Page 1

TABLE OF CONTENTS

1.0 Design BL2 wood chips probe (art. no. 12518) ……………………. 2

2.0 Measuring procedure BL2 wood chips probe ……………………... 3

3.0 Calibration curves BL2 wood chips probe …………………………. 4

4.0 Determination of the material reference moisture ………………… 4

5.0 Design BL2 hammer (art.no. 12520) ……………………………….. 5

6.0 Measuring procedure BL2 hammer ………………………………… 6

7.0 Information for measurement with BLW hammer ………………… 7

8.0 Sort of wood (calibration curves) BL2 hammer …………………… 8

9.0 Design FLW tester (art. no. 12119) ………………………………… 9

10.0 Measuring procedure FLW tester …………………………………... 9

11.0 Calibration curves FLW tester ………………………………………. 10

12.0 Menu level overview …………………………………………………. 11

13.0 Changing batteries ………………………………………………..….. 12

14.0 Running the instrument …………………………………………….... 13

15.0 List of calibration curves …………………………………………….. 13

16.0 Activation of the “super user” function ……………………………… 14

17.0 Changing the Userlevel …………………………………………….... 14

18.0 Device maintenance instructions ………………………………..….. 14

19.0 Transfer saved data to the PC ……………………………………… 15

20.0 Print saved data ………………………………………………………. 16

21.0 Technical data BL2 (Art. Nr. 12109) ………………………………... 17

22.0 Technical data BL2 wood chips probe (art. no. 12518) ………….. 17

23.0 Technical data BL2 hammer (art. no. 12520) ……………………… 18

24.0 Technical data FLW tester (art. no. 12119) ……………………….. 18

25.0 Exemption from liability …………………………………………….... 18

26.0 Most common reasons for miss readings with BL2 hammer ……. 19

27.0 Most common reasons for miss readings with FLW tester ………. 19

28.0 Most common reasons for miss readings with BL2 wood chips

probe …………………………………………………………………… 20

29.0 Warranty ……………………………………………………………….. 21

© Electromatic Equipment Co., In c.

