Page 1

OI-1110

11.0 WARRANTY

ELECTROMATIC Equipment Co., Inc. (ELECTROMATIC) warrants to the original

purchaser that this product is of merchantable quality and conrms in kind and quality

with the descriptions and specications thereof. Product failure or malfunction arising

out of any defect in workmanship or material in the product existing at the time of

delivery thereof which manifests itself within one year from the sale of such product,

shall be remedied by repair or replacement of such product, at ELECTROMATIC’s

option, except where unauthorized repair, disassembly, tampering, abuse or

misapplication has taken place, as determined by ELECTROMATIC. All returns

for warranty or non-warranty repairs and/or replacement must be authorized by

ELECTROMATIC, in advance, with all repacking and shipping expenses to the address

below to be borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR

PURPOSE OR APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE

NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR

NATURE, RESULTING FROM THE USE OF SUPPLIED EQUIPMENT, WHETHER

SUCH DAMAGE OCCURS OR IS DISCOVERED BEFORE, UPON OR AFTER

REPLACEMENT OR REPAIR, AND WHETHER OR NOT SUCH DAMAGE IS

CAUSED BY MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE WITHIN ONE

YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation may not apply to you. The duration

of any implied warranty, including, without limitation, tness for any particular

purpose and merchantability with respect to this product, is limited to the duration of

the foregoing warranty. Some states do not allow limitations on how long an implied

warranty lasts but, not withstanding, this warranty, in the absence of such limitations,

shall extend for one year from the date of invoice.

ELECTROMATIC Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516—USA

Tel: 1-800-645-4330/ Tel: 516-295-4300/ Fax: 516-295-4399

TABLE OF CONTENTS

01.0 Introduction ............................................................................................................. 0 02

02.0 Overview ................................................................................................................. 0 03

2.1 Operating Elements

2.2 Installing And Replacing The Battery

2.3 Turning The Power On and Off

2.4 Reversing The Display

2.5 Selecting The Unit Of Measure

2.6 Zero Adjustment of the Measuring Position

03.0 Removing and Re-Mounting The Filament Guide .................................................... 06

04.0 Taking A Measurement ............................................................................................. 07

4.1 Inserting The Process Material

4.2 Measuring

4.3 Removing The Process Material

05.0 Damping Mode .......................................................................................................... 08

5.1 Switching On The Damping Mode

5.2 Switching Off The Damping Mode

5.3 Changing the Damping Factor

06.0 Storing and Recalling Tension Values ....................................................................... 09

6.1 Storing Tension Values

6.2 Recalling Tension Values

6.3 Clearing Values Stored In Memory

6.4 Memory HOLD Function

6.5 Error Messages

07.0 Static Verication of Measuring Accuracy ................................................................ 12

08.0 Calibration ................................................................................................................. 13

8.1 Dynamic Calibration

8.2 Static Calibration

8.3 Error Messages

8.4 Restoring Factory Defaults

09.0 Specications ............................................................................................................ 17

Every precaution has been taken in the preparation of this manual. Electromatic

Equipment Co., Inc., assumes no responsibility for errors or omissions. Neither is any

liability assumed for damages resulting from the use of information contained herein.

Any brand or product names mentioned herein are used for identication purposes only,

and are trademarks or registered trademarks of their respective holders.

– 20 –

10.0 Appendix - Replacing the Rollers / Ceramic Pins ...................................................... 18

11.0 Warranty .......................................................................................................................20

– 1 –

– 1 –

Page 2

1.0 INTRODUCTION

Three long, closely-spaced slender shafts with precision guide rollers or pins at their

ends combine with the latest in microprocessor technology to make this instrument top

choice for all limited-access, tension measuring applications.

Store up to 4000 displayed tension values in memory and statistics (Last, AVG, MIN,

MAX, MIN-PEAK, MAX-PEAK), which can be transmitted using the serial output

port.

Choice of miniature, high speed rollers for lament speeds up to 2000 m/min or nonrotating, ceramic pins for speeds to 6000 m/min. Uses part number ETMX or ETMPX

to designate model with ceramic pins.

Available Models - The standard series is also available with the following

modications. (Special calibration using customer supplied material.)

Model

ETMB-100 0.5 - 100.0 24 PA: 0.20 mm Ø

ETMB-200 1 - 200 24 PA: 0.20 mm Ø

ETMB-500 1 - 500 24 PA: 0.20 mm Ø

ETMPB-100 0.5 - 100.0 24 PA: 0.20 mm Ø

ETMPB-200 1 - 200 24 PA: 0.20 mm Ø

ETMPB-500 1 - 500 24 PA: 0.20 mm Ø

Tension

Ranges

cN

1.1 Unpacking

Unpack the tension meter and inspect it for any shipping damage. Notice of defect must

be led immediately, at the latest, within 10 days of receipt of the goods.

