Page 1

1

OI407G-1000

TABLE OF CONTENTS

01.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

02.0 SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

03.0 CONTENTS OF COMPLETE OUTFIT . . . . . . . . . . . . . . . . . .3

04.0 OVERVIEW OF CDT-1000HD . . . . . . . . . . . . . . . . . . . . . . . . .4

4.1 LCD Display

4.2 Front Panel Key Functions

05.0 INSTALLING BATTERIES . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

06.0 REMOVING PROTECTIVE RUBBER SHELL . . . . . . . . . . . .5

07.0 MEASURING RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

08.0 MEMORY SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

99.0 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

10.0 SPARE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

11.0 WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

8

9.0 SPECIFICATIONS

10.0 SPARE PARTS

Measuring Ranges

RPM 1.00 – 99,999 rpm (non-contact)

Resolution .01 from 0 –100

.1 from 100 – 1,000

1 from 1000 – 99,999

Accuracy ± 0.02% of reading or ±1 digit

Display 5-Digit LCD, 10mm high

Decimal Point Automatic

Memory System Maximum, minimum, last reading and average (retained

in memory for the life of batteries)

Measurement System

Non-Contact Visible LED light beam

Engineering units

RPM RPM

Sensing Distance Up to 24 inches (60 cm)

Display Update Time 0.5 seconds

Auto Power Off After 30 seconds of non-use (minimum, maximum,

last and average reading retained in memory)

Battery Life 30 hours continuous use, approx.

Battery Type 2 AA (1.5V) or rechargeable

Weight 5 ounces (140 grams)

Housing Material ABS Plastic

Operating Temperature 32 to 122° F (0 to 50° C)

Storage Temperature – 4 to 150° F (–20 to 70° C)

Accessories Included Reflective tape, 2 AA batteries and operating instructions

in a foam-fitted, hard-plastic carrying case,

NIST-traceable calibration certificate

Warranty 5 years

P/N: CDT-TAPE 10 strips of reflective tape—1/2" x 4" (12 x 100mm)

Page 2

2

1.0 INTRODUCTION

The CDT-1000HD Digital Tachometer accurately measures RPM without

contacting the rotating element or object. A small piece of reflective tape

(supplied) is applied to the rotating element (shaft, wheel, etc.) The CDT1000HD utilizes a visible LED light beam to accurately measure the RPM

from a distance of up to 24 inches (60 cm) away from the “target.”

The CDT-1000HD is supplied with a built-in memory system which permits

the user to recall the maximum, minimum and last reading to the display for

viewing. It is powered by two (2) AA batteries (supplied).

1.1 Applications

Non-Contact RPM — Used when contact

measurement is not possible due to access

space restrictions, safety concerns, etc.

2.0 SAFETY PRECAUTIONS

All operators should wear safety goggles when using this or any other

tachometer. Failure to do so could result in serious injury!

