Page 1

User’s Guide

CAP-TA

CAP TORQUE TESTER

User’s Guide

Page 2

CAP-TA Cap Torque Testers

Page 3

User’s Guide

Thank you!

Thank you for purchasing a CAP-TA Cap Torque Tester. We are

confident that you will get many years of service from this product.

The CAP-TA can be used to test cap torque for a number of different closure shapes and sizes, along with other types of samples. To maintain normal functioning of the tester, avoid repetitive overloads and shock loads.

We hope that this User’s Guide will provide a comprehensive

explanation of the CAP-TAs operation and sufficient detail on its

specifications. However, if you have any other questions or concerns, our technical support and engineering teams will be eager to help you.

Thank you again for your purchase and happy testing!

TABLE OF CONTENTS

UNPACKING AND SETTING UP ............................................... 2

LIST OF INCLUDED ITEMS ....................................................... 2

CONTROLS ................................................................................ 3

DISPLAY ..................................................................................... 3

POWER ....................................................................................... 4

SETTING UP THE SAMPLE....................................................... 4

CONFIGURATION ...................................................................... 5

CALIBRATION ............................................................................ 6

OUTPUTS ................................................................................... 7

SPECIFICATIONS ...................................................................... 8

DIMENSIONS .............................................................................. 9

WARRANTY ............................................................................... 9

1

Page 4

CAP-TA Cap Torque Testers

UNPACKING AND SETTING UP

1. Carefully unpack the CAP-TA and check for any damage. Inspect the contents to ensure that you have received a tester complete with all accessories

– see “List of included items” below.

