Page 1

Panel Mount T achometer

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516–U.S.A.

TEL: 516-295-4300

• FAX: 516-295-4399

CHECK•LINE

®

INSTRUMENTS

Model DT-5TG (VDC)

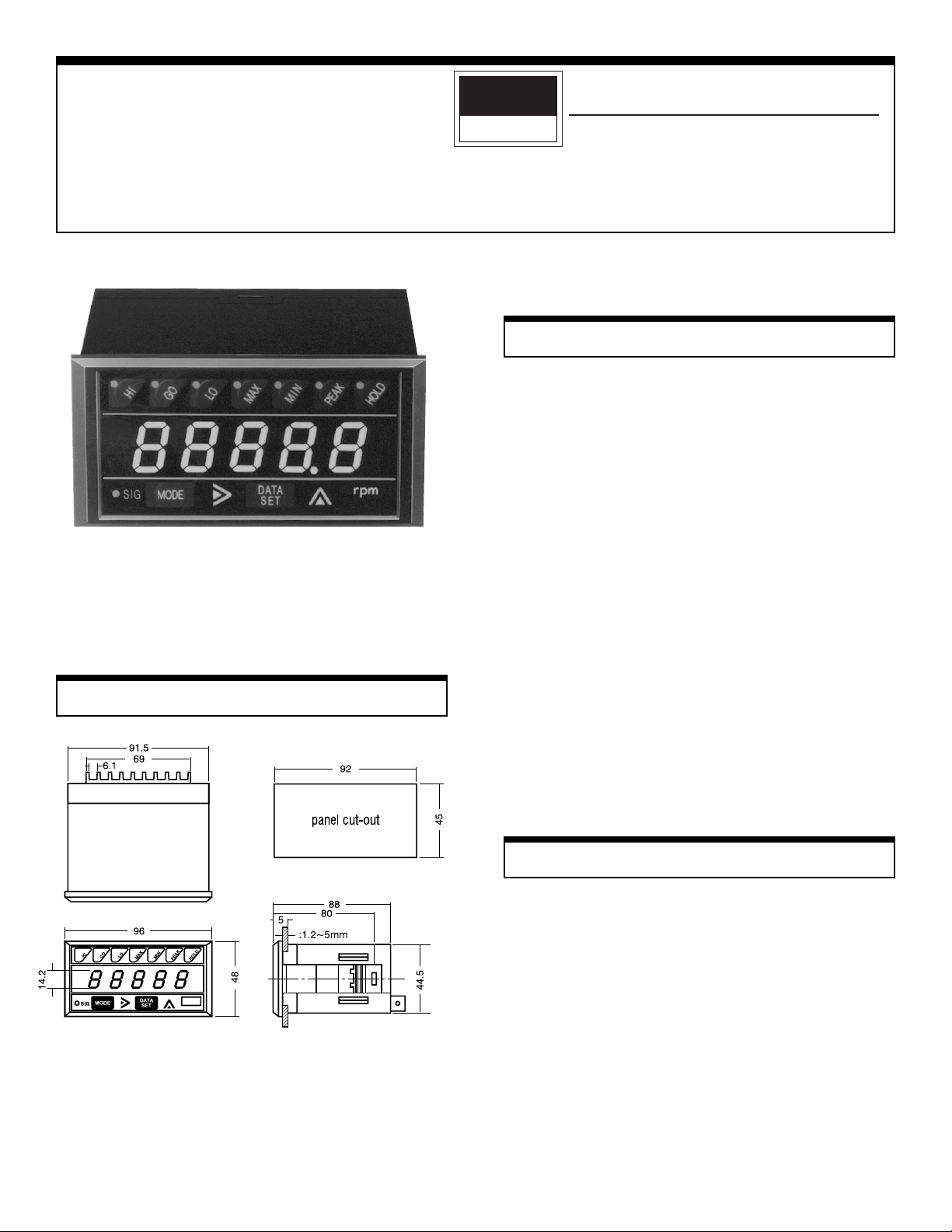

Dimensions (mm)

Instruction Manual

Features

One of the most advanced on the market today, this

microprocessor-based panel tachometer not only measures rotational, linear and flow rate speeds, but can also

function as an elapsed time counter and ratio meter. By

choosing the desired input/output module(s), you can

design virtually any system imaginable.

