Page 1

•

1n

MODEL

225P/230P

ULTRASOUND

I

I

~

~/;;~

----~-:==----

I

mPERATmR'S

MANUAL

• INSTALLATION

• mPERATimN

• MAINTENANCE

• PARTS

P.N.

73778

REV C

Page 2

table of

contents

Description

Page.

FOREWORD

...................................................................

2

WARRANTY

INFORMATION

....................................................

2

SAFETY INSTRUCTIONS

.......................................................

3

SPECIFICATIONS

..............................................................

4

ULTRASOUND

THERAPY INDICATIONS

........................................

5

ULTRASOUND

THERAPY CONTRAINDICATIONS

...............................

5

INTELECT

225P/230P

OPERATING CONTROLS

................................

6

OPERATING PROCEDURE

.....................................................

7

DESCRIPTION

OF

THE

UL

TRASDUND

FIELD

...................................

8

PLOT

OF

ULTRASOUND

FIELD SPATIAL DISTRIBUTIONS

......................

9

ABBREVIATIONS

..............................................................

9

TROUBLESHOOTING

.........................................................

1 0

MAINTENANCE

AND

SERVICE INSTRUCTIONS

...............................

11

ULTRASOUND

CALIBRATION

.................................................

12

COMPONENT

LOCATION, CIRCUIT BOARD

.......................

17,

19,

21,

23

PARTS LIST

.....................................................

18,

20, 22,

24

SCHEMATICS

............................................................

25-39

Page 3

foreword

This manual

has

been

prepared

for

the

owners

and

operators

of

the

lntelect®Model

225P/230P.

It

contains

general

instructions

on

operation.

safety

practices,

maintenance

and

parts

information.

In

order

to

obtain

maximum life and

efficiency

from

your

Model

225P/230P

and

to

aid in

the

safe

operation

of

the

unit,

read and

understand

this

manual

thoroughly

and become

totally

familiar

with

the

controls

on

the

panel and

the

applicator

that

comes

with

the

unit

before

operating

it.

The

specifications

put

forth

in

this

manual

were

in

effect

at

the

time

of

publication.

However.

owing

to

Chattanooga

Corporation's

policy

of

continuous

improvement,

changes

to

these

specifications

may be made

at

any

time

without

obligation on

the

part

of

Chattanooga

Corporation.

·

full one

year

warranty

Chattanooga

Corporation

("Company")

warrants

that

lntelect®Model

225P/230P

("Product")

is

free

of

defects

in

material

and

workmanship.

This

warranty

shall remain in

effect

for

one ( 1 l

year

from

the

date

of

the

original

consumer

purchase

of

this

Product

and

extends

to

any

owner

of

the

Product

during

the

warranty

period.

If

this

Product

fails

to

function

during

the

one

year

warranty

period because

of a defect

in

material

and

workmanship,

Company

or

the

selling

dealer

will replace

or

repair

this

Product

without

charge

within a period

of

thirty

(30J days

from

the

date

on which

the

defective

Product

is

returned

to

the

Company

or

the

dealer. Company

or

the

dealer

will ship

the

replacement

or

the

repaired

Product

to

the

consumer's

residence.

THIS

WARRANTY

DOES

NOT

COVER:

1.

Replacement

parts

or

labor

furnished

by anyone

other

than

the

Company,

the

dealer

or

an

approved Company

service

agent.

2.

Defects

or

damage caused by

labor

furnished

by

someone

other

than

the

Company,

the

dealer

or

an approved Company

service

agent.

3. Any

malfunction

or

failure

in

the

Product

while

it

is in

the

possession

of

the

owner

during

the

warranty

period

if

the

malfunction

or

failure is

not

caused by a

defect

in

material

and

workmanship

or

if

the

malfunction

or

failure

is caused by unreasonable use. including

the

failure

to

provide reasonable and

necessary

maintenance.

COMPANY

SHALL

NOT

BE

LIABLE

FOR

INCIDENTAL

OR

CONSEQUENTIAL

DAMAGES

TO PROPERTY OR

BUSINESS.

Some

states

do

not

allow

the

exclusion

or

limitation

of

incidental

or

consequential

damages.

so

the

above

limitation

or

exclusion may

not

apply

to

you.

TO

OBTAIN

SERVICE

from

the

Company

or

the

selling

dealer

under

this

warranty,

the

1

owner

must

do

or

abide by

the

following:

1 . A

written

claim

must

be made

within

the

warranty

period

to

the

Company

or

the

selling

dealer.

If

the

claim

is

made

to

the

Company,

written

claim should be

sent

to:

P.O. Box

4287,

101

Memorial

Drive,

Chattanooga,

Tennessee

37405.

2.

The

Product

must

be

returned

to

the

Company

or

the

selling

dealer

by

the

owner.

This

warranty

gives you

specific

legal

rights,

and you may also have

other

rights

which

vary

from

state

to

state.

Company does

not

authorize

any

person

or

representative

to

create

for

it

any

other

obligation

or

liability in

connection

with

the

sale

of

this

Product.

Any

representative

or

agreement

not

contained

in

the

warranty

shall be void and

of

no

effect.

2

Page 4

safety

instructions

1 . WARNING: Explosion hazard

if

used in

the

presence

of

flammable

anesthetics.

2. WARNING:

For

continued

protection

against

fire

hazard replace

fuses

only

with

ones

of

the

same

type

and rating.

3. Read,

understand

and

practice

the

safety

and operating

instructions.

Know

the

limitations

and

hazards

associated

with

the

Ultrasound.

Observe

the

safety

and operational decals placed on

the

unit.

4. Grounding-Make

certain

that

the

unit

is electrically grounded by plugging

into

an

electrical

outlet

with

a ground terminal

receptacle

CU-ground

outlet).

Follow

the

National

Electric

Code.

5. The

lntelect

Model

225P/230P

should

not

be

connected

to

any

other

device when

in

use.

6.

CAUTION: Federal law

restricts

this

device

to

sale by,

or

on

the

order

of, a physician

or

licensed

practitioner.

7. The

generator

should

be

routinely checked

before

each use

to

determine

that

all

controls

function

normally; especially

that

the

INTENSITY

control

does properly

adjust

the

intensity

of

the

ultrasonic

power

output

in a stable

manner. Also

determine

that

the

TREATMENT

TIME

control

does actually

terminate

ultrasonic

output

power

when

the

timer

reaches zero.

8.

CAUTION:-Use

of

controls

or

adjustments

or

performance

of

procedures

other

than

those

specified herein may

result

in

hazardous exposure

to

ultrasonic

energy.

3

Page 5

specifications

Frequency-

1.0

MHz

± 5%

Duty

Cycle - 1

00%

(continuous

mode)

50%

± 1

0%

(pulse model

20%

± 1

0%

(pulse model

Pulse

Duration

- 5

msec ± 20%

(50%

duty

cycle

pulsed mode)

2

msec ± 20%

£20%

duty

cycle pulsed

model

Pulse

Repitition

Rate

- 1

00

Hz ±

20%

Ultrasonic

Power-

variable

from 1 watt

to

20

watts,

lntelect

230P

variable

from 1 watt

to

10

watts,

lntelect

225P

Output

Meter

Accuracy-

±

20%

(for

any

output

above 1

0%

of

maximum)

Temporal Peak/Average

Intensity

Ratio-

2:1, ± 20%

for

50%

Duty

Cycle.

5:1,

±

20%

for

20%

Duty

Cycle.

Output:

1.

Continuous-1 MHz

signal

that

is on as long as

the

timer

is running.

2.

Pulse-1 MHz

signal modulated

100%

by

the

100

Hz

rectangular

wave

with

the

selected

Duty

cycle.

Timer

Accuracy:

1 .

Less

than

0. 5

minutes

for

settings

less

than 5 minutes

2. 1 0%

for

settings

from 5 minutes

to

1 0

minutes

3. 1

minute

for

settings

greater

than

1 0

minutes

Applicator:

1.

Effective

radiating

area-. 8. 5 CM2

± 1.

5CM2,

lntelect

230P

(±

18%)

4.0

CM2 ± 1.0

CM2,

lntelect

225P

(±

25%)

2.

Maximum

beam

non-uniformity

ratio-

6.0:1

3.

Beam

type

- collimating

Input

power

requirements:

£Domestic)

120V

± I

60

Hz 1

0%

£Export)

220V

± 1

50

Hz 1

0%

314

Amps

318

Amps

Size -

12"

wide x

5"

high x

12"

deep

(not

including handle)

Weight -11.

5 lbs.

4

Page 6

indications for ultrasound therapy *

Some indications

for

the

use

of

ultrasound

include adhesive capsulitus,

bursitis

with

slight

calcification, myositis,

soft

tissue

injuries,

shortened

tendons

due

to

past

injury, healing

scar

tissue

and

plantar

warts.

Ultrasouno

is

an

efficient

modality when used

for

the

treatment

of

all

types

of

joint

contractures

resulting

from

capsular

tightness

and

scarring.

Ultrasound

is

the

modality

of

choice

to

obtain

therapeutic

levels

of

heating

within

body

structures

covered

by

thick

layers

of

soft

tissue.

Neither

shortwave

or

microwave

diathermy

is able

to

heat

these

underlying

structures

to

produce

results

comparable

to

ultrasound.

contraindications for ultrasound therapy *

Ultrasound

SHOULD

NOT BE

USED

over

the

eyes

or

the

reproductive

organs. Also

ultrasound

SHOULD

NOT BE

USED

over a pregnant

uterus.

Other

contraindications

include

acute

infection

or

septis,

deep vein

thrombosis,

or

arterial

disease, and

over

anesthetized

areas

or

conditions

that

cause

impairment

of

sensations, such as chemotherapy.

Ultrasound

IS NOT TO BE

USED

over

cancerous

lesions.

REF: Lehmann,

J.F.,

Therapeutic

Heat

and Cold;

13:367-378,

1972.

