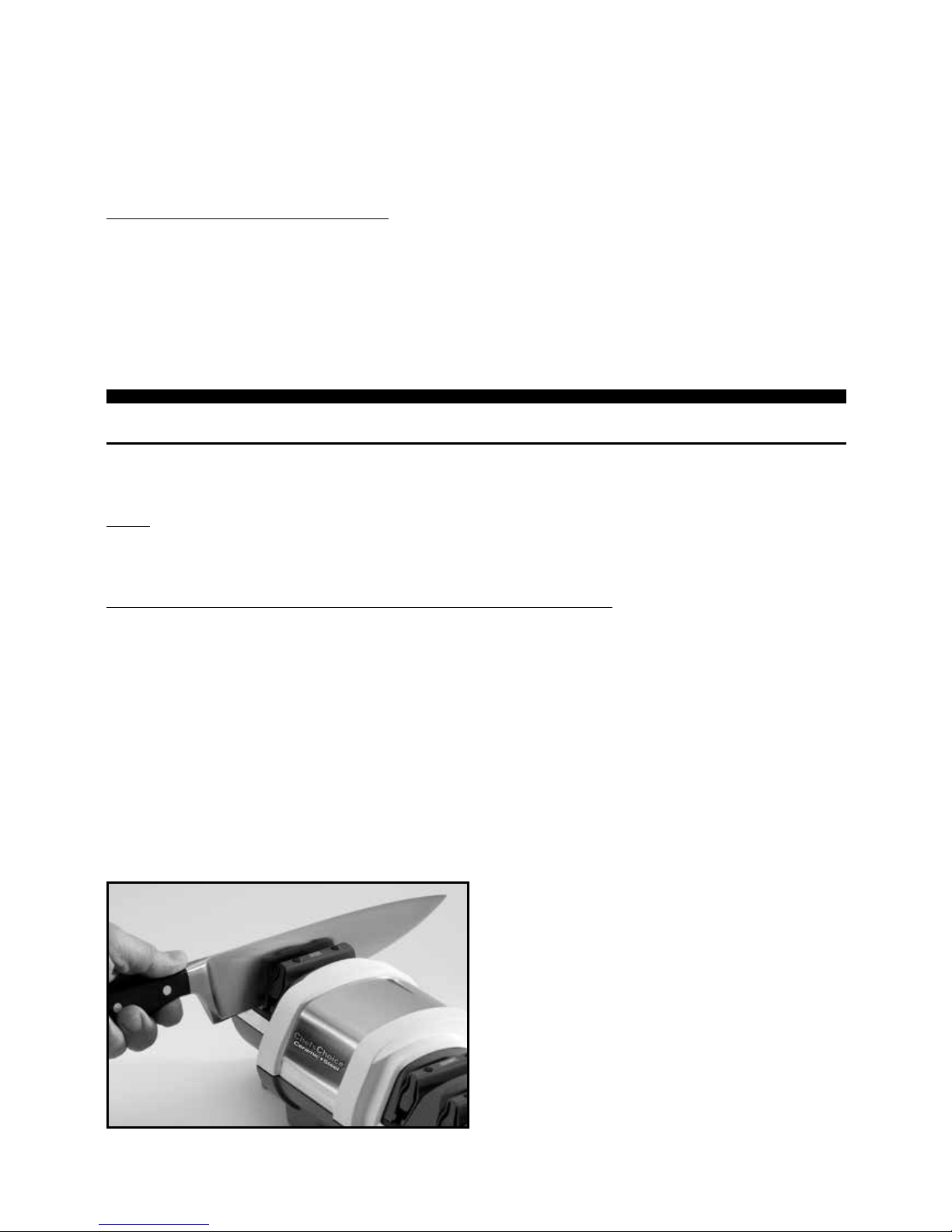

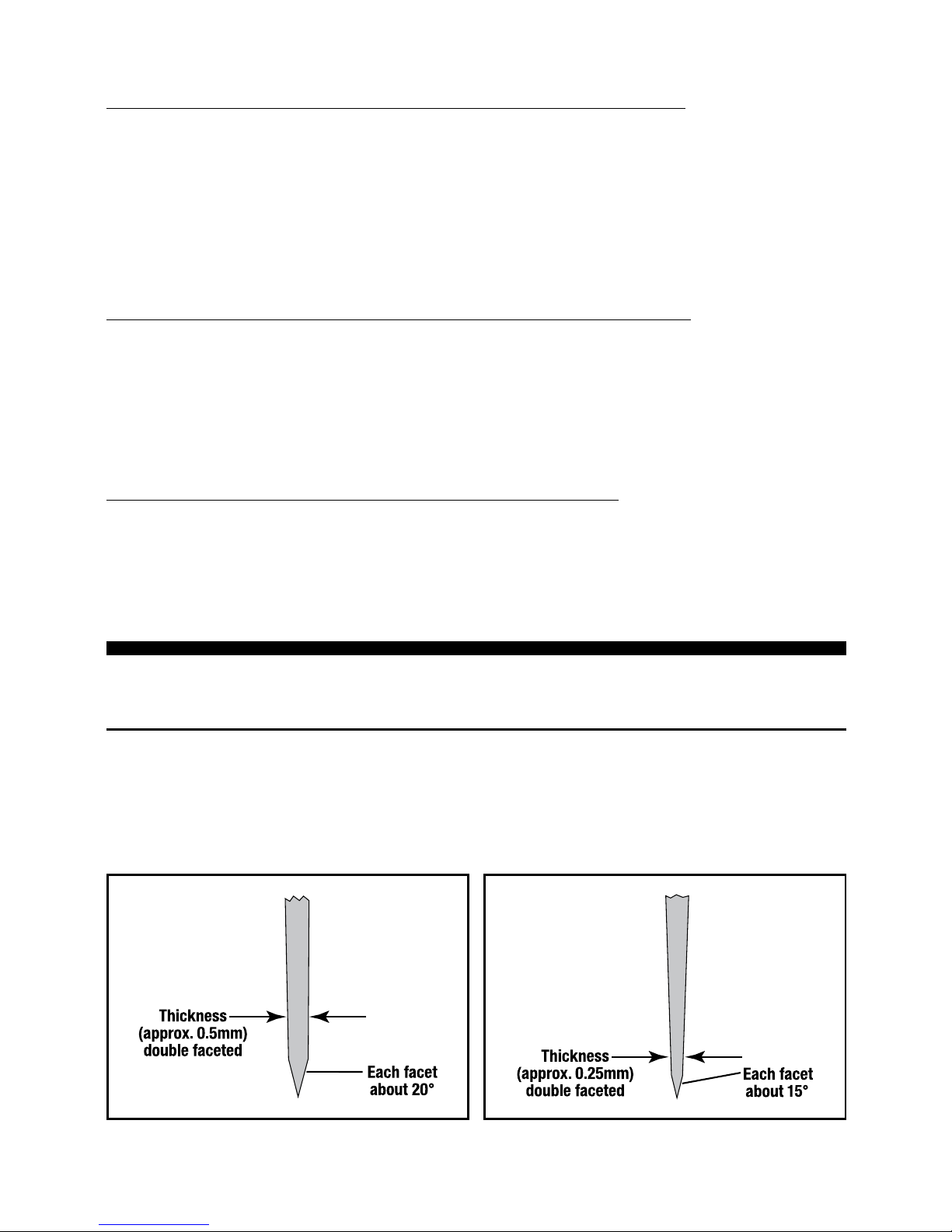

Figure 3. Typical edge cross section, illustrating the 15°

primary facet.

Figure 2. A typical ceramic kitchen knife.

Handle

Edge

Choil

Tip

Figure 4. Stage 1 sharpening of a metal knife.

6

SHARPENING THE CERAMIC KNIFE

Ceramic knives will have each of their edge facets sharpened at the standard 15 degrees to

create a total edge angle of 30º. Use only Stages 2 and 3.

SHARPENING THE EDGE IN STAGE 2 CERAMIC

Turn ON the power and pull the ceramic blade thru the left slot of Stage 2 Ceramic (Figure 5),

then thru the adjacent right slot of Stage 2. Repeat pairs of pulls in Stage 2 using the left and

right slots on alternate pulls. Take about 5-6 seconds for each pull for a 5” long blade (1 second

or more per inch of blade). It is important not to rush the process with ceramic knives. Slow pulls

are preferable. It may require more pulls for a blade that is severely worn or chipped. The first time

you sharpen a knife it may take up to 10 pair of alternating pulls (alternating left and right slots of

Stage 2) to fully re-angle the edge of a thin blade. Thicker blades will require more pulls. After 3

pairs of pulls check to see if blade will cut paper. For those familiar with metal knife sharpening

Ceramic knives will not develop a burr. Therefore, a gradual approach of pre-sharpening

followed by testing for sharpness is the suggested method.

