Chatillon DFS calibration

Rev April 2006

Calibrating Your Gauge

Section Contents |

|

|

Page |

Accessing Embedded Procedure ..................... |

2 |

Calibrating Your Gauge .................................... |

3 |

About DFS Series Calibration........................... |

3 |

Select Gauge Model ......................................... |

3 |

Select Calibration Units .................................... |

4 |

Select Calibration Midpoint Value..................... |

4 |

Stabilize the Gauge .......................................... |

4 |

Compression Calibration |

|

Attaching to Compression Fixture ............... |

4 |

“Flip Display”................................................ |

4 |

Exercising Loadcell...................................... |

4 |

Apply Zero Compression Load .................... |

5 |

Apply Mid-Scale Compression Load ........... |

5 |

Error Checking............................................. |

5 |

Apply Full Scale Compression Load............ |

5 |

Verify Compression Calibration ................... |

6 |

Zero Verification........................................... |

6 |

Tension Calibration |

|

Attaching to Tension Fixture ........................ |

6 |

“Flip Display”................................................ |

6 |

Exercise Loadcell ........................................ |

6 |

Apply Zero Tension Load............................. |

7 |

Apply Mid-Scale Tension Load .................... |

7 |

Apply Full-Scale Tension Load .................... |

8 |

Zero Verification........................................... |

8 |

Verify Tension Calibration ............................ |

8 |

Calibrate Analog Output ................................... |

9 |

Save Calibration ............................................... |

9 |

IMPORTANT

The sensor used in your DF Series gauge is temperature sensitive. The gauge should be turned ON and allowed to acclimate to ambient temperature before normal use and before being calibrated.

A 7 minute “warm-up” period is recommended.

chatillon.fl-lar@ametek.com |

- 1 - |

www.chatillon.com |

Rev April 2006

Calibrating Your Gauge

IMPORTANT

Gauge calibration should be performed by an authorized Chatillon Distributor or by AMETEK if you require a Certificate of Calibration. Organizations not recognized by AMETEK as Chatillon Distributors are not authorized to perform calibrations on these precision instruments. Visit www.chatillon.com for a listing of authorized Distributors.

Any changes made to the gauge using the calibration procedure voids the Certificate of Calibration that accompanied your DF Series force gauge. Customers electing to calibrate their gauge do so at their risk and with the understanding that they are effecting the performance of the gauge.

The Calibration Procedure described in the following pages will permit a user to calibrate and re-characterize the loadcell or sensor being used. Exercise extreme caution when calibrating any precision instrument.

Accessing Calibration Procedure

The DFS Series calibration procedure is embedded in the instrument’s firmware.

To access, you will need to depress multiple keys in a prescribed order. This procedure is designed to prevent unauthorized users from recalibrating or recharacterizing the sensor used with the gauge.

The customer is responsible for ensuring that only authorized personnel have access to the calibration procedure within the gauge firmware.

To enable the DFS Series calibration procedure, begin with the gauge power turned OFF.

Press the power ON key. Allow the gauge’s sensor to warm-up for a period of 7 minutes.

When the Title Display is shown, press the F2 key and then the F1 key.

Model |

DFS-100 |

Rev. No. |

1.00 |

Rev Date |

dd/mm/yyyy |

|

Chatillon |

T |

www.chatillon.com |

C |

|

|

|

|

|

|

Model |

DFS-100 |

|

|||

Rev. No. |

1.00 |

|

|||

Rev Date |

dd/mm/yyyy |

|

|||

|

Chatillon |

T |

www.chatillon.com |

C |

Gauge Service

The gauge is now in Service Mode. Select ENTER to begin the calibration procedure.

HELP

You must complete the entire calibration procedure in order for the new calibration to take effect.

HELP

You may abort the calibration routine at any time by pressing the HOME key.

>Calibrate Diagnostics

T

C DIAG

C DIAG

www.chatillon.com |

- 2 - |

chatillon.fl-lar@ametek.com |

Rev April 2006

Calibrating Your Gauge

Gauge calibration should be performed by an authorized Chatillon Distributor or by AMETEK if you require a Certificate of Calibration.

You may calibrate the gauge or verify the gauge calibration following this Gauge Calibration procedure.

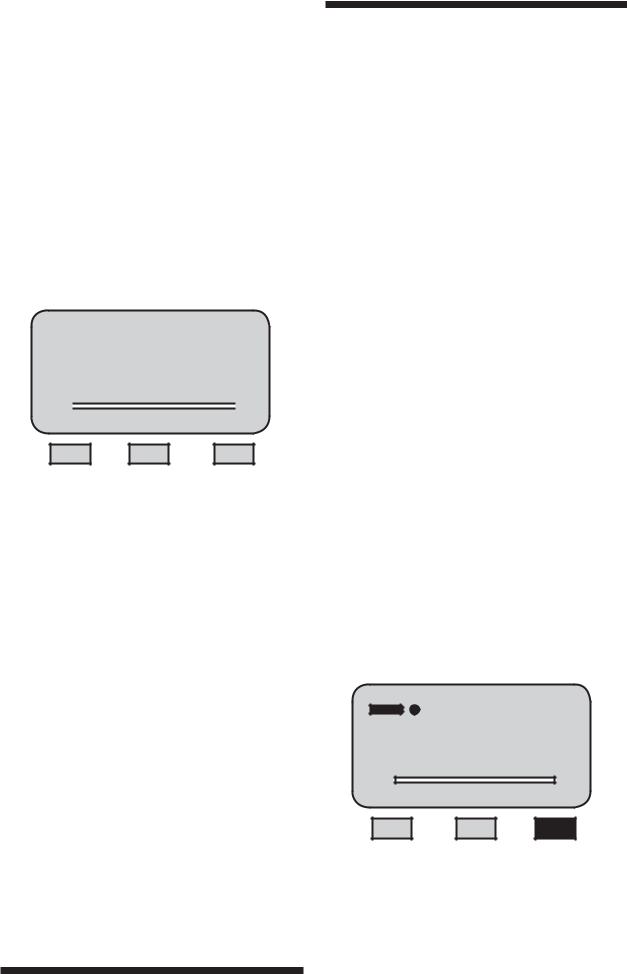

At the Gauge Service main menu, select Calibrate. Select Enter.

Gauge Service

>Calibrate Diagnostics

T

C

C

DIAG

Calibrating Your Gauge

About DFS Series Calibration

The DFS Series gauge requires a two point calibration in both Compression and Tension directions. Masses should be used that are CLASS 5 or better per ASTM E617. Masses should be calibrated to local gravity.

Select Gauge Model

Your DFS Series gauge will automatically scale itself based on the calibration and the gauge model selected. You must specify the Gauge Model prior to performing the calibration so the scaling is accurate.

Select F1 (Change) until the display indicates the gauge model you are calibrating. The gauge model is equivalent to the load capacity of the gauge in LBF. The available models are:

DFS-250G

DFS-002

DFS-010

DFS-025

DFS-050

DFS-100

DFS-200

DFS-500

DFS-1000 (Not used with integral loadcell models)

Select Gauge Model |

|

DFS-050 |

|

Enter to select |

|

T |

C |

Change |

Keep |

Select F3 (Keep) or ENTER to accept the displayed gauge mode.

chatillon.fl-lar@ametek.com |

- 3 - |

www.chatillon.com |

Loading...

Loading...