Page 1

Derby X™

Snapshot

OK on Dimmer

Outdoor OK

Sound Activated

DMX512

Master/Slave

Autoswitching

Transformer

Replaceable Fuse

User Serviceable

Duty Cycle

USER MANUAL

3000 N 29th Ct, Hollywood, FL 33020 U.S.A.

(800) 762-1084 – (954) 929-1115

FAX (954) 929-5560

www.chauvetlighting.com

Page 2

TABLE OF CONTENTS

1. Before You Begin ........................................................................................................ 3

What is included ................................................................................................................ 3

Unpacking Instructions ...................................................................................................... 3

AC Power .......................................................................................................................... 3

Contact Us ........................................................................................................................ 3

Safety Instructions ............................................................................................................. 4

2. Introduction ................................................................................................................. 5

Features ............................................................................................................................ 5

DMX Channel Summary ................................................................................................... 5

Product Overview .............................................................................................................. 5

3. Setup ............................................................................................................................ 6

Fuse Replacement ............................................................................................................ 6

Fixture Linking ................................................................................................................... 6

Data Cabling ..................................................................................................................... 6

DMX Data Cable ............................................................................................................... 6

Cable Connectors ............................................................................................................. 7

3-Pin to 5-Pin Conversion Chart ....................................................................................... 7

Setting up a DMX Serial Data Link .................................................................................... 7

Master/Slave Fixture Linking ............................................................................................. 8

Mounting ........................................................................................................................... 8

Orientation......................................................................................................................... 8

Rigging .............................................................................................................................. 8

Stacking ............................................................................................................................ 9

4. Operating Instructions .............................................................................................. 10

Operation ........................................................................................................................ 10

Stand-Alone Mode (Sound-Active): ................................................................................. 10

Master/Slave Mode (Master Sound): .............................................................................. 10

DMX Mode ...................................................................................................................... 10

DMX Channel Values ...................................................................................................... 11

Setting the starting address ............................................................................................ 12

DMX Quick Reference Chart ........................................................................................... 13

Blow-out Diagram ............................................................................................................ 14

General Troubleshooting ................................................................................................. 15

Technical Support ........................................................................................................... 16

5. Appendix .................................................................................................................... 16

DMX Primer ..................................................................................................................... 16

General Maintenance ...................................................................................................... 17

Returns Procedure .......................................................................................................... 17

Claims ............................................................................................................................. 17

Technical Specifications .................................................................................................. 18

Derby X™ User Manual 2 7/14/2008 1:27 PM

Page 3

1. BEFORE YOU BEGIN

What is included

¾ 1 x Derby X™

¾ Power Cord

¾ Warranty Card

¾ User Manual

Unpacking Instructions

Immediately upon receiving a fixture, carefully unpack the carton, check the

contents to ensure that all parts are present, and have been received in good

condition. Notify the shipper immediately and retain packing material for

inspection if any parts appear damaged from shipping or the carton itself shows

signs of mishandling. Save the carton and all packing materials. In the event that

a fixture must be returned to the factory, it is important that the fixture be returned

in the original factory box and packing.

AC Power

This fixture has an auto-switching power supply that can accommodate a wide

range of input voltages. The only thing necessary to do before powering on the

unit is to make sure the line voltage you are applying is within the range of

accepted voltages. This fixture will accommodate between 100V and 240V AC

50-60 Hz. All fixtures must be powered directly off a switched circuit and cannot

be run off a rheostat (variable resistor) or dimmer circuit, even if the rheostat or

dimmer channel is used solely for a 0% to 100% switch.

Contact Us

World Wide

General Information CHAUVET

3000 North 29

Hollywood, FL 33020

voice: 954.929.1115

fax: 954.929.5560

toll free: 800.762.1084

Technical Support CHAUVET

3000 North 29

Hollywood, FL 33020

voice: 954.929.1115 (Press 4)

fax: 954.929.5560 (Attention: Service)

World Wide Web www.chauvetlighting.com

th

Court

th

Court

Derby X™ User Manual 3 7/14/2008 1:27 PM

Page 4

Safety Instructions

Please read these instructions carefully, which includes

important information about the installation, usage and

maintenance of this product.

• Please keep this User Guide for future consultation. If you sell the unit to another

user, be sure that they also receive this instruction booklet.

• Always make sure that you are connecting to the proper voltage, and that the line

voltage you are connecting to is not higher than that stated on the decal or rear

panel of the fixture.