*Measuring

Head Width

mm

Calibration with

running filament

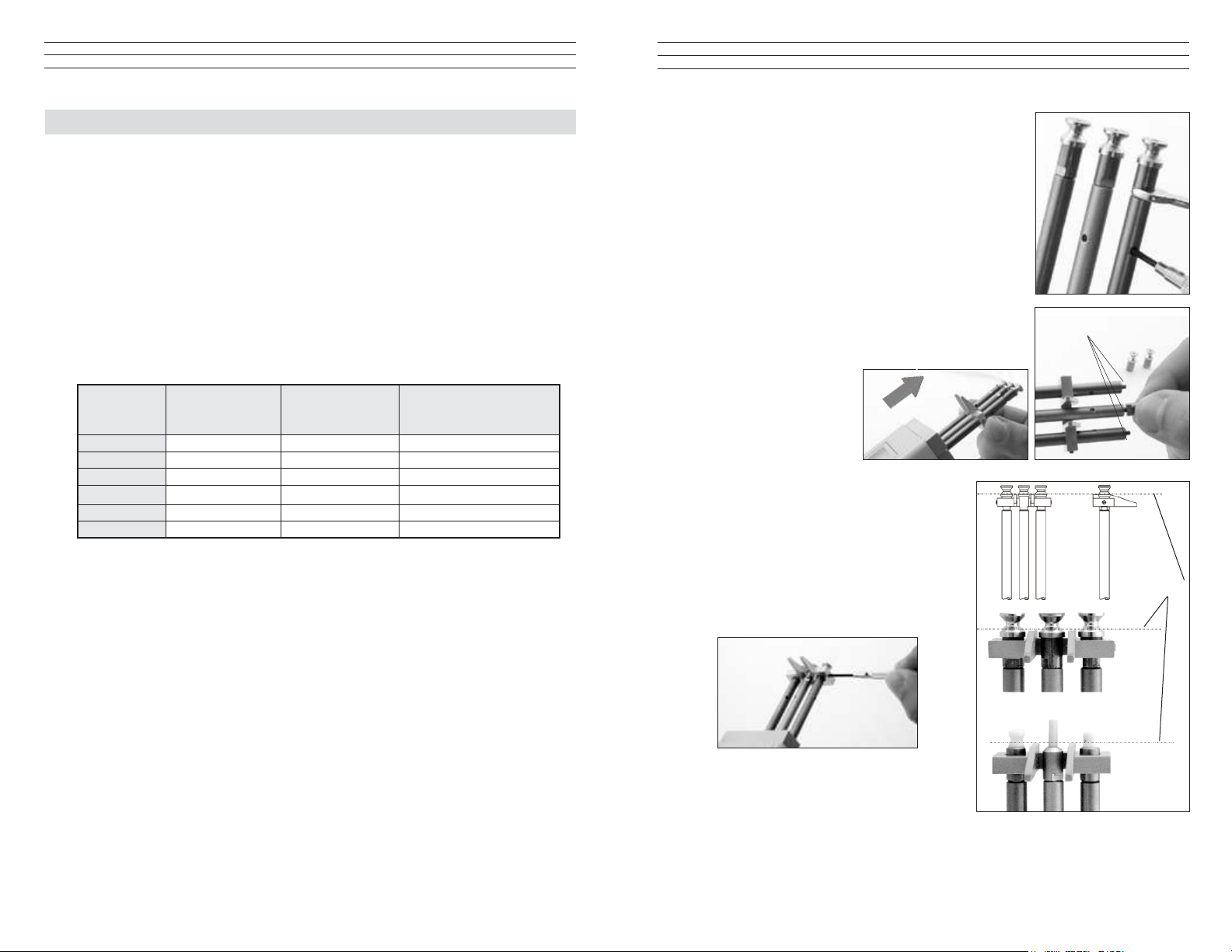

3. Unscrew and remove the GUIDE ROLLERS (2)

using the supplied open-end wrench (4mm jaw width).

Note: Should any of the three threaded studs be damaged,

replace it with one of the threaded studs supplied with the

new rollers.

4. Carefully screw the new GUIDE ROLLERS onto

the ROLLER SHAFTS.

5. Carefully tighten the new rollers with the open end

wrench until hand tight.

Note: When loosening or tightenng the rollers, steady

the roller bolt with the supplied screwdriver to prevent

the ROLLER SHAFTS from being twisted off.

6. Slide the FILAMENT

GUIDE up the roller

shafts in the direction

of the arrow.

7. Push the FILAMENT GUIDE upwards far

enough to ensure that the rollers do not rub

against the FILAMENT GUIDE and that

the process material can slide unhindered

from the FILAMENT GUIDE into the

roller grooves.

