Champion Pumps CPS3, CPS3VLT, CPSP3 User Manual

4

Pump operates but

delivers little or no

water

1. Plugged impeller

2. Check valve

installed backwards, or

faulty

3. Pump air locked

1. Clean out impeller

2. Reverse position of

check valve, or replace

3. Drill 1/8” hole in

discharge line between

pump and check valve

Product Warranty

Date of Manufacture and Warranty Tag is on pump cord.

LIMITED WARRANTY: We warrant to our immediate customer and to the

ultimate consumer that products of our manufacture will be free of defects

in material and workmanship under normal use and service for one year

(12 months) from the date of installation, or 18 months from the date of

manufacture, which ever comes first. We will repair or replace, at our

option, to the original purchaser any part or parts of our product found

upon our examination to be defective. Please call Champion Pump

Company, Inc. (419-281-4500) for instructions. Be prepared to provide

the model number, the date code and/or serial number and proof of the

date installed when exercising this warranty. Warranty tag (Required) is on

the pump power cord. All transportation charges on products or parts

submitted for repair or replacement must be paid by purchaser. This

limited warranty does not cover products which have been damaged as a

result of accident, abuse, misuse, neglect, improper installation, improper

maintenance, or failure to operate in accordance with Champion Pump

Company, Inc. written instructions. UNDER NO CIRCUMSTANCES WILL WE

BE RESPONSIBLE FOR ANY OTHER DIRECT OR CONSEQUENTIAL

DAMAGES, INCLUDING BUT NOT LIMITED TO LOST PROFITS, LOST

INCOME, LABOR CHARGES, DELAYS IN PRODUCTION, IDLE PRODUCTION

WHICH DAMAGES ARE CAUSED BY ANY DEFECTS IN MATERIAL AND/OR

WORKMANSHIP AND/OR DAMAGE OR DELAYS IN SHIPMENT. THIS

WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER EXPRESS OR IMPLIED

WARRANTY, INCLUDING ANY WARRANTY OF MERCHANTABILTIY OR

FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow

limitations on how long an implied warranty lasts, or do not allow the

exclusions or limitations of incidental or consequential damages, so the

above limitations might not apply to you. This limited warranty gives you

legal rights, and you may also have other legal rights which vary from state

to state.

12-0010-0000 www.championpump.com

4 05/12

Installation and Operation Manual

Model CPS3

Submersible Sump/Effluent Pump

Thank you for purchasing this CHAMPION PUMP! The CPS3 is

a high quality, energy efficient, heavy duty cast iron 1/3 HP sump/effluent

pump. We back these Champion products with Champion service and a

Champion attitude. Please read, save, and follow these instructions to

ensure Champion performance.

BEFORE OPERATION – Important Product and

Safety Information – WARNINGS – Personal Injury

and/or property damage could result if not adhered to.

! Risk of Electric Shock – Fatal electric shock could occur. Always

disconnect the power source before attempting to install, service,

relocate, or check the pump. Never touch pump, pump motor,

water, or discharge piping when pump is connected to electrical

power. Never enter a wet or flooded area, basement, basin, etc.

that is in contact with the pump or electrical circuit before power

supply has been disconnected.

! Pump has not been investigated for use in swimming pool areas

or any area that might reasonably expect aquatic, animal, or

human entrance. Precautions should be taken to prevent such

entrance during use.

! Connect only to a properly grounded, grounding type receptacle.

Use of a ground fault circuit interrupter (GFCI) is required for

maximum safety.

! All wiring must be performed by qualified electrician in

accordance with all local and national electric code.

! When power source or supply is turned off (in open position) a

lock and tag out should be used to prevent accidental power

application or activation.

! Do not use extension cord or cut off grounding pin. Should be

installed on separate 15 AMP circuit breaker.

! Use only with a properly sized (input AMPS, volts, HP) motor

controller.

! Do not use to pump flammable/explosive liquids such as

gasoline, fuel oil, kerosene, and /or chemicals, salt water, etc.

! Do not use pump in an explosive atmosphere or classified as

hazardous per NEC, ANSI/NFPA 70.

! Make sure pump is on hard level bottom in sump, do not set

directly on earth, gravel, or other debris. This could cause

excessive wear or possible jamming and flooding.

! Make sure pump is secure in basin and piping is firmly supported

so that pump cannot move, not allowing liquid level switch to

interfere with basin wall or other obstacle preventing proper

operation. Flooding or overheating could occur if not prevented.

!

CHAMPION PUMP COMPANY Phone: 419-281-4500

1102 Myers Pkwy Ashland, OH 44805 Fax: 419-616-1100

1

2

! All basins or sumps must have covers and installed to meet health

and plumbing codes with proper sealing and venting. Before

opening or entering sump safety precautions per OSHA

requirements should be strictly adhered.

