Page 1

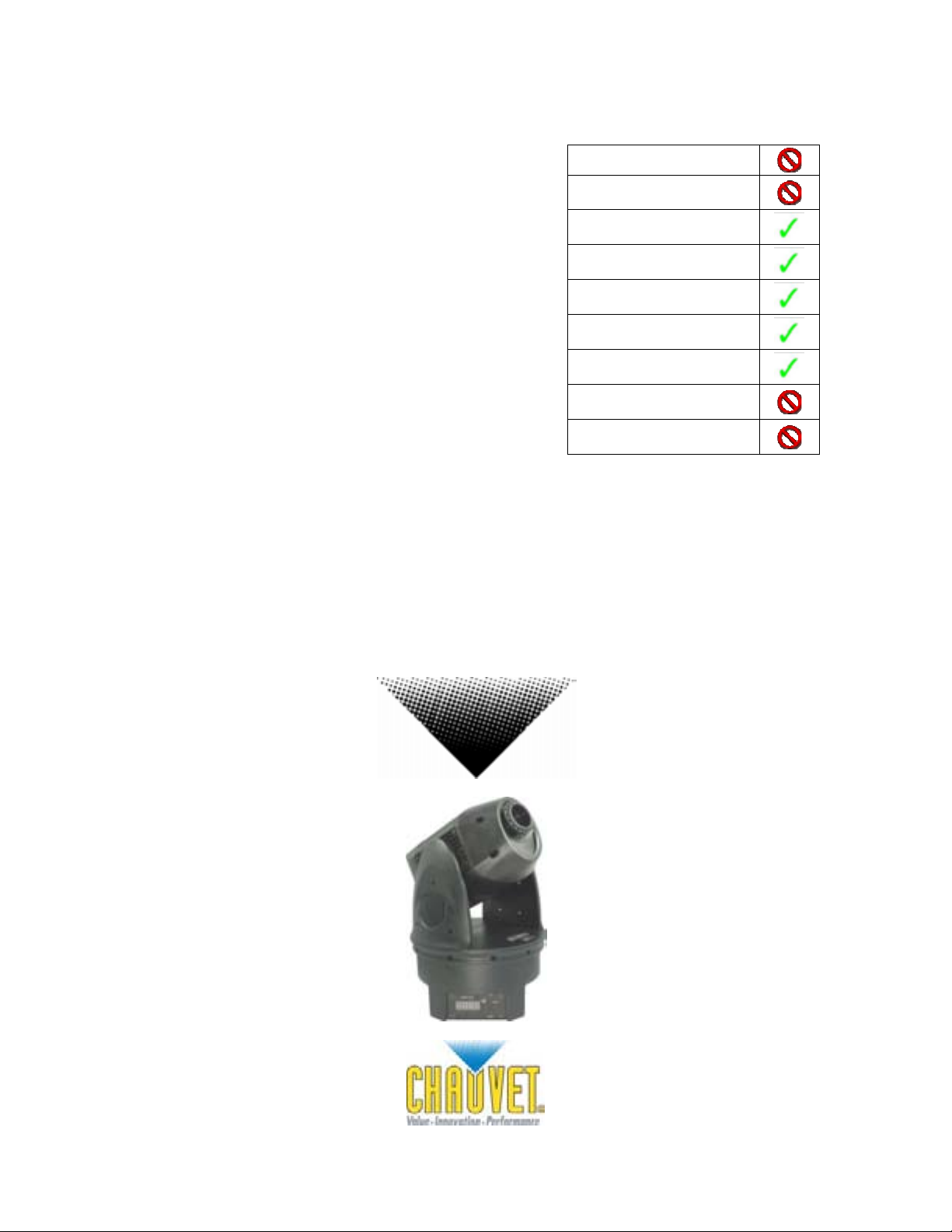

DMX-690

Intimidator Spot 2.0 HTI™

Snapshot

Ok on Dimmer

Outdoor OK

Sound Activated

DMX512

Master/Slave

115V/230V Switch

Replaceable Fuse

User Serviceable

Duty Cycle

USER MANUAL

Chauvet, 3000 N 29th Ct, Hollywood, FL 33020 U.S.A.

(800) 762-1084 – (954) 929-1115

FAX (954) 929-5560

www.chauvetlighting.com

Page 2

TABLE OF CONTENTS

1. BEFORE YOU BEGIN....................................................................................................................................................... 3

W

HAT IS INCLUDED.............................................................................................................................................................. 3

U

NPACKING INSTRUCTIONS.................................................................................................................................................. 3

POWER ......................................................................................................................................................................... 3

AC

C

ONTACT US ...................................................................................................................................................................... 3

S

AFETY INSTRUCTIONS........................................................................................................................................................ 4

2. INTRODUCTION ...............................................................................................................................

F

EATURES .......................................................................................................................................................................... 5

DMX

CHANNEL SUMMARY................................................................................................................................................... 5

RODUCT OVERVIEW .......................................................................................................................................................... 6

P

3. SETUP............................................................................................................................................................................... 7

L

AMP.................................................................................................................................................................................. 7

Lamp Replacement...............................................................................................................................

Lamp Alignment How-To ...............................................................................................................................

F

USE REPLACEMENT........................................................................................................................................................... 8

R

EPLACING GOBOS............................................................................................................................................................. 9

IXTURE LINKING............................................................................................................................................................... 10

F

Data Cabling...............................................................................................................................

DMX Data Cable...............................................................................................................................

Cable Connectors...............................................................................................................................

3-Pin to 5-Pin Conversion Chart..........................................................................................................................

S

ETTING UP A DMX SERIAL DATA LINK .............................................................................................................................. 11

TAND-ALONE/MASTER/SLAVE FIXTURE LINKING ............................................................................................................... 11

S

M

OUNTING........................................................................................................................................................................ 12

Orientation...............................................................................................................................

Rigging...............................................................................................................................

4. OPERATING INSTRUCTIONS...............................................................................................................................

N

AVIGATING THE CONTROL PANEL..................................................................................................................................... 13

ENU MAP........................................................................................................................................................................ 14

M

Menu Functions ...............................................................................................................................

User Configurations...............................................................................................................................

To set the pan to inverting or non-inverting:........................................................................................................

To set the tilt to inverting or non-inverting: ..........................................................................................................

To reverse the display: ...............................................................................................................................

To set the Fixture to 16-bit or 8-bit mode: ...........................................................................................................

To change the PAN RANGE:............................................................................................................................... 16

To change the Tilt RANGE:...............................................................................................................................

