Page 1

Operating Manual

Chattanooga Intelect F-SW

29097.0002

TT.####

Part No. 26933.0012

Published: October 2018

Original language: German

Publisher:

STORZ MEDICAL AG

Lohstampfestr. 8

CH-8274 Tägerwilen

Switzerland

Focus Shockwave

Operating Manual

Page 2

Table of Contents

1 General Safety Information 7

1.1 Instructions for safe use 7

1.1.1 Intended use and operational safety . . . . . . . . . . . . . 7

1.1.2 Safety during treatment of the patient. . . . . . . . . . . . . 9

1.2 Warning against damage to equipment and the device 9

1.3 Manufacturer‘s responsibility 11

1.4 Owner‘s responsibility 11

2 Principles 12

2.1 Physical principles 12

2.1.1 Indications . . . . . . . . . . . . . . . . . . . . . 12

2.1.2 Contraindications . . . . . . . . . . . . . . . . . . . 14

2.1.3 Side effects . . . . . . . . . . . . . . . . . . . . . 14

2.2 Preconditions for operation 15

2.2.1 Operating personnel . . . . . . . . . . . . . . . . . . 15

2.2.2 Training of the operator . . . . . . . . . . . . . . . . . 15

2

3 System Description 16

3.1 Control and functional elements 16

3.2 F-SW handpiece and optional C-ACTOR handpiece 17

3.3 Use of stand-off devices 18

4 Installation Instruction 20

4.1 Scope of supply 20

4.2 Unpacking 20

4.3 Correct positioning of the device 20

4.4 Handpiece holder installation 21

4.4.1 Installing the F-SW holding arm (optionally) . . . . . . . . . . . 21

4.4.2 Connecting power supply cables . . . . . . . . . . . . . . 22

4.4.3 Handpiece connection . . . . . . . . . . . . . . . . . 22

4.4.4 Connecting the optional foot switch . . . . . . . . . . . . . 23

4.4.5 Potential equalisation (optional). . . . . . . . . . . . . . . 23

4.4.6 USB connection . . . . . . . . . . . . . . . . . . . 23

4.5 Transport 24

4.6 Compatibility 24

Table of Contents

13 610 02 1018

Page 3

5 Operation 25

5.1 User interface 25

5.2 Overview of menu functions 29

5.3 Starting the instrument 32

5.4 Setting the treatment parameters 34

5.5 F-SW Energy display task 36

5.6 Storing the treatment parameters 37

5.7 Loading treatment parameters 39

5.7.1 Pre-programmed indications from the manufacturer . . . . . . . . 39

5.7.2 In-house applications . . . . . . . . . . . . . . . . . . 41

5.8 Patient record 42

5.9 Visual analogue scale (VAS) 44

5.10 Data transfer 45

5.11 Software updates 48

5.11.1 Loading the software onto the USB stick . . . . . . . . . . . . 48

5.11.1.1 Extracting the software using Windows . . . . . . . . . . . . 48

5.11.2 Extracting the software with WinZip . . . . . . . . . . . . . 49

5.11.3 Updating the software on the instrument . . . . . . . . . . . . 50

5.12 Resetting the treatment shock counter 50

5.13 “Autofrequency” function 51

5.14 Start-up 52

5.15 Functional checks 54

5.16 Standard settings 54

5.17 Treatment 55

5.18 Switching off the device 55

6 Cleaning, Maintenance and Overhaul 56

6.1 Cleaning the device 56

6.2 Cleaning the handpiece 57

6.2.1 Changing the stand-off device . . . . . . . . . . . . . . . 57

6.2.2 Reprocessing of the handpiece and the stand-off devices . . . . . . . 58

6.2.2.1 Cleaning. . . . . . . . . . . . . . . . . . . . . . 58

6.2.2.2 Disinfection . . . . . . . . . . . . . . . . . . . . . 58

6.3 Cleaning the optional foot switch 59

3

6.4 Water renewal 60

6.4.1 Draining the water circuit . . . . . . . . . . . . . . . . 60

13 610 02 1018

Table of Contents

Page 4

6.4.2 Filling the water circuit . . . . . . . . . . . . . . . . . 62

6.4.3 Bleeding the water circuit . . . . . . . . . . . . . . . . 64

6.4.4 Resetting the water renewal time . . . . . . . . . . . . . . 64

6.5 Fuse replacement 65

6.6 Maintenance and safety checks 65

6.7 Disposal 66

6.8 Repair 66

6.9 Service life 66

7 Status messages and trouble-shooting 67

7.1 Status messages 67

7.2 Trouble-shooting 69

8 Accessories 70

9 TechnicalSpecications 71

9.1 TechnicalSpecications 71

9.2 Type plate Chattanooga Intelect F-SW 75

9.3 Conformity with directives 75

4

9.4 Conformity with standards 75

9.5 Certicates 80

9.6 Symbols and labels 81

10 Warranty and Service 84

10.1 Warranty for the control device 84

10.2 Warranty for the F-SW handpiece and the C-ACTOR Handpiece 85

10.3 Service 85

Table of Contents

13 610 02 1018

Page 5

Preface

Warning notes

This manual contains warnings, safety instructions and specic operating instructions

in accordance with liability regulations.

DANGER refers to a situation of acute danger which, if not avoided, could lead to

serious or fatal injury.

DANGER!

The source of the danger is stated here.

These are the possible consequences!

• The instructions for avoiding the danger are given here.

WARNING refers to a situation of potential danger which, if not avoided, could lead

to serious injury.

WARNING!

The source of the danger is stated here.

These are the possible consequences!

• The instructions for avoiding the danger are given here.

CAUTION indicates that incorrect operation could lead to minor injuries.

CAUTION!

The source of the danger is stated here.

These are the possible consequences!

• The instructions for avoiding the danger are given here.

ATTENTION indicates that incorrect operation could lead to damage to the device.

ATTENTION!

The source of the danger is stated here.

These are the possible consequences!

• The instructions for avoiding the danger are given here.

5

13 610 02 1018

Other instructions

NOTE

Additional information concerning specic features or operating instructions is

preceded by the term 'NOTE'.

Preface

Page 6

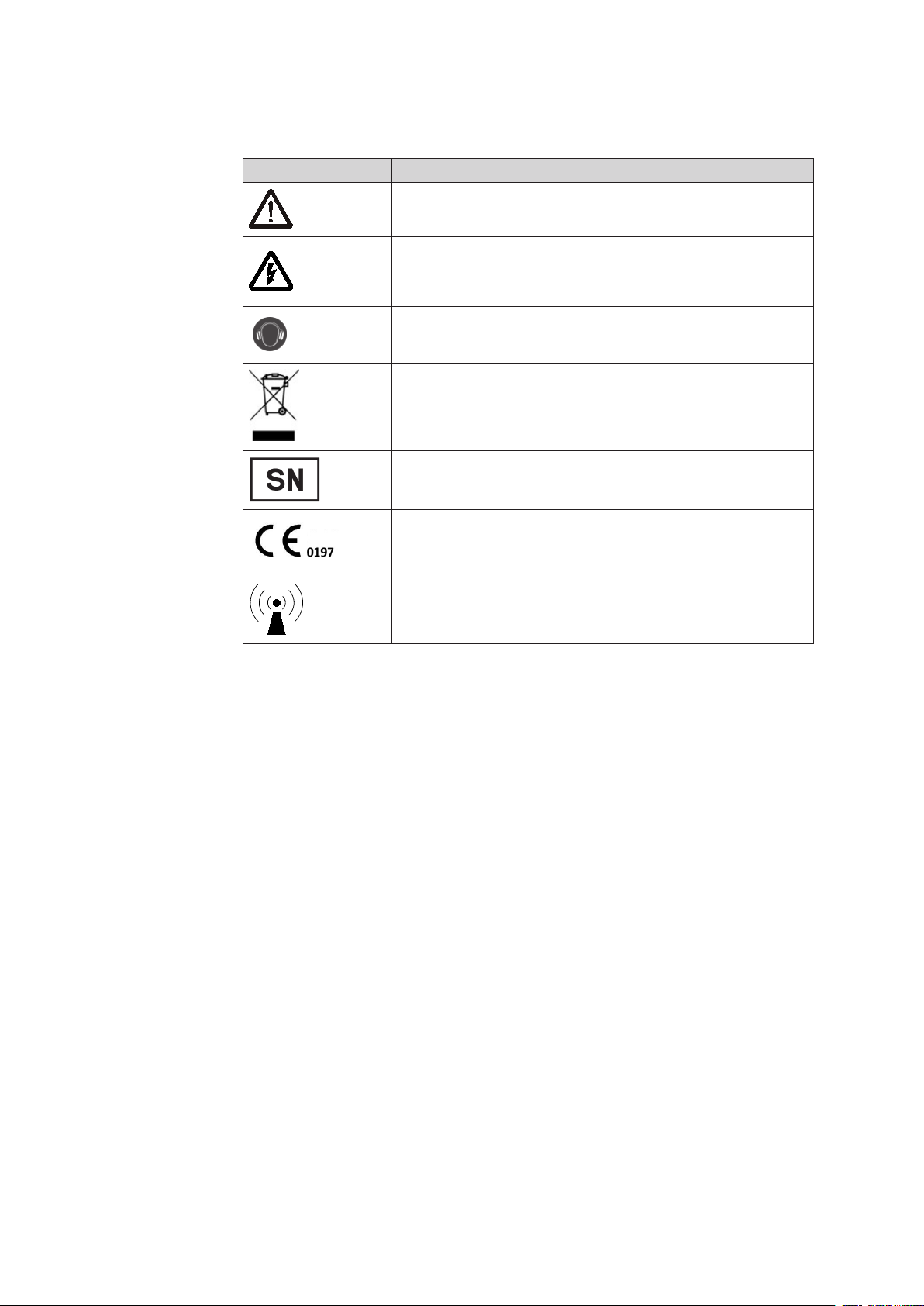

Safety signs and other symbols used in this manual

Symbol Name

General warning sign

Electrical warning sign

Table 1-1

Wear hearing protection!