Some Ceramic knives can vary widely from the industry standard 30º and even vary from one

side of the knife to the other. The Chef’sChoice

®

Ceramic + Steel Model 700 will sharpen to a

precise 30º and may require multiple sharpening strokes in Stage 2 to form the ideal 30º angle.

If you are sharpening an established brand name ceramic blade you will find that only a few

(2-3) pairs of alternating pulls (alternating left and right slots) will be needed in Stage 2 to

prepare it for Stage 3 Polish/Finish.

FINISHING THE EDGE IN STAGE 3 POLISH/FINISH

The Chef’sChoice® Model 700 has been developed with an advanced and proprietary blend of

materials to complete the sharpening of both ceramic and metal knives. This final stage of sharpening creates a sharper-than-factory edge unsurpassed by any other sharpener on the market.

Upon completion of sharpening in Stage 2 perform 5-7 slow even alternating pairs of pulls,

(alternating left and right slots) in Stage 3 (Figure 6) of the sharpener (take approximately

2 second per inch of blade). We suggest beginning with 5 pairs of slow (consistent speed)

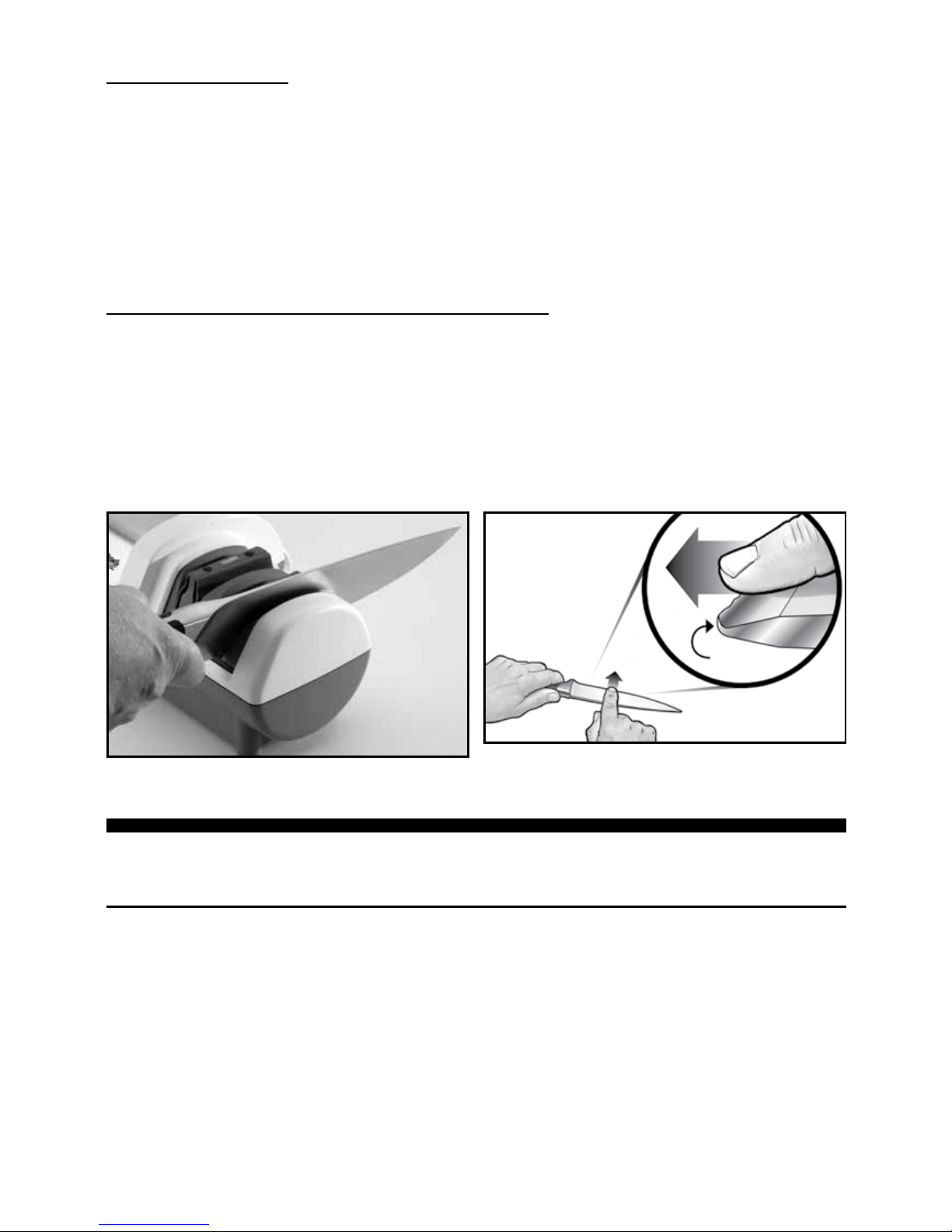

Figure 6. Stage 3 Polishing/Finishing a ceramic knife. Figure 5. Sharpening ceramic knife in Stage 2 Ceramic.