Service Functions ...............................................................................................................................

To reset the fixture:...............................................................................................................................

To restore all settings to their factory defaults:....................................................................................................

O

PERATION....................................................................................................................................................................... 17

Stand-Alone Mode (Sound-Active, Auto Mode, Easy Controller): ..............................................................................

Master/Slave Mode (Master Sound, Master Auto, Easy Controller):..........................................................................

Easy Controller Settings ...............................................................................................................................

DMX Mode...............................................................................................................................

DMX Channel Values (16-bit mode)...........................................................................................................................

DMX Channel Values (8-bit mode).............................................................................................................................

ENERAL TROUBLESHOOTING ........................................................................................................................................... 20

G

T

ECHNICAL SUPPORT........................................................................................................................................................ 21

5. APPENDIX...............................................................................................................................

PRIMER....................................................................................................................................................................21

DMX

G

ENERAL MAINTENANCE ................................................................................................................................................... 21

R

ETURNS PROCEDURE...................................................................................................................................................... 22

LAIMS............................................................................................................................................................................. 22

C

T

ECHNICAL SPECIFICATIONS.............................................................................................................................................. 23

................................ 5

........................ 7

............... 8

................................ 10

................... 10

................. 10

11

............................ 12

.................................. 12

......... 13

........................... 15

..................... 15

15

15

......... 15

15

.. 16

........................ 16

............... 16

16

17

17

.............. 17

................................... 18

18

19

........................................ 21

Intimidator Spot 2.0 HTI Manual 2 2007-01-24/09:36

Page 3

1. BEFORE YOU BEGIN

What is included

¾ 1 x Intimidator Spot 2.0 HTI™

150W HTI Lamp

¾

¾

Power Cord

¾ W

arranty Card

¾ User

Unpacking Instructions

AC Power

Warning! Verify that the voltage select switch on your unit matches the

Manual

Immediately upon receiving a fixture, carefully unpack the carton, check the contents to ensure that

all parts are present, and have been received in good condition. Notify the shipper immediately and

retain packing material for inspection if any parts appear damaged from shipping or the carton itself

shows signs of mishandling. Save the carton and all packing materials. In the event that a fixture

must be returned to the factory, it is important that the fixture be returned in the original factory box

and packing.

To determine the power requirements for a particular fixture, see the label affixed to the back plate of

the fixture or refer to the fixture’s specifications chart. A fixture’s listed current rating is its average

current draw under normal conditions. All fixtures must be powered directly off a switched circuit and

cannot be run off a rheostat (variable resistor) or dimmer circuit, even if the rheostat or dimmer

channel is used solely for a 0% to 100% switch. Before applying power to a

fixture, check that the source voltage matches the fixture’s requirement.

Check the fixture or device carefully to make sure that if a voltage selection

switch exists that it is set to the correct line voltage you will use.

line voltage applied. Damage to your fixture may result if the

line voltage applied does not match the voltage indicated on

the voltage selector switch. All fixtures must be connected to

circuits with a suitable Earth Ground.

Figure 1 - AC Voltage Switch

Not all fixtures have a voltage

select switch. Please be sure to

connect to the proper voltage.

Contact Us

World Wide

General Information Chauvet Lighting

3000 North 29

Hollywood, FL 33020

voice: 954.929.1115

fax: 954.929.5560

toll free: 800.762.1084

Technical Support Chauvet Lighting

3000 North 29

Hollywood, FL 33020

voice: 954.929.1115 (Press 4)

fax: 954.929.5560 (Attention: Service)

World Wide Web www.chauvetlighting.com

Intimidator Spot 2.0 HTI Manual 3

th

Court

th

Court

2007-01-24/09:36

Page 4

Safety Instructions

• Please keep this User Guide for future consultation. If you sell the unit to another user, be sure that

y also receive this instruction booklet.

the

• Always make sure that you are connecting to the proper voltage, and that the line voltage you are

connecting to is not higher tha

• This product is intended for indoor use only!

• To prevent risk of fire or shock, do not expose fixture to rain or moisture. Make sure there are no

flammable materials close to the unit w

• The unit must be installed in a location with adequate ventilation, at least 20in (50cm) from adjacent

surfaces. Be sure that no ventilation slots are blocked.

• Always disconnect from power source before servicing or replacing lamp or fuse and

replace with same lamp source.

• Secure fixture to fastening device using a safety chain. Never carr

its carrying handles.

• Maximum ambient temperature (Ta) is 104°F (40°C). Do not operate fixture at temperatures higher

than this.

• In the event of a serious operating problem, stop using the unit immediately

unit by yourself. Repairs carried out by unskilled people can lead to damage or malfunction. Please

contact the nearest authorized technical assistance center. Always use the same type spare parts.

• Don’t connect the device to a dimmer pack.

• Make sure the power cord is never crimped or damaged.

• Never disconnect the power cord by pulling or tugging on the cord.

• Avoid direct eye exposure to the light source while it is on.

Please read these instructions carefully, which includes important

information about the installation, usage and maintenance of this

product.

n that stated on the decal or rear panel of the fixture.

hile operating.

be sure to

y the fixture solely by its head. Use

. Never try to repair the

Caution! There are no user serviceable parts inside the unit. Do not open the housing or

attempt any repairs yourself. In the unlikely event your unit may require service,

please contact CHAUVET at: 954-929-1115.

Intimidator Spot 2.0 HTI Manual 4 2007-01-24/09:36

Page 5

2. INTRODUCTION

Features

• 6 to 8-channel DMX-512 moving yoke

• Pan: 540° / tilt: 270°

• Variable strobe/shutter

• Color wheel:

• Rotating gobo wheel:

• Variable motorized dimmer (0 – 100%)

Additional Features

• Gobo size: 23.5mm outside, 17.5mm image, 0.2mm max thickness

• Round base design for flush mounting

• User-selectable pan/tilt ranges

• Built-in automatic programs via master/slave

• Built-in sound activated programs via master/slave

• User-selectable 16bit or 8bit pan/tilt resolution

• Compact and lightweight

• Electronic transformer

• LED display menu with invert

• Display auto on/off

• Pan/tilt invert option

• Thermal switch

• Fan cooled

Optional Controllers

• CA-9 Easy Controller

7 colors + white

Rainbow color spin effect

7 interchangeable, rotating gobos + open

5 metal, 2 dichroic gobos

Gobo

wheel spin effect

Pan: 540

Tilt: 270°, 180°, 90°

°, 360°, 180°

DMX Channel Summary

CHANNEL FUNCTION (16-BIT MODE) CHANNEL FUNCTION (8-BIT MODE)