WEEE (waste electrical and electronic equipment)

Device serial number

CE mark

Electromagnetic interference may occur in the vicinity of

instruments marked with this symbol.

6

Preface

13 610 02 1018

Page 7

1 General Safety Information

1.1 Instructions for safe use

The following chapter contains all safety information that has to be followed when

working with the Chattanooga Intelect F-SW.

WARNING!

Incorrect handling of the device.

Possibility of injuries to the patient and the operating personnel!

• Read this chapter carefully before you start using the Chattanooga

Intelect F-SW.

• Read the separate operating manuals for all devices associated

with the Chattanooga Intelect F-SW.

1.1.1 Intended use and operational safety

To use this device in accordance with its intended use, the user must possess the

necessary technical prociency, and knowledge of the operating manual.

The Chattanooga Intelect F-SW is intended exclusively for use by healthcare

professionals who have been trained to use the device (see also chapter 2.2

precOnditiOns fOr OperatiOn).

The device is only allowed to be used for the applications described in chapter 2.1.1

indicatiOns.

Only perform treatments approved by the manufacturer!

Furthermore, the device is only allowed to be operated by trained personnel who

comply with the precOnditiOns fOr OperatiOn in chapter 2.2.

All status and error messages signaled during treatment must always be attended to

without delay.

While applying focused shockwaves at maximum adjustment, do not use more than

6.000 subsequent shocks and stick to a consecutive break of 5 minutes.

Checks and inspections prior to treatment

Before using the device, the user must make sure it is functioning safely and that it is

in proper condition.

• It is essential to perform the functional checks after switching on the Chattanooga

Intelect F-SW before starting treatment. Read about this in chapter 5.15 functiO-

nal checks.

7

13 610 02 1018

• Have the maintenance procedures recommended by the manufacturer carried out by

authorised personnel (see also chapter 6.6 Maintenance and safety checks).

No treatment ist permitted if a display on the control device or a touch screen fails.

General Safety Information

Page 8

Protection against electrical hazard

Sources of voltage can give rise to currents as a result of body resistance which not

only ow through the patient but can also impair or even endanger the physician and

the nursing staff.

• Therefore, always connect the potential equalisation connector of the Chattanooga Intelect F-SW in accordance with national guidelines.

• Devices which are not medical products in accordance with EN 60601 must be set

up outside the vicinity of the patient.

• Do not touch electrical connectors while you are touching the patient.

• Disconnect the connected handpieces from the device before carrying out cleaning

and maintenance work. Do not reconnect them until they have been completely

reassembled!

• Do not try to open the instrument! Risk of electric shocks!

Protection against high voltage

Very high voltages are generated when operating the device.

High-voltage components are identied as follows:

8

Protection against noise

The noise level during administration of shock waves is within the safe area.

Nevertheless, we recommend wearing suitable ear protection during treatment in

order to minimise exposure to noise.

Protection against explosion

Do not use the Chattanooga Intelect F-SW in potentially explosive environments, i.e.

in the presence of a ammable anaesthetic mixture with air or with oxygen or nitrous

oxide.

The optional foot switch must not be used in potentially explosive atmospheres accor-

ding to classication AP as per IEC 60601.

DANGER!

Contact with high-voltage parts

Severe or fatal injury!

• Only operate the device if the housing is intact and closed.

• Work in the area of high voltage is only allowed to be performed

by personnel suitably authorised by the manufacturer.

General Safety Information

13 610 02 1018

Page 9

1.1.2 Safety during treatment of the patient

General note:

Organs with gas inclusions, in particular parts of the lung, are NOT allowed to be

exposed to shock waves.

As it passes through tissue, the shock wave’s energy is slightly reduced; this reduction

is signicantly weakened by the bone structure.

Shock waves can give rise to undesirable heart reactions. The patient must be

continuously observed during the treatment.

• While applying focused shockwaves at maximum adjustment, do not use more

than 6.000 subsequent shocks and stick to a consecutive break of 5 minutes.

• Only perform treatments approved by the manufacturer!

The user is responsible for correctly positioning the handpieces and correctly selecting

the treatment zone.

Air bubbles reduce the effectiveness of shock waves. Therefore, air bubbles must

always be removed from the shock wave path.

1.2 Warning against damage to equipment and the device

Any damage to the device resulting from incorrect operation is not covered by the

manufacturer’s warranty.

Electromagnetic compatibility

This device complies with the requirements of the applicable standard on

electromagnetic compatibility.

Nevertheless, portable and mobile HF communications equipment (e.g. mobile

phones) can interfere with medical electrical equipment.

This device is subjected to special precautions regarding EMC and needs to be

installed according the EMC guidelines in chapter 9.4 cOnfOrMity with standards.

The use of accessories or cables that are not authorised by the manufacturer can

result in increased interference emissions or reduced resistance to interference

emissions by the device.

The Chattanooga Intelect F-SW is not allowed to be positioned immediately next

to or jointly with other devices. If the operation near or jointly with other devices is

required, the Chattanooga Intelect F-SW must be tested in that particular environment

to ensure operation according to technical specication.

9

13 610 02 1018

If the Chattanooga Intelect F-SW is connected to a 240 V mains supply with a mains

frequency of 60 Hz, the mains supply must be balanced

The system must only be connected to properly earthed and correctly installed

shockproof sockets!

General Safety Information

Page 10

Set-up and operation

• Check that the installation surfaces have sufcient carrying capacity to avoid

equipment damage!

There are ventilation slits on the left side of the device which must not be covered by

other objects.

• Check that the system is in perfect working order before each use. Read about this in

chapter 5.15 functiOnal checks.

• Never cover the device when in use!

• Make absolutely sure that no liquid can seep into the system housing or

handpiece.

Storage and transport

Incorrect storage and transport can result in damage to the device and device failure.

• Make sure that no cables are crushed or sheared.

Disposal

• Comply with national disposal regulations when disposing of the Chattanooga

Intelect F-SW or individual components.

• Comply with the relevant information in the operating manuals for the additional

devices.

10

General Safety Information

13 610 02 1018

Page 11

1.3 Manufacturer‘s responsibility

WARNING!

No modications are to be made to this device without the permission

of the manufacturer.

STORZ MEDICAL AG as the manufacturer of the Chattanooga Intelect F-SW is only

responsible for effects on the safety, reliability and performance of its product if:

– Maintenance of the device is performed at the intervals specied by the manu-

facturer

– Installation, expansions, conversions, new installations, modications or repairs

are performed by people authorised by the manufacturer

– The electrical installation in the rooms in question corresponds to the require-

ments of DIN/IEC

– The device is used in compliance with the operating manual

The periodic maintenance measures specied by the manufacturer must be performed

on schedule by authorised personnel.

The manufacturer‘s liability shall be rendered null and void if non-genuine parts are

used.

1.4 Owner‘s responsibility

The owner is responsible for complying with the relevant national statutory provisions

governing setting up and operating technical medical equipment. (For Germany, the

Medical Products Act.)

It is expressly stated that the use of unauthorised accessories and/or unauthorised

equipment combinations shall render the product liability null and void.

The device is exclusively allowed to be used with accessories, wearing parts and disposable articles that have been checked by the testing body responsible for testing the

device to ensure that they function without risk.

11

13 610 02 1018

General Safety Information

Page 12

12

2 Principles

2.1 Physical principles

The Chattanooga Intelect F-SW is a universal, compact shock wave unit that can be

used for treatment involving medium- to high-energy electromagnetically generated

shock waves - focused shock waves – referred to below as F-SW.

F-SW waves have a short pulse length and are concentrated on areas a few

millimetres in diameter, allowing pulse waves to be applied to a tightly localised area,

even in deeper tissue layers.

2.1.1 Indications

The Chattanooga Intelect F-SW is designed in order to treat the indications specied

below:

Orthopaedics / Pain Therapy

– Plantar fasciitis / heel spur / heel pain / calcaneal spur

– Trigger Point Therapy

– Treatment of deep muscle trigger points

– Treatment of supercial muscle trigger points

– Myofascial pain syndrome / Myofascial trigger points* / Acupuncture points

– e.g. chronic back pain (cervical and lumbar parts of vertebral column), trape-

zius, pelvic oor muscle trigger points

– Tendinopathy / Tendinitis / Tendonitis / Tendinosis / Tendon Pain

– Insertion tendonitis in general

– Supercial insertion tendonitis (paratendinary area)

– Shoulder pain with or without calcications / tendinopathy of the shoulder,

the supraspinatus, or / and the rotator cuff (with or without calcications)

– (Radial/ulnar humeral) epicondylitis / tennis elbow / golfer’s elbow / elbow

tendinopathy

– Greater trochanteric pain syndrome (GTPS) / Trochanteric tendonitis / Tro-

chanteric bursitis

– Hamstring tendinopathy

– Patellar tip syndrome/ proximal iliotibial band (friction) syndrome / Patellar

tendonitis / Jumper’s knee

– Tibial edge syndrome / tibial stress syndrome / tibial tendonitis

– Achillodynia / Achilles tendinitis

Principles

– Pseudarthrosis / non-unions / delayed unions

13 610 02 1018

Page 13

Dermatology

– Wound healing

– Ulceration

– Arterial ulcers

– Venous ulcers

– Diabetic foot ulcers

– Pressure sore / Decubital ulcer

– Burns

– Acute and chronic lesions

– Traumatic and post-traumatic skin lesions

– Wounds with disturbed healing

– Postsurgical wounds

– Cellulitis / lipo- / lymphedema

Urology

– CPPS / prostatitis

– IPP / Peyronie’s disease

– Vascular / vasculogenic / organic erectile dysfunction

Neurology

– Spastic muscle paralyses (caused by infantile cerebral palsy or stroke for exam-

ple)

* A sound knowledge of trigger point therapy and trigger point shock wave therapy (TrST) is required for

therapeutic application of the Chattanooga Intelect F-SW in the eld of trigger point shock wave therapy.

