Page 1

Model FGS-100PXH / FGS-100PXL

Programmable Motorized Test Stands

Congratulations on your purchase of the FGS-100PX series Shimpo test stand(s). This manual explains

how to operate your equipment safely and correctly.

Read the entire instruction manual before initial set-up and operation; the information

contained herein will help you in operating your Shimpo Programmable Motorized

Test Stand.

Page 2

For questions and inquiries regarding our product(s), call your local Shimpo representative or contact

Shimpo Instruments directly for assistance.

Nidec-Shimpo America Corporation

1701 Glenlake Avenue

Itasca, Illinois 60143

1-800-237-7079

Caution warning holds important safety information.

Reminder: holds important keep information for the product.

Manual Index

Inspection/Standard Accessories

1.0 Features and Benefi ts .............................................................................................. 3

2.0 Important Safety Instructions

Set up Procedures .......................................................................................................... 4

4. Units of Measure: English or Metric .........................................................................5

4.1 Display Panel .........................................................................................................6-7

5.0 Operation Modes

5.1 MANU (Manual Mode) ...............................................................................................8

5.2 JOG (Jog Mode) ........................................................................................................ 9

5.3 SING (Single Mode) ................................................................................................10

5.4 CONT (Continuous Mode) ......................................................................................11

5.5 PROG (PROGRAM Mode)..................................................................................12-15

6.0 RS232C Output Format (using FGV-X Force Gauges) ...................................15-16

7.0 Troubleshooting

8.0 Test Stand Specifi cations .................................................................................16-18

9.0 Dimensions and Drawings .....................................................................................19

Warranty ........................................................................................................................20

2

Page 3

Inspection/Standard Accessories

If any shipping damage is detected upon receiving the test stand, please do not unpack the unit.

Notify your shipping carrier immediately for damage claim instructions.

Refer to the nameplate located on the back of the test stand to confi rm model number ordered,

record serial number for future reference.

MODEL SPEED

FGS-100PXL 0.19 - 4.72 inch/min (5.00 - 120 mm/min)

FGS-100PXH

(3) M5 x 6 screws

(1) 5mm Allen wrench

(4) M4 x 8 screws

(1) Force gauge to Test Stand Interface cable (FGV-FGS250P)

(1) Analog output cable (FGS-ANALOG)

Manual

Warranty Card

0.79 – 19.69 inch/min (20-500 mm/min)

1.0 Features and Benefi ts

Shimpo’s FGS-100PXH (standard speed) and FGS-100PXL (low speed) Programmable Motorized

Test Stand offers:

All steel construction which guarantees durability and stability for production, laboratory

and quality control applications

Programmable FORCE and Distance(length)limits

Dual speed controls are optimally positioned to adjust test and return travel rates of the

drive assembly.

Drive assembly accepts a universal mounting plate, enabling the interfacing of a large

selection of force gauge models (contact Shimpo for specifi c models)

4½ digital LED display indicates displacement rate and distance of the drive assembly.

Analog output (10mV/mm) is convenient for data acquisition requirements.(used with

FGS-ANALOG cable)

3

Page 4

2.0 Important Safety Instructions

Read this section carefully before initial set up.

Position test stand on a level, heavy-duty table.

Confi rm that the test stand case is properly grounded to the AC line.

Keep hands, hair and jewelry away from stand when drive assembly is in motion.

Operate the membrane keypad with care. Do not use sharp objects that may puncture

the overlay.

Always wear eye protection when testing materials.

Do not store or use in oily, dusty, humid or wet areas

Ensure that AC power is removed (off) from test stand before making any adjustments.

If ALARM LED indicates drive assembly has been overloaded, immediately switch the

power switch to the off position and correct the overload condition. Wait at least two minutes

before restarting the test stand.

3.0 Set up Procedures

1. Connect all the necessary cables and AC cord before applying power to the test stand.

IF communication between the force gauge and test stand is desired, using an FGV-X or

FGV-XY force gauge, use cable part number FGV-FGS250PV to connect the force gauge

to the test stand.

IF communication between the force gauge and test stand is desired, using a DFS force

gauge, use cable part number FGS-50PCABLE to connect the force gauge to the test

stand.

2. If communication between the force gauge and test stand is desired, turn on the force gauge

before turning on the test stand; this is necessary for the test stand to recognize the connected

Shimpo force gauge.

