Page 1

NOTE

TABLE OF CONTENTS

1.0 Design of the device ……………………………………………… 2

2.0 Measuring procedure ………………………………………………… 3

2.1 Information of the measurement of sawdust

3.0 Calibration curves ……………………………………………….. 6

4.0 Determination of the material reference moisture ……………….. 6

5.0 Menu level overview ………………………………………………..… 7

6.0 Changing batteries ………………………….……………………..… 8

7.0 Transfer saved data to the PC …………….……………………….. 9

8.0 Print saved data ……………………………………….………….… 10

9.0 Online print and online send ……………………………….…………….. 10

10.0 Device maintenance instructions …………………………………… 11

11.0 Exemption from liability …………………….……………………….. 11

12.0 Technical data ……………………………………….…………….…. 12

13.0 Most common reasons for miss readings …………………………. 13

14.0 Warranty ……………..………………….……………………………... 14

Checkline-Europe

-16-

Checkline-Europe

-1-

Page 2

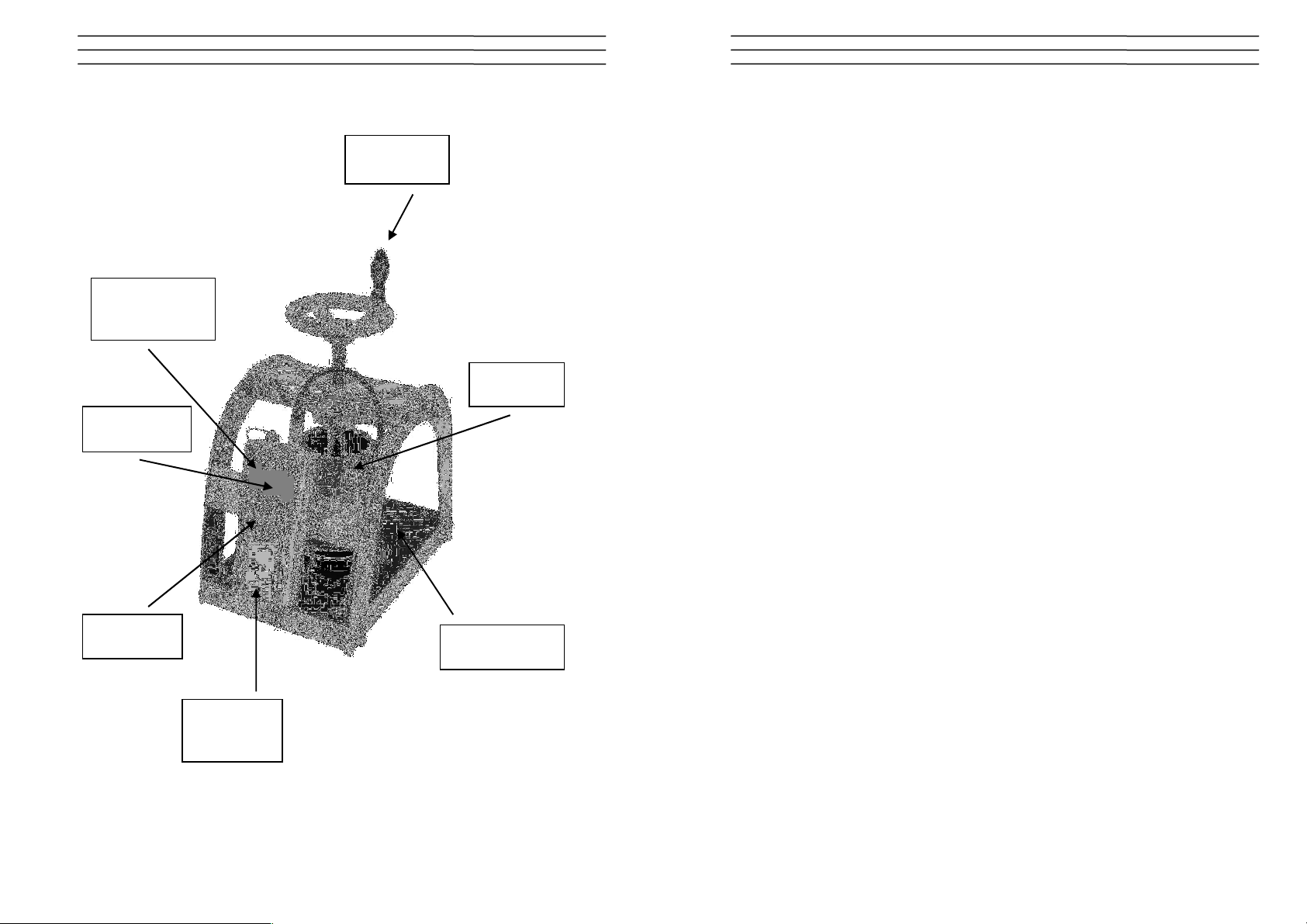

1.0 DESIGN OF THE DEVICE

chamber

button

Name of the

calibration

curve

Water

content

NOTE

Hand wheel

Measuring

Power

Batteries

slot

(flipside)

Checkline-Europe

-2-

LED (green /

orange)

Checkline-Europe

-15-

Page 3

14.0 WARRANTY

Electromatic Equipment Co., Inc. (Electromatic) warrants to the original purchaser

that this product is of merchantable quality and confirms in kind and quality with the

descriptions and specifications thereof. Product failure or malfunction arising out of

any defect in workmanship or material in the product existing at the time of delivery

thereof which manifests itself within one year from the sale of such product, shall be

remedied by repair or replacement of such product, at Electromatic’s option, except

