Page 1

2 YEAR WARRANTY (RESTRICTIONS APPLY)

Imada, Inc. warrants its products to the original purchaser to be free from defects

in workmanship and material under normal use and proper maintenance for two

years (one year for adapters, attachments and cables) from original purchase.This

warranty shall not be effective if the product has been subject to overload, shock

load, misuse, negligence, accident or repairs attempted by others than Imada, Inc.

During the warranty period, we will, at our option, either repair or replace

defective products. Please call our customer service department for a return

authorization number and return the defective product to us with freight prepaid.

The foregoing warranty constitutes the SOLE AND EXCLUSIVE WARRANTY, and we

hereby disclaim all other warranties, express, statutory or implied, applicable to the

products and/or software, including but not limited to all implied warranties of

merchantability, fitness, non-infringement, results, accuracy, security and freedom

from computer virus. In no event shall Imada, Inc.and/or its affiliated companies be

liable for any incidental, consequential or punitive damages in connection with the

use of its products and/or software.

Digital Force Gauge

Complete color

catalog available.

Call 800-373-9989

or E-mail us.

3100 Dundee Rd., Suite 707, Northbrook, IL 60062 USA

Telephone: (847) 562-0834 Fax: (847) 562-0839

www.imada.com E-mail: imada@imada.com

ISO 9001 & ISO/IEC 17025 Accredited

04/07

Specifications subject to change without notice.

Model: DS2

INSTRUCTION MANUAL

Page 2

INTRODUCTION

DS2 Series are state-of-the-art basic performance, easy-to-use

digital force gauges which feature giant, easy-to-read LCD displays

and provide RS-232, Digimatic and analog output. The Real time

measuring mode displays force transients and the Peak measuring

mode captures the peak force achieved during a test. Selectable

lbf(ozf), kgf(gf), and N measuring units.

IMPORTANT

Make sure to read this manual before operating.

1. WARNING!! Test samples and fixtures can break or shatter,

wear eye and body protection to avoid injury.

2. WARNING!! REGARDLESS of whether the unit is ON or OFF,

DO NOT exceed the capacity of the gauge.At 110% of the rated

capacity, the display flashes to warn. NEVER exceed 200% of the

rated capacity, or the load cell will be damaged.Avoid shock

load.

3. The gauge can be used between 30 – 100°F (0 – 40°C)

For the most accurate results, use the gauge at temperatures

close to ones on the certificate of calibration.

