Page 1

Force Test Stand Model ESM301 / ESM301L

Version 2

User’ s Guide

Page 2

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

Thank you…

Thank you for purchasing a Mark-10 ESM301 / ESM301L Version 2 Force

Test Stand, designed for producing up to 300 lbF (1.5 kN) of tension or

compression force. The ESM301 is an essential component of a force testing

system, typically also comprising a force gauge and grips.

With proper usage, we are confident that you will get many years of great

service with this product. Mark-10 test stands are ruggedly built for many

years of service in laboratory and industrial environments.

This User’s Guide provides setup, safety, and operation instructions.

Dimensions and specifications are also provided. For additional information or

answers to your questions, please do not hesitate to contact us. Our technical

support and engineering teams are eager to assist you.

Before use, each person who is to use the test stand should be fully

trained in appropriate operation and safety procedures.

TABLE OF CONTENTS

OVERVIEW .......................................................................................... 3

MECHANICAL SETUP AND SAFETY ................................................ 4

OPERATION BASICS ......................................................................... 6

TEST PARAMETER SETUP ...................................... …………………7

OPERATING MODES ........................................................................ 16

TM

COMMUNICATION WITH MESUR

FEATURE ACTIVATION ................................................................... 23

TROUBLESHOOTING ....................................................................... 24

MAINTENANCE AND SERVICE ....................................................... 25

SPECIFICATIONS ............................................................................. 26

DIMENSIONS .................................................................................... 26

GAUGE SOFTWARE ............. 23

2

Page 3

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

1 OVERVIEW

1.1 List of included items

Qty. Description

1 ESM301 or ESM301L test stand

4 Force gauge mounting thumbscrews

2 Limit switch thumbscrews (same as above, supplied in a separate package)

1 Power cord

1 Cable, controller to test frame 12” (longer cables are optional)

1 Cable, USB to RJ11 (for optional integrated travel indication)

1 ESM301-002-X column extension (optional)

1 ESM301-003 bench mounting kit (optional)

1 09-1162 multi-function cable (optional)

1 09-1056 serial cable (optional)

1 Accessories kit (small hook, medium hook, 2” diameter compression plate, 2” extension

rod, #10-32 coupler, tool kit)

1.2 Overview

Note: Unless otherwise indicated, all references to the model ESM301 also apply to the ESM301L.

The ESM301 has three functional modes:

1. OPERATING MODE

This is the operating mode in which testing sequences can be started and stopped.

2. TEST PARAMETER SETUP

In this mode, test parameters are configured, such as rate of speed, number of cycles, password

editing, and other parameters.

3. FEATURE ACTIVATION SETUP

This facility allows the user to enable features not originally purchased through a code activation

process.

DEMO MODE

The ESM301 is shipped in Demo Mode, during which time all available features are

temporarily activated for 160 hours of operation. At power-up, a counter displays the

number of hours remaining, as follows:

R E MA I N I N G D EMO

T I ME : 1 6 0 HOUR S

Press the STOP button to continue.

At the end of this period, any features not originally purchased will be deactivated.

Demo Mode can be suspended at any time by pressing and holding STOP while

turning on power to the test stand. This mode can be re-enabled in the same

manner, and will be active for the remaining time period.

Refer to the Feature Activation Setup section for instructions for field activation.

3

Page 4

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

2 MECHANICAL SETUP AND SAFETY

2.1 Safety / Proper Usage

Typical materials able to be tested by the ESM301 include many manufactured items, such as springs,

electronic components, fasteners, caps, films, mechanical assemblies, and many others. Items that

should not be used with the ESM301 include potentially flammable substances or products, items that

can shatter in an unsafe manner, and any other components that can present an exceedingly hazardous

situation when acted upon by a force.

1. Using Grips & Fixtures with the ESM301

Ensure that the grip or fixture is positioned to ensure axial load with respect to the loading shaft of

the force gauge.

prevented from slipping out during a test, preventing a potential safety risk to the operator and

others in the vicinity. If using a grip or fixture from a supplier other than Mark-10, ensure that it is

constructed of suitably rugged materials and components.

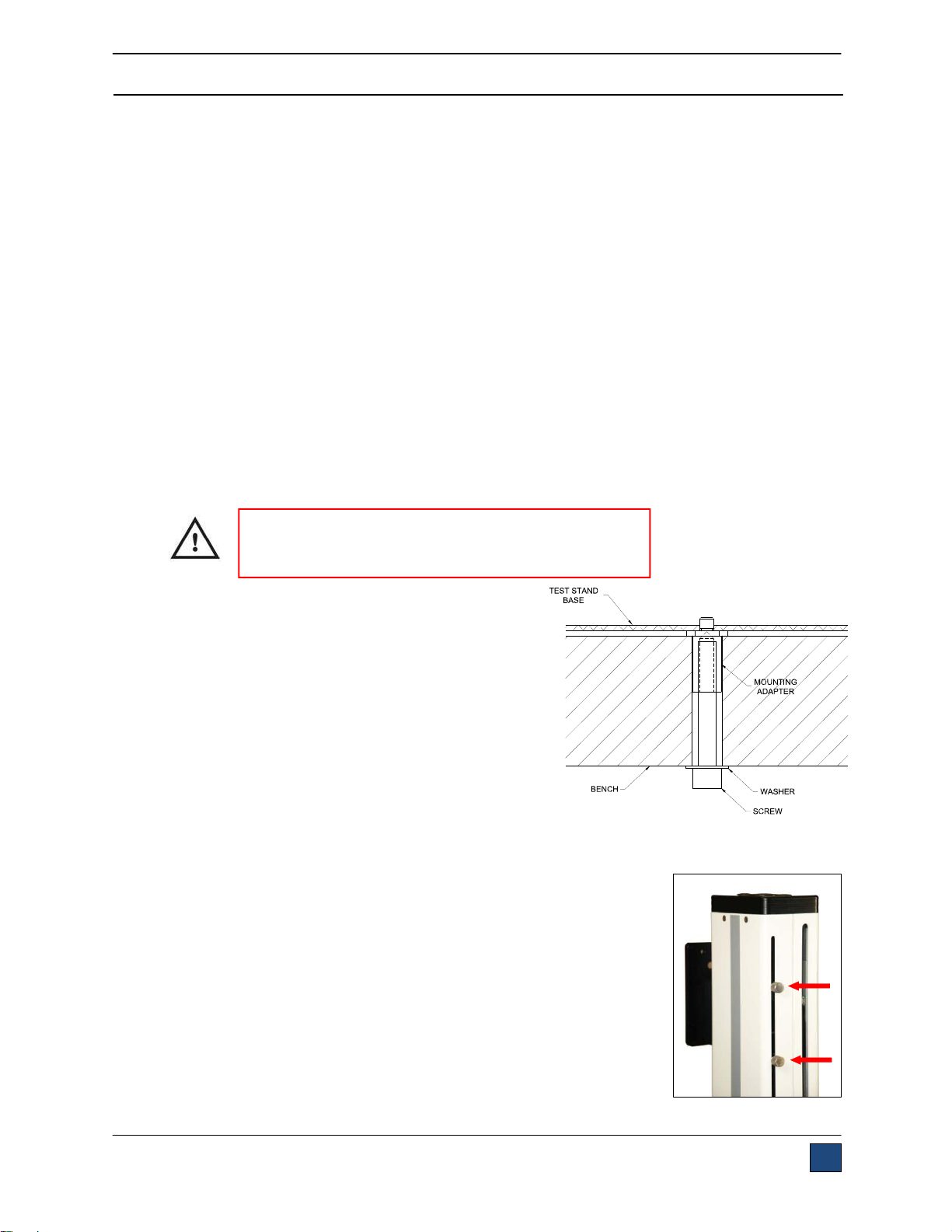

2. Mounting

Place the stand on a clean, flat and level work area free from vibration. If desired, the stand can

be secured to the work area with 1/4-20 screws fastened into the underside of the base. Failure

to properly mount the test stand may make it more vulnerable to tipping, causing a hazardous

situation.