8. Tighten the SETSCREWS (2) with the

supplied screwdriver (1.5mm blade).

ROLLER SHAFTS

Ideal line

Delivery includes:

1 Tension meter

1 AC-adapter with 3 country-specic adapters (EU/USA/UK)

1 Open end-wrench (4mm jaw width)

1 Screwdriver (1.5mm blade width)

1 Operating Instructions

1 Carrying case

– 2 –

– 19 –

Page 3

10.0 APPENDIX - REPLACING THE ROLLERS/CERAMIC PINS

GUIDE ROLLERS (2x)

MEASURING ROLLE

2.0 OVERVIEW

You should regularly inspect the rollers to assure that they are running easily and

smoothly. You can replace the rollers yourself, as necessary, by following the directions

in this section. Please indicate the tension meter model and the serial number (given on

the rear side of the tension meter) in your spare-parts order.

Model ID

Model: 03/04

ETMB-100

# 400 - 88888

Serial number

FILAMENT GUIDE

R

ROLLER SHAFTS (2x)

Procedure

1. Remove the FILAMENT GUIDE by loosening

the SETSCREWS (2) using the

supplied screwdriver (1.5m blade width).

GRUB SCREWS (2x)

NOTE: Replacing rollers with

ceramic pins or ceramic pins with

rollers can only be performed at

the manufacturer’s facility.