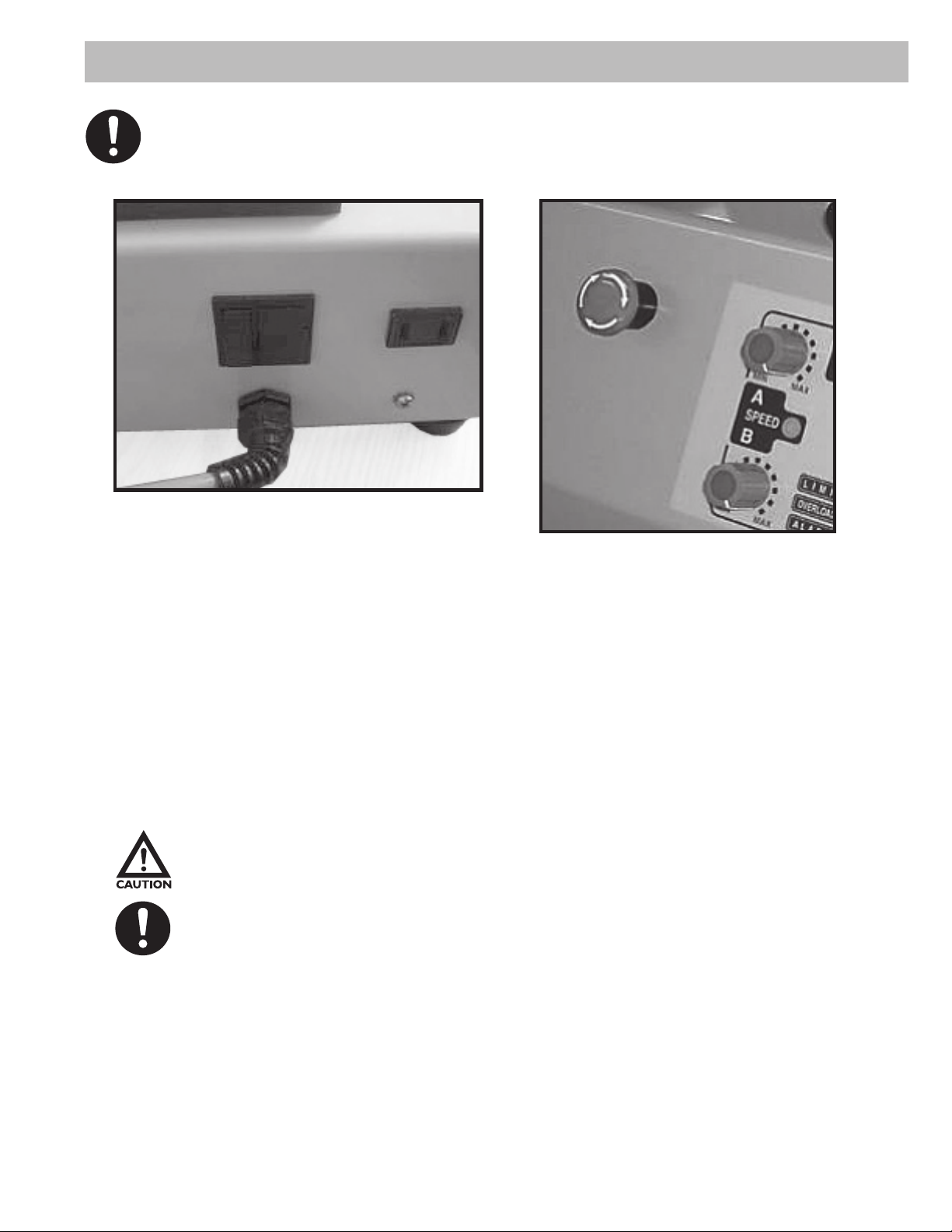

3. T 3. The power switch for the test stand is located on the rear of the unit. After power is applied,

all the segments and LED’s will execute a power up and self test. After the self test, the test stand

will display 0.00 (inches - English) or 0.0 (mm – metric).

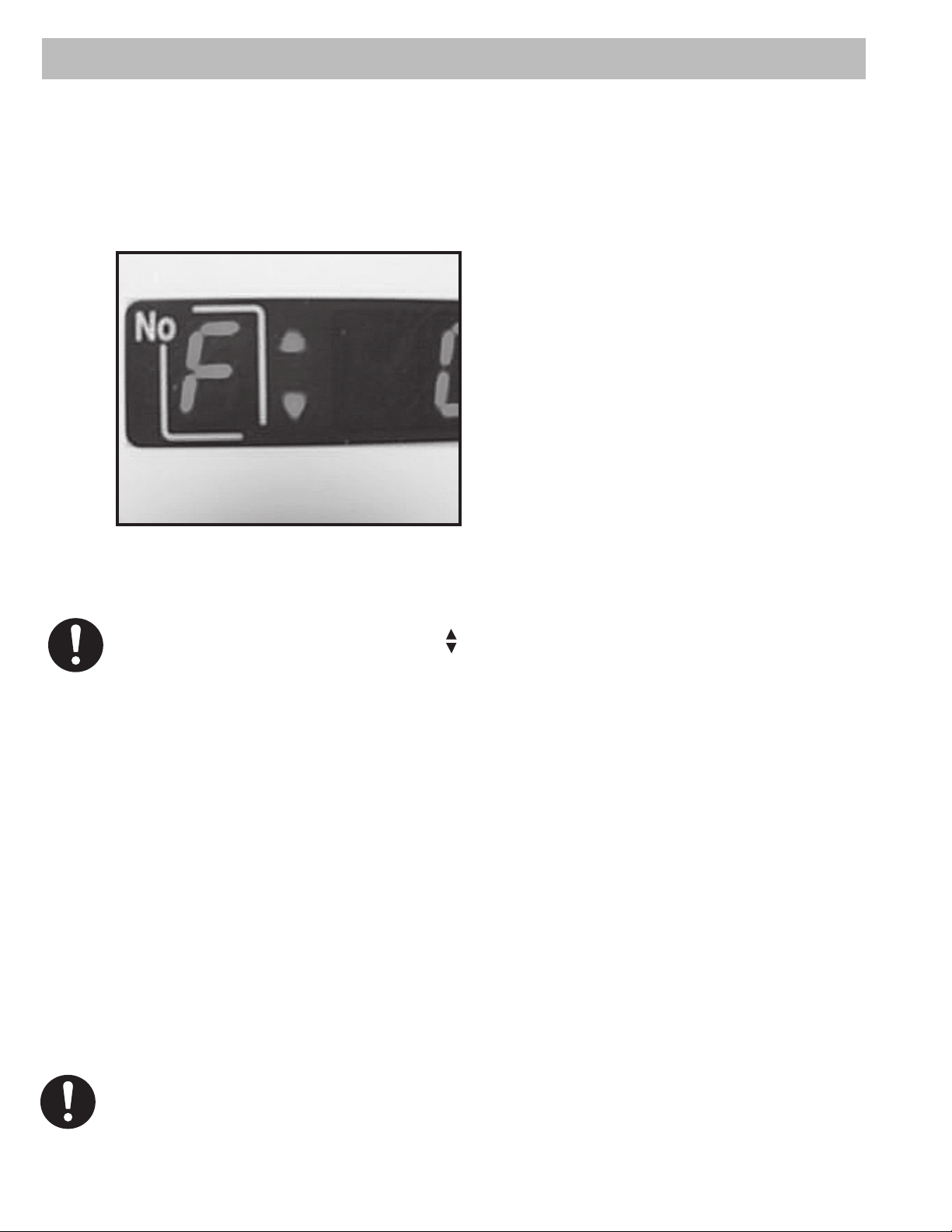

NOTE: I NOTE: If after power up, the test stand takes longer to initialize and a “no_F” display is observed

from the display, check the (force gauge to test stand) cable, FGV-FGS250PV, and the baud rate setting for

the FGV-X or FGV-XY force gauge (19200 baud). (See your force gauge manual for baud rate communication

and set-up) The FGS-100PXH/100PXL test stands communicate at 19200 baud with the Shimpo FGV-X and

FGV-XY force gauges. As noted above, if using a Shimpo DFS force gauge, (9600 baud max) use cable part

number FGS-50PCABLE, which provides DFS to test stand and PC communication capability.