• This product is intended for indoor use only! (If applicable)

• To prevent risk of fire or shock, do not expose fixture to rain or moisture. Make

sure there are no flammable materials close to the unit while operating.

• The unit must be installed in a location with adequate ventilation, at least 20in

(50cm) from adjacent surfaces. Be sure that no ventilation slots are blocked.

• Always disconnect from power source before servicing or replacing lamp or fuse

and be sure to replace with same lamp source.

• Secure fixture to fastening device using a safety chain. Never carry the fixture

solely by its head. Use its carrying handles.

• Maximum ambient temperature (Ta) is 104°F (40°C). Do not operate fixture at

temperatures higher than this.

• In the event of a serious operating problem, stop using the unit immediately.

Never try to repair the unit by yourself. Repairs carried out by unskilled people

can lead to damage or malfunction. Please contact the nearest authorized

technical assistance center. Always use the same type spare parts.

• Never connect the device to a dimmer pack.

• Make sure the power cord is never crimped or damaged.

• Never disconnect the power cord by pulling or tugging on the cord.

• Avoid direct eye exposure to the light source while it is on.

• Do not daisy chain power to more than # units. (If applicable)

Caution! There are no user serviceable parts inside the unit. Do not open the

housing or attempt any repairs yourself. In the unlikely event your

unit may require service, please contact CHAUVET at: 954-929-1115.

Derby X™ User Manual 4 7/14/2008 1:27 PM

Page 5

2. INTRODUCTION

Features

• 8-channel DMX-512 LED derby effect

• Blackout/static/strobe

• Individual control of red, green and blue LEDs within each cluster (6 total)

• Built-in automated programs via DMX

• Built-in sound activated programs via master/slave or DMX

Additional Features

• Mount multiple units together with adjustable, optional bracket (XBRACKET)

• Additional power output: max 27 units @ 120V (see manual for details)