!

Mounts easily — no brackets or screws or any other

hardware needed.

!

Tolerates a wide variation of voltages.

!

Immune to electrically noisy environments.

!

Programmable parameters and functions via front

panel membrane push-button switches.

!

Accepts a variety of input and output modules

!

No need to remember mathematical formulas.

!

Highly accurate.

!

Self-testing.

Operational Precautions

!

If the unit is used in a caustic environment, we

suggest you use a NEMA 4X enclosure.

!

Keep unit free of vibration and shock.

!

When installing unit, keep power and sensor wires

separate. Tie cable shield to terminal E (earth ground).

!

After inserting wires, tighten terminal screws securely.

Page 2

Specifications Installation

Function

Function Rate Measurement

FunctionFunction

Display Range

Display Range

Display RangeDisplay Range

Measuring range

Measuring range

Measuring rangeMeasuring range

Update Time

Update Time 0.25, 0.5, 1, 2, 4, 8, 16 sec., selectable

Update TimeUpdate Time

Display

Display 5-digit LED (0.56" or 14.2 mm high)

DisplayDisplay

Time base

Time base Controlled by a 4.194304 MHz crystal

Time baseTime base

Accuracy

Accuracy ±0.008% ± 1 digit

AccuracyAccuracy

Measuring system

Measuring system CPU controlled

Measuring systemMeasuring system

Input no. of p/r

Input no. of p/r 1–9999 (programmable)

Input no. of p/rInput no. of p/r

Input signal

Input signal

Input signalInput signal

characteristics

characteristics

characteristicscharacteristics

Input signal

Input signal

Input signalInput signal

amplitude

amplitude

amplitudeamplitude

Input impedance

Input impedance

Input impedanceInput impedance

Voltage output

Voltage output 12 VDC ±5% (50 mA max) to power sensors

Voltage outputVoltage output

Applicable Sensors

Applicable Sensors

Applicable SensorsApplicable Sensors

Ambient temperature

Ambient temperature 32°–113° F (0°–45° C)

Ambient temperatureAmbient temperature

Power consumption

Power consumption 1W (5W when using optional modules)

Power consumptionPower consumption

Voltage requirements

Voltage requirements 9–35 VDC

Voltage requirementsVoltage requirements

Dimensions

Dimensions

DimensionsDimensions

Weight

Weight 0.55 lbs (250g)

WeightWeight

Rate Measurement Elapsed Time Counter

Rate MeasurementRate Measurement

0.0000–9.9999

0.000–99.999

0.00–999.99

0.0–9999.9

0–99999

10–99999 rpm (at 1p/r), 0.2–30000 rpm

(at 60p/r)

Sine wave–max frequency 10 kHz

Square wave–max frequency 30 kHz

open collector

Contact closure–max frequency 20 Hz

Sine wave (0.3–30 VP–P)

Square wave LO: 0–1.5 V, HI 4–30 V

10 k ohms for magnetic pickup, rotary pulse

generator and proximity switch only

rotary pulse generator, magnetic pickup,

proximity switch, retro-reflective

3.46"L x 1.88"H x 3.78"W (88L x 48H x 96W

mm), includes bezel, fits 1/8 DIN cutout

Elapsed Time Counter

Elapsed Time CounterElapsed Time Counter

99.99 sec.

99 min. 59 sec.

99 hours 59 min.