where unauthorized repair, disassembly, tampering, abuse or misapplication has

taken place, as determined by Electromatic. All returns for warranty or non-warranty

repairs and/or replacement must be authorized by Electromatic, in advance, with all

repacking and shipping expenses to the address below to be borne by the

purchaser.

THE FOREGOING WARRANTY’S IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR

PURPOSE OR APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE

NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR

NATURE, RESULTING FROM THE USE OF SUPPLIED EQUIPMENT, WHETHER

SUCH DAMAGE OCCURS OR IS DISCOVERED BEFORE, UPON OR AFTER

REPLACEMENT OR REPAIR, AND WHETHER OR NOT SUCH DAMAGE IS

CAUSED BY MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE WITHIN ONE

YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation may not apply to you.

The duration of any implied warranty, including, without limitation, fitness for any

particular purpose and merchantability with respect to this product, is limited to the

duration of the foregoing warranty. Some states do not allow limitations on how long

an implied warranty lasts but, not withstanding, this warranty, in the absence of such

limitations, shall extend for one year from the date of invoice.

Electromatic Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516 - USA

Tel: 1-800-645-7330 / Tel: 516-295-4300 / Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of information contained herein. Any brand or product names mentioned herein

are used for identification purposes only, and are trademarks or registered trademarks of their

respective holders.