7

alternating pairs of pulls and then testing for sharpness. If the knife is still not sufficiently sharp,

try another 2-3 more pairs of alternating pulls. The knife should be paper-cutting sharp.

Ceramic knives are inherently more brittle at their edge than conventional metal knives. This

final Stage 3 with its unique diamond abrasive composition is critical to obtain razor sharp

ceramic knives.

RESHARPENING CERAMIC KNIVES

In order to freshen up the edge of your ceramic knives, it is not necessary to sharpen in stage

2. Simply use Stage 3 Polish/Finish with 4-5 pairs of slow alternating passes (take about 2

seconds per inch of blade) and then test for sharpness. If the knife is still not sufficiently sharp,

try another 2-3 pairs of alternating pulls. The knife should be paper-cutting sharp.

The “resharpening” process should not be used if the ceramic knife edge is chipped or very dull.

In that case, see page 6 for a complete sharpening.

SHARPENING A STEEL KNIFE

Steel knives with double edge facets, will have each of the facets sharpened at 15° to create

a super sharp edge with a total included angle of 30° (see Figure 3). Use only Stages 1 and 3.

Note: If you plan to sharpen a metal knife after a ceramic knife was sharpened in the Model 700,

please read the section “Cleaning the Sharpener” on page 13 and follow the cleaning instruction

prior to sharpening the metal knife.

SHARPENING THE EDGE OF A STEEL KNIFE IN STAGE 1 STEEL

Turn ON the power and pull the blade thru the left slot (Figure 7) of Stage 1 Steel, then thru the

adjacent right slot. Repeat pairs of pulls in Stage 1 using the left and right slots on alternate pulls.

Take about 4-5 seconds for each pull for a 5” long blade. Take longer for longer blades and slightly

less if shorter. The first time you sharpen a dull knife in Stage 1 it may take up to 10 pair of pulls

(alternating left and right slots) to fully re-angle the edge of a blade. Thicker blades will

require more pulls. After 3 pairs of pulls check for a burr as described below (Figure 9) and as

necessary continue to make more pairs of pulls until you create a small burr along the entire

length of the blade.

Do not over sharpen. When you have developed a burr along the full blade length proceed to the

Stage 3 Polish/Finish.

Figure 7. Stage 1 sharpening of steel knife.

8

DETECTING THE BURR

To confirm the presence of a burr (see Figure 9) move your forefinger carefully across the

edge in the direction shown. Do not move your finger along the edge – to avoid cutting your

finger. If the last pull was in the right slot, the burr will appear only on the right side of the blade

as you normally hold it and vice versa. The burr, when present, feels like a rough and bent

extension of the edge; the opposite side of the edge feels very smooth by comparison. If there

is no burr continue sharpening in the Stage 1, alternating left and right slots until a full burr

develops. When a burr is present along the entire blade length proceed as below to the Stage 3

Polish/Finish (Figure 8).

FINISHING A STEEL KNIFE IN STAGE 3 POLISH/FINISH

Pull the blade through the left slot and then through the right slot of the Stage 3 (see Figure 8).

Make 2 pairs of pulls, (each pull 4-5 seconds) alternating each pull in the left and right slots of

Stage 3.

Check the blade for sharpness. For a sharper edge, make a few more pairs of fast alternating

pulls (about 1 second each) in Stage 3 and check for sharpness. Repeat this procedure as

needed to create an exceedingly sharp edge. Using a piece of paper or slicing a tomato to test

sharpness is useful for reference.

