Page 1

1

Table of Contents

01.0 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

02.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

03.0 Operating Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

04.0 Preliminary Computations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

4.1 Determining Belt Density (d)

4.2 Determining Length of Free Belt Span (L) . . . . . . . . . . . . . . . . . . .

05.0 Preparing The Gauge For Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 05

5.1 Selecting the Language

5.2 Selecting the Measurement Units (Hz or N/lbf)

5.3 Selecting the Engineering Units (International or U.S.)

6.0 Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

06

07.0 Measuring Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 07

08.0 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09

9.0 Battery Installation & Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 09

10.0 Typical Belt Densities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

11.0 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

12.0 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figures

0

1. Complete BTM-400 Outfit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

0

3. Free Belt Span (L) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

0

4. Measuring Free Belt Vibration Frequency (Hz) . . . . . . . . . . . . . . . . . . . . 7

0

5. Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

12

12.0 WARRANTY

ELECTROMATIC Equipment Co., Inc. (ELECTROMATIC) warrants to the

original purchaser that this product is of merchantable quality and confirms

in kind and quality with the descriptions and specifications thereof. Product

failure or malfunction arising out of any defect in workmanship or material in the

product existing at the time of delivery thereof which manifests itself within one

year from the sale of such product, shall be remedied by repair or replacement of

such product, at ELECTROMATIC’s option, except where unauthorized repair,

disassembly, tampering, abuse or misapplication has taken place, as determined by

ELECTROMATIC. All returns for warranty or non-warranty repairs and/or replacement must be authorized by ELECTROMATIC, in advance, with all repacking and

shipping expenses to the address below to be borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT

LIMITED TO, THE WARRANTY OF MERCHANTABILITY AND FITNESS FOR

ANY PARTICULAR PURPOSE OR APPLICATION. ELECTROMATIC SHALL

NOT BE RESPONSIBLE NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE,

OF ANY KIND OR NATURE, RESULTING FROM THE USE OF SUPPLIED

EQUIPMENT, WHETHER SUCH DAMAGE OCCURS OR IS DISCOVERED

BEFORE, UPON OR AFTER REPLACEMENT OR REPAIR, AND WHETHER OR

NOT SUCH DAMAGE IS CAUSED BY MANUFACTURER’S OR SUPPLIER’S

NEGLIGENCE WITHIN ONE YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation may not apply to you. The duration of any implied warranty, including, without limitation, fitness for any particular

purpose and merchantability with respect to this product, is limited to the duration of

the foregoing warranty. Some states do not allow limitations on how long an implied

warranty lasts but, not withstanding, this warranty, in the absence of such limitations,

shall extend for one year from the date of invoice.

ELECTROMATIC Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516—USA

Tel: 1-800-645-4330/ Tel: 516-295-4300/ Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic Equipment Co., Inc., assumes

no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of

information contained herein. Any brand or product names mentioned herein are used for identification purposes only, and are trademarks or registered trademarks of their respective holders.