5

Page 7

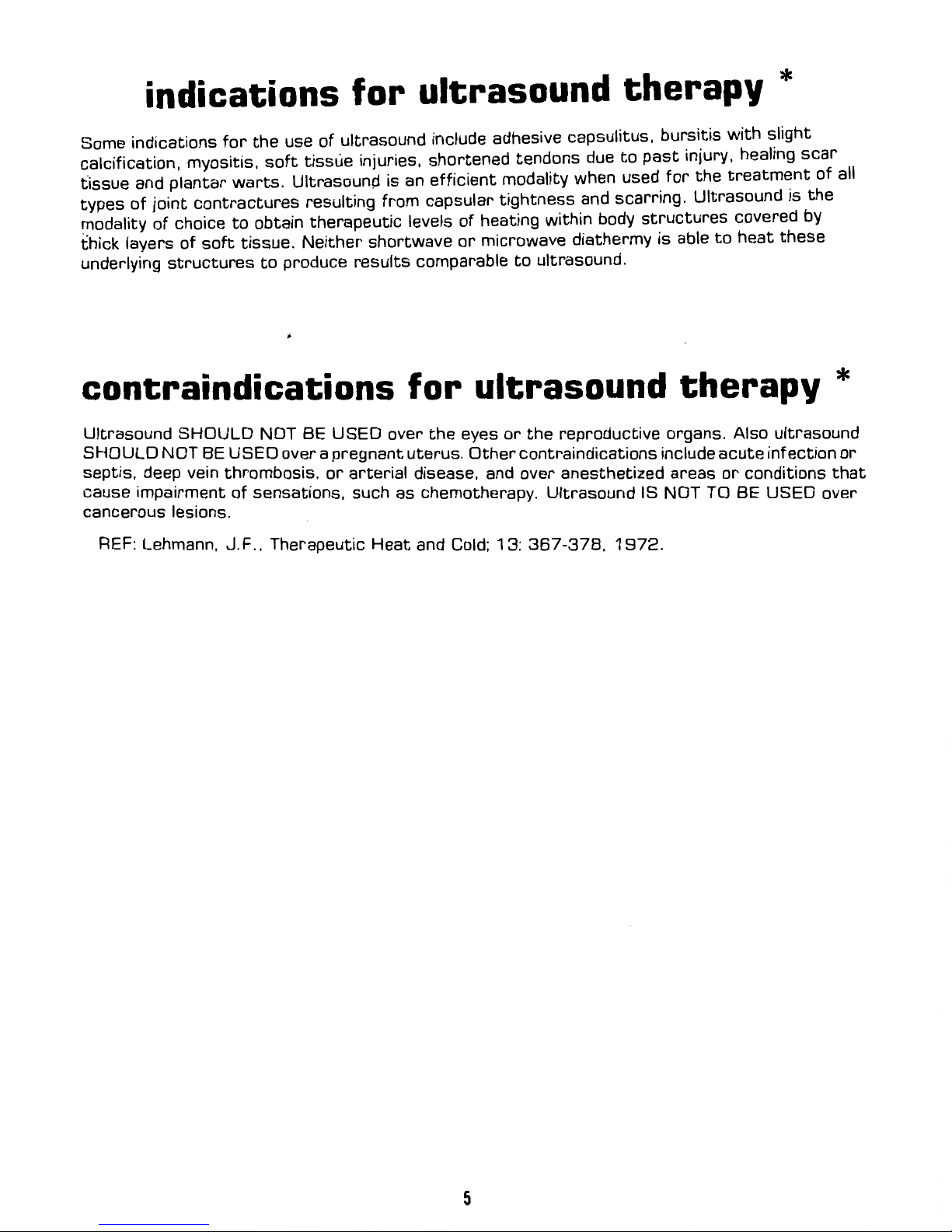

operating controls

OUTPUT

0

-------------------

ULTRASOUND

HEAD

I

ON

M

TEMP

2TYCY~E(O)

100%

50% 20%

CONTINUOUS PULSED

100

Hz

0 0

0

30

®-'···,5

' /

{ 0

~10

25

, '

, '

, '

'I I It\'

20

15

MINUTES

CHATTAN~.i?o~!':

1 .

TREATMENT

TIMER/

POWER SWITCH: This is a

0-29

minute

rotary

timer.

When

the

timer

is on,

the

green

LED

labeled

Ultrasound

On will be lit. When

Timer

is in

the

off

position,

power

to

the

generator

is

off.

2.

INTENSITY:

Rotating

this

control

knob

clockwise

increases

the

amount

of

ultrasound

power

being delivered.

3.

HEAD

MAX

TEMP

LED: This Red LED

comes

on when

the

temperature

of

the

ultrasound

head

(transducer)

reaches

approximately

140

degrees

F.

At

the

time

the

LED

comes

on,

the

unit

will

stop

producing

ultrasound,

the

Ultrasound

On

LED

will go out, and

the

Treatment

Timer

will

continue

to

run. When

the

transducer

cools

to

approximately

1

20

F,

the

LED

will go

off

and

the

ultrasound

power

will be

restored.

4.

ULTRASOUND

ON LED: This Green

LED

is

on

when

ultrasound

power

is being

transmitted

from

the

transducer

(sound head). This

LED

comes

on when

the

Treatment

Timer/Power

Switch

is

first

turned

on.

5.

20%

PULSED

SWITCH: By

pressing

this

switch,

the

operator

can

select

an

ultrasound

output

of

1

MHz

that

is pulsed

at 1 00

pulses

per

second. This

produces

rectangular

pulses

of

2

milliseconds

duration,

with

an

off

time

of

8 milliseconds

between

pulses.

6.

50%

PULSED

SWITCH: By

pressing

this

switch,

the

operator

can

select

an

ultrasound

output

of 1 MHz

that

is pulsed

at

1

00

pulses

per

second.

This

produces

rectangular

pulses

of

5

milliseconds

duration,

with

an

off

time

of

5 milliseconds

between

pulses.

7.

100%

CONTINUOUS

SWITCH: By

pressing

this

switch,

the

operator

can

select

an

ultrasound

output

that

is a

continuous

sinusodial

waveform

at a frequency

of 1 MHz

nominal.

8.

ULTRASOUND

OUTPUT

DISPLAY: This display

shows

the

amount

of

ultrasound

power

and

intensity

available

at

the

transducer

(sound head). The

upper

scale

is

calibrated

in

Watts

and

the

lower

scale in W/CM2.

Average

power

is

shown

when in

continuous

(1

00%1 mode. Peak

power

is

shown

when in pulsed £50%, 20%1 mode.

6

Page 8

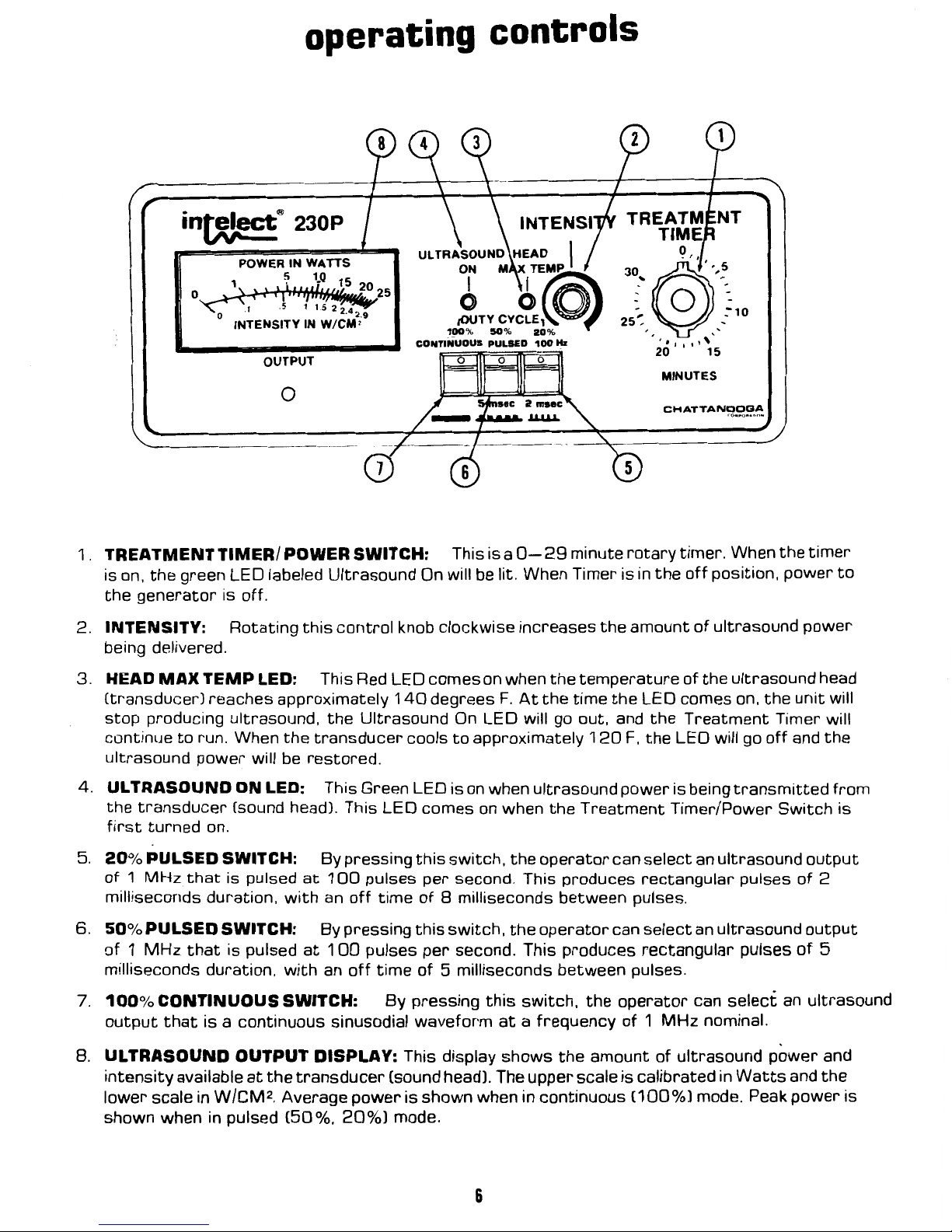

operating procedure

1 . Plug

the

unit

into

a properly grounded

outlet

of

the

proper

voltage and line

fre-

quency.

Refer

to

the

Nameplate on

the

rear

of

the

unit.

2.

Operator

should

adjust

the

applicator

handle

to

the

desired position. Tighten

the

thumbscrew

securely.

3.

Set

the

Treatment

Timer

at

the 0 (Qffl

position, and

the

Intensity

control

at

the

(fully

counter

clockwise position).

4.

At

this

point you may begin

the

treatment

by applying

lntelect

Ultrasound

Gel

to

the

area

of

the

patient

to

be

treated.

5.

Turn

the

Treatment

Timer knob

to

the

desired

treatment

time

by

turning

the

knob

beyond

the

desired

time

and

then

backing up

to

the

desired time.

6.

Select

the

operating mode by pressing

the

appropriate

switch.

Switch 5 for

the

20%

Pulsed Mode,

Switch 6 for

the

50%

Pulsed Mode,

or

Switch 7 for

the

100%

Continuous Mode. The

20%

Pulsed Mode is automatically

selected

upon

actuation

of

the

timer.

7.

You should

then

place

the

applicator

in

contact

with

the

patient's

body

with a firm

uniform

pressure.

You

must

keep

the

applicator

moving during

the

treatment.

Failure

to

keep

the

applicator

moving may

result

in

hazardous exposure

to

the

ultrasound

energy.

8.

Adjust

the

Ultrasound

Output

by

turning

the

Intensity

control

(2) until you reach

the

desired

output.

Use

the

Upper

scale

for

Watts

and

Lower

scale

forW/Cm2.

9.

If

you need

to

interrupt

the

treatment

for

any reason,

turn

the

Treatment

Timer

to

the

off

position (Bell will ringl. To resume

treatment

repeat

steps

4-8.

1

0.

At

the

end

of

the

treatment,

the

end

of

treatment

bell will sound and

the

unit

will

shut

off.

in~®

230P

POWER

IN

WATTS

5

10

~.

''f'tl~'f'~s

20

o •

'I"'

·ii:rlpe::.t;,.2s

.1

.s

11.5224

0 - . 2.1

INTENSITY IN W/CM2

OUTPUT

0

INTENSITY TREATMENT

TIMER

ULTRASOUND HEAD I 0

OIN

MAXITE(O)MP

30,@·'···

..

,5

0 0 0 : 0

~10

,OUTY

CYCLEt

25":.

,·

100%

10% 10%

, ,

''

CONnNUOUS

PULUO

100

Hz ' • ' , •

''

IEli~El

·~UTE;

s-c

·-

CHATTANOOGA

-

.....