-1-

Page 2

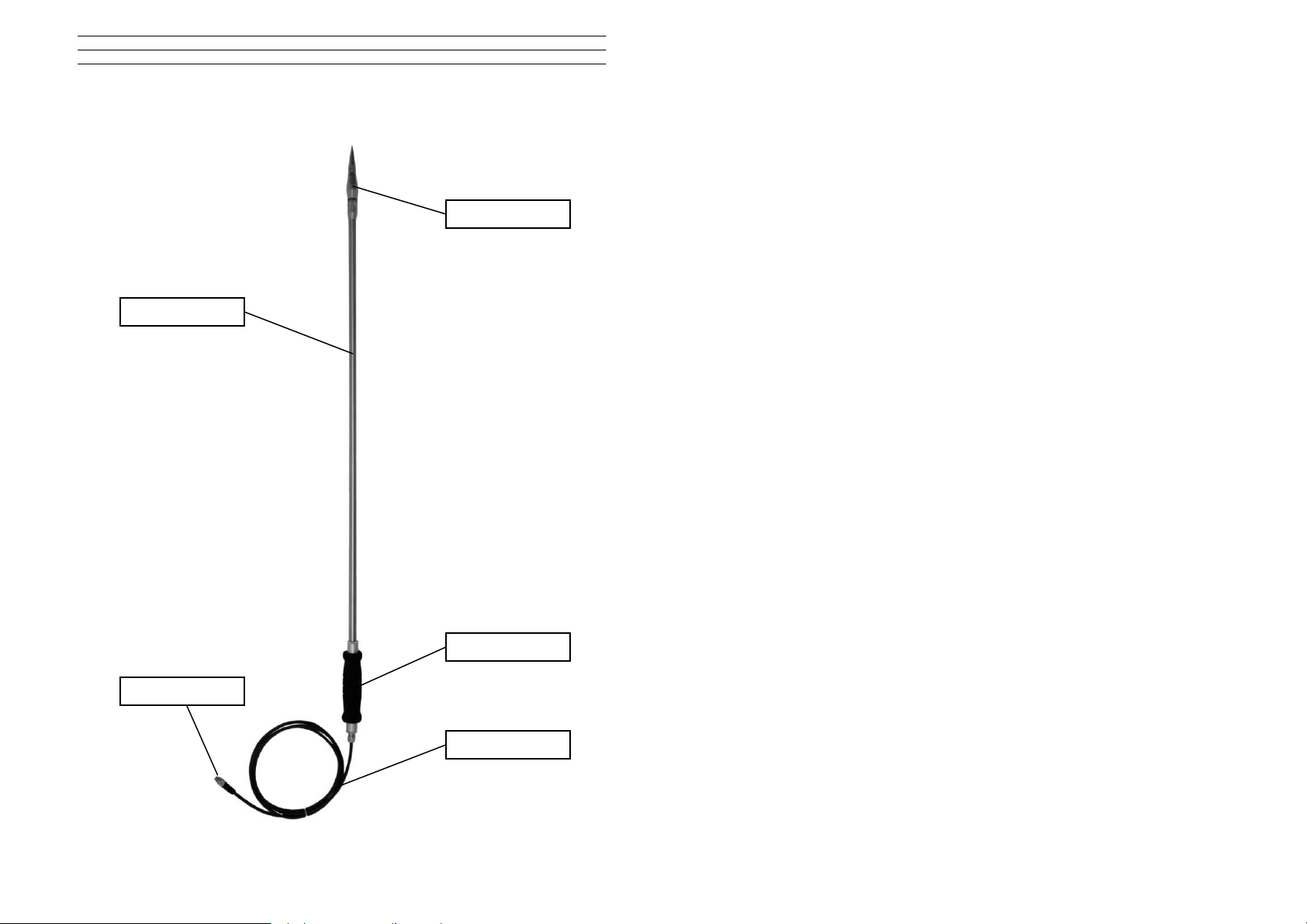

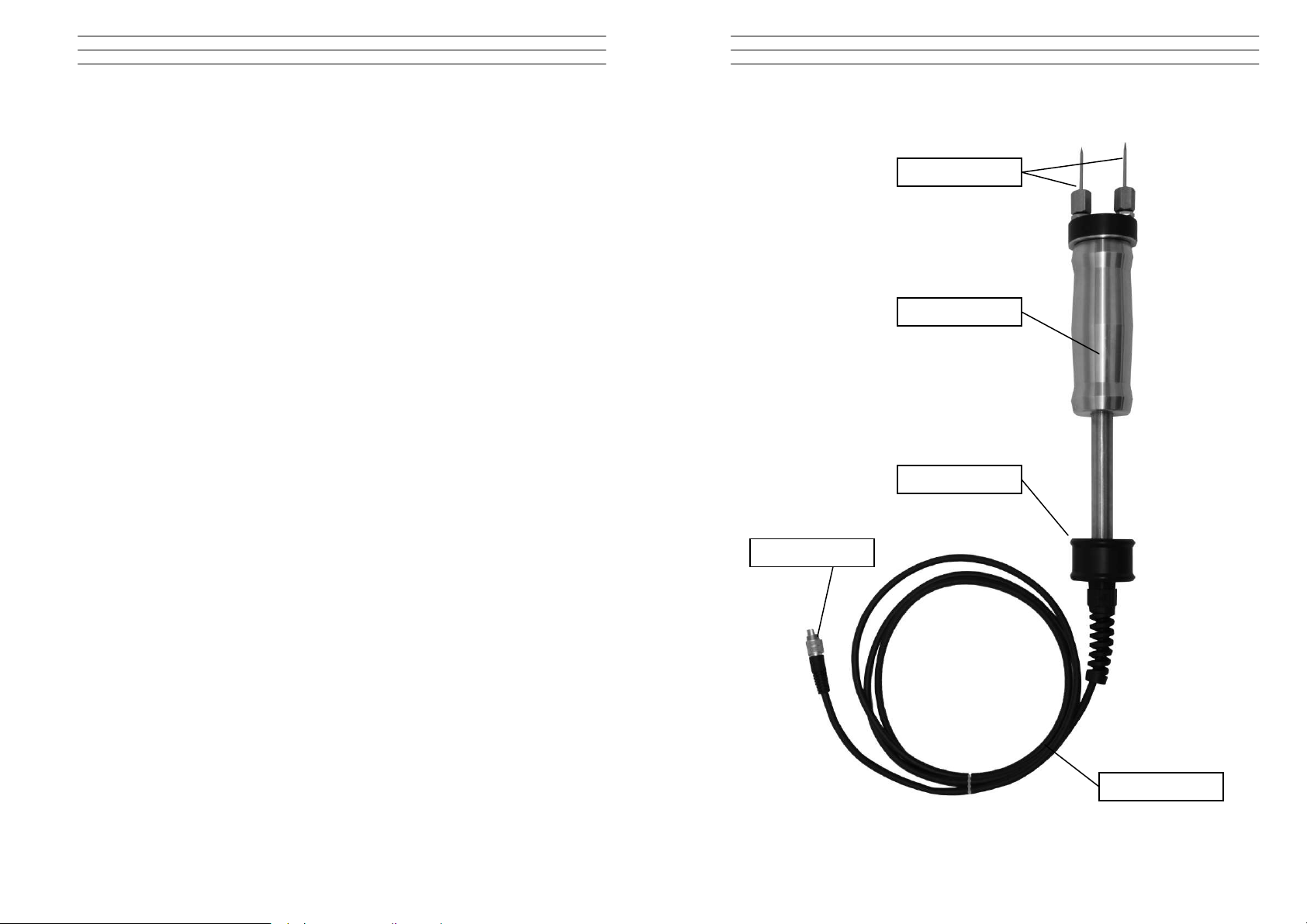

1.0 DESIGN BL2 WOOD CHIPS PROBE (ART. NO. 12518)

g

Insertion probe

Measuring head

Handle

Plu

Sensor cable

© Electromatic Equipment Co., In c.