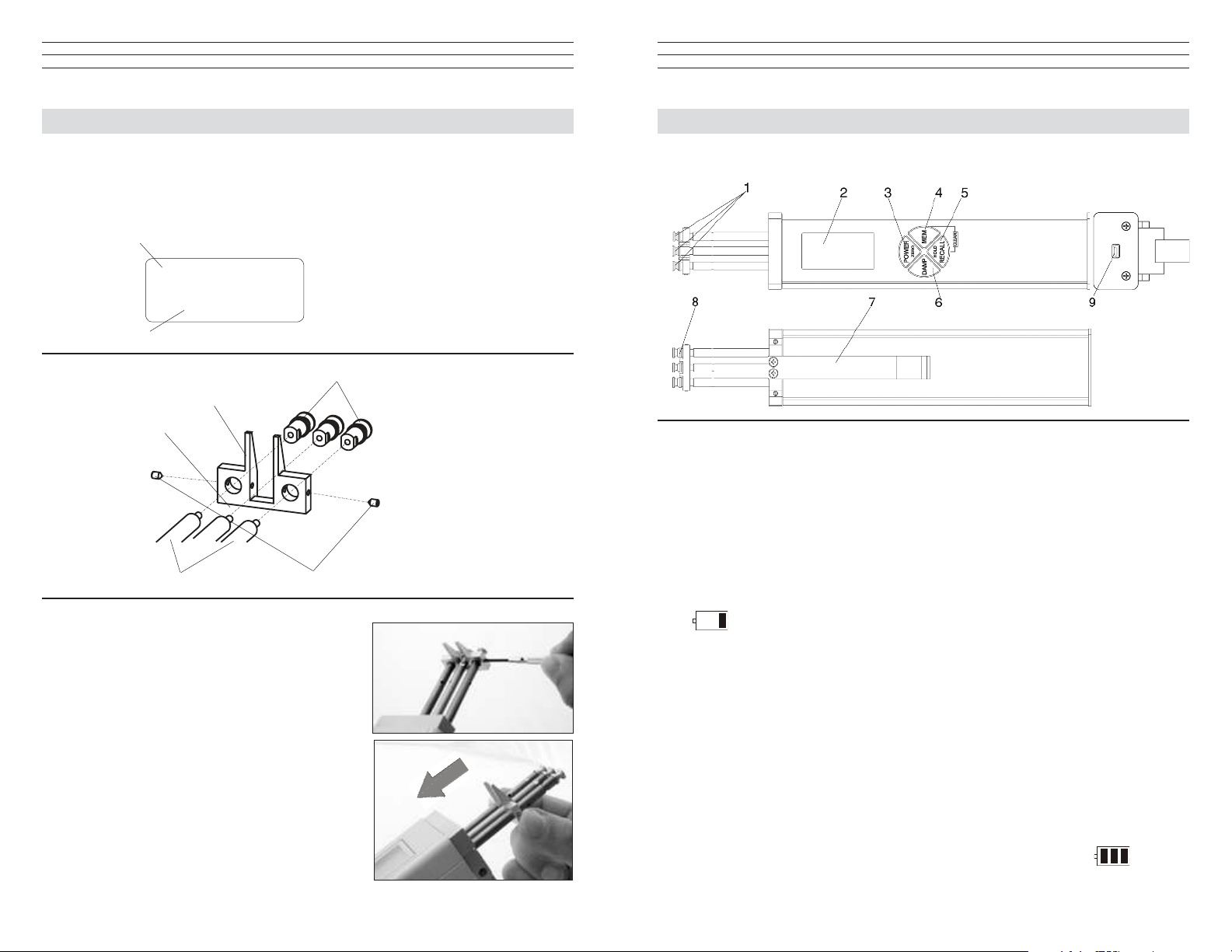

2.1 Operating Elements

1 ROLLERS or ceramic pins

2 DISPLAY

3 POWER / ZERO key

4 MEM key

5 RECALL / HOLD key

2.2 Battery Management & Charging

The tension meter has a built-in rechargeable LiPo battery, which has been charged at

the factory. The tension meter can only be switched on if the battery has enough charge.

If the instrument does not power up or if the battery level indicator shows only one bar

after power-up the battery needs to be recharged.

NOTE: To ensure maximum battery life, avoid discharging it completely or charging it

frequently for short periods. The battery should not be stored for a prolonged time when

empty. After a maximum storage period of one year, the battery has to be recharged.

6 DAMP key

7 LEVER

8 FILAMENT GUIDE

9 USB output (for connecting

the AC adapter

2. Slide the FILAMENT GUIDE down the

ROLLER SHAFTS in the direction of the

arrow.

–18 –

Charging the Battery

NOTE: The battery must be charged at a temperature between +5 °C and

+45 °C. Before connecting the AC adapter, verify that the supply voltage is

correct (100 V – 240 V). Electromatic provides no warranty or liability for

damage resulting from the use of AC adapters from other manufacturers.

To charge the battery, connect the cable of the AC adapter to the USB output. When

the battery is fully charged, the battery level indicator will show 3 bars

The charging time is approx. 3 ½ hours. Battery overcharging is not possible.

– 3 –

.