~

c~,..,..

1

Page 9

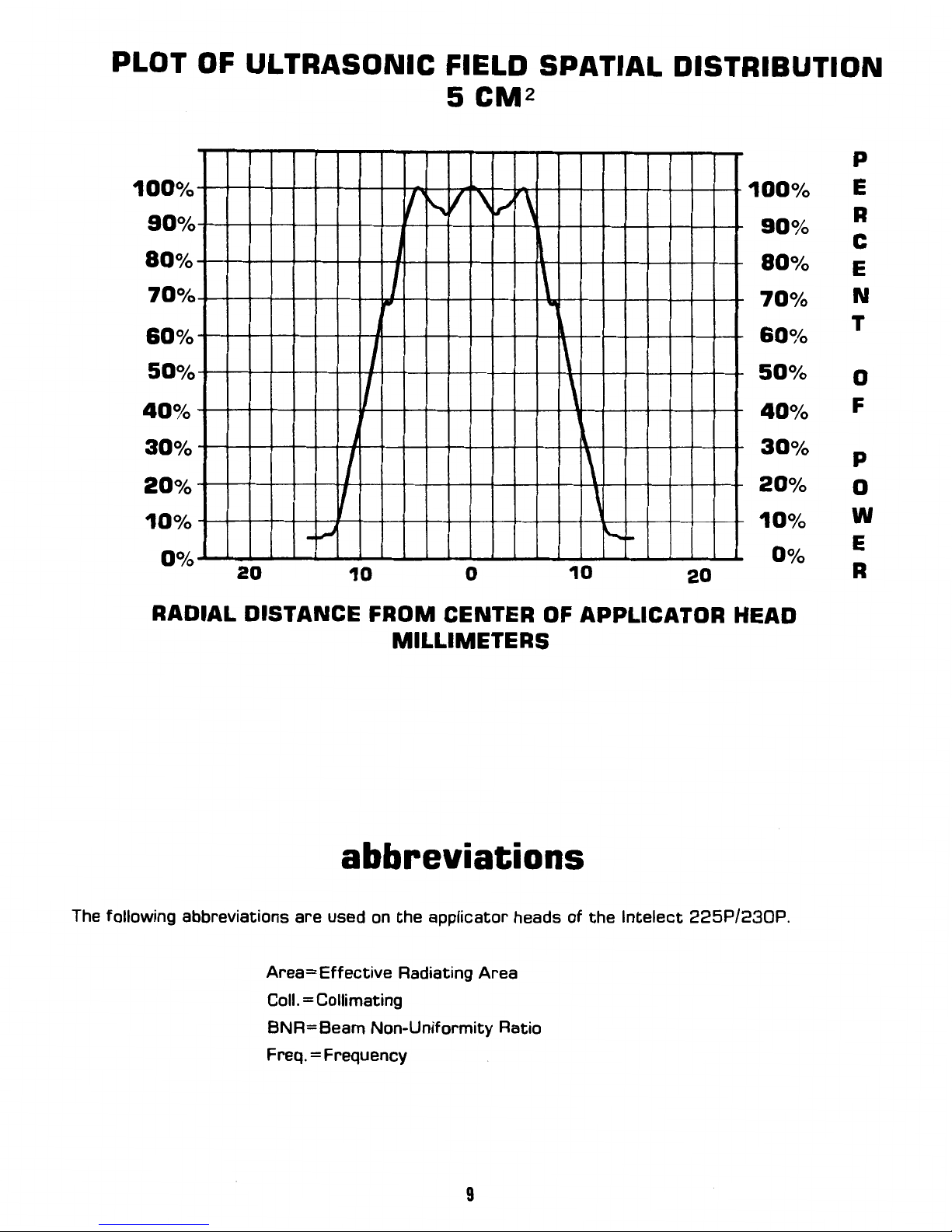

description of ultrasonic field

The spatial

distribution

of

the

radiated field

is

essentially a collimated beam

of

ultrasonic

energy

having a cross-sectional area

of

8.5

CM2

for

the

10

CM2

sound head when measured

at

a point 5

millimeters

from

the

transducer

face.

The energy

distribution

within

the

radiated field is

2.4

W/CM2 maximum, and

takes

a generally conic

shape having decreasing

intensity

at

progressively increasing distance

from

the

face

of

the

transducer.

This field

distribution

applies

for

the

radiation

emitted

into

the

equivalent

of

an

infinite medium

of

distilled degassed

water

at

30

deg.

C.

and

with

line voltage variations

in

the

range

of±

1 0

percent

of

the

rated

line voltage. The

ultrasonic

field spatial

distribution

of

the

5

CM

2

sound head is essentially

the

same as

the

field

of

the

10

CM2

sound head.

PLOT

OF

ULTRASONIC FIELD SPATIAL

DISTRIBUTION

10

CM2

90°/o

80°/o

70°/o

&Oo/o

50°/o

40°/o

30°/o

20°/o

10°/o

,...

1\

I

I

,,

"

"

1~

v

v

\'

t

~

I

\j

\~

u

\

....

1

'

l

I

\

J

~

"

)

\

/'

/

\

20

10

0

10

20

100°/o

90°/o

80°/o

70°/o

60°/o

SOo/o

40°/o

30°/o

20°/o

10°/o

....

RADIAL DISTANCE FROM CENTER

OF

APPUCATOA HEAD

MIWMETEAS

8

p

E

A

c

E

N

T

0

F

p

0

w

E

A

Page 10

PLOT

OF

ULTRASONIC FIELD SPATIAL DISTRIBUTION

5

CM

2

100o/o

90°/o

80°/o

70°/o

&Oo/o

50°/o

40°/o

30°/o

20°/o

10°/o

0°/o

-

~

20

I

j

I

I

I

~

10

v

~

v

'

~

~

fl"

0

.,

100°/o

90°/o

80°/o

\

'II

70°/o

1\

\

60~{:,

50°/o

40°/o

\

\

'

~

~

30°/o

20°/o

10°/o

Qo/o

10

20

RADIAL

DISTANCE FROM CENTER

OF

APPLICATOR

HEAD

MILLIMETERS

abbreviations

The following abbreviations

are

used

on

the

applicator heads

of

the

lntelect

225P/230P.

Area=

Effective

Radiating

Area

Call.= Collimating

BNR=

Beam Non-Uniformity Ratio

Freq.

=Frequency

9

p

E

R

c

E

N

T

0

F

p

0

w

E

R

Page 11

trouble shooting

The following

problems

and

solutions

are

presented

to

assist

you in solving some

of

the

roblems

that

could possibly happen

to

your

lntelect

225P

or

230P.

Problem

No

power

to

unit

Unit

has

power

but

no

Ultrasound

output.

1

JS

output

meter

only

•

dicates

about

half-scale

or

less when INTENSITY is

set

at

maximum.

When

unit

is

energized

HEAD

MAX.

TEMP

LED

(Red)

lights

and

beeper

sounds.

Timer

will

not

set

Cause

Action

To Take

1)

Unit

not

plugged in. 1 J Plug in unit.

21

No

power

to

the

receptacle.

2)

Check

for

tripped

circuit

breaker

or

blown

fuse

on

the

facility

circuit.

3)

Input

fuse

blown.

41

Internal

fuse

blown.

31

Change

the

3/4

amp. £.315 ampl

slo-blo

fuse

located

in

the

power

entry

receptacle

on

the

back

of

the

unit.

(3/8

amp

for

220 V units.)

Remove

Power

cord

prior

to

changing

the

fuse.

41

Check

the

3 amp and 1

/2

amp

picofuses

on

the

power

supply

board. This should be done only

by a Qualified

Service

Technician.

51

Loose connection inside

unit

51

Check

internal

connections

for

proper

seating

of

plugs in

receptacles

and

for

broken

wires.

6)

Applicator

cable loose.

61

Replug cable

into

the

shield box .

7)

Applicator

cable broken.

BJ

Oscillator

detuned.

91

Crystal

damaged.

1

OJ

Shorted

applicator

cable

71

Replace cable only

with

the

same

type

of

cable.

81

Recalibrate.

9J Replace

transducer

head in

the

applicator

and

recalibrate.

1

OJ

Check

the

cable

with

an ·ohmmeter,

If

the

cable is

shorted,

re-pl~ce

the

cable

with

the

same

type.

11 J

Water

in

applicator

head. 11 1 Remove

the

transducer

head

and

dry

out

the

inside

of

the

applicator.

If

the

D-ring is

defective, replace

it.

Consult

the

factory.

121

Timer

kriob loose

10

121 Remove cap on

the

knob and

tigtrten

the

collet.

Rotate

the

timer

fully clock-wise and

then

lassen

the

collet

so

that

the

knob is

free.

Align

the

white

line on

the

knob

with

the

29

min.

mark

on

the

timer

scale

and

re-tighten

the

knob collet.

Perform

section 4 of

calibration

procedure.

Page 12

maintenance and

service

instructions

1. To fully maintain compliance

with

Federal Regulation

Title

21 (21 CFRl

this

unit

must

be

recalibrated

annually.

It

is

recommended

that

all

Chattanooga

Corporation

Ultrasound

Products

be

returned

to

the

factory

or

an authorized servicing dealer

for

repairs

or

recalibrations.

It

is also recommended

after

the

replacement

or

repair

of

any

major

component. (See

Section

for

Calibration

Procedures.)

2.

The following

items

should be checked

at

least

monthly

to

insure

proper

operation

of

this

unit:

. 1

Power

cord

and plug. Check

to

make

sure

the

cord

is

not

frayed, kinked

or

has

torn

or

cut

insulation .

. 2

Transducer

(applicator) Cable. Check

to

make

sure

the

cable is flexible,

free

of

kinks,

not

frayed

and

that

insulation is

intact

.

. 3

Transducer

(applicator) Handle. Check

to

make

sure

that

it

is

not

cracked

or

broken .

.4

Transducer

(applicator) Face. Check

to

see

that

there

is no build-up

of

gel

of

foreign

material

on

the

stainless

steel

face

.

. 5 LED's. Check each

function

to

see

if

the

LED is

on

when you

are

using

that

function.

11

Page 13

calibration

CAUTION: An

Electrical

Shock

Hazard

is

present

during several

portions

of

the

calibration

-.procedure. Calibration should be

performed

by a Qualified

Service

Technician.

1.

TEST

EQUIPMENT

REQUIRED

.1

Power

line

monitor

(expanded scale

voltmeter

for

rated

line voltage ± 1 0%),

VI~

model

WV-1208

or

equivalent

for

120VAC

line .

. 2

Autotransformer,

adjustable

from

90%

to

11

0%

of

rated

line voltage,

150

watts

or

greater

.

. 3

Ultrasound

Power

Meter,

Ohmic

Instruments

Model

UPM-30

or

equivalent .

.4

Oscilloscope, Hameg

Hm

204-2

or

equivalent .

. 5 Probe,

voltate,

X1

0, Scope,

low

capacitance

.

. 6 Probe,

current,

Textronix

P6021

AC

current

probe

or

equivalent .

. 7

Voltmeter,

Digital,,

3~

1/2

digits, Simpson Model

461

or

equivalent .

. 8 Probe,

temperature,

Fluke Model

BOT-150

or

equivalent .

. 9

Source

of

approximately

1/2

gallon

of

distilled de-oxygenated

(<5

PPMJ

water

at

30

degrees

Celsuis

for

use in

UPM-30

power

meter

(item

#3)

.