13

13 610 02 1018

Principles

Page 14

2.1.2 Contraindications

CAUTION !

The contraindications listed here are examples. No claims are made

regarding the completeness or unlimited validity of this list of contraindications.

No patient treatment is allowed under the following circumstances:

– Air-lled tissue (in particular lung tissue) in the treatment area

– Brain or spine in the treatment area

– Untreated coagulopathies (hemophilia)

– Malignant tumor in the treatment area

– Epiphyseal plate areas in children

– Pregnancy

– Use of anticoagulants, especially Marcumar

– Thrombosis in the treatment area

– Cortisone therapy up to 6 weeks before rst treatment

14

CAUTION!

Shock waves must not be applied to target areas located above air

lled tissue (lungs), nor to any regions near large nerves, vessels,

the spinal column or head (apart from the face).

2.1.3 Side effects

– Swelling, reddening, hematoma

– Petechiae

– Pain

These side effects normally disappear after 5-10 days.

Principles

13 610 02 1018

Page 15

2.2 Preconditions for operation

2.2.1 Operating personnel

The Chattanooga Intelect F-SW is intended exclusively for use by healthcare

professionals who have been trained to use the device.

Such a specialist is expected to have practical knowledge of medical procedures and

applications as well as of the terminology, and should be experienced in treating the

indications stated in chapter 2.1.1 indicatiOns.

Users must have basic physical and cognitive abilities such as vision, hearing and

literacy, and have basic functional use of their upper extremities.

The device is designed for a demographic target group between 18 and 65 years.

2.2.2 Training of the operator

Operators of the Chattanooga Intelect F-SW must have been adequately trained in

using this system safely and efciently before they operate the device described in

this handbook. An introduction to the principles of operation will be provided by your

dealer with reference to this operating manual and will be documented in the system

logbook.

The operator must be instructed in the following points:

– Instruction in the operation and intended use of the device with practical exer-

cises

– Mechanism of action and function of the device and the energies delivered by

it

– All component settings

– Indications for use of the device

– Contraindications and side effects of the therapy waves

– Explanation of the warnings in all operating modes

– Instruction in how to perform the functional checks

Further training requirements vary from country to country. It is the operator’s responsibility to ensure that the training meets the requirements of all applicable local laws

and regulations. Further information about training in the operation of this system can

be obtained from your dealer. However, you can also contact the following address

directly:

DJO France

3 Rue de Bethar

Centre Européen de Frêt

64990 Mouguerre

France

T: +33 (0)5 57 52 86 90

F: +33 (0)5 57 52 86 91

E: sce.cial@DJOglobal.com

15

13 610 02 1018

Principles

Page 16

3 System Description

3.1 Control and functional elements

16

1

1 Monitor

2 Power indicator

Fig. 3-1 Front view of Chattanooga Intelect F-SW

2

3

3 Connection for foot switch

4 F-SW handpiece connection

1 2 3 4 5

4

Fig. 3-2 Rear view of Chattanooga Intelect F-SW

System Description

9

1 Potential equalisation connection

2 not used

3 Mains connection

4 Mains fuse holder

5 Mains switch

6 USB connection for USB stick, USB

mouse, USB keyboard

78

7 Water supply connection

8 not used

9 Type plate

6

13 610 02 1018

Page 17

NOTE

The following instruments can be connected to the USB connection:

– USB memory stick which supports the USB V1.1 protocol

– USB mouse

– USB keyboard

The connected instruments must be approved as medical products in accordance

with EN IEC 60601.

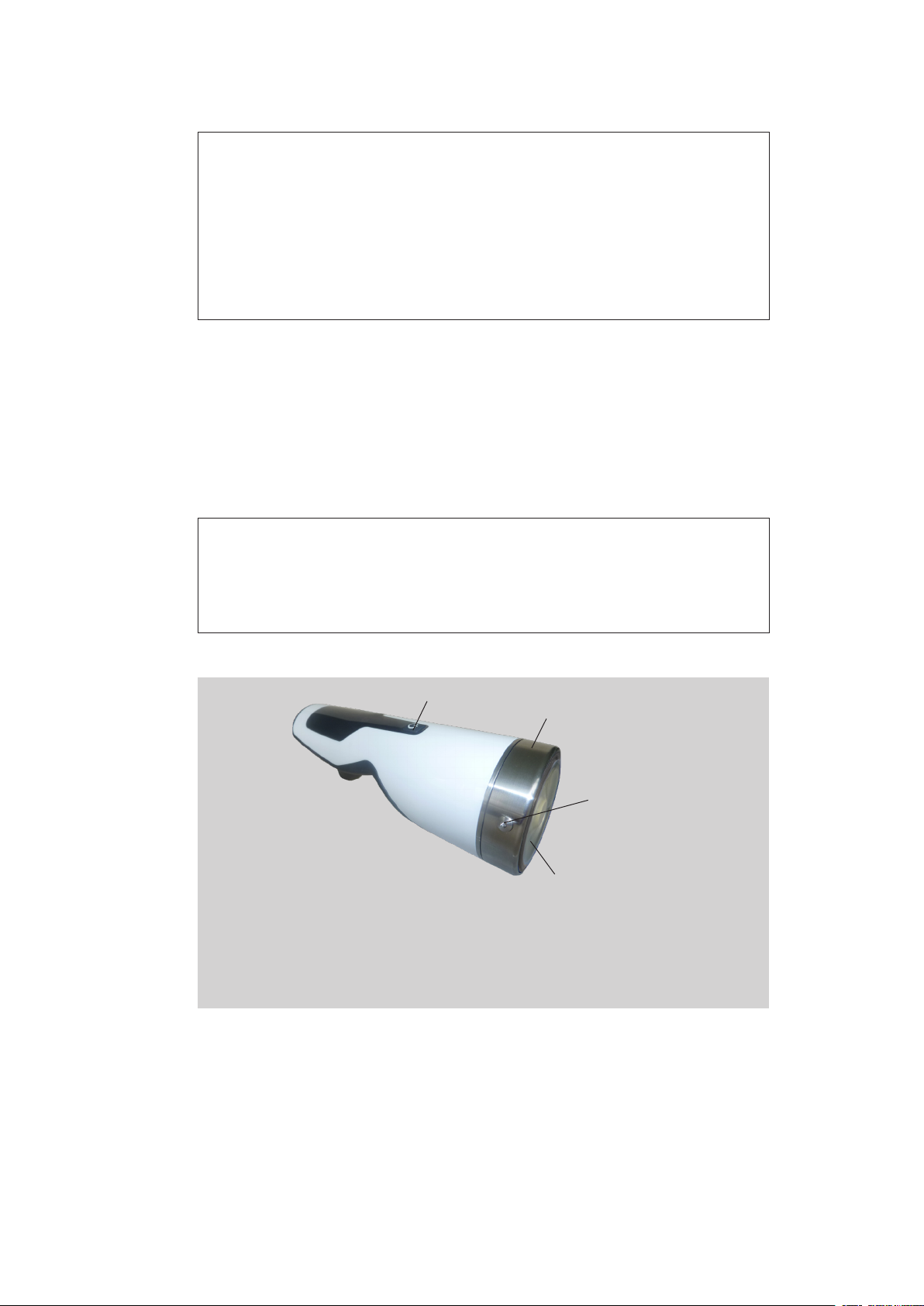

3.2 F-SW handpiece and optional C-ACTOR handpiece

Focused shock waves with a short wavelength that are concentrated on a focal zone

outside the handpiece are administered over the F-SW handpiece or the C-ACTOR

handpiece into the body at the treatment zone that has been established by diagnosis.

NOTE

Optical difference between F-SW handpiece and C-ACTOR handpiece:

The F-SW handpiece has a blue ring around the coupling diaphragm and the

C-ACTOR handpiece has a red ring around the coupling diaphragm.

1

2

3

4

1 Trigger button

2 Clamping ring

3 Fixing screws

4 Coupling diaphragm

Fig. 3-3 F-SW handpiece or C-ACTOR handpiece

The coupling diaphragm is xed by a clamping ring and 3 xing screws. It can only be

opened from authorised personnel with special tools.

The penetration depth of the shock wave can be varied by stand-off devices.