-2-

Page 3

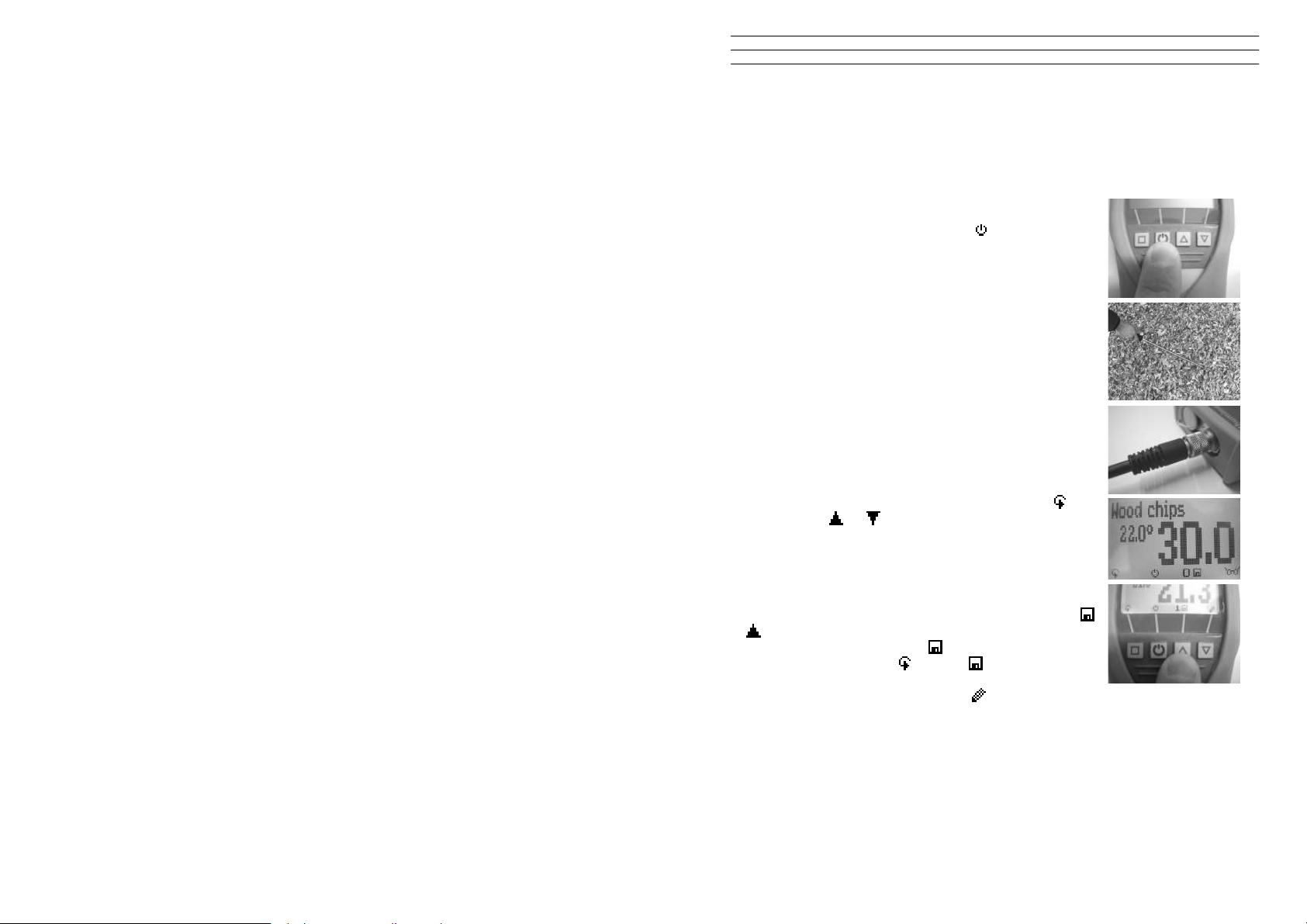

2.0 MEASURING PROCEDURE BL2 WOOD CHIPS PROBE

1. For a correct measurement please ensure that the device has the same

temperature than the wood chips (+/-3°C). For that reason, let your humimeter

BL2 adjust to the surrounding temperature of the material for at least half an

hour before measuring.

2. Switch on the device: Press the

key for three

seconds.

3. Plug the probe of your BL2 wood chips pr obe straight

into the wood chips. It is not allowed to load the

measuring head incorrect or drop it down!

4. Plug in the sensor cable into the socket of the BL 2. Take

care of the correct position and fix it with the knurled nut.

5. Change the calibration curve: Press one time the

key

and then the or key. The n ame of the calibration

curve can be seen at the head of the display.

6. Now the display shows the water content. Left hand

the temperature is displayed.

7. To save the results in the save menu press the

(

button). The storage was successful when the

number in front of the symbol

increased. To reach the

store menu please press until the appears.

8. To name the saved results press the

button.

9. Remove the BL2 probe straight with caution and clean the measuring head.

Risk of injury by measuring head!

Keep away from children!

© Electromatic Equipment Co., In c.