1

2

3

4

5

6

7

8

Intimidator Spot 2.0 HTI Manual 5 2007-01-24/09:36

Pan 1 Pan

Pan Fine

Tilt 3 Shutter

Tilt Fine

Shutter 5 Gobo

Color 6 Gobo Rotation

Gobo

Gobo Rotation

2

4

Tilt

Color

Page 6

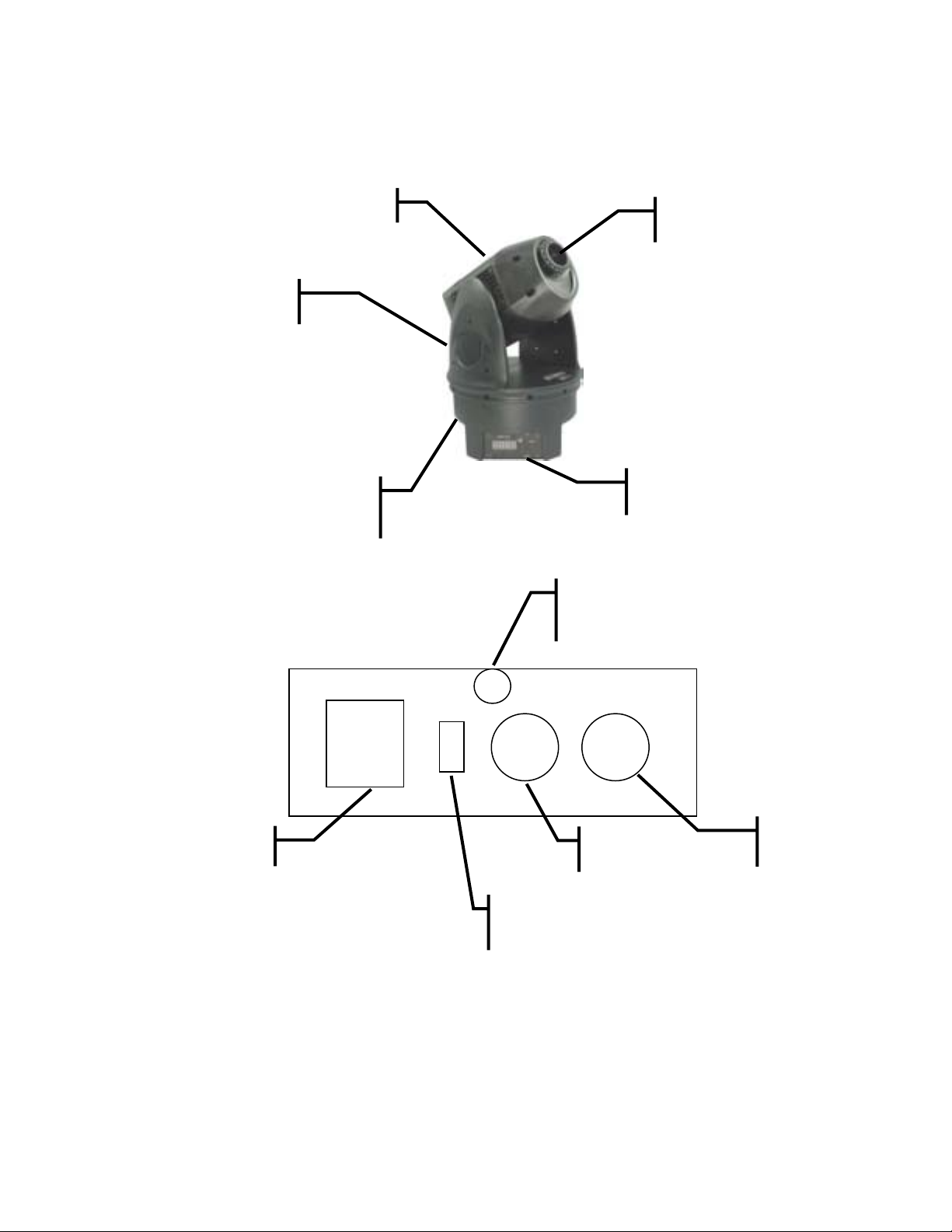

Product Overview

& Fuse Holder

Yoke

Rear of Base

Base

Head

Focusing

Lens

Control

Panel

Easy

Controller

Connector

AC Power Input

Intimidator Spot 2.0 HTI Manual 6 2007-01-24/09:36

Voltage

Selector

Sw

itch

DMX Input

Connector

DMX Output

Connector

Page 7

3. SETUP

Lamp

You will need to install a lamp prior to the initial operation of the fixture. A 150W HTI lamp is included.

Warning! When replacing the lamp, please wait 15 minutes after powering down to allow the

unit to cool down! Always disconnect from main power prior to lamp replacement.

Do not touch the envelope (glass area) of the bulb with bare hands. If this happens, clean the lamp

with alcohol and wipe it with a lint free cloth before installation.

Lamp Replacement

1) Remove the four screws indicated in

Figure A to access the lamp.

2) Hold the lamp with a lint-free cloth,

and pull the lamp directly

socket as shown in Figure B.

Note: One lead of the lamp is larger than

the o

ther. Make sure the large lead

goes in the large socket. If the lamp

won’t insert into the socket, try

turning it around and reinserting it.

3) Hold the new lamp with a lint-free

cloth, and insert directly

socket.

4) Reinsert the lamp housing into the

fixture, an

removed in step 1.

Note: The lamp may need to be aligned. If

so, follo

procedures on the following page.

