Page 1

OPERATION MANUAL

DAKOTA ULTRASONICS

DDFFXX--77

Ultrasonic Flaw Detector

(Manual 2 of 2)

P/N P-220-0002 Rev 1.0, June 2011

Page 2

Page 3

CHAPTER ONE INTRODUCTION ...................................................................... 1

CHAPTER TWO QUICK START GUIDE ............................................................ 3

CHAPTER THREE KEYBOARD, MENU, & CONNECTOR REFERENCE ......... 7

CHAPTER FOUR SETTING UP FOR MEASUREMENT .................................. 23

CHAPTER FIVE CALIBRATION ....................................................................... 35

CHAPTER SIX TRIGONOMETRY MODE ........................................................ 50

CHAPTER SEVEN AWS – WELD INSPECTION ............................................. 55

CHAPTER EIGHT DISTANCE AMPLITUDE CORRECTION (DAC) ................ 60

CHAPTER NINE TIME CORRECTED GAIN (TCG) ......................................... 66

CHAPTER TEN ADDITIONAL FEATURES OF THE DFX-7 ............................. 71

CHAPTER ELEVEN DATA STORAGE – SETUP, EDIT, & VIEW FILES ......... 95

CHAPTER TWELVE SETUPS – CREATE, STORE, EDIT, & RECALL ......... 120

CHAPTER THIRTEEN USING THE UTILITY SOFTWARE ............................ 130

APPENDIX A - VELOCITY TABLE ................................................................. 132

APPENDIX B - SETUP LIBRARY ................................................................... 134

Page 4

Page 5

CHAPTER ONE

INTRODUCTION

The Dakota Ultrasonics model DFX-7 is both, an ultrasonic flaw detector, as well as

an ultrasonic A/B Scan thickness scope, in a single unit. It’s a combination of both

our CMX DL+, as well as our new DFX-7 flaw detector series. Why is this

advantageous? Thickness gauge are specifically setup to very accurately measure

thickness, locate pits, flaws and blind surface corrosion. All the linearity tables,

correction curves for various types of longitudinal transducers and features are built

with dimensional thickness as its primary focus. Flaw detectors are designed to

detect, size, position, and differentiate between flaw types in various materials and

welded joints. A flaw detector must be fast, in terms of its sample and screen refresh

rate, as inspectors are generally scanning the surface of a part or test specimen at a

relatively high speed, rather than looking for the thickness at a specific point or

location. While flaw detectors can also measure material thickness with reasonable

accuracy, they are not designed with precision thickness as their primary focus.

The DFX-7 combines the two types of gauges into one powerful and full featured

instrument, that’s equipped with a number of comprehensive toolkits to provide the

user the arsenal necessary to address a number of common field applications. In

and effort to avoid complexity issues and differential between gauges types, this

manual focuses only on the flaw detector portion of the DFX-7.

Dakota Ultrasonics maintains a customer support resource in order to assist users

with questions or difficulties not covered in this manual. Customer support may be

reached at any of the following:

Dakota Ultrasonics Corporation

1500 Green Hills Road, #107

Scotts Valley, CA 95066 USA

Telephone: (831) 431-9722

Facsimile: (831) 431-9723

www.dakotaultrasonics.com

1.1 General Disclaimer

The manual should be read and understood prior to using the DFX-7. This operating

manual provides the user with all the general information necessary to use and

operate the features of the DFX-7. However, this manual is not a certified NDT

training course, nor is it intended to be one. Ultrasonic training for sound wave

theory, flaw detection and interpretation of defects is highly recommended, and will

be required by most companies and contract services. Contact the local NDT society

in your area to inquire about training available in your locality.

Page 6

1.2 Electrical Warning

The DFX-7 contains a high voltage pulser. It’s recommended that the gauge be

powered off prior to connecting or disconnecting your transducer, to avoid damaging

the DFX-7.

Page 7

CHAPTER TWO

QUICK START GUIDE

This section will cover a basic quick start guide to initially get up and running with the

DFX-7 for demonstration purposes only. However, in order to use the gauge and

features for actual applications, a thorough review of this manual is recommended.

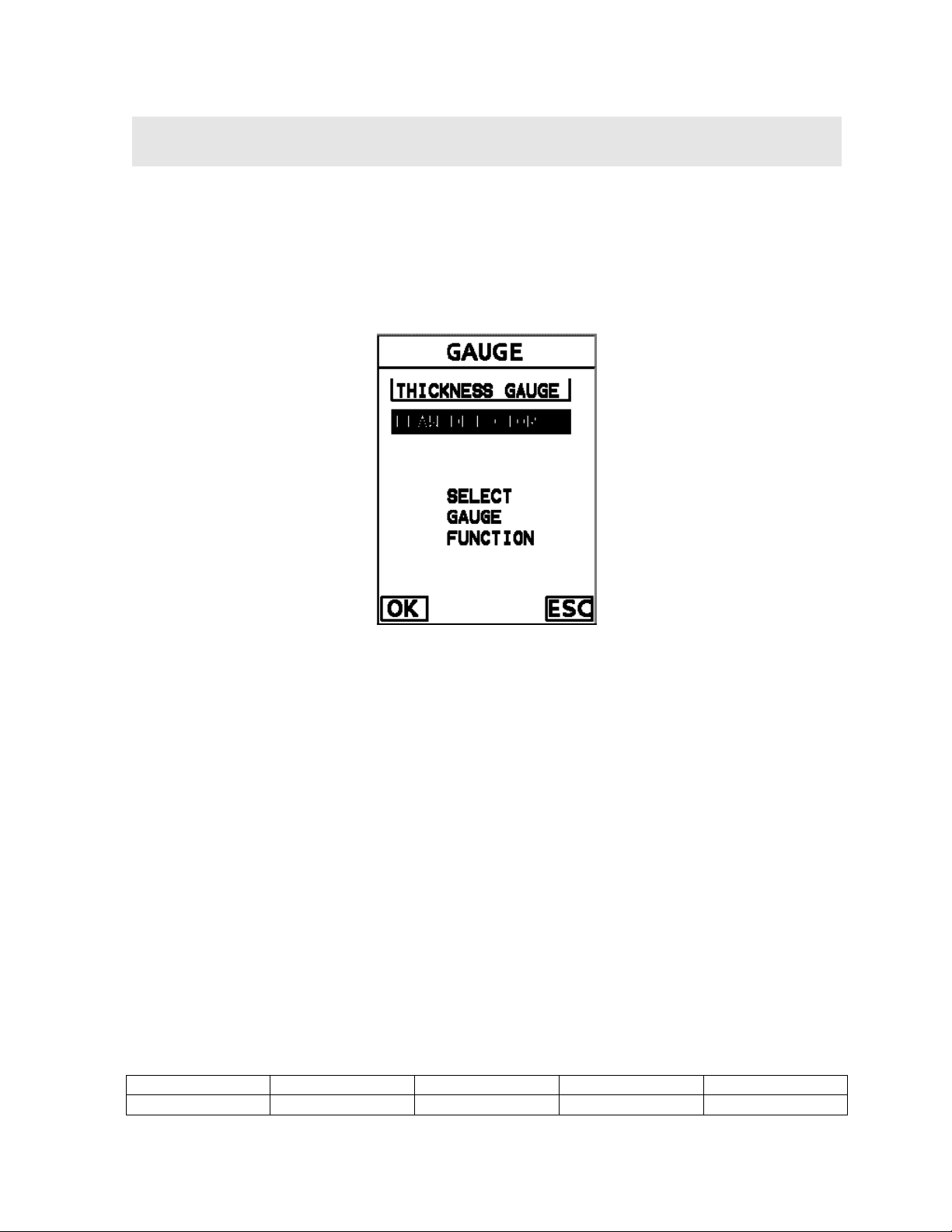

2.1 Gauge Type

Power up the DFX-7, by pressing the on/off key located in the bottom right corner of

the keypad. During initial boot up, a flash screen and lights will be displayed,

followed by a GAUGE TYPE selection screen. Since this manual will focus on the

flaw detector portion of the DFX-7, use the UP/DOWN arrow keys to select “flaw

detector”, followed by pressing the OK key start the DFX-7 in flaw mode. If this is the

first time the gauge has been used, a general startup configuration will automatically

be loaded and the DFX-7 is ready for general inspections. If this is not the first time

the gauge has been used, and the user would like to reload the basic default setup

parameters, refer to section 12.5 for further info.

Note: The default setup should only be considered as a basic setup. Proper

calibration and parameter settings should be done prior to an actual inspection.

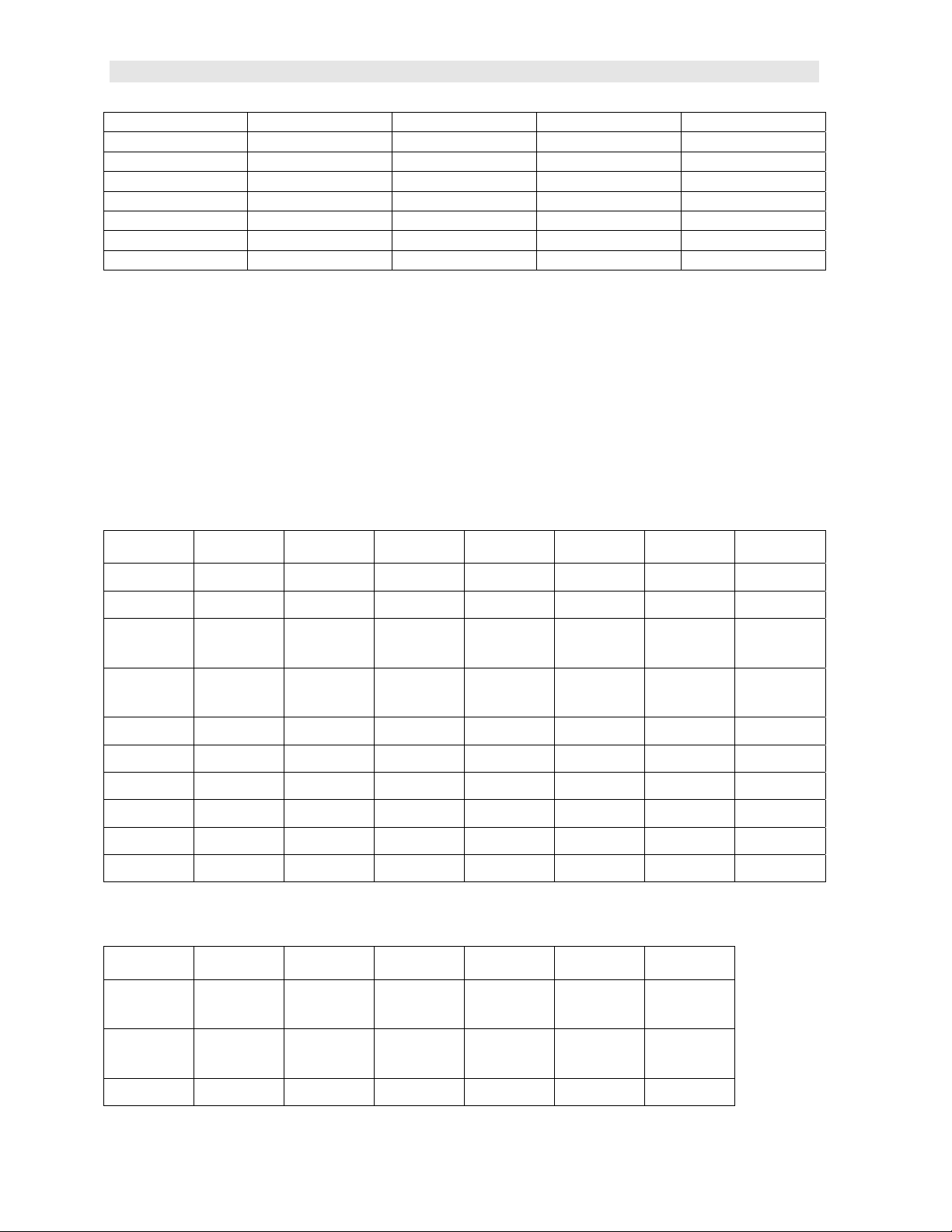

2.2 Basic Flaw Setup Reference

The following table lists all the settings for the basic flaw setup:

PRB CAL DISP TUNE GT1

Type: Single Matl: Steel 1020 View: +Rect Filters: Wide Alarm: On

3

Page 8

Dakota Ultrasonics

Pulse: Thin Matl 1pt: Uncal Delay: 0.000 Gain: 65 Gate1: 0.484

Max PRF: 66 Matl 2pt: Uncal Range: 5.011 Detect Mode: Z-Cross Thresh1: 40%

Damping: 600 Velocity: .2320 Units: inches Width1: INF

Pulser Volt: 200 Zero: 0.0 Brightness: 15 Detect: Above

View: Green 1 Polarity: Pos

Dim: Off

Rect Wave: Filled

Detect Mark: None

Note: The following features are set to off: GT2, TRIG, AWS, TCG, DAC, DGS.

2.3 Top & Submenu Reference

The following table is a quick menu reference guide. The DFX-7 has 15 top level

menu titles, and multiple submenu items as illustrated below. Refer to Chapter Three

for additional definitions and information on the keypad and menu items.