-3-

Page 4

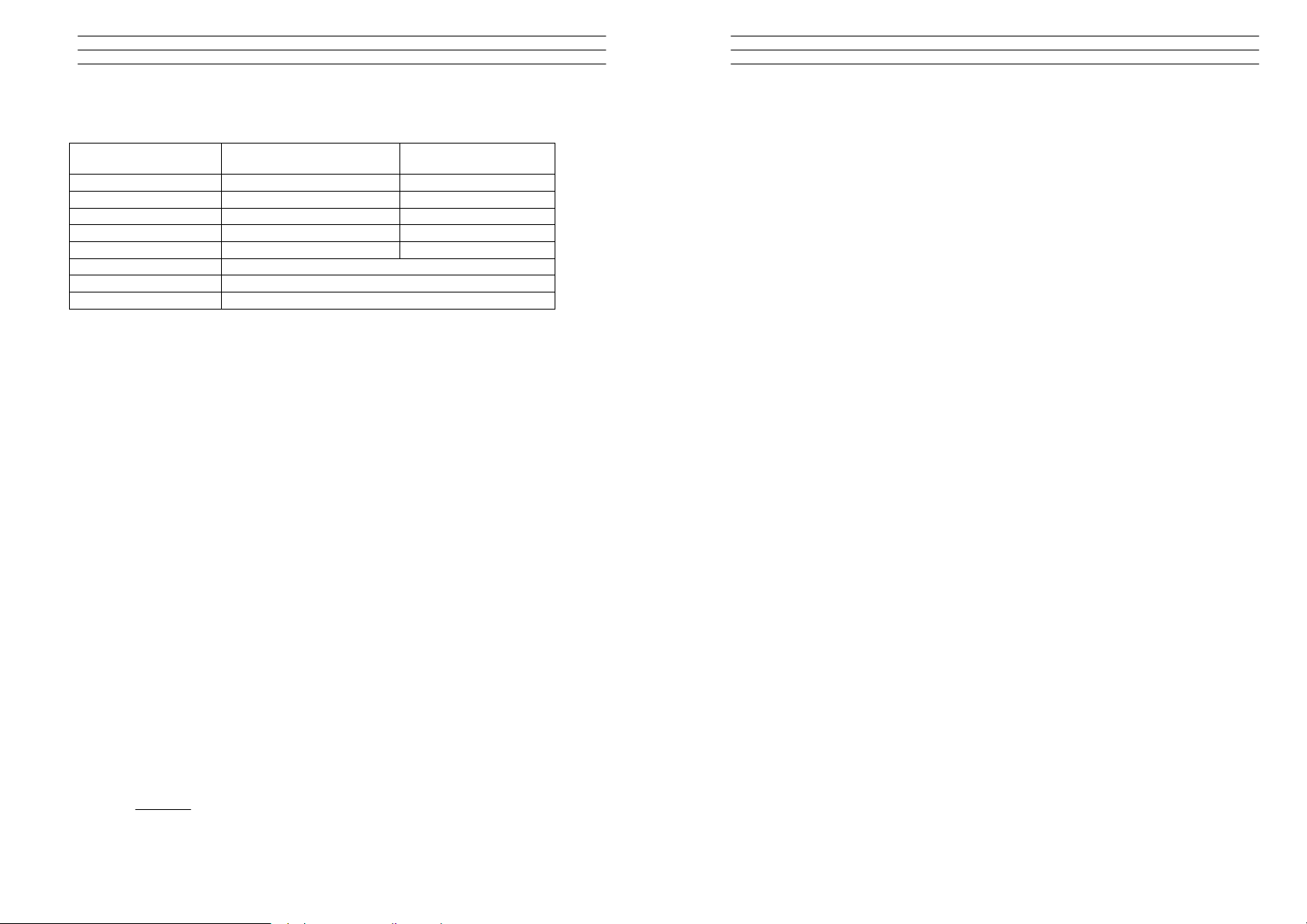

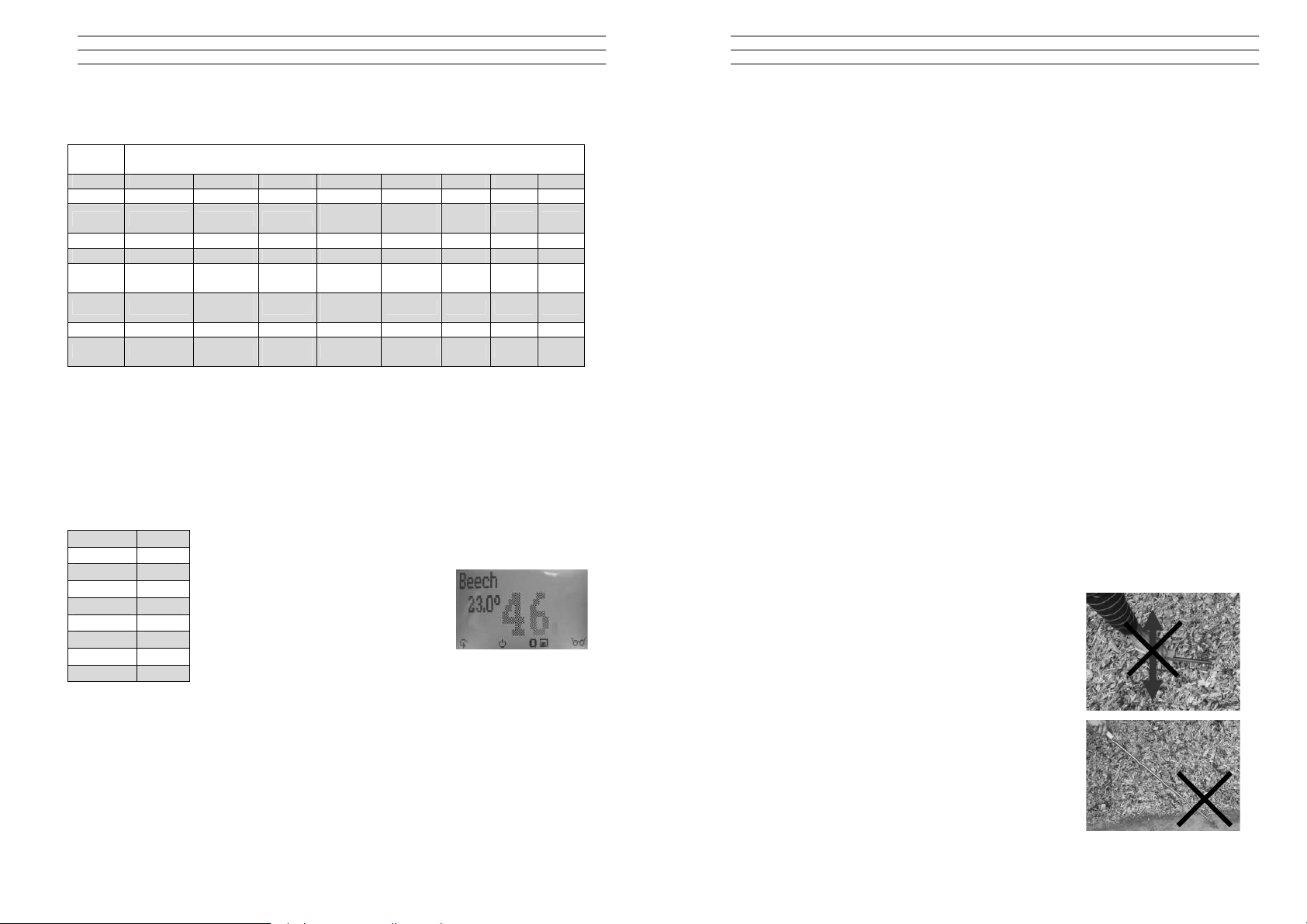

3.0 CALIBRATION CURVES BL2 WOOD CHIPS PROBE

Calibration curves Declaration Measuring range

Wood chips

Coarse chips

Industrial chips

Pellets

Sawdust

Digit 2

Empty 2

Test block

Standard woodchips 10 - 50 %

Coarse woodchips 10 - 50 %

Industrial woodchips 10 - 50 %

Pellets made of wood 11 - 20 %

Sawdust 14 - 50 %

For special product

Customer calibration made by Checkline Europe

! Only for testing the BL2 with the test block !

• Wood chips: standard chi ps of wood (forest wood chips) according to EU-norm

CEN/TS 14961 class P16 and P45.

• Coarse chips: for coarse wood chips P45 but with fewer fines.

• Industrial chips: for industrial chips of wood without barks and fines (similar

P63)

Definition of wood chips classes

The stated numbers refer to the particle size that goes through r ound gaps of the

corresponding diametres (e.g. P16: 16 mm).

• P16 minimum 80% of the bulk is between 3,15 and 16 mm

• P45 minimum 80% of the bulk is between 3,15 and 45 mm

• P63 minimum 80% of the bulk is between 3,15 and 63 mm

Compression of wood chips

The humimeter BL2 is calibrated for normally compressed wood chips. If the

measured wood chips are compressed to a much lesser or greater extent, this will

cause measuring imprecisions. Normally compressed wood chips are defined in

norm CEN/TS 15103 (determination of the bulk density).

4.0 DETERMINATION OF THE MATERIAL REFERENCE MOISTURE

The principle is a comparison measurement with the d ehydration method according

to CEN/TS 14774. Take the measured sample and weigh it. Dry it out in an oven

and weigh it again.

−

MtMn

=

F

Mn

100% ×

Mn: Mass with average moisture content

M

: Mass of the dried sample

t

NOTES

© Electromatic Equipment Co., In c.

-4-

© Electromatic Equipment Co., In c.

-25-

Page 5

NOTES

g

r

5.0 DESIGN BL2 HAMMER (ART.NO. 12520)

Measuring tips

Hamme

Handle

Plu

Sensor cable

© Electromatic Equipment Co., In c.

-24-

© Electromatic Equipment Co., In c.