DMX Channel Summary

Channel Description

1 Led Cluster 1

2 Led Cluster 2

3 Led Cluster 3

4 Led Cluster 4

5 Led Cluster 5

6 Led Cluster 6

7 Strobe

8 Auto Programs

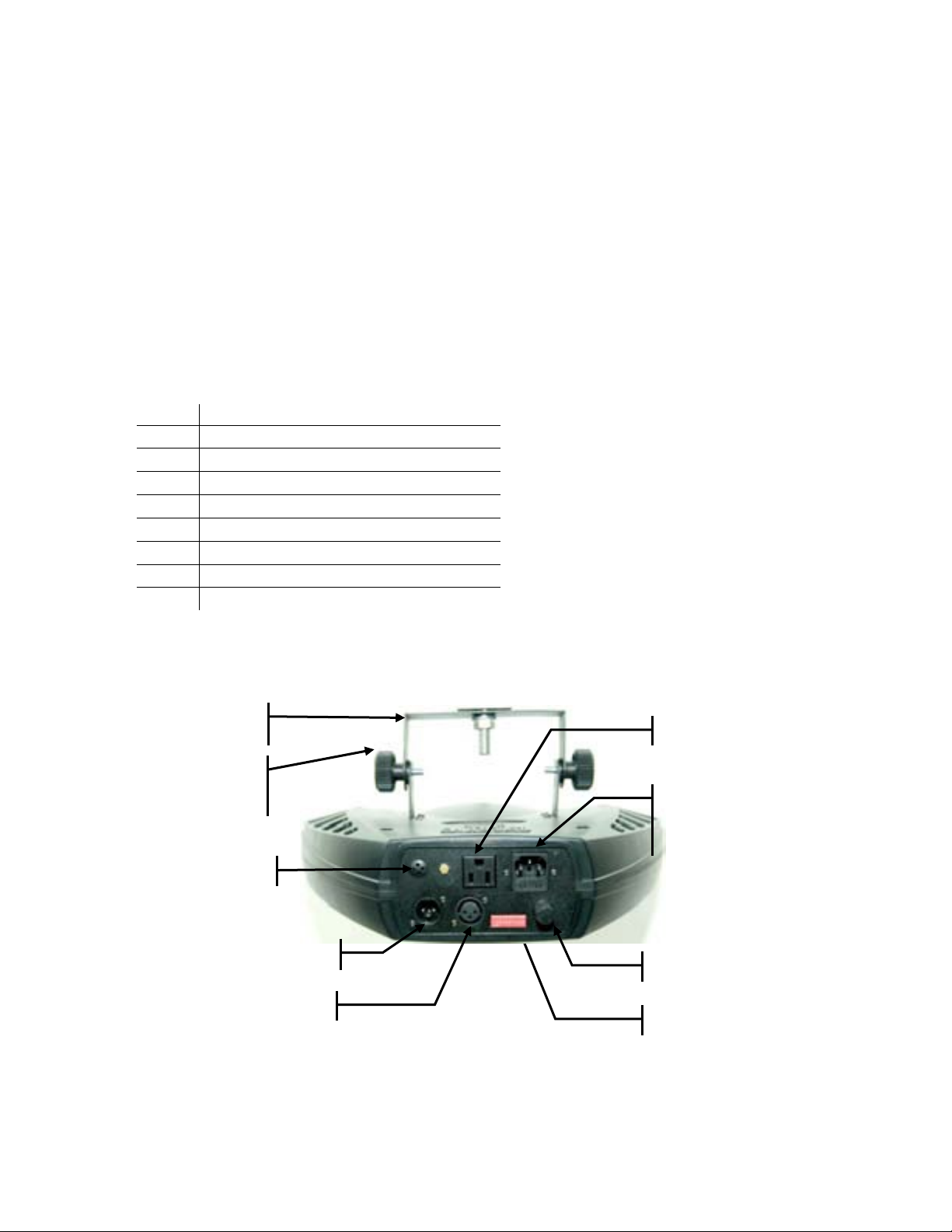

Product Overview

Power Link Out

Hanging

Bracket

Tilt

Adjustment

Knob

Microphone

DMX In

DMX Out

Power Out

Power In &

External

Fuse

Sound

Dipswitche

Derby X™ User Manual 5 7/14/2008 1:27 PM

Page 6

3. SETUP

y

Fuse Replacement

Disconnect the power cord before replacing a fuse and

alwa

With a flat head screwdriver wedge the fuse holder out of its housing. Remove

the damaged fuse from its holder and

replace with exact same type fuse.

Insert the fuse holder back in its place

and reconnect power.

Fixture Linking

You will need a serial data link to run

light shows of one or more fixtures using a DMX-512 controller or to run

synchronized shows on two or more fixtures set to a master/slave operating

mode. The combined number of channels required by all the fixtures on a serial

data link determines the number of fixtures the data link can support.

Important: Fixtures on a serial data link must be daisy chained in one single line.

Maximum recommended serial data link distance: 500 meters (1640 ft.)

Maximum recommended number of fixtures on a serial data link: 32 fixtures

s replace with the same type fuse.

The fuse is located

inside this

compartment.

Remove using a flat

head screwdriver.

To comply with the EIA-485 standard no more than 32 devices should

be connected on one data link. Connecting more than 32 fixtures on

one serial data link without the use of a DMX optically-isolated splitter

may result in deterioration of the digital DMX signal.

Data Cabling

To link fixtures together you must obtain data cables. You can purchase

CHAUVET-certified DMX cables directly from a dealer/distributor or construct

your own cable. If you choose to create your own cable please use data-grade

cables that can carry a high quality signal and are less prone to electromagnetic

interference.

DMX DATA CABLE

Use a Belden© 9841 or equivalent cable which meets the specifications for EIA

RS-485 applications. Standard microphone cables cannot transmit DMX data

reliably over long distances. The cable will have the following characteristics:

2-conductor twisted pair plus a shield

Maximum capacitance between conductors – 30 pF/ft.

Maximum capacitance between conductor and shield – 55 pF/ft.

Maximum resistance of 20 ohms / 1000 ft.

Nominal impedance 100 – 140 ohms

Derby X™ User Manual 6 7/14/2008 1:27 PM

Page 7

CABLE CONNECTORS

COMMO

Cabling must have a male XLR connector on one end and a female XLR connector on the

other end.

DMX connector

N

1

INPUT OUTPUT

3

2

DMX

+

-

1

3

2

CAUTION Do not allow contact between the common and the fixture’s chassis

ground. Grounding the common can cause a ground loop, and your

fixture may perform erratically. Test cables with an ohm meter to

verify correct polarity and to make sure the pins are not grounded or

shorted to the shield or each other.

3-PIN TO 5-PIN CONVERSION CHART

Note! If you use a controller with a 5 pin DMX output connector, you will

need to use a 5 pin to 3 pin adapter. CHAUVET Model No: DMX5M, or

DMX5F.