Start >>

PRB CAL DISP TUNE GT1 GT2 TRIG AWS

TYPE MAT VIEW FILTERS ALARM ALARM TRIG AWS

PULSE MATL 1PT DELAY MAX PRF DETECT DETECT THICKNESS SET REF GAIN

DAMPING MATL 2PT RANGE GAIN GATE1 GATE2 ANGLE % SCRN

HEIGHT

PULSER

VOLTAGE

ZERO BRIGHTNESS THRESHOLD1 THRESHOLD2

COLORS POLARITY1 POLARITY1

DIM

RECT WAVE

DETECT MARK

VELOCITY UNITS DETECT MODE GATE1 WIDTH GATE2 WIDTH X-OFFSET

>> End

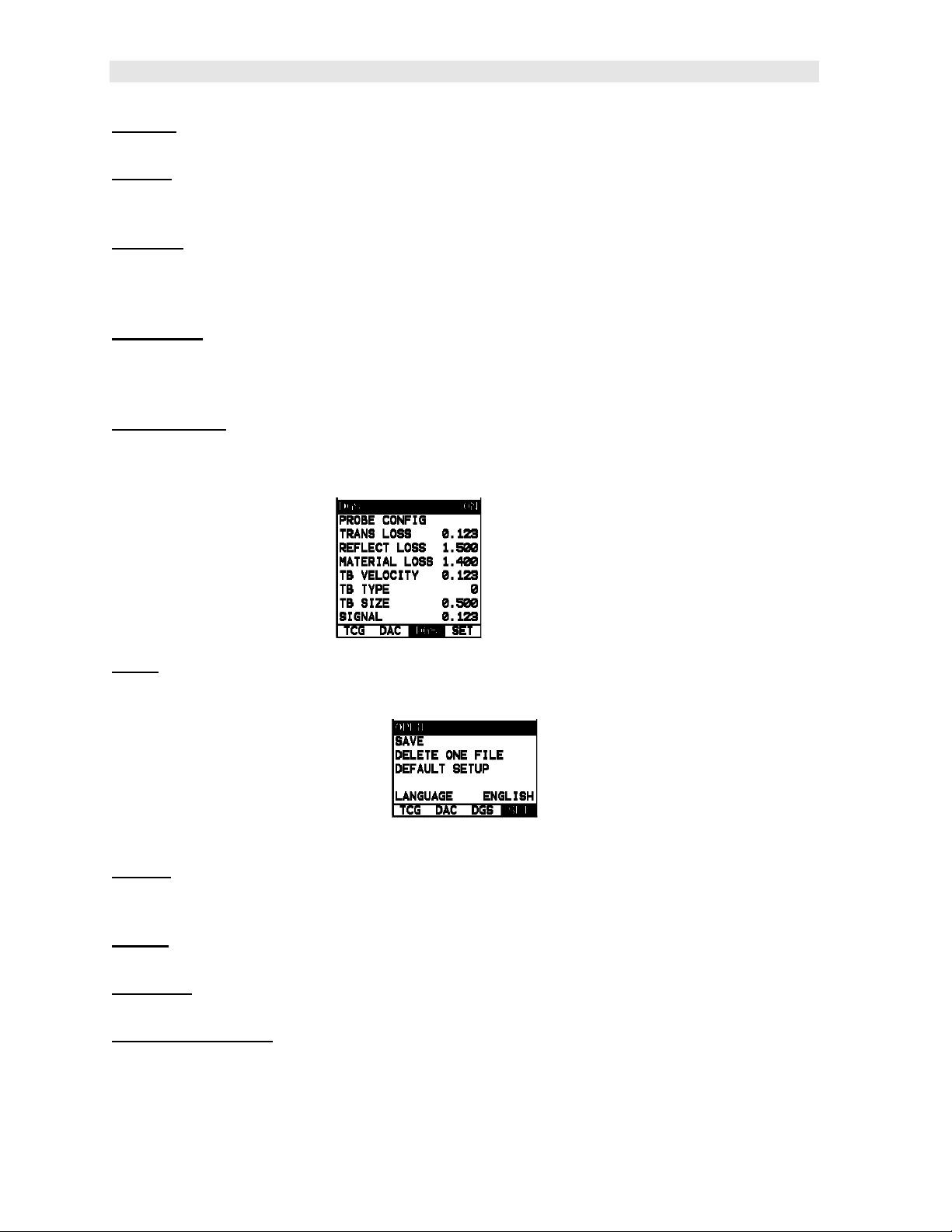

TCG DAC DGS SET DATA UTIL XFER

TCG DAC DGS OPEN NEW AUTO FIND BACKUP

SETUPS

DRAW DRAW PROBE

CONFIG

CURVE MEAS TRANS LOSS DELETE ONE OPEN BACKUP DATA

SAVE EDIT GAUGE RESTORE

SETUPS

4

Page 9

FILE

DFX-7 Ultrasonic Flaw Detector

% SCRN

HEIGHT

TRIGGER MATERIAL

DPOLARITY TB VELOCITY DELETE ALL

TB TYPE

TB SIZE

SIGNAL

CURVE REFLECT

LOSS

LANGUAGE DELETE ONE

LOSS

DEFAULT

SETUP

CLOSE RESTORE

DATA

ABOUT

FILE

DATA

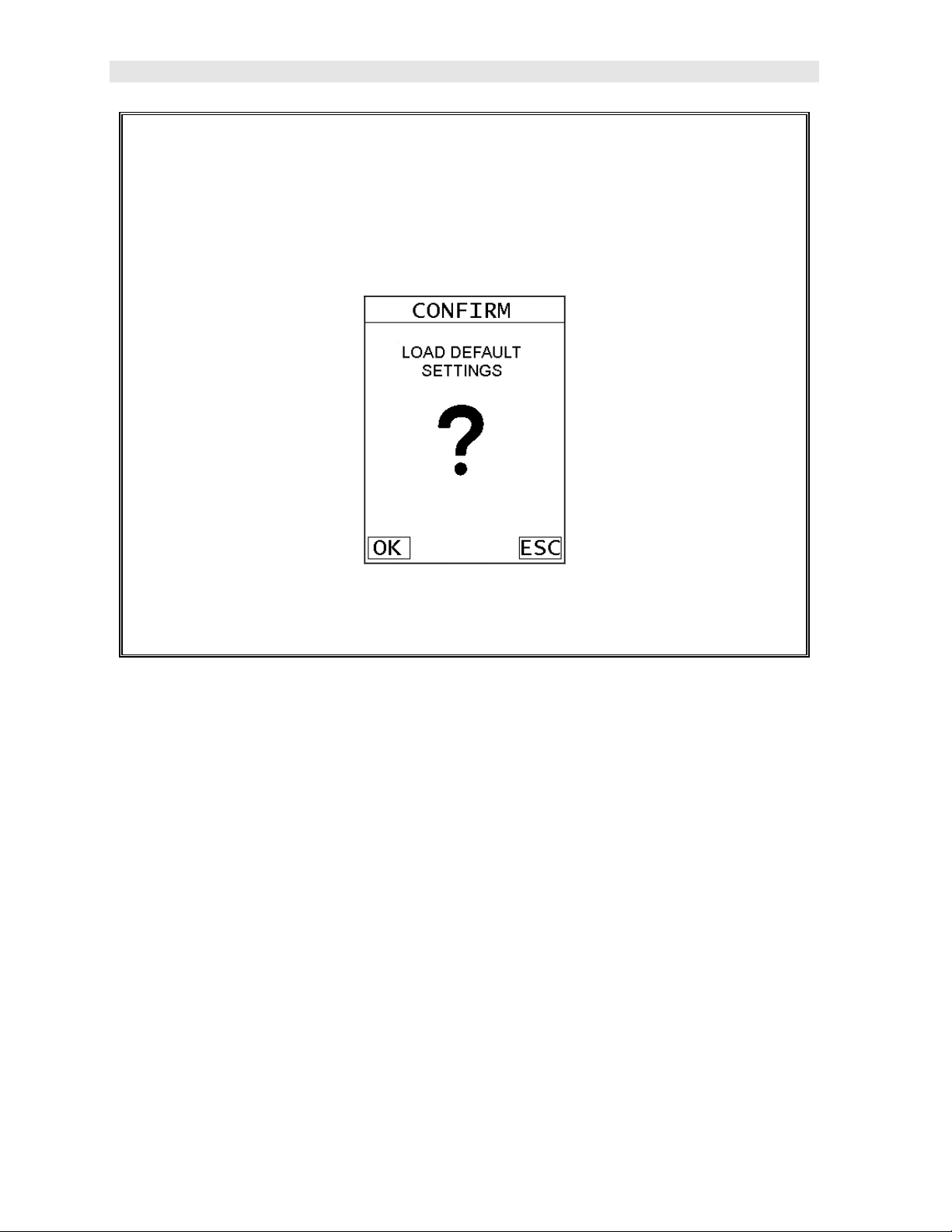

2.4 Loading the Default Setup

If the DFX-7 has previously been used, the basic default settings can be reloaded at

any time, as outlined below:

Load Default Setup

The following section assumes the gauge is powered up, the flaw detector

option selected, and the main measurement screen is being displayed.

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the SET menu is highlighted and displaying the submenu items.

5

Page 10

Dakota Ultrasonics

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until DEFAULT SETUP is highlighted.

3) Press the ENTER key to display the confirmation screen.

4) Press the OK key to load the default setup and return to the measurement

screen.

6

Page 11

CHAPTER THREE

KEYBOARD, MENU, & CONNECTOR REFERENCE

3.1 Menu Key (Operation & Sub Menus)

The Menu key activates the primary menu structure containing 15 menu tab groups.

These tab groups then contain sub menu items, or functions. The sub menu items

have been organized in the tab groups according to how closely they are related to

the individual tab group names. Let’s first get familiar with how to move around in

these tabs before continuing on to the sub menu functions. This procedure is

outlined below:

7

Page 12

Dakota Ultrasonics

Activating and Navigation of the Menu Items

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right, and the ESC key multiple times to tab left

until the desired tab group is highlighted and displaying the submenu items.

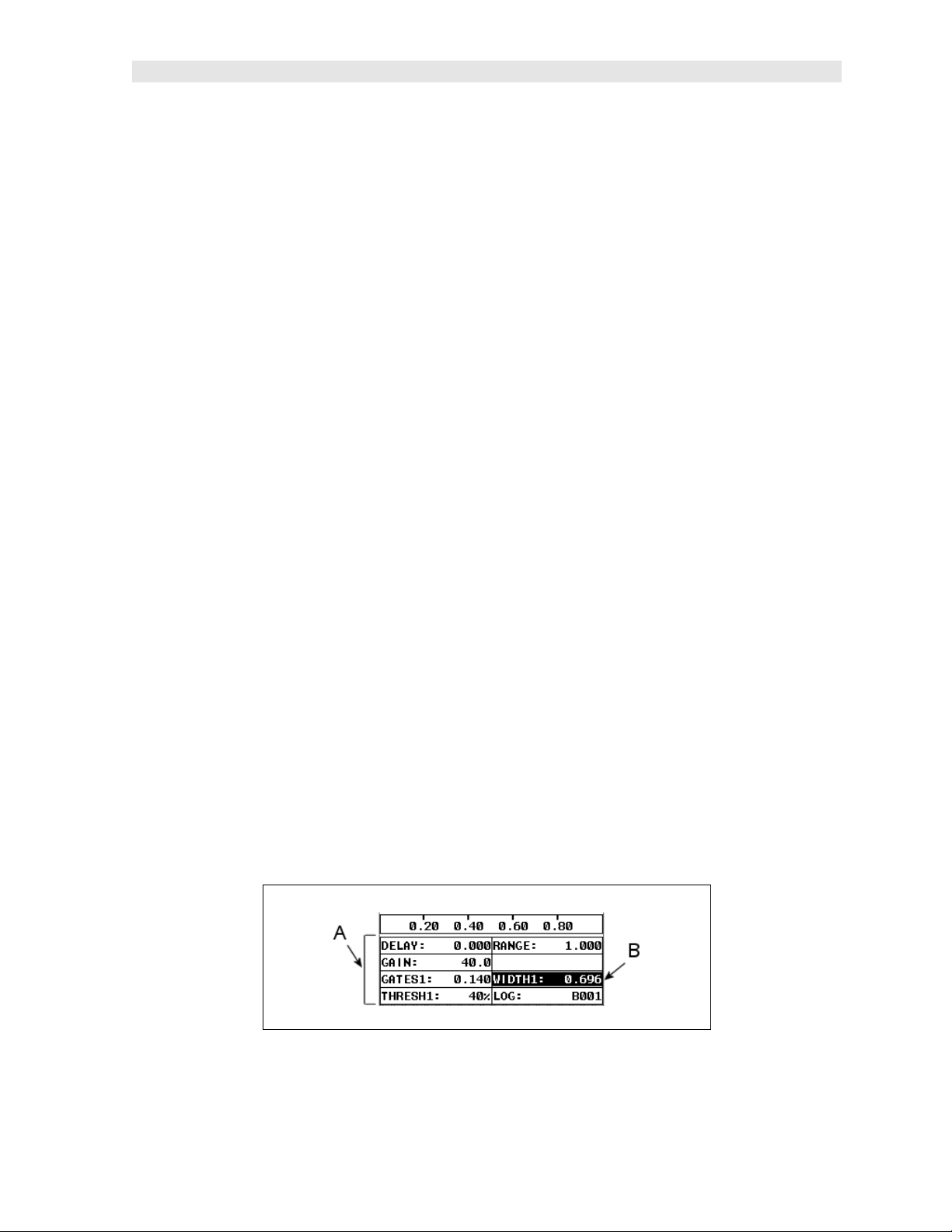

The tab groups are illustrated above (A).

Now that you’re familiar with activating and moving amongst the tab groups,

let’s have a look at how to move around in the sub menu items as follows:

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until the desired function is highlighted. The sub menu items are illustrated

in the diagram above (B).

3) Depending on which function is highlighted, use the LEFT, RIGHT, and

Enter keys to scroll the options or activate the Digit Edit and List Box

options.

The sections to follow will provide the user with an explanation of the sub menu

functions:

8

Page 13

DFX-7 Ultrasonic Flaw Detector

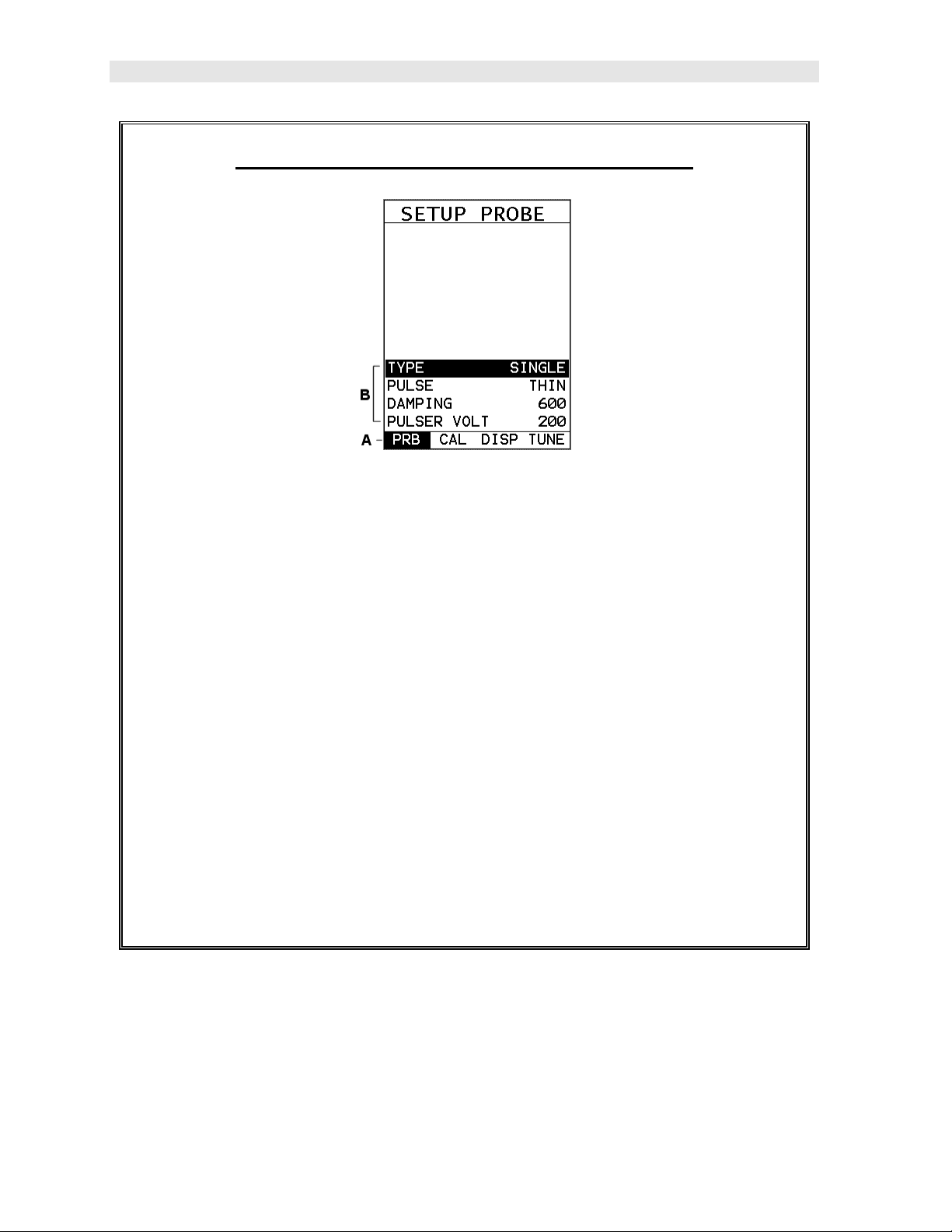

3.2 Probe – Menu

TYPE:

Dual.

PULSE: The DFX-7 has an adjustable pulse width for both high penetration and

resolution applications. The pulse width refers to the duration of time the pulser is

on. The options are Spike, Thin, and Wide. Refer to page 86 for a further

explanation.

MAX PRF: This feature controls the pulse repetition frequency of the DFX-7. The

maximum frequency is 333 Hz. However, the DFX-7 will automatically adjust the

PRF according to what the current delay and range settings have been adjusted to.

Larger the range, the slower the repetition frequency will automatically be set for.

DAMPING: The ability to control the amplifiers output impedance to match the

impedance of the transducer, and optimize overall transducer performance.

Adjustable at: 50, 100, 300, 600, 1500 ohms. Refer to page 90 for further info.

PULSER VOLT: Adjustable pulser voltage: 100, 150, and 200 volt. Refer to page

87 for a further explanation.

Enables the user to select the type of transducer being used, either Single or

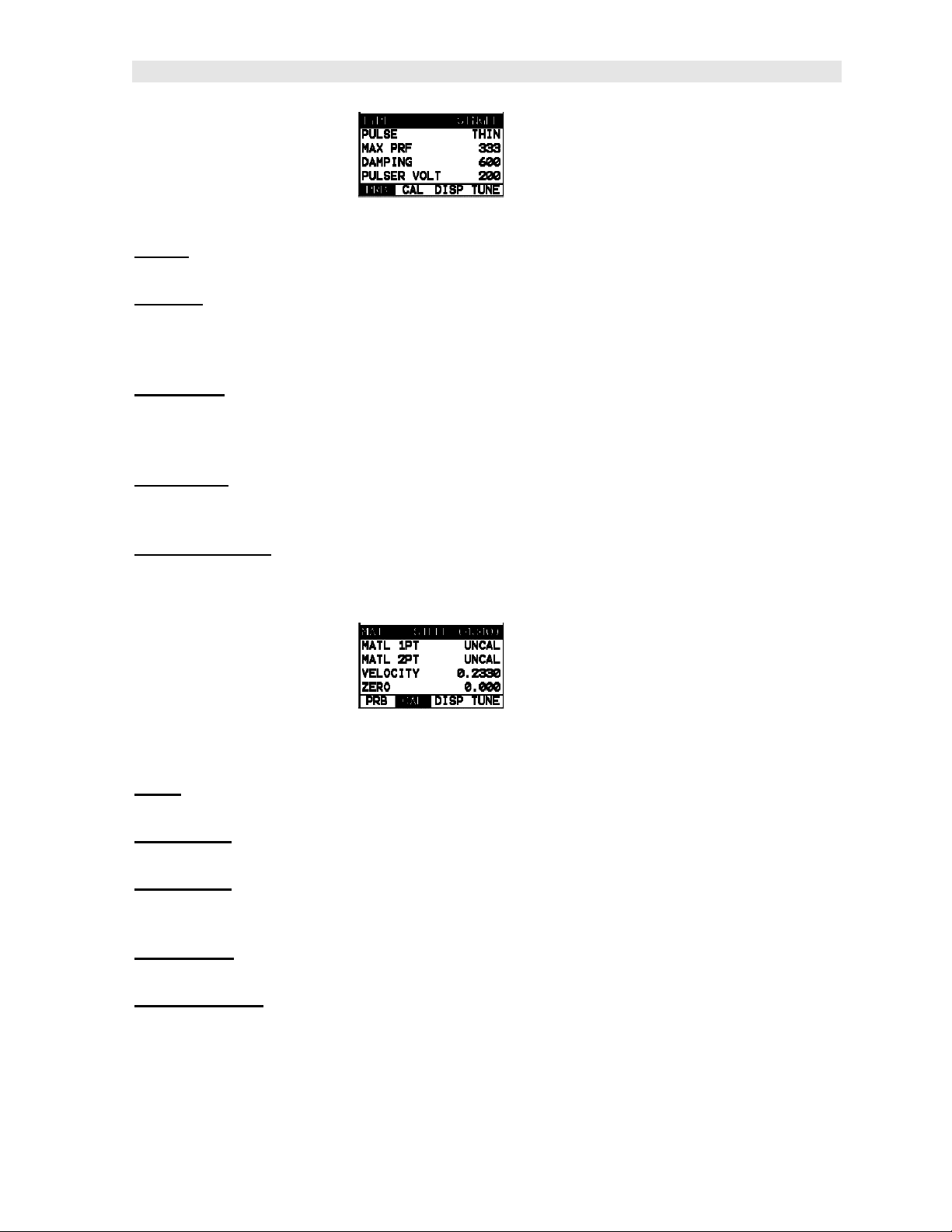

3.3 CAL – Menu

Select the material velocity from a chart of basic material types when a known

MAT:

sample thickness, or material velocity cannot be obtained.