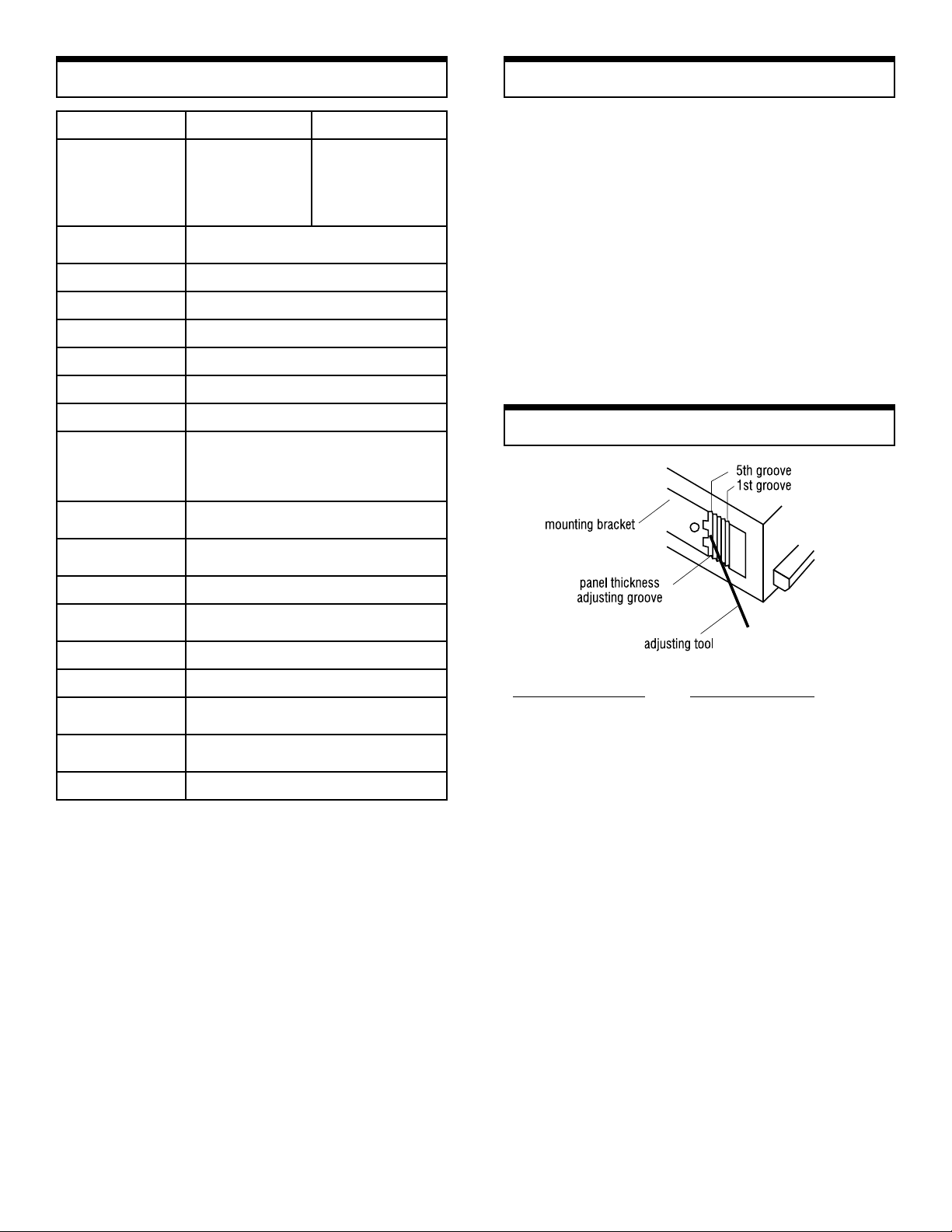

Mounting Unit

Our 1/8 DIN case design eliminates the need for brackets

and screws for installation. With the tachometer in a level

position, insert it into the panel cutout. Gently push the

face of the unit until the front bezel locks into place. If the

tachometer case is loose, adjust the integral bracket with

the enclosed tool.

Removing unit

From the rear of the tachometer, alternately push the unit

from the left and right. This will free it for easy removal.