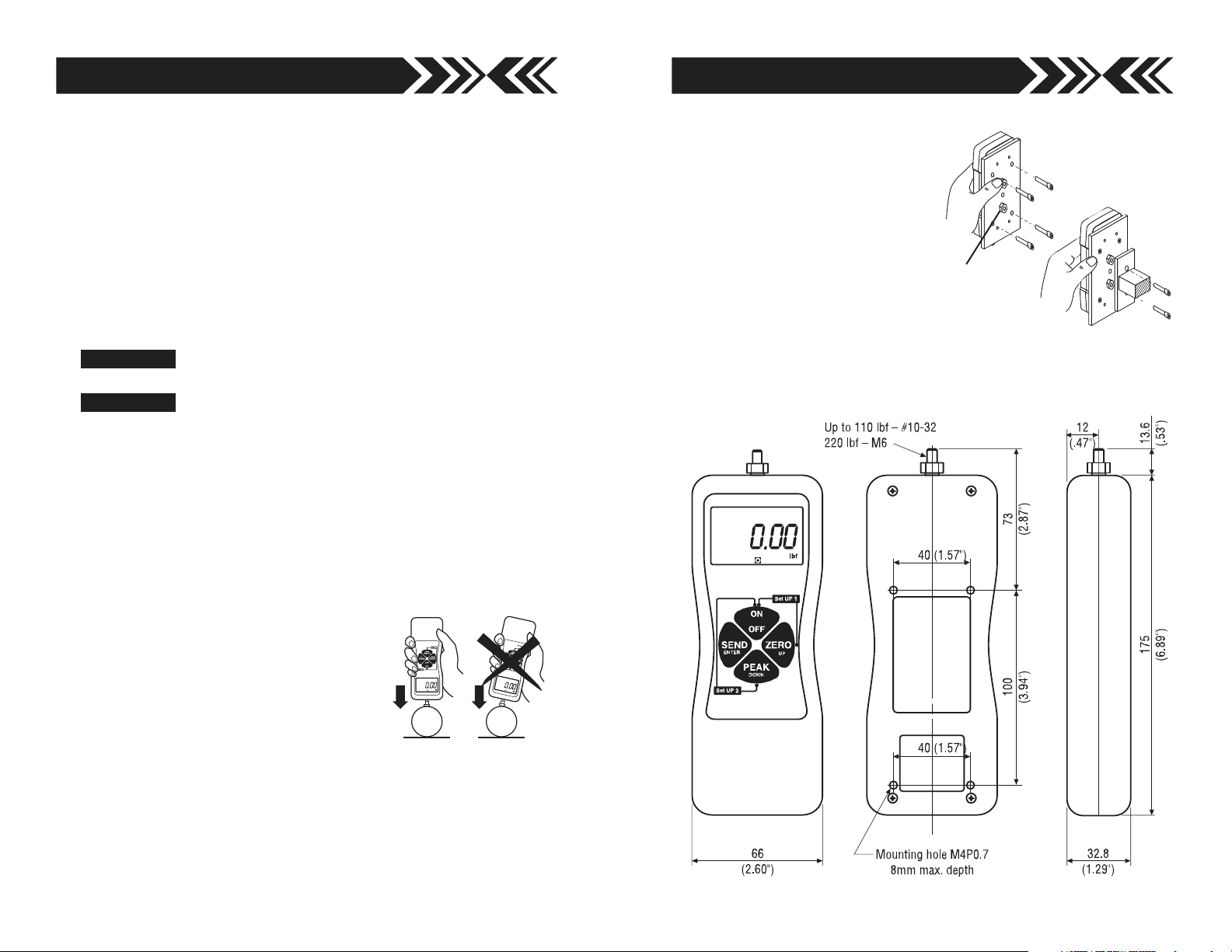

4. When mounting DS2 Series, use M4 mounting screws with a

maximum insertion depth of 8 mm into the gauge.

5. Measure in line tension and compression

forces only. DO NOT attempt to measure forces at an angle to the measuring

shaft – damage to load cell and/or shaft

may result.

6. Hand tighten attachments. DO NOT use

tools.

7. Make sure this gauge and all peripherals are powered down

before attaching any cables.

8. DO NOT disassemble the gauge. Disassembly voids warranty.

9. Use only Imada AD120 (or AD230) charger/adapter.

Optional Adapter Plate

AP-001 Adapter Plate mounts

DS2 gauges to most other

brands of test stands.

Use the 4 screws (included) to

mount the DS2 gauge to the AP001 adapter plate.Then use the

2 PEM nuts on the AP-001

adapter plate to mount to other

brands of test stand.

DS2 DIMENSIONS

AP-001

PEM NUTS

IMADA GAUGE

GAUGE MOUNTING

SCREWS (4)

OTHER BRAND TEST STAND

2 MOUNTING PLATE BOLTS

page 11page 2

Page 3

RECHARGING NI-MH BATTERY

1. To maximize the life of the battery, power is shut off after 10

minutes of non-use. Automatic shut off is bypassed when used

with the AC adapter/charger.

2. Battery icon will flash when the gauge needs to be recharged.

3. Turn off power. Only use the IMADA AC adapter/charger pro-

vided, AD120 for 115VAC, AD230 for 230VAC. Plug into the

correct AC output. It takes 10 hours to charge fully.

4. When the gauge is turned off, make sure the AC adapter/charger

is disconnected to avoid overcharging.

ACCESSORIES

Optional Handle

The OH-1 optional handle fits DS2 gauges.

Constructed of high quality steel for rugged use,

the handle facilitates measurements of heavy

loads. Complete with mounting screws.