2. Place the tester on a firm, flat and level working surface free from vibration. If

preferred, the CAP-TA can be secured to a work bench with screws through

the four tapped holes in the underside of the base. Then fasten the sample

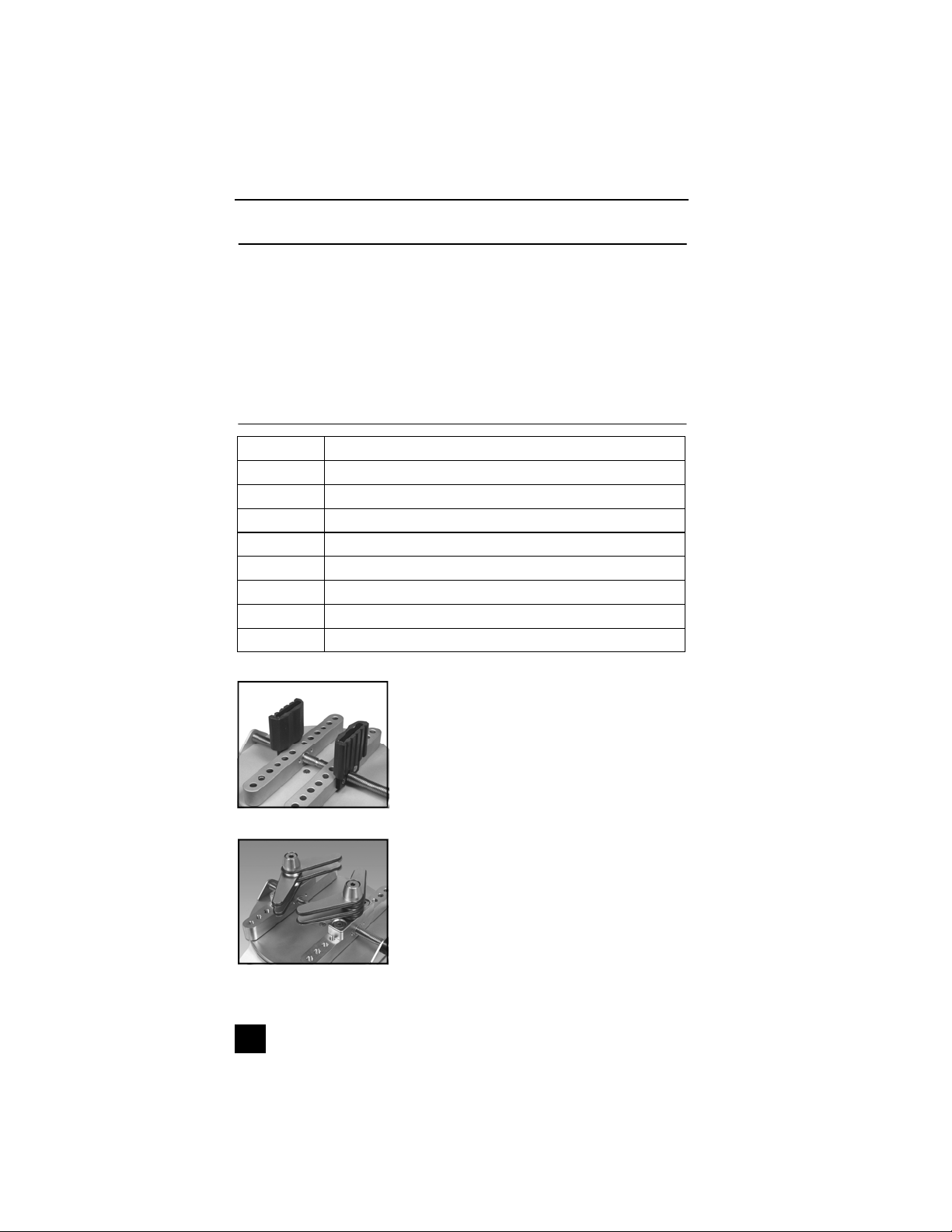

gripping posts into the desired holes on the sliders (see Fig. 1).

LIST OF INCLUDED ITEMS

Quantity Item

1 CAP-TA Torque Tester

1 User’s guide (this booklet)

4 Sample gripping posts

2 Sample gripping jaws (optional, see below)

1 Carrying case (optional)

1 AC adapter

1 Battery

1 Certificate of calibration

CT001 flat jaws (optional)

These jaws are designed for use with square or

other shaped containers, in addition to round samples. The jaws are reversible; one side has a Vgroove, while the other side is flat. These jaws can

be mounted to the inside of the sliders, or the outside.

CT003 adjustable jaws (optional)

These jaws are designed for use with unique

shaped samples. The four gripping arms per jaw

may be independently repositioned in 45° increments to accommodate unique profiles. Loosen the

screw at the top of the jaw to separate the arms

and reposition as desired.

2

Page 5

User’s Guide

CONTROLS

POWER / ENTER

Turns power on and off. Also used to select configuration menu items.

PEAK / ADVA NCE

Used to switch between Clockwise Peak,

Counterclockwise Peak and Normal (real

time) display modes. The actual peak

readings are always captured and can be

recalled at any time by pressing this button. Also used to step through configuration menu items.

ZERO

Zeros any tare value (up to the full capacity of the gauge) and clears the peak readings stored in memory.

DATA

Used to output the torque data point currently displayed.

UNITS

Changes measurement units between lbin, Ncm, and kgmm.

DISPLAY

The display consists of a 4 1/2-digit section and several indicators. Their functions are listed below.

LO BAT Low battery voltage indicator

CW Clockwise torque indicator

CCW Counterclockwise torque indicator

CW PEAK Peak clockwise torque indicator

CCW PEAK Peak counterclockwise torque indicator

LBIN, NCM, KGMM Units of measurement

- - - - (dashes) Overload (>110% of range)

Reduce torque immediately

3

Page 6

CAP-TA Cap Torque Testers

POWER

The CAP-TA can be operated by the included 9V non-rechargeable battery or by

the included AC adapter. Battery life is approximately 30 hours.

Do not use adapters other than supplied or instrument damage may occur.

There are three levels of low battery voltage indication. At the first level the dis-

play shows a steady "LO BAT" indicating approximately one hour of charge remaining. The second level is indicated by a flashing "LO BAT" indicator. At the

third level the whole display except the "LO BAT" indicator will flash for three

seconds after which time the instrument will turn itself off. This prevents the instrument from working at voltages too low for reliable operation.

To access the battery, loosen the four screws on the bottom plate.

SETTING UP THE SAMPLE

Place the sample between the posts or jaws of the tester, and tighten, using the

knob. Posts can be placed in any of the holes on the sliders (see Figs. 1 & 2

below). Ensure that the sample is gripped firmly, however, excessive tightening

of thin-walled closures may result in sample deformation, possibly affecting test

results. When the sample is secured, gradually exert torque by hand. Sudden

torque application may produce incorrect readings.

Fig. 1

Posts can easily be moved

between holes

4

Fig. 2

Optional jaws offer alternative

gripping methods

Page 7

User’s Guide

CONFIGURATION

CAP-TA torque testers have several features with programmable options allowing many user-specified choices. To enter the configuration menu, perform the

following:

1. Turn off the tester

2. Press and hold PEAK

3. Turn on the tester

4. Release PEAK

The version number of the internal software will be displayed for a short time.

The following secondary functions of keys are used during the configuration

process:

ENTER Used to select a menu choice

ADVANCE Used to step through menu choices

NOTE: Once the menu has been entered, it can only be exited if changes have

been made.

The following list shows all configuration options. Italics indicate factory set-

tings.