The chart below details a proper cable conversion:

3 PIN TO 5 PIN CONVERSION CHART

Conductor 3 Pin Female (output) 5 Pin Male (Input)

Ground/Shield Pin 1 Pin 1

Data ( - ) signal Pin 2 Pin 2

Data ( + ) signal Pin 3 Pin 3

Do not use Do not use

Do not use Do not use

1

3

2

Termination reduces signal errors. To

avoid signal transmission problems

and interference, it is always

advisable to connect a DMX signal

terminator.

Resistance 120

ohm 1/4w

between pin 2

(DMX -) and pin

Setting up a DMX Serial Data Link

Universal DMX Controller

1. Connect the (male) 3 pin connector side of the

DMX cable to the output (female) 3 pin connector

of the controller.

2. Connect the end of the cable coming from the

controller which will have a (female) 3 pin

connector to the input connector of the next fixture

consisting of a (male) 3 pin connector.

3. Then, proceed to connect from the output as

stated above to the input of the following fixture

and so on.

CHAUVET Certified DMX Data Cables

Order Code Description

DMX1.5 DMX Cable 1.5m/4.9ft

DMX4.5 DMX Cable 4.5m/14.8ft

DMX10 DMX Cable 10m/32.8ft

Continue the link

Derby X™ User Manual 7 7/14/2008 1:27 PM

This drawing provides

a general illustration

of the DMX

Input/Output panel of

a lighting fixture.

Page 8

Master/Slave Fixture Linking

Mounting

ORIENTATION

1. Connect the (male) 3 pin connector side of the DMX cable to the output (female) 3 pin

connector of the first fixture.

2. Connect the end of the cable coming from the first fixture which will have a (female) 3

pin connector to the input connector of the next fixture consisting of a (male) 3 pin

connector. Then, proceed to connect from the output as stated above to the input of the

following fixture and so on.

Often, the setup for Master-Slave

and Standalone operation requires

that the first fixture in the cha in be

initialized for this purpose via either

settings in the control panel or DIPswitches. Secondarily, the fixtures

that follow may also require a slave

setting. Please consult the

“Operating Instructions” section in

this manual for complete ins tructions

for this type of setup and

configuration.

This fixture may be mounted in any safe position provided there is adequate room for

ventilation.

Slave Slave Master

RIGGING

It is important never to obstruct the fan or vents pathway. Mount the fixture using, a

suitable “C” or “O” type clamp. Adjust the angle of the fixture by loosening both knobs and

tilting the fixture. After finding the desired position, retighten both knobs.

• When selecting installation location, take into consideration lamp replacement access and

routine maintenance.

• Safety cables must always be used.

• Never mount in places where the fixture will be exposed to rain, high humidity, extreme

temperature changes or restricted ventilation.

Hanging Clamp

Note!

Clamp is sold separately.

Derby X™ User Manual 8 7/14/2008 1:27 PM

Page 9

Stacking

The Derby X™ may be “stacked” by using multiple fixtures and the optional bracket

(XBRACKET). This bracket may be ordered from CHAUVET.

The bracket kit will ship with 2pcs bracket (as shown below) and will include 4 screws

for attaching it to the bottom of the fixture.

• Note: When you are installing this bracket, you must use the washers and

bracket tightening knob to secure one fixture to another.

• Note: You must only stack a maximum of 4 fixtures.

Optional XBRACKET

Derby X™ User Manual 9 7/14/2008 1:27 PM

Page 10

4. OPERATING INSTRUCTIONS

Operation

Stand-Alone Mode (Sound-Active):

This mode allows a single unit to run to the beat of the music, or the unit will auto change

in Auto Mode.

1) Set all dipswitches position to the Off position.

Mode Dipswitches

Sound Active 10 = Off

2) The unit will react to the low frequencies of music via the internal microphone in

Sound Active mode.

3) Use the audio sensitivity knob on the back of the unit to make the unit more or less

sensitive in Sound-Active mode. Turning the knob counterclockwise decreases the

sensitivity; turning the knob clockwise increases the sensitivity.

Master/Slave Mode (Master Sound):

This mode will allow you to link up to 32 units together without a controller.

1) Use standard DMX cables to daisy chain your units toget her via the DMX connector

on the rear of the units. For longer cable runs we suggest a terminator at the last

fixture. For more information about terminators, see page 7.