NOTE: The FGS-50PCABLE cable incorporates a segment of cable that attaches to the test stand and

another that attaches to a PC.

4

Page 5

4. Units of Measure: English or Metric

To switch from English to metric units, push the “Speed” and “RST” buttons while turning the power on.

To return to English units turn the stand off and push the “SPEED” and “Time/>” buttons while turning the

power back on.

AC Power cord and AC plug for the Force

gauge, located on the back of the rear of

the test stand.

Emergency Stop button located on

the side of the front plate. Turn the

button Clockwise to release.

To identify whether the stand is in metric or English units, turn the power on. (power switch is

located in the back of the unit), Metric units will show one decimal place (0.0), while English

units show two decimal places (0.00) To change to metric units, push “A/SPEED/B” and “RST/^”

switches while turning the power on. To change to English units, push “A/SPEED/B” and “TIME/<”

switches while turning the power on.

Caution warning holds important safety information.

REMINDER: holds important keep information for the product.

5

Page 6

4.1 Display Panel

4.1 Display Panel

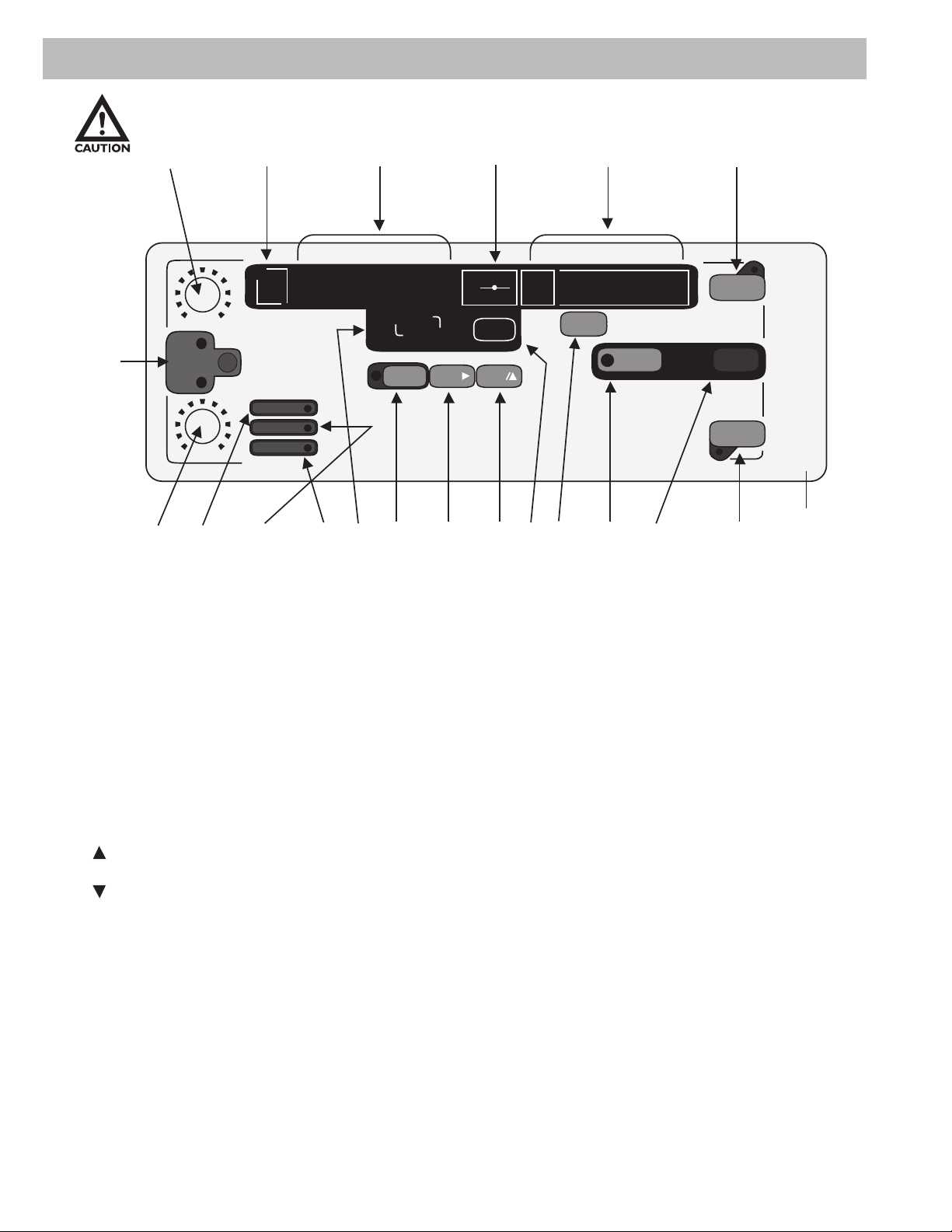

Figure 1

15

No

MIN MAX

A

3

SPEED

B

LIMIT

OVERLOAD

ALARM

14 15 8 18 17 16 12 19 24 22 23

2

MIN MAX

13

4, 6, 7 9, 10, 11 20 21

TIME

SEC

TIMESET

LENGHT

SPEED

ZERO

RST

PROG

CONT

MODE

SNG

JOG

PROG

START

MANU

PULL

STOP

PUSH

25

1. A Speed: Changes the left movement or upward speed (Continuous and Program Mode).

2. B Speed: Changes the right movement or downward speed. (Continuous and Program

Mode).