Page 2

2

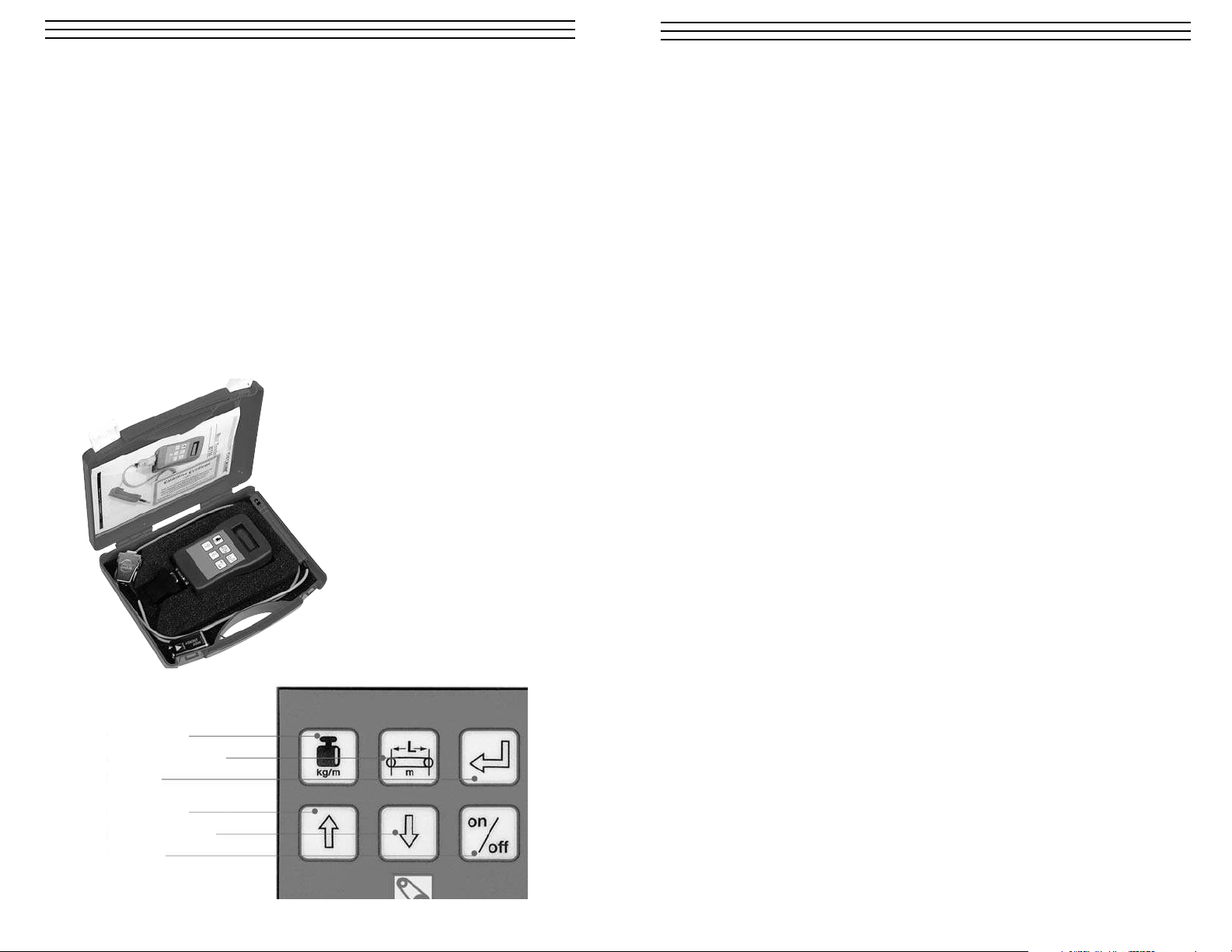

1.0 OVERVIEW

The CHECK-LINE®BTM-400PLUS Belt Tension Meter is an electronic measuring

instrument that precisely measures the static tension or natural frequency of flat, V-,

cog or toothed belts of rubber, leather, fabric, plastic and composite materials—at

standstill.

The BTM-400PLUS consists of a gauge body and two (2) separate sensor probes that

emit and receive a pulsed, ruby-red beam of light. One probe is a detachable type,

best for one-handed operation, and the other is a hand-held, cable-connected type, for

easier access to hard-to-reach and “small-window” measuring locations. After certain

belt characteristics have been entered into the gauge’s microprocessor, and a section of

the belt has been caused to vibrate, the probe is brought close to the vibrating belt.

The reflected light signal is then fed into the gauge’s microprocessor which converts it

into a pre-selected reading of either Belt Vibration Frequency (Hz) or Belt Tension

(Newtons (N) or Pounds Force (lbf).

Note: Where only Belt Vibration Frequency (Hz) is of interest, belt characteristics

need not be entered into the microprocessor.