d tighten the four screws

w the lamp alignment

out of the

into the

Lamp Access Screws

Figure A

Figure B

Intimidator Spot 2.0 HTI Manual 7 2007-01-24/09:36

Page 8

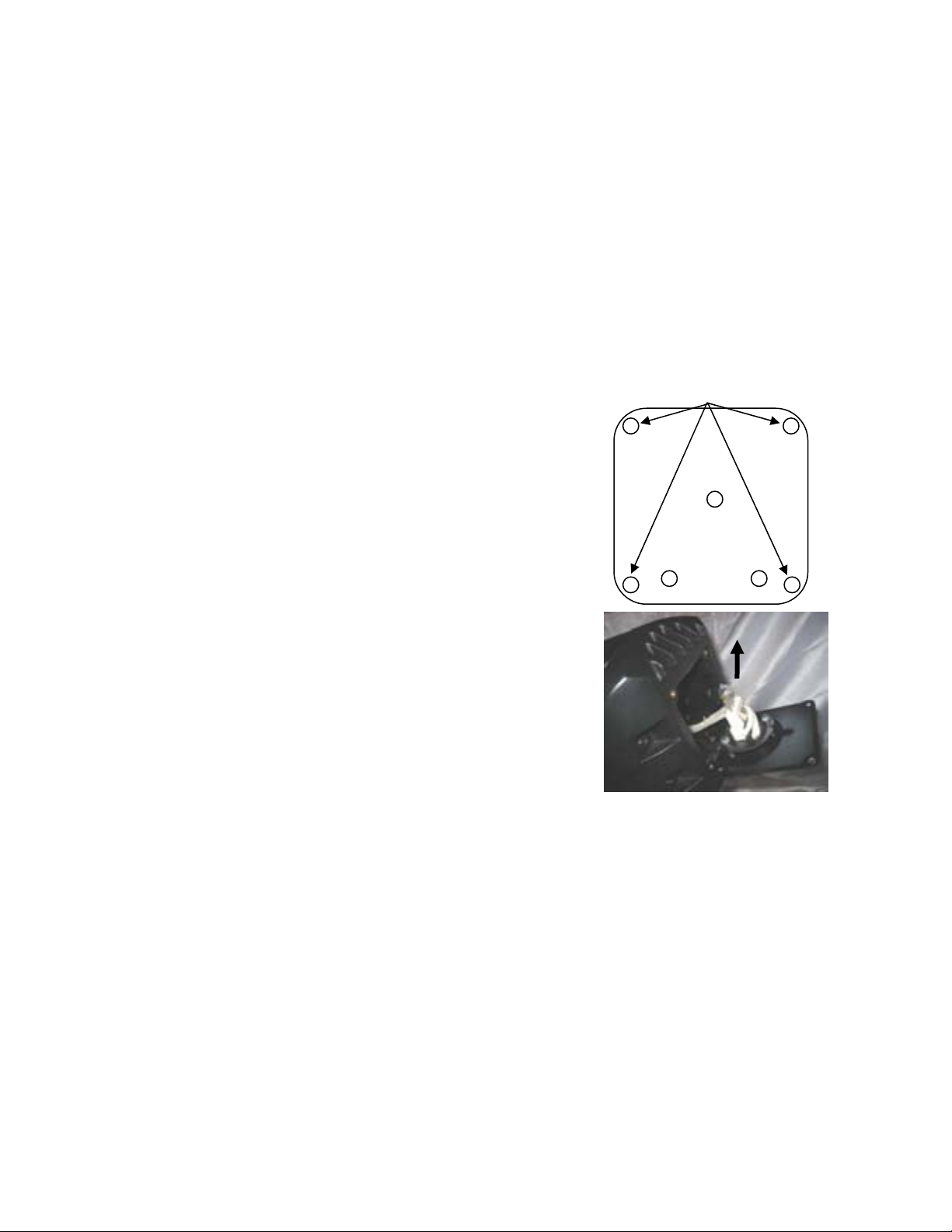

Lamp Alignment How-To

Often, after a new installation of a lamp, you will find that there is an uneven field of light or what is

refered to as a hot spot. This is due to the most intense point of the lamp source not being positioned

optimally within the reflector.

There are three lamp alignment screws provided at the base of

the fixture. Turning these screws allow you to optimize the

projection quality of the spot as well as the overall intensity of the

beam.

Lamp alignment screws

1) Project a white spot against any flat surface. Preferably the

surface should be white or pastel

2) Turning the lamp alignment screws, try to position t

as possible. This could require many attempts on your part. It is advisable to even out the

screws prior to lamp alignment as described in the illustration.

3) Once the hot spot is in the center of the spot, do your best to turn all screws equally as to affect

movement up or

4) As you move in and out of optimum lamp focus,

narrower. The goal is to either totally diminish the hot spot by having it widen and spread across

the entire spot or moving the hot spot so that it covers as much of the beam spot area as

possible.

Disconnect the power cord before replacing a fuse and always

replace with the same type fuse.

Fuse Replacement

With a flat head screwdriver wedge the fuse

holder out of its h

fuse from its holder and replace with exact

same type fuse. Insert the fuse holder back in

its place and reconnect power.

in color.

down within the reflector.

ousing. Remove the damaged

he hot spot in the center of the beam as best

you will see the hot spot either get wider or

The fuse is located

inside this

compartment.

Remove using a flat

head screwdriver.

Intimidator Spot 2.0 HTI Manual 8 2007-01-24/09:36

Page 9

Replacing Gobos

1) Remove the four screws indicated in

figure A to remove the back of the

head.

2) Remove the four screws indicated in

figure B to remove the front of the

head.

3) Orient the fixture so that it looks like

the fixture

4) Remove the glue from the gobo

(figure D

5) Remove the retaining spring from the

gobos.

6) Remove the existing gobo, and

replace

7) Replace the retaining spring.

8) If desired, add three small dabs of

high-temperature silicone glue to the

retaining spring.

9) Repeat steps 4-8 as many times as

necessar

gobos.

10) Replace the front cover and retighten

the four scre

in figure C.

) using tweezers.

with a new gobo.

y to replace all desired

ws removed in step 2.

Figure A

Figure B

11) Replace the back cover and retighten

the four scre

ws removed in step 1.

Figure C

Figure D

Intimidator Spot 2.0 HTI Manual 9 2007-01-24/09:36

Page 10

Fixture Linking

COMMO

You will need a serial data link to run light shows of one or more fixtures using a DMX-512 controller

or to run synchronized shows on two or more fixtures set to a master/slave operating mode. The

combined number of channels required by all the fixtures on a serial data link determines the number

of fixtures the data link can support.

Important: Fixtures on a serial data link must be daisy chained

Maximum recommended serial data link distance:

Maximum recommended number of fixtures on a serial data link: 32 fixtures

Data Cabling

To link fixtures together you must obtain data cables. You can purchase CHAUVET-certified DMX

cables directly from a dealer/distributor or construct your own cable. If you choose to create your own

cable please use data-grade cables that can carry a high quality signal and are less prone to

electromagnetic interference.

DMX DATA CABLE

Use a Belden© 9841 or equivalent cable which meets the specifications for EIA RS-485 applications.

Standard microphone cables cannot transmit DMX data reliably over long distances. The cable will

have the following characteristics:

in one single line. To comply with

the EIA-485 standard no more than 32 devices should be connected on one data

link. Connecting more than 32 fixtures on one serial data link without the use of a

DMX optically-isolated splitter may result in deterioration of the digital DMX signal.