The test stand can also be mounted using the

ESM301-003 mounting kit. Screws of various

lengths are supplied with this kit to accommodate a

range of bench thicknesses. Refer to the following

illustration at right proper assembly:

When using a grip, ensure that it secures the sample in such a way that it is

IMPORTANT: Do not fasten any screws more than

0.25 in [6 mm] into the base of the test stand, or

damage to internal components can occur.

In general, the ESM301 can be mounted at any angle, although extra care should be taken during

installation and operation.

Once the test stand is in a stable and secure position, install a force

gauge with four thumb screws (provided). Mark-10 gauges mount

directly without adapters. Grips can be mounted onto the force gauge

and test stand base.

3. Installing the limit switches

Upper and lower limit switches are provided to stop crosshead travel at

user-designated positions. Each limit switch consists of an internal

block riding along a rail, and an external thumbscrew. The

thumbscrews are shipped in a separate bag to avoid damage in transit.

Refer to the illustration at right for proper installation:

4

Page 5

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

2.2 Setting up the Controller

The power plug and controller cable must be connected to the rear of the controller, as shown in the

illustration below:

2

4 3 5

6

1. Fuse

2. Controller Cable Connector

Plug one end of the cable into this connector, and the other end into the connector as shown in

the illustration on the right.

3. PC Output Connector

Outputs force only or force and travel data via RS-232. Also allows for PC control, if appropriate

features are enabled. Plug one end of the 09-1056 serial cable into this connector, and the other

end into a serial connector on a computer.

4. Power Plug Receptacle

Plug the power cord in here.

5. Travel Indication Connector

Plug one end of the USB/RJ11 cable into this connector, and the other end into the mini USB

connector in the rear of the crosshead.

6. Force Gauge Cable Connector

Interfaces with a Series 5 or 4 force gauge. Plug one end of the 09-1162 cable into this

connector, and the other end into the gauge.

2.3 Connecting Power

Plug one end of the power cord into its receptacle at the rear of the controller and the other end into a

wall outlet with local earth ground (3-prong connector).

Before turning on power, the following safety checks and procedures should be performed:

1. Never operate the test stand if there is any visible damage to the power cord or the test stand

itself. The ESM301 is powered by 110V/220V. Any contact with this high voltage can cause

serious injury or even death.

2. Ensure that the test stand is kept away from water or any other electrically conductive liquids

5

Page 6

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

at all times.

3. Make sure the electrical outlet powering the test stand has local earth ground (3-prong

connector).

4. The test stand should be serviced by a trained technician only. Power must be disconnected

before the controller is opened.

After the above safety checks and procedures have been performed, the test stand may be powered on

and is ready for operation.

3 OPERATION BASICS

3.1 Operational Safety

The following safety checks and procedures should be performed before and during operation:

1. Always consider the characteristics of the sample being tested before initiating a test. A risk

assessment should be carried out beforehand to ensure that all safety measures have been

addressed and implemented.

2. Wear eye and face protection when testing, especially when testing brittle samples that have the

potential to shatter under force. Although the ESM301 has relatively slow moving mechanisms, be

aware of the dangers posed by potential energy that can accumulate in the sample during testing.

Extra bodily protection should be worn if a destructive failure of a test sample is possible.

3. Keep away from moving parts of the test stand. Loose articles of clothing should not be worn, and

long hair should be covered to avoid being caught in any moving parts. A Crush Hazard warning

label is located on the base of the test stand. It appears as follows:

Definition: Keep any body parts and clothing clear of the area between the base of the test stand and the

moving crosshead.

4. In certain applications, such as the testing of brittle samples that can shatter, or other applications

that could lead to a hazardous situation, it is strongly recommended that a machine guarding

system be employed to protect the operator and others in the vicinity from shards or debris.

5. When the test stand is not in use, ensure that the power is turned off to prevent accidental

engagement of any of the controls.