3. Speed: Selects speed control knob A or B.

4. Length, Speed or Cycle Display: Displays length, speed or cycle of a program when power

is on. Note: Cycle Display can only be selected in mode SING, CONT or PROG.

5. No: Displays program cycle (0-9).

6. : Indicates high limit value in all modes.

7. : Indicates low limit value in all modes.

8. TIME: Displays programmed delay time between program cycles.

9. LENGTH, SPEED, or Cycle: Selects display of length, speed or cycle of a program.

10. LED LENGTH Indicator: Indicates that length is being displayed.

11. LED SPEED Indicator: Indicates that speed is being displayed. Cycle display is indicated

when both Length and Speed LED’s are off.

12. ZERO: Resets length measurement to zero.

6

Page 7

13. LIMIT LED: Indicates one of the manual limit switches has been tripped.

14. OVERLOAD LED: Indicates that the force gauge has been overloaded.

15. ALARM LED: Indicates test stand’s motor has been overloaded.

16. RST/ : Changes the increment point upward.

17. TIME/ : Changes digit position when programming force limits, also changes delay be

tween cycles.

18. SET: Stores a program cycle to a value that the user selects using RST/ and TIME/ .

19. MODE: Selects mode of operation: Manual, Jog, Single, Continuous or Program.

20. Operation Display: Informs user of current mode of operation.

21. PULL: Test stand moves in the left movement or upward direction.

22. STOP: Stops test stand movement.

23. PUSH: Test stand moves in a tight movement or downward direction.

24. PROG START: Start the program.

25. Emergency Stop (located on the top of the test stand.

7

Page 8

5.0 Operation Modes

5.1 Manual (Manu)

5.2 Jog (Jog)

5.3 Single (Sing)

5.4 Continuous (CONT)

5.5 Program (Prog)

5.1 MANU (Manual Mode)

The MANU (Manual Mode) of operation is ideal for manually recording force measurements. The

test stand will only operate between the limits that are set by the test stand user. These limits may

be manually adjusted distance limits or programmed Force Limits when using a Shimpo FGV-X or

FGV-XY force gauge. (If using a Shimpo model DFS force gauge, see DFS Force Limit instructions

below)

Note: In this mode of operation, when using either a Shimpo “FGV-X” or “FGV-XY” or Shimpo

“DFS” force gauge, no RS232C output is produced.

MANU (Manual Mode): The test stand can display Length or Speed. You may display Length

by pressing the “LENGTH/SPEED” button until the LED adjacent to the indicator “LENGTH” is

illuminated. To display Speed, push the “LENGTH/SPEED” button until the LED adjacent to the

indicator “SPEED” is illuminated.

Distance Limits: Manual

To manually adjust distance limits, partially unscrew each of the two knobs on the metal plates that

control the test stand (force gauge) platform movement from side to side. IMPORTANT: Adjust the

right knob to set the left distance limit and the left knob to set the right distance limit. Tighten the

knobs after the limits are set.

Limit switch knobs

located on the side of

the drive assembly.

Make sure the correct limit knobs are set for right and left distance limits. The distance limit switches

engage and stop the test stand (force gauge platform) when the left distance limit is set with the RIGHT knob

and the right distance limit is set with the LEFT knob.

8

Page 9

5.2 JOG (Jog Mode)

This mode of operation is identical to “MANU”, except that the movement in any direction will

occur ONLY while the “PUSH” or “PULL” buttons are continuously pressed.

NOTE: In this mode of operation, no RS232C output is produced

FORCE LIMITS

How to program Force Limits:

If using a Shimpo FGV-X or FGV-XY model force gauge, you may program a Force Limit on the test

stand. The DFS force does not utilize this test stand function since it has a 9600 baud rate maximum.

The DFS force limits are only set from the force gauge itself by utilizing the HI/LO comparator

feature.

Setting Force limits w/ FGV-X or FGV-XY force gauge:

First make sure that communication exists between the force gauge and the test stand. If the FGV-X

or FGV-XY force gauge is not connected with the FGV-FGS250P cable, a force limit programmed

into the test stand will not function.

Remember to fi rst, turn on the force gauge before turning on the test stand. This will ensure

that the test stand recognizes the attached force gauge.

When using an FGV-X or FGV-XY force gauge, to program a force limit, press the “SET” button

on the front panel display. Note that the display “No” box shows “F ”. The “F” and the two arrows

indicate that it is ready to accept the force limits for both push and pull operation. (The programmed

force limits are the same for JOG and SING modes.) Use the “TIME/> to change digit position and

“RST/^” to increment each digit until the desired limit force is displayed.

Press the “TIME/<” button until no digits are blinking. This allows the user to select a negative sign by

pressing the “RST/^” button. IF there is no negative sign displayed,(-) the test stand force limit is programmed

as a compression force limit. IF the negative sign is displayed, the test stand force limit is programmed as a

tension force limit. Press “SET” to store the force limit in memory.

Setting Force limits w DFS force gauge:

If using the DFS force gauge, force limits are set on the force gauge using the DFS HI/LO comparator

feature. To stop the stand at a force limit using a DFS force gauge, you will need the FGS-50PCABLE

cable. This cable permits the DFS to send a signal to stop the stand’s movement when the DFS HI/

LO comparator force limits are activated.

The test stand will move in the left or right direction when the respective “PUSH” or “PULL” button is

selected. The stand will continue to move in the selected direction until one of the following events

occurs: “STOP” button is pushed, one of the manual limit switches are tripped, the emergency reset

button is pushed, or a force limit is reached.

9

Page 10

5.3 SING (Single Mode)

This mode of operation is ideal for completing one cycle between manual distance limits and/or force

limit. The initial starting direction can be either in the compression or tension direction depending on

whether the “PUSH” or “PULL” buttons are pressed.

If using a Shimpo FGV-X or FGV-XY force gauge, you may set a force limit on the test stand.

Front panel display indicating force

limit for both direction.