500 meters (1640 ft.)

2-conductor twisted pair plus a shield

Maximum capacitance between conductors – 30 pF/ft.

Maximum capacitance between conductor and shield – 55 pF/ft.

Maximum resistance of 20 ohms / 1000 ft.

Nominal impedance 100 – 140 ohms

CABLE CONNECTORS

Cabling must have a male XLR connector on one end and a female XLR connector on the other end.

DMX connector configuration

1

3

N

1

INPUT OUTPUT

3

2

DMX

+

-

2

1

3

Termination reduces signal errors and

2

to avoid signal transmission problems

and interference, it is always

advisable to connect a DMX signal

terminator.

CAUTION Do not allow contact between the common and the fixture’s chassis ground.

Grounding the common can cause a ground loop, and your fixture may perform

erratically. Test cables with an ohm meter to verify correct polarity and to mak

the pins are not

grounded or shorted to the shield or each other.

Intimidator Spot 2.0 HTI Manual 10 2007-01-24/09:36

RESISTANCE 120

OHM

1/4W BETWEEN

PIN

2 (DMX -) AND

PIN

3 (DMX +) OF

THE LAST FIXTUR E

.

e sure

Page 11

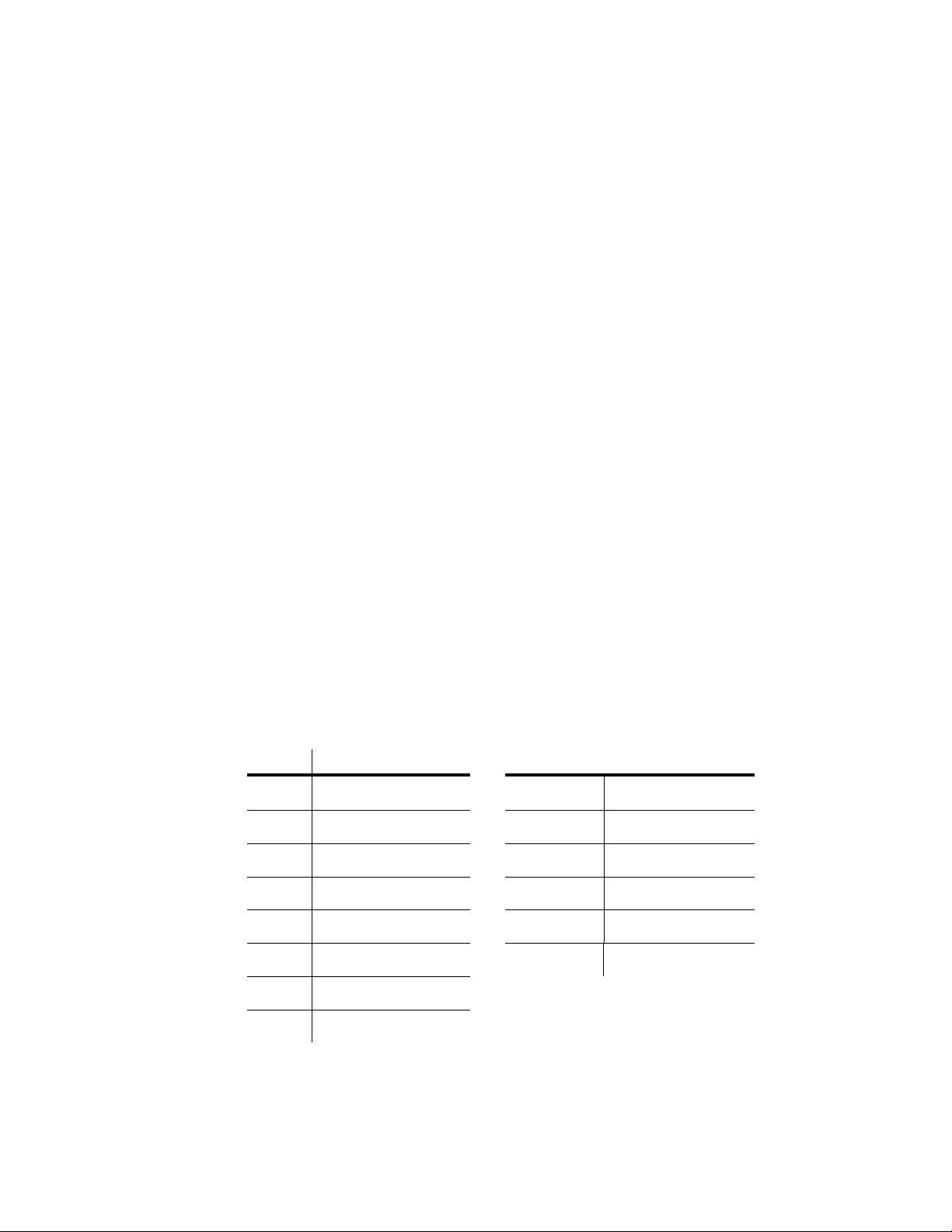

3-PIN TO 5-PIN CONVERSION CHART

Note! If you use a controller wi

pin to 3 pin adapter. CHAUVET Model No: DMX5M, or DMX5F.

The chart below details a proper cable conversion:

PIN TO 5 PIN C

3

duc 3 Pin Female (output) 5 Pin Male (Input)

Con tor

ONVERSION CHART

Ground/Shield Pin 1 Pin 1

Data ( - ) signal Pin 2 Pin 2

Data ( + ) signal Pin 3 Pin 3

Do not use Do not use

Do not use Do not use

Setting up a DMX Serial Data Link

1. Connect the (male) 3 pin connector sid

the DMX cable to

connector of the controller.

2.

Connect the end

the controller which will have

pin connector to the input connector of the

ure consisting of a (male) 3 pin

next fixt

connector.

3. t

Then, proceed to connect from the outpu

as stated ab

fixture and so on.

the output (female) 3

of the cable coming from

a (female) 3

ove to the input of the following

th a 5 pin DMX output connector, you will need to use a 5

U X Controller niversal DM

e of

pin

This drawing provides a

general illustration of the

DMX Input/Output panel of

a lighting fixture.

AUVET Certified DMX Data Cables

CH

Order Code D

escription

DMX1.5 DMX Cable 1.5m/4.9ft

DMX4.5

DMX Cable 4

.5m/14.8ft

DMX10 DMX Cable 10m/32.8ft

Stand-Alone/Master/Slave Fixture Linking

1. Connect the (male) 3 pin connector side of the DM

of the first fixture.