232 - RS-232 settings sub-menu

232d Output Disabled

232E Output Enabled

300 300 baud

600 600 baud

1200 1200 baud

2400 2400 baud

4800 4800 baud

9600 9600 baud

7-1E 7 data bits, 1 stop bit, even parity

7-1o 7 data bits, 1 stop bit, odd parity

7-2E 7 data bits, 2 stop bits, even parity

7-2o 7 data bits, 2 stop bits, odd parity

7-2n 7 data bits, 2 stop bits, no parity

8-1E 8 data bits, 1 stop bit, even parity

8-1o 8 data bits, 1 stop bit, odd parity

8-1n 8 data bits, 1 stop bit, no parity

8-2n 8 data bits, 2 stop bits, no parity

Ft F Full data (numeric + units)

Ft n Numeric data only

bcd - Mitutoyo BCD settings sub-menu

bcdd Output disabled

bcdE Output enabled

nPOL No polarity (absolute value)

POL Data with polarity (+ for CW, - for CCW)

5

Page 8

CAP-TA Cap Torque Testers

AoFF - Automatic shutoff settings sub-menu

no Disabled

1 1-minute automatic shutoff

5 5-minute " “

10 10-minute “ “

20 20-minute " "

30 30-minute " "

init - Initial (default) settings sub-menu

LBIN Pound-inch as default unit

KGMM Kilogram-millimeter as default unit

NCM Newton-centimeter as default unit

CCW Real time display at turn on

PEAK CW Peak clockwise display at turn on

PEAK CCW Peak counterclockwise display at turn on

CAL - Calibration sub-menu. See CALIBRATION section.

CALIBRATION

To properly calibrate the CAP-TA, application of a precise torque value equal to

the full capacity of the tester in pound-inches (regardless of the displayed units)

is required.

While holding PEAK, turn on power to the tester. When ‘CAL’ appears on the

display, press ENTER three times to select the calibration mode. At the ‘null’

prompt, press ZERO. At the ‘SPAn’ prompt, apply the calibration torque and

press ENTER. The display will show ‘uuuu’ or ‘nnnn’ if the calibration torque is

insufficient or excessive, respectively. If this happens, the only way to terminate

the calibration mode is by momentarily disconnecting the battery or connecting

the AC adapter to the tester without plugging the other end into a wall outlet.

This will stop the calibration procedure without making any changes to the previous calibration data.

Successful calibration is indicated by ‘donE’ on the display. Press ENTER to

save the changes and resume normal operation.

6

Page 9

User’s Guide

OUTPUTS

RS-232

Data transmission can be initiated by pressing DATA or through an external

device by sending ASCII "?". The tester will respond by sending the current reading in either full or numeric format, depending on the configuration setting (see

Configuration section). Polarity sign indicates CW (+) or CCW (-) torque. The

transmitted string has the following format:

[POLARITY (SPACE OR -)][DATA][SPACE][UNITS (IF ENABLED)][CRLF]

Mitutoyo BCD

This output is useful for connection to data collectors, printers, multiplexers or

any other device capable of accepting Mitutoyo BCD data. The transmission is

initiated by pressing DATA or by the receiving device.

I/O connector pin diagram

1 RS-232 receive Input

1298345

7

6

DB-9P

2 RS-232 transmit Output

3 Mitutoyo request Input

4 Mitutoyo clock Output

5 Signal ground 6 No connection

7 No connection

8 Mitutoyo ready Output

9 Mitutoyo data Output

7

Page 10

CAP-TA Cap Torque Testers

SPECIFICATIONS

Accuracy: ±0.5% of full scale ±1digit

Sampling rate: 65/s

Display update rate: 2.5/s in normal mode, 65/s in peak mode

Safe overload:

Outputs (optional):

RS-232: Baud rates between 300 and 9600

Mitutoyo: Standard Mitutoyo BCD output

Connector: 9-pin D-type male

Power: 9V battery or AC adapter

Battery life: 30 hours of continuous operation

Weight: 6.5 lb [2.9 kg]

Capacity x resolution:

CAP-TA-12 12 x 0.01 lbFin, 140 x 0.1 kgFmm, 135 x 0.1 Ncm

CAP-TA-50 50 x 0.05 lbFin, 580 x 0.5 kgFmm, 570 x 0.5 Ncm

CAP-TA-100 100 x 0.1 lbFin, 1150 x 1 kgFmm, 1150 x 1 Ncm

150% of gauge capacity. Display shows

---- (dashes) above 110%.