Figure 1. Complete BTM-400PLUS Outfit

11

11.0 SPECIFICATIONS

Measuring range 10 – 400 Hz

Digital sampling error < 1%

Indication error ±1 Hz

Total error < 5%

Nominal temp. 68 °F (20 °C)

Operating temp. 50 to 122 °F (10 to 50 °C)

Max. storage temp. 23 to 158 °F (–5 to 70 °C)

Gauge body material Plastic (ABS)

Dimensions, body* 3.15 in. x 6.5 in. x 1.47 in (80 x 165 x 37mm)

Probe cable length 3.9 ft. (1.2 m) overall

Dimensions, case 8.9 in x 7.0 in x 2.0 in.(226 x 178 x 50mm)

Display 2-line LCD, 16 char./line

Languages German, English, French, Italian, Spanish,

Portugese, Danish, Swedish, Norwegian, Finnish

Free span length, max. 30 ft. (10 m)

Belt density, max. 10 kg/m

Power supply 9 volt alkaline battery

* Includes detachable type probe.

Note: All specifications subject to change without notice.

Free Span Length

Belt Density

Keys on the membrane

keypad

ENTER

ARROW UP

ARROW DOWN

ON/OFF

Figure 2. Keypad

Page 3

3

2.0 INTRODUCTION

A belt drive achieves its maximum lifetime and efficiency when:

1. It is properly configured and rated for the application.

2. The belt is tensioned to the manufacturer’s recommended tension.

3. The pulleys are perfectly aligned.

The CHECK•LINE

®

BTM-400PLUS Belt Tension Meter affords the user an easy,

reliable method for accurately measuring the tension in a belt system at standstill.

3.0 OPERATING PRINCIPLE

When the Free Span* of a belt is plucked, tapped or struck, it will vibrate at a

frequency known as its “natural” frequency, the value of which depends on the

existing tension in and the total mass of the Free Belt Span, according to the

following relationship:

f = T/4dL

2

or T = 4dL2f

2

where:

f = Natural frequency of the Free Belt Span (Hz)

T = Tension in belt (N or lbf)

d = Belt density (kg/m or lb/ft)

L* = Length of the Free Belt Span (m or ft), which vibrates when struck.

* For definition of Free Span, refer to 4.2 and Figure 2.

The d and L parameters are fixed in the design of the belt, while the “natural”

frequency (f) varies with the applied Belt Tension (T). The BTM-400PLUS picks

up the vibration frequency of the Free Belt Span and displays it, or the corresponding

belt tension, on the instrument’s LCD display panel.