Optional SW-1 Data Acquisition Software

Use SW-1software to capture and analyze peak data from DS-2 force

gauges.A running log of all the data is displayed along with a chart.

Calculate max/min, average, and standard deviation.

Optional Cables

CB-101 Analog cable (10')

CB-203 RS-232C cable

(10', 9 pin female)

CB-301 Digimatic Cable (10')

page 10

Measuring Shaft

Attach any of the included

standard attachments or

optional special attachments to measure tension

or compression forces.

up to 110 lbf– #10-32

220 lbf– M6

Send

Transmit display value

Charger Port

Recharge the internal

NiMH ba

Imada AD120 or AD230

adapters only.

t

t

tery or use the

LCD DISPLAY

1

Compression icon

Indicates compression measurement

2

Tension icon

Indicates tension measurement

3

Units indicator

Displays selected measuring unit. (ozf,

lbf, kgf or N).

4

Battery icon

Flashes when gauge needs to be

recharged

5

GO/NG Indicator

under low setpoint

–

between low and high setpoints

O

over high setpoint

+

6

Negative sign

Displayed when measuring tension

7

Peak icon

Displays continuously when peak

mode is active

On/Off

Power ON, capacity is displayed.After 10 minutes, unit

powers down if no key is

pressed.

Zero

Tares weight of attachment

and resets peak value

Peak

Press to activate Peak mode

RS-232 Port

See page 8 for pin assignments

6

7

1 2

page 3

345

Page 4

GENERAL OPERATION

Selecting Units

Selecting Units

2. Mitutoyo Digimatic

Connect the CB-301 cable to the communications port and the

device receiving the data. Set up parameters as instructed from the

Mitutoyo processor manual.

Press to turn on the gauge.The display briefly shows the gauge

capacity, then zero with a measuring unit.To change to other units:

1. Turn off the gauge.

2. Hold and press once. Press to cycle units (ozf or

lbf, gf or kgf, and N), then press to select. The LCD display

briefly shows the gauge capacity, then zero with the newly

selected measuring unit, which is retained as a default.

Reversing the Display

Reversing the Display

Press and the LCD display briefly shows the

gauge capacity and then zero. To reverse the display:

1. Turn off the gauge.

STANDARD

DISPLAY

REVERSE

DISPLAY

2. Hold and press once. Press to cycle between

standard and reverse display, then press to select. The

LCD display briefly shows gauge capacity and then zero with

3. ±1 VDC Analog Signal

Connect the CB-101 analog cable to the communications port and

the device receiving the data.

DS2 Ranges (Resolution) Accuracy: ±0.2% F.S. ±1 LSD

Model Capacity (Resolution)

Ounces (ozf)/ Grams (gf)/ Newtons

Pounds (lbf) Kilograms (kgf)

DS2-0.4 7.00 (0.01 ozf) 200.0 (0.1 gf) 2.000 (0.001 N)

DS2-1 18.00 (0.01 ozf) 500.0 (0.1 gf) 5.000 (0.001 N)

DS2-4 4.400 (0.001 lbf) 2.000 (0.001 kgf) 20.00 (0.01 N)

DS2-11 11.00 (0.01 lbf) 5.000 (0.001 kgf) 50.00 (0.01 N)

DS2-44 44.00 (0.01 lbf) 20.00 (0.01 kgf) 200.0 (0.1 N)

DS2-110 110.0 (0.1 lbf) 50.00 (0.01 kgf) 500.0 (0.1 N)

DS2-220 220.0 (0.1 lbf) 100.0 (0.1 kgf) 1000 (1 N)

DS2 Specifications

Accuracy ± 0.2% F.S., ± 1 LSD

Selectable Units lbf(ozf), kgf(gf) or Newtons

Overload Capacity 200% of F.S. (Overload indicator flashes beyond 110% of F.S.)