.

10

Counter,

frequency,

10

MHz,

Triplett

7000

or

equivalent .

. 11

Stopwatch,

Siliconix Model

705

or

equivalent .

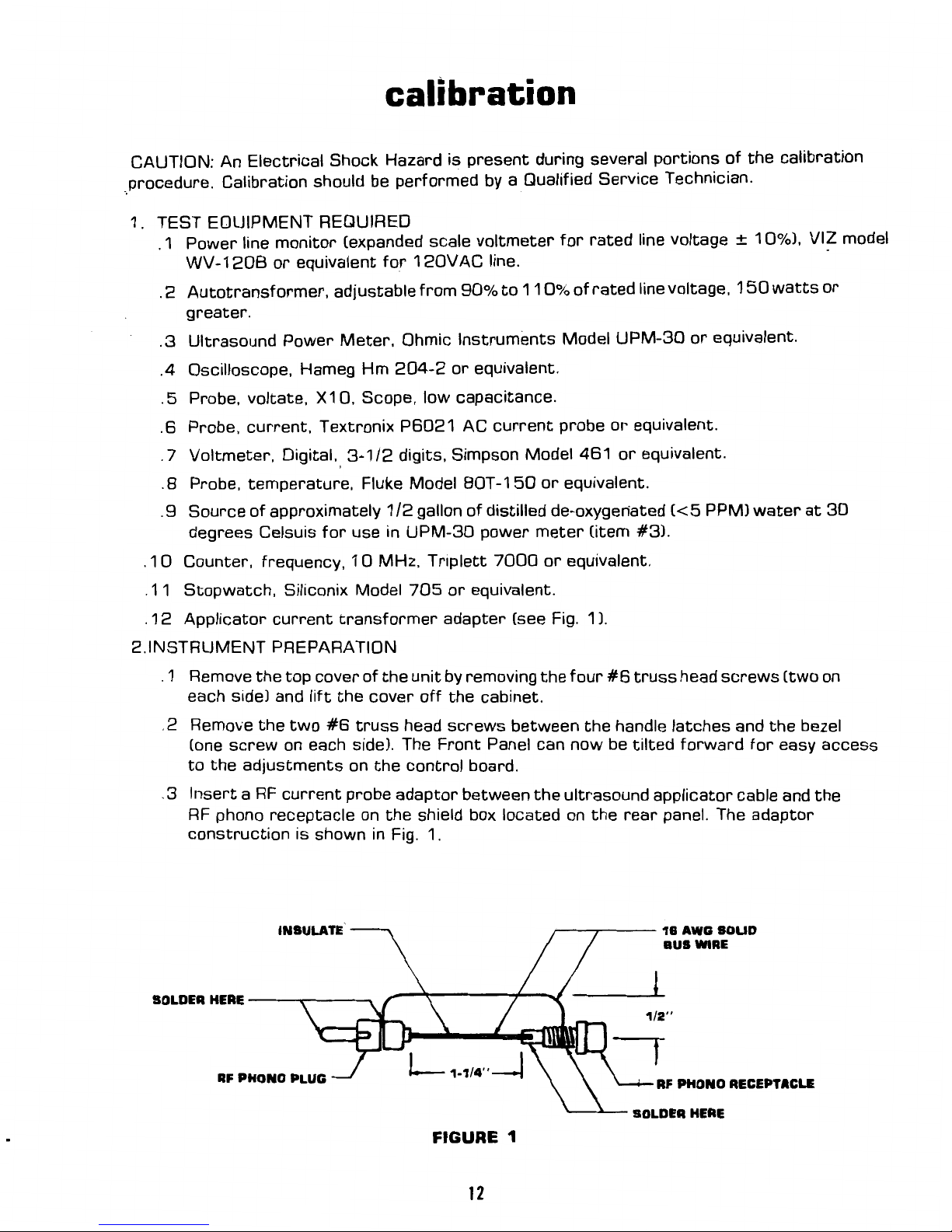

.

12

Applicator

current

transformer

adapter

(see Fig. 1

J.

2.1NSTRUMENT

PREPARATION

. 1 Remove

the top

cover

of

the

unit

by removing

the

four

#6

truss

head

screws

(two

on

each side) and

lift

the

cover

off

the

cabinet

.

. 2 Remove

the

two

#6

truss

head

screws

between

the

handle

latches

and

the

bezel

Cone

screw

on

each sidel. The

Front

Panel can

now

be

tilted

forward

for

easy

access

to

the

adjustments

on

the

control

board .

. 3

Insert a RF

current

probe

adaptor

between

the

ultrasound

applicator

cable and

the

RF

phono

receptacle

on

the

shield box

located

on

the

rear

panel. The

adaptor

construction

is

shown

in Fig. 1.

r---~----16AWGSOUD

BUS WIRE

l

1/2"

RF

PHONO PLUG

RF

PHONO RECEPTACLE

FIGURE 1

12

Page 14

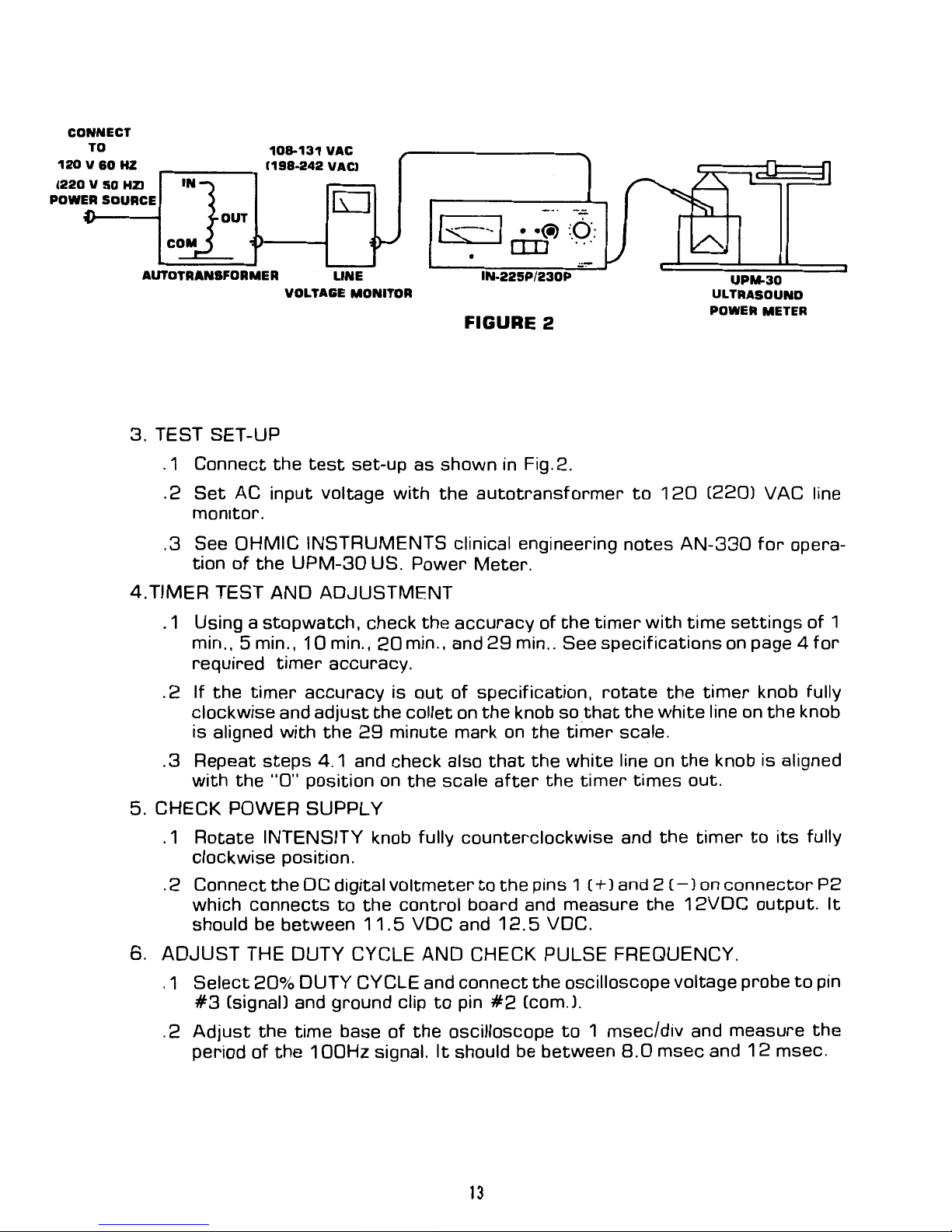

CONNECT

TO

120 V 60HZ

1220 V 50

HZJ

POWER SOURCE

108-131

VAC

,--------.

(198-242

VACJ

J:

N

UT

co

ls----1

•

·(i)

J):

O:IJ

...

•

AUTOTRANSFORMER

LINE

IN-225P/230P

UPM-30

ULTRASOUND

POWER

METER

VOLTAGE

MONITOR

FIGURE 2

3.

TEST

SET-UP

. 1

Connect

the

test

set-up

as

shown

in Fig. 2 .

. 2

Set

AC

input

voltage

with

the

autotransformer

to 1 20

C220J

V AC line

monitor

.

. 3 See

OHMIC

INSTRUMENTS

clinical engineering

notes

AN-330

for

opera-

tion

of

the

UPM-30

US.

Power

Meter.

4.TIMER

TEST

AND

ADJUSTMENT

.1

Using a

stopwatch,

check

the

accuracy

of

the

timer

with

time

settings

of

1

min

..

5 min.,

10

min.,

20

min., and

29

min

..

See

specifications

on page 4

for

required

timer

accuracy

.

. 2

If

the

timer

accuracy

is

out

of

specification,

rotate

the

timer

knob fully

clockwise

and

adjust

the

collet

on

the

knob so

that

the

white

line

on

the

knob

is aligned

with

the

29

minute

mark

on

the

timer

scale .

. 3

Repeat

steps

4.

1 and check also

that

the

white

line on

the

knob is aligned

with

the

"0"

position

on

the

scale

after

the

timer

times

out.

5.

CHECK

POWER

SUPPLY

. 1

Rotate

INTENSITY

knob fully

counterclockwise

and

the

timer

to

its

fully

clockwise

position

.

. 2

Connect

the

DC digital

voltmeter

to

the

pins 1 ( + J and 2

(-Jon

connector

P2

which

connects

to

the

control

board and

measure

the

12VDC

output.

It

should be

between

11.5

VDC

and

12.5

VDC.

6.

ADJUST

THE

DUTY

CYCLE

AND

CHECK

PULSE

FREQUENCY

.

. 1

Select

20%

DUTY

CYCLE and

connect

the

oscilloscope

voltage

probe

to

pin

#3

(signaiJ and ground clip

to

pin

#2

(com. J .

. 2

Adjust

the

time

base

of

the

oscilloscope

to 1 msec/div

and

measure

the

period

of

the

1OOHz signal.

It

should be

between

8.0

msec

and

12

msec.

13

Page 15

. 3

Adjust

the

scope

time

base

for

1 0 divisions

of

one cycle

of

the

sign.,al.

On

the

control

board.

adjust

RS

for

a pulse

width

of

7. 9 divisions .

. 4

Select

50%

DUTY

CYCLE and

adjust

R4

on

the

control

board

for

a pulse

width

of

4.