Page 4

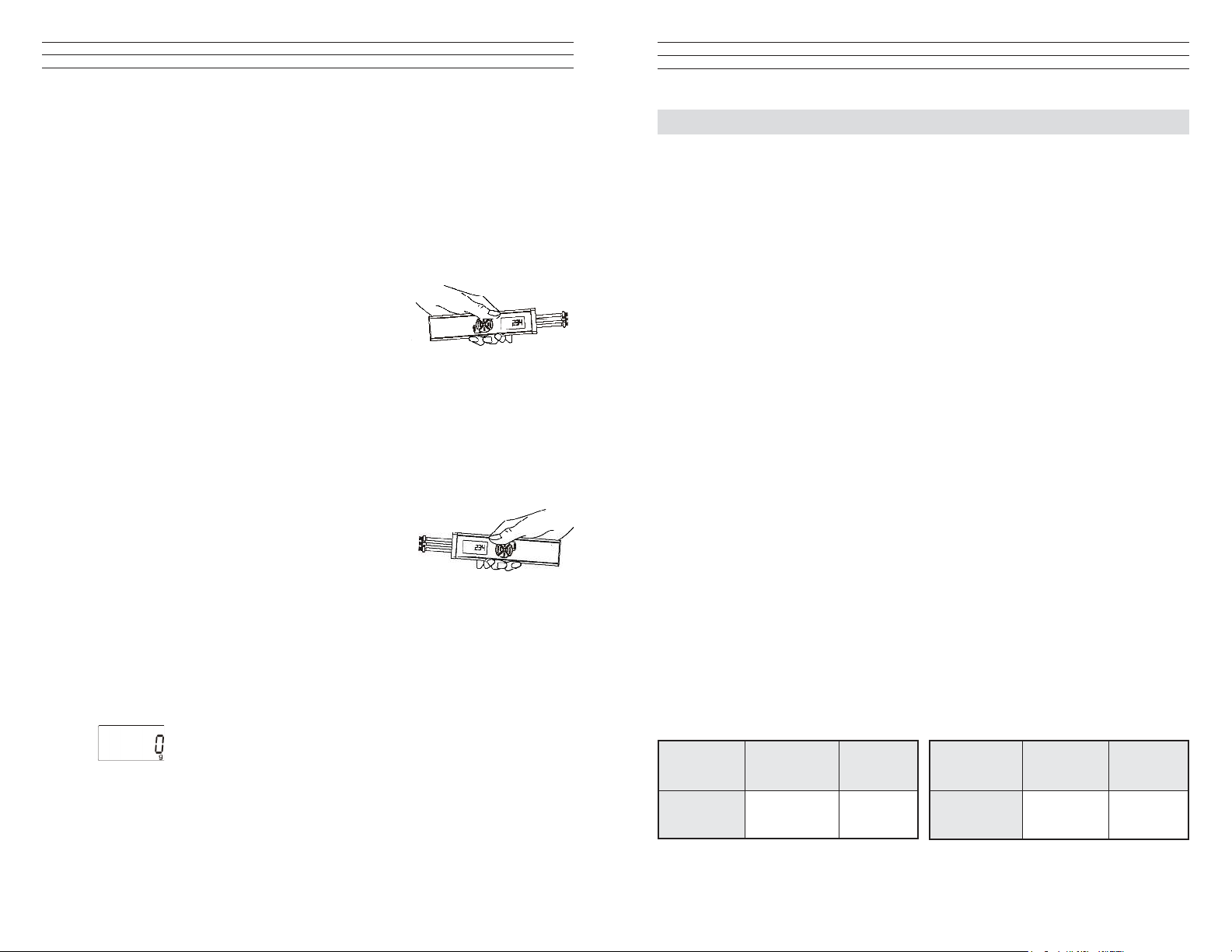

2.3 Turning the Power On and Off

Power On: Press the POWER key until the DISPLAY momentarily shows the tension

range and the software version, e.g. E 1.0, followed by random values or “0.”

Auto Power Off: The tension meter switches off automatically after

3 minutes of non-use.

Manual Switch-Off: Press the POWER key for 5 seconds.

2.4 Reversing the Display

When you shift the tension meter from the right to the left

hand, you can rotate the readings on the DISPLAY by

180°.

Measuring with the left hand:

If you would like to use the left hand for measuring, you should reverse the readings on

the DISPLAY to make them easier to read.

1. Tension meter switched off as described in Chapter 3.3.3.

2. Press and hold the DAMP and POWER keys until the DISPLAY shows the

readings the other way around.

Measuring with the right hand:

1. Tension meter switched off as described above

2. Press and hold the DAMP and POWER keys until

the DISPLAY shows the readings in the default

(right-handed) orientation.

2.5 Selecting the Unit of Measure

You can set the ETMB to the cN or g unit of measure, depending on the required tension

range. The default setting is cN.

1. Tension meter switched off as described aboveTo select the unit of measure:

2. Press and hold the RECALL and POWER keys until the new unit of measure

is indicated on the DISPLAY.

9.0 SPECIFICATIONS

Calibration According to factory procedure

Units of Measure cN / g, user selectable

Accuracy ± 1% FS* ± 1 digit (typical ± 0.5% FS*)

Overrange 10% FS*, without accuracy guarantee

Overload Protection 200% FS*

Measuring Principle Strain gauge bridge

Meas. Roller Deflection 0.5 mm, max.

Signal Processing Digital, 24 bit A/D converter

Damping Adjustable electronical (averaging)

Meas. Frequency Approx. 1 kHz internal

Display Update Rate 2x per sec.

Display 4-digit LCD, 11 mm high

Memory Average, last value, maximum, minimum, MAX

MIN

PEAK

Temperature Coefficient Gain: less than ± 0.01% FS*/°C

Converter Frequency 30 Hz

Temperature Range 10 - 45° C

Air Humidity 85% RH, max.

Auto Power Off Automatical after approx. 3 min. of non-use

Power Supply LiPo accumulator (60 h continouse use, 3 ½ h charging

time) and AC adapter 100 ... 240 V AC with country specic adapters (EU/USA/UK)

Housing Material Aluminium prole with plastic outer casing (PVC)

Housing Dimensions 197 mm x 58 mm x 47 mm (L x W x H)

Weight (net /gross) Approx. 340 g / 1250 g

*FS = Full Scale

ETMB Guide Rollers: ETMPB Guide Pins:

V - grooved

Standard 2000

Line Speed

m/min max.

Roller

Material

Aluminium

hard

chromed

V - grooved

Standard 6000

Line Speed

m/min max.

,

PEAK

Pin

Material

Oxide

ceramic

– 4 –

– 17 –

Page 5

8.3 Restoring Factory Calibration

You can restore the factory calibration at any time with the following procedure:

1. Switch off the tension meter.

2. Press and hold the MEM and POWER keys until the Display shows E-0 cN .

3. Release rst the POWER key and then the MEM key.

4. Press and hold the DAMP and RECALL keys, then additionally

press and hold MEM until the Display shows - - - -cN .

The factory calibration is restored.

5. Release the DAMP, RECALL and MEM keys.

6. Press the POWER key. The instrument switches off.

E-0

D cN

----

D cN

2.6 Zero Adjustment of the Measuring Position (Auto Zero)

A Zero Adjustment is automatically carried out for the current measuring postion.

A Zero Adjustment must be carried out whenever the tension meter

does not display “0” in measuring position. The process material must

not yet be inserted!

Procedure:

1. Switch on the tension meter as described in Sec 2.3.

2. Select the unit of measure as described in Sec 2.5.

Do not insert the process material.