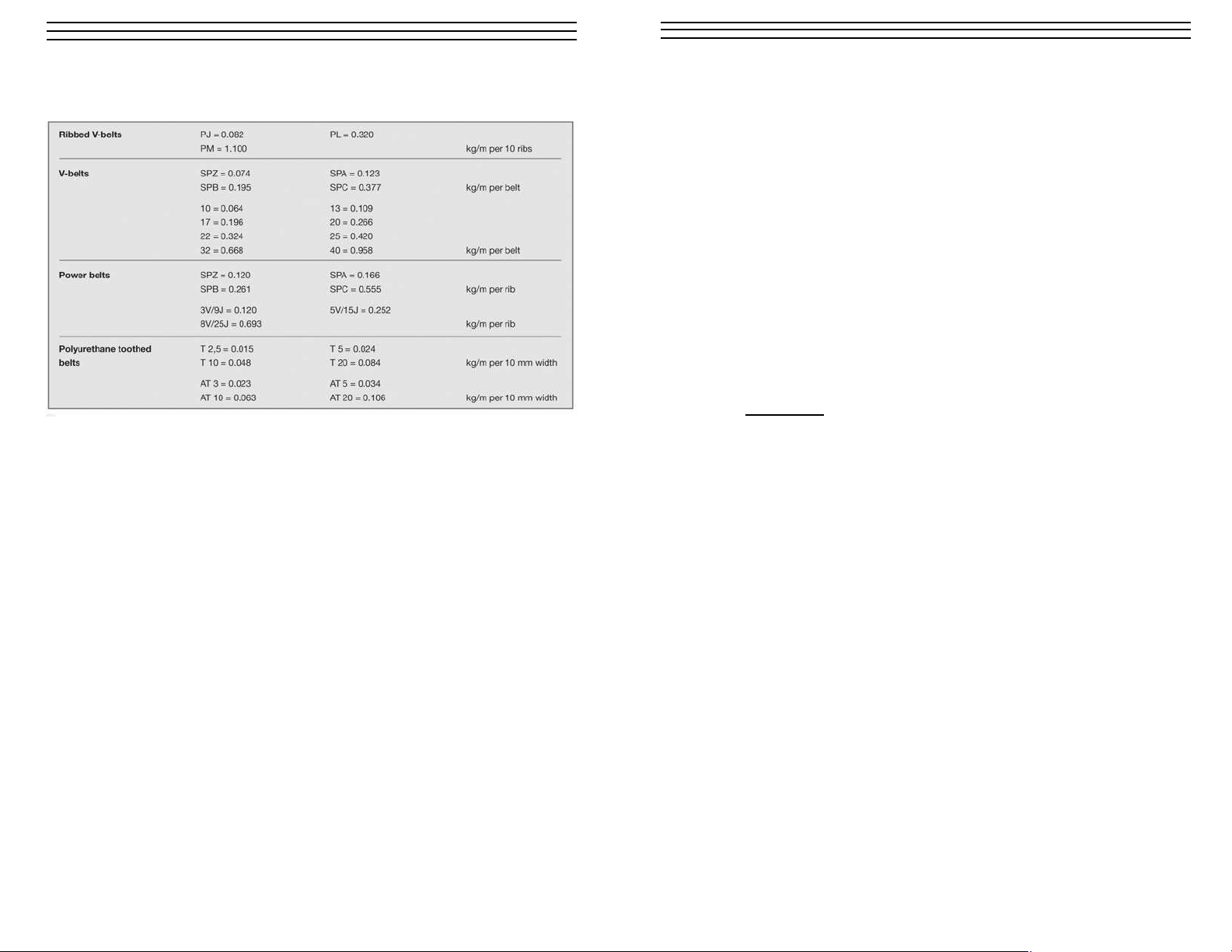

10.0 TYPICAL BELT DENSITIES

10

√

Page 4

9

9.0 BATTERY INSTALLATION & REPLACEMENT

The BTM gauge is shipped with a 9-volt DC alkaline battery. To install it, or replace it

when the display shows LOW BAT, proceed, as follows:

1. Turn the gauge over. Using your forefinger press down on the battery

compartment latch, located just above the belt clip. Pull the battery

compartment cover towards you and off.

2. Install the new battery being sure that the terminals are completely attached.

3. Replace the cover by inserting the two plastic tabs into the slots at the base

of the compartment and press forward until the latch clicks shut.

4

4.0 PRELIMINARY COMPUTATIONS

Before beginning the measurement process, the following parameters must be

determined. As previously noted, the Belt Density (d) and Length of Free Belt Span

(L) are fixed for any particular installation. The belt and pulley manufacturer or supplier can usually supply those parameters. Refer to chart in 10.0, for typical densities.

If this information is not readily available, proceed to determine them, as follows:

4.1 Belt Density (d = kg/m or lb/ft)

1. Weigh the entire belt to determine kg or lb.

2. Measure the developed length of the entire belt, in meters or feet.

3. Calculate d = kg/m or lb/ft.

4.2 Length of Free Belt Span (L)

1. Referring to the fig. 2, measure L, the belt segment that will

be vibrated. It is equal to the belt length between tangential points

where the belt contacts opposite pulley wheels or sheaves.

OR

2. Calculate L, using the following formula:

L =

√C

2

– [(D1 – D2)/2]

2

where

L = Free Span length (m or feet)

C = Center-to-center (c:c) distance between pulley centers.

D1 = Pitch diameter of larger pulley, P1

D2 = Pitch diameter of smaller pulley, P2.

All dimensions are in meters (m) or feet (ft).

Figure 3. Measuring Free Belt Span (L)

Latch

Cover

Belt Clip

9-volt Battery

Plastic tabs

L

P1

P2

C

Page 5

5

5.0 PREPARING THE GAUGE FOR USE

NOTE: Prior to first time use, install a new 9-volt DC alkaline battery, as shown in

Section 9.0, page 9.