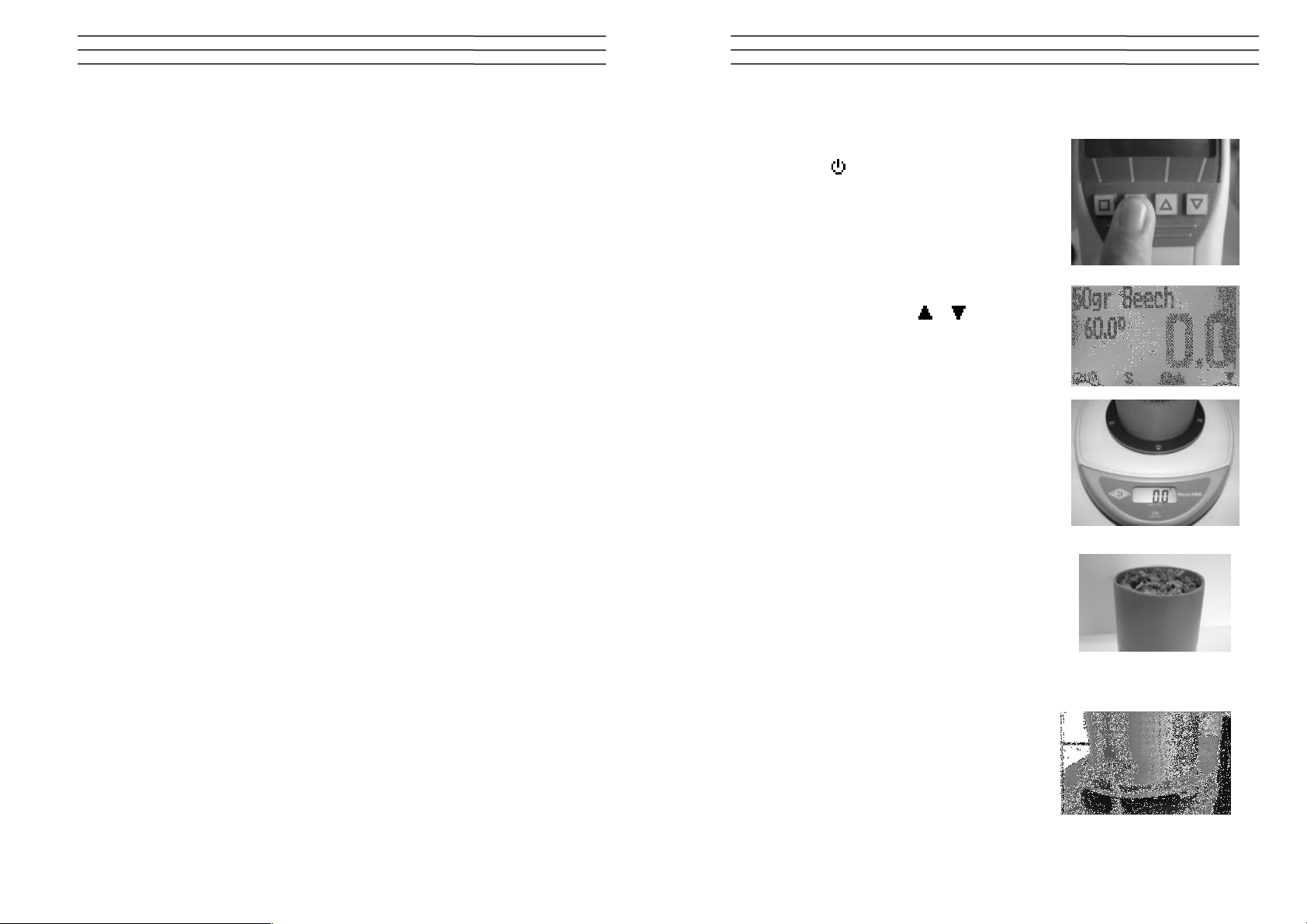

2.0 MEASURING PROCEDURE

1. Switch on the humimeter BLH by pressing the

power button (

2. Select the right calibration curve for your material

under test using the buttons

3. Place the scale on an even surface. Place the

humimeter BLH in the centre of the scale. Zero the

scale to show 0.0g.

4. Fill the measuring chamber with the appropriate

amount of wood shavings. The cup must be filled

either 50g or 100g material. During filling the cup,

the material must not be compressed too much. If

you have no place in the cup for 100g, the cup must

be emptied again and 50g wood chips have to be

filled into the cup.

CAUTION: Excessive force may be destroyed: the cup!

5. Put the measuring chamber into the device. The

sticker has to be facing the electronics housing.

)for 3 sec.

or .

Checkline-Europe

-14-

Checkline-Europe

-3-

Page 4

6. Compress the material in the measuring chamber now by turning the hand

LED off

LED

green

LED

orange

wheel (1 turn per second) until the LED turns green. Now slowly (0.5 turns per

second) must be rotated until the LED flashes orange once.

7. Then immediately press the start button on the

device

8. After a few seconds, the display shows stable

water content.

9. The water content of the sample is now visible on

the display.

10. If the measure value is blinking, the valid

measuring range is exceeded (limits see list on

page 5). In this case the accuracy will be

decreasing.

11. To save the results in the save menu press the

(

button). The storage

was successful when the number in front of the

symbol

reach the store menu please press (

increased. To

) until the

appears.

12. To name the saved results press the

button.

13. Empty the humimeter BLH and ensure that no

material rests are accumulated in the measuring

chamber.

13.0 MOST COMMON REASONS FOR MISS READINGS

• Product temperature out of application range

Material below 0°C resp. above +40°C (32 to 104 °F) may cause faulty

measurements. The storage of cold material in a warm storage area usually

creates condensed water which may lead to major measuring errors.