7

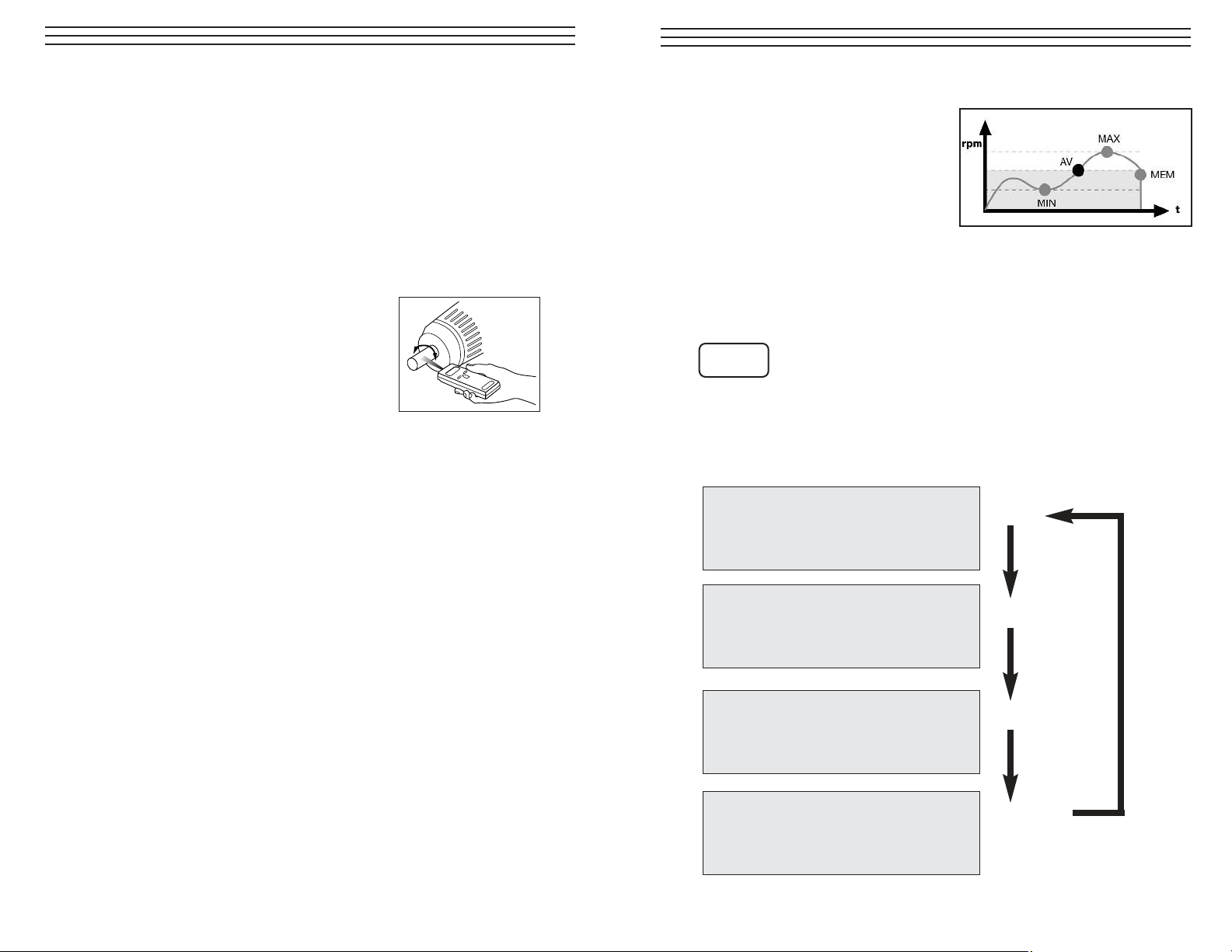

8.0 MEMORY SYSTEM

The CDT-1000HD is supplied with

a built-in memory system which

stores the last measurement, maximum

measurement, minimum measurement,

and the average measurement which

occurred during a measuring period.

A measuring period is the interval of time while the Measure key is

depressed. The stored values are retained in memory even when the power

turns off (auto power off). To recall the stored values after auto power off:

1. Press the Measure key to turn the power on

2. Press the MEM key to recall the desired value

The Memory key accesses the CDT-1000HD’s built-in

memory. Each time the MEM key is pressed the values

stored in memory will be recalled to the display in the sequence listed

below. The appropriate memory indicator will be shown together with

the recalled value on the display.

Note: When the batteries are removed, the values stored in memory

will be lost.

MEM

MEM

MAX

MIN

AV

rpm

8.8.8.8.8

MEM

MAX

MIN

AV

rpm

8.8.8.8.8

MEM

MAX

MIN

AV

rpm

8.8.8.8.8

MEM

MAX

MIN

AV

rpm

8.8.8.8.8

Last

Maximum

Minimum

Average

Page 3

3

3.0 CONTENTS OF COMPLETE OUTFIT

1

3

2

The CDT-1000HD is supplied with the following accessories in a foam-fitted,

carrying case:

1. Meter with molded rubber shell

2. Reflective Tape (10 strips)

3. Two AA Batteries

4. NIST-traceable Calibrations Certificate (not shown)

5. Instruction Manual (not shown)

6

7.0 MEASURING RPM

1. Attach a piece of reflective tape to the rotating

element (shaft, pulley, etc.).

2. Aim the CDT-1000HD at the target

using the red visible light beam for

alignment assistance.

3. Press and hold the Measure key to begin taking

measurements. The “On-Target” indicator on the

LCD will flash on and off if the instrument is

properly aimed at the target (reflective tape).