5.1 Selecting the Language

1. Press ON/OFF key to turn power ON. The software version number appears,

followed by Measurement Units frequ. [Hz]) or tens. [N] and menu = enter.

2. Press ENTER and then DOWN ONCE, until display reads

sprachwahl (language), etc. If correct, exit the program by pressing

the ON/OFF key. If not, proceed.

3. Press ENTER . Display will show current language selection (flashing).

4. Press UP and DOWN keys to scroll to the desired language.

5. Press ENTER to accept.

6. Press ON/OFF to turn power OFF.

The selected language will be retained in memory. To change the language,

repeat this procedure.

5.2 Setting The Measurement Units

1. Press ON/OFF key to turn power ON. Display will show: V 8.0 and then

frequ. [Hz] or tens. [N]), depending on last setting, and menu = enter.

If setting is CORRECT, no further action is required. If INCORRECT,

proceed:

2. Press ENTER . Display reads display Hz/N/lbf.

3. Press ENTER . Flashing display now reads,

display in Hz or display Tension (N or lb/f ).

4. Press DOWN . Display will now start flashing, showing the

other units (Hz or N/lbf).

5. Press ENTER to accept the flashing units of measurement

(Hz or N/lbf). Display now shows display Hz/N/lbf.

6. Press ON/OFF key to turn power off.

5.3 Setting The Engineering Units (International or U.S.)

1. Press ON/OFF key to turn power ON. Display shows menu = enter.

2. Press ENTER once and then DOWN TWICE until display reads

SI / US.

3. Press ENTER . Display will show current engineering units selection.

4. Press UP and DOWN keys to scroll to the desired engineering units,

either International (SI) or U.S.

5. Press ENTER to accept.

6. Press ON/OFF key to turn the power off.

8

8.0 TROUBLESHOOTING

Measurement deviations of up to ± 10% for several measurements taken on the same

drive belt are, as a rule, not caused by a measurement error or fault in the unit. In most

cases, measurement deviations are due to the mechanical tolerances of the drive systems. If no measurement results are displayed despite careful preparations, this may

be due to one of the following two reasons:

1. The drive belt vibrates below the minimum measurement limit of 10 Hz.

Remedy

Tighten the belt or, if the Free Span length is very long and open, support

the belt in order to shorten the length. Enter the shorter Free Span belt

length (L) before repeating measurement.

2. Either no or low measuring values are displayed despite the drive belt

being correctly tensioned.

Remedy

It may be that the light from the measuring probe is not sufficiently

reflected. To improve reflection, affix a piece of light-colored reflective tape

to the belt or slightly moisten the belt at the measuring point.