2) Choose a unit to function as the Master. Turn dipswitches to the Master position on

the unit. The unit must be the first unit in line. Then simply chain the units together

using DMX cable.

DMX Mode

Mode Dipswitches

Master Sound 10 = Off

3) Turn switch to the Slave position on the slave units, and they will react the same as

the Master.

Mode Dipswitches

Slave 1 = On, 10 = On

This mode allows the unit to be controlled by any universal DMX controller. If you are

unfamiliar with DMX, please read the DMX Primer on page 16.

1) Set the dipswitches to DMX mode.

Mode Dipswitches

DMX 10 = On

2) Connect a DMX controller to the fixture.

3) Set the start address according to standard binary code.

a. Note: If you are unfamiliar with DMX addressing, we suggest you refer to the

section on DMX Primer.

Derby X™ User Manual 10 7/14/2008 1:27 PM

Page 11

DMX Channel Values

A

Channel Value Function

1

2

3

4

5

6

7

8

000 Ù 010

011 Ù 045

046 Ù 080

081 Ù 115

116 Ù 150

151 Ù 185

186 Ù 220

221 Ù 255

000 Ù 010

011 Ù 255

000 Ù 010

011 Ù 024

025 Ù 038

039 Ù 052

053 Ù 066

067 Ù 080

081 Ù 094

095 Ù 108

109 Ù 122

123 Ù 136

137 Ù 150

151 Ù 164

165 Ù 178

179 Ù 192

193 Ù 206

207 Ù 220

221 Ù 250

251 Ù 255

Cluster Control

No Function

Red

Green

Blue

Red/Green

Red/Blue

Green/Blue

Red/Green/Blue

Strobe

No Function

Strobe 0%~100%

uto Speed

No Function

Auto 1

Auto 2

Auto 3

Auto 4

Auto 5

Auto 6

Auto 7

Auto 8

Auto 9

Auto 10

Auto 11

Auto 12

Auto 13

Auto 14

Auto 15

Auto 16

Audio Trigger

Derby X™ User Manual 11 7/14/2008 1:27 PM

Page 12

SETTING THE STARTING ADDRESS

This DMX mode enables the use of a universal DMX controller devic e. Each fixture requires a "start

address" from 1 to 512. A fixture requiring one or more channels for control begins to read the data

on the channel indicated by the start address. For example, a fixture that uses 6 DMX channels

and was addressed to start on DMX channel 100, would read data from channels: 100, 101, 10 2,

103, 104, and 105. Choose start addresses so that the channels used do not overlap, and note the

start address selected for future reference.

If this is your first time addressing a fixture using the DMX-512 control protocol, we suggest

jumping to the Appendix Section and reading the heading “DMX Primer”. It contains very useful

information that will help you understand its use.

Set the start address using the group of DIP switches located usually on bottom of the fixture. Each

dip switch has an associated value. Adding the value of each switch in the ON position will provide

the start address. Figuring out which switches to toggle ON given a specific start address can be

accomplished by determining which switch values will add up to the address value and turning

these switches on. Do so by doing the following:

1) Determine the largest value switch that is less than the start address. Turn this switch on.

2) Subtract the value of the switch you just turned on from the starting address number.

3) Determine the largest value switch that is less than the remainder from the previous

subtraction. Turn this switch on.

4) Subtract the value of the switch you just turned on from the remainder of the previous

subtraction.

5) Repeat steps three and four until you have a remainder of zero.

Example Starting Address

Address 10

Switch # 4 = 8

Switch # 2 = 2

Total = 10

Address 24

Switch # 5 = 16

Switch # 4 = 8

Total = 24

Resolving address

using simple math.

Address 233

233 – (128) = 105, Turn ON Dip # 8

105 – (64) = 41, Turn ON Dip # 7

41 – (32) = 9, Turn ON Dip # 6

9 – (8) = 1, Turn ON Dip # 4

1 – (1) = 0, Turn ON Dip # 1

256

256

256

256

256

256

256

256

256

256

256

256

128

128

128

128

128

128

128

128

128

128

128

128

64

64

64

64

64

64

64

64

64

64

64

64

32

32

32

32

32

32

32

32

32

32

32

32

16

16

16

16

16

16

16

16

16

16

16

16

8

4

8

4

8

4

8

4

8

4

8

4

8

4

8

4

8

4

8

4

8

4

8

1

2

1

2

1

2

1

2

1

2

13456789

13456789

13456789

13456789

13456789

12222223456789

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

1

2

1

2

1

2

1

2

1

2

1

2

123456789

123456789

123456789

123456789

123456789

123456789

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

DIPSWITCH(DMXVALUE)