2. Connect the end of the cable coming from the first f

connector to the input connector o

proceed to connect from the output as stated above to the input of the following fixture and

O

ften, the setup for Master-Slave

and Standalone operation requires

that the first fixture in the cha in be

initialized for this purpose via either

settings in the control panel or DIPswitches. Secondarily, the fixtures

that follow may also require a slave

setting. Please consult the

“Operating Instructions” section in

this manual for complete ins tructions

for this type of setup and

configuration.

f the next fixture consisting of a (male) 3 pin connector. Then,

Continue the link

X cable to the output (female) 3 pin connector

ixture which will have a (female) 3 pin

so on.

Intimidator Spot 2.0 HTI Manual 11 2007-01-24/09:36

Page 12

Mounting

ORIENTATION

This fixture may be mounted in any position provided there is adequate room for ventilation.

RIGGING

It is important never to obstruct the fan or vents pathway. Mount the

fixture using, a suitable “C” or “O” type clamp. Adjust the angle of

the fixture by loosening both knobs and tilting the fixture. After

finding the desired position, retighten both knobs.

• When selecting installation location, take into consideration lamp

replacement access and routine maintenance.

• Safety cables must always be used.

• Never mount in places where the fixture will be exposed to rain, high

humidity, ext

reme temperature changes or restricted ventilation.

INCLUDED MOUNTING BRACKET

Hanging Clamp

NOTE!

C

LAMP IS SOLD SEPARATELY.

Safety Cable

Attachment Points

Intimidator Spot 2.0 HTI Manual 12 2007-01-24/09:36

Page 13

4. OPERATING INSTRUCTIONS

Navigating the Control Panel

Access control panel functions using the four panel buttons located directly underneath the LCD

Display. NOTE: The display will turn off after 30 seconds if no buttons are pushed.

Button Function

<MODE/ESC>

<UP>

<DOWN>

<ENTER>

Used to access the menu or to scroll

through to

Scrolls through menu options in ascending

order

Scrolls through menu options in descending

order

Used to select and store the current menu

or option

The Control Panel LED Display shows the menu items you select from the menu map on page 13.

When a menu function is selected, the display will show immediately the first available option for the

selected menu function. To select a menu item, press <ENTER>.

Press the <MO

again will scroll through the different top-level menu options available. Use the <UP> and <DOWN>

buttons to navigate the menu options. Press the <ENTER> button to access the menu function

currently displayed or to enable a menu option. To return to the previous option or menu without

changing the value, press the <MODE/ESC> button.

p-level menu items.

within a menu

DE/ESC> button once to activate the control panel. Pressing the <MODE/ESC> button

NTROL PANEL

CO

DMX Signal Indicator

MODE

/ESC

UP

ENTER

DOWN

Intimidator Spot 2.0 HTI Manual 13 2007-01-24/09:36

Page 14

Menu Map

Intimidator Spot 2.0 HTI Manual 14 2007-01-24/09:36

Page 15

Menu Functions

MENU OPTION DESCRIPTION

DMX: The fixture will be controlled by a DMX signal coming from a DMX controller.

The starting ad

buttons.

Automatic – Master Unit: Sets t

operation and the built in programs will be triggered automatically. No data link is

required; all fixtures can be set to this mode for Stand-alone operation.

Sound Active – Master Unit: S

operation and the built in programs will be triggered by the sound. No data link is

required; all fixtures can be set to this mode for Stand-alone operation.

Easy Controller – Master Unit: S

operation and the built in programs will be triggered by the setting on the easy

controller.

Slave Unit: Sets

fixture in the data link to “Master” otherwise nothing will happen.

dress must be selected, and can be set using the up and down

he fixture to Master status for Master-Slave

ets the fixture to Master status for Master-Slave

ets the fixture to Master status for Master-Slave

the fixture to run in sync with the Master. You must set the first

User Configurations

TO SET THE PAN TO INVERTING OR NON-INVERTING:

1) Press <MODE/ESC> until is displayed. Use the <UP> and <DOWN> buttons to

scroll through the two options.

is non-inverting; is inverting.

TO SET THE TILT TO INVERTING OR NON-INVERTING:

1) Press <MODE/ESC> until is displayed.

2) Use the <UP>

inverting;

and <DOWN> buttons to scroll through the two options.

is inverting.

TO REVERSE THE DISPLAY:

1) Press <MODE/ESC> until or is displayed.

2) Use the <UP>

and <DOWN> buttons to scroll through the two options. is normal;

is reversed.

TO SET THE FIXTURE TO 16-BIT OR 8-BIT MODE:

1) Press <MODE/ESC> until or is displayed. Use the <UP> and

is non-

<DOWN> buttons to scroll through the two options.

bit.

Intimidator Spot 2.0 HTI Manual 15 2007-01-24/09:36

is 16-bit; is 8-

Page 16

TO CHANGE THE PAN RANGE:

1) Press <MODE/ESC> until , , or is displayed..

2) Use the <UP>

Note: These settings only apply if the fixture is in master/slave or stand-alone modes. These

setti

ngs will not affect a fixture operating in DMX mode.

and <DOWN> buttons to scroll through the three options.

is 360°; is 180°

TO CHANGE THE TILT RANGE:

1) Press <MODE/ESC> until , , or is displayed..

2) Use the <UP>

Note: These settings only apply if the fixture is in master/slave or stand-alone modes. These

setti

ngs will not affect a fixture operating in DMX mode.

and <DOWN> buttons to scroll through the three options.

is 180°; is 90°

Service Functions

TO RESET THE FIXTURE:

1) Press the <MODE/ESC> button until is displayed, and then press the <ENTER>

button. The fixture will now reset itself.

is 540°;

is 270°;

TO RESTORE ALL SETTINGS TO THEIR FACTORY DEFAULTS:

1) Press the <MODE/ESC> button until is displayed, and then press the <ENTER>

button. The fixture will now load all factory default settings.

Intimidator Spot 2.0 HTI Manual 16 2007-01-24/09:36

Page 17

Operation

Stand-Alone Mode (Sound-Active, Auto Mode, Easy Controller):

This mode allows a single unit to run to the beat of the music, or the unit will auto change in Auto

Mode.

1) Press <MO

2) Use the <UP>

press the <ENTER> button.

3)

sound-active mode is selected;

selected.

4) The unit will react to the low frequencies of music via the internal microphone in Sound Active

mode, or th

DE/ESC> until

and <DOWN> buttons to scroll through until the desired mode is displayed and

is easy controller mode.

will be displayed when auto mode is selected; will be displayed when

e unit will auto change in Auto Mode.