MATL 1PT: Performs a single point calibration. Used in conjunction with the MATL

2PT option for the calibration process. Refer to page 35 for further info.

MATL 2PT: Performs a two-point calibration. This option allows the user to

automatically calculate the velocity by entering a second known sample thickness.

Refer to page 35 for further info.

VELOCITY: Function to calibrate the DFX-7 by setting the velocity to a known

material velocity. Refer to page 71 for further info.

ZERO PROBE: Used to zero the transducer and calibrate the screen. The DFX-7 is

zeroed in much the same way that a mechanical micrometer is zeroed. If the DFX-7

is not zeroed correctly, all of the measurements made using the DFX-7 may be in

error by some fixed value. Refer to the section on page 35, for further info.

9

Page 14

Dakota Ultrasonics

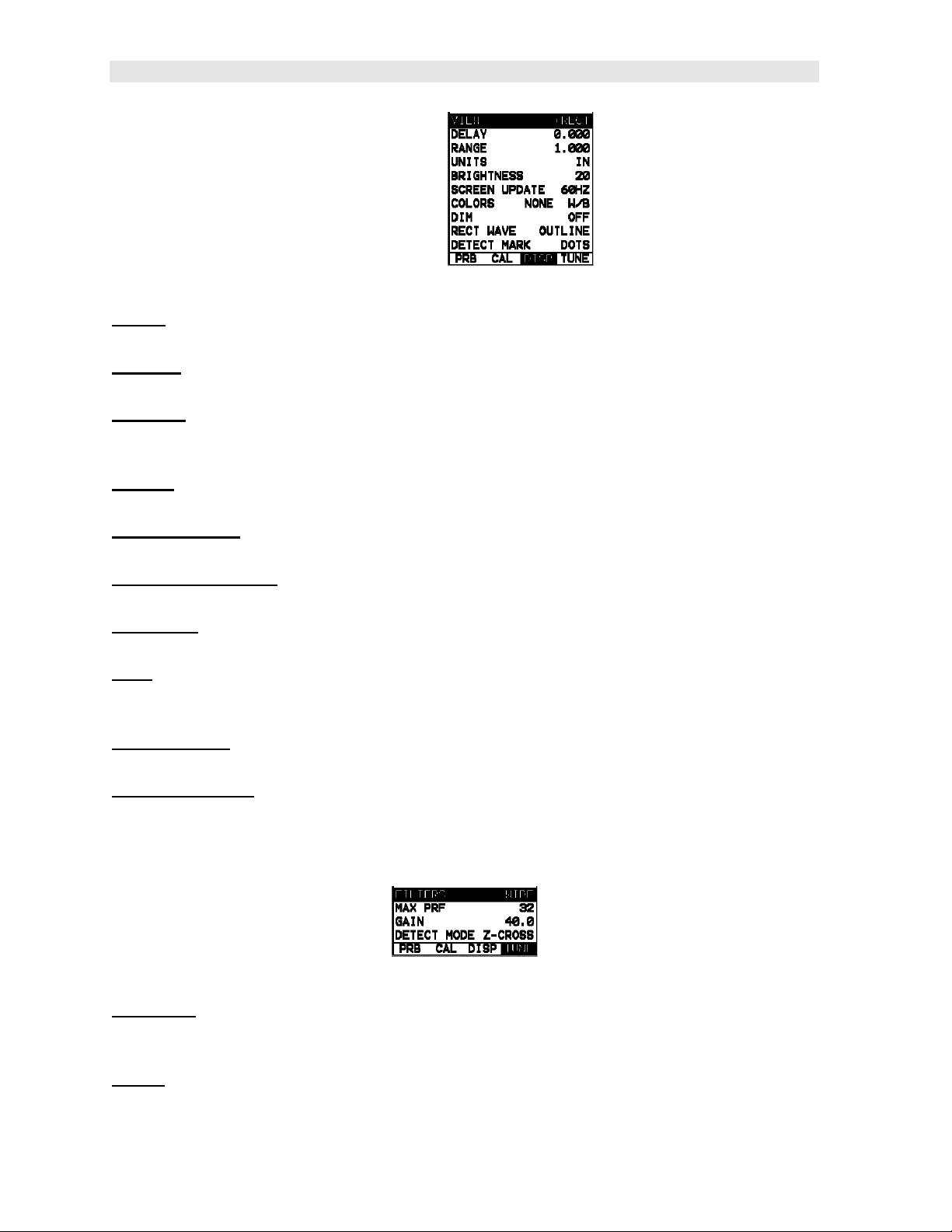

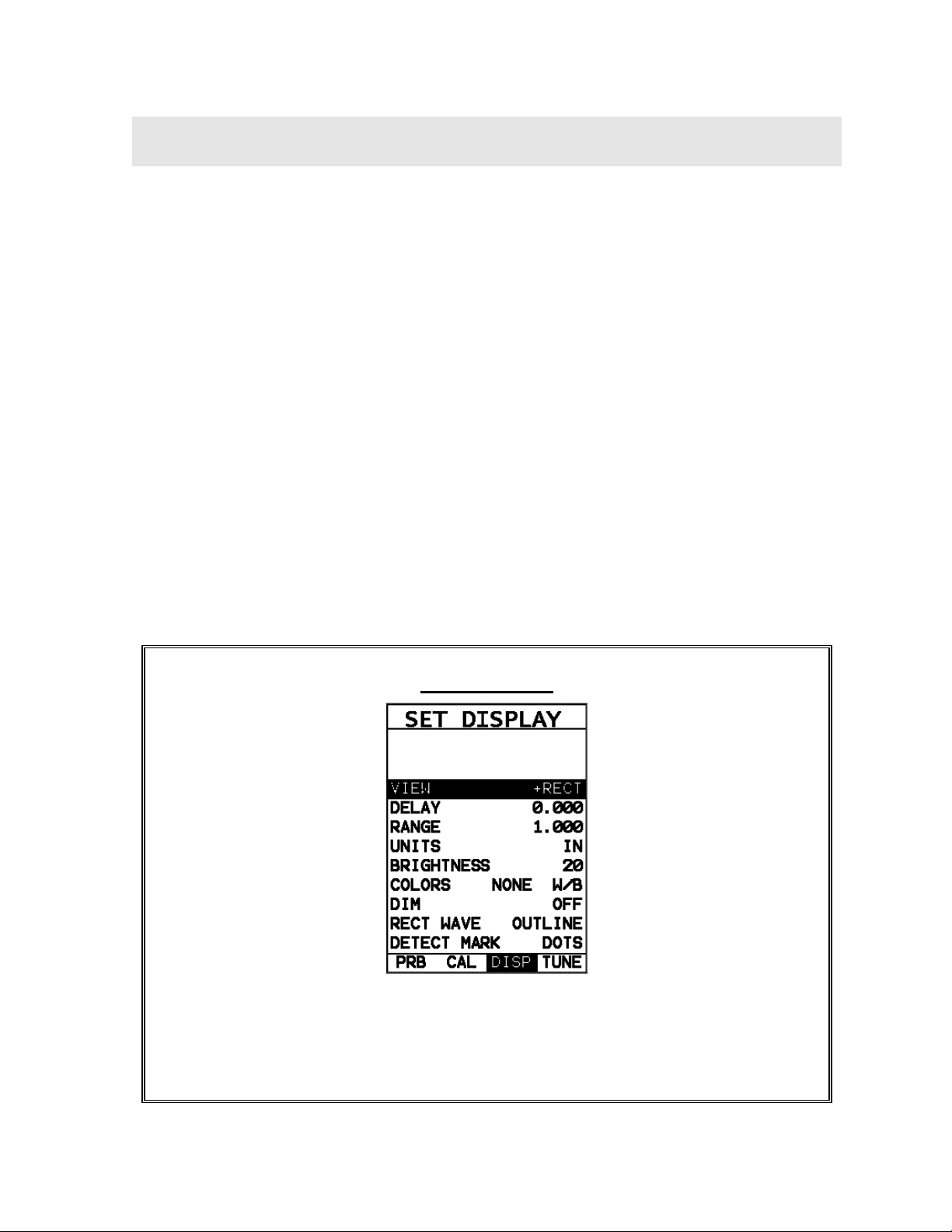

3.4 DISP (display) – Menu

VIEW: Selectable RF, +RECT, -RECT, RECTFW views. Refer to page 23 for further

info.

DELAY:

views. Refer to page 24 for further info.

RANGE:

viewable measurement area. It functions a lot like a zoom on a camera. Refer to

page 24 for further info.

UNITS: Toggle between English or Metric units. The readout will change from

inches to millimeters.

BRIGHTNESS: AMOLED high speed color display. An arbitrary scale of 1-20 has

been implemented, with the brightest setting at 20. Refer to page 76 for further info.

SCREEN UPDATE: Toggles how fast the display will redraw. Options are 60Hz or

120Hz. The 60Hz option conserves battery life. Refer to page 88 for further info.

COLORS: Provides the user with a variety of different color schemes to select from.

There are two schemes for each main color option. Refer to page 77 for further info.

DIM: Allows the user to conserve battery life by diming the display after idle for a

specific amount of time – OFF, 30, 60, 90, 120 seconds. Once dimmed, a single

press of any key will restore the screen brightness. Refer to page 79 for further info.

RECT WAVE: Provides the user an outlined or filled view option when the display

setting is in RECT (rectified) wave mode only. Refer to page 80 for further info.

DETECT MARK:

waveform: Line, Box, Dots, None. Offers the user a graphics preference on how

they prefer to view the detection on the waveform.

Provides the user the ability to change the start position of the A-SCAN

Provides the user the ability to change the overall range/depth of the

Selectable graphics option for the point of detection on the

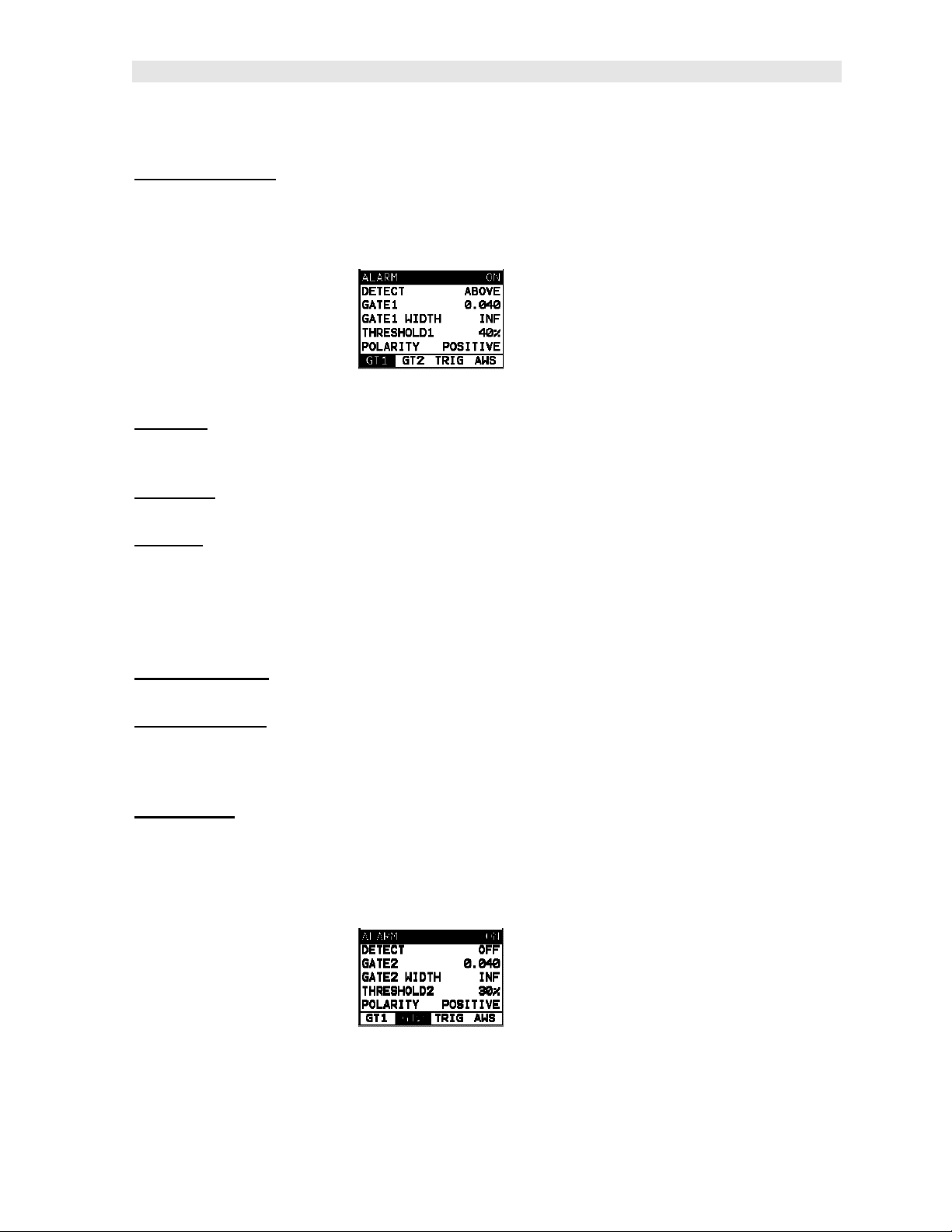

3.5 TUNE – Menu

FILTERS:

19 MHz (-3dB). The DFX-7+ is additionally equipped with selectable narrow band

filters at; 2, 5 & 10 MHz. Refer to page 91 for further info.

GAIN:

used to increase/decrease the strength or amplitude of the signal. This might easily

The DFX-7 is a wide band flaw detector with a frequency range of 1.8 to

The DFX-7 has a 0-110dB gain range with 2dB resolution. This feature is

10

Page 15

DFX-7 Ultrasonic Flaw Detector

be considered as similar to turning the volume up or down on a stereo receiver.

Refer to page 27 for further info.

DETECT MODE: The DFX-7 is equipped with optional detection modes; PEAK,

FLANK, or Z-CROSS (zero crossing). This options allows the user to decide where

the detection is acquired on the waveform echo. Refer to page 84 for further info.