1

1

2

2

4

3

8

4

16

5

32

6

64

7

128

8

256

9

1

2

4

Derby X™ User Manual 12 7/14/2008 1:27 PM

Page 13

DMX QUICK REFERENCE CHART

DMX Address Quick Reference Chart

Dip Switch Position

DMX DIP

SWITCH SET

0=OFF #8 0 0 0 0 1 1 1 1 0 0 0 0 1 1 1 1

1=ON #7 0 0 1 1 0 0 1 1 0 0 1 1 0 0 1 1

X=OFF or ON #6 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1

#1 #2 #3 #4 #5

0 0 0 0 0 32 64 96 128 160 192 224 256 288 320 352 384 416 448 480

1 0 0 0 0 1 33 65 97 129 161 193 225 257 289 321 353 385 417 449 481

0 1 0 0 0 2 34 66 98 130 162 194 226 258 290 322 354 386 418 450 482

1 1 0 0 0 3 35 67 99 131 163 195 227 259 291 323 355 387 419 451 483

0 0 1 0 0 4 36 68 100 132 164 196 228 260 292 324 356 388 420 452 484

1 0 1 0 0 5 37 69 101 133 165 197 229 261 293 325 357 389 421 453 485

0 1 1 0 0 6 38 70 102 134 166 198 230 262 294 326 358 390 422 454 486

1 1 1 0 0 7 39 71 103 135 167 199 231 263 295 327 359 391 423 455 487

0 0 0 1 0 8 40 72 104 136 168 200 232 264 296 328 360 392 424 456 488

1 0 0 1 0 9 41 73 105 137 169 201 233 265 297 329 361 393 425 457 489

0 1 0 1 0 10 42 74 106 138 170 202 234 266 298 330 362 394 426 458 490

1 1 0 1 0 11 43 75 107 139 171 203 235 267 299 331 363 395 427 459 491

0 0 1 1 0 12 44 76 108 140 172 204 236 268 300 332 364 396 428 460 492

1 0 1 1 0 13 45 77 109 141 173 205 237 269 301 333 365 397 429 461 493

0 1 1 1 0 14 46 78 110 142 174 206 238 270 302 334 366 398 430 462 494

1 1 1 1 0 15 47 79 111 143 175 207 239 271 303 335 367 399 431 463 495

0 0 0 0 1 16 48 80 112 144 176 208 240 272 304 336 368 400 432 464 496

1 0 0 0 1 17 49 81 113 145 177 209 241 273 305 337 369 401 433 465 497

0 1 0 0 1 18 50 82 114 146 178 210 242 274 306 338 370 402 434 466 498

1 1 0 0 1 19 51 83 115 147 179 211 243 275 307 339 371 403 435 467 499

0 0 1 0 1 20 52 84 116 148 180 212 244 276 308 340 372 404 436 468 500

1 0 1 0 1 21 53 85 117 149 181 213 245 277 309 341 373 405 437 469 501

0 1 1 0 1

1 1 1 0 1 23 55 87 119 151 183 215 247 279 311 343 375 407 439 471 503

0 0 0 1 1 24 56 88 120 152 184 216 248 280 312 344 376 408 440 472 504

1 0 0 1 1 25 57 89 121 153 185 217 249 281 313 345 377 409 441 473 505

0 1 0 1 1 26 58 90 122 154 186 218 250 282 314 346 378 410 442 474 506

1 1 0 1 1 27 59 91 123 155 187 219 251 283 315 347 379 411 443 475 507

0 0 1 1 1 28 60 92 124 156 188 220 252 284 316 348 380 412 444 476 508

1 0 1 1 1 29 61 93 125 157 189 221 253 285 317 349 381 413 445 477 509

0 1 1 1 1 30 62 94 126 158 190 222 254 286 318 350 382 414 446 478 510

1 1 1 1 1 31 63 95 127 159 191 223 255 287 319 351 383 415 447 479 511

Dip Switch Position DMX Address

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

#9

22 54 86 118 150 182 214 246 278 310 342 374 406 438 470 502

Derby X™ User Manual 13 7/14/2008 1:27 PM

Page 14

Blow-out Diagram

3

8

1

2

6

7

Description PartNumber

1 MasterPCB P172‐DERBYX

2 ElectronicTransformer P140‐DERBYX

3 Casecover P111‐DERBYX

4 LEDPCB P222‐DERBYX

5 FrontLens P150‐DERBYX

4

5

6 Bracketknob P111‐DERBYX

7 Poweroutput P176‐PWERIN

8 Powerinput P176‐PWROUT

Derby X™ User Manual 14 7/14/2008 1:27 PM

Page 15

General Troubleshooting

Symptom(s) Possible Solution(s)