-5-

Page 6

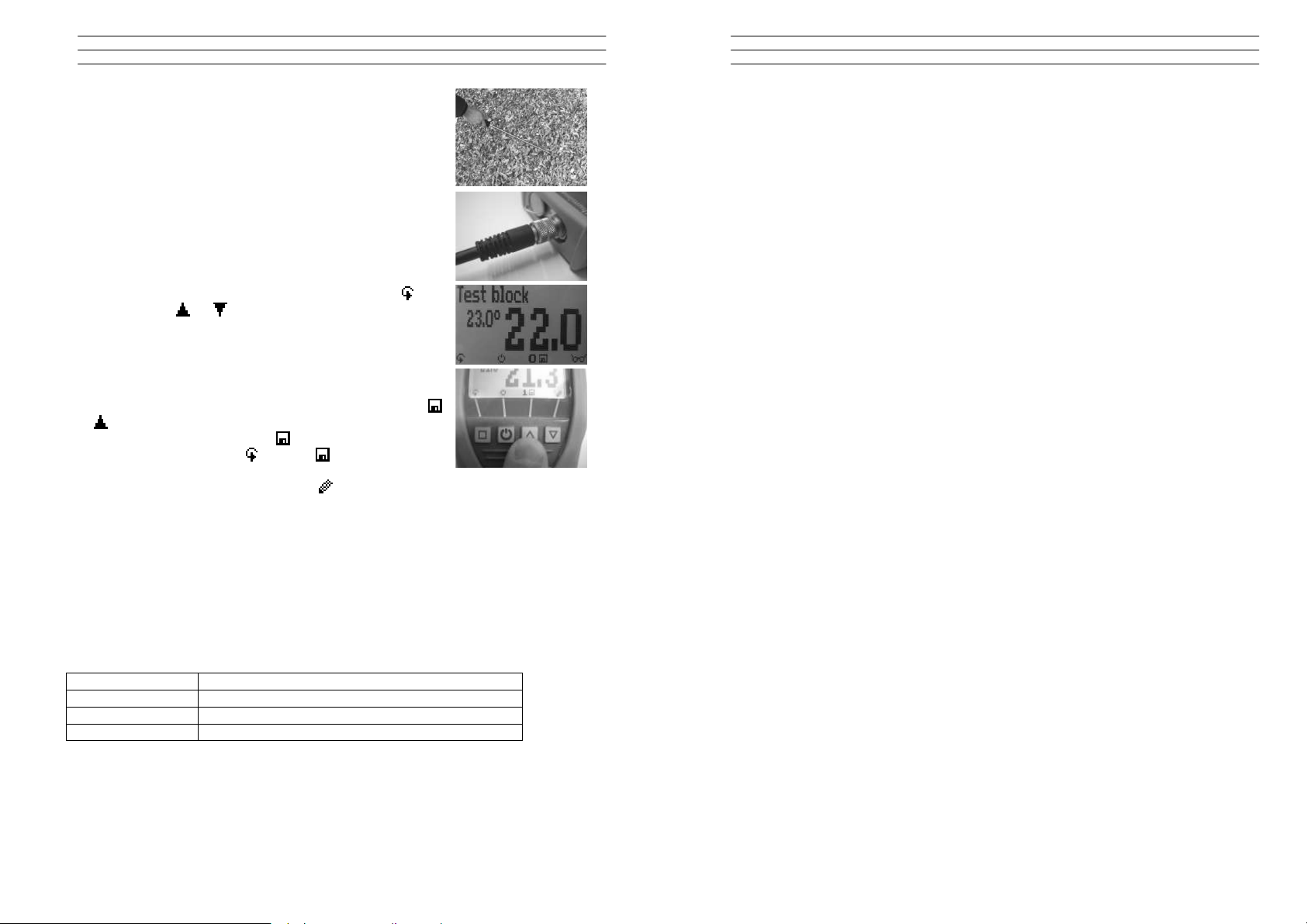

6.0 MEASURING PROCEDURE BL2 HAMMER

1. For a correct measurement please ensure that the

device has the same temperature than the wood (+/3°C). For that reason, let your humimeter BL2 hammer

adjust to the surrounding temperature of the material for

at least half an hour before measuring.

2. Switch on the device: Press the

key for three

seconds.

3. Choose a part of the wood, WITHOUT bark, branches,

pitch pockets or cracks and drive the ram electrode i n

the right angle to the grain into the wood. Hold the top of

the electrode with one hand, take the handhold with the

other hand and push down the handhold with active

force. Drive the nails about 2 cm deep into the wood.

Attention: Risk of injury!!!

4. Plug in the sensor cable into the socket of the BL2. Take

care of the correct position and fix it with the knurled nut.

5. Change the calibration curve: Press one time the

key

and then the or key. The name of the c alibration

curve can be seen at the head of the display.

6. Now the display shows the water content. Left hand

the temperature is displayed.

7. To save the results in the save menu press the

( button). The storage was successful when the

number in front of the symbol

increased. To reach the

store menu please press until the appears.

8. To name the saved results press the

button.

9. Push out the ram electrode of the wood with caution.

NOTES

© Electromatic Equipment Co., In c.

-6-

© Electromatic Equipment Co., In c.

-23-

Page 7

29.0 WARRANTY

Electromatic Equipment Co., Inc. (Electromatic) warrants to the original purchaser

that this product is of merchantable quality and confirms in kind and qua lity with the

descriptions and specifications thereof. Product failure or malfunction arising out of

any defect in workmanship or material in the product existing at the time of deliver y

thereof which manifests itself within one year from the sale of such product, shall be

remedied by repair or replacement of such product, at Electromatic’s option, exc ept

where unauthorized repair, disassembly, tampering, abuse or misapplication has

taken place, as determined by Electromatic. All returns for warranty or non-warranty

repairs and/or replacement must be authorized by Electromatic, in advanc e, with all

repacking and shipping expenses to the address below to be borne by the

purchaser.

THE FOREGOING WARRANTY’S IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR

PURPOSE OR APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE

NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR

NATURE, RESULTING FROM THE USE OF SUPPLIED EQUIPMENT, WHETHER

SUCH DAMAGE OCCURS OR IS DISCOVERED BEFORE, UPON OR AFTER

REPLACEMENT OR REPAIR, AND WHETHER OR NOT SUCH DAMAGE IS

CAUSED BY MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE WITHIN ONE

YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation may not ap ply to you.

The duration of any implied warranty, including, without limitation, fitness for any

particular purpose and merchantability with respect to this product, is limited to the

duration of the foregoing warranty. Some states do not allow limitations on how long

an implied warranty lasts but, not withstanding, this warranty, in the absence of such

limitations, shall extend for one year from the date of invoice.

Electromatic Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516 - USA

Tel: 1-800-645-7330 / Tel: 516-295-4300 / Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of information contained herein. Any brand or product names mentioned herein

are used for identification purposes only, and are trademarks or registered trademarks of their

respective holders.

7.0 INFORMATION FOR MEASUREMENT WITH BLW HAMMER

• With the standard nails the wettest part over the whole measuring depth will be

measured. If you need the water content in a defined measuring depth, you

should use the isolated green nails (article number 11426), because they are

only measuring at the points.

• Important: You have to remove the bark before you can start to measure.

• The measuring depth should be a quarter o f the wood diameter. In the worst

case you have to cut away a part of the diameter.

• Statistically, the spot that shows best the average moisture of the wood is at

about 20% of the total wood length.

