CHART MVE TS Quick Reference Manual

i

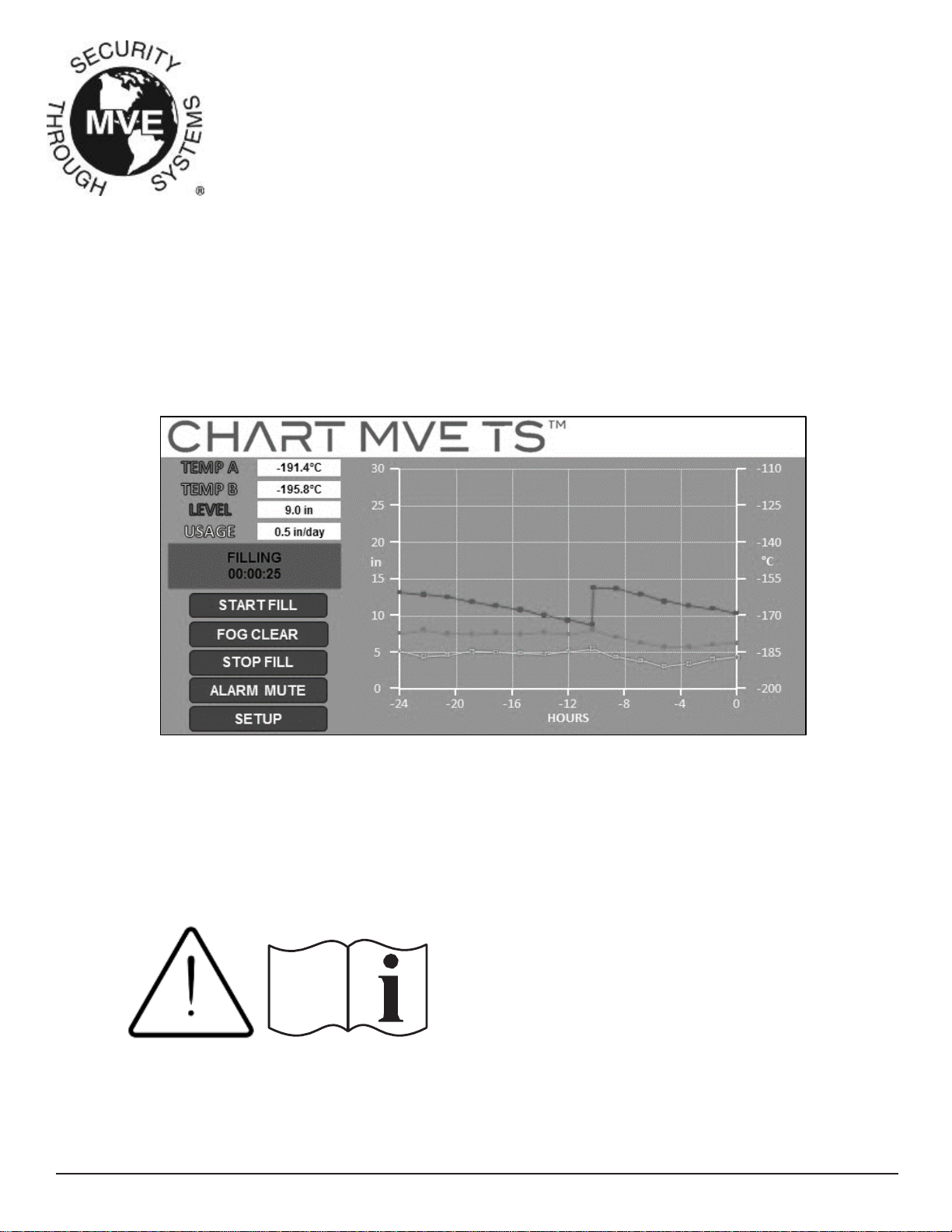

MVE TS Controller (Touch Screen)

Quick Reference

G

uide

MVE TS Quick Reference Guide

1 — 21081123 A

Table of Contents

Product Identification

Display / Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Bottom Panel / Electrical / Physical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dewar Plumbing Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Adjusting Temperature Alarm Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Adjusting Inlet Temperature Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Adjusting Liquid Level & Liquid Level Alarm Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