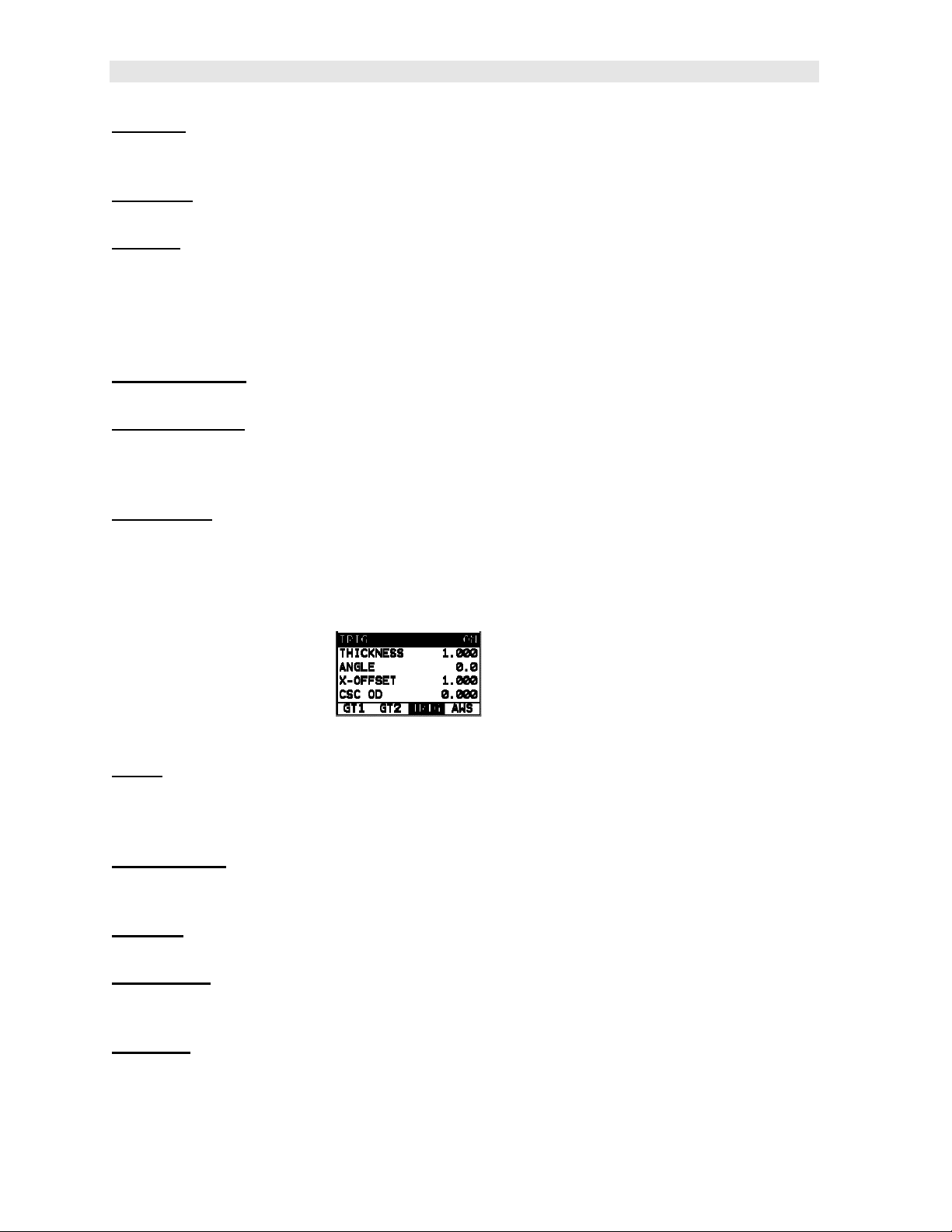

3.6 GT1 – Menu

ALARM: Toggles the alarm function of gate 1; on, off, audible. The audible feature

sounds a beeper when the waveform breaks the threshold level, either above or

below, depending on the current DETECT setting. Refer to page 30 for further info.

DETECT: Enables the user to set the alarm detection to occur either above or below

the gates threshold level. Refer to page 30 for further info.

GATE1: Gates allow the user to view a specific inspection/measurement range, or

specific regions of the waveform, while ignoring others. In order to detect on a

waveform echo, and display the amplitude as a percentage of full screen height, the

echo must be inside the boundaries of the gate settings. The GATE1 feature adjusts

where the gate begins, according to the depth/thickness. Refer to page 30 for further

info.

GATE1 WIDTH: This feature allows the user to set the overall width of the gate, in

terms of distance, from the GATE1 setting. Refer to page 30 for further info.

THRESHOLD1: Enables the user to set the sensitivity level of Gate1 to a calibrated

screen height percentage. The threshold level will act as a starting point for the

alarm trigger, and is directly associated with the DETECT setting outlined above.

Refer to page 30 for further info.

POLARITY:

polarity, or stroke, of the half or full wave cycle. It should be noted that if the VIEW is

set to positive, and the gate negative, the DFX-7 will not display an amplitude

percentage of full screen height. Refer to page 30 for further info.

The gates can be set to detect on either the positive or negative

3.7 GT2 – Menu

11

Page 16

Dakota Ultrasonics

ALARM: Toggles the alarm function of gate 2; on, off, audible. The audible feature

sounds a beeper when the waveform breaks the threshold level, either above or

below, depending on the current DETECT setting. Refer to page 30 for further info.

DETECT: Enables the user to set the alarm detection to occur either above or below

the gates threshold level. Refer to page 30 for further info.

GATE2: Gates allow the user to view a specific inspection/measurement range, or

specific regions of the waveform, while ignoring others. In order to detect on a

waveform echo, and display the amplitude as a percentage of full screen height, the

echo must be inside the boundaries of the gate settings. The GATE2 feature adjusts

where the gate begins, according to the depth/thickness. Refer to page 30 for further

info.

GATE2 WIDTH: This feature allows the user to set the overall width of the gate, in

terms of distance, from the GATE2 setting. Refer to page 30 for further info.

THRESHOLD2: Enables the user to set the sensitivity level of Gate2 to a calibrated

screen height percentage. The threshold level will act as a starting point for the

alarm trigger, and is directly associated with the DETECT setting outlined above.

Refer to page 30 for further info.

POLARITY: The gates can be set to detect on either the positive or negative

polarity, or stroke, of the half or full wave cycle. It should be noted that if the VIEW is

set to positive, and the gate negative, the DFX-7 will not display an amplitude

percentage of full screen height. Refer to page 30 for further info.

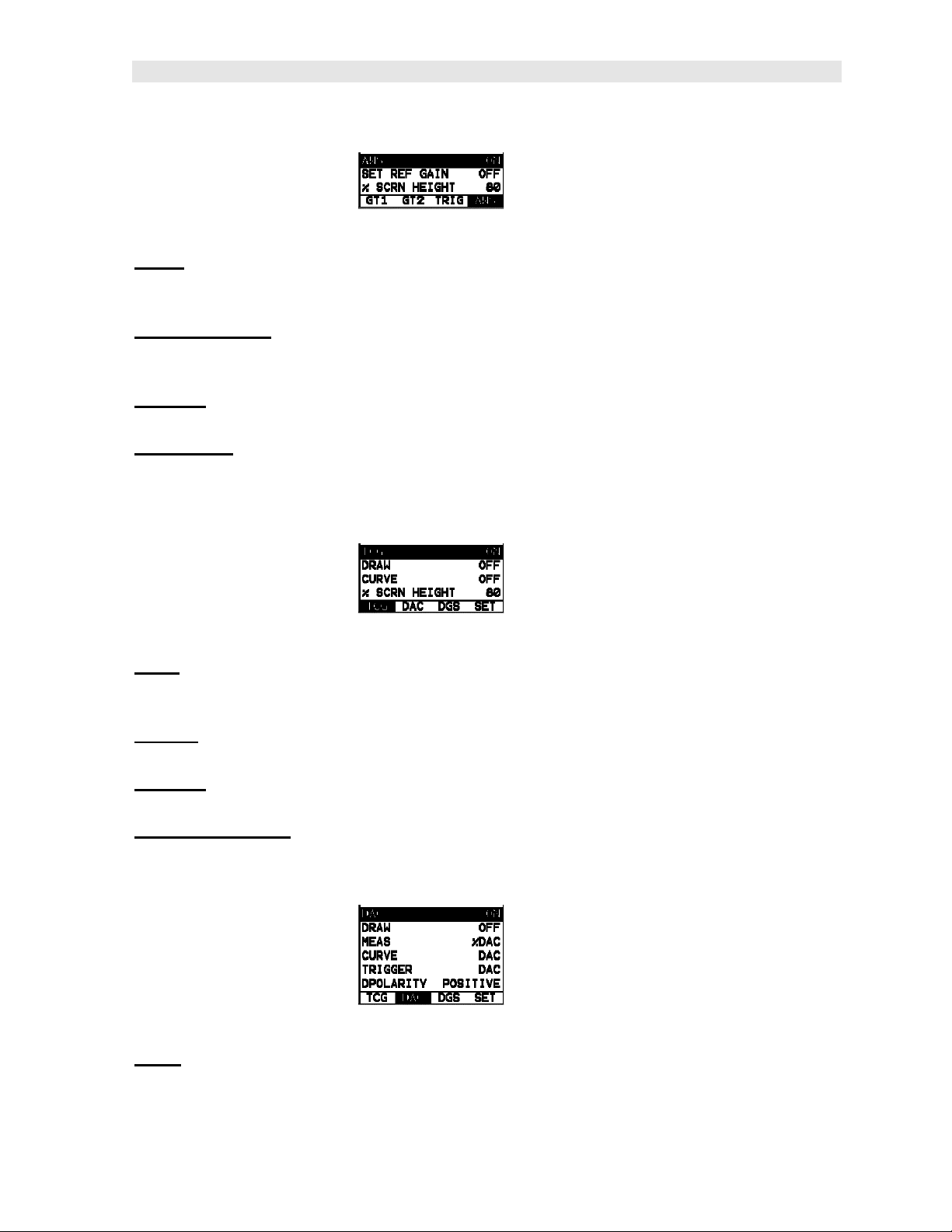

3.8 TRIG – Menu

TRIG: This feature toggles trigonometry feature on/off. This feature is used with

angle beam transducers for the inspection of welds, to calculate three

measurements: Beam path distance (Ì), Surface distance (Æ), and Depth (È) from

the index point of the transducer. Refer to page 50 for further info.

THICKNESS: Used to set the thickness of the test material. The thickness will be

used to determine which skip/leg the DFX-7 is detecting on. Refer to page 50 for

further info.

ANGLE:

Refer to page 50 for further info.

X-OFFSET:

function, as is a physical measurement from the index point of the probe to the front

of the wedge/can/shoe/case. Refer to page 50 for further info.

CSC OD: Curved surface correction to compensate for changing sound path

distance and angle. This feature is used in conjunction with ‘thickness’ in order to

calculate a correction factor. Refer to page 50 for further info.

Used to set the angle of the transducer, and used in the calculations above.

This feature is used to calculate the surface distance in the trigonometry

12

Page 17

DFX-7 Ultrasonic Flaw Detector

3.9 AWS – Menu

AWS:

according to American Welding Society’s structural welding code D1.1-94, to

calculate the Indication Rating (IR). Refer to page 55 for further info.

SET REF GAIN:

percentage of full screen height (FSH). This value will typically be set somewhere

between 20%–90%. Refer to page 55 for further info.

ANGLE: This is used to set the angle of the transducer used for the calculations

above. Refer to page Error! Bookmark not defined. for further info.

X-OFFSET: This feature is used to calculate the surface distance in the trigonometry

function, as is a physical measurement for the index point of the probe to the front of

the wedge/can/shoe/case. Refer to page 55 for further info.

This feature toggles the AWS feature on/off. Used in the analysis of welds

The gain (in dB) required to set the indication level to a specific

3.10 TCG – Menu

TCG: This feature toggles the TCG feature on/off. The Time Corrected Gain (TCG)

feature displays reflectors of equal size at equal A-Scan amplitudes, regardless of the

reflector’s depth in the test material. Refer to page 66 for further info.

DRAW: Toggles the DRAW mode on/off, and used to draw the TCG curve. Refer to

page 66 for further info.

CURVE:

screen. Refer to page 66 for further info.

% SCRN HEIGHT: This feature enables the user to set the reference level of the

TCG as a percentage of full screen height (FSH). Refer to page 66 for further info.

Toggles the TCG correction curve on/off, and the curve is displayed on the

3.11 DAC – Menu

DAC: Toggles the DAC feature on/off/audible. A Distance Amplitude Correction

(DAC) curve is used to configure a variable threshold for the gate, using the same

size reflector at different distances. Refer to page 60 for further info.

13

Page 18

Dakota Ultrasonics

DRAW: Toggles the DRAW mode on/off/audible, and used to draw the DAC curve.

Note: TCG curve cannot be drawn in RF view. Refer to page 60 for further info.

MEAS: Toggles the units displayed as a relationship of either the signal amplitude

and DAC curve, or just the signal according to screen height. The units are as:

%FSH, %DAC, and dB. Refer to page 60 for further info.

CURVE: Selectable signal or multi DAC curve options. The displayed curve options

are: DAC, -2dB, -6dB, -10dB, (-6dB/-12dB), (-6dB/-14dB). Once the DAC curve has

been generated, these options can be toggled at any time. Refer to page 60 for

further info.

TRIGGER: Used to set the alarm threshold for the DAC curve. The options are; at

DAC, -2dB, -6dB, -10dB, -12dB, -14dB, or using an independent gate. The list of

trigger options will change according to which CURVE option has been selected.

Refer to page 60 for further info.

DPOLARITY: Used to select the polarity of the DAC curves generated, either

positive or negative. Refer to page 60 for further info.

3.12 DGS – Menu

DGS: Coming Soon.

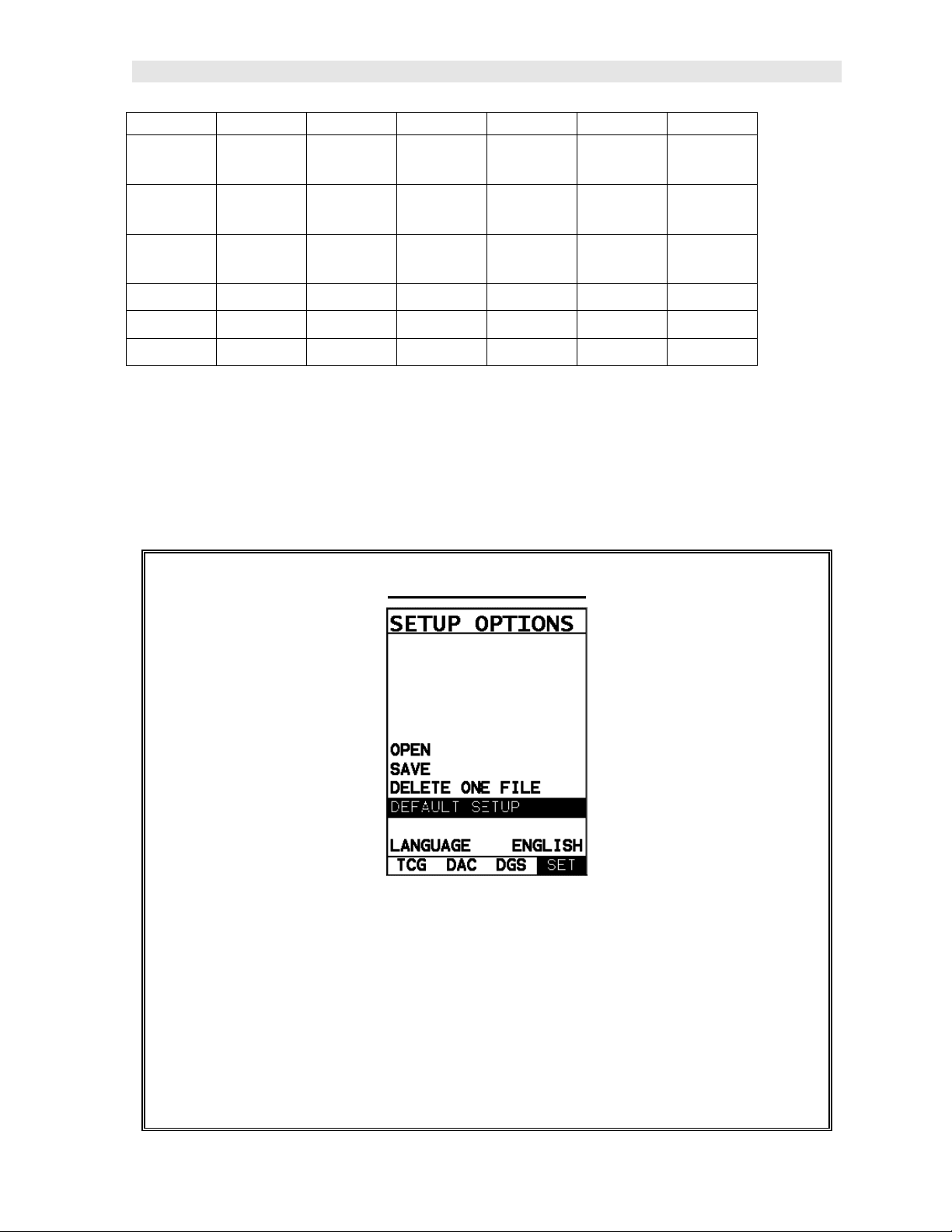

3.13 SETUP – Menu

OPEN:

These setups can be recalled and used at any time. Refer to page 120 for further

info.

SAVE:

modified or created by the user. Refer to page 122 for further info.

DELETE:

in memory. Refer to page 125 for further info.

DEFAULT SETUP:

setups in the DFX-7 have been corrupted and a computer is not accessible. Refer to

page 127 for further info.

Displays a list of factory and user defined setups currently stored in memory.

