Page 1

TORQUE MEASUREMENT

10/12

2 YEAR WARRANTY (RESTRICTIONS APPLY)

Imada, Inc. warrants its products to the original purchaser to be free from defects in

workmanship and material under normal use and proper maintenance for two years (one year

for adapters, attachments, batteries, and cables) from original purchase. This warranty only covers

defective material and labor and does not cover calibration, freight, fees and expenses and shall

not be effective if the product has been subject to overload, shock load, improper battery

charging, misuse, negligence, accident or repairs attempted by others than Imada, Inc.

During the warranty period, we will, at our option, either repair or replace defective products.

Please call our customer service department for a return authorization number and return the

defective product to us with freight prepaid.

The foregoing warranty constitutes the SOLE AND EXCLUSIVE WARRANTY, and we hereby

disclaim all other warranties, express, statutory or implied, applicable to the products and/or

software, including but not limited to all implied warranties of merchantability, fitness, noninfringement, results, accuracy, security and freedom from computer virus. In no event shall

Imada, Inc. and/or its affiliated companies be liable for any incidental, consequential or punitive

damages in connection with the use of its products and/or software.

Specifications subject to change without notice.

INSTRUCTION MANUAL

Digital Torque Tester

for impact drivers & air tools

Model: DI-1M

V-62334

Page 2

page 11page 2

TORQUE MEASUREMENTTORQUE MEASUREMENT

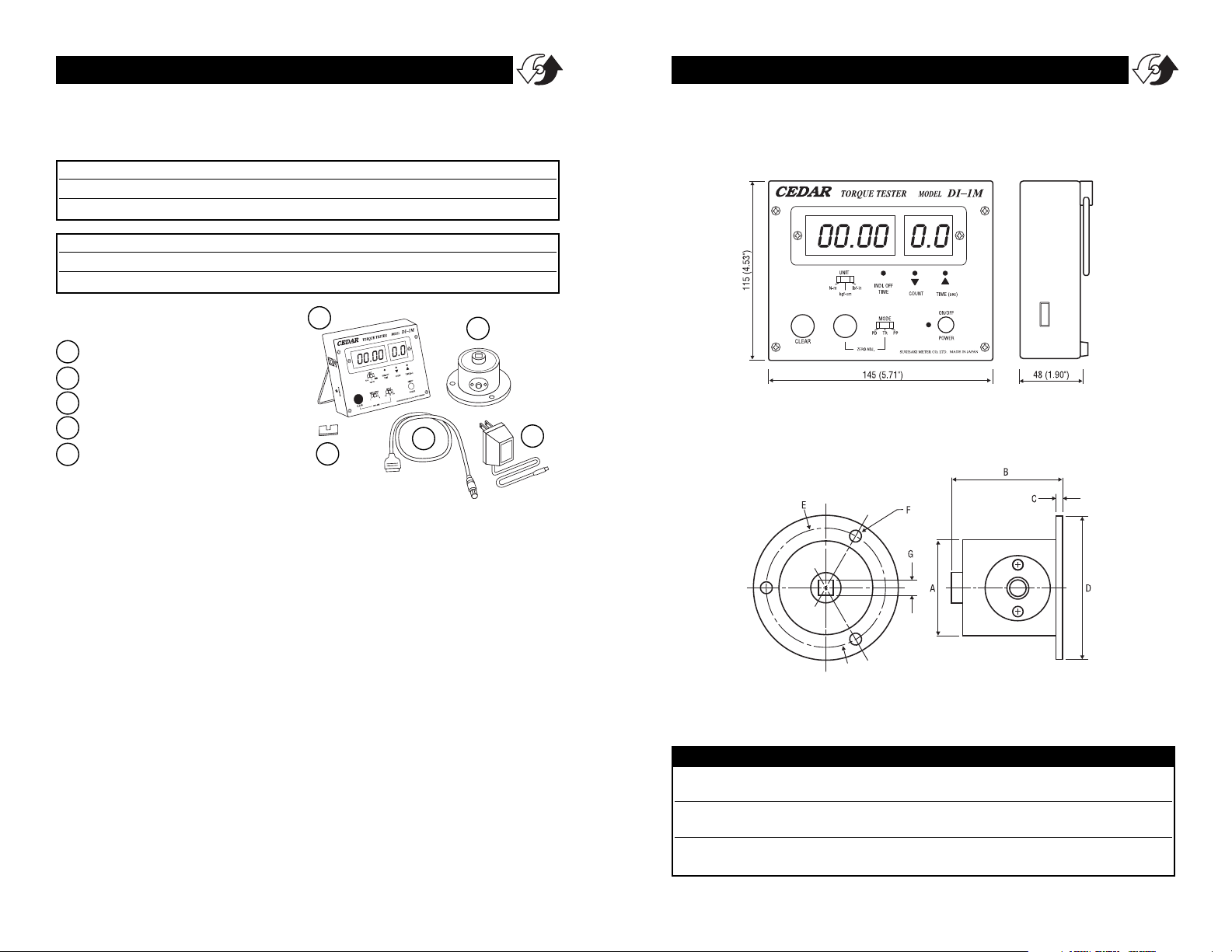

SPECIFICATIONS

LIST OF EQUIPMENT

Torque Tester Display Unit

Torque Sensor

Cable

AC adapter/charger

Units designator

1

2

3

4

5

1

2

3

4

5

READ FIRST: SAFETY INFORMATION

For safety, and for damage avoidance, be sure to read this manual