Mounting Bracket Adjustment

Panel Thickness

Thickness of Panel Adjusting Groove

1.2 – 1.6 mm 5th groove (factory setting)

1.8 – 2.5 mm 4th groove

2.8 – 3.6 mm 3rd groove

4.0 – 4.5 mm 2nd groove

5.0 mm 1st groove

2

Page 3

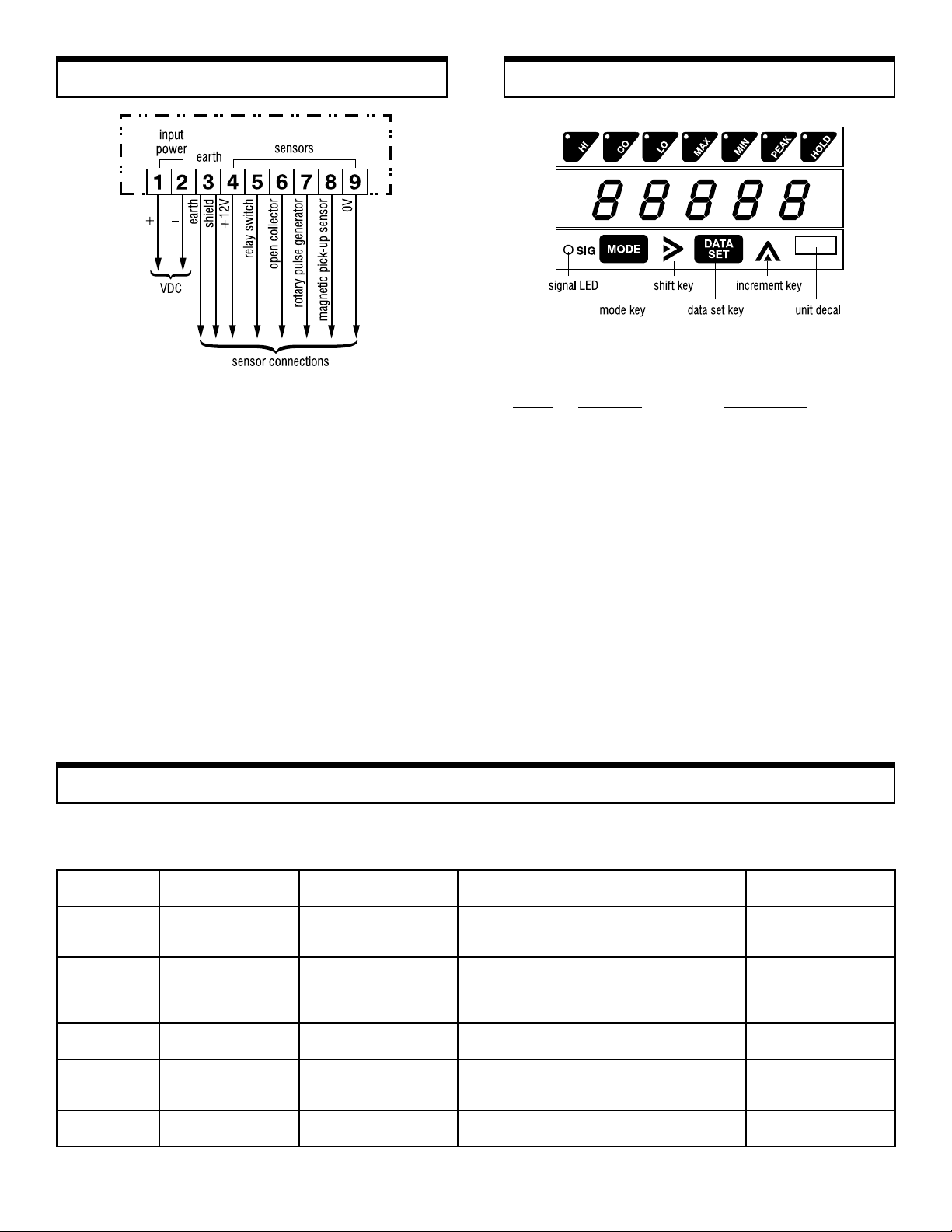

Connections

1&2 DC input terminals.

3 Earth ground. Connect all cable shielding to this

terminal.