, , , or is displayed.

is auto mode; is sound-active,

will be displayed when easy controller mode is

Master/Slave Mode (Master Sound, Master Auto, Easy Controller):

This mode will allow you to link up to 32 units together without a controller.

1) Use standard DMX cables to daisy chain your units together via th

of the units. For longer cable runs we suggest a terminator at the last fixture. For more

information about terminators, see page 10.

2) Choose a unit to function as the master. Press <MO

, or is displayed on the master unit.

3) Use the <UP>

press the <ENTER> button.

and <DOWN> buttons to scroll through until the desired mode is displayed and

is auto mode; is sound-active,

DE/ESC> until

e DMX connector on the rear

, ,

is easy controller mode.

4)

sound-active mode is selected,

selected.

4) Press <MO

on the slave units. Use the <UP> and <DOWN> buttons to scroll through until

displayed and press the <ENTER> button.

5)

will be displayed when auto mode is selected; will be displayed when

will be displayed when easy controller mode is

DE/ESC> until

will be displayed when slave mode is selected.

, , , or is displayed

is

Easy Controller Settings

BUTTON DESCRIPTION

Stand By Blacks out the unit.

Function First click: strobe on. Second click: strobe off.

Mode

Intimidator Spot 2.0 HTI Manual 17 2007-01-24/09:36

First click: sound-active mode (LED will be on). Se

off).

cond click: auto mode (LED will be

Page 18

DMX Mode

This mode allows the unit to be controlled by any universal DMX controller. If you are unfamiliar with

DMX, please read the DMX Primer on page 21.

1) Press <MODE/ESC> until

2) Use the <UP>

button.

and <DOWN> buttons to select the desired address and press the <ENTER>

DMX Channel Values (16-bit mode)

HANNEL VALUE FUNCTION

C

1

000 Ù

2 000 Ù 255 Pan Fine

3

000 Ù

4 000 Ù 255 Tilt Fine

000 Ù

5

109 Ù

134 Ù

250 Ù

000 Ù

016 Ù

032 Ù

048 Ù

064 Ù

6

080 Ù

096 Ù

112 Ù

128 Ù

192 Ù

000 Ù

016 Ù

032 Ù

048 Ù

7

064 Ù

080 Ù

096 Ù

112 Ù

128 Ù

192 Ù

Pan

255

0 – 540 (1

Tilt

255

0 – 270 (1

Shutter and Dimmer

Closed > Open

108

Open

133

Strobe (Fast > Slow)

249

Open

255

Color Wheel

015

White (Open)

UV

031

Pink

047

Green

063

Red

079

Blue

095

Y

ellow

111

127

Magenta

191

Scroll counter-clockwise (Slow > Fast)

255

Scroll clockwise (Slow > Fast)

Gobo Wheel

015

Open

031

Gobo 1

Gobo 2

047

Gobo 3

063

Gobo 4

079

Gobo 5

095

Gobo 6

111

Gobo 7

127

Scroll counter-clockwise (Slow > Fast)

191

Scroll clockwise (Slow > Fast)

255

28 = halfway point)

28 = halfway point)

is displayed.

Gobo Rotation

000 Ù

010 Ù

8

117 Ù

245 Ù

Stop

009

Rotate counter-clockwise (Slow > Fast)

116

Rotate clockwise (Slow > Fast)

244

Boomerang gobo rotation* (Fast > Slow)

255

*Boomerang gobo rotation automatically rotates the

gobo in one direction, and then automatically rotates

it in the opposite direction an equal number of times.

Intimidator Spot 2.0 HTI Manual 18 2007-01-24/09:36

Page 19

DMX Channel Values (8-bit mode)

CHANNEL VALUE FUNCTION

1

000 Ù

2

000 Ù

000 Ù

109 Ù

3

134 Ù

250 Ù

000 Ù

016 Ù

032 Ù

048 Ù

064 Ù

4

080 Ù

096 Ù

112 Ù

128 Ù

192 Ù

000 Ù

016 Ù

032 Ù

048 Ù

064 Ù

5

080 Ù

096 Ù

112 Ù

128 Ù

192 Ù

Pan

255

0 – 540 (1

Tilt

255

0 – 270 (1

Shutter and Dimmer

Closed

108

Closed > Open

133

Open

249

Strobe (Fast > Slow)

255

Open

Color Wheel

015

White (Open)

UV

031

Pink

047

Green

063

Red

079

Blue

095

Y

ellow

111

127

Magenta

191

Scroll counter-clockwise (Slow > Fast)

255

Scroll clockwise (Slow > Fast)

Gobo Wheel

015

Open

031

Gobo 1

047

Gobo 2

063

Gobo 3

Gobo 4

079

095

Gobo 5

Gobo 6

111

Gobo 7

127

Scroll counter-clockwise (Slow > Fast)

191

Scroll clockwise (Slow > Fast)

255

28 = halfway point)

28 = halfway point)

Gobo Rotation

009

000 Ù

010 Ù

6

117 Ù

245 Ù

Stop

116

Rotate counter-clockwise (Slow > Fast)

Rotate clockwise (Slow > Fast)

244

255

Boomerang gobo rotation* (Fast > Slow)

*Boomerang gobo rotation automatically rotates the

gobo in one direction, and then automatically rotates

it in the opposite direction an equal number of times.

Intimidator Spot 2.0 HTI Manual 19 2007-01-24/09:36

Page 20

General Troubleshooting

Applies to

Symptom Solution(s)

Auto shut off Check fan thermal switch reset

Beam is very dim or

not bright

Breaker/Fuse keeps

blowing

Chase is too slow Check users manual for speed adjustment

Device has no power Check for power on Mains.

Fixture is not

responding

Fixture is on but

there is no

movement to the

audio

Lamps cuts off

sporadically

Light will not come

on after power failure

Loss of signal Use only DMX cables

Moves slow Check 220/110v switch for proper setting

Clean optical system or replace lamp

Check 220/110v switch for proper setting

Check total load placed on device

Check device’s fuse. (internal and/or external)

Check DMX Dip switch settings for correct addressing

Check DMX cables

Check polarity switch settings

Make sure you have the correct audio mode on the

control switches. If audio provided via ¼” jack, make

sure a live audio signal exists

Adjust sound sensitivity knob

Possible bad lamp or fixture is overheating.

Lamp may be at end of its life.

Some discharge lamps require a cooling off period

before the electronics in the fixture can kick start it

again, wait 5 to 10 minutes before powering up

Install terminator

Note: Keep D

or black lights.