6

Page 7

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

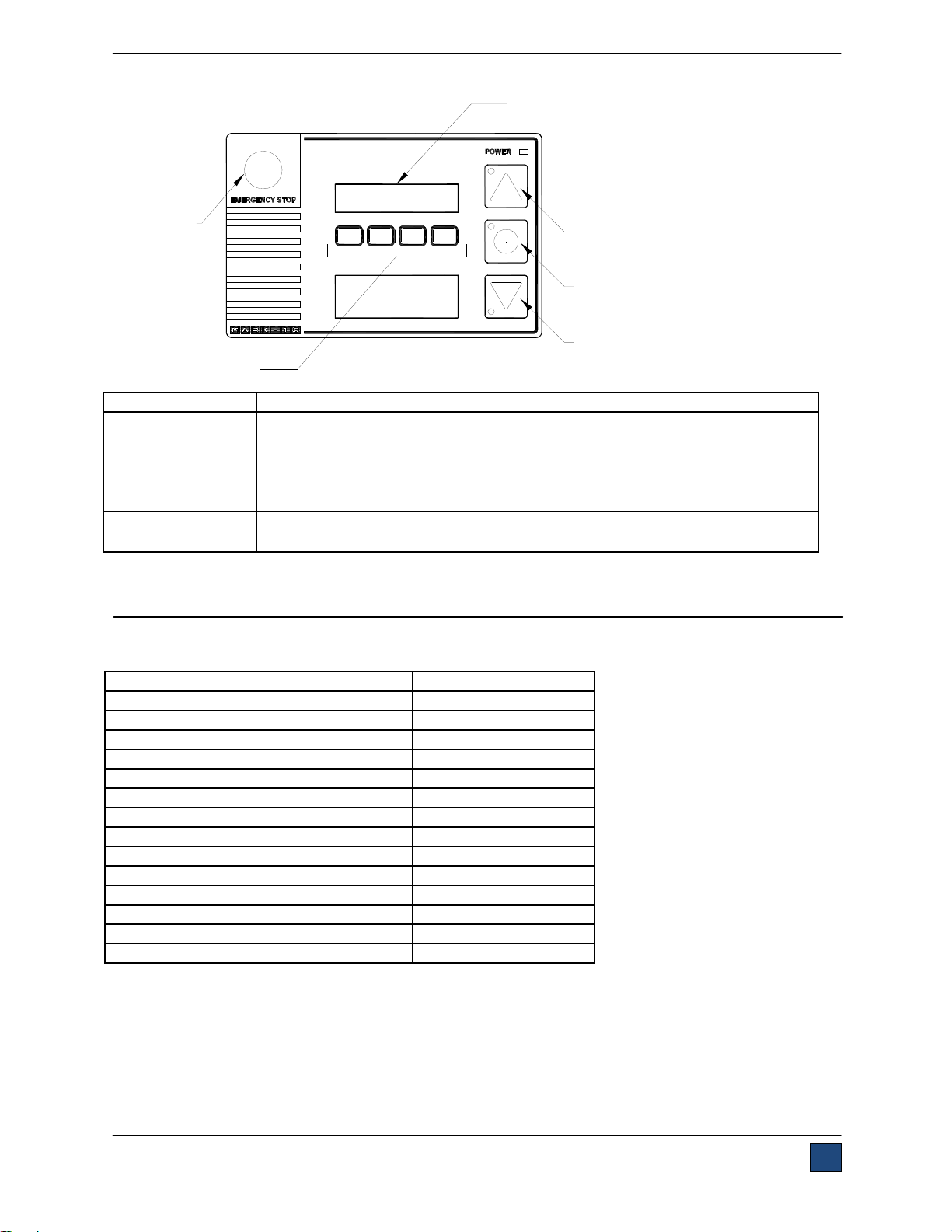

STOP

DISPLAY

UP

STOP /

ZERO TRAVEL DISPLAY

DOWN

SOFT KEYS

3.2 Controls

EMERGENCY

Key Primary Function

SOFT KEYS

UP

DOWN

STOP / ZERO

TRAVEL DISPLAY

EMERGENCY

STOP

Functions are determined by the corresponding text on the display.

Commences movement in the up direction.

Commences movement in the down direction.

Stops crosshead movement / zeroes travel display (if travel indication is

enabled).

Stops crosshead movement and disables the test stand until reset.

4 TEST PARAMETER SETUP

This section provides configuration instructions for each test parameter. Parameters include:

Parameter Standard / Optional

Speed (same for both directions) Standard

Independent up and down speeds Optional

Auto return Optional

Cycling with dwell time Optional

Programmable travel limits Optional

Overload protection Optional

Preload Optional

Load Holding Optional

Break Detection Optional

PC control Optional

Communication parameters Standard

Units of speed Standard

Programmable button configuration Standard

Password protection Standard

All ESM301 test stands are shipped in Demo Mode, as explained in Section 1.2. After Demo Mode

expires, only installed features will be displayed in Test Parameter Setup. The initial Test Parameter

Setup screen appears as follows:

7

Page 8

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

S P E E D : 1 0 . 0 0

E S C < − − > E N T R

Label Description

ESC

< –

– >

ENTR

When the parameters have been configured as desired and are ready to be saved, press ESC to exit

Test Parameter Setup. The screen will show SAVE CHANGES? Pressing YES will save the changes and

the display will revert to current status. Pressing NO will not save the changes and return to the Test

Parameter Setup menu.

Note: Changes can be made to an unlimited number of settings before saving.

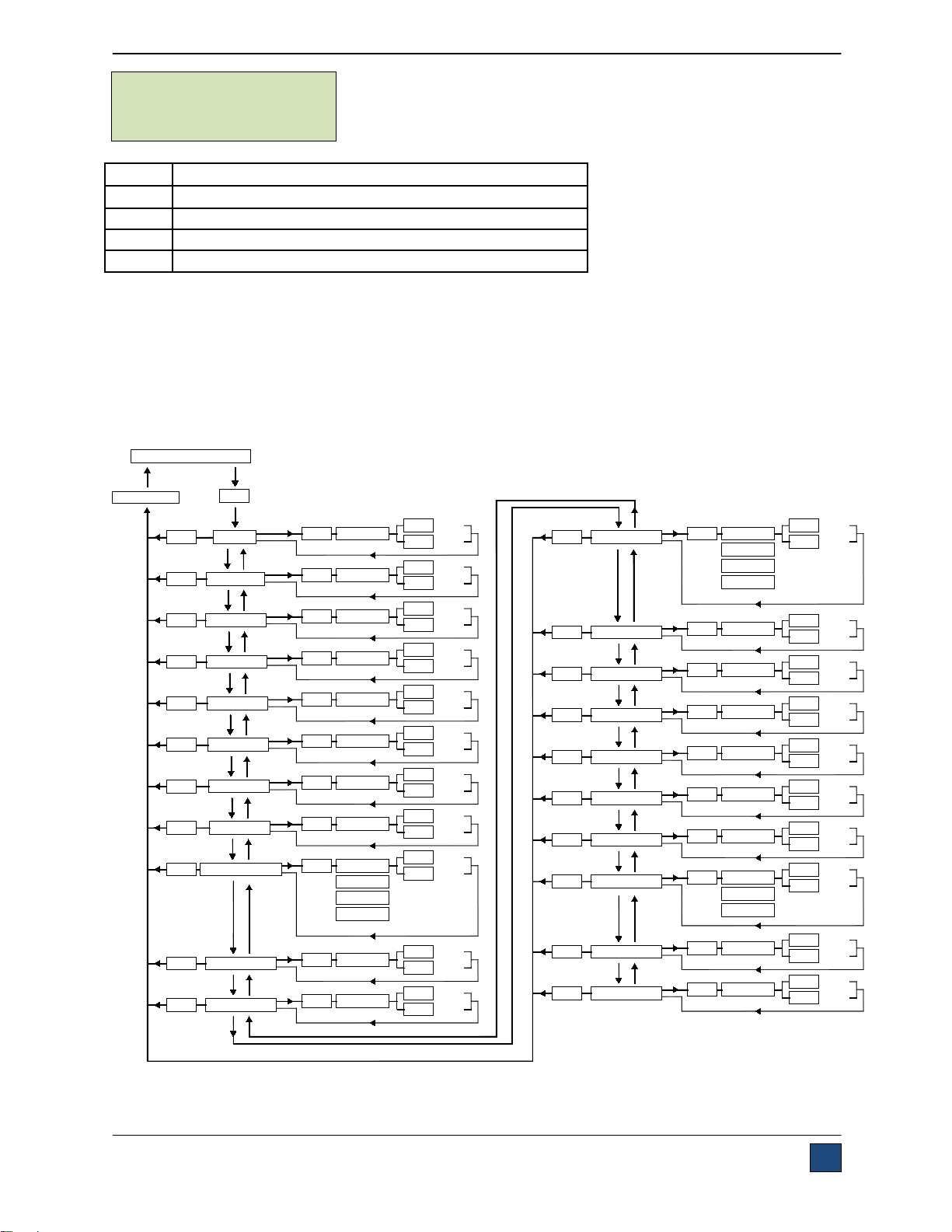

The following is a flow chart for the menu structure:

Exits Test Parameter Setup, reverts to Operating Mode

Scrolls to the previous parameter

Scrolls to the next parameter

Selects the parameter, allowing it to be modified

OPERATING MODE

SAVE CHANGES

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

MENU

UP SP.

DOWN SP.