4 12 VDC 50mA max. This sensor power supply is for

any sensor that requires external power

5 Switch closure input. To be used with a relay or

solenoid. The input frequency must be less than 20Hz.

6 For use with open collector sensors. Connect the

sensor's signal output wire. No need for an external

pull-up resistor.

7 Terminal to accept signals from rotary encoders or

pulse generators.

8 Standard input terminal for magnetic pick-ups and

proximity switches.

9 Signal ground or common.

Mode Selections

The DT-5TG has five modes of operation. Each mode

uses separate parameters for you to program:

Mode Function Application

1 Rate measurement Measures rotational

(frequency input) linear or flow rate speeds.

Factory set.

2 Elapsed time counter Times variable processes.

3 Rate measurement For tachogenerator or

voltmeter. Requires input

module DOP-VF.

4 Ratio meter Compares two signals in

either absolute or percent

ratio. Requires input

module DOP-RM.

5 Self test Diagnostically tests LED

display, panel switches

and input circuitry.

Sensors

Shimpo offers a large selection of sensors to meet you application needs. The chart below shows

the optimum sensor to use when designing your system. Please call us for more information.

ROSNESEPYTYCNEUQERFSREBMUNLANIMRETEGNARMPRROYCNEUQERF

C06B1ER

C006B1ER

C0001B1ER

21S2IB

G2JD

GES

H022SR

526SCM

NA0303

01PM

*A0703

hctiwS

erusolC

* explosion proof

esluPyratoR

rotareneG

hctiwSytimixorP

hctiwSytimixorP

raeGytimixorP

rosneS

evitcelfeRorteR

rosneS

pu-kciPcitengaM

dioneloSroyaleR,9,5zH02<

,9,7,4

,9,7,4

,9,7,4

,9,6,4

,8,4

,9,7,4

,9,7,4

,9,6,4

,3,9,8

,3,9,8

,9,8,3

mpr00050

mpr00030

mpr00810

zHK20

ZHK10

zHK80

zH0050

zH0520

NOITAREPO

ERUTAREPMET

F°221+otF°41+

F°221+otF°41+

F°221+otF°41+

F°851+otF°31F°041+otF°86-

F°851+otF°4-

F°041+otF°41+

F°021+otF°22-

F°522+otF°001-

F°122+otF°04-

F°002+otF°001-

3

Page 4

Setting ParametersSetting Modes

1.Apply any voltage between

9–35 VDC to terminals 1 and

2. When power is applied, the

display will show all zeroes. After

half a second, the display will

change to

00

0.

00

2.Press mode and data set keys for

at least 5 seconds. A zero will

flash until

11

1 appears on the

11

display.

3.Press the increment key to select

the mode you want. Mode

sequence will depend on input

module

4.Press mode key. You're now

ready to program the parameters

for the mode you have selected.

Mode 1: Rate Measurement

Parameter 1:

Pulses Per Revolution from Sensor

Here's how to change the parameter from 1 to 60 pulses

per revolution ("p/r"):

1. Set unit to mode 1.

2. Press mode key.

3. Press shift key to select the

desired digit.

4. Press increment key 6 times.

5. Press shift key.

6. Press increment key 9 times.

Parameter 1 is now set for 60 p/r.

Parameter 2: Sensing RPM

To change the parameter from 50,000 to 1,000 rpm.

The DT-5TG can easily measure any rotational, linear or

flow rate speed. Each parameter function dictates the

necessary steps when preparing a system application.

Parameters 2 and 3 can be measured with a hand-held

digital tachometer (no need for arithmetic calculations).