• Not adjusted material under test

Please ensure that the device and the material under test are being stored at the

same temperature (+/-3°C) before measuring. A very high temperature

difference has a negative effect on the stability of the measurement results.

• Wrong calibration curve

Before you measure your sample, double check the correct selection of the

calibration curve.

• Wrong filling quantity

Fill in exactly the right weight of wood chips in the measuring chamber.

• Wet or moldy material

• Frozen measuring material

• The steel plate which is mounted on the spindle part has to be cleaned at

regular intervals. As well as the pressure pin on the base plate (use a dry cloth

or something like that). Specifically, after measurement of wet material can be

located on the disk. This material can interfere with the following measurements!

• Compression function has to be done smoothly

To compress the hand wheel approximately one turn per second should be

rotated. When the green LED is on, the hand wheel has to be turned a half turn

further per second until the LED is orange is on.

Checkline-Europe

-4-

Checkline-Europe

-13-

Page 5

12.0 TECHNICAL DATA

Resolution of the display 0.5% water content

0.5°C temperature

Measuring range 15 up to 65% depending on the material

Operation temperature 0°C up to +40°C

Storage temperature -20°C to +60°C

Temperature compensation Automatically

Power supply 4 pcs. 1.5 Volt AA Alkaline batteries (900

Auto Switch OFF After app. 6 minutes (adjustable)

Current consumption 60mA (with light)

Display 128 x 64 matrix display, lighted

Dimensions 275 x 180 x 290 mm

Weight ca. 2,9 kg (including batteries)

Degree of protection IP 40

measurements)

Scope of supply Device including measuring cup

4x1.5 Volt AA Alkaline batteries

Software LogMemorizer

USB interface for PC transfer

USB cable

2.1 Information of the measurement of sawdust

Enclosed you will find instructions for measuring sawdust. If you are not sure what

type of wood you use, we recommend a one-time measurement compared with the

drying method according CEN / TS 14774.

The calibration curves using 100g filling quantity only be used in very wet material.

In general, the sample size of 50gr has to be used. If at the 50gr curve to less

pressure is in the measuring cup (LED don´t lights up orange!), than the 100gr

calibration curve must be used.

Material less than 15% water content cannot be measured.

Information: It is possible that other calibration curves (e.g., other types of wood,

defined mixtures, etc.) are calibrated by the Schaller GmbH in the humimeter

device.

Checkline-Europe

-12-

Checkline-Europe

-5-

Page 6

3.0 CALIBRATION CURVES

Type of wood

Filling quantity

Measuring range

Beech

Beech

Birch

Birch

Oak

Oak

Spruce

Spruce

Poplar

Poplar

Reference

−

Mn

50 g 15 % to 45%

100 g 40 % to 60 %

50 g 15 % to 45%

100 g 35 % to 55%

50 g 15% to 45%

100 g 40% to 55%

50 g 15% to 60%

100 g 50% to 65%

50 g 15% to 60%

100 g 50% to 60%

------ ------

To verify the calibration curve only the standardized drying method is permissible

because many other methods used are doubtful and can lead to incorrect

comparison values. If no existing curve fit, then a calibration by the company

Schaller is required.

4.0 DETERMINATION OF THE MATERIAL REFERENCE MOISTURE

The principle is a comparison measurement with the dehydration method according

to CEN/TS 14961:2005. Take the measured sample and weigh it. Dry it out in an

oven and weigh it again.

F

=

MtMn

100% ×

Mn: Mass with average moisture content

: Mass of the dried sample

M

t

%F: Calculated moisture content

10.0 DEVICE MAINTENANCE INSTRUCTIONS

To provide a long life of your device please does not expose it to strong mechanical

loads or heat e.g. dropping it or direct sunlight exposure. Clean your device using a

dry cloth. Any kind of wet cleaning damages the device.

It is not allowed to load the measuring head incorrect (stress, bending), otherwise it

can be broken. Plug and remove the insertion probe of your BLH straight into the

wood chips.

The instrument is not rainproof. Keep it in dry areas. When the device isn’t used for

a longer period (2 months) or when the batteries are empty, they should be removed

to prevent a leakage of the battery acid.