AUTO RETURN

CYCLES

HI DWELL

LO DWELL

HI LIMIT

LO LIMIT

OVERLD

COMP OVERLD

TEN OVERLD

ENTR

ENTR

ENTR

ENTR

ENTR

ENTR

ENTR

ENTR

ENTR

ENTR

ENTR

+ (inc) - (dec)

+ (inc) - (dec)

+ (on) - (off)

+ (inc) - (dec)

+ (inc) - (dec)

+ (inc) - (dec)

+ (inc) - (dec)

+ (inc) - (dec)

OFF

MARK-10

OTHER 2V

OTHER 4V

+ (inc) - (dec)

+ (inc) - (dec)

ENTR

ESC

ENTR

ESC

ENTR

ESC

ENTR

ESC

ENTR

ESC

ENTR

ESC

ENTR

ESC

ENTR

ESC

ENTR

ESC

ENTR

ESC

ENTR

ESC

save

ignore

save

ignore

save

ignore

save

ignore

save

ignore

save

ignore

save

ignore

save

ignore

save

ignore

save

ignore

save

ignore

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

PRELOAD

LOAD HOLDING

BREAK DETECT

CONTROL

BAUD RATE

STOP & PAR

UNITS

KEYS

DEFAULT SETTINGS

NEW PASSWORD

ENTR

ENTR

ENTR

ENTR

ENTR

ENTR

ENTR

ENTR

ENTR

ENTR

OFF

STOP

STOP, ZERO

ZERO, GO

+ (on) - (off)

+ (on) - (off)

+ (PC) - (CONSOLE)

+ (inc) - (dec)

+ (inc) - (dec)

+ (in) - (mm)

MAINTAINED

MOMENTARY

AUTO

+ (inc) - (dec)

+ (inc) - (dec)

ENTR

ESC

ENTR

ESC

ENTR

ESC

ENTR

ESC

ENTR

ESC

ENTR

ESC

ENTR

ESC

ENTR

ESC

ENTR

ESC

ENTR

ESC

save

ignore

save

ignore

save

ignore

save

ignore

save

ignore

save

ignore

save

ignore

save

ignore

save

ignore

save

ignore

8

Page 9

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

4.1 Speed, Up Speed, Down Speed (SPEED, UP SPEED, DOWN SP)

If the independent up and down speed option has not been enabled, the up and down speeds will be the

same, and is programmed in the SPEED parameter. If independent up and down speeds are enabled, UP

SPEED and DN SPEED parameters will be present, and may be set individually.

Default setting: 10 in/min

Available settings: 0.02 – 45 in/min

U P S P E E D : 1 0 . 7 3

E S C − + E N T R

Label Description

+

–

ENTR

ESC

4.2 Auto Return (AUTO RETURN)

With this feature, the crosshead moves to a limit switch or soft limit (force set point, distance limit,

preload, or break detection), whichever occurs first, and stops. Then, the crosshead returns to the other

limit and stops. The test speed is dictated by the SPEED setting or the UP SPEED and DOWN SP

settings. The return speed is always maximum speed. The maximum speed depends on whether or not

the optional high speed range has been enabled.

Default setting: off

Available settings: off, on

Increments the speed setting by .01 in or .5 mm.

Holding down + will increment at an increasingly faster

rate.

Decrements the speed setting by .01 in or .5 mm.

Holding down – will decrement at an increasingly

faster rate.

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

A U T O R E T U R N o f f

E S C − + E N T R

Label Description

+ or –

ENTR

ESC

Note: If AUTO RETURN is turned on, CYCLING is automatically turned off and the KEYS parameter is

automatically set to MAINTAINED mode. See following pages for details on the CYCLING and KEYS

parameters.

Cycles through the available settings

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

9

Page 10

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

4.3 Cycling (CYCLES)

This setting allows the user to configure the number of up and down cycles through which the crosshead

will sequence. One cycle consists of the crosshead moving to a limit switch or soft limit, whichever occurs

first, at the specified speed, stopping for the specified amount of dwell time, and returning to the other

limit at the specified speed. If the independent up and down speed feature is not enabled, the speed will

be the same in both directions.

Default setting: 00000 (off)

Available settings: 00000 – 99999

C Y C L E S : 0 0 0 0 0

E S C − + E N T R

Label Description

+

–

Press and hold

+ and –

simultaneously

ENTR

ESC

4.4 Upper Limit Dwell Time and Lower Limit Dwell Time (HI DWELL and LO DWELL)

This setting corresponds to the amount of time, in seconds, for which the crosshead stops at the limit

during a cycle sequence.

Note: The dwell time setting is unavailable for an auto return sequence.

Default setting: 0 (no dwell time)

Available settings: 0 – 9999.9

H I D WE L L : 0 0 0 0 . 0

E S C − + E N T R

Label Description

+

–

ENTR

ESC

Increases dwell time in increments of .1. Holding down + will increment at an

increasingly faster rate. If 9999.9 is reached the next number will be 0 and

continue incrementing.

Decreases dwell time in increments of .1. Holding down – will decrement at

an increasingly faster rate. If 0 is reached the next number will be 9999.9

and continue decrementing.

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

Increases the number of cycles in increments of 1. Holding down +

will increment at an increasingly faster rate. If 99999 is reached

the next number will be 00000 and continue incrementing.

Decreases the number of cycles in increments of 1. Holding down

– will decrement at an increasingly faster rate. If 00000 is reached

the next number will be 99999 and continue decrementing.

If pressed and held for 2 seconds or longer the number of cycles

will change to 0.

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

10

Page 11

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

%

4.5 Upper and Lower Travel Limits (UPPER LM and LOWER LM)

This setting corresponds to the travel distance the crosshead moves before stopping or cycling. Upper

and lower limits are programmed individually. The programmed distances are relative to the zero position

of the crosshead. The travel indicator can be zeroed by pressing and holding STOP for 3 seconds.

Default settings: +12.000 in, -12.000 in

Available settings: From -19.000 to +19.000 in

H I L I M I T : 2 . 0 5 8

E S C − + E N T R

Label Description

+

–

ENTR

ESC

Increases the travel limit setting by .001 in or .02 mm.

Holding down + will increment at an increasingly faster rate.

Decreases the travel limit setting by .001 in or .02 mm.

Holding down – will increment at an increasingly faster rate.

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

4.6.1 Overload Protection (OVERLD)

The ESM301 protects a force gauge from overload by measuring incoming analog voltage and stopping

crosshead travel when the programmed percentage of full scale has been reached (see Section 4.7). The

default setting is for Mark-10 gauges (±1V), however, the setting may be changed to ±2V or ±4V to

accommodate other force gauges.

Default setting: OFF

Available settings: MARK-10, OTHER 2V, OTHER 4V, OFF

O V E R L D : MA R K - 1 0

E S C − + E N T R

4.6.2 Compression and Tension Overload Settings (COMP OVERLD and TEN OVERLD)

This setting corresponds to the percentage of force gauge full scale at which crosshead travel stops. For

example, a setting of 80% for a 50 lbF capacity force gauge would stop crosshead travel when

approximately 40 lbF is reached.

Note: When the crosshead is moving in the UP direction, only the tension overload setting applies. When

the crosshead is moving in the DOWN direction, only the compression overload setting applies.