thoroughly. The warranty is only valid when the product is used following the instructions provided within this manual.

l

Do not use tester in high temperature, high humidity, or in

damp or wet areas.

l

Recommended operating temperature is between 0-42ºC (32100ºF).

l

Do not apply torque exceeding the rated capacity, regardless of

whether the unit is On or Off.

l

When charging the battery, be sure to use the provided AC

adapter/charger exclusively.

l

When measuring torque, the unit will have a tendency to turn. In

order to avoid spinning and possible accident, it is very important to securely mount the unit to a stable work bench.

l

Do not use lacquer thinner or any solvent to clean the unit.

l

Do not disassemble or modify the unit.

Model

lbf-in kgf-cm N-m

DI-1M-50 3.0~440.0 3.0~500.0 30~5000 (

N-cm)

DI-1M-200A 30~1800 30~2000 3.0~200.0

Model

lbf-ft kgf-m N-m

DI-1M-200 3.0~145.0 0.30~20.00 3.0~200.0

DI-1M-500 3.0~362.0 0.30~50.00 3.0~500.0

DI-1M Ranges Accuracy: ±0.5% F.S. ±1 LSD

DIMENSIONS

ABCDEFG

DI-1M-50IP ∅50 63 10 ∅90 ∅76 ∅6.5 9.5

(1.97") (2.48") (.39") (3.54") (2.99") (.26") (3/8" Female Drive)

DI-1M-200IP ∅60 72 10 ∅110 ∅90 ∅9.0 12.7

(2.36") (2.83") (.39") (4.33") (3.54") (.35") (1/2" Female Drive)

DI-1M-500IP ∅80 99 15.5 ∅140 ∅116 ∅10.5 19

(3.15") (3.89") (.61") (5.51") (4.57") (.41") (3/4" Female Drive)

Page 3

page 3page 10

TORQUE MEASUREMENTTORQUE MEASUREMENT

ON/OFF Switch Press to turn on, press again to turn off (click

once, do not hold). After 10 minutes of non-use the unit shuts off.

Mode Select Switch

PD (Peak Down): To capture critical first peak value.

C (Real Time): To display torque transients.

PP (Peak): To capture peak torque achieved during a test.

CLEAR Switch To reset the display or output peak data

Zero Adjustment Pot.

LED Display Displays torque and low battery icon (LOBAT).