Provides the user with the ability to save a custom setup that has been

Provides the user with the ability to delete specific setups previously save

Loads a basic default setup. Use only as a last resort when the

14

Page 19

DFX-7 Ultrasonic Flaw Detector

LANGUAGE: Provides the user the ability to select different languages for the DFX-

7. Refer to page 129 for further info.

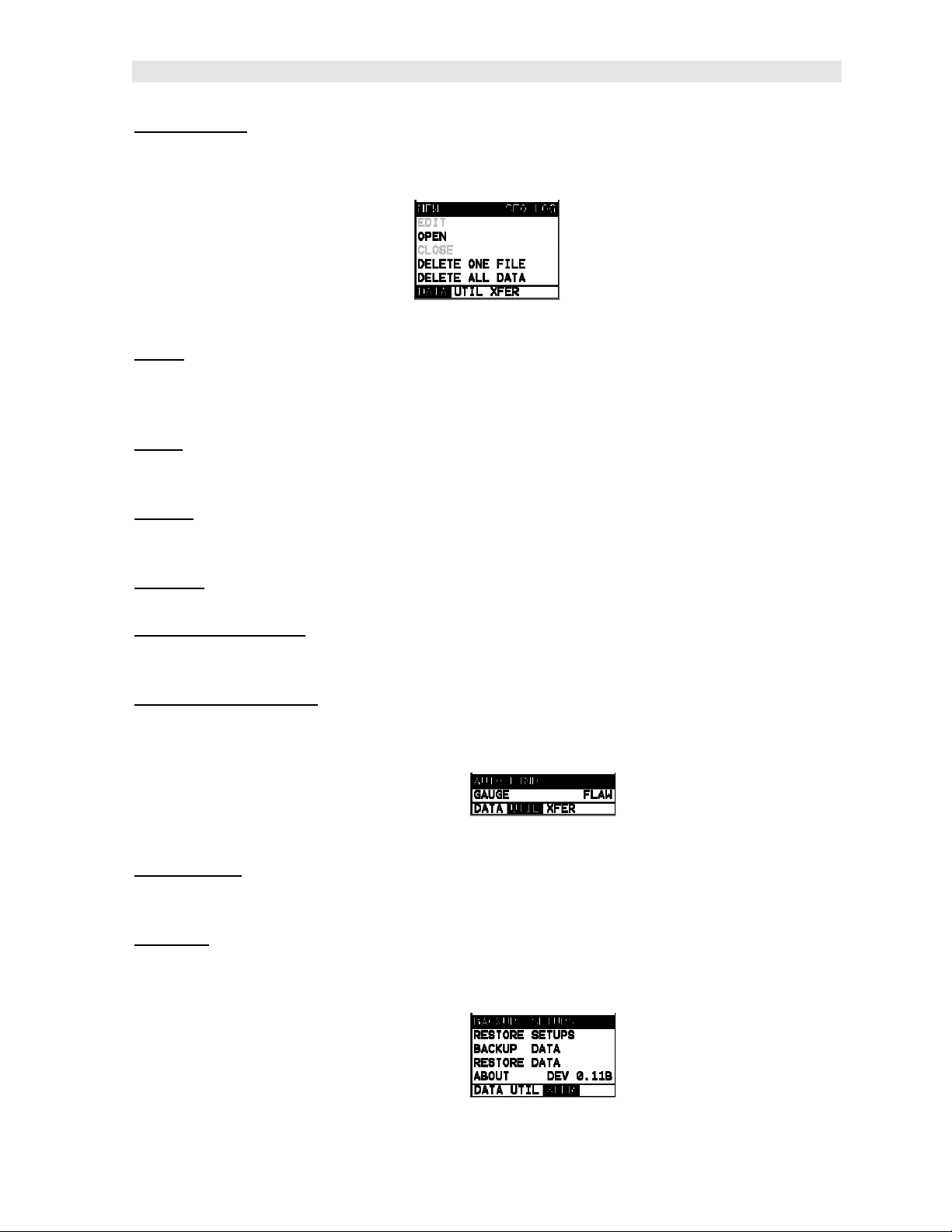

3.14 DATA – Menu

NEW: Allows the user the ability to create a new alpha numeric grid, or sequential

log file with auto identifiers. It is equipped with custom parameters, rows, and

columns depending on the user’s application reporting requirements. Refer to page

96 for further info.

EDIT: Gives the user the ability to change parameters of grid or sequential file

previously saved. Note: Pre-defined coordinates cannot be changed once they have

been created. Refer to page 114 for further info.

OPEN: This function provides the user with the ability to recall grids or sequential log

files that currently exist in memory, from a list of grids. Refer to page 116 for further

info.

CLOSE: Provides the user the ability to close a currently opened grid or sequential

log file. Refer to page 118 for further info.

DELETE ONE FILE: This function provides the user with the ability to delete one

individual grid or sequential log file from a list of multiple grids/files previously saved

in memory. Refer to page 111 for further info.

DELETE ALL DATA: This function provides the user with the ability to delete all files

currently stored in memory. Refer to page 112 for further info.

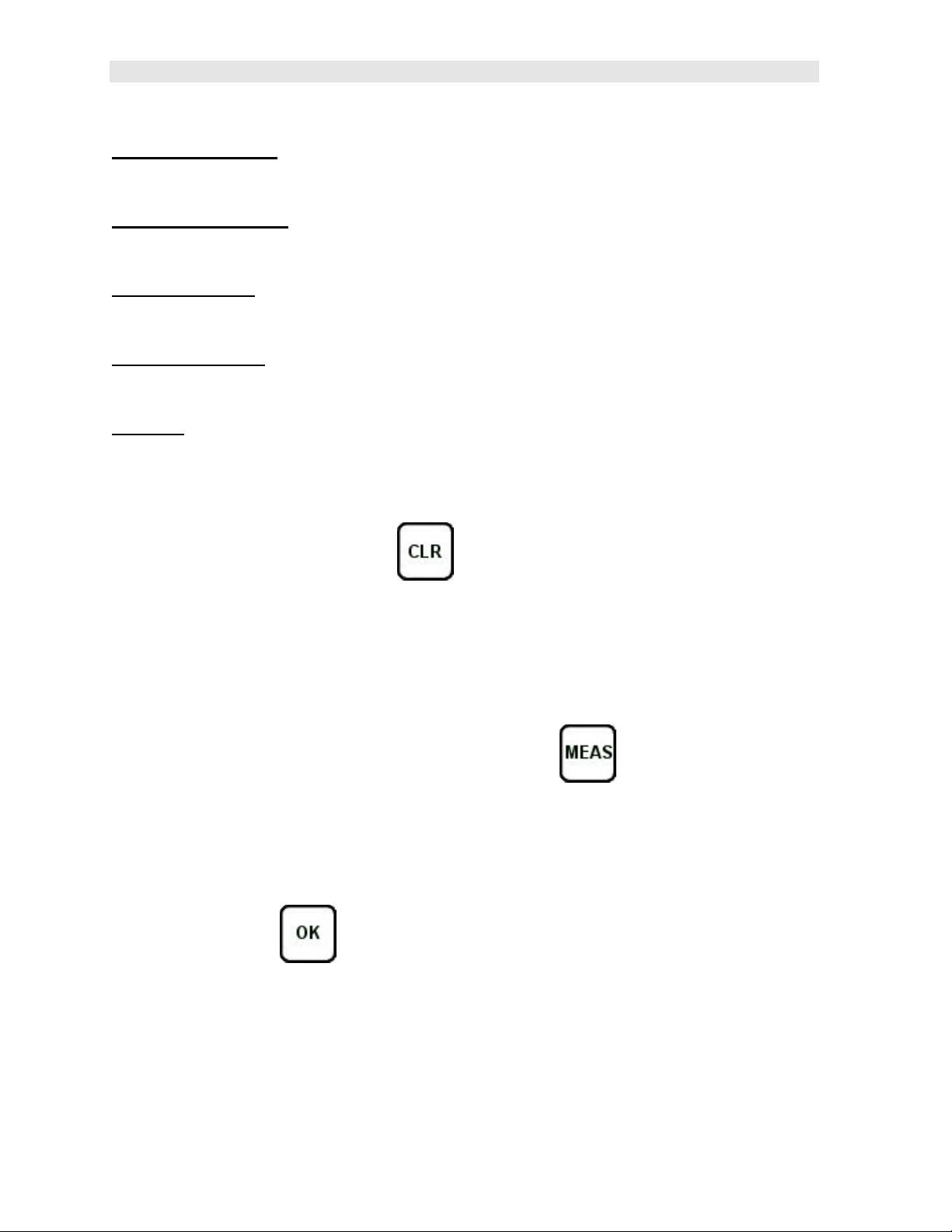

3.15 UTIL (utilities) – Menu

AUTO FIND:

the viewable display area, and automatically sets up the gauges scope settings.

Refer to page 71 for further info.

GAUGE:

detector, or a thickness gauge. Refer to page 3 for further info.

Automatically locates the detection point if the measurement is out of

Gives the user the ability toggle the DFX-7 gauge type to either a flaw

3.16 XFER (transfer) – Menu

15

Page 20

Dakota Ultrasonics

BACKUP SETUPS: Enables the user the ability to backup the setups currently

stored in the DFX-7 to a PC via RS232 port. USB adaptor included. Refer the help

section of the DFX-7 DakView software for a complete electronic manual.

RESTORE SETUPS:

saved on a PC to an DFX-7 via RS232 port. Refer the help section of the DFX-7

DakView software for a complete electronic manual.

BACKUP DATA:

currently stored in the DFX-7 to a PC via RS232 port. Refer the help section of the

DFX-7 DakView software for a complete electronic manual.

RESTORE DATA: Enables the user the ability to restore grids or sequential log files

currently saved on a PC to an DFX-7 via RS232 port. Refer the help section of the

DFX-7 DakView software for a complete electronic manual.

ABOUT: Provides the user with Dakota Ultrasonics contact information and the

DFX-7 software version. Refer to the Dakota Ultrasonics web site for information on

the latest firmware versions available for download.

Enables the user the ability to restore the setups currently

Enables the user the ability to backup grids or sequential log files

3.17 CLR (clear) Key

The primary functions of the CLR key, is to clear a measurement from a grid or

sequential log files cell location or set obstruct, backspace in an Alpha Edit Box, or

clear a DAC reference point used to generate a curve. Use this key to clear saved

measurement & waveform.

3.18 MEAS (measurement mode) Key

The MEAS key puts the DFX-7 into it’s primary mode of operation. In this mode, the

user has a complete view of the LCD. When pressed multiple times, navigates the

hot menu items.

3.19 OK Key

The primary function of the OK key is confirmation of a change or selection. The OK

key also toggles the Hot Menu area, while in measurement mode, to a large digits

display area. If the DFX-7 is displaying a grid log, the OK key toggles an advance to

row number option.

16

Page 21

DFX-7 Ultrasonic Flaw Detector

3.20 ESC Key

The ESC key is used in the MENU, MEAS, and EDIT functions as a back or escape

function. If the DFX-7 is displaying a grid or sequential log, the OK key toggles the

display options: RF, +RECT, -RECT and RECTFW views.

3.21 Arrow Keys

The Arrow Keys are used to navigate through the menus, increase/decrease values,

and toggle specific function keys.

3.22 ENTER key

The ENTER key is used in the overall menu selection process, to activate list and

edit boxes, display and save measurements/waveforms to grid or sequential file

locations.

3.23 MULTI MODE Key

The MULTI MODE key provides the user with a set of flaw mode options: Normal,

Peak, or Freeze. The normal mode is the standard flaw detector mode. The Peak

mode draws, holds, and updates the waveform for the entire duration of the

inspection. The Freeze mode ‘freezes’ the current waveform on the screen, allowing

the user the time to analyze the wave.

3.24 ON/OFF Key

The ON/OFF key simply powers the unit either ON or OFF. Note: Unit will

automatically power off when idle for 5 minutes. All current settings are automatically

saved prior to powering off.

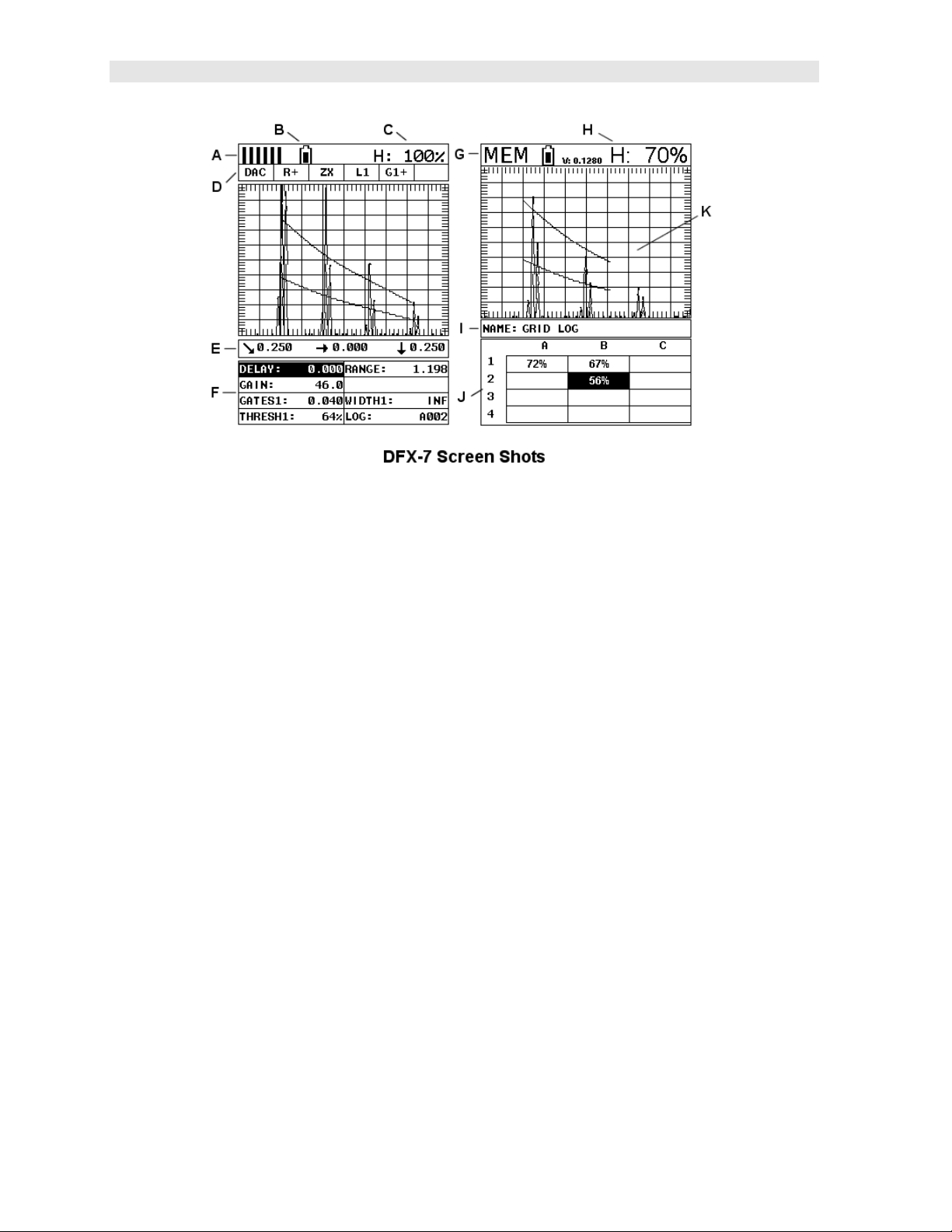

3.25 DFX-7 Overview

17

Page 22

Dakota Ultrasonics

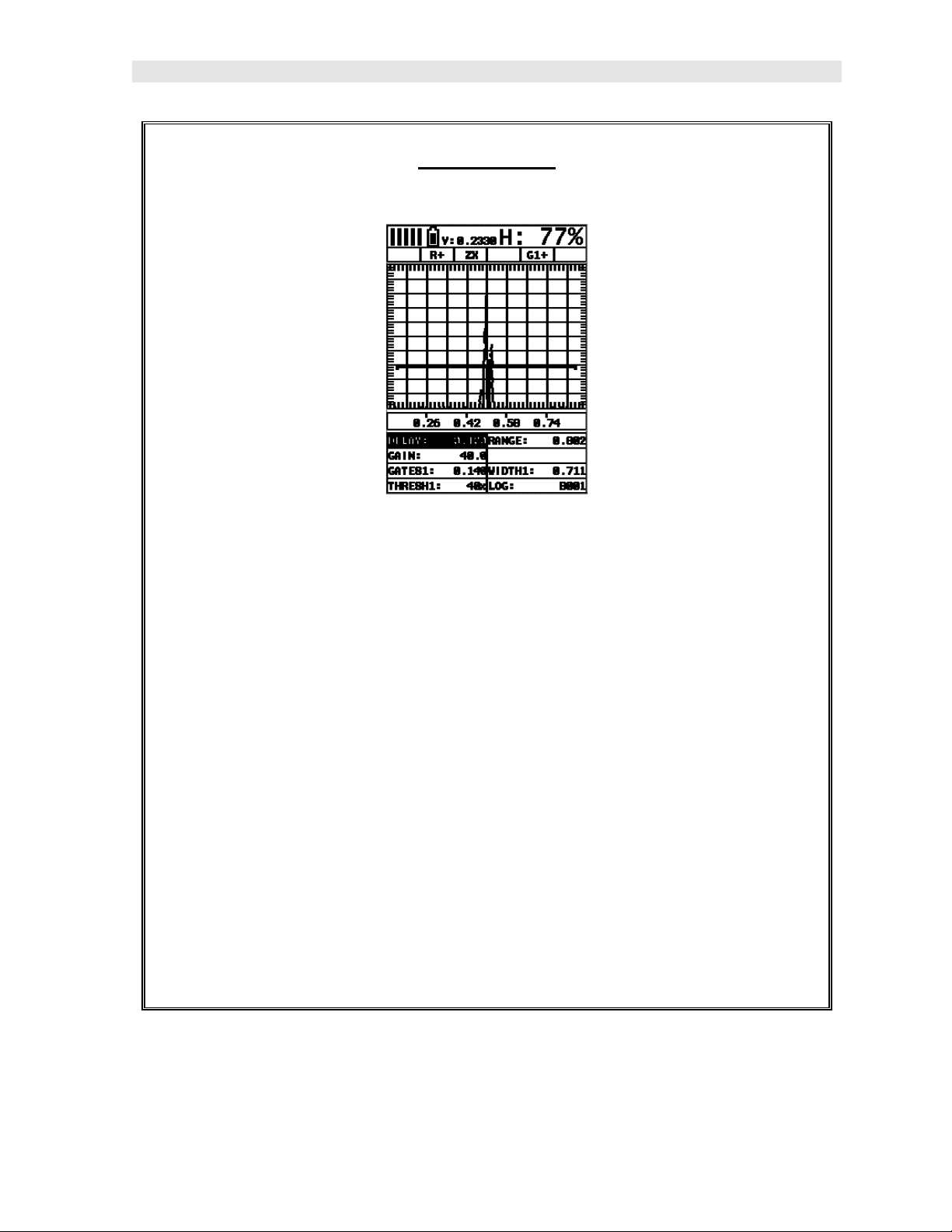

In order to understand how to operate the DFX-7, it’s best to start off with an

understanding of what we’re looking at. The DFX-7 has a lot of great features and

tools that will prove to be a huge benefit for the variety of applications you’re

constantly facing on a continual basis. Let’s have a brief look at the screens you’ll be

looking at most often:

A. Repeatability/Stability Indicator – This indicator shows the

stability/repeatability of the sound path signal. When all the vertical bars are

fully illuminated, the repeatability of the sound path is stable.