Parameter

Parameter Function Setting

ParameterParameter

1

2 Sensing rpm 50,000 rpm

3 Display units

4 Decimal point none 0 – 4th place

5

6 Update time 1 .25, .5, 1, 2, 4, 8, 16

7 Acceleration 0 0, 1, 2

Function Setting Factory

Function SettingFunction Setting

Pulses per

revolution

Minimum rpm

(sensor)

Factory Range

FactoryFactory

1p/r 1 – 9999

50,000 rpm

(rpm, fpm, ips)

10 rpm

Range

RangeRange

1. Press mode key

2. Press shift key

3. Press increment key five times.

4. Press shift key

5. Press increment key.

4

Page 5

Setting Parameters (cont'd)

Parameter 3: Display Units

Program this parameter to the desired display value

corresponding to the parameter 2 setting. For example,

suppose a conveyor is running at 157 fpm and 1,000 rpm

sensing speed. This parameter would then be programmed for 157.

1. Press mode key.

2. Press increment and shift keys

to change display.

To get a decimal point, increase the parameter 3 setting

by a power of 10, depending on the number of decimal

places needed. For one decimal place (in this example),

program the display for

program

1570015700

15700.

1570015700

0157001570

01570. For two places,

0157001570

Parameter 7: Acceleration

This parameter is useful when rate speeds accelerate or

stop rapidly. If the tachometer senses a large rate

change, the update time automatically switches to .25

seconds. When the tachometer senses a constant rate, the

update time is determined by parameter 6.

1. Press mode key

2. Press shift key to set parameter:

00

0 = No function

00

11

1 = Rapid stop

11

22

2 = Acceleration (input

22

frequency must be ≥7 Hz)

Parameter settings are now complete. Press data set key

to start measuring.

Parameter 4: Decimal Point

1.Press mode key (Skip to

parameter 5 if you don't want a

decimal point).

2.Press shift key to select position

of decimal point.

Parameter 5: Minimum RPM (sensor)

Set this parameter to the highest value possible.

1. Press mode key.

2. Press shift and increment keys

to change display.

Parameter 6: Update Time

1. Press mode key.

2. Press shift key to select update

time.

Field Adjustment

In the rate measurement mode, parameter 3 can be

adjusted without following the parameter sequence. For

example, suppose the initial parameter 2 and 3 settings are

50,000 rpm. But during actual measurements, the display

shows 3,800 rpm when the sensing speed is 3,500 rpm.

The DT-5TG can be quickly adjusted:

1. Press mode and increment keys simultaneously for

5 seconds.

2. Press shift and increment keys to make adjustment.

3. Press data set key — you're now ready to measure

speed.

If the display shows

eter 2 and 3 is too large. Press data set key and readjust

these parameters according to the parameter setting

procedure outlined earlier.

EE-00EE-00

EE-00, the ratio between param-

EE-00EE-00

5

Page 6

Mode 2: Elapsed Time Mode

This mode monitors the time of a continuously variable

process. Say, for example, a baker wants to know the

amount of time needed to bake cookies. By using a

stopwatch, he could measure the amount of time it takes

at a known speed of the conveyor. Or, the baker could

calculate this time by using the distance formula d=vt.

By knowing the calculation time (parameter 4) and rpm of

the sensing gear (parameter 2), the baker can continu-

ously monitor the time as the process varies.

Parameter

Parameter Function Setting

ParameterParameter

1

2 Sensing gear –rpm 200

3 Time units (=.)

4 Calculation time 02=.00

5 Update time 1 .25, .5, 1, 2, 4, 8, 16

Function Setting Factory

Function SettingFunction Setting

Sensing gear

–pulses/ revolution

Factory Range

FactoryFactory

Range

RangeRange

1 1 – 9999

(–.)=sec/sec

(=.)=min/sec

or hr/min

Parameter 3: Time Units

1. Press mode key.

2. Press shift key to select units.

Unit symbols:

=. hour/minute or minute/second

–. second/second

Parameter 4: Calculation Time

1. Press mode key.

2. Press shift and increment keys to

program time calculated.

Parameter 1:

Sensing Gear – Pulses per Revolution

This example shows how to change the parameter from 1

to 60 pulses per revolution.

1. Set the unit to mode 2.

2. Press mode key.

3. Press shift key 4 times.

4. Press increment key 6 times.

5. Press shift key.

6. Press increment key 9 times.

Parameter 2: Sensing Gear — RPM

Here's how to change the parameter from 200 to 100 rpm:

If the display shows

--=.E9--=.E9

--=.E9, an entry error has been

--=.E9--=.E9

made. Reprogram the unit using the shift and increment

keys.