SHARPENING THE TRADITIONAL (SINGLE SIDED)

JAPANESE STEEL BLADE

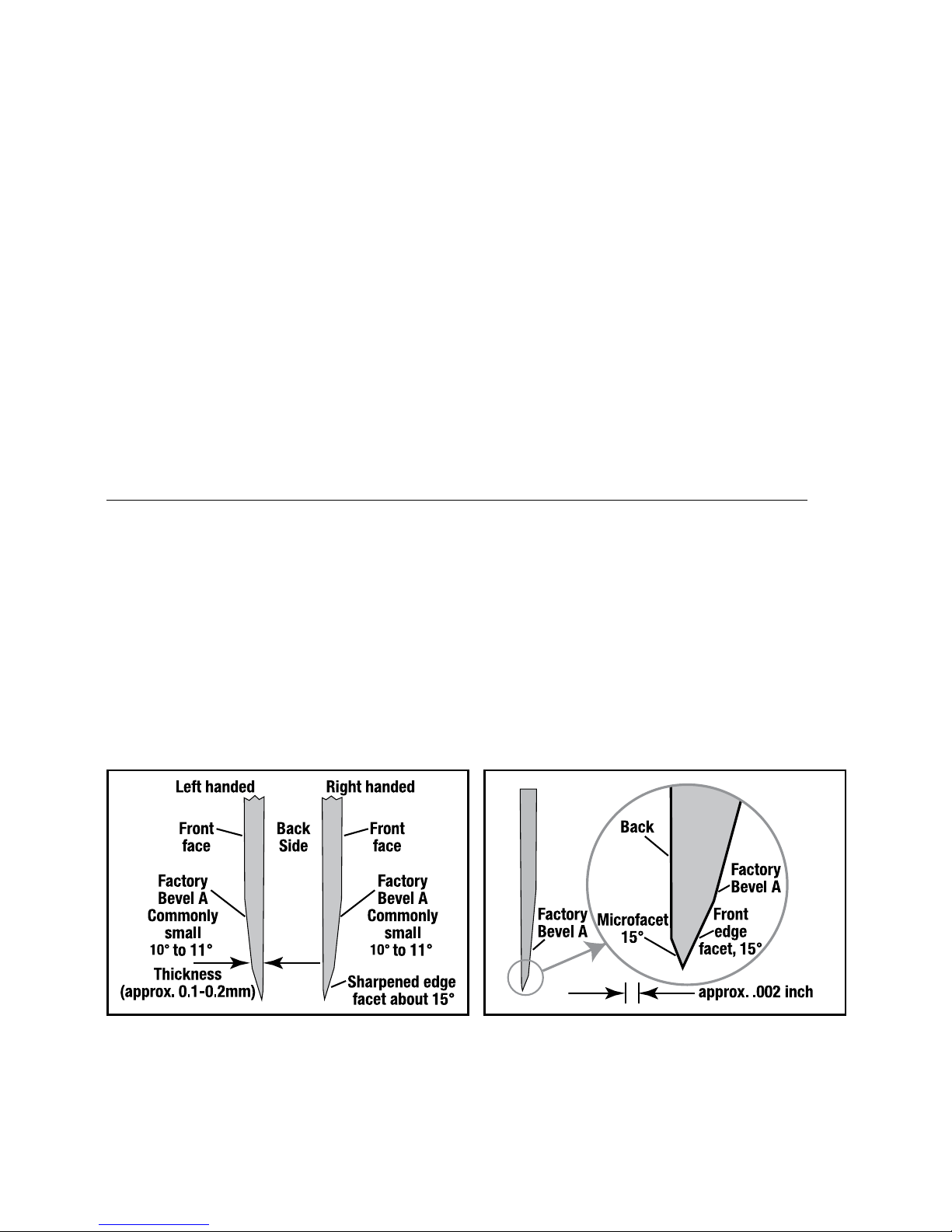

Traditional Japanese knives such as the sashimi blade are single sided and have a large factory

bevel (Bevel A, Figure 10) on the one side of the blade. There are a large number of manufacturers

of knives of this type used widely to prepare sashimi. The factory bevel (Bevel A) is commonly

ground at about 10 degrees, but there are exceptions as that angle is not standardized at the

factories. Designs of the traditional Japanese knives and the detailed structure of the cutting

edges likewise varies widely from one manufacturer to the next, however there are some

similarities. The cutting edge consists of a small primary facet on the front face of the blade

below the large factory bevel and includes a much smaller secondary microfacet along the

back face. Commonly the back side microfacet (Figure 11) can be easily seen only with a hand

Burr

Figure 9. When you create a distinct burr along the

blade edge, it can be detected by sliding finger across

and away from the edge. Caution! See text.

Figure 8. Polish/Finishing stage of metal knife.

9

magnifier. The back face is ground flat at the factory or more commonly it is slightly hollow

ground to ensure that an effective microfacet can be formed there as part of the cutting edge.