To program the force limit, press the “SET” button on the front panel display while in the “SING” mode. Note

that the display adjacent the “No” box shows “F ”. Use the “TIME” and “RST” buttons to select the desired

force limit. Press “SET” to store the force limit into memory.

TIME DELAY:

A time delay in seconds can be programmed between changes in direction by cycling the “TIME”

button through “0”, “1”, “2”, “3”, “4”, or “5”.

In this mode of operation the user can display length, speed or cycle count. Display length by pressing

the “LENGTH/SPEED” button until the LED adjacent “LENGTH” is illuminated. To display speed, push

the “LENGTH/SPEED” button until the LED adjacent “SPEED” is illuminated. Finally, to display Cycle

count, press the “LENGTH/SPEED” button until there are no LED’s illuminated. When the stand is

moving in the “pull” direction, the LED next to “SPEED A” is active. When the stand platform is moving

in the “push” direction the LED next to “SPEED B” is active.

The test stand will move left or right when the respective “PUSH” or “PULL” button is selected. The

stand will continue to move until one of the following events occurs: the “STOP” button is pushed,

one of the manual limit switches are tripped, the emergency reset button is pushed, or a force limit is

reached.

10

NOTE: An RS232C output is produced when using this mode of operation; see RS232C Output Section 6.0 for

details.

Page 11

5.4 CONT (Continuous Mode)

This mode of operation is ideal if the user wants the test stand to repeatedly cycle left or right

continuously or for a user-programmed number of times. The stand will start in either direction

depending on whether “PUSH” or “PULL” is selected.

Length, speed or cycle count can be displayed as described in 5.3 SING mode of operation.

To begin programming the test stand, press the “SET” key. The display will indicate a “C” in the

“No” box. The “C” designates that the digits programmed into the adjacent LED’s will determine the

number of cycles (number of times) a program will run. Using the “TIME/<” and the “RST/^” buttons

select the number of cycles you want the program to complete (0001-9999) or select four “0’s” if you

want the program to run continuously. Press “SET” to go to the next step.

The letter F appears in the LED’s in

the “No” box. This indicates that it is

ready to accept the upper force limit.

Use the “TIME/<” and “RST/^” buttons

to select the desired force limit.

NOTE: Pressing the “TIME/<”

button until no digits are blinking.

Allows the user to select a negative

sign by pressing the “RST/^”

button.

Set up for continuous cycle

With no negative sign displayed, the test stand platform is programmed to move downward. With the

negative sign displayed, the test stand platform will move upward. Press “SET” to store the upper

force limit in memory. The down arrow LED (F ) will light, indicating that the test stand is ready

to have its lower force limit programmed. Program the force limit using the “TIME/>” and “RST/^”

buttons.

Note: The upper force limit must be greater than the lower force limit (Fupper > Flower). Again

press “SET” to store the lower force limit into memory. You may delay the time between upward and

downward movements by selecting 0, 1, 2, 3, 4 or 5 seconds using the “TIME/>” button. You may

view distance traveled by pressing “LENGTH/SPEED” until the LED adjacent “LENGTH” is lit. Speed

can be displayed by pressing “LENGTH/SPEED” until the LED adjacent to the indicator “SPEED” is

lit. Finally, the number of cycles completed can be displayed by pressing “LENGTH/SPEED” until no

LED’s are lit.

NOTE: An RS232C output is produced when using this mode of operation; see RS232C Output

Section 6.0 for details.

11

Page 12

5.5 PROG (PROGRAM Mode)

Press the “MODE” key until the light emitting diode, LED, adjacent “PROG” is lit.

Length, speed or cycle count can be displayed as described in 5.3 SING mode of operation.

Cycles

To begin programming the test stand, press the “SET” key. The display will indicate a “C” in the

“No” box. The “C” designates that the digits programmed into the adjacent LED’s will determine the

number of cycles (number of times) a program will run. Using the “TIME/<” and the “RST/^” buttons

select the number of cycles you want the program to complete (0001-9999) or select four “0’s” if you

want the program to run continuously. Press “SET” to go to the next step.

Entering four zeros on cycle allows the test stand to perform the same programmed test continuously

until one of the three events occurs, the “STOP” button is pushed, emergency stop buttons is pressed,

or an overload condition is detected.

Force Limits

The display in “No” box now shows “F ”. The two arrows adjacent the “F” indicates that the test

stand is ready to accept compression or tension force limits. To program a force, use the “TIME/<”

and “RST/^” buttons to select a force value, and then press “SET”.

Home Position

The display in “No” box now shows “H”. The “H” designates the home position. Select “PUSH” or

“PULL” button to set the HOME position. Press “SET”. The test stand platform will automatically

move to the selected home direction, it will travel the set distance until the limit switch is activated.

Home position set to pull direction. Test

stand will look for the upper limit knob

Force “Zero”

The display in “No” box now shows “F”. The “F” designates the auto zero function. This function is

only available when using the Shimpo FGV-X or FGV-XY force gauges. Use the “TIME/<” and “RST/^”

buttons to program the “zero” force.

12

Page 13

NOTE: The recommended minimum zero force that the user should program into the test stand is 0.2% of

the full scale (rating of the force gauge), i.e. if using an FGV-50X or FGV-50XY force gauge, the programmed

“zero” force should be 0.1-lb (0.002 X 50 = 0.1).

If no force is programmed in this step and the display reads all zeros, the test stand will not

zero the distance and this feature is inoperative.

Press the “SET” button to move on to the next step. This is a very useful function that allows the

operator to reset the distance display and RS232 output data to zero once the force gauge senses

a force measurement.

Tare

The display in the “No” box now shows “t”. The “t” designates the tare function at “0” position. Select

“on” or “off” by using the “RST/^” button and press the “SET” button.

The tare function allows the user to use attachments on the force gauge and then set the force gauge display

to zero. This function is useful as some attachments weigh more than others and this function sets the

display to zero, provided that the attachment does not weigh more than 50% of the gauge’s capacity.

Note: Shimpo recommends taring not more than 20% of the gauge’s rated capacity; this

guarantees the availability of the force gauge’s full capacity.