B. Battery Icon – Indicates the amount of battery life the DFX-7 has remaining.

C. Height – Shows the signal amplitude height as a percent of 100% full screen

height.

D. Feature Status Bar – Indicates the features currently enabled and in use in

the following order:

• Feature Toolkits

i. Trig – Trigonometry w/ Curved Surface Correction

ii. AWS – American Welding Society

iii. TCG – Time Corrected Gain

iv. DAC – Distance Amplitude Correction

v. DGS – Distance Gain Size

• View

i. RF: Radio Frequency.

ii. R+: Rectified positive.

iii. R- : Rectified negative

iv. FW: Rectified full wave.

18

Page 23

DFX-7 Ultrasonic Flaw Detector

• Detect

i. Zero crossing (ZX)

ii. Flank (FK)

iii. Peak (PK)

• Leg – Skip leg reference, (L1…L4…)

• High Speed Scan Mode

• Alarm Mode

• Gain Setting

E. Leg (skip leg) – Indicates which skip/leg the detection in on. The thickness of

the material is used to calculate the leg.

F. Hot Menu items – We call this menu section our “hot menu”, as these items

are the most commonly adjusted features, requiring quick access from the

user. They can be displayed and scrolled by pressing the MEAS key at

anytime. The ESC key is used in conjunction with MEAS key to reverse the

direction scrolled.

G. Memory – Indicates that the currently displayed measurement screen and

values have been previous stored in memory. When MEM is displayed, all

measurement functions are disabled until the user advances to an empty

storage location, or the current measurement is cleared by pressing the CLR

key.

H. Height – Displays the amplitude of the signal as a percentage of full screen

height. Depending on the quantity selected, this could also be displayed in

dB, or D.

I. Grid or Seq Log Name – References the name of the log file currently open.

J. Log File – Shows the storage cells of the current log file open. Depending on

the quantity currently selected, show either the %height or dB value stored.

K. A-Scan Display – The actual echo reflections returned from the backwall or

defect.

3.26 Navigating the Hot Menu

The diagram above is a screenshot of the “Hot Menu” feature of the DFX-7. The Hot

Menu’s contain all the most regularly adjusted features of the gauge. The primary

19

Page 24

Dakota Ultrasonics

purpose of the design, was to provide the user with an efficient way to make

adjustments on the fly during inspections. The following procedure outlines the steps

to navigate and make adjustments as follows:

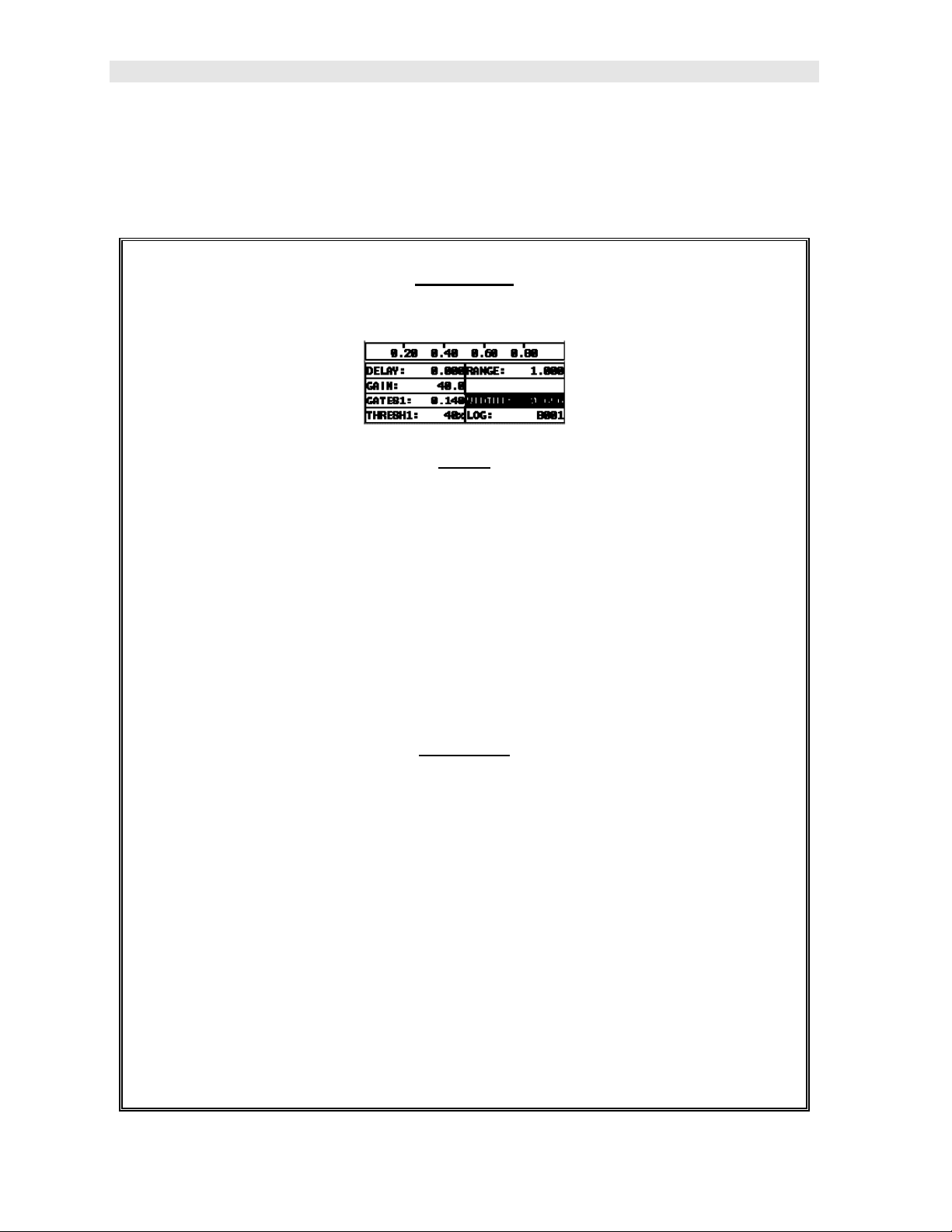

Hot Menu

Gate1

1) Press the MEAS key once to activate the Hot Menu. Press the MEAS key

multiple times to advance the cell right, and the ESC key multiple times to

advance the cell left, until the WIDTH1 cell is highlighted.

2) Press the LEFT and RIGHT arrow keys to toggle the value or status.

Note: This is a coarse adjustment. It’s the fastest and easiest way to

increment, decrement, or toggle the status, however it does so in coarse steps.

Set Detect

1) Press the UP and DOWN arrow keys until DETECT is highlighted.

2) Press the LEFT and RIGHT arrow keys to toggle the ABOVE or BELOW.

Note: Above will trigger the alarm when a signal meets or exceeds the height

of the gate, and below will detect on anything that meets or is below the height

of the gate.

3) Alternatively, press the ENTER key to display the Digits Edit Box.

4) Press the UP and DOWN arrow keys to scroll the highlighted value.

5) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

20

Page 25

DFX-7 Ultrasonic Flaw Detector

6) Repeat steps 4 & 5 until the start position is correctly displayed.

7) Press the OK key to set the WIDTH1 position and return to the menu

screen, or ESC to cancel entering the WIDTH1 position.

Note: This procedure is universal for all the features in the Hot Menu cell

locations.

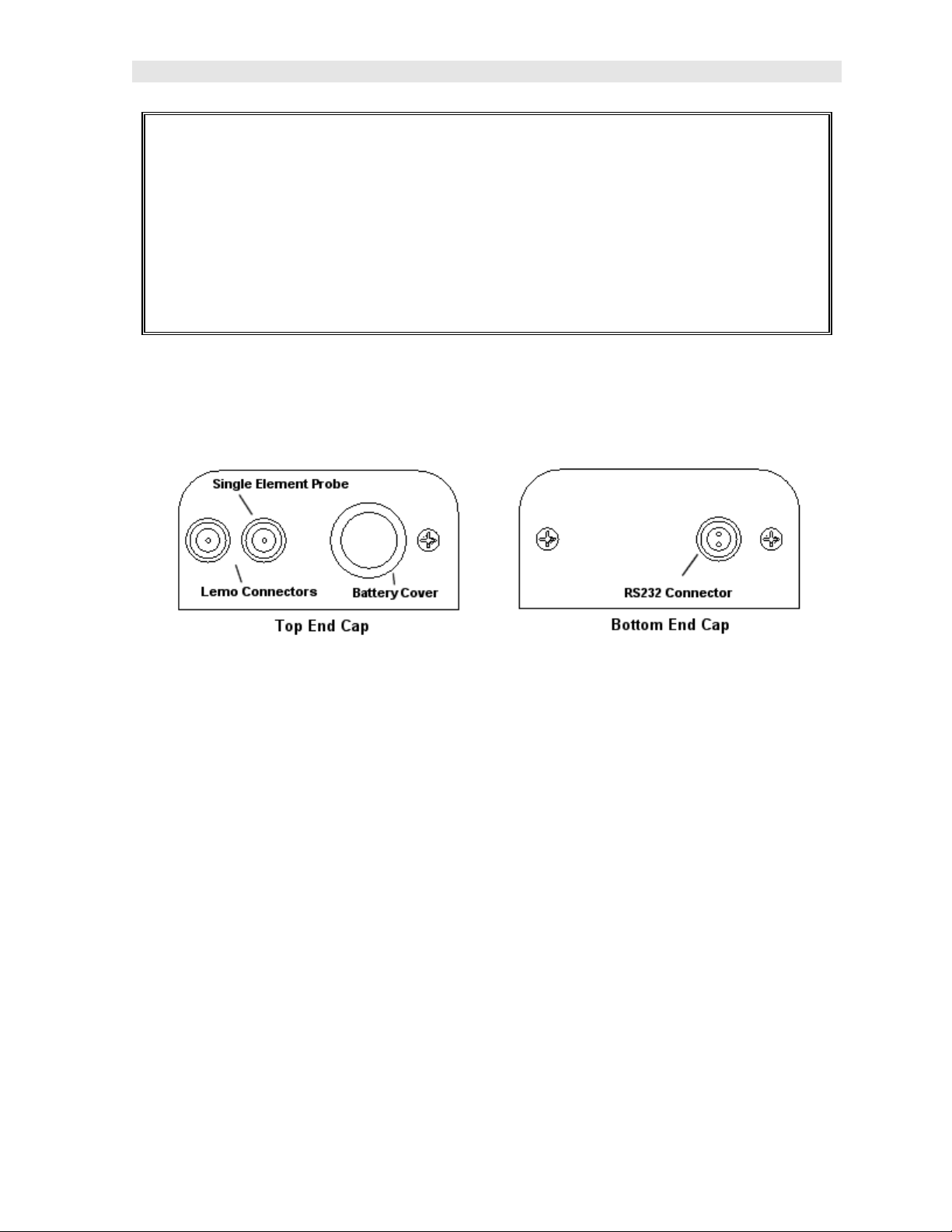

3.27 Top & Bottom End Caps

The top & bottom end panels are where all connections are made to the DFX-7. The

diagram above shows the layout and description of the connectors:

Transducer Connectors

Refer to Diagram: The transducer connectors, and battery cover/probe zero disk are

located on the DFX-7’s top end cap. The transducer connectors are of type LEMO

“00”. A single element transducer must be plugged into the inside LEMO jack as

illustrated above. Note: There is no polarity associated with connecting a dual

element transducer to the DFX-7.

Battery Cover

Refer to Diagram: The Battery cover is the large round disk shown in the diagram.

Be sure to check the polarity indicator diagram, located on the back label of the DFX-

7. Note: Rechargeable batteries can be used, however must be recharged outside

of the gauge in a standalone battery charger.

RS-232 Connector

Refer to Diagram: The RS-232 connector, located on the bottom end cap, is a 2 pin

female Lemo connector. It is designed to connect directly from the DFX-7 to a

standard AT serial port on a PC. The cable supplied with the DFX-7 is a Lemo to 9

21

Page 26

Dakota Ultrasonics

pin serial cable. Note: This connector is also used to upgrade the DFX-7 with the

latest version of firmware.

USB Serial to USB Converter Cable

A converter cable can be attached to the 9 pin serial cable in needed (part no. N-402-

0510).

22

Page 27

CHAPTER FOUR

SETTING UP FOR MEASUREMENT

4.1 Selecting Display View

The DFX-7 includes a variety of viewing options for the waveform display. There are

three primary options waveform options with selectable polarity. These are all outline

below as follows:

Radio Frequency (RF): Displays the entire sine wave signal, much like an

oscilloscope, from a reflector or return echo. This view shows both the positive and

negative peaks.

Rectified (RECT): Displays half sine wave signal, either positive or negative, from

the reflector or return echo. The user can select the polarity or “phase” displayed.

This is typically determined by first using RF view to select the most optimal polarity

“phase”, to fine tune the scopes settings. The RECT view is commonly used as the

primary “flaw detection” view.

Full Wave (RECTFW): Display entire sine wave signal in a rectified view. There is

no polarity.

The following procedure outlines the steps to select the view:

Display View

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the DISP menu is highlighted and displaying the submenu items.

23

Page 28

Dakota Ultrasonics

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until VIEW is highlighted.

3) Use the LEFT and RIGHT arrow keys to scroll the view options (RF,

+RECT, -RECT, RECTFW).

4) Once the view is displayed, press the MEAS key to return to measurement

mode.

4.2 Adjusting the display

This section will cover the procedures for adjusting the viewable range, or area, of

the display, in terms of thickness. A basic overview example for this section would

be as follows: Suppose we had a 50” widescreen television set. The left side of the

television screen is considered the Delay for all view options. The right side of the

television screen is the Range + Delay. By adjusting the left and right side of the

television screen, to control the viewable area/range, we can zoom in and out of any

part of the 50” screen we’d like, and focus on only the specific areas of the screen

necessary.

Setting Delay

The Delay represents the left side of the display, and can be adjusted to start at any

thickness value within the overall range of the DFX-7.

Note: Once the delay is set, it will remain the same for the views: RF, +RECT, RECT, RECTFW.

The procedures to adjust the Delay are outlined below:

24

Page 29

Setting Delay

DFX-7 Ultrasonic Flaw Detector

1) Press the MEAS key once to activate measure menu items. Press the

MEAS key multiple times to move right and the ESC key multiple times to

move left, until the DELAY cell is highlighted.

2) Press the UP, DOWN, LEFT, and RIGHT arrow keys to scroll the highlighted

value.

3) Alternatively, press the ENTER key to display the Digits Edit Box.

4) Press the UP and DOWN arrow keys to scroll the highlighted value.

5) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

6) Repeat steps 4 & 5 until the DELAY value is correctly displayed.

7) Press the OK key to return to the measurement screen, or ESC to cancel

entering the DELAY.

8) Finally, press the MEAS key to return to the measurement screen.

Setting Range

25

Page 30

Dakota Ultrasonics

The Range is the distance from the delay that will be viewable on the screen. It can

be adjusted to any value greater than the Delay. The procedures to adjust the range

are outlined below:

Setting Range

1) Press the MEAS key once to activate measure menu items. Press the

MEAS key multiple times to move right and the ESC key multiple times to

move left, until the RANGE cell is highlighted.