Because of the lack of standardization, commonly, the manual approach is used to sharpen

these knives, has proven to be difficult, laborious and time consuming. The Chef’sChoice

®

Model 700 Sharpener is designed to sharpen virtually all traditional, single sided, Asian blades

and to create a factory-quality edge.

Before you start to sharpen a traditional Japanese blade, examine it carefully in order to confirm

that you have the traditional single bevel blade and to determine whether you have a right

or left handed type as described in Figure 10. It is essential that you follow carefully the

sharpening procedure and sequence as described below in order to achieve the optimum edge

on your traditional blade.

Confirm which side of the blade has the large factory Bevel A. Hold the blade in your hand

(as when you are cutting) and if the large factory bevel is on the right side of the blade, the blade

is right handed. For the right handed blades sharpen only in the left slot of Stage 1 so that

only the beveled side (right side) of the edge will contact the sharpening wheel. Proceed as

described below.

SHARPENING TRADITIONAL JAPANESE KNIVES IN STAGE 1 (RIGHT HANDED BLADES)

In this example which assumes your traditional blade is right handed, you must sharpen only

in the left slot of Stage 1 Steel. The number of pulls that you will need to make depends on the

factory angle of Bevel A (Figure 10 and 11) and how dull your blade may be. Make five (5) to ten

(10) pulls (1-2 seconds per inch) in only the left slot of Stage 1 and then check for a burr along

the entire back side of the blade edge. (The burr created in Stage 1 will be small but can be felt

as shown in Figure 9). Make certain the burr is present along the entire length of the edge. If

there is no burr or only a partial burr, continue to make additional pulls all in the left slot about

five (5) at a time and check for a burr after each group of five (5) pulls. In general 10-20 total

pulls in the left slot will be adequate to raise a burr; it is unlikely to take more than 20 left slot

pulls to create the burr. When a burr is confirmed, proceed to Stage 3 Polish/Finish.

Figure 10. Cross-section of a single beveled traditional

Asian blades are thinner and sharpened primarily on

one side.

Figure 11. Cross-section of a typical factory traditional

Asian knife edge, magnified 50x (right-handed).

Figure 12. Traditional European/American blades are

generally thicker.

Figure 13. Double faceted contemporary European/

American and Asian blades are usually thinner.

10

POLISHING/FINISHING THE FINAL EDGE ON

TRADITIONAL JAPANESE BLADE IN STAGE 3 (RIGHT HANDED BLADES)

a. Make two to three (2-3) slow pulls, 3-4 seconds each, only in the left slot of Stage 3

Polish/Finish and then proceed to remove the burr in step below.

b. Make one (1) regular pull in right slot of Stage 3 along the back side of the edge.

(about 3-4 seconds.)

c. Make 1-2 pair of fast pulls (1-2 seconds each) alternating in left and right slots of Stage 3.

Test blade for sharpness using a thin sheet of paper or a tomato. It should be razor sharp

but if not repeat steps a, b and c above.

RESHARPENING THE TRADITIONAL JAPANESE BLADE (RIGHT HANDED)

In general you will be able to re-sharpen quickly by following the sequence of Steps a, b, c

above. Repeat this if necessary to obtain a razor sharp edge. When re-sharpening only in Stage

3 fails to develop a sharp edge or if the edge has been substantially dulled you will need to

re-sharpen the edge in Stage 1. Use only the left slot of Stage 1. Generally you will find that

about five (5) pulls in the left slot of Stage 1 will be sufficient. In any event develop a burr before

moving again to Stage 3. Finish the edge in Stage 3 following Steps a, b and c, above.

SHARPENING LEFT HANDED TRADITIONAL JAPANESE BLADES

The procedure you must use with left handed blades is similar to that procedure for right handed

blades as detailed above – Except in all cases the slots you must use are reversed. Where the

sharpening procedure for right handed blades calls for use of just the left slot, you must use only

the right slot when sharpening a left-handed blade. Likewise use the left slot where ever the right

handed instructions call for using the right slot.

CONVERTING TRADITIONAL EURO/AMERICAN 20°

EDGE TO CONTEMPORARY 15°

The Model 700 sharpens steel knives to typical 15 degree angles. If you would like to convert a

traditional 20° European edge knife to 15° angles, the Model 700 can facilitate that by following

the Steel knife sharpening instructions. To make this conversion, follow the Instructions for

Sharpening A Steel Knife, pages 7 to 8. Initial sharpening in Stage 1 Steel will take longer than

you might expect but subsequent re-sharpening time will be normal (Figures 12 and 13).

Loading...

Loading...