Page 6

6

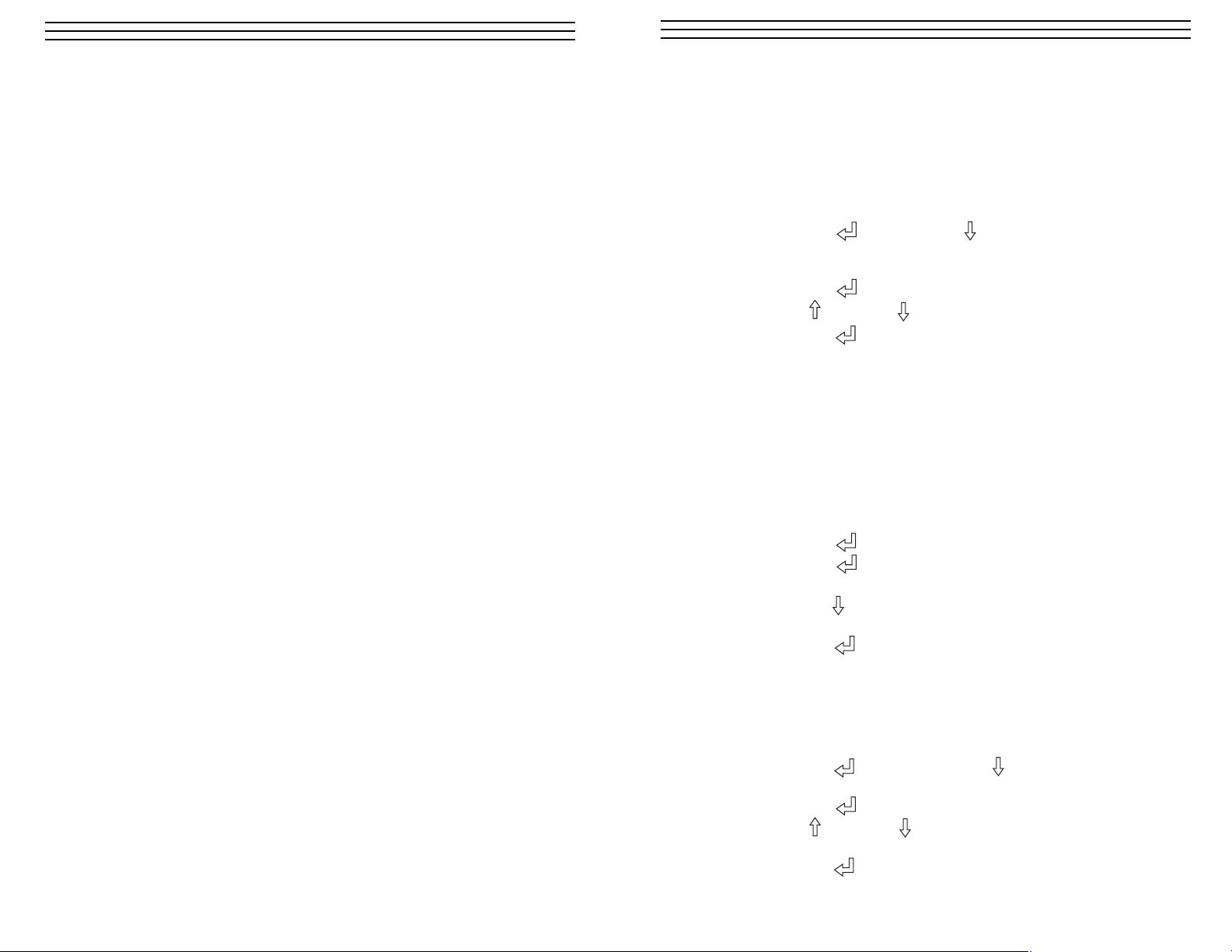

6.0 MENU STRUCTURE

7.0 MEASURING PROCEDURE

WARNING: All measurements and adjustments must be made with

the belt at a standstill.

1. Switch on the BTM-400PLUS by pressing the ON/OFF pad key.

2. Check that the belt density (kg/m or lb/ft} and Free Belt Span (L) settings

for the belt involved have been entered into the microprocessor by pressing

the corresponding pad keys. When the key is pressed, the display will flash

the last value of the parameter selected. If correct, press ENTER to

confirm the setting. If incorrect, press the UP or DOWN key to adjust

to the correct value, then press ENTER to accept revised value.

3. Tap or pluck the drive belt at the middle of the Free Belt Span so that it

begins to vibrate. Hold the sensor probe approximately at the center of

the L span, and at a distance of 3 to 20 mm above the belt, with its light

directed to the belt. Refer to Figure 3. Readings will appear on the display

4. Successful measurement is acknowledged by an acoustic signal and the

indication “process busy” appears on the display.

5. The measured value is displayed in Hz or N/lbf, as pre-selected.

NOTE: If frequency (Hz) alone is of interest, disregard step 2, above.

Figure 4. Measuring Free Belt

Vibration Frequency

Figure 5. Keypad

Free Span Length

Belt Density

Keys on the membrane

keypad

ENTER

ARROW UP

ARROW DOWN

ON/OFF

7

Page 7

BELT TENSION METER

BTM-400PLUS

Operating Instructions

CHECK•LINE

®

BY ELECTROMATIC

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516–U.S.A.

TEL: 516-295-4300 • FAX: 516-295-4399

CHECK•LINE

®

INSTRUMENTS

Loading...

Loading...