• Take a few logs on different positions of each piece of wood you intend to

measure, and the humimeter BL2 will calcul ate automatically the average val ue

of the series.

• The measure value which is shown at the display of your humimeter BL2,

represents the “water content” of the wood. So there is no conversion for m the

“wood moisture” into “water content” for use. It is also possible to change the

value into “wood moisture”. If you need this, contact us.

• Definition water content:

The water content is declared as the amount of water in a wood, which sta nds in

relationship to the whole weight of the wood. For e xample: You have 1kg Wood

with 40% water content; the wood consist of 0,4kg water and 0,6kg wood.

• Definition wood moisture:

The wood moisture is declared as the amount of water in a wood, which stands

in relationship to the weight of the dried wood. The same example: You have

0,6kg Wood with 0,4kg water; the 0,6kg wood represents 100%, so the 0,4kg

water will be 66,7% wood moisture.

© Electromatic Equipment Co., In c.

-22-

© Electromatic Equipment Co., In c.

-7-

Page 8

8.0 SORT OF WOOD (CALIBRATION CURVES) BL2 HAMMER

Main

Group

Beech Rubber

Oak Mahogany Wenge

Alder Acacia Alstonia Birch

Ash Keruing

Spruce

Pine Balsa Yew Tree

Larch Maple

Fir Ceiba Linden

Willow Pear Hickory

Douglas

Fir

Stone

Pine

Hemlock

Olive

wood

Sub groups

European

chestnut

Cotton

Wood

Ramin Teak

Horse

chestnut

Elm

Cherry

Tree

Walnut Okan

Declaration: The main group of wood is the wood sort, which is shown on the

measurement display of your humimeter BL2. Do you want to measure wood, which

is not in the list of the main group, you should search it at the sub groups in the table

above. Then use the wood of the main group for the measuring. For exam ple: If you

want to measure “Cherry Tree”, you have to choose the “Alder” wood at you device.

Valid measuring Range

Beech 32%

Oak 32%

Alder 40%

Ash 35%

Spruce 40%

Pine 35%

If the measure value is grey, the standard valid measuring

range is exceeded (limits see Table). In this case the

accuracy will be decreasing.

A blinking measuring value shows you

the upper end of the measuring range.

Larch 32%

Fir 37%

Willow 40%

28.0 MOST COMMON REASONS FOR MISS READINGS WITH BL2 WOOD

CHIPS PROBE

• Product temperature out of application range

Material below 0°C resp. above +40°C (32 to 104 °F) may cause faulty

measurements.

• Temperature differen ce between meter and sample

Please ensure that the device and the material under test are being stored at the

same temperature (+/-3°C) before measuring. A high temperature difference has

a negative effect on the stability of the measurement results.

• Wrong calibration curve

Before you measure your sample, double check the correct selection of the

calibration curve.

• Wet or mouldy material

• Frozen wood chips

If you measure such products, the accuracy will decrease.

• Water film at the measuring head

After measuring wet material a water film can arise on the sensor head. This

could lead to a too high result in the following measurement. After measurin g

wet material clean both black plastic parts accurately with a dry cloth.

It is not allowed to load the measuring head

incorrect (stress, ben ding), other wise it can be broken.

Plug and remove the insertion probe of your BL2 wood

chips probe straight into the wood chips.

Do not move the BL2 probe crosswise to the insertion

direction after plugging in.

Do not drop the measuring head or use it for any ulterior

purposes.

A broken measuring head is no case of warranty!

© Electromatic Equipment Co., In c.

-8-

© Electromatic Equipment Co., In c.

-21-

Page 9

26.0 MOST COMMON REASONS FOR MISS READINGS WITH BL2 HAMMER

g

• Product temperature out of application range

Material below 0°C resp. above +50°C (32 to 122 °F) may cause faulty

measurements.

• Temperature difference between meter and sample

Please ensure that the device and the material under test are being stored at the

same temperature (+/-3°C) before measuring. A high temperature difference has

a negative effect on the stability of the measurement results.

• Wrong calibration curve

Before you measure your sample, double check the correct selection of the

calibration curve.

• Frozen wood or beetle infested wood

If you measure such products, the accuracy will decrease.

• Measurement through bark

In fact of that the accuracy will decrease.

• Direct solar radiation

27.0 MOST COMMON REASONS FOR MISS READINGS WITH FLW TESTER

• Product temperature out of application range

Material below 0°C resp. above +40°C (32 to 104 °F) may cause faulty

measurements.

• Temperature differen ce between meter and sample

Please ensure that the device and the material under test are being stored at the

same temperature (+/-3°C) before measuring. A high temperature difference has

a negative effect on the stability of the measurement results.

• Water film at the measuring head

After measuring wet material a water film can arise on the sensor head. This

could lead to a too high result in the following measurement. After measurin g

wet material clean both black plastic parts accurately with a dry cloth.

9.0 DESIGN FLW TESTER (ART. NO. 12119)

Insertion probe

10.0 MEASURING PROCEDURE FLW TESTER

1. For a correct measurement please ensure that the

device has the same temperature than the material (+/3°C). For that reason, let your FLW tester adjust to the

surrounding temperature of the material before

measuring.

2. Switch on the device: Press the

seconds.

Plu

key for three

Measuring tip

Handle

Sensor cable

© Electromatic Equipment Co., In c.

-20-

© Electromatic Equipment Co., In c.

-9-

Page 10

3. Plug the probe of your FLW tester straight into the

material. It is not allowed to load the measuring head

incorrect or drop it down!

4. Plug in the sensor cable into the socket of the BL2. Take

care of the correct position and fix it with the knurled nut.

5. Change the calibration curve: Press one time the

and then the

or key. The n ame of the calibration

key

curve can be seen at the head of the display.

6. Now the display shows the water content. Left hand

the temperature is displayed.

7. To save the results in the save menu press the

( button). The storage was successful when the

number in front of the symbol

increased. To reach the

store menu please press until the appears.

8. To name the saved results press the

button.

9. Remove the FLW tester straight with caution and clean the measuring head.

Risk of injury by measuring head!

Keep away from children!

11.0 CALIBRATION CURVES FLW TESTER

Calibration curve Material

Digit 3

Empty 3

Test block

For special product

Customer calibration made by Checkline Europe

! Only for testing the BL2 with the test block !

and the guarantee stamp. If those are broken, no claims for guarantee can be

made. In case of a faulty device, please contact Checkline Europe.

© Electromatic Equipment Co., In c.

-10-

© Electromatic Equipment Co., In c.