1 or more LED’s are not

illuminating

An LED may have failed, resulting in an open circuit. In this event, all of

An LED may have failed, resulting in a short circuit. In this event, only

1 or more LED’s are producing

very low output

Breaker/Fuse keeps blowing Che c k total load placed on the electrical circuit

Check for a short in the electrical wiring: internal and/or external

Device has no power Check device’s fuse (internal)

Check for power on Mains

Fixture is not responding to

DMX

Check DMX cables

Check polarity switch settings on the controller

Check cable connections

Call service technician

See page #10 for proper settings to operate in DMX mode

Loss of signal Use only DMX cables

Install terminator

Note: Keep DMX cables separated from power cables or black lights

Clean the fixture regularly to avoid any such failure. This fixture is

convection cooled, which means that if the surface is kept clean and free

of debris, then proper cooling will be allowed to occur

the red, green, or blue in a single module will no longer illuminate. This

does not mean that all of the LEDs have failed, but the circuit is wired in

series.

the single LED which has failed will no longer function. This does not

mean that all of the LEDs have failed, but the circuit is wired in series.

-Note: In the event of LED failure, a replacement LED PCB assembly

may be purchased directly from CHAUVET Part#: P222-DERBYX

Check that the lens assembly is installed properly. If the lens assembly

is not aligned properly over the LEDs, then they will not project fully

-See section on Lens Assembly Installation

-Note: In the event of LED failure, a replacement LED PCB assembly

may be purchased directly from CHAUVET Part#: P222-DERBYX

-Note: In the event of autoswitching transformer failure, the unit can be

sent in for repair; however, a replacement part can be ordered directly

from CHAUVET Part#: P140-DERBYX

Check Control Panel settings for correct addressing

-Note: In the event of Master PCB failure, a replacement PCB can be

ordered directly from CHAUVET Part#: P172-DERBYX

Stand alone operation problem See page #8 & #10 for details on proper settings and connections

If you still have a problem after trying the above solutions, please contact

CHAUVET Technical Support at the location on the next page.

Derby X™ User Manual 15 7/14/2008 1:27 PM

Page 16

Technical Support

Address: Service Dept.

3000 N 29th Ct, Hollywood, FL 33020 (U.S.A.)

Support (Email): tech@chauvetlighting.com

Telephone: (954) 929-1115 - (Press 4)

Fax: (954) 929-5560 - (Attention: Service)

Website: http://www.chauvetlighting.com

5. APPENDIX

DMX Primer

There are 512 channels in a DMX-512 connection. Channe ls may be assigned in any

manner. A fixture capable of receiving DMX 512 will require one or a number of sequential

channels. The user must assign a starting address on the fixture that indicates the first

channel reserved in the controller. There are many different types of DMX controllable

fixtures and they all may vary in the total number of channels required. Choosing a start

address should be planned in advance. Channels should never overlap. If they do, this will

result in erratic operation of the fixtures whose starting address is set incorrectly. You can

however, control multiple fixtures of the same type using the same starting address as

long as the intended result is that of unison movement or operation. In other words, the

fixtures will be slaved together and all respond exactly the same.

DMX fixtures are designed to receive data through a serial Daisy Chain. A Daisy Chain

connection is where the DATA OUT of one fixture connects to the DATA IN of the next

fixture. The order in which the fixtures are connected is not important and has no effect on

how a controller communicates to each fixture. Use an order that provides for the easiest

and most direct cabling. Connect fixtures using shielded two conductor twisted pair cable

with three pin XLR male to female connectors. The shield connection is pin 1, while pin 2

is Data Negative (S-) and pin 3 is Data positive (S+). CHAUVET carries 3-pin XLR DMX

compliant cables, DMX-10 (33’), DMX-4.5 (15’) and DMX-1.5 (5’)

Derby X™ User Manual 16 7/14/2008 1:27 PM

Page 17

General Maintenance

To maintain optimum performance and minimize wear fixtures should be cleaned

frequently. Usage and environment are contributing factors in determining frequency. As

a general rule, fixtures should be cleaned at least twice a month. Dust build up reduces

light output performance and can cause overheating. This can lead to redu c ed lamp life

and increased mechanical wear. Be sure to power off fixture before conducting

maintenance.