11.0 EXEMPTION FROM LIABILITY

For miss readings and wrong measurements and of this resulting damage we refuse

any liability. This is a device for quick determination of moisture. The moisture

depends on multiple conditions and multiple materials. Therefore we recommend a

plausibility check of the measuring results. Each device includes a serial number

and the guarantee stamp. If those are broken, no claims for guarantee can be

made. In case of a faulty device, please contact Checkline Europe (www.checklineeurope.eu) or our dealer.

Checkline-Europe

-6-

Checkline-Europe

-11-

Page 7

8.0 PRINT SAVED DATA

Keypad symbols

To print your saved data, connect the device to the

printer using the printer cable that was delivered with

your device. Carefully loose the protection cap on the

humimeter BLH. At first plug in the side of the connector

with the close plastic casing at the humimeter BLH.

Then switch on the device.

Not till then the other side of the cable has to be plugged

in at the printer. Switch on the printer by pressing

Now the green LED is blinking. If it does not blink,

please change the batteries and try again.

Press the

the menu (see image on the right). Choose „Print Logs“

and confirm by pressing

Now you can select if you want to print the last saved

measuring series or all saved measuring series (logs).

Confirm by pressing

printed out now.

To save paper, please think of clearing the data storage

regularly.

9.0 ONLINE PRINT AND ONLINE SEND

Your device supports the function “Online Print” and

“Online Send”, this can be activated in the menu

„Options“. If an option is active, every newly recorded log

will immediately be printed or transferred to the PC after

pressing

button at your humimeter until you reach

.

again. The selected logs are

key.