17

13 610 02 1018

System Description

Page 18

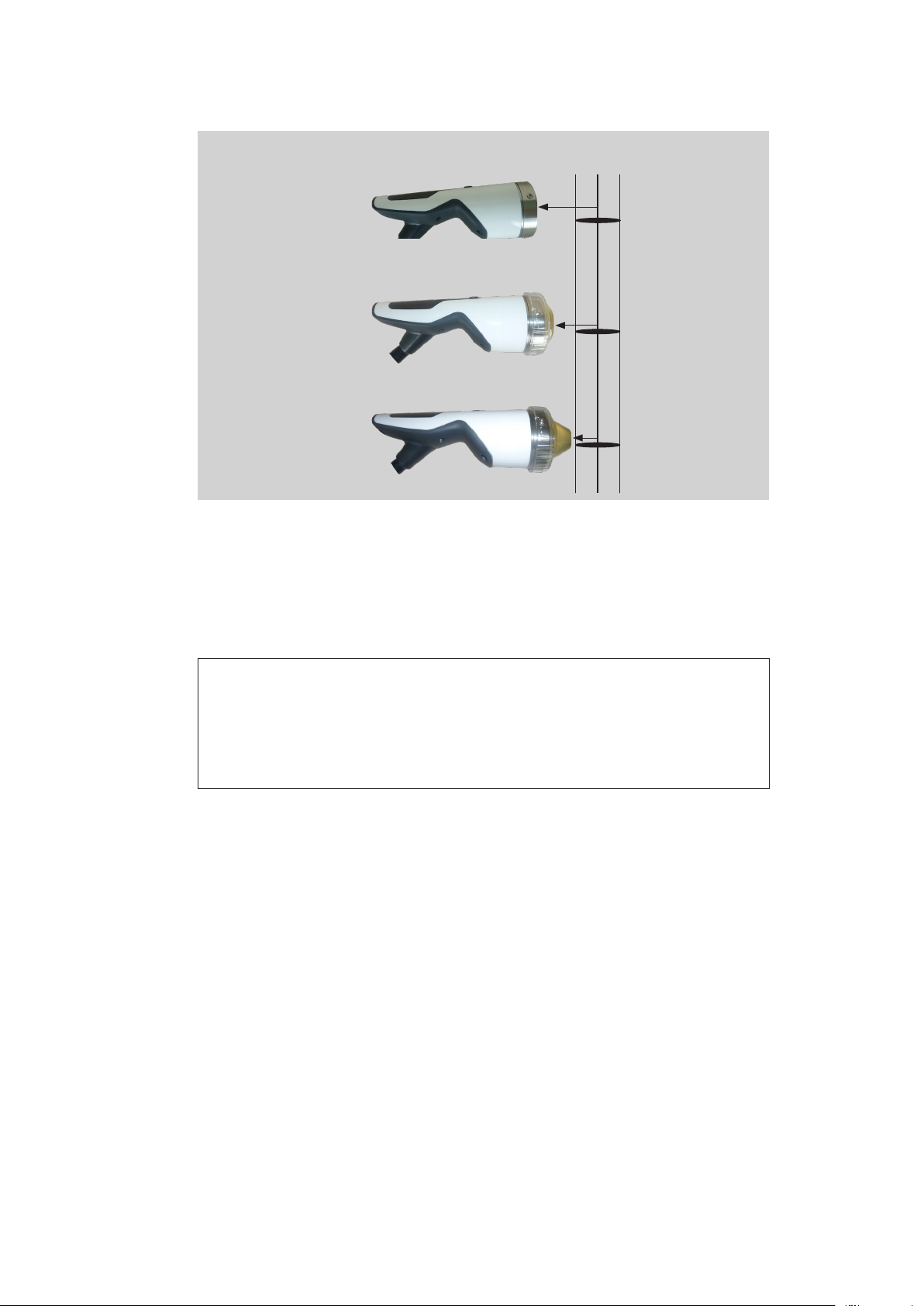

3.3 Use of stand-off devices

The penetration depth of the shock wave can be adjuted by using different stand-off

devices.

without stand-off device

with stand-off device I with stand-off device II

Fig. 3-4 F-SW handpiece or C-ACTOR handpiece

18

Therapeutically effective

penetration depth 5 MPa

50 mm

0 - 125 mm

0 - 105 mm

30 mm

15 mm

0 - 90 mm

Fig. 3-5 Depth of therapeutical effect of F-SW handpiece

Depth of

focal zone

35 - 65 mm

15 - 45 mm

0 - 30 mm

System Description

13 610 02 1018

Page 19

Therapeutically effective

penetration depth 5 MPa

0 - 65 mm

Depth of

focal zone

30 mm

20 - 40 mm

0 - 50 mm

15 mm

5 - 25 mm

0 mm

0 - 35 mm

0 - 10 mm

Fig. 3-6 Depth of therapeutical effect of C-ACTOR handpiece

• Perform changing of the stand-off devices as described in chapter 6.2.1 changing

the stand-Off device.

NOTE

The stand-off has a limited service life. It should be replaced if there are visible

changes in the material (discolouration, tarnishing, streaks, gas bubbles), deformation of the surface in the coupling area or leaks.

The stand-off should be replaced at least every 12 months.

19

13 610 02 1018

System Description

Page 20

4 Installation Instruction

4.1 Scope of supply

The standard scope of supply of the Chattanooga Intelect F-SW:

– Chattanooga Intelect F-SW

– F-SW SEPIA LT handpiece

– Handpiece holder

– Mains cables

– Gel bottle

– Silicone oil bottle

– Water bag

– User manual

4.2 Unpacking

20

• Carefully remove the instrument and accessories from the packaging container.

• Check that all items are included in the packaging container and that they are not

damaged.

• Contact your supplier or the manufacturer immediately if any items are missing or

damaged.

• Retain the original packaging. It may prove useful for any later equipment transport.

4.3 Correct positioning of the device

Make sure that the device is positioned at a distance from the wall so that the mains

plug can be pulled without restriction.

Installation Instruction

13 610 02 1018

Page 21

4.4 Handpiece holder installation

The handpiece holder can be mounted on the right as well as on the left side.

• Use a 2.5 mm Allen key for installation.

• Screw the handpiece holder onto the right side wall of the Chattanooga Intelect

F-SW, as shown in the picture below.

Fig. 4-7 Mounted handpiece holder

1

4.4.1 Installing the F-SW holding arm (optionally)

To facilitate handling of the F-SW handpiece, you can hook the F-SW

handpiece onto the optionally available holding arm.

• Use a 2.5 mm Allen key for installation.

• Screw the holder for the arm rmly onto the holes provided for it on the left of the

instrument (see picture below).

21

13 610 02 1018

Fig. 4-8 Attachment holes for the holding arm

• Place the holding arm into the holder.

Installation Instruction

Page 22

22

Fig. 4-9 Holding arm attached

4.4.2 Connecting power supply cables

• Connect the Chattanooga Intelect F-SW via the mains cable to the mains connector (Fig. 3-2/3).

4.4.3 Handpiece connection

• Connect the connector of the F-SW handpiece to the handpiece connection

provided on the Chattanooga Intelect F-SW and secure it using the black locking

screw. The locking screw must be tightened up to the stop until nger-tight.

Fig. 4-10 Connecting the F-SW handpiece

NOTE

Fill the water circuit of the Chattanooga Intelect F-SW rst when the F-SW handpiece is rst connected after delivery. The instrument will signal “water level too

low” when it is switched on.

Installation Instruction

13 610 02 1018

Page 23

4.4.4 Connecting the optional foot switch

• Connect the connection cable of the foot switch to the appropriate connection

on the front side of the instrument.

NOTE

The foot switch is protected against ingress of water according to classication

IPX8 as per IEC 60529.

4.4.5 Potential equalisation (optional)

The Chattanooga Intelect F-SW features a potential equalisation connection.

• Connect one end of the potential equalisation cable to the PE connection on the

Chattanooga Intelect F-SW and the other end to your PE connection.

CAUTION!

The potential equalisation connection on the Chattanooga Intelect

F-SW must be connected in accordance with the relevant national

regulations.

4.4.6 USB connection

The USB connection acts as an interface for data input and output.

• Connect if required

– a USB memory stick which supports the USB V1.1 protocol

– a USB mouse

– a USB keyboard

The connected instruments must be approved as medical products in accordance with

IEC 60601.

23

13 610 02 1018

Installation Instruction

Page 24

4.5 Transport

NOTE

Make sure that your hands are dry and free of grease.

ATTENTION !

The side walls of the device can be bent if it is not transported correctly.

Defect of the touchscreen or other components!

• DO NOT carry the device by means of mounted accessory parts (e.g. F-SW

plug).

• Dismount the handpiece holder before transporting the device.

• To transport the instrument, grip the indentations on the side of the housing as

shown in the picture below (1) and lift it carefully.

24

1

Fig. 4-11 Transporting the device

• Set the device slantly down in order to avoid squeezing the ngers.

4.6 Compatibility

The Chattanooga Intelect F-SW is allowed to be operated with the following accessories:

– Handpiece F-SW SEPIA LT Art. no. 19000

– Handpiece C-ACTOR SEPIA LT Art. no. 29204.0001

– Foot switch

Installation Instruction

13 610 02 1018

Page 25

5 Operation

The Chattanooga Intelect F-SW is operated using a colour TFT LCD monitor with

touch screen function and a graphical user interface.

5.1 User interface

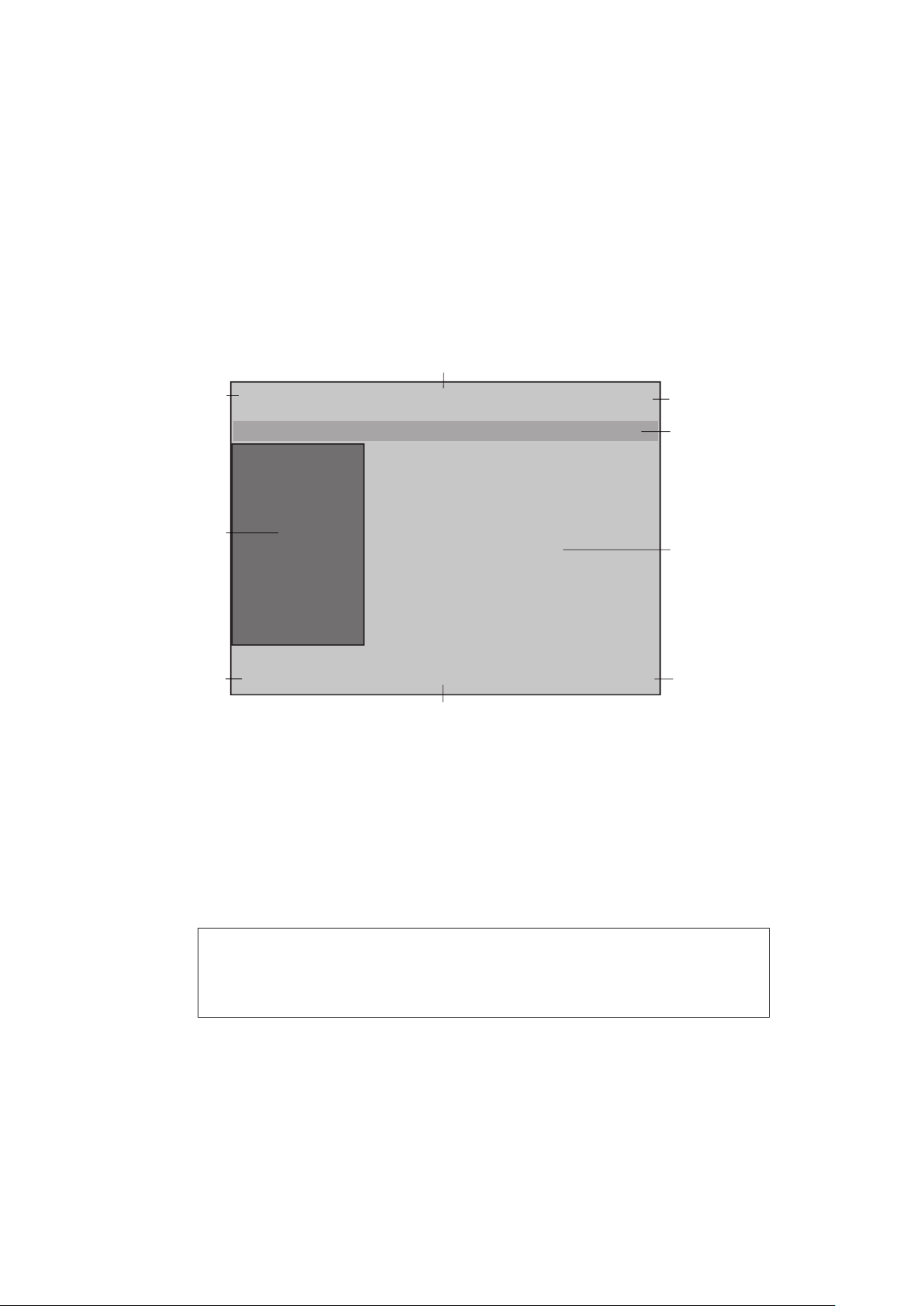

The user interface of the Chattanooga Intelect F-SW is divided into various areas for