7 divisions .

. 5

Select 1 00%

DUTY

CYCLE and observe

that

the

signal is a DC level less

than

.5V.

7.CHECK

AND

ADJUST

THE R.F. OSCILLATOR

. 1 Connect

the

scope

current

probe around

the

center

conductor

of

the

cur-

rent

probe

adaptor

and

connect

the

voltage

probe

to

the

outside

conductor

.

. 2

Rotate

the

INTENSITY

control

clockwise as you observe

the

voltage and

current

waveforms

on

the

dual channel scope. The

waveforms

should be

within 5 degrees

of

being in phase and oscillation should be

stable

.

. 3 Repeat

step

7. 2

with

50%

duty

cycle and

then

with

20%

duty

cycle

selected

.

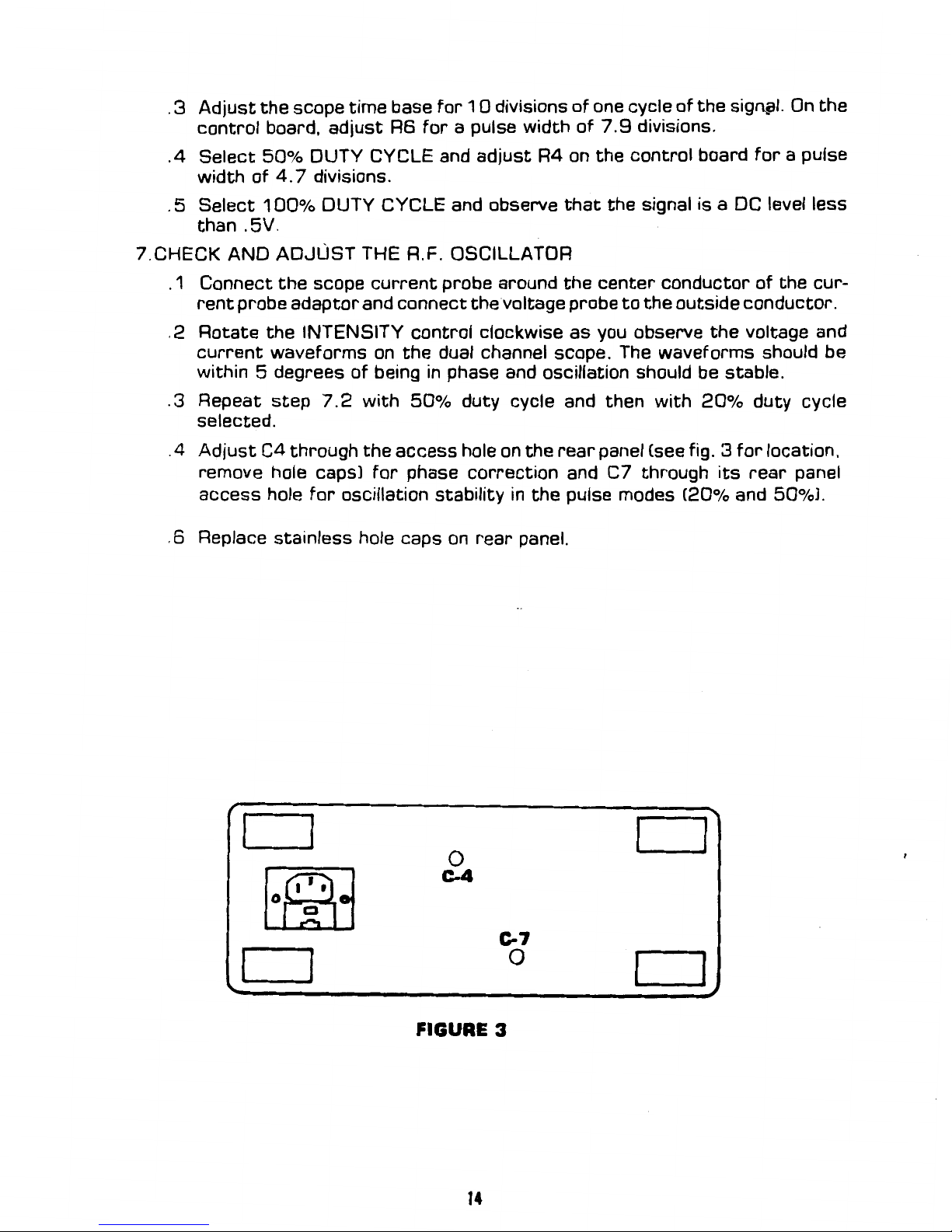

.4

Adjust

C4

through

the

access

hole

on

the

rear

panel (see fig. 3

for

location.

remove hole capsJ

for

phase

correction

and C7

through

its

rear

panel

access

hole

for

oscillation

stability

in

the

pulse modes £20% and

50%)

.

. 6 Replace

stainless

hole caps

on

rear

panel.

D

D

0

E@j

C-4

c-7

CJ

0

D

FIGURE 3

14

Page 16

\

\,

;

'

\

'

....

... ~ ...............

0

....

,_

,.

.

;

'

-~

......

~

.,_

(

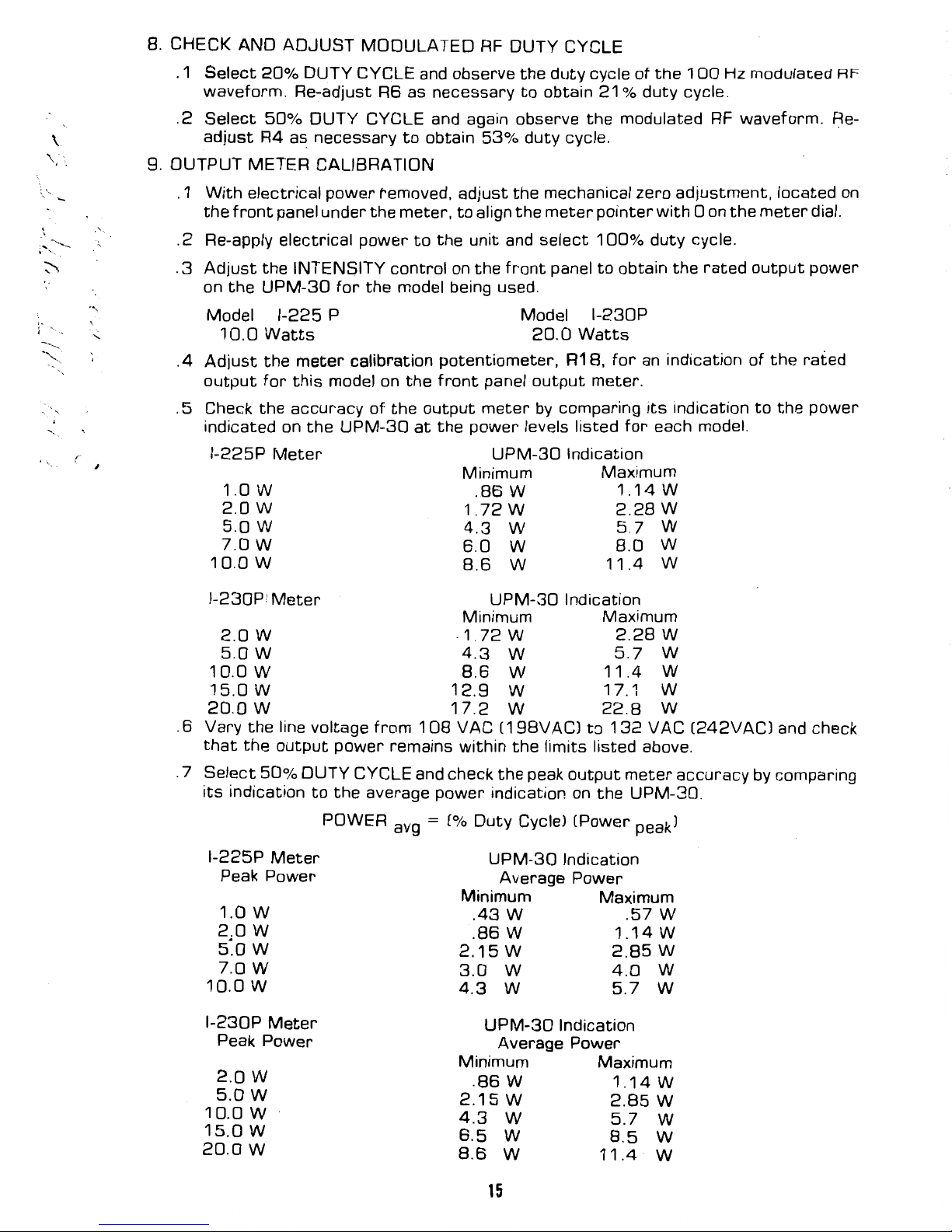

8.

CHECK

AND

ADJUST

MODULATED

RF

DUTY

CYCLE

.1

Select

20%

DUTY

CYCLE and observe

the

duty

cycle

of

the

100Hz

modulated

RF

waveform.

Re-adjust

R6

as

necessary

to

obtain

21%

duty

cycle .

. 2

Select

50%

DUTY

CYCLE and again observe

the

modulated

RF

waveform.

Re-

adjust

R4

as

necessary

to

obtain

53%

duty

cycle.

9.

OUTPUT

METER

CALIBRATION

.1

With

electrical

power

removed,

adjust

the

mechanical

zero

adjustment,

located

on

the

front

panel

under

the

meter,

to

align

the

meter

pointer

with

0 on

the

meter

dial.

. 2 Re-apply

electrical

power

to

the

unit

and

select 1 00%

duty

cycle .

. 3

Adjust

the

INTENSITY

control

on

the

front

panel

to

obtain

the

rated

output

power

on

the

UPM-30

for

the

model being used .

Model 1-225 P Model

I-230P

10.0

Watts

20.0

Watts

.4

Adjust

the

meter

calibration

potentiometer,

R18,

for

an

indication

of

the

rated

output

for

this

model on

the

front

panel

output

meter

.

. 5 Check

the

accuracy

of

the

output

meter

by comparing

its

indication

to

the

power

indicated

on

the

UPM-30

at

the

power

levels

listed

for

each model.

I-225P

Meter

UPM-30

Indication

1.0

w

2.0W

5.0

w

7.0W

10.0

w

I-230PI

Meter

Minimum

.86W

1.72

w

4.3

w

6.0

w

8.6

w

Maximum

1.14

w

2.28

w

5.7

w

8.0

w

11.4

w

UPM-30

Indication

Minimum Maximum

2.0

w

-1.72

w

2.28

w

5.0

w

4.3

w 5. 7 w

10.0

w

8.6

w 11

.4

w

15.0

w

12.9

w

17.1

w

20.0

w

17.2

w

22.8

w

.6

Vary

the

line voltage

from

108

VAC

(198VACJ

t:::>

132

VAC

C242VACJ and check

that

the

output

power

remains

within

the

limits

listed

above .

. 7

Select

50%

DUTY

CYCLE and check

the

peak

output

meter

accuracy

by comparing

its

indication

to

the

average

power

indication on

the

UPM-30.