Default setting: 100%

Available settings: 20% - 100% (10% increments)

C O MP O V E R L D : 1 0 0

E S C − + E N T R

Label Description

+ or –

ENTR

ESC

Cycles through the available settings

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

11

Page 12

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

4.7.1 Preload (PRELOAD)

This setting corresponds to the test stand’s response to an initial load, referred to as a preload. The

crosshead can stop and/or zero the travel display when the preload has been reached. This function is

useful for applications such as spring testing, elongation testing, and tensile and compression testing of

various materials. For details about setting the preload value, refer to Section 4.7.2.

Default setting: OFF

Available settings: STOP, STOP/ZERO, ZERO/GO, OFF

P R E L O A D : Z E R O , G O

E S C − + E N T R

Label Description

+ or –

STOP

STOP, ZERO

ZERO, GO

ENTR

ESC

4.7.2 Preload Value (PRELD %FS)

This setting corresponds to preload value, defined as a percentage of the force gauge’s full scale in lbF

units. The test stand’s response, as described in the previous section, occurs when this value has been

reached.

Note: In low force applications, consider test stand vibration and crosshead acceleration, as they can be

prominent enough to produce a force exceeding the preload value.

Default setting: 1%

Available settings: 0 – 100%

P R E L D %F S : 0 1 . 0

E S C − + E N T R

Cycles through the available settings listed below:

Crosshead stops when preload has been reached

Crosshead stops when preload has been reached, then zeroes the travel display

Travel display is zeroed when preload has been reached, crosshead does not stop

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

Label Description

+ or –

ENTR

ESC

4.8 Load Holding

This setting directs the test stand to dynamically adjust the crosshead position to maintain a programmed

force. The force is programmed as a set point in a Series 5 force gauge (refer to the user’s guide for

details). If the CYCLING option has been enabled, load holding will be active for the period of time as

defined in the Upper Dwell and Lower Dwell settings. If CYCLING has not been enabled, load holding will

continue indefinitely.

Default setting: OFF

Available settings: ON, OFF

Cycles through the available settings

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

12

Page 13

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

L O A D H O L D I N G : O N

E S C − + E N T R

Label Description

+ or –

ENTR

ESC

4.9.1 Break Detection

This setting directs the test stand to stop when a sample break has occurred. The test stand is triggered

when the force has decreased to a specified percentage of peak. For details about programming the

percentage of peak, refer to Section 4.9.2.

Default setting: OFF

Available settings: ON, OFF

B R E A K D E T E C T : O N

E S C − + E N T R

Cycles through the available settings

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

Label Description

+ or –

ENTR

ESC

4.9.2 Break Detection Percentage Drop

This setting corresponds to the force trigger for break detection, defined as a percentage of peak force.

For example: A sample is pulled until 50 lbF, then breaks. The break detection percentage drop setting is

50%. After the sample breaks, the force rapidly decreases to 25 lbF (50% of peak), then triggers the test

stand to stop.

Default setting: 80%

Available settings: 10% - 90% (10% increments)

B R E A K D E T E C T : O N

E S C − + E N T R

Cycles through the available settings

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

Label Description

+ or –

ENTR

ESC

4.10 Control Source (CONTROL)

This setting corresponds to the source of test stand control. The default value CONSOLE sets the test

stand to accept commands only from the console (front panel). Any external commands received through

the serial port are ignored, except for the following: Request Load, Request Travel, Zero Gauge, Zero

Travel, Clear Peaks (refer to Section 5.8 for details).

PC refers to external control via serial communication. If any parameters are changed on the front panel,

these settings will be ignored, except for Auto Return or Cycling. If either of these parameters are turned

on, PC control will be turned off.

Cycles through the available settings

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

13

Page 14

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

Default setting: CONSOLE

Available settings: CONSOLE, PC

C O N T R O L : C O N S O L E

E S C − + E N T R

Label Description

+ or –

ENTR

ESC

4.11 Baud Rate (BAUD RATE)

This setting corresponds to the baud rate setting of the computer program controlling the test stand.

Default setting: 115200

Available settings: 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200

B A U D R A T E : 1 1 5 2 0 0

E S C − + E N T R

4.12 Stop Bits and Parity (STOP & PAR)

This setting corresponds to the stop bits and parity settings of the computer program controlling the test

stand.

Default setting: 8-1n

Available settings:

8-1E 8 stop bits, 1 stop bit, even parity

8-1o 8 stop bits, 1 stop bit, odd parity

8-1n 8 data bits, 1 stop bit, no parity

8-2n 8 data bits, 2 stop bits, no parity

7-1E 7 data bits, 1 stop bit, even parity

7-1o 7 data bits, 1 stop bit, odd parity

7-2E 7 data bits, 2 stop bits, even parity

7-2o 7 data bits, 2 stop bits, odd parity

7-2n 7 data bits, 2 stop bits, no parity

S T O P & P A R : 8 - 1 n

E S C − + E N T R

Cycles through the available settings

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

Label Description

+ or –

ENTR

ESC

4.13 Units of Speed (UNITS)

This setting corresponds to units of speed measurement.

Default setting: in/min

Available settings: in/min, mm/min

Cycles through the available settings

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

14

Page 15

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

U N I T S : i n / mi n

E S C − + E N T R

Label Description

+ or –

ENTR

ESC

4.14 Programmable Button Function (KEYS)

Three button function modes are available:

Default setting: maintained

Available settings: maintained, momentary, auto

Cycles through the available settings

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

1. Maintained

The crosshead will move continuously once the button has been pressed and held.

Subsequently pressing the UP, DOWN, or STOP during a test will stop crosshead motion.

2. Momentary

The crosshead will move only if the button is held down. Releasing the button will stop

movement immediately.

3. Auto

Holding down the button for more than 0.5 seconds will enter momentary mode, at which time

an audible indicator will sound and the LED indicator on the button pushed will be illuminated.

A short tap on the button will operate the test stand in maintained mode. Pressing UP,

DOWN, or STOP during maintained mode will stop crosshead motion.

K E Y S : M A I N T A I N E D

E S C − + E N T R

Label Description

+ or –

ENTR

ESC

4.15 Return to Default Settings (DEFAULT SETTINGS)

This setting provides a quick return to factory settings, as follows:

HI LIMIT: +12.000

LO LIMIT: -12.000

OVERLD: off

PRELOAD: off

LOAD HOLDING: off

BREAK DETECT: off

CONTROL: CONSOLE

BAUD RATE: 115200

Cycles through the available settings

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

SPEED: 10 in/min

UP SPEED: 10 in/min

DOWN SP: 10 in/min

AUTO RETURN: off

CYCLING: 00000 (off)

STOP & PAR: 8-1n

15

Page 16

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

UNITS: in/min

KEYS: maintained

PASSWORD: 0000 (off)

Default setting: off

Available settings: off, on

D E F A U L T ? : N O

E S C − + E N T R

Label Description

+ or –

ENTR

ESC

4.16 Password (NEW PWORD)

If desired, a password can be set to prevent unwanted changes to test parameters. The password can be

set to any number between 0000 and 9999. The default setting of 0000 indicates that the password is

disabled, and that the user can freely enter the Test Parameter Setup menu. If misplaced or forgotten, the

password may be reset through a code activation process. Details on this may be found in Section 9.