High Level Alarm Setting

High Level Setting

Low Level Setting

Low Level Alarm Setting

Adjusting Display and Output Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Password and Security Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Alarms and Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

MVE TS Quick Reference Guide

2 — 21081123 A

3

4

1

5

6

Table 1: Front Panel Identification

Display

6” touchscreen, backlight

Freezer Status

Displays “IDLE”, “BYPASSING”, or “FILLING” based on the

current freezer status

START FILL

Key

Used to manually initiate a fill

FOG CLEAR

To clear fog when opening the lid or to perform a manual fill.

Momentary circuit

STOP FILL

Key

Used to manually terminate a fill – Disables Auto Fill for 30

minutes

ALARM

MUTE Key

Used to silence the audible alarm. Will reset the latching alarm

once it has been corrected

SETUP Key

Used to access Setup Menus and parameters

Trend Graph

Adjustable graph of historical level and temperature data.

Visual X,Y Graph parameters adjustable in days, temperature,

and level ranges.

MVE TS Quick Reference Guide

3 — 21081123 A

.

1

Temp A Port

Connection for Temp A probe

2

Temp B Port

Connection for Temp B probe

3

Serial Number Barcode

Chart TS serial number written below barcode

4

30 VDC Power Input

Main power supply connection

5

Serial Port

RJ-45 connection for Serial/COM

6

Ethernet Port

Ethernet connection for networking

7

Global/Discrete Alarm

Contacts

15 pin alarm output. Output connection for the remote

monitoring of alarm conditions.

8

Wire Harness Connection

12-pin wire harness connection to plumbing assembly, lid

switch, and battery backup

9

Level Connection

Level signal input. Clear, vinyl tube connects to hose barb

1 2 3 4 5

6 7 8

9

4 — 21081123 A

MVE TS Quick Reference Guide

Dewar Plumbing Connections

Connect a transfer line (included with freezer) from an LN2 supply tank to the fill connection at the rear of the

freezer. Optimum supply tank pressure is 22 to 35 psi (1.5 to 2.4 bar). Although the plumbing assembly has a

50 psi (3.45 bar) pressure relief device, it is recommended that the supply tank be pressurized below 35 psi

(2.4 bar) to reduce the LN2 “flash-off” rate during filling and to maximize the cryogenic valve life. The supply

line can be insulated to minimize LN2 transfer losses. After the transfer hose is securely coupled to the freezer

and supply tank, ensure all connections are leak free by opening the valve of the LN2 supply tank and apply a

soap and water solution to each field joint. You should not see bubbles forming at any joint. Wipe away excess

soap and water when finished. Before removing the transfer hose, ensure the LN2 supply tank valve is closed.

Slowly and carefully loosen the transfer hose connection to vent any remaining pressure in the line before

disconnecting the hose.

5 — 21081123 A

MVE TS Quick Reference Guide

A & B and Inlet (Hot Gas Bypass)

The following section describes how to adjust temperature alarm settings. At any time

during the following procedure, the user may exit the menu by pressing the “EXIT” button

to return to the “monitor” display mode. After 60 seconds of inactivity, the controller will

automatically return to the “monitor” display mode.

NOTE: Security Level 2 or higher is required to adjust temperature settings (see

“Password and Security Setup” section for details).

To exit any menu screen and return to the previous menu, press “<” key.

1. Press “Setup”

Controller will prompt for a password. Type in the password using the number pad that appears and

press “Enter”.

2. Press “Temperature Settings”

6 — 21081123 A

MVE TS Quick Reference Guide

3. Press “Temperature A Settings”

NOTE: To access Temperature B Settings select “Temperature B Settings” instead.

4. Press “ENABLED” or “DISABLED” next to “Temperature Probe A”

This will enable or disable the selected temperature probe. Pressing “ENABLED” will change the

probe status to “DISABLED” and pressing “DISABLED” will change the probe status to “ENABLED”.

Loading...

Loading...