3. Hold the tension meter in the desired measuring position. Be careful to hold the

instrument absolutely steady.

4. Press the POWER key.

The DISPLAY momentarily shows and then switches to .

The tension meter is now adjusted for the new material path and is ready to measure.

– 16 –

– 5 –

Page 6

3.0 REMOVING AND REMOUNTING THE FILAMENT GUIDE

The tension meter is supplied with a FILAMENT GUIDE for fast and easy material

acquisition. For application in hard-to-reach areas with limited access space, you can

remove the FILAMENT GUIDE.

GUIDE ROLLERS (2x)

FILAMENT GUIDE

MEASURING

GRUB SCREWS (3x)

ROLLER SHAFTS (2x)

Removal Procedure

1 Loosen the SETSCREWS (2x) with the supplied screwdriver (1.5 mm blade).

2. Unscrew and remove the GUIDE ROLLERS (2x) with the supplied open end

wrench (jaw width 4 mm).

3. Slip the FILAMENT GUIDE off the ROLLER SHAFTS.

4. Screw the GUIDE ROLLERS (2x) back onto the ROLLER SHAFTS and carefully

tighten using the supplied open end wrench (jaw width 4 mm) until hand-tight.

Remounting Procedure

1. Unscrew and remove the GUIDE

ROLLERS (2x) with the supplied

open end wrench jaw width 4 mm).

2. Slip the lament guide on to the

ROLLER SHAFTS.

3. Screw the GUIDE ROLLERS (2x)

back on to the ROLLER SHAFTS

and carefully tighten them using the supplied open end wrench (jaw width 4 mm)

until hand-tight.

4. Push the FILAMENT GUIDE forward far nough to ensure that the rollers do not rub

against the FILAMENT GUIDE and that the process material can slide unhindered

from the FILAMENT GUIDE into the roller grooves (g. CENTER LINE).

5. Carefully tighten the SETSCREWS (2x) with the supplied screwdriver

(blade width 1.5 mm) until hand-tight.

SETSCREWS (2x)

CENTER LINE

ROLLER

o3rd calibration point:o

1. Repeat steps 1 through 4 from the preceding procedure using a weight which

corresponds to 70% of the tension range

2. Press the RECALL key. As long as the RECALL key is

depressed, the DISPLAY shows a decimal value which is

higher than the second decimal value, e.g., 8000. This decimal

value may vary from instrument to instrument. Write down the

value.

3. Release the RECALL key when the value shown on the

DISPLAY is stable (the reading might uctuate greatly).

The DISPLAY shows E 100

o4th calibration point:o

1. Repeat steps 1 through 4 from the preceding procedure using a weight which

corresponds to 100% of the tension range

2. Press the RECALL key. As long as the RECALL key is

depressed, the DISPLAY shows a decimal value which is

higher than the third decimal value, e.g., 9500. This decimal

value may vary from instrument to instrument. Write down the

value

3. Release the RECALL key when the value shown on the DISPLAY is stable (the

reading might uctuate greatly).

4. Press and then release the RECALL key. the DISPLAY switches off after

approximately 1 second. The new calibration is stored.

5. Press the POWER key. the instrument switches off.

6. Verify the new calibration, following the directions in Sec. 7.0 If this procedure

shows a deviation, you can recalibrate the tension meter again or restore the factory

calibration as described in Sec. 8.3.

If the verication of the calibration according Sec.7.0 shows a deviation beyond

the allowable tolerance and a reliable operation is no longer allowed, the

instrument has to be returned to Electromatic for factory recalibration.

8000

E 100

9500

– 6 –

– 15 –

Page 7

2. Release the RECALL key when the value shown on the Display is fairly stable

(the reading might uctuate greatly).

3. The Display shows E –10

o1st calibration point:o

1. Hang a weight which

corresponds to 10% of

the tension range from the

measured material, vertically,

as shown.

2. Press the LEVER down

all the way. Thread the

PROCESS MATERIAL

through the MEASURING

and GUIDE ROLLERS.

Slowly release pressure on

the LEVER until the GUIDE ROLLERS return to their original position.

3. Before starting the calibration, move the instrument slowly up and down to

compensate for possible mechanical friction losses and thus ensure repeatability of

the measurements.

4. Press the RECALL key. As long as the RECALL key is

depressed, the DISPLAY shows a decimal value which is

higher than the rst decimal value, e.g., 3500. This decimal

value may vary from instrument to instrument.

Write down the value

5. Release the RECALL key when the value shown on the

DISPLAY is stable (the reading might uctuate greatly).