-19-

Page 11

23.0 TECHNICAL DATA BL2 HAMMER (ART. NO. 12520)

Resolution of display 0.1% water content

0.5°C temperature

Measuring range 8% to 60% water content

Operation temperature 0°C to +50°C

Temperature measuring range -10°C to +60°C

Dimension 360 x 45 x 45 mm

Weight 1500 g

Protection class IP 40

Option Replacement tips 60mm insulated, measuring

tips set 255mm for bales of hay- and straw (art.

no. 12521)

24.0 TECHNICAL DATA FLW TESTER (ART. NO. 12119)

Resolution of display 0.1% water content

0.5°C temperature

Measuring range depending of the material

Operation temperature 0°C to +40°C

Temperature measuring range -10°C to +60°C

Dimension 1150 x 35 x 35 mm

Gewicht 530 g

Protection class IP 40

25.0 EXEMPTION FROM LIABILITY

For miss-readings and wrong measurements and of this resulting damage we refuse

any liability. This is a device for quick determination of moisture. The moisture

depends on multiple conditions and multiple materials. Therefore we recommend a

plausibility check of the measuring results. Each device includes a serial number

© Electromatic Equipment Co., In c.

-18-

12.0 MENU LEVEL OVERVIEW

Edit Logs

Manual Logs

Clear Logs

Print Logs

Last Log

All Logs

Clear Logs

Send Logs

Manual Logs

Clear Logs

Options

Status

Store menu

Watch the saved data (logs)

Save new value

Power off (3 sec.)

Type selection menu

Next calibration curve

Previouse calibration curve

Power off (3 sec.)

Main menu

Switch upper

Switch lower

Open this menu / Enter

Overview main menu

Options

Date / Time

Log Time

Language

Unlock

°C / °F

o Userlevel

BL On Time

Auto Off Time

Materialcalib.

Password

Reset

© Electromatic Equipment Co., In c.

-11-

Keypad symbols

Measuring window:

Rolling Menu

Power ON / OFF

Switch upper

Switch lower

Save

Hold

Watch the

saved data

Suppliers data

can be added

Rotate display

Menu:

Enter

Switch upper

Switch lower

Exit

Enter numbers

Enter letters

Next or right

Left

Yes

No

Shift

OK

Page 12

13.0 CHANGING BATTERIES

Please find enclosed the manual for changing of

batteries:

1. At first remove the rubber protective housing. For

that, hold the rubber housing at the upper side and

pull it over. If your BL2 is provided with an optional

USB port, you have to remove the protection cap

before.

2. Press with your finger onto the arrow of the battery

cap und pull it back.

3. Remove the empty batteries.

4. Put four new batteries in the device. Make sure that

the positions of the battery poles are correct.

5. Press down the batteries and close the cap.

If the battery symbol appears in the measuring window

resp. if a critical charge of battery is shown in the

status, the batteries have to be changed

IMMEDIATELY. If you do not use your humimeter

device for a longer period, remove the batteries. For

eventual resulting damages we cannot provide any

warranty.

21.0 TECHNICAL DATA BL2 (Art. Nr. 12109)

Operation temperature 0°C to +50°C

Storage temperature -20°C to +60°C

Temperature compensation Automatically

Data logger Approximately 10.000 values

Menu languages German, English, French, Italian, Spanish,

Power supply 4 pcs. 1.5 Volt AA Alkaline batteries (900

Auto Switch OFF After approx. 4 minutes

Current consumption 60mA (with light)

Display 128x64 matrix display, lighted

Dimension 150 x 75 x 30 mm

Weight 270 g (with batteries)

Protection class IP 40

Scope of supply Humimeter BL2, 4 x 1.5Volt AA Alkaline batteries

Options Wooden case for BL2, test block, humimeter

22.0 TECHNICAL DATA BL2 WOOD CHIPS PROBE (ART. NO. 12518)

Resolution of display 0.5% water content

0.5°C temperature

Measuring range 10% to 50% water content

Operation temperature 0°C to +40°C

Temperature measuring range -10°C to +80°C

Dimension 1150 x 35 x 35 mm

Weight 710 g

Protection class IP 40

Russian

measurements)

rubber protective housing

USB-data interface modul, portable thermoprinter

© Electromatic Equipment Co., In c.

-12-

© Electromatic Equipment Co., Inc.