POWER avg = (%

Duty

Cycle)

(Power

peak)

1-225P

Meter

UPM-30

Indication

Peak

Power

Average

Power

1.0

w

2.0W

5:o

w

7.0W

10.0

w

1-230P

Meter

Peak

Power

2.0W

5.0W

10.0

w

15.0

w

20.0W

Minimum Maximum

.43

w

.57

w

.86

w

1.14

w

2.15

w

2.85

w

3.0

w

4.0

w

4.3

w

5.7

w

UPM-30

Indication

Average

Power

Minimum Maximum

.86

w

1.14

w

2.15

w

2.85

w

4.3

w

5.7

w

6.5

w

8.5

w

8.6

w

11.4

w

15

Page 17

. 8

Select

20%

Duty

Cycle and

check

the

accuracy

of

the

output

meter

by

comparing

its

indication

to

the

UPM-30

indications

as

listed

below.

I-225P

Meter

UPM-30

Indication

Peak

Power

Average

Power

1.0

w

2.0W

5.0W

7.0W

10.0

w

I-230P

Meter

Peak

Power

2.0W

5.0W

10.0

w

15.0

w

20.0W

Minimum

Maximum

.18

w

.23

w

.34

w

.46

w

.86

w

1.14

w

1.20

w

1.60

w

1.72

w

2.28

w

UPM-30

Indication

Average

Power

Minimum

Maximum

.34

w

.46

w

.86

w

1.14

w

1.72

w

2.28

w

2.58

w

3.42

w

3.44

w

4.56

w

10.

CHECK

HEAD

MAXIMUM

TEMP

TRIP

. 1 Apply maximum

power

at 1 00%

duty

cycle

to

the

ultrasound

applicator

w1th

it

coupled

to

the

air

.

. 2 Allow

the

applicator

to

heat

until

the

HEAD

MAX

TEMP

LED

lights,

the

beeper

sounds

and

the

ultrasound

energy

is

removed

from

the

head

(the

output

meter

indication

will go

to

zeroJ .

. 3

After

the

head cools,

power

will be re-applied

to

the

head

(LED

goes

off

and

meter

mdication

returns

to

max1mumJ.

. 4

Let

the

head max.

temp

control

cycle on and

off 5 times

and

then

with

the

tempera-

ture

probe

check

the

surface

temperature

of

the

stainless

steel

head immediately

after

the

HEAD

MAX.

TEMP

LED

lights.

The

temperature

must

be

between

133

degrees

F.

and

14 7 degrees

F.

RLJ

c.::-

0

C'").

(\

,.

c.-

- -

..)

,-jj

u

~..._.,

.-:;;

e 1

Rb

R

IY

~

I

WT

C-rRL--

·g

11>

:::

16

Page 18

parts~

225P/230P

rear

panel

assembly

120V

\1

Page 19

Ref

Part

No.

1

70398

2

74723

3

70179

4

70316

5

71208

6

72167

7

73604

3

73605

9

70099

10

79118

11

73655

12

73571

13

79119

14

72970

15

73644

16

71368

17

71404

71407

18

72102

19

73436

73824

20

60768

21

73772

22

72970

23

70628

24

72435

parts

list

225P/230P

rear

panel

Description

Screw

4-40

x

3f4

Pan Hd Phil

Pit

Receptacle,

Power,

AC

Fuse

MOA

3f4

AMP

250V

Slo-Bio

Fuseholder

Plug

Button

NKL

5/16

Fedscrew

121

Screw

4-40 x 5/16

Rd

Phil

Pit

Holder

Cord

PP-40058-01

Spacer

Cord

Holder

PP-40058-01

Screw

6-32

x

3fs

Rd

Hd Phil

Pit

lnsul

TO-BERGQ

332307-FR54

Pnl

lnt

Port

Back

Pnt

Trnstr

045H11

Washer

Sholder

7721-7PPS

Nut

4-40

Kep

Pit

Stand-off

1-5/16

B-731 7 -632-0mf

Stand-off

6 x

3

/4

4538H-632-B12

PCB

OSC

Power

1-205 Assembled

PCB

OSC

Power

1-210 Assembled

Stand-off

6 x

1

/2

4534-632-B

12

PCB

Power

Supply

Assy,

IN-230P

PCB

Power

Supply

Assy,

IN-225P

Nut

6-32

ESNA

#22NM-62

Plated

Cover Shield

Assy

ln-225P/230P

Nut

4-40

Kep

Pit

Nut

4-40

ESNA

TRNSTR

045C11

18

Oty.

2

1 1

1

1

1

2

3

4

4

5

3

1

3

3

1

4

1

1

4

1

1

5

1

10

2

2

Page 20

parts -225P/230P

assembly

220V

19

Page 21

Ref

Part

No.

1

70398

2

73421

3

73885

4

73426

5

71208

6

72167

7

73604

8

73605

9

70099

10

79118

11

73655

12

73571

13

79119

14

72970

15

73644

16

71368

17

71404

71407

18

72102

19

73436

73824

20

60768

21

73772

22

72970

23

70628

24

72435

parts

list

225P/230P

rear panel

Description

Screw

4-40

x

3f4

Pan Phil

Pit

Rec

DBLfuse

Pnlcmp

83010280

Fuse

MDA

3fa

AMP

250V

Slcr.Bio

Fuse

Carrier

PNLCMP

83020130

Plug

Button

NKL

5/16

Fedscrew

121

Screw

4-40

x 5/1 6

Fedscrew

1 21

Holder Cord

PP-40058-01

Spacer

Cord Holder

PP-40058-01

Screw

6-32

x

3fe

Ad

Hd Phil

Pit

lnsul TO-BERGQ

332307~FR54

Pnl

lnt

Port

Back

Pnt

Trnstr

045H11

Washer

Sholder

7721-7PPS

Nut

4-40

Kep

Pit

Stand-off

1-5/16

B-7317-632

Omf

Stand-Off

6 x 3f4

4538H-632-B

1 2

PCB OSC Power 1-205 Assembled

(225Pl

PCB OSC Power 1-210 Assembled

(230Pl

Stand-Off

6 x

1

/2

4534-632-B12

PCB Power Supply

Assy

IN-230P

PCB Power Supply

Assy

IN-225P

Nut

6-32

ESNA

#22NM-62

Plated

Cover Shield

Assy

ln-225P/230P

Nut

4-40

Kep

Pit

Nut

4-40

ESNA

Trnstr

045C11

20

Qty.

2

1

2

2

2

3

4

4

5

3

1

1

3

3

1

4

1

1

4

1

1

5

1

10

2

2

Page 22

parts-

225P/230P

cabinet

assembly

120V.

21

Page 23

Ref

Part

No.

1

73663

73664

2

70628

3

21791

4

73784

5

73445

73760

6

70058

7

73529

8

21790

9

73468

73467

10

73585

11

74579

12

73607

13

73670

14

73606

15

72519

16

21733

17

73490

18

60768

19

70484

20

73587

21

70105

22

73657

23

79041

24

21024

25

73611

26

73188

27

21016

28

73783

29

79115

30

73474

31

70782

32

73593

33

71319

34

74582

745~

.c...

.......

c .

74-'1~'

~

q

\, j .../

parts

list

225P/230P

cabinet assembly

120V.

Description

Meter

IN-225P

MOUTEC

930368-107

Meter

IN-230P

MOUTEC

930368-106

Nut

4-40

ESNA

Screw

6-32 x 33/e

Pan Hd. Phil.

Plated

Timer

Deihl

30

Minute

w/cut

shaft

11 0 V

60

Hz

PCB

Control

BD

Assy,

I-230P

PCB

Control

BD

Assy.

I-225P

Screw

4-40

x

3fa

Round Hd. Phil.

Plated

Panel

lntelect

Port.

Front

Screw

6-32

x

3fa

Flat

Hd. Phil.

Plated

Decal

Front

Panel Overlay

IN-225P

Decal

Front

Panel Overlay

IN-230P

Bezel 11

''

Knob Wing

ELMA

026-5425

Knob Cap

ELMA

040-3615

Knob Cap

ELMA

040-5015

Knob Wing

ELMA

023-3426

Holder

LED

#HLMP01

03

Black

Nut

8-32

ESNA

Transformer

A41-80-28

Signal

Nut

6-32

ESNA

Filter

Line

3A/250V

60Hz

Bracket

Mounting

Side, Right

Washer

# 1 0

Flat

Plated

Panel,

Bottom

lntelect

Portable

painted

Jack,

Banana

Smith 1 508-1

03

Black

Nut

8-32

Hex,

S/S

Holder

Applicator

U S

Portable

Screw

8-32

x

3f4

Screw

8-32 x 3fs

Handle

ELMA

66-330-14,

cut

11.6"

Foot, Black Rubber

M-195

13/16 X 25/32

Support

Case

ELMA

63-140

Screw

8-32 x 5fs

Bracket

Mounting

Side,

Left

Screw

6-32

x

114

Applicator

Ultrasound,

Adjustable

5 CM2

Applicator

Ultrasound,

Adjustable

10

CM2

Yi ~ ,.

. '

I-3

.,

/,

")

Jt'-~r

22

Oty.

1

1

2

5

1

1

1

6

1

2

1

1

1

1

1

1

1

2

10

1

3

1

1

2

1

1

2

1

4

4

1

4

1

2

1

2

1

1

Page 24

parts -225P/230P

cabinet

assembly

220V

23

Page 25

Ref

Part

no.

1

73663

73664

2

70628

3

21791

4

73785

5

73445

73760

6

70058

7

73529

8

21790

9

73877

73876

10

74585

11

74579

12

73607

13

73670

14

73606

15

72519

16

21733

17

73490

18

60768

19

70496

20

73587

21

70105

22

73657

23

79041

24

21024

25

73611

26

73188

27

21016

28

73783

29

79115

30

73474

31

70782

32

73593

33

71319

34

74582

74590

parts

list

225P/230P

cabinet assembly

220V.

Description

Meter

U S

Portable

1-225

Meter

U S

Portable

1-230

Nut

4-40

ESNA

Screw,

6-32 x 3fs

Timer, Diehl

30

min.

cut

shaft

PCB

Control

BD Assy.

I-230P

PCB

Control

BD Assy.

I-225P

Screw,

4-40

x

3/e

Panel, Int.

Port

Frt.

Screw

6-32 x 3fs

Decal.

Frt.

Panel

225P

50

Hz Timer

Decal,

Frt.

Panel

230P

50

Hz

Timer

Bezel

11"

Knob Wing

ELMA

026-5425

Knob Cap

ELMA

040-3615

. Knob Cap

ELMA

040-5015

Knob Wing

ELMA

023-3426

Holder

LED

#HLMP01

03

BLK

Nut

8-32

Esna

Trsnfmr

A41-80-28

Signal

Nut

6-32

Esna

#22NM-62

Plated

Filter

Line

2.5A/250V

Schaffner

Brkt

Mtg

Side Box

Port

Right

Washer

# 1 0

Flat

Plated

Pnl

lnt

Port

Bottom

Pnt

Jack

Banana Blk

Smith 1 508-1

03

Nut

8-32

Hex SS

Holder Appl U S

Port

Screw

8-32

x

3f4

Screw

8-32

x

3fs

Handle

66-330-14

Elm a

Cut

11 . 6

Feet

Blk Rub M-1

95

13/16 x 25/32

Support

Case

63-140

Elma

Screw

8-32

x

5fs

Brkt

Mtg

Side Box

Port

Left

Screw

6-32

x 1f4

Applicator

Ultrasound,

Adjustable

8

iMP

10

Applicator

Ultrasound,

Adjustable

1:88fel•

":5'

24

Qty.