2) Press the UP, DOWN, LEFT, and RIGHT arrow keys to scroll the highlighted

value.

3) Alternatively, press the ENTER key to display the Digits Edit Box.

4) Press the UP and DOWN arrow keys to scroll the highlighted value.

5) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

6) Repeat steps 4 & 5 until the RANGE value is correctly displayed.

7) Press the OK key to return to the measurement screen, or ESC to cancel

entering the RANGE.

8) Finally, press the MEAS key to return to the measurement screen.

26

Page 31

DFX-7 Ultrasonic Flaw Detector

4.3 Gain

The gain feature of the DFX-7 is used to adjust the signal amplitude to a

predetermined reference height for the inspection process. The higher the gain the

more the sound is amplified. The gain, or amplification of the return echoes, can be

adjusted in the DFX-7 to accommodate a variety of applications. The setting of the

gain is crucial in order to obtain valid readings during the inspection process.

Too much gain may result in erroneous measurements, by detecting on noise rather

than the actual reflector or defect. Not enough gain may result in intermittent

detection. It may also result in lack of detection on internal flaws, pits, or porosity.

The gain can easily be compared to the volume control of a home stereo system. If

you turn it up too much, you can’t hear the music clearly. If it’s turned down too

much, you can’t hear it at all. The DFX-7 commands a 110dB gain range using 3

stages of amplification. The overall range makes the DFX-7 extremely versatile

regarding a variety of applications and material types.

The procedures to adjust the Gain are outlined below:

Adjusting Gain

1) Press the MEAS key once to activate measure menu items. Press the

MEAS key multiple times to move right, and the ESC key multiple times to

move left until the GAIN cell is highlighted.

27

Page 32

Dakota Ultrasonics

2) Press the UP, DOWN, LEFT, and RIGHT arrow keys to scroll the highlighted

value.

3) Alternatively, press the ENTER key to display the Digits Edit Box.

4) Press the UP and DOWN arrow keys to scroll the highlighted value.

5) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

6) Repeat steps 4 & 5 until the GAIN value is correctly displayed.

7) Press the OK key to return to the measurement screen, or ESC to cancel

entering the GAIN.

28

Page 33

DFX-7 Ultrasonic Flaw Detector

The user can also access and adjust the gain from the tabbed menus. However, this

method is more tedious than making the adjustments using the Hot Menus. The

procedure using the tabbed menus is outlined below:

Adjusting the Gain using the Tabbed Menus

1) Press the MENU key once to activate the menu items tab. Press the

MENU key multiple times to tab right, and the ESC key multiple times to tab

left, until the TUNE menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until GAIN is highlighted.

3) Press the LEFT and RIGHT arrow keys to scroll the value. When the

correct Gain is being displayed, proceed to step 8.

4) Alternatively, press the ENTER key to display the Digits Edit Box.

5) Press the UP and DOWN arrow keys to scroll the highlighted value.

6) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

7) Repeat steps 5 & 6 until the Gain value is correctly displayed.

8) Press the OK key to set the Gain and return to the menu screen, or ESC to

cancel entering the Gain.

29

Page 34

Dakota Ultrasonics

9) Finally, press the MEAS key to return to the measurement screen.

4.4 Gates

The gates are an important part of any ultrasonic device, in this case a flaw detector.

The primary purpose of using a flaw detector is to “detect” and estimate the “size” of

of flaws according to calibrated reference standards or simulated defects. The gates

play an important role in this process, as without them a detection/measurement isn’t

possible. The height of a gate is also a threshold, or controls the level of sensitivity.

They can be adjusted to a specific reference height, based a predetermined reflector,

and set to act as an alarm during the inspection process.

The more flexible a gate is, the better the possibilities for the user to setup an

application. For example, a test block with a target size and depth is optimized on

the A-Scan display with a signal amplitude at 70% full screen height. The inspector

wants to know of any defects during the inspection that are greater than or equal in

size to the calibrated test specimen. A gate is then enabled and set to a reference

height of 70%. The width and range are adjusted to cover the range tested, and the

inspection is underway.

The DFX-7 is equipped with 2 fully independent gates. Each gate has a start and

stop or width, a threshold, a polarity switch, and a detect option. A gate can only

detect on reflections that occur inside the boundaries of the gate. Anything outside of

the start and range/width of the gate will be ignored. Both gates can be enabled and

set for different detects, polarities, and positioned anywhere on the A-Scan display

independent of one another. The following sections cover enabling and setting up

gates:

4.5 Activating and Setting Up a Gate

30

Page 35

DFX-7 Ultrasonic Flaw Detector

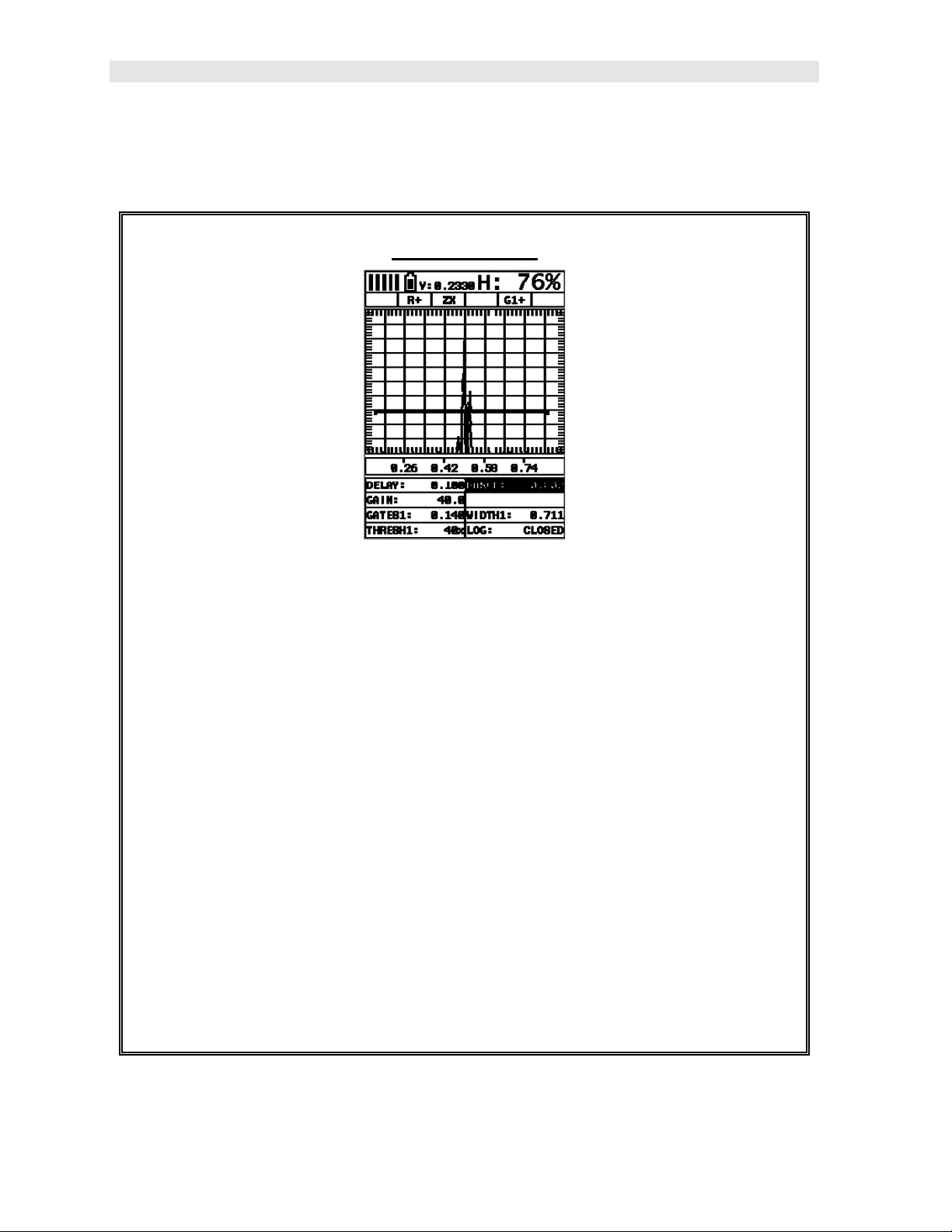

No Gate Gate On

The screenshots above show a rectified waveform with and without a gate enabled.

The following steps outline how to enable a gate as follows:

Activating a Gate

Gate1

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right, and the ESC key multiple times to tab left,

until the GT1 menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until ALARM is highlighted.

3) Press the LEFT and RIGHT arrow keys to toggle ALARM to ON. The menu

items should now become active and adjustable, as the gate is now active.

Set Detect

1) Press the UP and DOWN arrow keys until DETECT is highlighted.

2) Press the LEFT and RIGHT arrow keys to toggle the ABOVE or BELOW.

31

Page 36

Dakota Ultrasonics

Note: Above will trigger the alarm when a signal meets or exceeds the height

of the gate, and below will detect on anything that meets or is below the height

of the gate.

Set Gate1 Start

1) Press the UP and DOWN arrow keys until GATE1 is highlighted, followed by

pressing the LEFT and RIGHT arrow keys to scroll the value. When the

correct start position is displayed, proceed to the next setting.

2) Alternatively, press the ENTER key to display the Digits Edit Box.

3) Press the UP and DOWN arrow keys to scroll the highlighted value.

4) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

5) Repeat steps 3 & 4 until the start position is correctly displayed.

6) Press the OK key to set the GATE1 start position and return to the menu

screen, or ESC to cancel entering the GATE1 start position.

Note: This where the gate first turn on relative to the horizontal axis or depth.

Sets the left boundary of the gate, or where it turns on.

Set Gate1 Width

1) Press the UP and DOWN arrow keys until GATE1 WIDTH is highlighted,

followed by pressing the LEFT and RIGHT arrow keys to scroll the value.

When the correct width is displayed, proceed to the next setting.

2) Alternatively, press the ENTER key to display the Digits Edit Box.

3) Press the UP and DOWN arrow keys to scroll the highlighted value.

4) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

5) Repeat steps 3 & 4 until the width is correctly displayed.

32

Page 37

DFX-7 Ultrasonic Flaw Detector

6) Press the OK key to set the GATE1 WIDTH and return to the menu screen,

or ESC to cancel entering the GATE1 WIDTH.

Note: This sets the overall width of the gate in terms of the horizontal axis or

depth. Sets the right boundary of the gate, or where it turns off.

Set Threshold1 Level

1) Press the UP and DOWN arrow keys until THRESHOLD1 is highlighted,

followed by pressing the LEFT and RIGHT arrow keys to scroll the value.

When the correct threshold level is displayed, proceed to the next setting.

2) Alternatively, press the ENTER key to display the Digits Edit Box.

3) Press the UP and DOWN arrow keys to scroll the highlighted value.

4) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

5) Repeat steps 3 & 4 until the threshold level is correctly displayed.

6) Press the OK key to set the THRESHOLD1 level and return to the menu

screen, or ESC to cancel entering the THRESHOLD1 level.

Note: This sets the overall sensitivity level of the gate which is the threshold.

Select Gate Polarity

1) Use the UP and DOWN arrow keys to scroll through the sub menu items

until POLARITY1 is highlighted.

2) Press the LEFT and RIGHT arrow keys to toggle the POLARITY feature

positive or negative.

3) Press the MEAS key to return to the measurement screen.

Note: The GATE1 and WIDTH1 values can now be adjusted or tuned directly

from the Hot Menus on the main measurement screen.

33

Page 38

Dakota Ultrasonics

Note: Sets where the detection will occur, on the negative or positive going

echoes.

34

Page 39

CHAPTER FIVE

CALIBRATION

In this section we’ll focus on calibrating the DFX-7. There are a number of ways to

go about performing a calibration, but we’ll be focusing on the simplest and most

accurate method, which is performing a two point calibration. This method is very

convenient, as it will automatically calculate the material velocity and zero using a

minimum and maximum calibration standard of know thickness and material type.

The DFX-7 can certainly be manually calibrated by adjusting the velocity and zero

features, but this is a tedious and redundant process overall.

The two point calibration method can be used for both straight and angle beam

transducers. A number of certified calibration standards are available to address

inspection code requirements, specifications, and applications. It should be noted

again that the DFX-7 has virtually 2 gauges built into a single gauge; a flaw detector,

and a thickness gauge. Therefore, while the flaw detector option can be calibrated

for straight beam contact and angle beam style transducers, the thickness gauge

option contains a number of tools for using single and dual element style transducers

with linearity tables and v-path correction curves. In addition, it should also be noted

that the thickness gauge option has a fully functional scope with the same precision

linearity as the flaw detector option. Therefore, the user should consider the current

application to determine which gauge option will produce the best results. The

following sections outline how to setup and calibrate your DFX-7 for field use, given a

specific range and material type.

5.1 Setting Up For Calibration

This section covers performing a two point automatic calibration using a single

element straight beam contact transducer with a range from 1 to 4 inches. In order to

accomplish this, a set of calibration standards covering range is required. The steps

are outlined as follows:

DFX-7 Setup

35

Page 40

Dakota Ultrasonics

The gauge will require a few basic adjustments in order to get underway with

the calibration process. For this example, in order to avoid multiple steps for

setting the gauge features/options, the default setup will be loaded as a starting

point. However, the user should invest the necessary time getting to know the

features and options included in the DFX-7, as well as gaining a good

understanding of their function:

Loading Default Setup

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the SEUTP menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until DEFAULT SETUP is highlighted.

3) Press the ENTER key to display the CONFIRM screen.

4) Press the OK key to load the DEFAULT SETUP.

Setting the Range

1) Press the MEAS key once to activate the measure menu items. Press the

MEAS key multiple times to move right and the ESC key multiple times to

move left, until the RANGE cell is highlighted.

36

Page 41

DFX-7 Ultrasonic Flaw Detector

2) Press the ENTER key to display the Digits Edit Box.

3) Press the UP and DOWN arrow keys to scroll the highlighted value.

4) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

5) Repeat steps 3 & 4 until the desired range value is displayed.

6) Press the OK key to set the value and return to the GT1 menu.

Note: Our range calibration range for this example is 4 inches. Therefore

setting a range of 5 inches will enable the user to view the entire range on the

display.

Enabling and Setting Up a Gate

Refer to the illustrations above. In order to measure, a gate is required. The

width of the gate should be small enough, in terms of its width, in order to select

specific reflections to measure. The screenshot above shows a gate enabled to

select the 1 inch calibration standard, and in the second the 4 inch calibration

standard.

37

Page 42

Dakota Ultrasonics

Activating a Gate

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the GT1 menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until ALARM is highlighted.

3) Press the LEFT and RIGHT arrow keys to toggle the gate ON.

Setting the Detect

1) Use the UP and DOWN arrow keys to scroll through the sub menu items

until DETECT is highlighted.

2) Press the LEFT and RIGHT arrow keys to toggle the option ABOVE.

Gate1 Start

1) Use the UP and DOWN arrow keys to scroll through the sub menu items

until GATE1 is highlighted.

2) Press the ENTER key to display the Digits Edit Box.

3) Press the UP and DOWN arrow keys to scroll the highlighted value.

4) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

38

Page 43

DFX-7 Ultrasonic Flaw Detector

5) Repeat steps 3 & 4 until the desired GATE1 value is displayed.

Note: In our example, a value less than 1 inch should be selected.

6) Press the OK key to set the value and return to the GT1 menu.

Gate1 Width

1) Use the UP and DOWN arrow keys to scroll through the sub menu items

until GATE1 WIDTH is highlighted.

2) Press the ENTER key to display the Digits Edit Box.

3) Press the UP and DOWN arrow keys to scroll the highlighted value.

4) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

5) Repeat steps 3 & 4 until the desired GATE1 WIDTH value is displayed.

Note: In our example, a value greater than 1 inch should be selected.

6) Press the OK key to set the value and return to the GT1 menu.

Threshold Level

1) Use the UP and DOWN arrow keys to scroll through the sub menu items

until THRESHOLD1 is highlighted.

2) Press the ENTER key to display the Digits Edit Box.

3) Press the UP and DOWN arrow keys to scroll the highlighted value.

4) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

5) Repeat steps 3 & 4 until the desired THRESHOLD1 value is displayed.

Note: In our example, a value of 20% has been selected. However, the user

should set a value that will be close enough to the baseline to avoid a “Peak

Jump”, or missing the first cycle.

6) Press the OK key to set the value and return to the GT1 menu.

39

Page 44

Dakota Ultrasonics

Setting Polarity

1) Use the UP and DOWN arrow keys to scroll through the sub menu items

until POLARITY1 is highlighted.

2) Press the LEFT and RIGHT arrow keys to toggle the polarity POSITIVE.

3) Press the MEAS key to return to the measurement screen and get started

with the two point calibration.