Parameter 5: Update Time

1. Press mode key.

2. Press shift key to select update

times.

The parameter settings are now

complete. Press data set key to start

elapsed time counter.

1. Press mode key.

2. Press shift key 3 times.

3. Press increment key 9 times.

6

Page 7

Mode 5: Self Test

Display Switches & Functions

This mode lets you check the LED display and input

circuitry.

1.Press mode and data set keys for

five seconds.

2.Press increment key and select

mode 5.

3.Press mode key to test display

segments and decimal points.

4. Some display functions switches

can also be checked. Press these

keys to test:

MAX

MIN

PEAK

HOLD

5.Press mode key. The display will

10001000

show

1000 and signal

10001000

flash.

6.Press data set key. The display will

go back to the previous mode of

operation.

LEDLED

LED will

LEDLED

The DT-5TG has seven display functions located above

the display. All functions have an LED indicator and all

but GO have a membrane switch. Here is a brief description of each function:

HI If the display is equal to or greater than the HI

limit setting, the LED will light and a contact

will close.* To program, press HI and mode keys

for one second. Use the increment and shift

keys to set limit.

GO If the display is between the HI and LO settings,

the LED will light and a contact will close.*

LO If the display is equal to or less than the low limit

setting, the LED will light and a contact will

close.* To program, press LO and mode keys for

one second. Use increment and shift keys to set

limit.

MAX The display will hold the average maximum

measurement. To program, press MAX and

mode keys until LED lights.

MIN The display will hold the average minimum

measurement. To program, press MIN and

mode keys until LED lights.

PEAK The display will hold the absolute peak measure-

ment. To program, press mode and PEAK keys

until LED lights.

HOLD This function will hold the display indefinitely as

long as the unit is powered. To program, press

mode and HOLD keys until LED lights.

*Requires the DOP-CP Triple Relay Output Module.

Note:

! The HI, GO and LO functions are non volatile

and may be reset by programming to zero.

! The MAX, MIN, PEAK and HOLD functions

must be used separately. These functions may be

reset by pressing the data set key or by interrupt-

ing power.

Error Codes

Display Type of Error What to Do

EE-00EE-00

EE-00 Parameter setting Press data set key. Enter parameter according to setting range.

EE-00EE-00

EE-01EE-01

EE-01 Hi/Lo setting Press data set key. Enter the upper and lower limits.

EE-01EE-01

EE-02EE-02

EE-02 Internal setting Press data set key. Interrupt power at terminals 1 and 2.

EE-02EE-02

EE-03EE-03

EE-03 Memory recall Press data set key. In sequence, press HI, hold, increment and mode keys.

EE-03EE-03

EE-04EE-04

EE-04 Communication Check connections with module. Press data set key.

EE-04EE-04

EE-05EE-05

EE-05 error with

EE-05EE-05

EE-06EE-06

EE-06 module

EE-06EE-06

7

Page 8

Available Modules

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516–U.S.A.

TEL: 516-295-4300

• FAX: 516-295-4399

CHECK•LINE

®

INSTRUMENTS

Optional modules are available from Shimpo. Choose any

of the following modules – no internal hardware modifi-

cation is required.

Module connectors:

DOP-1A For single module

DOP-2A For dual module

Modules:

DOP-VF Voltage input

DOP-RM Ratio input

DOP-SD RS232C/Mitutoyo output

DOP-CP Tripl e r el ay o ut put

DOP-BC BCD output

DOP-FV Voltage/current output

DOP-PO Parallel output

The DT-5TG is available with one, two, or three module

connectors. Each type is indicated by its suffix:

DT-5TG-0 No connector

DT-5TG-1 1 connector

DT-5TG-2 2 connectors

Multiple Modules:

In most applications, two modules may be interfaced with

the DT-5TG-2. Below are the specific combinations:

CP

CP

CP

CPCP

SD

SD

SDSD

PO

PO

POPO

BC

BC

BCBC

FV

FV

FVFV

VF

VF

VFVF

RM

RM

RMRM

CP SD

CPCP

SD PO

SDSD

! ! ! ! ! ! !