1

1

2

5

1

1

1

6

1

2

1

1

1

1

1

1

1

2

6

1

6

1

1

2

1

1

2

1

4

4

1

4

1

2

1

2

1

1

Page 26

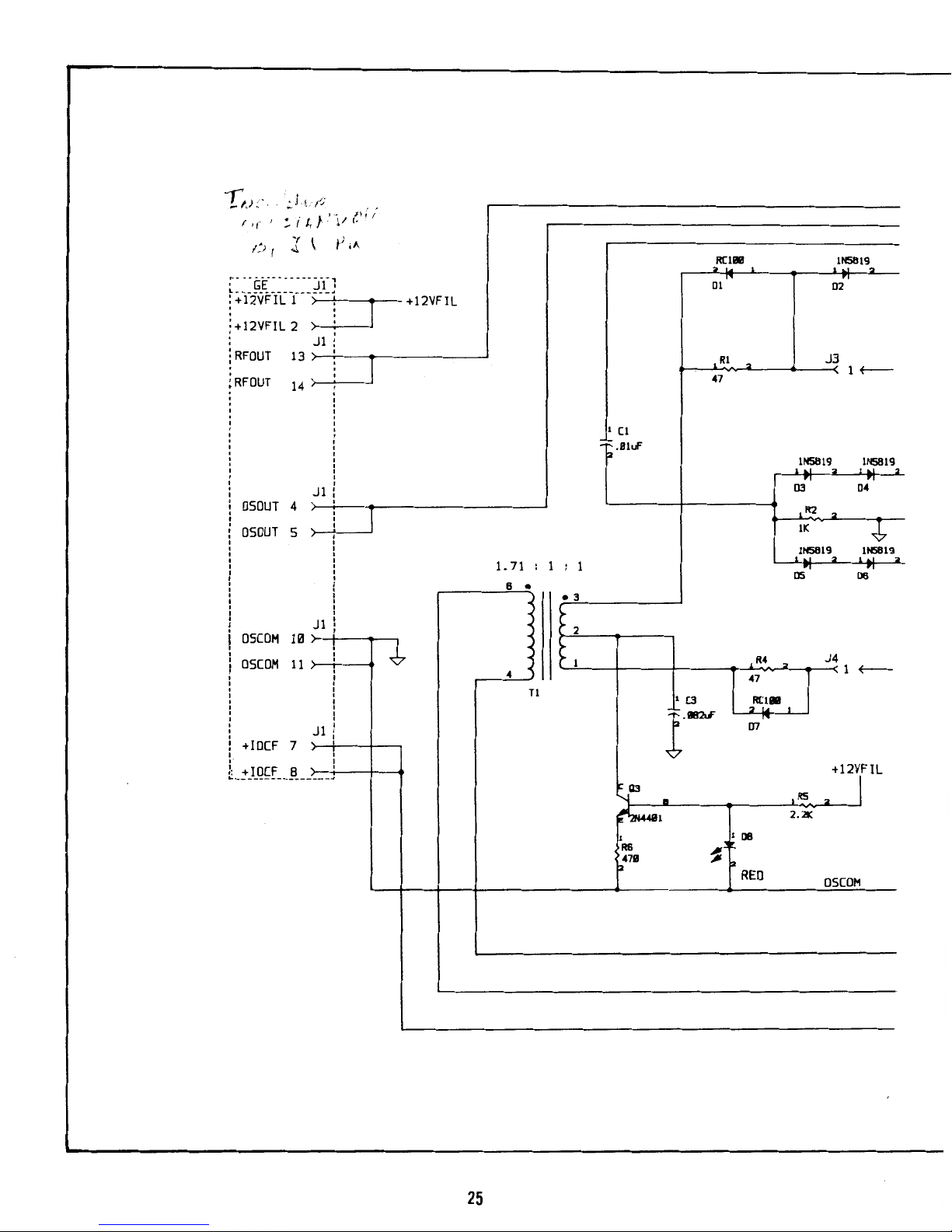

;) t /;:

r

1,..

'

~

i

lr

},

'-~~~

{.l!

1

I

I

I

/)

r

GE

+i-:2vF-rcc-

+12VFIL 2

RFOUT

13

RFOUT

14

OSOUT

4

DSOUT

5

OSCDM

1111

DSCDM

11

~

+IDCF 7

I

\

xu

: l

J1

:

I

.

.

I

J1

J1

J1

L~_I_~C::f

__

!l

__

_

---~

t)

•"

J

+12VFIL

1.

1 Cl

.li!luf

2

1.

71

:

1 : 1

6

•

• 3

2

I

It

T1

~Q3

'-4"

~I

1

R6

'p.471!

25

RCIIllll

IN5819

2

2

01

02

J3

Rl

2

1~

47

1

1N5819

2

IN581\

Y"

03

04

1R2

2

IK

.&

IN5819,

IN5819,

--,.

05

06

R4

.,

J4

1

f---

47

1(3

2RC.,~Illll

r·EU

~

07

..

RS

.,

+12V,FIL

2.21(

1[J6

~

FRE!l

OS

COM

Page 27

~j2·--:

-

-------------------------------------------------------------;r---::=:1:

RFOUT

L--------':'---l

2 i

RFOUT

+IDCF

-

J3

3

~·

5(11

31JB-lliJIIIJPF

2

~(4

2

'

J3

1 : 1

:

1

3

4

..

--1..-

>--

cp,

2

>-

828PF

1

6

05(011

•

•

T2

J4

2

iu

3

J4

+IOCF

l

(2

::-_33uf

p

-

r-

----

-:-

~

3 l

05(011

-

-----:-~

4:

05COI1

l

(8

!

______

.,!

;;: ~ .33uf

l

l

~l'

L3

R7

ta~

:: 39lif

"

p

L1

II====

2

l:Mi

26

05(011

I

3

•I.A.

------------

------------

T3

5 : 5111

..

..

•

4

6

R3

_a_

271

~(7

__,.

r-

r---1..-t'

DESIGNATORS

LAST

USED

5PAa:

~

R7

(8

(5

<Cali

Q3

T3

DB

L3

J3

ELECTRICAL

SCHEMATIC

P.C. BOARD ASSY., OSC. POWER,

5CM

2

E.S.

71404-D

Page 28

L~~~~~~~~~~~

:

+12VFIL

1

'

:

+12VFIL

2

iRFOUT

'

!RFOUT

'

I

I

13

14

:

OSOUT

4

I

'

:

OSOUT

5

I

I

I

I

:

I

I

I

I

I

I

I

I

I

I

:

OSCOM

10

I

I

i

OSCOM

11

I

I

I

I

I

I

I

I

I

I

I

I

: +IDCF 7

I

I

: +IOCF 8

~I(J

:

1

J1

'

J1

Jl

J1

:

I

~-------------

---~

J

+12VFIL

~

27

1.

71

: 1 :

1

6

•

• 3

2

I

4

Tl

'I

'•

-

:--;,;_'-;

~

:,

<

c

.....

.....-:

,~

v·)

'"

ftCI8fll

INS819

2

-,.

01

02

,IU

.,

J3

47

1~

1

(I

i2

.IJiuF

INS819,_

INS819

2

o{

04

(~~)

~

~

INS819

2

INS819

2

05 00

R4

2

J4

1

~

47

I

(3

,.ftCI8fll

l.l&r

07,...

'~

"--.103

R

RS

2

+12V,FIL

r;44111

2.2K

1

1[)8

R6

~

p471J

p

REO

OSCOM

Page 29

~"j:f"

------------------------------------------------------------~~~·~1

RFOUT

.

:

'~

+IDCF

-~~-·

---<

....

J3

3

-1

--llall'f

11

2

~42

t'.,.

J3

1 : 1

:

1

3 4

~L

2

.NhF

____1__..

_~_Cft

2

~

I

6

OS

COM

•

•

T2

J4

2

-1"

3

'

J4

+IDCF

l(2

~:a·33<*

-

l

(8

2

.33<*

ll

l

R7

li'

L3

~~

::

2tUf

r''

...

,.

'

•.

L1

.~,.

<Uf

I

3

•

l.A...

------------

-----------

.

4

R3

.~

271

~(7

,;

F

~II!IB'F

~2

•

....a....

=

4lliF""

'

OSCOH

T3

3

:

511.1

•

6

.__-----;~

2

RFOUT

·-·---:-~

3

OSCOM

-·····t~~-

OSCOM

~

.

j

DESIGNATORS

LAST

USED

SI'IIIE

R7

(8

Q3

T3

011

L3

J3

ELECTRICAL SCHEMATIC

28

P.C. BOARD ASSY., OSC POWER,

10CM2

E.S.

71407-D

Page 30

f

\I

'~~

f

' f -· f

l

-.

/

I

';-

./.

( ; l

'.

"',

'.:-·

:ICON

IIICH

S.lK

}

{

'i

'

...

\

~

''

~~

RSS

S.lK

29

~c

v

,..,

+45

R3S

llliiK

(6

l.llllll.F

lN~l~B

I

CR'I

Page 31

-

-..--"''""'--""-·"--

-.:

~

'·--

-

1

C8

'];.

lllSLF

.&

.,

·.,"""

'--

~~1N4743

l

Cft21

p_

Rl

471

l

.33RlV

+12Y

2

Ll

fa

1'1111745

"a.s

l

-,....,

,

-~

RSl

PS.liC

b

liC

~

J

C4

llU

RS

,

IOR2W

I

taRS2

liiC

l

+12 VtLTS

U5QJT

+VOSC:

OSC:CII

Rf'llJT

~Rll

491(9

l

~

._

____________

_.

____

+-;'~204~-~~~~~

,·+i~----~,u

[2R2S

\

!lit..~

)

~

734551

L2

15611U1

._,~INS359

-:;;

CR4

1

111::

""'·,"'-

/ 1

CR8

L-

____

_._R,..,2"'7

_.

2

L-___.

2R29

l

7.SK

_._~__,_15"'-1

V

EB

,..!!_f-

-f---~16~

+SV

CB

~

l

R32

!all(

--~~2~

IN+

CA

JL

j!l

_.__,_I~

IN-

ER

!-cl!.!.l

__

.._.,L...,R3v7.__J._....___..,4V.ill...c;:;,_,...gs~

.----"9~

CIM'

GNO

~

IIIC

!(',.....,

N/(

..!_

RT

CL-

~

-+---'-7

CT

Cl+

~

ua524

l

U4

lt41

~SIIC

~(11

l.IIILI'

2IC

+ l

Cll

IlaaE

ELECTRICAL

SCHEMATIC

~

~

~

;--

~

~

~

:--

!"r-

F.-

\-!.-

~

~

~

=

1401

1 N

L.{t4'6

b•

C£

t-1~

PWR SUPPLY.

INT.

SMP

50W

5CM

S.

73824-C

30

Page 32

~

lNTENSlTY

-4-

11m'

:T[

.£

q

f--.;

-+12

YO..TS

r--;

--:

ClJIDI

___,

lOUT

l'

OV!R

TDP

=

t.:N

:;('f'

s

'

+45

~2

ACI

2A.4

~

.

--~·

J2

FH=

":~IN5!59

l:a

.Ia

Cl

~

C2

=

t

C:!l

•

CJt2

2CIIN

r-

lltl

1157

~

1

-

DC

f

22IU'

fa

22IU'

~.ll.f'

&Nl

1

AC2

1'12

2.