The DISPLAY shows

o2nd calibration point:o

1. Repeat steps 1 through 4 above using a weight which corresponds to 40% of the

tension range

2. Press the RECALL key. As long as the RECALL key is

depressed, the DISPLAY shows a decimal value which is

higher than the second decimal value, e.g., 6000. This decimal

value may vary from instrument to instrument. Write down the

value

3. Release the RECALL key when the value shown on the

DISPLAY is stable (the reading might uctuate greatly).

The DISPLAY shows E –70

MEASURING

ROLLERS

E –10

PROCESS

MATERIAL

WEIGHT

3500

E –40

6000

E –70

4.0 TAKING A MEASUREMENT

NOTE: Before taking a measurement, be sure that the correct unit of

measurement (g or cN) has been selected and a zero adjustment

has been performed.

4.1 Inserting the process material

1. Press the LEVER to tilt the outer GUIDE ROLLERS sidewards.

2. Thread the PROCESS

MATERIAL through the

MEASURING and

GUIDE ROLLERS

(lament guide).

3. Slowly release pressure on

the LEVER until the GUIDE

ROLLERS returnto their

original position.

NOTE: It is important to

assure that the PROCESS

MATERIALruns smoothly

between the MEASURING

and GUIDE ROLLERS.

4.2 Measuring the process

material

The DISPLAY now shows the

measured tension values. Error

messages which might be displayed

are described in Sec. 6.5.

4.3 Removing the process material

1. Press the LEVER and remove the PROCESS MATERIAL.

2. Slowly release pressure on the LEVER until the GUIDE ROLLERS

return to their original position.

– 14 –

– 7 –

Page 8

5.0 DAMPING MODE

8.0 CALIBRATION

The tension meter is equipped with an electronic damping that ensures steady readings

when tension ucutates. This is achieved by averaging the measured values at the preset

update rate.

5.1 Switching On the Damping Mode

NOTE: Before switching on the damping mode, it is recommended that you measure

the rst values without damping enabled.

1. Insert process material as described in section 4.1.

2. Press and hold the DAMP key. The display shows the currently set damping factor.

3. Release the DAMP key. The display shows DAMP below the

currently measured value.

5.2 Switching Off the Damping Mode

1. Press and release the DAMP key. If display shows only the

currently measured value, damping is off.

5.3 Changing the Damping Factor

The tension meter is factory preset to a damping factor of 12. The tension values are

thereby averaged for the display in the following way:

12 old values + 4 new values

16

The damping factor can be modied in 15 steps from 01 = low damping:

1 old value + 15 new values

16

to 15 = high damping:

15 old values + 1 new value

16

1. Switch on the tension meter

2. Press and hold the DAMP key. The Display shows the set damping factor.

3. You can now increase the damping factor by pressing the MEM key and

decrease it by pressing the RECALL key.

4. Release the DAMP key to return to the measuring mode.

NOTE: The selected damping factor remains stored in memory even

after the gauge is turned off.

22.1

D cN

22.1

D cN

8.1 Dynamic Calibration of the ETX

All tension meters are calibrated with standard materials—such as polyamide

monolament (PA)—ccording to the factory procedure. The diameters are given in

section 1.0. In 95% of all industrial applications, the factory calibration has been proven

to provide the best results and is used for comparative purposes. The basic setup for a

dynamic calibration is shown below.

Line speed Vmax. = ETMB 100 m/min

Vmax. = ETMPB 60 m/min

Hang twice the weight (pulley effect) which corresponds to

the tension to be measured from the measured material,

vertically, as shown here. Please keep in mind to include

the weight of the lower deection pulley when you calculate the suspended weight. Pay attention to the correct

unit of measure cN.

NOTE: The gauge has been calibrated dynamically according to factory procedure.

Therefore, differences may occur between static and dynamic readings.

8.2 Static Calibration

NOTE: The tension meter is factory calibrated for a vertical material path

Recalibration thus also has to be carried out with a vertical material path.

Before beginning:

Acquire one cN weight each (or several weights adding up to the required value),

corresponding to 10%,40%, 70% and 100% of the tension range. Make sure the tension

meter is switched off and that no process material is inserted between the rollers.

To select the calibration mode:

1. Press and hold the MEM and POWER keys until the Display

shows E –0

2. Release rst the POWER key and then the MEM key.

To calibrate the zero point:

1. Press the RECALL key. As long as the RECALL key is

depressed, the Display shows a random decimal value between

–2000 and 2000, e.g. 800 cN. This decimal value may vary from

instrument to instrument.Write down the decimal value.

NOTE: If the value is outside this range, calibration cannot be guaranteed.

E –0

800

– 8 –

– 13 –

Page 9

7.0 STATIC VERIFICATION OF MEASURING ACCURACY

6.0 STORING AND RECALLING TENSION VALUES

All tension meters are calibrated with standard materials—such as polyamide

monolament (PA)—according to the factory procedure. The diameters are given in

section 1.0. Any difference in process material size and rigidity from the standard

material may cause a deviation of the accuracy.

