Page 1

Series FGE-XY Force Gauges

Operation Manual

Do not operate or store instrument in the following

locations:

Explosive areas, near water, oil, dust or chemicals; areas where the temperatures can exceed 104°F

(40° C)

Take precaution to not drop the force gauge. Damage

to the sensor may occur.

Do not modify, disassemble or attempt to repair the

unit. Send to the factory for proper repair.

If upon delivery damage to the unit is detected, do not

operate the unit. Notify the shipping carrier immediately to obtain damage claim instructions.

Only measure forces that are in line with the measuring shaft. Do not attempt to take any measurements

(tension or compression) at any angle. Failure to keep

measurements in line will damage the instrument.

NIDEC-SHIMPO INSTRUMENTS

The Series FGE-XY Digital Force Gauges combine a rugged, ergonomic and compact design with exceptional accuracy to provide

a solid force testing instrument. These instruments are utilized in

a variety of applications such as, incoming quality inspection, finished goods testing, R&D or almost any portable or force stand

testing requirement.

Simple one button adjustment alters units, while pressing the

peak button quickly produces the highest recorded value during

the test. The 180° reversible display combined with the adjustable

excel in both compression and tension applications in any direction. Models are available from 0.5 lb to 200 lbs ranges providing

a large offering for various testing requirements.

Typical applications include wallboard, wire pull, wire crimps, trigger pull, brake pedal, aerospace ceramic, springs, food ripeness,

corrugated paper strength, blister pack, medical component,

muscle strength, ergonomic testing, adhesives, syringe plunger,

needle sharpness and many more.