displaying different information. The individual controls are arranged in function

groups (see picture below):

1

Control buttons

9

2

Control buttons

3

4

5

Control buttons

8

7

Fig. 5-12 Controls

1 - 3 Top navigation bar

4 Status bar

5 Selection area

6 - 8 Bottom navigation bar

9 Parameter display (nominal and actual values)

NOTE

The following functional description refers to control software version

13441.19.x.x or later (this can be seen in the Info menu).

Control buttons

6

25

13 610 02 1018

Operation

Page 26

Navigation bars:

The top and bottom navigation bars (Fig. 5-12/1 to Fig. 5-12/3 and 3, Fig. 5-12/6

to Fig. 5-12/8) contain control buttons that you can use for navigating through

the menus:

Parameter entry screen:

Open the sub-menu

Jump to the “Load conguration” sub-menu (call

up saved parameter congurations or patient

records)

Main and sub-menu:

Step back

Return to parameter entry screen

Delete congurations

Save congurations

Conrm entries, acknowledge messages

26

The arrow keys can be used for changing (increasing

or decreasing) the parameter values.

If you are in a sub-menu that contains more menu

items than can be displayed in the top part of the

display, you can use the arrow keys to scroll to the

bottom of the list (page up/down).

Press the date key on the parameter input page to

open the “Info” window.

Status bar:

The ag on the right of the status bar displays the

menu language. Touching the ag icon takes you

directly to the “Languages” sub-menu where you

can select a different menu language.

A warning symbol appears at the far left of the

status bar if there is an error. Touching this symbol

takes you directly to the “Warnings” sub-menu

that displays all warning messages that are currently

active.

The name of the loaded conguration/patient

record (* indication/patient name) is displayed.

Operation

13 610 02 1018

Page 27

Parameter display:

The treatment parameters are displayed in the parameter display eld

(Fig. 5-12/9) in the following sequence:

F-SW

Actual energy level in mJ/mm2 or in MPa

Nominal number of shocks or nominal total

energy

Actual frequency

Actual number of shocks

Actual total energy in J

After the rst start-up of the unit as well as after operating mode change,

conguration loading and parameter change, the display ashes and must be

conrmed by touching the display eld or a parameter.

Selection area:

– The selection area (see picture below) of the parameter entry screen contains

the nominal value selection elds “Energy level”, “Number of shocks” and

“Frequency”

Fig. 5-13 Parameter entry screen

– When you open a menu, the name of the opened menu appears in the top line

against a dark blue background. The sub-menu items are indented.

– A sub-menu item is selected by touching the corresponding display area.

– The selected sub-menu item appears against a dark blue background.

– Sub-menu items that themselves have an additional sub-menu are identied by

a green arrow to the right (Fig. 5-14/2).

– If there are more than 4 menu items, they can be selected using the arrow keys

(Fig. 5-14/1). If one of the arrow keys disappears, this means no more selections can be made in this direction.

– Once a sub-menu has been selected, it is opened using the “OK” button.

27

13 610 02 1018

Operation

Page 28

28

1 2

Fig. 5-14 List of sub-menu items

Operation

13 610 02 1018

Page 29

5.2 Overview of menu functions

2nd sub-menu

Keyboard

Keyboard

Language

Warnings

Data transfer

End control program

Service

Time

Touch screen calibration

Warning history

Software update

Specification of mJ/mm2 /Mpa

Specification SW number/total energy

Autofreq. [on]

Reset water change time

Setup

Drain the water circuit

Fill the water circuit

Save configuration

Load configuration

Bleed the water circuit

Urological indications

In-house applications

Orthopaedic indications

Info

Setup

Predefined applications

Language

Parameter entry screen

Menu

Save configuration

Load configuration

Reset counter

Main menu

1st sub-menu

29

13 610 02 1018

Fig. 5-15 Menu overview

Operation

Page 30

30

Parameter entry window

Main menu

Reset counter - Resetting the actual values in the selected operating mode

Save conguration - Saving indication-specic (preceded by *) or patient-specic

Load conguration - Loading already stored treatment parameters, opening the

Warnings - List of current warnings

Data transfer - Export treatment data (using this sub-menu, it is possible to

1st sub-menu

Setup See 1st sub-menu

Info - Total shock count and instrument operating hours (depending

- Determining the treatment parameters

(treatment shock counter, total energy, close patient record)

treatment parameters

patient record.

The keyboard window in the 2nd sub-menu enables you to

make your own text entries. However, you can also do this by

connecting a separate USB keyboard.

transfer the treatment data as les onto a USB memory stick

and open them in Excel)

- Backup settings (backup)

- Restore settings (backup)

on operating mode selected)

- Total number of shocks of the respective handpiece, data on

monitoring software, operating system, hardware serial num-

bers and modication status

- Information about modules: To view serial numbers and

indexes of the modules, scroll to the second page of the Info

window by using the arrow key.

Operation

13 610 02 1018

Page 31

Warning history - List of the last 100 warning and error messages

Language - Setting the language

Time - Setting the date and time

Touch screen calibration - This function makes it possible to recalibrate the touch

screen, i.e. for correct recognition of the touch coordinates

Draining the water circuit

Filling the water circuit

Bleeding the water circuit - The corresponding sequences for bleeding the water

Resetting water renewal time - Reset the reminder function for the water renewal

Software update - Transferring a software update from the USB memory

Specication of shock wave number/total energy

Autofreq. on / off - Only in F-SW mode:

- The corresponding sequences for emptying or lling the

water circuit are activated.

circuit are activated.

stick

- Changeover between shock number and total energy

nominal value specication

Selecting an energy level causes the instrument to switch

to the maximum permitted frequency automatically.

If this function is not activated, the selected frequency is

not exceeded when the energy level is changed. However, it is adapted according to the energy level.

31

13 610 02 1018

Operation

Page 32

5.3 Starting the instrument

• Switch on the Chattanooga Intelect F-SW using the main switch.

WARNING!

If a control panel display or a touchscreen / operating monitor should

fail, the safety of the patient can no longer be ensured.

Risk of patients being placed under strain due to ineffective

treatment or even impairments to their health!

• Abort the treatment.

• Inform your service centre.

Filling the water circuit

The rst time the instrument is switched on and each time the F-SW handpiece is

replaced, the instrument will display the message “Fill water circuit”.

• Touch “OK” to conrm the message.

The instructions on the display will guide you through the steps required.

– Connect the full water bag

– Filling the water circuit

32

– Remove the water bag

A detailed description can be found in chapter 6.4.2 filling the water circuit.

Warm-up phase

Once a day, the Chattanooga Intelect F-SW starts a warm-up phase lasting about 3

minutes, the progress of which is shown in the progress indicator.

The water circuit is bled.

• Check that the F-SW handpiece is correctly positioned in the holder and that no

stand-off is tted.

Fig. 5-16 Warm-up phase

Operation

NOTE

No F-SW shock triggering is possible during the warm-up phase. All other functions of the instrument can be used, however.

13 610 02 1018

Page 33

Load test

A load test is performed once a day when the Chattanooga Intelect F-SW is switched

on for the rst time. This test takes place after the warm-up phase.

• When prompted to do so, briey touch the trigger button on the F-SW handpiece

or the foot switch.

Fig. 5-17 High-voltage test

33

13 610 02 1018

Operation

Page 34

5.4 Setting the treatment parameters

Once the unit has been started, the display automatically shows the last setting.

• Touch the ashing parameter display or one of the parameter selection elds to

conrm the operating mode.

• Select the line of the parameter that you would like to change.

• Set the value using the arrow keys.

• Release shocks.

NOTE

The maximum possible frequency with which shock waves are generated depends

on the selected energy level (see tables below and next side). Increasing the

energy level may reduce the therapy wave frequency.

F-SW

EnergyuxdensityinmJ/mm

0,55 3 Hz

2

Maximum frequency Handpiece

34

0,50 3 Hz

0,45 3 Hz

0,40 3 Hz

0,35 4 Hz

0,30 4 Hz

0,25 4 Hz

0,20 5 Hz

0,15 6 Hz

0,12 6 Hz

0,10 6 Hz

0,07 6 Hz

0,05 7 Hz

0,03 8 Hz

0,02 8 Hz

0,01 8 Hz

Table 5 -1 Setting the treatment parameters in F-SW mode

Operation

13 610 02 1018

Page 35

C-ACTOR

EnergyuxdensityinmJ/mm

1,24 3 Hz

1,14 3 Hz

1,02 3 Hz

0,88 3 Hz

0,76 4 Hz

0,69 4 Hz

0,56 4 Hz

0,45 5 Hz

0,33 6 Hz

0,25 6 Hz

0,13 7 Hz

0,08 8 Hz

0,05 8 Hz

0,03 8 Hz

Table 5 -2 Setting the treatment parameters in C-ACTOR mode

2

Maximum frequency

35

13 610 02 1018

Operation

Page 36

5.5 F-SW Energy display task

To make sure that the energy level is correctly displayed at all times, the system includes a self monitoring function.