I

t·

~

Ia

IlS

23

J

TL'.

IJIIIC

2IC

,laS

2

1

8

7

IIIII

2.

5

IK

1

U2B

1-uase

1

1

I.

1

R12

111:!1

R14

RIS

Ia

lUII

!:aS.lK

~S.lK

!a

IlK

p211K

1

IlK

1119

1

p21C

Ia

(17

'¢

l:aR54

.'\7

.¢.

l.lll.f'

t

11121

2

lK

2

R18

'¢

1

8.21C

l

\

'¢

51K

1'124

..

1

;7,

·~

~

113

lK

i

/1

}.~~

12

(8

R25,.

1

..

1~

l~

I

lK

U2R

...

~

"l..M!!i8

1

'¢

l

+12V

R55

'¢

!:aS.lK

il

-

t-t.

7

d

1t

"'C!!58

1

·'

;

+12V

1

R2tl

31

1

211K

1131

~-94K

2

....

1

:!1

I.

LIQ:i8

l:aR:!I:!I

~~

SKll

2

R:!l5

1

1

1-

Ql,

..

\(::1

,( \-c /;, y !

(.

!

,

l•Y

.¢.

211M1411

l(RCJ

2R:!Il ..--

lK

~l;:s

--

Page 33

+12¥

2

~

~(12211

PRS2

,07

I.

21l53

l

IK

..,~IN4743

"¢'

• ~-Clt21

l

2

+12

Yll.TS

,.A.

1.----

Ul

ta,u

471

l

.DUll

ll

,.,.

12111'745

,CIIIII

~

(4

liU

"¢'

Rll

2

J

..

IOR2W

p

~

f.IR23

,510

-2~

1

-

L3

IMI

(9

l.lll'

:

U5CliT

+¥05C

OSClJI

II'OJT

13

1m

4CJC9

l

~

._

________

~----~2~~-~ll~~·._

____

~LJ2

fllt26

31o.rli

fi73455~

L2

ISIUI

i:allm5l

IK

' l

Clllll

14V

'<t;;.'

(]Uti

l

,~

7

2

.___

___

~

"¢'

L._

__

..J.......:zK.,.,_iL-~

l

"¢'

7.51C

•'

(II

-

L..iiL2'104

_

_._~...!15~

v

fl

~

r-

--=221_.......__,1~11

+SV

C11

rJ..L

----+--'2t.....l

IN+

CA

~

..----.._...._1--l

l,._

ER

u _.llm

.&c

.---...!!'-f

CCIII'

Iiiii

~

I.

NIC...!...

In

CL-

~

-+-~~-..:.

7

-fCT

CL+

~

1JG524

~-

...

1M

IMl

lt1/t.

~lK

<~~7

lacu

l

..

lll'

r---

i--

r---

r--

-

lr--

-

II-I

~

"'--"--

UCN

"''.~i.~·,"

,~":

·,·.,~.\ ( \,J~_·:r

>.""'!

:·

\;

---:_:~

ELECTRICAL SCHEMATIC, PCB

PWR SUPPLY

INT.

SMP

SOW

10CM

573438-D

32

Page 34

l

'\'~

\ .

33

Page 35

l

(2

--'

liLIF

p

'""'<II,

CRl

1cs

~

l~

l

lfOl

1

LE02

~~

~

~

~

[;]

X

.

-

I>

, ...

,<II

,CRS

l

(9

1

(13

lBl~

I~

+12

YIJ..T5

,.n_

l

(QIIQI

llJTY

OYEA

TEll'

INTEIISI

[llJT

;-

~

J·

r£

'

,.,.,

;z.;;

Rl3

l

~>'"

l11331.f'

2

-LI<l5ll

U5ll

CR3

~7

l

RlS

lN.l48

~o'"

CRS

Rl7 •

[IIJII(

l

6

Rl9

7

2"!/f.

~~:,

USB

l

;L.

R22

1

CUI

lH

p6.8K

lliLIF

-¢-

~

1

'

~

34

'

ce

l'IILIF

..

--------

I

lPTJ(Jrfl..

:

'[P

I l C

: !!!L.LjHC

I

I

__

_j

l

________

Ql

4111

l

l

2

1!ll-

.

~

-

iW!II

ELECTRICAL

SCHEMATIC,

PCB,

CONTROL

INT

PORT.

US

SCM

S.

73760-B

Page 36

METER

S!G

!NTEHSITY

R25

llll<l'll

35

Page 37

l

(2

lillf'

1N4148

01

CRl

'

(6

EJ'

JCS

4--1:

-r- .ll56Uf

/3

lB3Y

[~1

~~

J

1

LEOt

1

Lf02

~

~0 ~ ~EN

'

RlS

[;[]

p[l[]

21N-4148

~>'"

X

.

CRS

-

Rl7

>

'"""

~

lN<l<B

'

6

Rl9

7

l

(R6

3K

5

~·~

USB

1

R2l >

l

(9

l

R22

1

Clll

'"

l

Cl3

I~

1>6.81(

l'u

l"'~

7

7

36

•12

V(LT5

P-

(

OOTY

CYCLE

OVER

TEll'

INTENSITY

lllJT

~

lN-*148

CR3

'

(8

l'Oillf'

r--------

l

Of'TIOIR.

I

BZl

I

2

+

I l

(

3

-

I

N/(

•

NC

I

I

CHBS

L

________

,

v'"g,

..

,

l

l

~ill-

2

~~

~

I

I

I

I

__

J

ELECTRICAL

SCHEMATIC. PCB.

CONTROL

INT

PORT.

US

10CM

S.

73445-B

Page 38

TO

P2

OF

CONTROL

BOARD

IJ~

§~~~~~~~~~~~~~

t

~~---------------------_-_-_-

__

-_-_-_-_-

7

4588

PN...

FNT

IN225P

ASSY.

c

--~

~ @ .-~-·~-1~

"~

••

'"'

•=m•

'"'·

0

I

j

~-

73528

HARN

INT

POR1

METER

I

I

BK

leGAl

3'

I

I

I

73-44'5

PCB

tNT

~T

CTRL

ASSY.

<Ct>o!TRD....

BOARD)

T2617

22-18

<71576 TE.IiM

F"S'TON'S

ME

USED

ON

ALL

TJMER

CONNECTIONS

AND ~ ALL

LINE

r(L

TER

CCNNECTIIJNS.l

I

I I

)/

"/(

DETAIL

'A'

TRANSFORH(R

IS

SHO'w'N

ON

IT'S

SIIIf

TO

Sl-IO'w'

\/HUNG

CONN[CTJON 1,...-!JlMATIDN

LINE FILTER

\

~

I •

j}<

~

60768

NUT

6-32

ESNA

122NM-62

PLATED

--.r-

____

C£;_

~

•u'"'"

PN£L

~

37

SEE

DETAk

"A'

Page 39

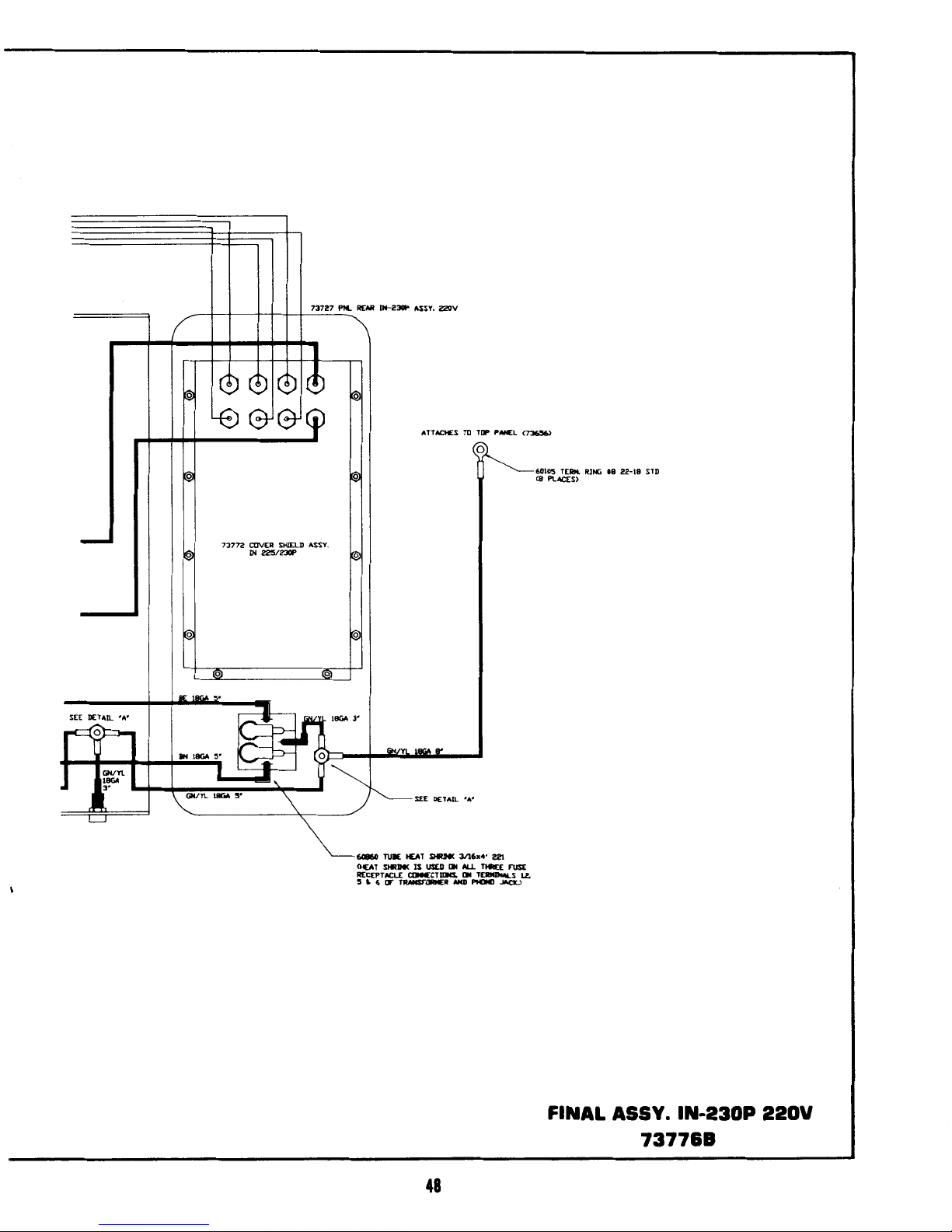

7377Z

COVER

SHIELD

ASSY.

IN

225/~

0

ATTACHES

TO

ToP PANEL

<73656)

0

60860 TUIE

HEAT

SHRINC.

3/16x4'

221

<HEAT

SHRINK

IS

US0

DH

ALL

T-E

rusE

RECEPTACLE

CliNNECTlllNS.

ON

TEaMJNALS

8,!L

5 ~ 6

or

TRANSrOIIIIER

AND

I'IOil

JACI<)

38

6010'5

TERI'4

RlNG

18

22-18

STD

<8

PLACES)

FINAL

ASSY.

IN-225P

120V

73775

Page 40

,----------------

1

I

PCB

llJI1IIL

Ill

A55Y.

IN-ZISI'

I

I

1'2

I

I

I

I

I

I

~---------------------~

Ofl55!5

GICl

PN

7 4588

PNL

FRONT

IN-

225P

RSSY.

J2

I

4