Default setting: 0000 (off)

Available settings: 0000 – 9999

N E W P WO R D 0 0 0 0

E S C − + E N T R

Cycles through the available settings

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

Label Description

+ or –

ENTR

ESC

Cycles through the available settings

Returns to the Test Parameter Setup menu

Exits the parameter without saving changes

5 OPERATING MODES

5.1 Mode Overview

The ESM301 can be operated in several modes, including combinations of these modes:

1. Basic Mode

Manual control of crosshead motion.

2. Auto Return Mode

Crosshead moves to a limit switch or force set point, travel distance, preload, or sample

break (referred to as soft limits), whichever occurs first. Then, it reverses and moves at

maximum speed to the other limit, whichever occurs first.

3. Cycling Mode

Crosshead cycles between limits at the selected speed(s), and pauses at each limit or set

point for a selected period of time.

4. Preload Mode

Crosshead moves until the preload has been reached, and performs the action programmed

in the setting. An auto-return, cycle/dwell time, or break detection sequence may follow.

16

Page 17

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

5. Load Holding Mode

Crosshead moves to a force set point, stops, then dynamically adjusts position to maintain

the programmed force. An auto-return or cycle/dwell time sequence may follow.

6. Break Detection

Crosshead stops when a sample break has been detected. An auto-return or cycle/dwell time

sequence may follow.

7. PC Mode

Test stand is controlled through a serial connection with a PC.

The Operating Mode home screen appears as follows:

S P E E D : 0 . 0 0

me n u m i n ma x S E T

If the travel indication option is enabled, the screen appears as follows:

TRAVEL

SPEED

1 . 2 7 5 0 . 0 0

me n u m i n ma x S E T

The item selected will be capitalized, as shown in the figure above. The set speed can be changed in

Test Parameter Setup. If enabled, the up and down speeds can be configured independently of each

other (UP SPEED and DN SPEED). Otherwise, the SPEED setting corresponds to crosshead speed in

both directions.

5.2 Menu Navigation

At power-up, the display will show the operation screen for whichever mode was used last. The display

will appear as one of the following:

1. Basic & Auto Return Modes (travel indication not enabled):

S P E E D : 0 . 0 0

me n u m i n ma x S E T

2. Basic & Auto Return Modes (travel indication enabled):

TRAVEL

1 . 2 7 5 0 . 0 0

me n u m i n ma x S E T

SPEED

17

Page 18

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

m

3. Cycling Mode (travel indication not enabled):

TRAVEL

C Y C L E S : 0 0 0 2 4

CYCLES REMAINING

5.3 Basic Mode

The crosshead moves upward when UP is pressed, and downward when DOWN is pressed. When the

crosshead is in motion, an LED indicator on the button pushed will be illuminated. The KEYS setting

controls how crosshead movement responds to the push of the UP and DOWN buttons. The three

settings are:

1. Maintained (default)

2. Momentary

3. Auto

Pressing EMERGENCY STOP will immediately stop crosshead motion in any mode. To release, twist the

e n u mi n ma x S E T

Note: The min and max keys will not appear when a password has been set.

4. PC Mode

Appears the same as in Basic and Auto Return modes.

Label Description

menu

min

max

set

Pressing menu will enter Test Parameter Setup. If a password has been programmed, the

display will prompt the following:

Enters Test Parameter Setup

Sets speed to minimum speed. Will not appear when a

password has been set.

Sets speed to maximum speed. Will not appear when a

password has been set.

Sets speed to the programmed SPEED, UP SPEED, or

DN SPEED setting

P A S S WO R D 0 0 0 0

E S C − + E N T R

The password is a four digit number. The first digit in the password will be flashing, signifying that

it is active and can be incremented by pressing +. To advance to the next digit, press –>. Change

subsequent digits in the same fashion. Once the complete password has been entered, press

ENTR. If correct, the display will enter Test Parameter Setup Mode. If the password is incorrect,

the words INCORRECT PASSWORD will flash, and the display will revert to Operating Mode.

The crosshead will move continuously once the button has been pressed. Subsequently

pressing STOP during a test will stop crosshead motion.

The crosshead will move only if the button is pressed and held. Releasing the button will

stop movement immediately.

Holding down the button for more than 0.5 seconds will enter Momentary mode, at which

time an audible indicator will sound and the LED indicator on the button pushed will be

illuminated. A short tap on the button will operate the test stand in Maintained mode.

Pressing STOP during Maintained mode will stop crosshead motion. To resume the test,

press UP or DOWN again.

18

Page 19

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

button counter-clockwise until it assumes its original position. To resume the test, press UP or DOWN.

Crosshead movement will take place until a limit has been reached. If the crosshead has stopped at a

soft limit, the limit condition may be overridden by pressing and holding UP or DOWN.

5.3.1 Travel Indication

If enabled, travel indication is displayed in the upper left corner of the display. The displayed units are the

same as programmed in the UNITS parameter. Indicated travel is a relative value. To zero out travel

distance, ensure that the crosshead is not moving, then press and hold STOP.

If the cable connecting the crosshead to the rear of the controller is unplugged, the position value will not

change when the crosshead moves.

5.3.2 Limit Switch Operation

Limit switches allow the operator to set a location along the column at which

point the crosshead will stop moving. Limit switches are located at the rear of

the test stand column, as shown in the image to the left. Adjust the switches’

positions by loosening, repositioning, and re-tightening the thumb screws. The

thumb screws must be installed after unpacking. They are shipped separately

to avoid damage in transit.

5.3.3 Overload Protection

The 09-1162 cable is required for overload protection of a Mark-10 force gauge. If overload protection is

enabled, the crosshead will stop when the programmed percentage of full scale of the force gauge has

been reached.

When overload protection is enabled, if the 09-1162 cable is disconnected, and/or if the force gauge is

turned off, an error message will appear. Plug in the cable and/or turn on the force gauge to clear the

message.

Note: When the crosshead is moving in the UP direction, only the tension overload setting is active.

When the crosshead is moving in the DOWN direction, only the compression overload setting is active.

5.4 Auto Return Mode

In this mode the crosshead moves to whichever limit it encounters first and stops. Then, the crosshead

returns at maximum speed to the other limit, whichever occurs first, and stops. The speed at which the

crosshead travels is dictated by the SPEED setting or UP SPEED and DN SPEED settings (if

independent speeds are enabled). Press UP or DOWN to initiate an Auto Return sequence.

The crosshead can be stopped at any time during an Auto Return sequence by pressing STOP. To

resume the test, press UP or DOWN.

Note: If the crosshead has stopped at a soft limit, the limit condition may be overridden by pressing and

holding UP or DOWN for two seconds.

ycling Mode

5.5 C

This mode cycles the crosshead between limits, whichever occurs first. One cycle consists of the

following steps:

1. Crosshead moves to a limit at the specified speed.

2. Crosshead stops for the specified amount of dwell time.

19

Page 20

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

3. Crosshead reverses direction, returns to the other limit at the specified speed, and stops for

the specified amount of dwell time.

A cycling sequence can be initiated from any position and can start in either direction. If the crosshead is

at a limit, however, cycling can only be started in the direction of the other limit. To initiate a cycle

sequence, press UP or DOWN. During a cycle sequence, a counter will be displayed, indicating the

number of cycles remaining, as shown below:

C Y C L E S 0 0 0 2 4

me n u m i n ma x S E T

As in Basic Mode, the min, max, and set soft keys are active during crosshead movement.