Therefore, during shockwave release the system constantly compares the nominal

energy value with the actual energy value.

If these values do not match the energy level is displayed in grey and turns white as

soon as the required set value is reached.

Fig. 5-18 Energy level is not yet reached

36

If the difference persists shock wave release is disabled and an error message is displayed.

Fig. 5-19 Error: Energy level not set

In case the warning appears, you can acknowledge it by touching “OK”.

Inform your service centre if the fault continues.

Operation

13 610 02 1018

Page 37

5.6 Storing the treatment parameters

• Touch the “Menu” button.

• Select the “Save conguration” function as shown in the picture below (1) to save

the current setting of the treatment parameters.

• Touch the “OK” button.

1

2

Fig. 5-20 Storing the treatment parameters

A list with a total of 100 memory locations appears on the touch screen display in the

“Save conguration” sub-menu. The system automatically stores the new parameter

congurations at the end of the list with the corresponding creation date and time as

shown in the picture below (1).

• Touch the “Save” key to save the current setting (see picture below).

1

3

Fig. 5-21 “Save conguration” sub-menu

NOTE

If you select a eld that is already occupied, you are asked if you want to overwrite the content. Conrm by touching “OK” or revoke your selection by touching the “Back” key.

2

37

13 610 02 1018

Operation

Page 38

• To rename the conguration, touch the button again that has already been selected. This activates the keyboard window.

Fig. 5-22 Keyboard window

You can save your parameter setting either as an indication or under a patient’s name.

• To save the parameters as an indication, place an “*” before the name of the

indication or leave it in place (“*Indication name”).

The saved and selected or loaded indication appears in the status bar. This display

disappears if a parameter is subsequently changed.

38

• To save the parameters for a particular patient (patient record), store the setting

directly under the name of the patient (“last name, rst name”).

The conguration stored for a patient name is also displayed in the status bar. The

display of patients’ names does not disappear when the parameters are changed. All

parameter changes are logged in a table. The patient record is closed when:

– a new patient record is called up (loaded),

– an indication is loaded,

– a parameter reset is performed (actual value),

– the unit is switched off.

• Conrm each of your entries by touching the “OK” button.

• Delete a stored conguration that is no longer required using the “Delete” button

(Fig. 5-21/3).

Up to 1000 treatments can be stored.

Operation

13 610 02 1018

Page 39

5.7 Loading treatment parameters

The alphabetical list of treatment parameters that have already been stored or of the

patient record can be opened either directly from the parameter entry screen or from

the main menu screen.

• If you are in the parameter entry screen, touch the “Conguration” button (Fig.

5-18).

• If you are in the main menu, select the “Load conguration” function from the list

(Fig. 5-20/2).

The “Load conguration” menu contains the following indication groups:

– In-house applications

– Orthopaedic indications

– Urological indications

5.7.1 Pre-programmed indications from the manufacturer

• Touch the button on which the required application area is displayed (see picture

below).

• Touch the “OK” button.

Fig. 5-23 Loading a conguration I

• Select the required indication.

39

13 610 02 1018

Fig. 5-24 Loading a conguration II

Operation

Page 40

Prior to loading an indication, you can view further information on the selected indication.

• To accomplish this, touch “Note.”

The treatment notes will be displayed.

To load the indication, touch “Back” to return to the previous screen.

• Touch “Load”.

The indication has been loaded successfully when the loaded indication is displayed

on the grey status bar (see picture below).

40

Fig. 5-25 Loaded indication

• To review the treatment notes, touch the name of the indication on the grey status

bar.

The loaded indication is exited by

– Opening a new indication

– Changing a treatment parameter range

– Switching off the instrument

Operation

13 610 02 1018

Page 41

5.7.2 In-house applications

• Touch the “In-house application” button (see picture below).

• Touch “OK”.

Fig. 5-26 In-house applications

• Touch the button for the indication required (see picture below).

Fig. 5-27 In-house indications

If additional information for the selected indication has been saved, this can be

accessed by touching “Note”.

• To add additional information, touch the text box (see picture below) to display

the on-screen keyboard.

1

41

13 610 02 1018

Fig. 5-28 Text box for treatment notes

Operation

Page 42

• Save the text by touching “OK”.

• Touch the “Back” button to view the list of in-house applications.

• Touch the “Load” button.

The highlighted indication will be loaded. The indication has been loaded successfully

when the loaded indication is displayed on the grey status bar.

• To review the treatment notes, touch the grey status bar.

The loaded indication is exited by

– Opening a new indication

– Changing a treatment parameter range

– Switching off the instrument

5.8 Patient record

• Touch the “In-house applications” button (see picture below).

• Touch “OK”.

• Touch the button on which the required patient name is displayed

42

Fig. 5-29 Loading a patient record

• Touch the “Protocol” button.

The patient record will be displayed.

Text elds

Operation

Fig. 5-30 Patient record – treatment details

13 610 02 1018

Page 43

A patient record consists of treatment details and a table of treatment parameters

that is created by the instrument automatically.

Each time a patient is accessed, a new treatment with the current date is saved to his

or her patient record.

Fig. 5-31 Treatment parameters

• To add additional treatment details, touch the text eld to display the on-screen

keyboard.

• Save the text by touching “OK”.

• Touch the “Back” button to view the list of in-house applications.

• Touch the “Load” button.

The treatment parameters for the highlighted patient will be loaded.

The treatment parameters have been loaded successfully when the patient’s name is

displayed on the grey status bar on the protocol screen.

• To review the patient record, touch the grey status bar.

The patient record is closed by

– Opening a new patient record or indication

– Resetting the shock counter

– Switching off the instrument.

43

13 610 02 1018

Operation

Page 44

5.9 Visual analogue scale (VAS)

The visual analogue scale in the patient record can be used for assessing the progress

of the therapy.

The VAS measures the patient’s subjective pain sensation on a scale from 0 to 10,

within which the patient can classify his or her pain intensity. The starting point (0)

stands for “no pain” while the ultimate point (10) stands for the “worst imaginable

pain”.

In each therapy session, the patient is asked once again to assign a value to the pain

he/she has felt since the last treatment.

The reduction in VAS values over the course of the therapy gives an indication of the

success of the treatment.

• Touch and drag the arrow to move it to the point on the scale

(see picture below) where the patient has assigned his or her pain intensity.

• Touch “OK” to x the arrow.

VAS scale

44

Fig. 5-32 Setting the VAS value

The arrow can then no longer be moved and the set value appears at the

left-hand edge of the VAS scale.

Fig. 5-33 Set VAS value

Operation

13 610 02 1018

Page 45

5.10 Data transfer

Using this function, treatment data can be exported onto a USB memory stick in a

format that can be opened in Excel. Also, operating data can be saved (backup) or

restored following a repair or if the instrument is replaced.

• Ensure that your USB memory stick supports the USB V1.1 protocol. You can order

a validated USB stick from your dealer.

Exporting treatment data

• Load a patient-specic parameter record.

• Select the “Data transfer” / “Export treatment data” function in the 1st sub-menu

(see picture below).

1

2

3

Fig. 5-34 Data export

• Connect the memory stick to the USB port as soon as you are prompted to do so

(see picture below) and conrm by touching “OK”.

Fig. 5-35 Data export

The USB connection is established.

45

13 610 02 1018

Operation

Page 46

46

Fig. 5-36 Establishing the USB connection

The data is transferred once the USB connection has been established. The export le

name of the patient record is protocol_name.csv.

All data is exported if no patient record or no indication has been opened. The export

le name of the record data is protocol_DateTime.csv.

• Wait until the “Export completed” message appears on the display

(see picture below), then remove the memory stick.

Fig. 5-37 Data export complete

Backing up the settings

Operation

Using the “Backup settings” function, you can save conguration settings, patient

and indication data onto a USB memory stick as a backup (in a le format that can

only be read by the instrument).

• Select the “Data transfer” / “Backup settings” function in the 1st sub-menu (Fig.

5-34/2).

• Connect the memory stick to the USB connector as soon as you are prompted to

do so and conrm by touching “OK”.

After the USB connection has been established, the data backup is performed and the

text window shows the name of the backup le.

• Remove the USB memory stick.

13 610 02 1018

Page 47

Restoring the settings

The system is restored to the data status of the last backup using the “Restore

settings” function.

• Select the “Data transfer” / “Restore settings” function in the 1st sub-menu (Fig.

5-34/3).

• Connect the memory stick with the backup le to the USB port as soon as you are

prompted to do so and conrm by touching “OK”.

The backup le is loaded onto the system once the USB connection has been estab-

lished. You are prompted to restart the system when the loading procedure has

nished.

• Remove the USB stick and restart the instrument.

47

13 610 02 1018

Operation

Page 48

5.11 Software updates

5.11.1 Loading the software onto the USB stick

5.11.1.1 Extracting the software using Windows

• Save the ZIP le onto your computer’s hard disk.

• Right-click on the ZIP folder icon.

• In the shortcut menu that appears, select the “Explorer” item.

Fig. 5-38 Selecting “Explorer”

The folder with the update les appears on the left of the window.

48

Fig. 5-39 Folder with update les

• In this folder, select the “combiselect_update.ini” and “combiselect_update_img.

ini” les and the “ffsdisk” folder and copy them onto your USB stick.

• Start the software update as described.

Operation

13 610 02 1018

Page 49

5.11.2 Extracting the software with WinZip

• Connect the USB stick to your computer.

• Save the ZIP le onto the USB stick.

Fig. 5-40 Zip le saved on USB stick

• Right-click on the ZIP le icon.