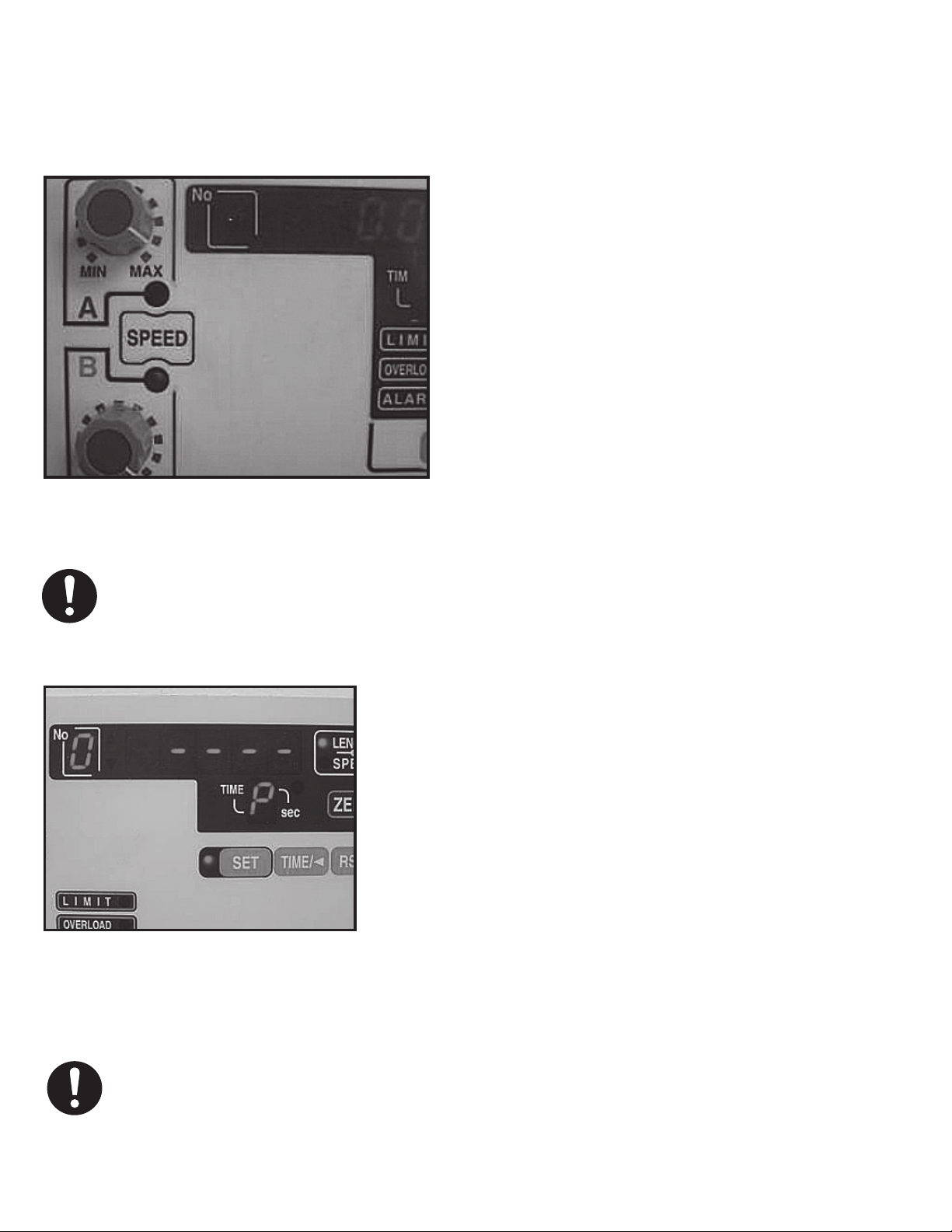

The display in the “No” box shows “0”, and the “LENGTH, SPEED, CYCLE” display shows “----”. The

“0” designates that the test stand begins each cycle from this position. Using the “PUSH” or “PULL”

and the “SPEED A” or “SPEED B” buttons, adjust the test stand to the position from which the force

gauge will begin force/distance tests. A time delay (pause) up to 5 seconds can be programmed

between programmed points. Use the “TIME/<” button to cycle through “0”, “1”, “2”, “3”, “4”, “5” or

“P”. If “P” is selected, the user must press the “PROG START “, key to restart the test stand program.

Position “0” is called the set point zero position, the test stand will return to this position at

the beginning of each cycle. The FGV-X or FGV-XY force gauge will also tell the test stand to

stop and return to the set point zero position if a programmed force limit is reached. If the force does

not attain a programmed force limit, the test stand will execute an entire cycle, then return to the

set point zero position and begin the next cycle. To delete an unwanted set position, press “RST/^”.

Then, press the “SET” key to move to the next programming step.

The force gauge plate will only go back to HOME position after all the cycles are completed. Each cycle