ot YX-EGF eht elbane dapyek delebal laud dna noitcerid ecrof

Page 2

E

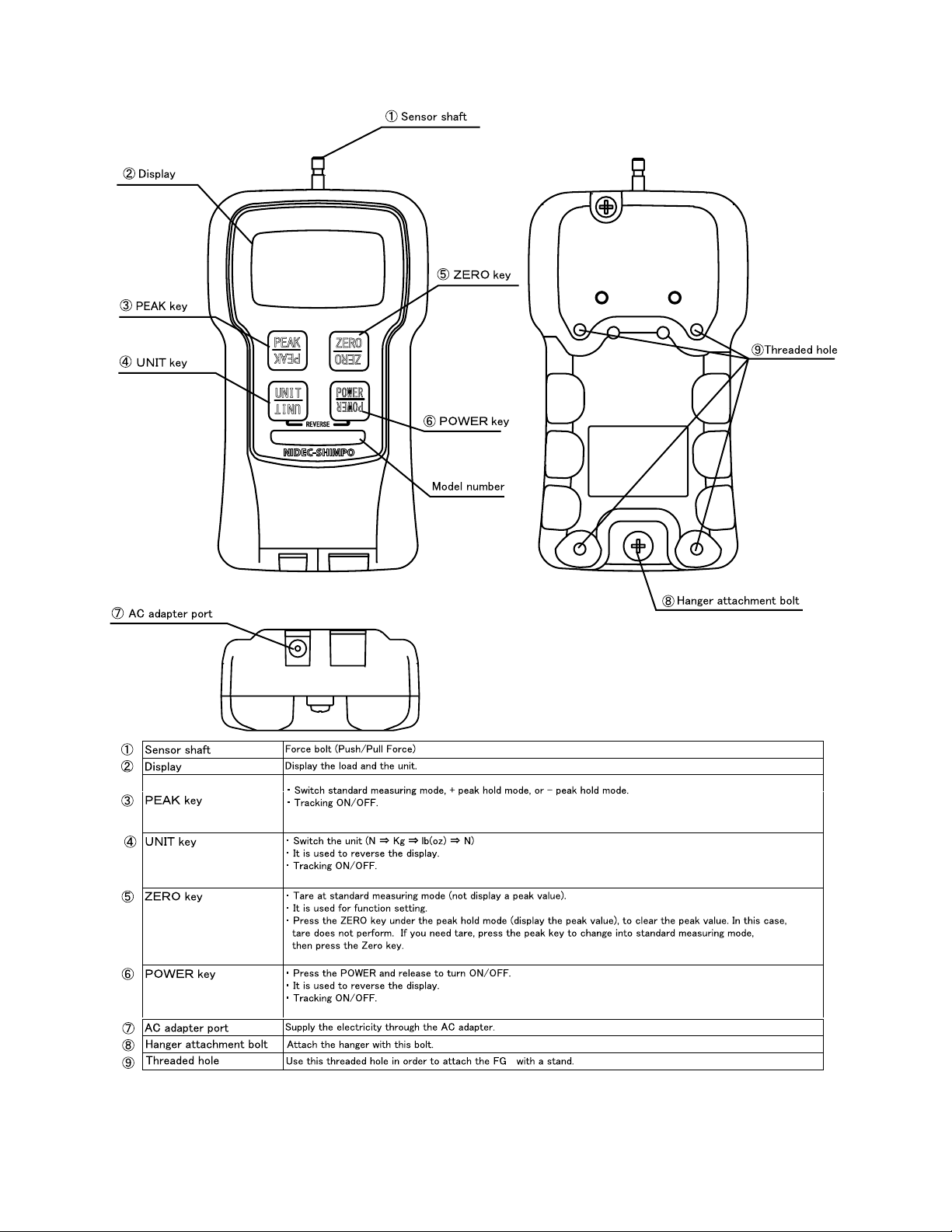

PRODUCT DIAGRAM

2

Page 3

SPECIFICATIONS

FGE-XY Model

Capacity

Resolution

Accuracy ±0.2% F.S.

Display 4-Digit LCD, 0.5” (12 mm) high, Units 0.29” (7 mm). Reversible by the push of a button. Minus sign for tension

Display Update 0.05, 0.1, 0.2, 0.3, 0.5, 1 sec

Sampling Rate 1000 Hz

Overload 200% of F.S. (200 lb.: 150% F.S.)

Power Rechargeable Ni-MH battery or AC adapter/charger

Auto Power Shut-Off Yes (not active if adapter/charge is in use)

Battery Charge 10 hours (when fully charged)

Recharge Time Approximately 17 hours when fully discharged

Temperature Range 32 - 104°F (0 - 40°C)

Dimensions 5.8 x 3 x 1.5” (147 x 75 x 38 mm)

Product Weight Approx. 1 lb (450 g); FGE-200XY Approx. 1.1 lb (500 g)

Package Weight Approx. 2.25 lb ( 1.02 kg) for 0.5 lb and 1 lb ranges; 2.4 lb (1.09 kg) for 2 to 100 lb ranges; 2.75 lb (1.25 kg) for 200 lb range.

Certification CE, RoHs

Included

Accessories

FGE-0.5XY FGE-1XY FGE-2XY FGE-5XY FGE-10XY FGE-20XY FGE-50XY FGE-100XY FGE-200XY

8 oz

0.5 lb

200.0 g

2.000 N

0.01 oz

0.001 lb

0.1 g

0.001 N

16 oz

1 lb

500.0 g

5.000 N

0.01 oz

0.001 lb

0.1 g

0.001 N

32 oz

2 lb

1,000 g

10.00 N

0.01 oz

0.001 lb

1 g

0.01 N

5 lb

2.000 Kg

20.00 N

0.001 lb

0.001 Kg

0.01 N

10 lb

5.000 Kg

50.00 N

0.01 lb

0.001 Kg

0.01 N

20 lb

10.00 Kg

100.0 N

0.01 lb

0.01 Kg

0.1 N

50 lb

20.00 Kg

200.0 N

0.01 lb

0.01 Kg

0.1 N

100 lb

50.00 Kg

500.0 N

0.1 lb

0.01 Kg

0.1 N

200 lb

100 Kg

1000N

0.1 Kg

AC adapter/charger, carrying case, hook, chisel, flat head, notched head, hanger, cone head, thread Adapter, extension rod

0.1 lb

1N

OPERATION

To Begin:

1. Charge the batteries for approximately 17 hours before using

the gauge. The batteries come discharged from the factory.

2. Hand-tighten appropriate attachment to units measuring

shaft. Do not use wrench or any other device or tool to

tighten the attachments to the shaft.

3. Press Power and release. The unit will display model name in

the upper display and the capacity in the main display.

Change Display Units

To change the display units, simply press UNIT and the units will

change with each subsequent press of the button.

Reverse the Display

If the gauge is used with the included hanger or mounted on a test

stand, the display must be reversed.

1. Press POWER and hold. The display will go blank.

2. Press and hold UNIT.

3. Release POWER while still continuing to hold down UNIT. Display will still remain blank.

4. Press POWER once more and release it while still holding UNIT.

At this point the display will appear and be reversed.

5. Release UNIT; the display stays now in the reverse mode.

To return to the normal mode, repeat steps 1-5.

Select Average or Peak

The unit can display the live Averaged reading or the Peak reading. Standard is Average.

If you want to measure the Peak force, follow this procedure:

1. Press PEAK; the word PEAK will appear in the upper left corner

of the display. If you wish to have a minus sign on the Peak, press

PEAK again.

2. The display will freeze and show only the peak force on any

given test.

3. To reset the Peak reading, press ZERO to clear the current

Peak reading and start over.

If you wish to go back to Average reading mode, press PEAK

again. The PEAK icon will disappear from the display.

3

Page 4

Taking a Measurement

After the appropriate attachment has been hand-tightened on the

instrument, tare the unit by pressing ZERO.