Checkline-Europe

-10-

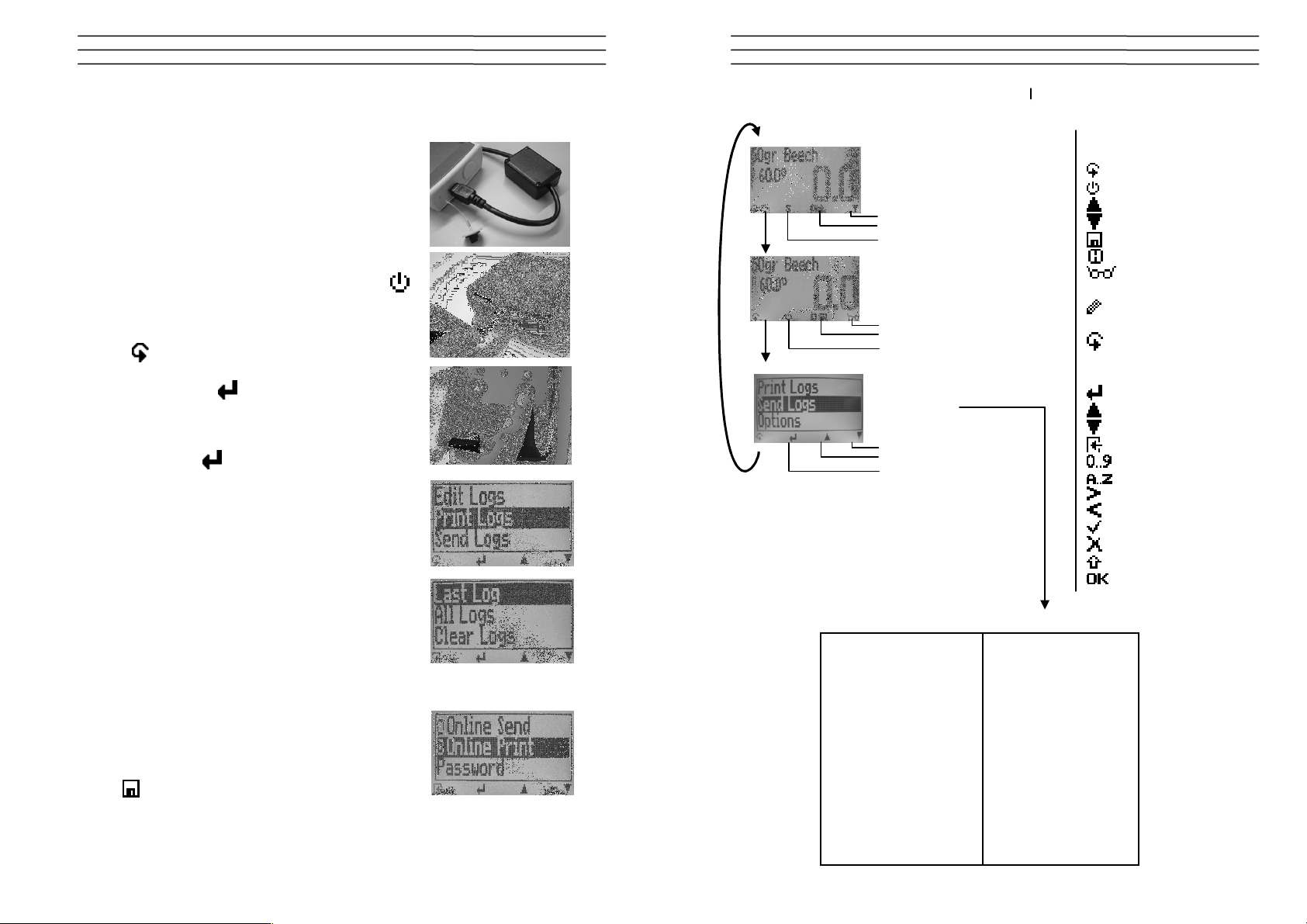

5.0 MENU LEVEL OVERVIEW

Type selection menu

Next calibration curve

Previous calibration curve

Start measurement

.

Store menu

Watch the saved data (logs)

Save new value (log)

Power off (3 sec.)

Main menu

Switch upper

Switch lower

Open this menu / Enter

Measuring window:

Rolling Menu

Power ON / OFF

Switch upper

Switch lower

Save

Hold

Watch the

saved data

Suppliers data

can be added

Rotate display

Menu:

Enter

Switch upper

Switch lower

Exit

Enter numbers

Enter letters

Next or right

Left

Yes

No

Shift

OK

Edit Logs

Manual Logs

Clear Logs

Print Logs

Last Log

All Logs

Clear Logs

Send Logs

Manual Logs

Clear Logs

Options

Status

Overview main menu

Checkline-Europe

Options

Date / Time

Log Time

Language

Unlock

°C / °F

o Userlevel

BL On Time

Auto Off Time

Materialcalib.

o Online Send

o Online Print

Password

Reset

-7-

Page 8

6.0 CHANGING BATTERIES

Please find enclosed the manual for changing of

batteries:

1. Press with your finger onto the arrow of the battery

cap and pull it back.

2. Remove the empty batteries.

3. Put four new batteries in the device. Make sure

that the position of the battery poles is correct.

4. Press down the batteries and close the cap.

If the battery symbol appears in the measuring window

resp. if a critical charge of battery is shown in the

status, the batteries have to be changed

IMMEDIATELY. If you do not use your humimeter

device for a longer period, remove the batteries. For

eventual resulting damages we cannot provide any

warranty.

7.0 TRANSFER SAVED DATA TO THE PC

To send your saved logs to the PC, connect the

humimeter device to your PC using the USB cable that

was delivered with your device. Carefully loose the

protection cap on your humimeter and plug in the USB

mini B connector. The bigger connector has to be

connected to a USB slot on your PC.

Start the LogMemorizer software on your PC and

switch on your humimeter BLH.

The data transfer can be started on your humimeter or

on the software.

Starting the data transfer on the humimeter:

Press the key until you reach the menu (see

image on the right). Then choose „Send Logs“ and

confirm by pressing the

„Manual Logs“ and confirm with

logs will be sent to your PC.

Starting the data transfer on your PC:

Press the button „remote control“ in the

LogMemorizer software. A drop-down menu with

several options opens (see image below).

For transferring the data you can select „Import last

manual log“ (the last saved measuring series is

transferred) or „Import all manual logs“ (all saved

logs are transferred).

If you click on one of these menu items, the transfer

starts immediately.

For the basic adjustments of the software please look

through the instructions on the LogMemorizer CD.

key. Now choose

again. All saved

Checkline-Europe

-8-

Checkline-Europe

-9-

Page 9

WOOD SHAVINGS MOISTURE METER

BLH

OPERATING INSTRUCTIONS

Loading...

Loading...