• In the shortcut menu, select the WinZip icon.

• Select “Extract to here” (see picture below).

Fig. 5-41 Extracting les

• Following extraction, the following les are displayed on the USB stick: “combise-

lect_update.ini”, “combiselect_update_img.ini” and “ffsdisk” folder.

Fig. 5-42 Files have been extracted

• Remove the USB stick and start the software update as described in the following

chapter.

49

13 610 02 1018

Operation

Page 50

5.11.3 Updating the software on the instrument

• Select the “Update software” function in the “Setup” menu.

• Connect the USB stick to the USB port of the Chattanooga Intelect F-SW as soon

as you are prompted to do so and conrm by touching “OK” .

Fig. 5-43 Software update

The update is performed once the USB connection has been established.

• Wait until the update has nished.

50

5.12

Fig. 5-44 Installation completed

• Touch “OK”.

• Remove the USB stick.

The instrument is ready for use.

Resetting the treatment shock counter

• To reset the applied shock counter to “0”, select the “Act. val. reset” menu option

(see picture below) or touch the counter display.

Operation

Fig. 5-45 Resetting the treatment shock counter

13 610 02 1018

Page 51

5.13 “Autofrequency” function

If the “Autofrequency” function is activated, the frequency is automatically increased

to the maximum possible setting when the energy level is reduced in F-SW mode (see

chapter 5.4 setting the treatMent paraMeters, Table 5 -1).

• Select the F-SW operating mode if this function should be deactivated.

• Activate the “Autofreq. on” item in the “Setup” menu (see picture below).

1

Fig. 5-46 Autofreq. on

The instrument automatically changes to “Autofreq. [off]” status (see picture below).

1

Fig. 5-47 Autofreq. off

The selected frequency will now not be exceeded even when the energy level is

changed.

• Touch the “Exit” button to return to the main menu.

NOTE

This frequency can be reduced manually.

51

13 610 02 1018

Operation

Page 52

5.14 Start-up

Switch the instrument on as described in chapter 5.3 starting the instruMent.

• Check that there are no bubbles in the F-SW handpiece.

• If bubbles are visible under the coupling diaphragm, proceed as follows: Position

the handpiece in the handpiece holder. No stand-off should be attached

52

Fig. 5-48 Optimum handpiece position

This ensures that air bubbles will always be sucked out of the handpiece.

• Secure the handpiece in this position for approx. 3 minutes until the suction

procedure has nished.

• To work in F-SW mode, set the shock energy to an initial value of 0.1 mJ/mm2.

The maximum energy level corresponds to an energy ux density of 0.55 mJ/mm2.

• Optional: To work in C-ACTOR mode, set the pulse energy to an initial value of

0.03 mJ/mm2.

The maximum energy level corresponds to an energy ux density of 1.24 mJ/mm2.

NOTE

The highest permitted frequency is always set when an energy level is selected

(see chapter 5.4 setting the treatMent paraMeters, table 5 -1 and table 5 -2) This

frequency can be reduced manually. (See also chapter 5.13 “autOfrequency” func-

tiOn.)

Operation

• Press the F-SW trigger button.

13 610 02 1018

Page 53

The trigger button functions as an on/off switch when it is pressed briey

(< 1.5 s). Pressing it for longer (> 1.5 s) causes it to function as a tip switch, i.e. the

shocks will continue until the button is released.

NOTE

If a nominal shock wave value of less than 1000 shock waves is selected (e.g. 400

shock waves), a window with the following text appears after the nominal value

has been reached: “Number/energy set value reached”.

The message can be acknowledged by touching the “OK” button or the corres-

ponding trigger button. Further treatment is possible.

If the nominal shock value is 0 (displayed as “ - ”), the stop only occurs at 19,999

shocks.

This message is activated again as soon as a multiple of the set nominal value is

reached (e.g. 800 shock waves, 1200 shock waves, etc.).

If a nominal value above 1000 shock waves is selected (e.g. 1700 shock waves),

the instrument automatically triggers a safety stop at 1000 shock waves (see

picture below). The next stop occurs when the set nominal value is reached. Following this, the counter continues to stop at intervals of 1000 (e.g. 2700, 3700,

etc.).

Fig. 5-49 Safety stop

53

13 610 02 1018

Operation

Page 54

5.15 Functional checks

Perform the following functional checks after the system has been installed:

• Check the control unit and handpieces for damage.

• Start the Chattanooga Intelect F-SW (see chapter 5.14 start-up).

• Set the energy level in F-SW mode to 0.2 mJ/mm2.

• Optional: Set the energy level in C-ACTOR mode to 0.69 mJ/mm2.

• Reset the actual number of shocks on the parameter display of the control panel

(see chapter 5.12 resetting the treatMent shOck cOunter).

• Release shocks with a shock frequency of 4 Hz.

• Release shocks by means of the foot switch, if used.

• Check that the triggered shocks are correctly counted on the treatment shock

counter.

NOTE

If necessary, the functional capability of the F-SW handpiece can be checked with

the aid of special Colour sensitive pressure sensors sensors.

54

5.16 Standard settings

• Before each treatment, make sure that the number of shocks and the actual energy value are set to zero (see chapter 5.12 resetting the treatMent shOck cOunter).

NOTE

Set the nominal value counter to the required value. The "-" symbol appears if

zero is selected. The instrument then operates without a nominal value specication.

• Start the F-SW treatment at an energy level of 0.1 mJ/mm2 and a frequency of 6

Hz.

• Start the C-ACTOR treatment at an energy level of 0.03 mJ/mm2 and a frequency

of 6 Hz.

Operation

13 610 02 1018

Page 55

5.17 Treatment

Safety information

Before using the device, the user must make sure it is functioning safely and in proper

condition.

• Each time after the device has been transported, make sure that all functional

checks have been performed on the device before you start treatment. Read about

this in chapter 5.15 functiOnal checks.

• Read chapter 1 general safety infOrMatiOn before beginning treatment.

CAUTION!

Handpiece not positioned correctly.

Impairment to health due to ineffective treatment!

• Dene the treatment zone and make sure that the handpiece

• Make sure that the treatment is only administered by users who

position always corresponds to the treatment zone.

meet the conditions in chapter 2.2 precOnditiOns fOr OperatiOn.

• For safety reasons, using the device for applications other than those specied in

chapter 2.1.1 indicatiOns is not permitted!

All status and error messages signaled during treatment must always be attended to

without delay!

CAUTION!

Injuries to patients and therapists

• No cleaning and maintenance work is to be carried out while the

device is being used on the patient.

• Apply a sufcient amount of coupling gel to the patient’s skin in the treatment

area and to the F-SW coupling diaphragm or the coupling cushion.

5.18 Switching off the device

• Switch off the Chattanooga Intelect F-SW using the main switch.

55

13 610 02 1018

Operation

Page 56

6 Cleaning, Maintenance and Overhaul

CAUTION!

Injuries to patients and therapists

• No cleaning and maintenance work is to be carried out while the

device is being used on the patient.

6.1 Cleaning the device

Regular cleaning of the system ensures perfect hygiene and operation of the

Chattanooga Intelect F-SW.

CAUTION!

Electrical hazard!

Disconnect the device and the accessories from the mains before

starting any cleaning and overhauling work!

• Unplug the mains plug !

56

Overall external cleaning depends on the frequency of use and application of the

device.

All parts which come into contact with the patient must be cleaned after each

treatment.

• Wipe down the device parts with a damp cloth.

• For cleaning, use a lukewarm, dilute solution of non-vegetable soapy water.

ATTENTION

It is essential that no uid be permitted to penetrate either the device or its

tubing.

Ventilation slits

• Keep the ventilation slits clear.

Monitor and Touchscreen

To clean the LC display only a tissue dampened with water but without any cleaning

additives may be used.

• Wipe the display.

• Dry the screen with a cotton tissue.

• Remove contamination (eg. contrast media spots) immediately.

Cleaning, Maintenance and Overhaul

13 610 02 1018

Page 57

6.2 Cleaning the handpiece

6.2.1 Changing the stand-off device

NOTE

To change the stand-off device, apply a drop of silicone oil to the coupling diaphragm as a coupling medium.

• Screw the stand-off device rmly onto the handpiece using the clamping ring.

To attach the

stand-off device

To release the

stand-off device

1 stand-off device

2 clamping ring

1

2

Fig. 6-50 Mounting the stand-off devices

• To release: Press the clamping ring towards the rear and then unscrew it.

Fig. 6-51 To release the stand-off device

57

13 610 02 1018

Cleaning, Maintenance and Overhaul

Page 58

NOTE

The stand-off has a limited service life. It should be replaced if there are vis-

ible changes in the material (discolouration, tarnishing, streaks, gas bubbles),

deformation of the surface in the coupling area or leaks.

The stand-off device should be replaced at least every 12 months.

6.2.2 Reprocessing of the handpiece and the stand-off devices

After each therapy session all parts of the handpiece which have been in contact with

the patient must be thoroughly cleaned and disinfected for further treatments.

Therefore the instruction must be strictly followed in order to avoid damage to the

parts and prevent malfunctions.

Make sure that the following means and tools are available for cleaning and disinfection:

– clean, soft and lint-free cleaning tissues

– cleaning agent

– alcohol-based surface disinfectant

58

6.2.2.1 Cleaning

• Screw off the stand-off device from the handpiece as described in chapter 6.2.1

changing the stand-Off device.

• Clean the handpiece and the stand-off devices of coupling gel, residual oil and

other water-soluble contaminants using a damp tissue.

6.2.2.2 Disinfection

• Disinfect the handpiece and the stand-off devices with a alcohol-based surface

disinfectant.

• Spray the handpiece and the stand-off devices with a desinfectant spray.

• Wipe the handpiece and the stand-off devices with a damp soft tissue.

• Dry the handpiece and the stand-off devices with a dry, absorbent soft and lint-

free tissue.

NOTE

Coupling cushion and stand-off devices must be protected against mechani-

cal damage. Do not use metallic or sharp objects for cleaning.