In 95% of all industrial applications, the factory calibration has been proven to provide

the best results and is used for comparative purposes.

NOTE: Before beginning, make sure that the tension meter is factory calibrated

for a vertical material path. The required reference weight is available.

Verication procedure:

1. Switch on the tension

meter.

2. Hang a weight

which corresponds

to the tension to be

measured from the

measured material,

vertically, as shown.

NOTE: Pay attention to the correct unit of measure cN or g (gram).

3. Press the LEVER down all the way down and thread the process material through

the MEASURING and GUIDE ROLLERS as described in section 4.1, then

slowly release pressure on the LEVER until the GUIDE ROLLERS return to

their original position.

4. Before verifying the calibration, move the instrument slowly up and down to

compensate for possible mechanical friction losses and thus ensure repeatability of

the measurements.

5. The tension value shown on the Display should be equal to the value of the

suspended weight (pay attention to the measuring units).

If this procedure shows a deviation, you can recalibrate the instrument following the

directions in Sec 8.0

MEASURING- and

GUIDE ROLLERS

Process

material

The tension meter features a data logger which stores the followng data obtained during

a measuring period:

Average value

Last value

Maximum value (MAX),

Minimum value (MIN),

Minimum peak value (MIN PEAK)

Maximum peak value (MAX PEAK)

NOTE: The measured data remain stored in the ETMB memory even after the

instrument is switched off.

6.1 Storing Tension Values

NOTE: The stored tension values remain stored in the ETMB memory even after the

instrument is switched off.

1. Turn off the tension meter.

2. Insert the process material.

3. Press the MEM key to start the measuring period.

While the tension data are stored, the MEM indicator blinks on the

DISPLAY and the currently measured value is displayed.

When you want to end the measuring period, press the MEM key once again. Data

logging is stopped. The DISPLAY shows MEM and the current reading.

6.2 Recalling Stored Tension Values

1. Be sure that the tension meter is ON.

NOTE: You can end recall at anytime by pressing the POWER key.

2. Press the RECALL key. The display blinks, showing

the average value of the measuring period and the

indicated symbol.

3. Press the RECALL key. The display blinks, showing the

last value of the measuring period (no symbol).

4. Press the RECALL key. The display blinks, showing

the maximum value of the measuring period and the

indicated symbol.

5. Press the RECALL key. The display blinks, showing

the minimum value of the measuring period and the

indicated symbol.

D cN

MEM

D cN

D cN

D cN

D cN

3

22

23

24

21

– 12 –

– 9 –

Page 10

6. Press the RECALL key. The display blinks, showing the

maximum peak value of the measuring period and the

indicated symbol.

7. Press the RECALL key. The display blinks, showing the

maximum peak value of the measuring period and the

indicated symbol.

8. Press the RECALL key. The tension meter switches back to

the measuring mode. The display shows MEM and the current

reading.

The tension meter is ready for a new measuring period.

6.3 Clearing Tension Values Stored In Memory

If values are stored in the tension meter memory, the DISPLAY

hows with the MEM indicator.

1. To clear the memory, simultaneously press the MEM and

RECALL keys.

and all values stored inmemory are deleted.

6.4 Memory Function HOLD

When the tension meter memory is empty, you can retain the last reading on the Display

by using the memory function HOLD.

To retain the last reading:

Press the RECALL / HOLD key once for about 1 second. The

Display shows the last readingand the “:” colon symbol.

To switch back to measuring mode:

Press the RECALL / HOLD key once for about 1 second.The tension meter switches

back to measuring mode.

The MEM indicator disappears

26

D cN

19

D cN

3

D cN

MEM

3

D cN

MEM

3

D cN

MEM

2:2.8

D cN

MEM

2. The Display shows -E.E. The lower limit of the tension range

has fallen below by more than 10%.

Properly insert the process material.

OR

AUTO ZERO is no longer possible.

Recalibrate the instrument following the directions inSec. 8.0.

–EE

D cN

6.5 Error Messages

1. The Display shows EEE. The upper limit of the tension range was

exceeded by more than 10%. Reduce the line tension.

OR

AUTO ZERO is no longer possible.

Recalibrate the instrument following the directions in Sec. 8.0.

– 10 –

EEE

D cN

– 11 –

Page 11

ETMB1110

CHECK•LINE

BY ELECTROMATIC

Tension Meters

ETMB-ETMPB

®

CHECK•LINE

INSTRUMENTS

®

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516 – USA

TEL: 516-295-4300 • FAX: 516-295-4399

Operating Manual

Loading...

Loading...