Unplug fixture from power. Use a vacuum or air compressor and a soft brush to remove

dust collected on external vents and internal components. Clean all glass when the fixture

is cold with a mild solution of glass cleaner or Isopropyl Alcohol and a soft lint free cotton

cloth or lens tissue. Apply solution to the cloth or tissue and drag dirt and grime to the

outside of the lens. Gently polish optical surfaces until they are free of haze and lint.

The cleaning of internal and external optical lenses and/or mirrors must be carried out

periodically to optimize light output. Cleaning frequency depends on the environment in

which the fixture operates: damp, smoky or particularly dirty surrounding can cause

greater accumulation of dirt on the unit’s optics. Clean with soft cloth using normal glass

cleaning fluid. - Always dry the parts carefully. - Clean the external optics at least every 20

days. Clean the internal optics at least every 30/60 days.

Returns Procedure

Returned merchandise must be sent prepaid and in the original packing, call tags will not

be issued. Package must be clearly labeled with a Return Merchandise Authorization

Number (RMA #). Products returned without an RMA # will be refused. Call CHAUVET

and request RMA # prior to shipping the fixture. Be prepared to provide the model

number, serial number and a brief description of the cause for the return. Be sure to

properly pack fixture, any shipping damage resulting from inadequate packaging is the

customer’s responsibility. CHAUVET reserves the right to use its own discretion to repair

or replace product(s). As a suggestion, proper UPS packing or double-boxing is always a

safe method to use.

Note: If you are given an RMA #, please include the following information on a

piece of paper inside the box:

1) Your name

2) Your address

3) Your phone number

4) The RMA #

5) A brief description of the symptoms

Claims

Damage incurred in shipping is the responsibility of the shipper; therefore the damage

must be reported to the carrier upon receipt of merchandise. It is the customer's

responsibility to notify and submit claims with the shipper in the event that a fixture is

damaged due to shipping. Any other claim for items such as missing component/part,

damage not related to shipping, and concealed damage, must be made within seven (7)

days of receiving merchandise.

Derby X™ User Manual 17 7/14/2008 1:27 PM

Page 18

Notes

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

Derby X™ User Manual 18 7/14/2008 1:27 PM

Page 19

Technical Specifications

WEIGHT & DIMENSIONS

Length..................................................................................................... 11.9 in (302 mm)

Width ......................................................................................................... 15 in (382 mm)

Height ....................................................................................................... 7.4 in (187 mm)

Weight ........................................................................................................... 4 lbs (1.8 kg)

POWER

Autoswitching power supply .......................................................... 100-240V AC 50.60Hz

Fuse ...................................................................................................................... 2A 250V

Power Consumption ................................................................... 24W (0.2A) max at 120V

Inrush Power .............................................................................................. (0.2A) at 120V

Power Output ................................................................................... 27 units max at 120V

LIGHT SOURCE

LED .............................................................. 90 (30 Red, 30 Green, 30 Blue) 100,000 hrs

PHOTO OPTIC

Coverage Angle ............................................................................................................ 96°

THERMAL

Maximum ambient temperature ................................................................... 104°F (40°C)

CONTROL & PROGRAMMING

Data input .......................................................................... locking 3-pin XLR male socket

Data output ..................................................................... locking 3-pin XLR female socket

Data pin configuration ....................................................... pin 1 shield, pin 2 (-), pin 3 (+)

Protocols ................................................................................................. DMX-512 USITT

DMX Channels ................................................................................................................. 8

ORDERING INFORMATION

Derby X™ ............................................................................................................ DERBYX

Optional bracket ............................................................................................. XBRACKET

WARRANTY INFORMATION

Warranty ........................................................................................ 2-year limited warranty

Derby X™ User Manual 19 7/14/2008 1:27 PM

Page 20

3000 N 29 Ct, Hollywood, FL 33020 U.S.A.

th

(800) 762-1084 – (954) 929-1115

FAX (954) 929-5560

www.chauvetlighting.com

Derby X™ User Manual 20 7/14/2008 1:27 PM

Loading...

Loading...