Torque Value

Number of Blows

Sensor Cable Receptacle

AC Charger/Adapter Receptacle If LOBAT icon appears,

8-hour battery recharge is required.

System Reset Button When battery has been depleted completely and a recharge has been executed, the system may not

yet work. In this case, press the System Reset Button.

Unit Switch To select measuring units (lbf-in, kgf-cm & N-cm)

USB port (Virtual RS-232 Output)

Blow Counter Duration Timer Use a paper clip to push the

switches, right to increase, left to decrease.

Auto Zero Reset Switch

123 4

5a

5b

6

7

8

91012

11

1

2

3

4

5a

5

5b

6

7

8

9

10

11

12

DI-1M-IP SPECIFICATIONS

DI-1M-IP50 DI-1M-IP200 DI-1M-IP500

Measuring Range 0.30 50 N-m 3.0 200 N-m 3.0 500 N-m

3.0 500 kgf-cm 30 2000 kgf-cm 30 5000 kgf-cm

3.0 430 lbf-in 30 1800 lbf-in 30 4500 lbf-in

Peak Down 0.70N-m 7.0N-m

Operating Range 7.0kgf-cm/lbf-in 70kgf-cm/lbf-in

Accuracy ±0.5 F.S.

Display 4 digit LED

Operation Both CW and CCW

Measuring Modes P-P Peak Mode displays PEAK torque value

that will not change until a higher value is measured.

T-R Real Time Mode displays TRANSIENT torque values.

P-D Output Torque Data every 1/87 seconds.

Auto Clear Automatically zero the display, 0.5 - 3.0 sec,

selectable at 0.5 sec intervals (0.0 sec for manual)

Blow Measurement 0 - 99 blows; 0.1 - 9.9 seconds

Data Output ASCII format (baud rate 19,200)

Power Supply Ni-Cad rechargeable battery 1.2Vx5cells (700mAh)

Auto Shut Off Automatic shut off after 5 minutes of non-use

Charging Time 8 hours

Working Time 8 hours continuous

Meter Weight Approx. 600g

Sensor Weight Approx. 600g Approx. 1kg Approx. 2.5kg

Meter Dimensions 146mm(W) x 115mm(D) x 48mm(H)

Accessories Carrying case, AC/DC adapter

Page 4

page 9

TORQUE MEASUREMENT

page 4

TORQUE MEASUREMENT

GENERAL OPERATION

IMPORTANT! Always make sure that the sensor is mounted securely

to a stable workbench to avoid spinning and possible accident.

1. Connect the torque sensor to the tester display unit with cable

provided. When connecting the cable to the torque sensor,

rotate the round connector to find the matching groove, then

push in until it makes positive connection (When disconnecting

the cable, hold the silver metal part of the round connector and

pull out).

2. Select measuring unit (lbf-in/lbf-ft, kgf-cm/ kgf-m, or N-cm/N-m).

If desired, affix unit designator to prevent it from being accidentally changed.

3. Select among the following

Measurement Modes (For normal testing, PP mode is recommended).

PP (Peak Mode): Capture peak torque

PEAK Torque reading will not change

until a higher value is measured (peak

data output).

C (Real Time Mode): Display torque transient (no output).

PD (Peak Down Mode): Capture first peak value and will not

change even if a higher value is subsequently measured (peak data

output).

4. Press ON/OFF, if the unit does not display zero, select TR mode

and use the Zero Adjustment Pot. to make sure the display

reads zero.

5. Select Peak Mode (PP) or Peak Down mode (PD).

6. The blow counter counts the number of pulses

for a specified time, up to 9.9 seconds. The counter

works in PP mode only. Set the time duration by

using a pointed tool like a paperclip to push the

switches , right to increase, left to decrease.

7. Insert wrench drive securely into the sensor, hold

perpendicularly (not at an angle), and turn on

the tool to measure.

8. After taking measurement, press CLEAR to

zero the display for the next test.