MX cables separated from power cables

Lights

9

9

Foggers

& Snow

Controllers

Dimmers

& Chaser

9

9

9

9 9

9 9

9

9

9

9 9

9 9 9 9

9

9

No flash Re-install bulb, may have shifted in shipping

No laser output Bounce mirror motor may have shifted during shipping,

readjust

No light output Check slip ring & brushes for contact

Install bulb

Call service technician

Relay will not work Check reset switch

Check cable connections

Remote does not

work

Stand alone mode All Chauvet lighting fixtures featuring stand-alone

Intimidator Spot 2.0 HTI Manual 20 2007-01-24/09:36

Make sure connector is firmly connected to device

functions do not require additional settings, simply

power the fixture and it will automatically enter into this

mode

If you still have a problem after trying the above solutions, please contact CHAUVET Technical

ort at the location on the next page.

Supp

9

9

9

9 9

9

9

Page 21

Technical Support

Address: Service Dept.

3000 N 29th Ct, Hollywood, FL 33020 (U.S.A.)

Support (Email): tech@chauvetlighting.com

Telephone: (954) 929-1115 - (Press 4)

Fax: (954) 929-5560 - (Attention: Service)

Website: http://www.chauvetlighting.com

5. APPENDIX

DMX Primer

There are 512 channels in a DMX-512 connection. Channels may be assigned in any manner. A

fixture capable of receiving DMX 512 will require one or a number of sequential channels. The user

must assign a starting address on the fixture that indicates the first channel reserved in the controller.

There are many different types of DMX controllable fixtures and they all may vary in the total number

of channels required. Choosing a start address should be planned in advance. Channels should

never overlap. If they do, this will result in erratic operation of the fixtures whose starting address is

set incorrectly. You can however, control multiple fixtures of the same type using the same starting

address as long as the intended result is that of unison movement or operation. In other words, the

fixtures will be slaved together and all respond exactly the same.

DMX fixtures are designed to receive data through a serial Daisy

where the DATA OUT of one fixture connects to the DATA IN of the next fixture. The order in which

the fixtures are connected is not important and has no effect on how a controller communicates to

each fixture. Use an order that provides for the easiest and most direct cabling. Connect fixtures

using shielded two conductor twisted pair cable with three pin XLR male to female connectors. The

shield connection is pin 1, while pin 2 is Data Negative (S-) and pin 3 is Data positive (S+). CHAUVET

carries 3-pin XLR DMX compliant cables, DMX-10 (33’), DMX-4.5 (15’) and DMX-1.5 (5’)

General Maintenance

To maintain optimum performance and minimize wear fixtures should be cleaned frequently. Usage

and environment are contributing factors in determining frequency. As a general rule, fixtures should

be cleaned at least twice a month. Dust build up can cause overheating. This can lead to increased

mechanical wear. Be sure to power off fixture before conducting maintenance.

Unplug fixture from power. Use a vacuum or air co

collected on external vents and internal components.

Cleaning frequency depends on the environment in which the fixture operates: damp, smoky or

particularl

using normal glass cleaning fluid. Always dry the parts carefully.

y dirty surrounding can cause greater accumulation of dirt in the unit. Clean with soft cloth

Chain. A Daisy Chain connection is

mpressor and a soft brush to remove dust

Intimidator Spot 2.0 HTI Manual 21 2007-01-24/09:36

Page 22

Returns Procedure

Returned merchandise must be sent prepaid and in the original packing, call tags will not be issued.

Package must be clearly labeled with a Return Merchandise Authorization Number (RA #). Products

returned without an RA # will be refused. Call CHAUVET and request RA # prior to shipping the

fixture. Be prepared to provide the model number, serial number and a brief description of the cause

for the return. Be sure to properly pack fixture, any shipping damage resulting from inadequate

packaging is the customer’s responsibility. CHAUVET reserves the right to use its own discretion to

repair or replace product(s). As a suggestion, proper UPS packing or double-boxing is always a safe

method to use.

Note: If you are given an RA #, please include the following information on a piece of paper

inside the box

1) Your name

2) Your address

3) Your phone number

4) The RA #

5) A brief description of the symptoms

Claims

Damage incurred in shipping is the responsibility of the shipper; therefore the damage must be

reported to the carrier upon receipt of merchandise. It is the customer's responsibility to notify and

submit claims with the shipper in the event that a fixture is damaged due to shipping. Any other claim

for items such as missing component/part, damage not related to shipping, and concealed damage,

must be made within seven (7) days of receiving merchandise.

:

Intimidator Spot 2.0 HTI Manual 22 2007-01-24/09:36

Page 23

Technical Specifications

WEIGHT & DIMENSIONS

Length..............................................................................................................................

Width ...............................................................................................................................

Height.................................................................................................................................9 in (229 mm)

Weight ................................................................................................................................22 lbs (10 kg)

POWER

Switch-selectable power settings....................................................120V 50/60Hz AC or 230V 50/60Hz

Fuse....................................................................................................20mm Glass 10A 250V Fast Blo

Power Consumption.................................................................................................. 312W at 120V Ma

Inrush Power .....................................................................................................................

LIGHT SOURCE

Lamp................................................................................................................HTI 150W 6500

PHOTO OPTIC

Beam Angle........................................................................................................................................

Pan................................................................................................................................................... 540°

Tilt.....................................................................................................................................................

Illuminance at 1m ....................................................................................................1,246 fc (13,40

GOBOS

Outside diameter........................................................................................................................

Image diameter (maximum) .......................................................................................................17.5 mm

Thickness .....................................................................................................................................

THERMAL

Maximum ambient temperature...........................................................................................104°F (40°C

CONTROL & PROGRAMMING

Data input................................................................................................ locking 3-pin XLR male socket

Data output...........................................................................................locking 3-pin XLR female socket

Data pin configuration ..............................................................................pin 1 shield, pin 2 (-), pin 3 (+)

Protocols........................................................................................................................

DMX Channels ....................................................................................................................................6-8

ORDERING INFORMATION

Intimidator Spot 2.0 HTI ............................................................................................................DMX-690

WARRANTY INFORMATION

Warranty.............................................................................................................. 2-year limited w

16 in (406 mm)

10 in (254 mm)

w

x

384W at 120V

°K 750hrs

13°

270°

7 lux)

23.5 mm

0.2 mm

)

DMX-512 USITT

arranty

Intimidator Spot 2.0 HTI Manual 23 2007-01-24/09:36

Loading...

Loading...