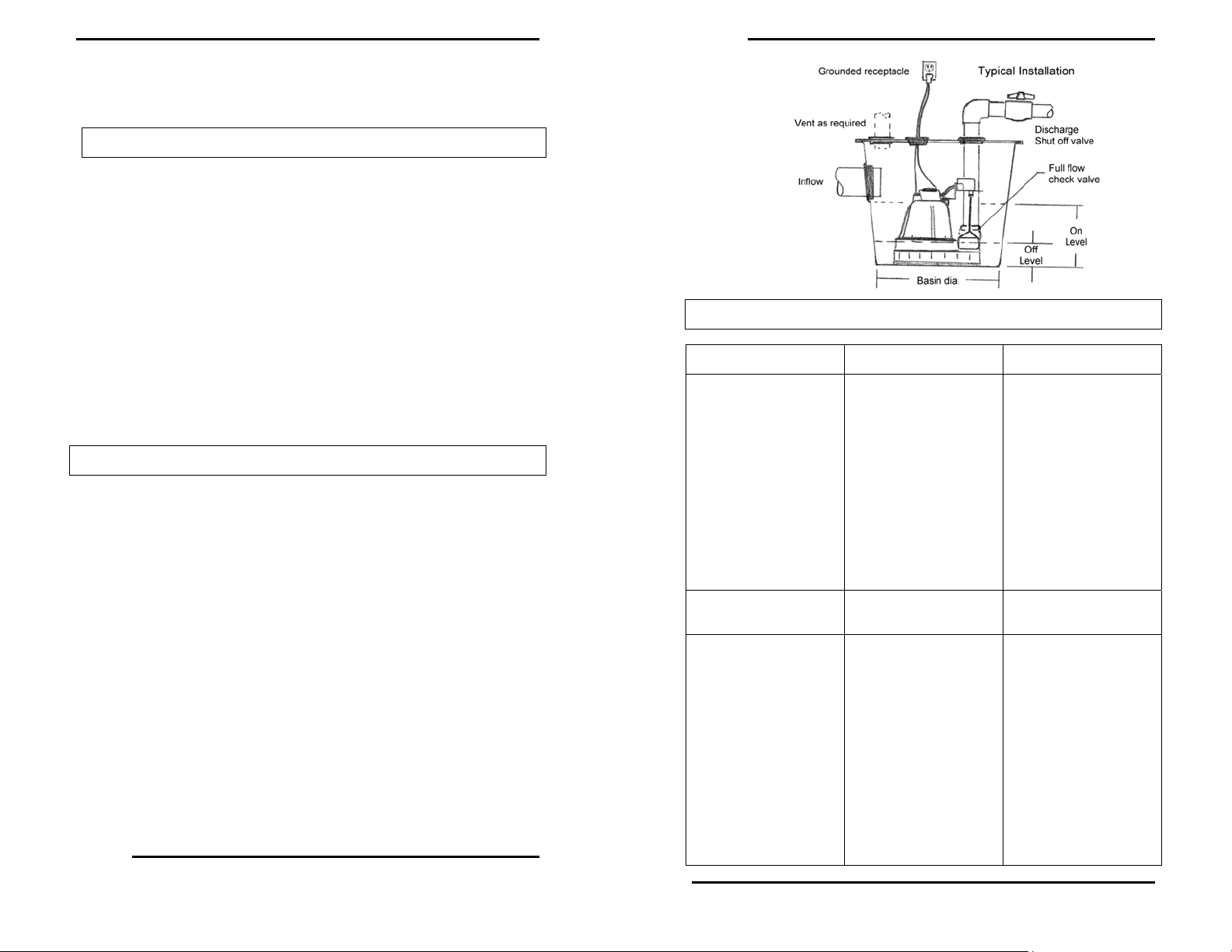

General Information

Model CPS3 is a manual sump pump and needs a liquid level motor control

switch, 28-0007-0010 vertical switch, 13-0001-1001 float switch to

operate properly in the basin. The control switch easily mounts to the

discharge piping and is adjustable for different basin and liquid levels.

Pump plug is plugged into back of piggyback receptacle on switch cord.

Model CPS3 is also offered with an attached vertical switch (CPS3V) or

attached float switch (CPS3A).

CPS3 --- minimum discharge pipe and fitting size – 1 ½”

Min. Basin Dia. Approx. on level Approx. off level

CPS3V 12” 7 1/8” 3”

CPS3A 14” 12 ¼” 5”

These pumps have an air bleed hole and a small stream of water during

operations maybe noticed. This is normal.

Dewatering/Sump/Effluent Installation

1. Provide proper sump basin size. A larger size is

recommended as it allows more reserve, and reduced

switching.

2. Make sure level control switch has full motion without

possible interference or hang up.

3. Make sure pump is on solid, clean, debris free base.

4. Schedule 40 PVC pipe is recommended, check local code.

Hand tighten piping into pump. Install a union or other

means of separating discharge line for easy pump removal.

5. A full flow check valve is recommended just above or in place

of the union to prevent water backflow. Connect additional

piping as needed to direct discharge to desired location.

Keep piping as short as possible with minimum number of

turns. Secure piping.

6. A ball or gate valve is recommended after the check valve to

prevent backflow when removal is necessary.

7. In effluent applications check with health and plumbing

codes for proper basin size, sealing, venting requirements.

8. An audible high water alarm, such as CP Model 1011421

should be installed for additional protection against flooding.

9. Check for proper operation once installed and power

connected by filling basin with water.

2

3

Maintenance and Troubleshooting

Symptom Possible Cause(s) Corrective Action

Pump will not start or

run

Pump starts and stops

too often

Pump will not shut off

or thermal protector

turns off

1. Blown fuse, trip

breaker

2. Low line voltage

3. Defective motor

4. Defective float

switch

5. Impeller bound

6. Float obstructed,

low water

1. Backflow of water

from piping

2. Faulty float switch

1. Defective float

switch

2. Obstacle in piping,

valve shut

3. Float obstructed

4. Low line voltage

5. Too many

appliances on circuit

3

1. If blown, replace

with proper sized fuse

or reset breaker.

2. If voltage is under

108 volts, check wiring

size.

3. Replace pump

4. Replace float switch

5. If impeller will not

turn, remove housing

and remove blockage

6. Make sure float

moves freely up and

down, check level

1. Install or replace

check valve

2. Replace float switch

1. Replace float switch

2. Remove pump and

clean pump and

piping, open valve

3. Make sure float

move freely up and

down

4. If voltage is under

108 volts, check wiring

size

5. Install pump on

dedicated circuit.

IMPORTANT: Do not

use extension cord to

power pump

Loading...

Loading...