4. Release the Measure key prior to removing the

instrument from the target. The last reading

will be retained on the LCD display.

Hints for Non-Contact Measurements

1. The non-reflective area should be larger than the reflective area.

2. If the rotating element is highly reflective, cover it with black

tape or paint to improve the contrast between the reflective tape

and the surface of the rotating element.

Reflective Tape

Page 4

4

4.0 OVERVIEW OF CDT-1000HD

4.1 LCD Display

1. On-Target Indicator — Indicates that the unit is lined up

correctly for an accurate measurement

2. Memory Indicators — Indicates which measurement

stored in memory (last, max., min., avg) is displayed.

3. Low Battery Indicator — Illuminates to indicate that

batteries need replacement.

4.2 Front Panel Key Functions

4. MEM: Acesses the memory. Each time the key is pressed

the values stored in memory will be recalled to the display.

5. MODE: Not functional in this model.

6. MEASURE: Performs the following functions:

• Turns on the power

• Starts and stops the measuring period

• Exits from the memory mode

1

2

5

6

4

3

5

5.0 INSTALLING BATTERIES

1. Turn the gauge over and locate the battery

compartment. You do not have to remove

the rubber shell.

2. Open the battery compartment by pulling

down on the tab located at the top of the

battery cover and remove the cover.

Insert two AA batteries following the

orientation engraved on the inside of the

battery compartment.

3. Replace the battery cover by inserting the

two tabs located on the bottom edge of the

cover into the matching slots in the housing.

4. Push the cover closed until the tab at the top

of the battery cover “clicks” into position.

5. Replace the cut-out section of the protective

rubber shell.

6.0 Removing Protective Rubber Shell

The gauge is supplied with a durable rubber

shell that provides an added measure of

physical and environmental protection in

harsh applications.

To remove the shell, follow the procedure

outlined below:

1. Using your thumbs, slide the rubber shell

up and off of one corner of the gauge.

Repeat for the other corner

2. Pull the shell down until it is completely

off the corners of the gauge, the pull the

gauge forward and out of the shell.

3. Replace the shell by sliding the gauge

bottom first into the large center opening,

then, one at a time, slip the corners of the

shell back over the gauge.

click

Page 5

12.0 WARRANTY

ELECTROMATIC Equipment Co., Inc. (ELECTROMATIC) warrants to the

original purchaser that this product is of merchantable quality and confirms in

kind and quality with the descriptions and specifications thereof. Product failure or

malfunction arising out of any defect in workmanship or material in the product

existing at the time of delivery thereof which manifests itself within one year from

the sale of such product, shall be remedied by repair or replacement of such product,

at ELECTROMATIC’s option, except where unauthorized repair, disassembly, tampering, abuse or misapplication has taken place, as determined by ELECTROMATIC. All

returns for warranty or non-warranty repairs and/or replacement must be authorized by

ELECTROMATIC, in advance, with all repacking and shipping expenses to the

address below to be borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR

PURPOSE OR APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE

NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR

NATURE, RESULTING FROM THE USE OF SUPPLIED EQUIPMENT, WHETHER

SUCH DAMAGE OCCURS OR IS DISCOVERED BEFORE, UPON OR AFTER

REPLACEMENT OR REPAIR, AND WHETHER OR NOT SUCH DAMAGE IS

CAUSED BY MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE WITHIN

ONE YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation may not apply to you. The duration

of any implied warranty, including, without limitation, fitness for any particular

purpose and merchantability with respect to this product, is limited to the duration of

the foregoing warranty. Some states do not allow limitations on how long an implied

warranty lasts but, not withstanding, this warranty, in the absence of such limitations,

shall extend for one year from the date of invoice.

ELECTROMATIC Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516—USA

Tel: 1-800-645-4330/ Tel: 516-295-4300/ Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic Equipment Co., Inc., assumes

no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of

information contained herein. Any brand or product names mentioned herein are used for identification purposes only, and are trademarks or registered trademarks of their respective holders.

Page 6

CDT-1000HD

Non-Contact Tachometer

Operating Instructions

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516–U.S.A.

TEL: 516-295-4300 • FAX: 516-295-4399

CHECK•LINE

®

INSTRUMENTS

CHECK•LINE

®

BY ELECTROMATIC

Loading...

Loading...