When the cycling sequence and the crosshead has stopped at a soft limit, the limit condition may be

overridden by pressing and holding UP or DOWN.

5.5.1 Dwell time

Dwell time is the amount of time, in seconds, for which the crosshead stops at a limit during a cycle

sequence. When the crosshead has reached a limit, a counter will be displayed, shown as follows:

D WE L L : 0 0 0 1 . 5

me n u m i n ma x S E T

If the DWELL U and/or DWELL L settings are set to 0, the crosshead will immediately reverse direction

upon reaching the corresponding limit, and no counter will be displayed.

The cycle sequence may be interrupted before it has been completed by pressing STOP. A soft key

labeled RESET will appear as follows:

C Y C L E S : 0 0 0 2 4

R E S E T

At this point, there are two options:

1. Canceling the cycle sequence:

Press RESET to stop and reset the cycle sequence. The cycle counter will revert to the

number of cycles originally programmed.

2. Resuming the cycle sequence:

Press UP or DOWN to resume.

Once the sequence has been completed, the screen will revert to the number of cycles programmed

originally. To begin another cycle test, press UP or DOWN.

Travel indication and limit switch operation is the same as in Basic Mode.

5.5 Preload Mode

In this mode, the crosshead moves at an approach speed of 10 in/min (250 mm/min) until the

programmed preload value has been reached. If moving in the up direction, a tension preload is required.

If moving in the down direction, a compression preload is required. When the preload is reached, the

sequence of events programmed in the Preload setting occurs (see Section 4.7.1). If the ZERO,GO

setting is selected, the crosshead speed will revert to the set speed after travel indicator is zeroed.

Note 1: Before the start of a preload sequence, the crosshead must be positioned at either the upper or

20

Page 21

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

lower limit switch.

Note 2: Preload and Load Holding cannot be enabled simultaneously.

5.6 Load Holding Mode

In this mode, the crosshead moves until the set point value programmed in the force gauge is reached.

The crosshead then dynamically adjusts its position to maintain a programmed force. The force gauge’s

capacity should be as close as possible to the intended load, for best performance.

In the force gauge, both set points must be set. The upper set point refers to a force limit in the up

(tension) direction. The lower set point refers to a force limit in the down (compression) direction. The

opposite set point must be set to any value in the opposite measuring direction. For example, for a test

requiring load holding at 10 lbF of compression force, set the upper set point to 30 lbF tension (as an

example), and the lower set point to 10 lbF compression.

If the CYCLING option has been enabled, load holding will be active for the period of time as defined in

the Dwell Time settings. If CYCLING has not been enabled, load holding will continue indefinitely.

Before the start of a load holding sequence, the crosshead must be positioned at either the upper limit

switch to begin compression load holding or at the lower limit switch to begin tension load holding.

The test speed should be adjusted according to the sample under test. Fine tuning may be necessary to

ensure optimal crosshead dynamic adjustment. Stiff samples require a lower test speed; softer samples

can be tested at higher speeds. If the speed of approach is too high for a given sample stiffness, the

crosshead may overshoot the set point value, requiring an adjustment sequence where the crosshead

reverses, then moves again in the original direction multiple times before settling at the set point value. A

high enough speed may cause this correction cycle to repeat indefinitely.

For softer samples the amplitude of oscillation will be smaller, but could still be present for the duration of

the load holding period. This is typical for samples which may relax, such as rubber, foam, etc. Lowering

the test speed will reduce the oscillation.

For non-relaxing materials such as metal springs, the oscillation should stop shortly after the holding force

is reached.

Note: Preload and Load Holding cannot be enabled simultaneously.

5.7 Break Detection Mode

In this mode, the crosshead will stop when a sample break has occurred. The test stand is triggered when

the force has decreased to a specified percentage of peak.

For example: A sample is pulled until 50 lbF, then breaks. The break detection percentage drop setting is

programmed to 50%. After the sample breaks, the force rapidly decreases, reaches 25 lbF (50% of peak),

then triggers the test stand to stop.

Break detection becomes active only after 5% of the force gauge’s full scale has been reached. For

example, if a force gauge with 50 lbF capacity is used, the break detection feature will not become active

until 2.5 lbF has been reached.

If enabled, an auto-return sequence or single-cycle sequence may follow break detection.

5.8 PC Mode

The ESM301 can be controlled by a PC via serial communication. A list of supported ASCII commands is

provided below. All commands must be lowercase.

a Request speed

b Set travel units to inches

c Enter cycle mode

21

Page 22

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

d Move crosshead down

e Set speed (ex. e10.00 = 10.00 in/min)

f Set cycles (ex. f0500 = 500 cycles)

g Set lower travel limit (ex. g05.375 = 5.375 in)

h Set upper travel limit (ex. h10.250 = 10.250 in)

i Set travel units to millimeters

j Set crosshead speed to maximum speed

k Set crosshead speed to minimum speed

l Enter travel limit mode

m Enter manual mode

n Transmit travel and force readings

o Set crosshead speed to programmed speed

p Request stand status*

q Request number of cycles completed

r Request number of cycles set

s Stop crosshead

t Reset cycle counter to zero

u Move crosshead up

v Request upper travel limit

w Request lower travel limit

x Request travel value

z Reset travel to zero

*The transmission of ASCII “p” will return the stand status. The following are the return codes and their

definitions:

Crosshead status U = crosshead moving up

D = crosshead moving down

S = crosshead stopped

Operating mode C = cycle mode

L = limit mode

M = manual mode

Limit switch status UL = crosshead at upper limit

DL = crosshead at lower limit

Commands relating to Mark-10 force gauges are not the same as indicated in their respective user’s

guides. A list of supported ASCII commands is provided below. All commands must be uppercase:

A Displays current unit

F Toggles between Normal and Data Collect modes

P Steps through Normal mode, Tension Peak mode, and Compression Peak mode

R Zeroes the force gauge (zeroes all modes)

S Sends current mode (Normal, Tension Peak, Compression Peak, or Data Collect)

U Steps through units

X or ? Sends currently displayed reading

Y Enables RS-232 output and sends continuous data stream when in Data Collect mode

Z Zeroes the peak values

The ESM301 is compatible with legacy Nexygen

TM

TCD software, which also utilizes the above

commands. The 09-1162 cable is needed to communicate between a Mark-10 gauge and the test stand.

The 09-1056 serial cable is needed to communicate between a PC and the test stand. Baud rate, stop

bits and parity must be programmed in the stand to correspond with the PC software’s settings.

While in PC control, if any parameters are changed on the front panel, these settings will be ignored,

except if Auto Return or Cycling are turned on. If so, PC control will be turned off automatically.

22

Page 23

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

6 COMMUNICATING WITH MESURTMGAUGE

The ESM301 can communicate with MESUR

either force data only or force data combined with travel data (if the ESM301(L)-001 integrated travel

indication option is installed). To communicate with MESUR

force gauge are required, as follows:

1. Check physical connections (refer to Section 3.4)

2. Force gauge settings

1. Set to RS-232 output.

2. Set the baud rate 9,600.

3. Test stand settings

1. Set the baud rate to 115,200.

4. MESUR

TM

gauge settings

1. Select System Configuration, Gauge + ESM301 / DC Controller with Travel or without

Travel for force vs. time or force vs. distance measurement, respectively.