! ! ! ! ! ! !

! ! ! ! ! ! !

! ! ! ! ! ! !

! ! ! ! " " "

! ! ! ! " " "

! ! ! ! " " "

PO BC

POPO

BC FV

BCBC

FV VF

FVFV

VF RM

VFVF

RM

RMRM

!#available

#can't be combined

"

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

SHIMPO ONE-SHIMPO ONE-

SHIMPO ONE-

SHIMPO ONE-SHIMPO ONE-

LIMITED EXPRESS WARRANTY:LIMITED EXPRESS WARRANTY:

LIMITED EXPRESS WARRANTY: Shimpo Instruments warrants, to the original purchaser of new

LIMITED EXPRESS WARRANTY:LIMITED EXPRESS WARRANTY:

products only, that this product shall be free from defects in workmanship and materials under

normal use and proper maintenance for one year from the date of original purchase. This warranty

shall not be effective if the product has been subject to overload, misuse, negligence, or accident,

or if the product has been repaired or altered outside of Shimpo Instruments’s authorized control in

any respect which in Shimpo Instruments’s judgment, adversely affects its condition or operation.

DISCLAIMER OF ALL OTHER WARRANTIES:DISCLAIMER OF ALL OTHER WARRANTIES:

DISCLAIMER OF ALL OTHER WARRANTIES: The foregoing warranty constitutes the SOLE AND

DISCLAIMER OF ALL OTHER WARRANTIES:DISCLAIMER OF ALL OTHER WARRANTIES:

EXCLUSIVE WARRANTY, and Shimpo Instruments hereby disclaims all other war ranties, expressed,

statutory or implied, applicable to the product, including, but not limited to all implied warranties

of merchantability and fitness.

LIMITLIMIT

AA

TION OF REMEDTION OF REMED

LIMIT

A

TION OF REMED

LIMITLIMIT

AA

TION OF REMEDTION OF REMED

TO REPAIR OR REPLACE the defective product or part, at Shimpo Instruments’s option. Shimpo

$$$$$$$$$$$

YY

::

Y

: Under this warranty, Shimpo Instruments’s SOLE OBLIGATION SHALL BE

YY

::

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

YEAR WYEAR W

YEAR W

YEAR WYEAR W

ARRANTYARRANTY

ARRANTY

ARRANTYARRANTY

Instruments reserves the right to satisfy warranty obligation in full by reimbursing Buyer for all

payments made to Shimpo Instruments, whereupon, title shall pass to Shimpo Instruments upon

acceptance of return goods. To obtain warranty service, Purchaser must obtain Shimpo Instruments’s

authorization before returning the product, properly repackaged, freight pre-paid to Shimpo Instruments.

INDEMNIFICATION & LIMITATION OF DAMAGES:INDEMNIFICATION & LIMITATION OF DAMAGES:

INDEMNIFICATION & LIMITATION OF DAMAGES: Buyer agrees to indemnify and hold Shimpo

INDEMNIFICATION & LIMITATION OF DAMAGES:INDEMNIFICATION & LIMITATION OF DAMAGES:

Instruments harmless from and against all claims and damages imposed upon or incurred arising,

directly or indirectly, from Buyer’s failure to perform or satisfy any of the terms described herein. In

no event shall Shimpo Instruments be liable for injuries of any nature involving the product, including

incidental or consequential damages to person or property, any economic loss or loss of use.

MERGER CLAUSE:MERGER CLAUSE:

MERGER CLAUSE: Any statements made by the Seller’s representative do not constitute warranties

MERGER CLAUSE:MERGER CLAUSE:

except to the extent that they also appear in writing. This writing constitutes the entire and final

expression of the par ties’ agreement.

$$$$$$$$$$$

Loading...

Loading...