Data processing speed 1,000 data/second (30 data/second rate selectable)

Display Update 10 times/second

Power Rechargeable NI-MH battery pack or AC adapter

Battery Indicator Display flashes battery icon when battery is low

CPU 8-bit CMOS

Setpoints Programmable high/low setpoints with LCD indicators

Outputs RS-232C, Digimatic and ±1 VDC analog output

Operating Temp. 32° to 100°F (0° to 40°C)

Accessories included AC adapter/charger, hook, flat tip, conical tip, chisel tip,

notched tip, extension shaft

the newly selected display, which is retained as a default.

page 9page 4

Page 5

COMMUNICATIONS PORT

Port Pin Assignments

Pin# Definition

1 RS-232C and Digimatic Ground

2 RS-232C Transmit Data

3 Analog Output ±1VDC

4 Digimatic Data Request

5 RS-232C Receive Data

6 Analog Ground

7 Digimatic Clock

8 Digimatic Transmit Data

1. RS-232C Bi-directional Interface Functions

Connect the gauge and device receiving data with a CB-203 cable.

All gauge functions can be duplicated from a remote location by

using the RS-232C interface.All commands must be sent in uppercase ASCII character format followed by a carriage return (CR).

Signal level: RS-232C, 8 data bits, 1 stop bit, no parity bit

Baud rate: 19200 bps

Hand Tighten Attachments

Hand Tighten Attachments

Do not use tools to tighten attachments to the measuring shaft.

Selecting Peak or Real time Measuring Mode

Selecting Peak or Real Time Measuring Mode

Press to turn on the gauge and enter real time mode. For peak

measurement press . ‘Peak’ appears on the display. Peak read-

ings will not change until a higher value is measured.Press

again to return to real time mode.

Tare

Tare

If necessary, press to tare the weight of the attachment and

shaft. Pressing also clears the peak reading.

RS-232C Interface Functions (Upper case ASCII format)

Command Function Response*

K[CR] Select “kgf/gf” units

N[CR] Select “N” units

O

[CR]

P[CR] Select peak mode

T[CR] Select real time mode

Z[CR] Tare Display

Q[CR] Turn off power

EHHHHLLLL[CR]** Set high/low setpoints(4 digit)

E[CR]** Read high/low setpoints EHHHHLLLL[CR]**

D[CR] Transmit display data [value][units][mode][CR]

*E[CR] response if the command is not accepted.

**Ignore decimal point for high low setpoints

Select “lbf/ozf” units

R[CR] executed

E[CR] error*

HHHH=High, LLLL=Low

setpoint values (4 digit)

HHHH=High, LLLL=Low

Apply Force and Measure

Apply Force and Measure

Make sure to apply force in line with the

gauge measuring shaft.

Collecting Data

Collecting Data

Connect the gauge and PC with a CB203 cable. Measure and press

to transmit data to the PC. Use optional SW-1 (see page 10) or

other software to collect and display data.

page 5page 8

Page 6

OPTIONAL SETTINGS

The following steps are not necessary for most test applications and

may be skipped entirely.

Selecting Test Type (continued from step 2)

Select rapid data processing for Destructive Testing.

Selecting High and Low Setpoints

Program High and Low setpoints to enable GO/NG testing.

1. Turn off the gauge.

2. Hold and press once. The LCD display will

briefly show HI, then the High setpoint value with flashing

HI. Press to increase and to decrease the High

value, then press to select. The LCD display briefly

shows Lo and then Low setpoint value with flashing L.

Press to increase and to decrease the Low value,

then press to select.

3. After is pressed in step 2, the display briefly shows

F-AdC and then FA with flashing F.

4. Press or to cycle between FA (for Destructive

Testing) or SL (for Non-destructive Testing: Factory default),

then press to select.The LCD display briefly shows

the gauge capacity and then zero.

SL: Non-destructive Testing

(for most testing, 30 data/second)

FA: Destructive Testing

(for very rapid force changes, 1,000 data/second)

For example, 5 lbf is set as Low setpoint and 10 lbf as the

High setpoint, the GO/NG indicator on the LCD display

shows for measurements less than 5 lbf (Low setpoint).

O

10 lbf (High setpoint).

–

for measurements between 5–10 lbf and for over

+

page 7page 6

Loading...

Loading...