8

Page 11

User’s Guide

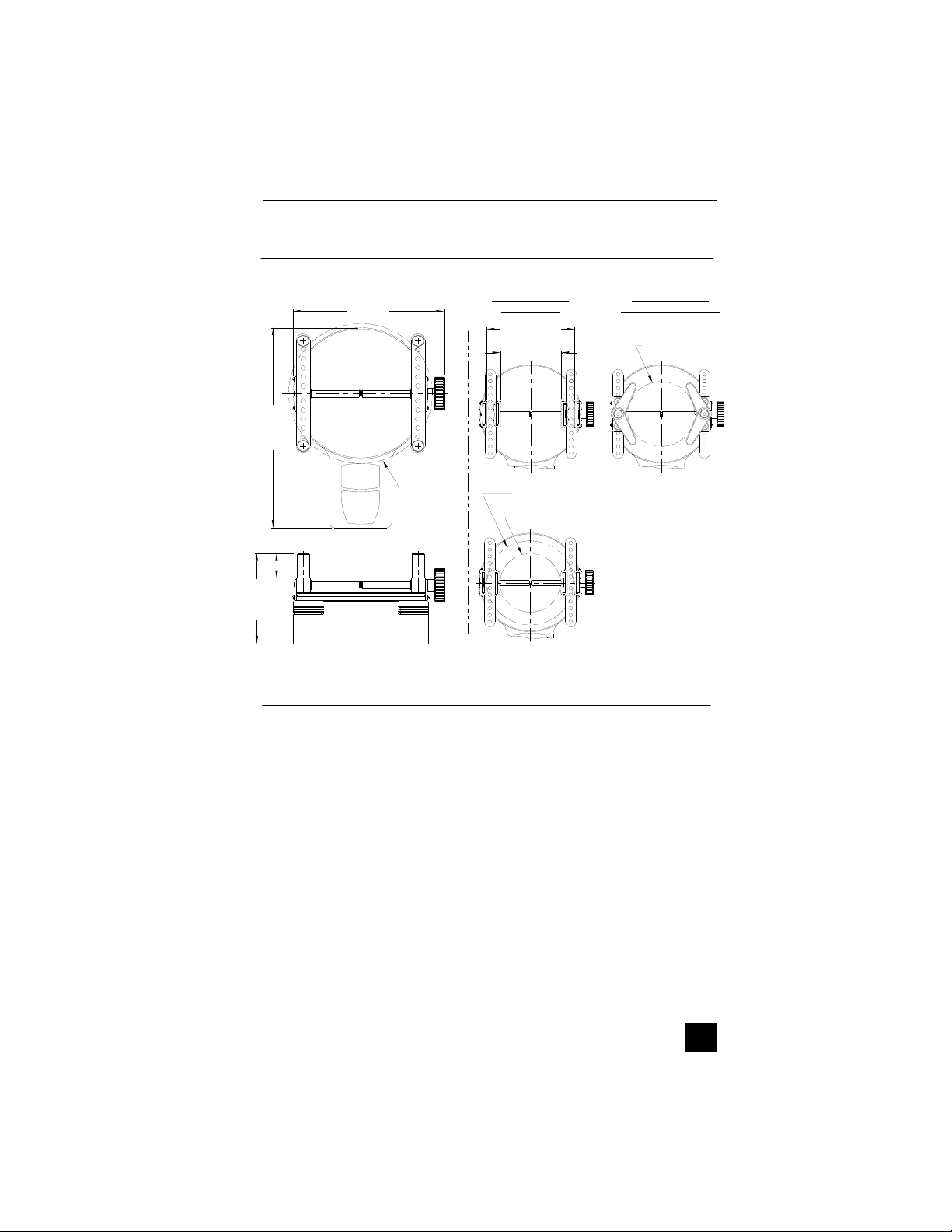

DIMENSIONS in [mm]

WITH OPTIONAL

7.8 [199.3]

10.7 [270.5]

Ø7.5 [189.4] MAX

Ø0.5 [12.7] MIN

4.8 [121.8]

1.3 [33.0]

FLAT JAWS:

5.9 [149.9] MAX

1.3 [33.0] MIN

4.4 [111.8] MAX

0 MIN

Ø6.0 [151.9] MAX

Ø1.3 [33.0] MIN

Ø4.4 [111.8] MAX

Ø0.25 [6.35] MIN

WITH OPTIONAL

ADJUSTABLE JAWS:

Ø4.6 [116.8] MAX

Ø0 MIN

WARRANTY

EEC Corporation expressly warrants to its buyer for three (3) years from the date

of delivery that the goods sold are free from defects in workmanship and materials. EEC Corporation will, at its option, repair or replace or refund the purchase

price of goods found to be defective. This remedy shall be the buyer’s sole and

exclusive remedy. Any modification, abuse, exposure to corrosive environment

or use other than intended will void this warranty. This warranty is in lieu of all

other warranties, including implied warranties of merchantability and fitness for

an intended purpose. In no event shall EEC Corporation be liable for any incidental and consequential damages in connection with goods sold or any part

thereof.

9

Page 12

CAP-TA Cap Torque Testers

ELECTROMATIC Equip’t Co., Inc

600 Oakland Ave.

Cedarhurst, NY 11516

Tel: 800-645-4330 / 516-295-4300

Fax: 516-295-4399

Email: info@checkline.com

Website: www.checkline.com

Loading...

Loading...