2. In the Port Configuration tab, set the COM Port number to match the number

assigned by Windows, accessible in Device Manager.

7 FEATURE ACTIVATION

This menu displays the list of available features and indicates which ones are enabled and disabled.

Those that are disabled can be activated in the field. Features that are enabled are indicated by ON, and

those that are disabled are indicated by OFF.

7.1 Accessing Feature Activation Menu

While in Operating Mode, press and hold STOP, then press menu simultaneously, and release both

buttons. The display will appear as follows:

K E Y S : O F F

E S C < − −> E N T R

Label Description

< –

– >

ENTR

ESC

7.2 Enabling Features

Features not originally purchased can be activated with an authorization code. To activate the feature,

scroll through the menu until the desired feature is displayed, then press ENTR. If the feature is already

enabled (indicated by on), pressing ENTR has no effect. If the feature is off, pressing ENTR will generate

a request code on the display.

Scrolls to the previous feature

Scrolls to the next feature

Selects the feature

Exits Feature Activation Menu

TM

gauge data collection software. The test stand can output

TM

gauge, certain settings in the test stand and

23

Page 24

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

An example is shown below:

K E Y S : 0 1 3 9 0 2 7

E S C + − E N T R

The request code must be supplied to Mark-10 or a distributor, who will then provide a corresponding

authorization code to activate the feature.

The process for entering the authorization code is as follows:

1. The first digit of the request code will be flashing. Press + to increment the digit. Pressing +

when the number 9 is displayed will return to 0.

2. Press –> to advance to subsequent digits, and change them in the same manner.

4. Press ENTR when complete. If an incorrect code is entered, the controller will return to the

Feature Activation Setup menu, without enabling the feature. If this happens the above process

must be repeated.

The Feature Activation Menu also includes a utility with which to disable the password. Scroll through the

features until the following is displayed:

D I S A B L E P A S S WO R D

E S C < − − > E N T R

Press ENTR to generate the request code, then follow the authorization code procedure as indicated

above.

7.3 Demo Mode

All ESM301 test stands are shipped in Demo Mode, which provides full functionality of all available

features for an evaluation period of 160 operating hours. Demo Mode can be suspended by pressing

STOP while turning on power to the test stand. This mode can be re-enabled in the same manner, and

will be active for the remaining time period.

8 TROUBLESHOOTING

1. The ESM301 displays several error messages, as follows:

Error Message Description

The force gauge is powered off, in a menu, or not connected to the

CHECK GAUGE

GAUGE COMM ERROR

GAUGE OVERLOAD

M5 1.7+ REQD

stand controller. Message appears when overload protection is

turned on.

The stand is attempting to move the crosshead up or down, but it

cannot establish communication with the force gauge. The

communication settings in the force gauge are not correct or the

gauge is in a menu.

The programmed overload percentage of the force gauge’s full scale

has been reached. Immediately reduce the force or adjust the

overload settings.

A Series 5 force gauge with firmware version 1.7 or later is required

for proper operation of the selected functions in the stand.

24

Page 25

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

To clear any of the above errors, press STOP. The amber light in the STOP button will be blinking

when the error message is displayed.

2. The crosshead will move only in one direction, or not at all.

Possible causes:

1. Ensure all cables are plugged in properly, as described in Section 2.2.

2. Ensure that the force value has not exceeded the overload limits configured in the gauge.

3. Ensure that force gauge set points have been configured properly. Refer to Section 5.6 for

details.

3. The travel display value does not change when the crosshead moves.

Check to make sure the encoder cable is plugged in properly.

4. Certain menu items are no longer displayed.

All test stand functions are temporarily enabled for 160 hours of operation in Demo Mode. When

demo mode has expired, any functions (and their associated menu items) not originally

purchased will no longer be available.

9 MAINTENANCE AND SERVICE

The ESM301 should be operated in a dry and clean area. Under these circumstances only a few periodic

maintenance operations are required:

9.1 Acme screw lubrication – twice per year

1. Remove the right column cover by loosening the screws, as shown above.

2. Using a brush, apply a small amount of silicon-based grease to the lead screw.

3. Cycle the crosshead up and down several times until the newly applied grease has been spread

evenly over the length of the screw. Re-install the column cover.

9.2 Check for loosened grips and attachments - daily

Check to ensure that the grips attached to the force gauge and base plate are firmly secured. Looseness

could result in a potentially hazardous situation.

Check for loosened components – once per month

1. Remove the test sample from the test stand.

2. Turn off power to the test stand and disconnect the power cord. Attempt to loosen

25

Page 26

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

subcomponents of the test stand (ex. fasteners, brackets, etc). All components should be firmly

attached. If any looseness is detected, stop using the test stand and contact Mark-10 or a

distributor for instructions.

10 SPECIFICATIONS

Load capacity:

Standard speed range: 0.5-13 in/min [13-330 mm/min]

Maximum travel:

Speed setting accuracy: ±0.2%

Speed variation with load: ±0% [Stepper motor driven]

Limit switch repeatability: 0.001 in [0.03 mm]

Travel accuracy: ±0.002 in [0.05 mm]

Travel repeatability: 0.001 in [0.03 mm]

Travel resolution: 0.001 in / 0.02 mm

Power: Universal input 80-240 VAC, 50/60 Hz

Fuse type: 1.2 A, 250V, 3AG, SLO BLO

Weight (without options):

Included accessories:

Environmental Conditions:

11 DIMENSIONS

300 lbF [1.5 kN] @ up to 24 in/min [610 mm/min]

200 lbF [1 kN] @ >24 in/min [>610 mm/min]

ESM301: 11.5 in [292 mm]

ESM301L: 18.0 in [457 mm]

ESM301: 34 lb [15.4 kg]

ESM301L: 39.5 lb [23.7 kg]

Extension rod, small hook, medium hook, #10-32 coupler,

compression plate, force gauge mounting hardware, tool kit

40 - 100°F [5 - 40°C], max. 96% humidity, non-condensating

#10-32 UNF-2B

X 0.350 DEEP

X24

0.500 [12.7]

TYP

5/16-18 UNC-2B

X 0.350 DEEP

A

4.90 [124.5]

4.20 [106.7]

6.50 [165.0]

B

0.35 [8.9]

0.500 [12.7]

TYP

3.26 [82.8]

2.800 [71.1]

2.300 [58.4]

2.76 [70.1]

3.00 [76.2]

C

13.20 [335.3]

MOUNTING PLATE

TOP VIEW

Model A

ESM301 24.5 [622]

B (Series 3) C (Series 5/4)

3.5 - 15.0 [89 - 381] 2.3 - 13.8 [58 - 351]

ESM301L 31.5 [800] 3.5 - 21.5 [89 - 546] 2.3 - 20.3 [58 - 516]

26

Page 27

Model ESM301 / ESM301L Version 2 Test Stand User’s Guide

NOTES:

27

Loading...

Loading...