11

3

4

SW-1SV-USB is a highly customized

Excel spreadsheet specifically

designed for capturing and analyzing real-time data from Cedar

torque instruments with a USB

port. SW-1SV-USB provides a running log of all measurements along

with a graph and statistical information including min, max, mean,

median, standard deviation, average

deviation and variance.

Requirements

1. PC computer with Windows XP or later and Excel 2000 or later.

2. CB-208 or CB-209 cable

Optional Data Acquisition Software SW-1SV-USB

Page 5

page 5

TORQUE MEASUREMENT

page 8

TORQUE MEASUREMENT

Auto Power Off

To maximize the life of the battery, power will automatically shut

off after 10 minutes of non-use.

System Reset Button

When battery has been depleted completely and a recharge has

been executed, the system may not yet work. In this case, press the

System Reset Button .

Low Battery Indicator

“–L– –” will appear when tester needs to be recharged. Turn off

power.

IMPORTANT! Use the provided IMADA/CEDAR AC adapter/charger

exclusively and plug into the correct AC output. It takes 8 hours to

charge fully. Do not recharge for more than 12 hours. When it is

fully charged, make sure the AC adapter/charger is disconnected to

avoid overcharging.

In order to avoid high heat, explosion or toxic fumes, please note

the following precautions:

Be sure to use the provided AC charger exclusively.

Do not plug the charger into unspecified higher voltage.

Do not recharge until LOBAT icon appears.

8

Auto Zero Reset Switch for Peak or Peak Down mode

Rather than resetting manually for each test, the Automatic Zero

Reset can be programmed by using a paperclip to push the Auto

Zero Reset Switch .

As the Auto Zero Reset Switch is pressed (use a pointed tool,

like a paperclip end), the Automatic Zero Reset durations cycle.

(0.0C Þ 0.5C Þ 1.0C Þ 1.5C Þ 2.0C Þ 2.5C Þ 3.0C) Select the

desired duration. For example, 0.5C means 0.5 second and 0.0C

means MANUAL RESET. If a selection is not made within 3 seconds,

the cycle begins again.

12

12

Virtual RS-232C Serial Output

Output is available in PD, PP and C modes. In PD and PP modes peak

data is output when ZERO is pressed or activated by the AUTO ZERO

function.

Comport signal

8 data, 2 stop, no parity. Baud Rate: 19,200 bps.

Output Connector

USB A/B cable

Peak Data Output Format

[CAN] _ _ _ [SO] [value] _ [SI] [unit] [CR]

(_ _ _ is memory location)

[CAN]: ASCII control code 24

_: Space (code 32)

[SO]: ASCII control code 14

[value]: Output data with sign and decimal point. Plus sign

represents for CW torque and minus sign for CCW.

[Value] always occupy six locations and empty

locations will be filled with spaces.

[SI]: ASCII control code 15

[unit]: N*m _ _ _=N.m

kgf*cm = kg.cm

lb*in _ = lb.in

[CR]: ASCII control code 13 (Carriage Return)

Continuous Output Data Format

[CAN] [value] [CR]

Page 6

page 7

TORQUE MEASUREMENT

page 6

TORQUE MEASUREMENT

OUTPUT

USB Virtual COM Port

When the tester is connected to a computer’s USB port and turned

on, Windows XP or Vista will recognize the tester and ask to connect to the Internet. Allow Windows Update to connect to the

Internet and follow the instructions on your screen to download

and install two drivers for the USB virtual com port. For Windows

98, ME and MAC go to www.ftdichip.com/Drivers/VCP.htm.

The PC and tester will communicate through the USB port the same

as a com port. To verify the COM port number open the Device

Manager.

Output is available in PD, PP and C modes. In PD and PP modes peak

data is output when ZERO is pressed or activated by the AUTO ZERO

function. In C mode, the gauge outputs data continuously 180

data/second.

Loading...

Loading...