5.2 Straight Beam Calibration

Now that the DFX-7 is setup with a valid range and a gate enabled, we’re ready to

perform a two point, calibration using a single element contact style transducer, as

follows:

Two Point Calibration – Straight Beam

Note: Calibration standards representing the minimum and maximum

thickness of the overall inspection range intended are required. They must also

be of the same material type as the intended application. For our example,

we’ll be using a 1 and 4 inch standard for calibration.

40

Page 45

DFX-7 Ultrasonic Flaw Detector

Coupling to the 1” Cal Standard (1st Point)

Apply a drop of couplant on the transducer and place the transducer in steady

contact with the 1” calibration standard. Be sure that the reading is stable and

the repeatability indicator, in the top left corner of the display, is fully lit and

stable. Also, be sure there is sufficient signal amplitude in order to avoid ‘peak

jumping’ or missing the first cycle.

Adjusting the Gate

1) Press the MEAS key once to activate the measure menu items. Press the

MEAS key multiple times to move right and the ESC key multiple times to

move left, until the GATE1 cell is highlighted.

2) Press the LEFT and RIGHT arrow keys to move the gate over the waveform

to be measured, as demonstrated in the screen shot above.

Note: In order to trigger on a signal, the waveform must be inside the

boundaries of the gate.

Calibrating the First Point

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the CAL menu is highlighted and displaying the submenu items, as shown in

the screenshot above.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until MATL 1PT is highlighted.

41

Page 46

Dakota Ultrasonics

3) Press the ENTER key to display the Digits Edit Box.

4) Press the UP and DOWN arrow keys to scroll the highlighted value.

5) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

6) Repeat steps 4 & 5 until the known thickness value is correctly displayed.

7) Press the OK key to calculate the velocity and return to the menu screen, or

ESC to cancel the one point calibration.

Apply a drop of couplant on the transducer and place the transducer in steady

contact with the 4” calibration standard. Be sure that the reading is stable and

the repeatability indicator, in the top left corner of the display, is fully lit and

42

Page 47

DFX-7 Ultrasonic Flaw Detector

stable. Also, be sure there is sufficient signal amplitude in order to avoid ‘peak

jumping’ or missing the first cycle.

Adjusting the Gate

1) Press the MEAS key once to activate the measure menu items. Press the

MEAS key multiple times to move right and the ESC key multiple times to

move left, until the GATE1 cell is highlighted.

2) Press the LEFT and RIGHT arrow keys to move the gate over the waveform

to be measured, as demonstrated in the screen shot above.

Note: In order to trigger on a signal, the waveform must be inside the

boundaries of the gate.

Calibrating the Second Point

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the CAL menu is highlighted and displaying the submenu items, as shown in

the screenshot above.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until MATL 2PT is highlighted.

3) Press the ENTER key to display the Digits Edit Box.

43

Page 48

Dakota Ultrasonics

4) Press the UP and DOWN arrow keys to scroll the highlighted value.

5) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

6) Repeat steps 4 & 5 until the known thickness value is correctly displayed.

7) Press the OK key to calculate the velocity and return to the menu screen, or

ESC to cancel the one point calibration.

Note: A velocity and zero value will be calculated and displayed in the fields a

shown above.

8) Finally, press the MEAS key to return to the measurement screen.

In order to trigger on anything that’s detected in the calibrated range, the

boundaries of the gate must be adjusted to include the entire range. Caution:

in both z-cross & flank detection settings, the first signal to cross the gate will be

triggered on. However, if the peak detection setting has been enabled, the

signal with the most amplitude will be detected.

44

Page 49

DFX-7 Ultrasonic Flaw Detector

Adjusting the Gate to Calibrated Range

1) Press the MEAS key once to activate the measure menu items. Press the

MEAS key multiple times to move right and the ESC key multiple times to

move left, until the GATE1 cell is highlighted.

2) Press the LEFT and RIGHT arrow keys to move the gate start to a position

less than 1 inch.

3) Press the MEAS key once to highlight the WIDTH1 cell.

4) Press the LEFT and RIGHT arrow keys to move the gate start to a position

greater than 4 inches.

45

Page 50

Dakota Ultrasonics

Note: CHECK YOUR CALIBRATION! Place the transducer back on the one

inch point, and any others in the given range, to confirm linearity. If the velocity

and zero values we calculated correctly, the thickness reading will match the

known thickness of the calibration standards. If the thickness is not correct,

repeat the steps above.

5) Press the OK key once to display the thickness, or the MEAS key to return

to the hot menus at any time.

5.3 Angle Beam Calibration

In the first example we demonstrated how to perform a two point calibration using a

single element straight beam contact transducer. With the exception of a handful of

additional comments, calibration using an angle beam transducer is virtually identical

in the scope of the overall step by step process. To avoid copying the procedures

from the previous section, we’ll focus only on the additional comments. Refer to

section 5.1 and 5.2, regarding the procedures to setup and calibrate the DFX-7. The

following are a list of additional items to consider when using an angle beam

transducer, as follows:

Calibration Standards:

There are a number of calibration block options available in a variety of common

material types, and according to specific code requirements. The user should

consider the application, codes applicable, and purchase the necessary calibration

standards.

46

Page 51

DFX-7 Ultrasonic Flaw Detector

Shear versus Longitudinal Velocity:

Unlike the previous straight beam calibration, which uses a longitudinal wave, an

angle beam transducer uses a shear wave. The following is a brief review of the

waves:

• Longitudinal –

o Particle motion is parallel to the direction of wave travel.

o Travels in solids, liquids, and gasses.

o Fastest mode of vibration.

• Shear –

o Particle motion is perpendicular to the direction of wave travel.

o Travels only in solids.

o Is approximately ½ the velocity of longitudinal waves.

o Has a shorter wavelength than a longitudinal at the same frequency.

Therefore, a two point calibration using an angle beam transducer will result in a

velocity approximately ½ the speed of the velocity calculated from the straight beam

calibration in the previous section.

Gain and Amplitude Ratio:

During an angle beam calibration the overall amplitude height of the waveform is

critical for “peaking up”. Therefore the maximum amplitude of the waveform must be

visible on the display in order to correctly position the transducer on the calibration

standard. The user should select a screen height and gain level that will enable the

entire waveform to be visible on the display.

Peaking Up the Signal Amplitude:

During an angle beam calibration, it’s important to peak up the overall amplitude of

the waveform to its maximum potential. The primary purpose is to be sure the

transducer is positioned properly on the calibration standard, that’s producing return

echoes at different distances. For example: If the operator is using a DSC block to

calibrate the velocity and zero, a DSC block will produce echoes at 3 & 7 inches.

The operator then positions the transducer on an index point, moves the transducer

in both directions forward and backward, rotates it side to side, and watches the

signal amplitude to find the maximum potential. At the maximum potential, the

transducer is correctly positioned to measure both multiple echoes at the correct

distances, and ready to proceed with the calibration.

Selecting the Material Type:

The user can also select a material type directly from a table built into the DFX-7 with

shear wave values. This would only get the user close, in terms of velocity, to the

calibration standards material type. In order to display the material chart with shear

47

Page 52

Dakota Ultrasonics

wave values, the TRIG mode must be enabled. The following outlines the steps to

enable the shear wave velocity table and select a material type from the chart:

Selecting the Material Type

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the TRIG menu is highlighted and displaying the submenu items.

2) Press the LEFT and RIGHT arrow keys to toggle TRIG mode ON.

3) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple times to tab left until

the CAL menu is highlighted and displaying the submenu items.

4) Use the UP and DOWN arrow keys to scroll through the sub menu items

until MAT is highlighted.

5) Press the ENTER key to display the list of material types.

6) Press the UP and DOWN arrow keys to scroll through the material list until

the appropriate material is highlighted.

48

Page 53

DFX-7 Ultrasonic Flaw Detector

7) Press the ENTER key to select the material type and initiate the overwrite

confirmation screen.

8) Press the OK key to confirm the material selection, or ESC key to cancel

changing the material type.

49

Page 54

CHAPTER SIX

TRIGONOMETRY MODE

6.1 Introduction to TRIG

Trig mode is most commonly used for inspecting welded joints using an angle beam

transducer. Based on the location, orientation, and geometry of the weld, a straight

beam transducer is typically not suitable for inspection. As a result, a transducer

emitting sound at a given angle will allow the operator to position the transducer

away from the actual weld, and “skip” into the weld at a given angle. Therefore, in

order to determine the location of a defect, given a specific angle, the trigonometry

mode is used. This section will cover the steps to setup and utilize trigonometry

mode.

6.2 Additional Comments

Prior to proceeding on to the next section outlining how to enable and setup the TRIG

mode, a few additional items should be clarified:

Angle Beam Transducer Weld Inspection

Refer to the Angle Beam Transducer diagram above:

SP – Sound Path X-Offset – Front of wedge less Index

Angle – Transducer Angle SD – Surface Distance

Thickness – Material Thickness Depth – Depth of flaw from surface

Screenshot Trig mode:

50

Page 55

DFX-7 Ultrasonic Flaw Detector

When TRIG mode is enabled, the calculated measurements will be displayed below

the waveform display area at (A), and the signal amplitude as a percentage of full

screen height at (B).

Curved Surface Correction:

The DFX-7 will also compensate for convex curved surfaces of longitudinally welded

pipes. A curved surface will produce a greater sound path than a flat surface will,

using a transducer with a given angle. The user should consider the angle used on

curved surfaces, with respect to the material thickness, in order to be sure a

reflection will occur from the opposite surface of the test material. In order to utilize

the curved surface compensation, the outside diameter must be entered into the

DFX-7.

6.3 Setup Trigonometry Mode

This section provides a step by step procedure to enable and setup the TRIG mode.

Note: A two point calibration should be done prior to proceeding. Refer to Chapter

Five for the calibration procedures.

51

Page 56

Dakota Ultrasonics

Activating & Setting the Parameters

Activate Trig Mode

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right, and the ESC key multiple times to tab left,

until the TRIG menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until TRIG is highlighted.

3) Press the LEFT and RIGHT arrow keys to toggle the TRIG feature ON. The

menu items should now become active and adjustable, as illustrated above.

Enter Material Thickness

1) Press the UP and DOWN arrow keys until THICKNESS is highlighted,

followed by pressing the LEFT and RIGHT arrow keys to scroll the value.

When the correct thickness is displayed, proceed to the next setting.

2) Alternatively, press the ENTER key to display the Digits Edit Box.

3) Press the UP and DOWN arrow keys to scroll the highlighted value.

52

Page 57

DFX-7 Ultrasonic Flaw Detector

4) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

5) Repeat steps 3 & 4 until the thickness is correctly displayed.

6) Press the OK key to set the THICKNESS and return to the menu screen, or

ESC to cancel entering the THICKNESS.

Note: Thickness is used to calculate the depth.

Transducer Angle

1) Press the UP and DOWN arrow keys until ANGLE is highlighted, followed

by pressing the LEFT and RIGHT arrow keys to scroll the value. When the

correct angle is displayed, proceed to the next setting.

2) Alternatively, press the ENTER key to display the Digits Edit Box.

3) Press the UP and DOWN arrow keys to scroll the highlighted value.

4) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

5) Repeat steps 3 & 4 until the angle is correctly displayed.

6) Press the OK key to set the ANGLE and return to the menu screen, or ESC

to cancel entering the ANGLE.

X-Offset

1) Press the UP and DOWN arrow keys until X-OFFSET is highlighted,

followed by pressing the LEFT and RIGHT arrow keys to scroll the value.

When the correct X-Offset is displayed, proceed to the next setting.

2) Alternatively, press the ENTER key to display the Digits Edit Box.

3) Press the UP and DOWN arrow keys to scroll the highlighted value.

4) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

5) Repeat steps 3 & 4 until the X-Offset is correctly displayed.

53

Page 58

Dakota Ultrasonics

6) Press the OK key to set the X-OFFSET and return to the menu screen, or

ESC to cancel entering the X-OFFSET.

Note: The X-Offset is used for purposes of marking, and is physically

measured with a ruler from the index point to the front edge of the transducer.

Curved Surface Outside Diameter

1) Press the UP and DOWN arrow keys until CSC OD is highlighted, followed

by pressing the LEFT and RIGHT arrow keys to scroll the value. When the

correct CSC OD is displayed, proceed to the next setting.

2) Alternatively, press the ENTER key to display the Digits Edit Box.

3) Press the UP and DOWN arrow keys to scroll the highlighted value.

4) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

5) Repeat steps 3 & 4 until the CSC OD is correctly displayed.

6) Press the OK key to set the CSC OD and return to the menu screen, or ESC

to cancel entering the CSC OD.

Note: The CSC OD value is only used for curved surfaces of longitudinally

welded pipes.

54

Page 59

CHAPTER SEVEN

AWS – WELD INSPECTION

7.1 Introduction to AWS

AWS provides a toolkit for evaluating defects according to the American Welding

Society D1.1 welding code. The code offers inspectors a method to classify

discontinuities by calculating and Indication Rating (IR) using ultrasonics. This toolkit

can be used in conjunction with TRIG mode, outlined in the previous chapter, to

simultaneously display the sound path (SP), surface distance (SD), and depth (D).

The following sections provide an outline for using the AWS feature.

7.2 Additional Comments

Since the DFX-7 is a gain controlled instrument, the following formula applies:

A – B – C = D

Where:

A = Discontinuity Indication Rating (DI)

B = Reference Indication Level (IL)

C = Attenuation Factor (AF); or 2(SP – 1)

SP = sound path in inches (2dB loss per inch of material thickness)

D = Indication Rating (IR)

Note: all values are in dB.

Calibration Standards & Calibration:

In order to use the AWS feature, the operator must have calibration standards made

with the same size reflector at different distances within the testing range. The

standards should also be made of the same material type as the material to be

inspected.

AWS D1.1 Standard:

There are specific transducers that are required by the D1.1 standard. The

frequency specified by the standard is 2-2.5MHz. The user should refer to the

standard for further information.

7.3 Setup AWS

This section provides a step by step procedure to enable and setup the AWS feature.

Note: A two point calibration should be done prior to proceeding. Refer to Chapter

Five for the calibration procedures. The TRIG mode will also be used for weld

55

Page 60

Dakota Ultrasonics

inspection, and should additionally be setup prior to enabling the AWS feature. Refer

to Chapter Six for instructions on setting up TRIG mode.

Activating & Setting AWS

Activate Trig Mode

1) Press the MENU key once to activate the menu items tab. Press the MENU

key multiple times to tab right, and the ESC key multiple times to tab left,

until the AWS menu is highlighted and displaying the submenu items.

2) Use the UP and DOWN arrow keys to scroll through the sub menu items

until AWS is highlighted.

3) Press the LEFT and RIGHT arrow keys to toggle the AWS feature ON. The

menu items should now become active and adjustable, as illustrated above.

Enter % Screen Height

1) Press the UP and DOWN arrow keys until % SCRN HEIGHT is highlighted,

followed by pressing the LEFT and RIGHT arrow keys to scroll the value.

When the correct height is displayed, proceed to the next setting.

2) Alternatively, press the ENTER key to display the Digits Edit Box.

56

Page 61

DFX-7 Ultrasonic Flaw Detector

3) Press the UP and DOWN arrow keys to scroll the highlighted value.

4) Press the LEFT and RIGHT arrow keys to scroll the digit locations.

5) Repeat steps 3 & 4 until the height is correctly displayed.

6) Press the OK key to set the % SCRN HEIGHT and return to the menu

screen, or ESC to cancel entering the % SCRN HEIGHT.

Note: % Screen Height is an arbitrary level, and is not specified by the AWS

D1.1. The user should set a value that will optimize viewing defects that are

larger and smaller than the reference level. Typically this level is set between

50%-80% full screen height.

Setting the Reference Gain

1) Press the UP and DOWN arrow keys until SET REF HEIGHT is highlighted,

followed by pressing the LEFT and RIGHT arrow keys to toggle the feature

ON.

2) Press the MEAS key once to activate measure menu items. Press the

MEAS key multiple times to move right and the ESC key multiple times to

move left, until the GATE1 cell is highlighted.

Note: A gray cursor should be visible in the waveform area of the display.

Also, since the DFX-7 has been previous calibrated and the TRIG feature has

been setup, a gate should be enabled and active.

Peak Up on the Reflector

1) Apply couplant on the calibration standard, place the transducer in the

correct area in position with the reflector, and slide the transducer around to

locate the maximum amplitude.

57

Page 62

Dakota Ultrasonics

2) Press the LEFT and RIGHT arrow keys to position the start of GATE1 to

trigger on the waveform.

3) Optionally, press the MEAS key multiple times to move right and the ESC

key multiple times to move left, until the WIDTH1 cell is highlighted.

4) Press the LEFT and RIGHT arrow keys to adjust the size or width of

GATE1.

Note: When the signal is in the gate, the height indicator will detect and display

the % full screen height.

Setting the Level

1) Press the MEAS key multiple times to move right and the ESC key multiple

times to move left, until the AWS BOX: cell is highlighted.

2) Press the LEFT and RIGHT arrow keys to position the cursor box over the

waveform.

3) Press the ENTER key to set the REFGN (reference gain).

Note: This process can be repeated and reset multiple times, or until the SET

REF GAIN feature is toggled OFF.