Tension Measurement

To measure tensile forces, use the hook attachment provided.

The display will show the force measured with a minus sign (-) to

the left of the digits.

Note: To eliminate the minus (-) sign during tensile operation, this

may be changed. Review the “Function Setting” section.

Compression Measurement

To measure compression forces, use the flat head attachment

provided. The display will not show any sign for compression.

Note: To display a minus sign (-) for compression forces, consult

the “Function Settings” section for making the change.

Low Battery

When the battery charge is low, LO BAT will appear indicating

the batteries need to be charged. To completely charge fully depleted batteries requires approximately 17 hours of charging time

with the unit off. The units possess a smart charging system that

shuts off the charging circuit once the batteries are fully charged.

Note: The unit may operate with the charging adapter while the

batteries are being charged. This will however lengthen charging

time.

Note: To modify the auto power off function, consult the “Function

Setting” section.

Tracking Function

The tracking function accounts and compensates for temperature

drift. It is advised to keep this function running for optimal performance. However, when measuring very minute forces (a few

ounces or grams) at a very slow rate, it may be advisable to disable this function.

To turn the tracking function off, follow these steps:

1. Turn POWER off

2. Press PEAK and UNIT switches simultaneously and hold. Then

press and release POWER. If the tracking function was on, the

display will show TRK OFF momentarily to confirm successful disable.

3. Release PEAK and UNIT

The tracking function is now off. Repeat these steps to activate

the tracking function. The gauge displays TRK SET when reactivated.

FUNCTION SETTING

To change the default parameters of the gauge, follow the procedure to access the settings:

1. Press and hold the ZERO button.

Auto Power Off

If the gauge is on and there is no activity for 10 minutes, the unit

automatically powers off to conserve the batteries. At 9 minutes

without activity, PWR appears to notify that there is 1 minute before

auto power-off. If the charging adapter is powering the gauge, the

auto off function is inactive.

Power OFF;

Press and hold ZERO button. Press and release the POWER button.

Plus or Minus

Sign

PEAK

Display Update

Time

PEAK

Auto Power

Off

ZERO;

Save and Exit

F01

0001

F02

F03

UNIT

MINUS

UNIT

3

UNIT

10

UNIT UNIT

F01

-0001

UNIT UNIT UNIT

F02

5

UNIT UNIT

F03

OFF

F01

0001

PLUS

F02

10

F03

10

2. Press and release the POWER button

3. Each time the PEAK button is pressed, the unit will scroll

through each of the functions.

4. Press the ZERO button to exit.

F02

UNIT

20

F02

1

UNIT UNIT

F02

2

F02

3

4

Page 5

CALIBRATION REqUIREMENTS

1. Secure and mount force gauge to a calibration stand and mount

the gauge upside down.

2. Obtain the appropriate full scale Metric range calibration weight

of your unit.

12. If calibration was unsuccessful, the display will show ERR. Remove the calibration weight, then press UNIT. Repeat the procedure to attempt for a correct calibration.

Err

3. Turn POWER OFF

4. Attach the fixture on the shaft of the force gauge. Thread and

tighten onto shaft by hand only.

5. Press and hold the UNIT, PEAK and ZERO switches.

6. Press and release the POWER switch while still holding the

other 3 switches. Continue holding the 3 switches until the display

reads CAL, now release the three switches.

CAL

-00-

7. Press the UNIT switch. The display will blink SCN for 10 seconds then show ZER. The force gauge is now ready for zero point

calibration.

“SCN”

-00-

8. Press ZERO to zero calibrate. Wait approximately 18 seconds.

The display will blink SCN then PEK. Do not press any other

switches or move the sensing shaft during calibration.

ZER

88888

88888

TROUBLESHOOTING

The following are general checkpoints. Please call Shimpo or your

dealer for further assistance.

Force Gauges does not turn on: Check that power adapter is connected properly to unit and outlet.

Error codes are displayed: Turn unit off, then back on to reset. If

error codes continue, see table below

Small Display Condition Action

OVR

ERR

3

ERR

4

The load exceeds

120% of its capacity

EEPROM reading

error

EEPROM writing error

Remove excessive

load.

Turn off, then turn on

again, if the display

does not return to

normal operation

send unit in for repair.

9. Hang the calibration weight on the hook and stabilize. The process values will change. The gauge is now ready for full-scale

calibration.

10. Press the PEAK switch to begin full scale calibration. Display

blinks SCN. Do not press any keys or touch the unit or weight

during calibration. After approximately 18 seconds, the display

blinks END. After an additional 5 seconds, the display blinks OK

if successful.

“SCN”

88888

11. Press the UNIT button, the unit automatically powers off.

“End”

88888

“oK”

88888

5

Page 6

DIMENSIONS

Loading...

Loading...