-17-

Page 13

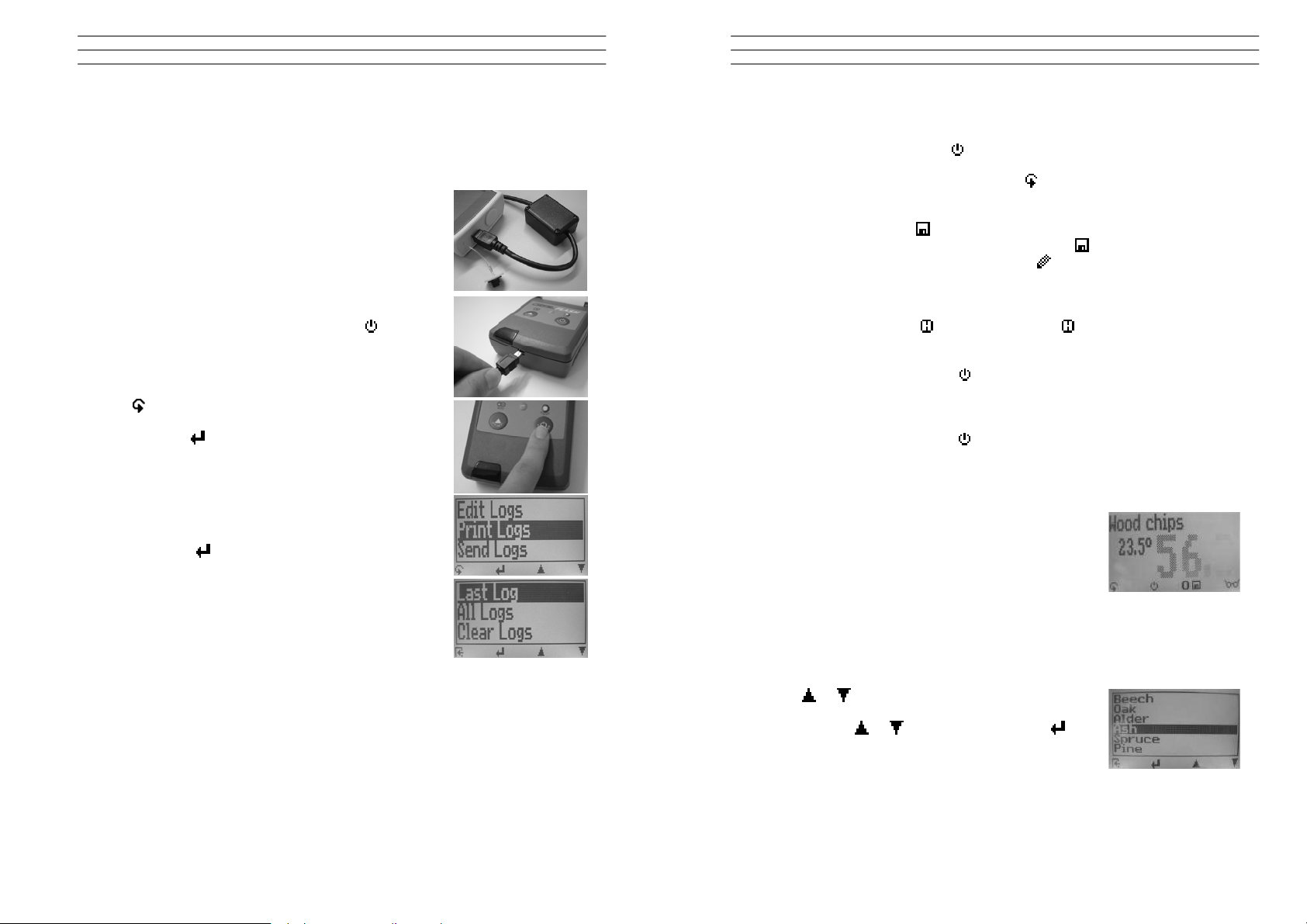

20.0 PRINT SAVED DATA

(Only possible with humimeter USB interface mo dule in combination with Schaller

thermo printer)

To print your saved data, connect the device to the printer

using the printer cable that was delivered with your device.

Carefully loose the protection cap on the humimeter BL2. At

first plug in the side of the connector with the close plastic

casing at the humimeter BL2. Then switch on the device.

Not till then the other side of the cable has to be plugged in

at the printer. Switch on the printer by pressing

. Now the

green LED is blinking. If it does not blink, please change th e

batteries and try again.

Press the

button at your humimeter until you reach the

menu (see image on the right). Choose „Print Logs“ and

confirm by pressing

.

Now you can select if you want to print the last saved

measuring series or all saved measuring series (logs).

Confirm by pressing again. The selected logs are printed

out now.

To save paper, please think of clearing the data storage

regularly.

14.0 RUNNING THE INSTRUMENT

Switch on: Press the key for three seconds

Set the clock: Press three times the key -> Options -> Date/Time

Save measuring value: Save the measuring value by pressing the button below

the symbol. The storage was successful when the

number in front of the symbol

saved results press the button.

Hold measuring value: At first activate the function in the menu Options ->

Datalog time by choosing “Hold”. Then press the left key

until appears. Press the key. The measuring value

remains on the display until another button is pressed.

Display lighting: Press the

key; Backlight will turn off automatically

after 30 seconds. Backlight will be activated by pressing

any key.

Power off: Press the key for five seconds; the device will be

switched off when you leave the key. The device also

switches off automatically when no key is pressed for

four minutes.

Measuring range limit: If the measuring value is

blinking, the valid measuring

range is exceeded. In this case

the accuracy will be decreasing.

15.0 LIST OF CALIBRATION CURVES

Pressing the

or key in the measuring for at least three

seconds and a list with all available sorts will appear. Sele ct

your sort by pressing

or and confirm it with the key.

The measurement will continue automatically.

increased. To name the

© Electromatic Equipment Co., In c.

-16-

© Electromatic Equipment Co., In c.

-13-

Page 14

16.0 ACTIVATION OF THE “SUPER USER” FUNCTION

Two times

- Options – Unlock

Enter the 4-digit password by using the button (standard is the 4-digit serial

number) and confirm by pressing the button.

17.0 CHANGING THE USERLEVEL

Changing from advanced user to single user:

Make sure that you have activated the “super user” functions according to the

instructions above. Afterwards change to the menu and choose „Options“.

In the submenu please select „o Userlevel“ (two times

Confirm by pressing the

button. Now the single user is activated.

– Options – o Userlevel)

Changing from single user to advanced user:

Keep both the buttons

and pressed directly after switching on the device. Your

humimeter automatically starts the main menu. Activate the the “super user”

functions according to the instructions above.

Navigate to “Options – o Userlevel” and confirm by pressing the

button.

18.0 DEVICE MAINTENANCE INSTRUCTIONS

To provide a long life of your device please does n ot expose it to strong mechanical

loads or heat e.g. dropping it or direct sunlight exposure. Clean yo ur device using a

dry cloth. Any kind of wet cleaning damages the device.

It is not allowed to load the measuring head incorrect (stress, bending), ot her wise it

can be broken. Plug and remove the insertion probe of your BL 2 straight into the

wood chips.

The instrument is not rainproof. Keep it in dry areas. When the device isn’t used for

a longer period (2 months) or when the batteries are empty, they should be removed

to prevent a leakage of the battery acid.

19.0 TRANSFER SAVED DATA TO THE PC

(Only possible with humimeter USB interface module)

To send your saved logs to the PC, connect the humimete r

device to your PC using the USB cable that was delivered

with your device. Carefully loose the protection cap on your

humimeter and plug in the USB mini B connector. The

bigger connector has to be connected to a USB slot on your

PC. Start the LogMemorizer software on your PC and switch

on your humimeter BL2.

The data transfer can be started on your humimeter or on

the software.

Starting the data transfer on the humimeter:

Press the key until you reach the menu (see image on the

right). Then choose „Send Logs“ and confirm by pressing

the

key. Now choose „Manual Logs“ and confirm with

again. All saved logs will be sent to your PC.

Starting the data transfer on your PC:

Press the button „remote control“ in the LogMemorizer

software. A drop-down menu with several options opens

(see image below).

For transferring the data you can select „Import last manual

log“ (the last saved measuring series is transferred) or

„Import all manual logs“ (all saved logs are transferred).

If you click on one of these menu items, the transfer starts

immediately.

For the basic adjustments of the software please look

through the instructions on the LogMemorizer CD.

© Electromatic Equipment Co., In c.

-14-

© Electromatic Equipment Co., In c.

-15-

Page 15

UNIVERSAL BIOMASS MOISTURE METER

BL2

OPERATING INSTRUCTIONS

Loading...

Loading...