returns to the zero set point position

13

Page 14

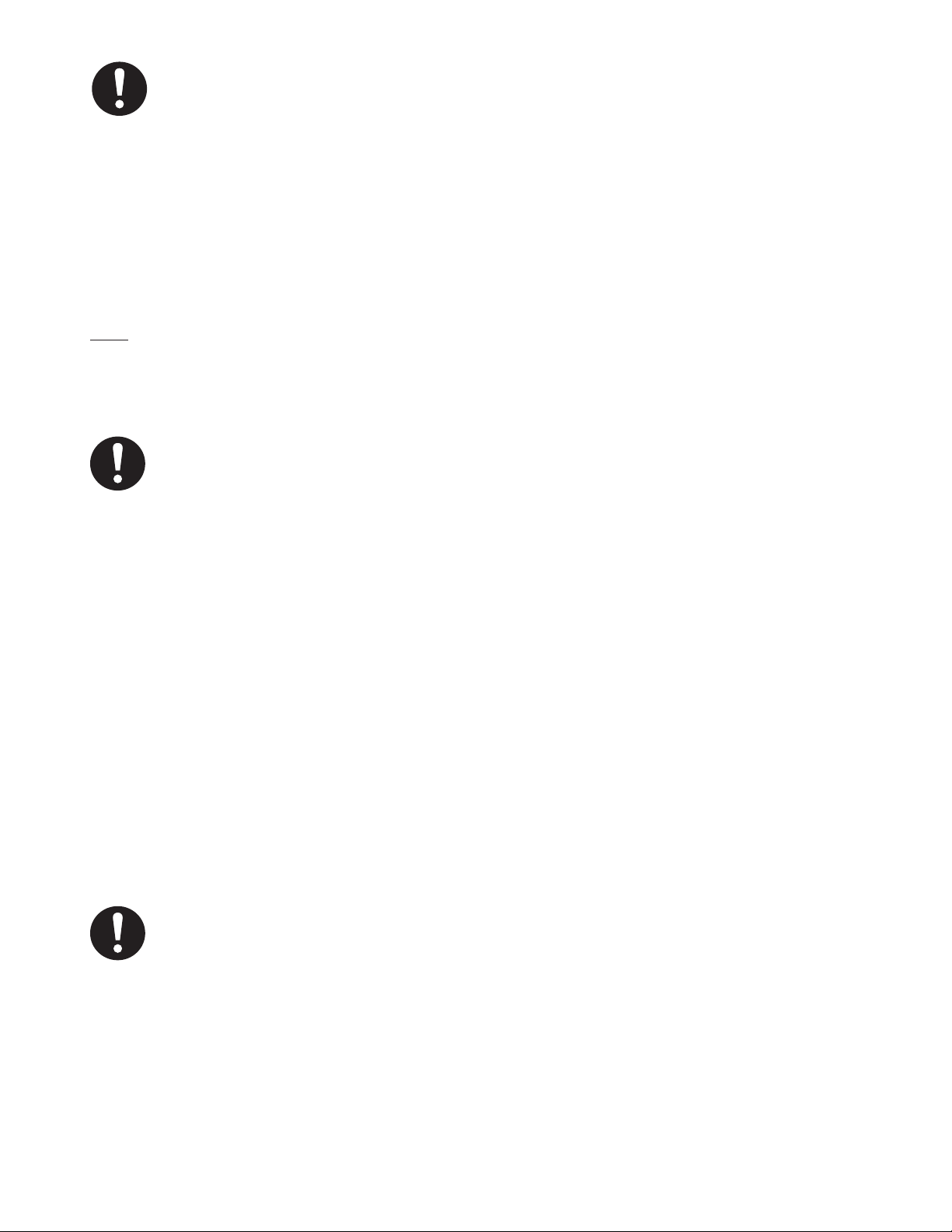

The display in the “No” box shows “1”, and the “LENGTH, SPEED, CYCLE” display shows “----”. The

“1” designates the next position of a cycle that the test stand will move to. This position is defi ned as

set point 1. Ensure that the correct LED indicator for “Speed A” or “Speed B” is illuminated so that

the test stand will travel at the intended speed. (see photo)

Using the “PUSH” or “PULL” button, move the

test stand force gauge platform to position 1.

Press the “SET” key.

(Note: If a programmed force limit is detected

by the force gauge, the test stand will not move

through the entire programmed distance and the

test stand will then return to set point zero.)

The display in the “No” box shows “2”, and the

“LENGTH, SPEED, CYCLE” display shows “---”. The “2” designates the next position of a cycle

that the test stand will move to. This position

is defi ned as set point 2. Using the “PUSH” or

Speed knob A and B. Desired speed can be

“PULL” and the “SPEED A” or “SPEED B” control

knobs move the force gauge to position 2

selected by pressing the “Speed” Button.

NOTE: If the programmed force limit is detected by the force gauge the test stand will not move the entire

programmed distance and the force gauge will return to set point zero.

Press the “SET” key.

Shown point zero ready to accept entry.

Use Push and Pull button to increment

and decrement value.

The display in “No” box shows “3”, and the “LENGTH,

SPEED, CYCLE” display shows “----”. Repeat these steps

outlined in the above paragraph up to a maximum of 5

points.

If no more steps are desired, press the “SET” key while

the “LENGTH, SPEED, CYCLE” display shows “----” to

fi nish programming the test stand.

14

It is not necessary to provide entries for all 5 set points. The test stand will work with one set point. If more

than two set points are entered and a change in the value of the second set point is required, re-enter the set

points for both entries. The distances (length) for the test stand program are accumulative, and dependent

on the previous set point. The distances (length) for the test stand program are accumulative, and

dependent on the previous set point.

Page 15

To Run Program:

Run the program by selecting “PROG START” on the display panel.

Clearing the previously stored program helps in eliminating program confl icts. To reset the program

memory, press and hold “RST/^” and then press “SET”. The display will read “CCCC”.

NOTE: An RS232C output is produced when using this mode of operation. See 6.0 RS232C Output

below for details.

Clearing the previously stored program helps

in eliminating program confl icts.

6.0 RS232C Output Format (using FGV-X Force Gauges)

“Cr” means carriage return

SING/CONT Mode

Plus Peak

Direction A: PULL

B: PULL

Minus Peak Distance

NOTE: Direction A: PULL, B: PUSH

“Cr” means carriage return or Enter

Data will be outputted when stand platform reaches a manual limit switch or a programmed

force limit.

15

Page 16

PROG Mode

Plus Peak Minus Peak Distance

Point

Number

Data will be sent when the test stand force gauge platform reaches every set position or if a force

load exceeds the force limit.

NOTE: If the auto zero function is selected, data will be outputted at the fi rst zero position, when the test

stand platform reaches every set position or if the force gauge exceeds a force limit.

“CR” means carriage return or Enter

7.0 Troubleshooting

Stand does not turn on: FIRST INSPECT all parts for physical interference

Check all electrical components:

• Check for correct AC power source, power cord condition, fuse condition, power switch

(should be “ON”), Emergency cut-off switch setting

• I Inspect test stand fi xtures and force gauge for overload conditions. To disengage

emergency switch, carefully press and turn clockwise.