Cleaning, Maintenance and Overhaul

13 610 02 1018

Page 59

ATTENTION

Cleaning agents and disinfectants may impair the characteristics of

the coupling diaphragm.

• Do not use vegetable-based soap solutions or vegetable oils.

• Do not use agents containing any of the following:

– Aniline

– Dimethylformamide

– Ethyl acetate

– Methylene chloride

– N-methylpyrrolidone

– Nitric acid, 20 percent

– Hydrochloric acid, 20 percent

– Sulphuric acid, 20 percent

– Trichlorethylene

– Tetrahydrofurane

– Toluene

NOTE

The constituents listed here are non-binding examples. No claims

are made regarding the completeness of the list.

6.3 Cleaning the optional foot switch

• Clean the foot switch with soapy water or a mild cleaning agent.

NOTE

The foot switch is protected against ingress of water according to classication

IPX8 as per IEC 60529.

59

13 610 02 1018

Cleaning, Maintenance and Overhaul

Page 60

6.4 Water renewal

The water in the cooling circuit of the F-SW handpiece should be renewed every 6

months or so.

The instrument automatically displays a message to this effect when it is switched on

if the water renewal is due (see the picture below).

Fig. 6-52 Prompt for water renewal

• Touch the “OK” button to acknowledge this message.

– The message no longer appears once the water has been renewed.

60

6.4.1 Draining the water circuit

The water circuit must be drained if the instrument will not be used for several weeks.

• Make sure that the instrument is standing on a smooth surface.

• Select F-SW mode.

• Activate “Bleed water circuit” operating mode in the “Setup” menu (see picture

below).

1

2

3

4

Fig. 6-53 Water renewal

• Connect the water bag to the Chattanooga Intelect F-SW as soon as the message

appears (see picture next side).

Cleaning, Maintenance and Overhaul

13 610 02 1018

Page 61

.

Fig. 6-54 Draining the water circuit I

The “Please wait” message and a progress indicator appear on the display.

• Allow the remainder of the water to drain out of the handpiece by holding the

F-SW handpiece vertically above the instrument as soon as you are prompted to do

so. Make sure that the coupling diaphragm of the handpiece is pointing upwards.

Fig. 6-55 Draining the water circuit II

The “Please wait” message and a progress indicator appear on the display.

• Wait until the instrument is ready. The display shows when the water circuit is

empty.

61

13 610 02 1018

Fig. 6-56 Draining the water circuit III

• Open the lock on the tube connection and pull the tube out of the tube connector.

• Remove the full water bag and dispose of the contents.

Cleaning, Maintenance and Overhaul

Page 62

6.4.2 Filling the water circuit

• Make sure that the instrument is standing on a smooth, horizontal surface.

• Rinse out the water bag.

• Use only deionised water (in compliance with VDE 0510, e.g. water for batteries or

clothing irons) to rinse or ll the water bag.

• Fill the water bag to the brim.

Fig. 6-57 Filling the water bag

62

ATTENTION

• Do not use water that has been distilled more than once!

• After the water bag has been lled, there should be as few bubbles as possible

in the connection tube. Press the closing valve inwards to let the air escape (see

picture below) until the hose is fully lled with water.

Fig. 6-58 Venting the connection tube

• Place the F-SW handpiece into the F-SW handpiece holder so that any air bubbles

that form will be immediately sucked up by the bubble trap.

• Activate “Fill water circuit” operating mode in the “Setup” menu

• Connect the water bag to the water tube connection on the rear of the instrument

as soon as the message appears.

Cleaning, Maintenance and Overhaul

13 610 02 1018

Page 63

Fig. 6-59 Filling the water circuit I

• At the same time, hold the water bag above the instrument so the water can ow

out optimally. Hook the bag onto an infusion stand if necessary.

• Touch “OK”.

A progress display with the message “Please wait” appears on the display.

• As soon as the water circuit has been lled, the instrument prompts you to remove

the water bag (see picture below). There may be water left in the bag.

Fig. 6-60 Filling the water circuit II

63

13 610 02 1018

• Push the lock on the tube connector and pull the tube out of the connection.

• Conrm by touching “OK”.

There might be air bubbles in the system after the water has been changed.

The instrument needs about 15 minutes to remove these air bubbles. A progress bar

will be displayed (see picture next side).

Cleaning, Maintenance and Overhaul

Page 64

64

Fig. 6-61 Venting the water circuit

• Wait for the message to disappear, then return to the parameter entry screen by

touching the “Menu exit” button.

• Check that there are no bubbles under the coupling diaphragm of the F-SW hand-

piece. If bubbles are present, briey hold the handpiece pointing downwards in a

vertical position. The air bubbles will then be automatically sucked in by the bubble

trap.

6.4.3 Bleeding the water circuit

• Select “Bleed water circuit” from the “Setup” menu (Fig. 6-53/3).

A progress bar will be displayed (Fig. 6-61).

• Wait for the message to disappear, then return to the parameter entry screen by

touching the “Menu exit” button.

• Check that there are no bubbles under the coupling diaphragm of the F-SW hand-

piece. If bubbles are present, briey hold the handpiece pointing downwards in a

vertical position. The air bubbles will then be automatically sucked in by the bubble

trap.

6.4.4 Resetting the water renewal time

Every six months, the instrument prompts you to renew the water; the prompt does

not disappear permanently until the water has been renewed.

The “Reset water renewal time” function can be selected to cancel this reminder

function or to adapt it to a new date setting.

• Activate “Reset water renewal time” operating mode in the “Setup” menu

The time when the water renewal reminder is triggered is automatically moved

forwards by six months. A window showing the new date of water renewal appears

briey on the display.

• Press the “Exit” button to open the parameter entry screen.

Failure to renew the water regularly may shorten the service life of the instrument.

Cleaning, Maintenance and Overhaul

13 610 02 1018

Page 65

6.5 Fuse replacement

The mains fuse holder is located on the rear panel of the Chattanooga Intelect F-SW.

• Push the clip of the mains fuse holder to the right and take the holder off the

housing.

Fig. 6-62 Mains fuse holder

• Pull the old fuses out of the mains fuse holder.

1

1

Fig. 6-63 Fuse replacement

• Replace the fuses (T 5 AH / 250 VAC).

• Push the mains fuse holder back into the opening until it engages.

6.6 Maintenance and safety checks

Preventive maintenance is not necessarily required. However, regular maintenance

may help to identify possible defects at an early stage and thus increase the safety and

service life of the instrument.

Maintenance services can be ordered from our regional representatives in your area.

We recommend that functional and safety checks be performed at least once a year.

National accident prevention regulations and test and inspection intervals prescribed

for medical devices must, of course, be observed.

The following checks should be performed to ensure that the Chattanooga Intelect

F-SW operates safely.

1 Earth leakage current test according to national regulations.

2 Earth impedance test (with mains cable, incl. applicator housing) according to nati-

onal regulations.

3 Checks essential performance

65

13 610 02 1018

NOTE

For further details on content and performance of the safety checks please contact your local dealer.

Cleaning, Maintenance and Overhaul

Page 66

6.7 Disposal

When disposing of this medical product, please proceed in accordance with applicable

country-specic regulations. After expiration of its service life, dispose of the

Chattanooga Intelect F-SW as waste electronic equipment.

Never dispose of the device together with municipal household waste.

• Please contact the manufacturer or distributing company in relation to this.

• When disposing of wear parts, you must comply with the relevant national

disposal regulations.

• Comply with the relevant information in the operating manuals for the additional

devices.

6.8 Repair

66

Repair work on defective instruments must only be carried out by personnel suitably

authorised by the manufacturer. Only original spare parts may be used for this

purpose. The personnel suitably authorised can be from representatives agencies and

dealers.

6.9 Service life

The average expected service life (MTTF) in accordance with IEC 60601-1:2005 +

A1:2012 / EN 60601-1:2006 + A1:2013 is

– 15,000 operating hours for the Chattanooga Intelect F-SW

– 5 million shocks for the F-SW SEPIA LT handpiece

– 5 million shocks for the C-ACTOR SEPIA LT handpiece

Exceeding the service life can be expected to result in a failure of the device and

accessories. This also applies to handpieces.

No warranty claims shall be accepted beyond the information given in chapter 10

warranty and service.

Cleaning, Maintenance and Overhaul

13 610 02 1018

Page 67

7 Status messages and trouble-shooting

7.1 Status messages

CAUTION!

Malfunction of the device or its components

Various injuries are possible!

• Immediately comply with all status and error messages which

appear during the treatment.

Speciednumberofshock

waves reached

Shock wave safety stop

F-SW: load test

unsuccessful

F-SW: charging timeout

F-SW: water temperature

too high

F-SW: water temperature

too low

F-SW: water level too low

F-SW: water circuit fault

Acknowledge message,

further treatment is possible.

Acknowledge message,

further treatment is possible.

Restart the instrument and repeat

the test.

Do not continue to use the

instrument if the fault continues.

Notify your Service centre

Acknowledge message.

Inform your Service centre if the fault

continues.

Acknowledge message,

further treatment is possible once

the water temperature has returned

to permitted values.

Acknowledge message,

further treatment is possible once

the water temperature has returned

to permitted values.

Fill the water circuit (see chapter

6.4.2 filling the water circuit)

Pump defect

Treatment is not possible.

Bleed the water circuit (see chapter

6.4.3 bleeding the water circuit).

Inform your Service centre if the fault

continues.

67

13 610 02 1018

F-SW: water pump current

too low

F-SW: pump temperature

too high

Acknowledge message.

Inform your Service centre if the fault

continues.

Acknowledge message,

further treatment is possible once

the pump temperature has returned

to permitted values.

Status messages and trouble-shooting

Page 68

F-SW: therapy head

overtemperature

F-SW: water temperature

sensor failure

Acknowledge message,

further treatment is possible once

the therapy head temperature has

returned to permitted values.

Restart the instrument.

Inform your Service centre if the fault

continues.

68

Shock wave limit for

current handpiece reached