The force gauge mounting platform does not move:

• Check manual limit knobs and adjust accordingly

• Check to see if the full travel range has already been achieved.

• Check test stand for correct operating mode.

• Check Emergency cut-off switch setting.

Force set points are not stopping the test stand (force gauge platform) movement

Check that communication exists between the force gauge and the test stand

Check that correct cable is fi rmly attached.

Check if the proper baud rate for communication is set from the force gauge. Required

baud rate is 19200 baud rate for FGV-X, FGV-XY. Communication with Shimpo DFS force

gauges bypasses the test stand to the PC when using the FGS-50PCABLE

16

Page 17

Display indicates “no_F” after power up

Check for proper force gauge cable (only for FGV-X and FGV-XY models).

Check for proper baud rate from the force gauge.

Reset the whole system, powering up in this particular order Force Gauge>Test Stand.

Initialization takes longer and a no_F display

indicates there is no communication established

between the test stand and the force gauge.

Shimpo DFS models transfer data directly

using the FGS-50PCABLE. Length/

Distance of the test is programmed in

the test stand. When using Shimpo DFS

force gauge, “MANU” and “SING” (modes)

function the same.

Limit switch not stopping the test stand/force gauge from moving Check if the limit switch shoe

behind the knob has been turned in the wrong position. (See photos for proper orientation and

installation).

Actuator limit switch rollers should hit

this side of the shoe limit switch.

Insert the washer before the knob.

The limit switch shoe has a lip guide

preventing it from spinning. Orient

the Limit switch shoe properly before

installation.

17

Page 18

Getting incorrect distances during a test

Re-enter all the test points distances (Remember that the distance is dependent on

previous set points and set points are accumulative).

Check if a previous or incorrect force limit is set in memory

RS-232 output not working correctly

Check that proper cables are selected and attached to the force gauge test stand and PC.

Cable DESCRIPTION

FGV-FGS250P

FGS-50PCABLE DFS cable for transferring data directly from the Shimpo DFS force gauge to PC.

FGV-RS232 Interface cable for data output from test stand to PC. (for FGV-X and FGV-XY Models)

FGS-ANALOG Analog output cable for data acquisition requirements. (provided with stand)

Communication cable between the test stand and the force gauge.

(for FGV-X and FGV-XY Models) (provided with stand)

8.0 Test Stand Specifi cations

Model

Capacity

Travel speed

Stroke

Repetition number

Operation mode

Output

signal

Input

Horizontal attachment

table-height range

Horizontal table

dimensions

Operating Temperature

Power supply

Weight

Standard parts

Options

Analog

voltage

RS-232C

Overload

input

FGS-100PXL FGS-100PXH

Low speed High speed

110 lbs (500N,50kgf)

0.19 - 4.72 inch/min

(5-120mm/min)

2 types of speed switch

5.51in (140 mm) with mechanical backlash 0.2 -

Manual, Jog, Single, Continuous cycling,

Program mode

Output the displacement of the stand 10mV/mm

MAX: ±1.4V

19200 Baud rate

Stops operation due to force overload on Shimpo

DFS or FGV-X or FGV-XY

0 - 1.38 inch (0 - 35mm)

5.90 X 5.70 inch (150×145mm)

0~45(non condensing)

AC115V (±10%)

40 lbs (18 kg)

120Vac socket for force gauge, FGS-250P cable

for FGV-X and FGV-XY, FGS-ANALOG cable for

test stand analog output.

FG-HORIZ-ADAP: Horizontal mounting block for

grip/fixtures. FG data cables, digital and

mechanical force gauges, data collection

0.79 - 19.69 inch/min

(20 - 500mm/min)

0.5 mm)

0 -9999

software

18

Page 19

9.0 Dimensions and Drawings

Test Stand Dimensions

Horizontal Table

Force Gauge Mounting Plate

19

Page 20

Warranty

LIMITED EXPRESS WARRANTY

Shimpo Instruments warrants, to the original purchase of new products only, that this product shall be

free from defects in workmanship and materials under normal use and proper maintenance for one year

from the date of original purchase. This warranty shall not be effective if the product has been subject to

overload, misuse, negligence, or accident or if the product has been repaired or altered outside of Shimpo

Instruments authorized control in any respect which in Shimpo Instruments judgment, adversely affects its

condition or operation.

DISCLAIMER OR ALL OTHER WARRANTS

The foregoing warranty constitutes the SOLE AND EXCLUSIVE WARRANTY, and Shimpo Instruments

hereby disclaim all other warranties, expressed, statutory or implied, applicable to the product, including,

but not limited to all implied warranties of merchantability and fi tness.

LIMITATION OF REMEDY

Under this warranty, Shimpo Instruments’ SOLE OBLIGATION SHALL BE TO REPAIR the defective product

or part, at Shimpo Instruments’ option. Shimpo Instruments reserves the right to satisfy warranty obligation

in full by reimbursing Buyer for all payment made to Shimpo Instruments, whereupon, title shall pass to

Shimpo Instruments upon acceptance of return goods. To obtain warranty service, Purchaser must obtain

Shimpo Instruments’ authorization before returning the product, properly repackaged, freight pre-paid to

Shimpo Instruments.

INDEMNIFICATION & LIMITATION OF DAMAGES

Buyer agrees to indemnify and hld Shimpo Instruments harmless from and against all claims and damages

imposed upon or incurred arising, directly or indirectly, from Buyer’s failure to perform or satisfy any of the

terms described herein. In no event shall Shimpo Instruments be liable for injuries of any nature involving

the product, including incidental or consequential damages to person or property, any economic loss or

loss of use.

MERGER CLAUSE

Any statements made by the Seller’s representative do not constitute warranties except to the extent that they

also appear in writing. This writing constitutes the entire and fi nal expression of the parties’ agreement.

Copyright © Nidec-Shimpo America Corporation 2001. All right reserved. Product specifi cations are subject

to change without notice.

20

Loading...

Loading...