Champion Pumps CP4NC SS User Manual

CP4NC-SS

2.8, 3.7 & 5HP

Submersible Non-Clog

No: CPNC4_ss - 04/15

INSTALLATION, SERVICE & PARTS MANUAL

www.championpump.com

Series: CP4NC2824SS

CP4NC2834SS, CP4NC2844SS

CP4NC3724SS, CP4NC3734SS,

CP4NC3744SS, CP4NC3764SS,

CP4NC5024SS, CP4NC5034SS,

CP4NC5044SS, CP4NC5064SS

1750RPM, 60Hz

Champion Pump Company, Inc • P.O. Box 528 • Ashland, OH 44805

Phone 419-281-4500 • toll free 800-659-4491 • fax 419-616-1100

1

General Safety Information

Before installation, read the following

instructions carefully. Failure to follow

instruction and Safety information could

cause serious bodily injury, death and/or

property damage. Each Champion pump is

individually factory tested to insure proper

performance. Closely following these

instructions will eliminate potential operating

problems, assuring years of trouble-free

service.

“Danger” indicates

an imminenty

hazardous situation which, if not avoided,

WILL result in death or serious injury.

“Warning” indicates

an imminenty

hazardous situation which, if not avoided,

MAY result in death or serious injury.

“Caution” indicates

an potentially

hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

IMPORTANT - Champion Pump Company

is not responsible for losses, injury or

death resulting from failure to observe

these safety precautions, misuse, abuse or

misapplication of pumps or equipment.

ALL RETURNED

PRODUCTS MUST BE

CLEANED, SANITIZED,

OR RECONTAMINATED

PRIOR TO SHIPMENT, TO

INSURE EMPLOYEES WILL NOT BE EXPOSED

TO HEALTH HAZARDS IN HANDLING SAID

MATERIAL. ALL APPLICABLE LAWS AND

REGULATIONS SHALL APPLY.

Installation, wiring,

and junction

connections must be in accordance with

the National Electric Code and all applicable

state and local codes. Requirements may

vary depending on usage and location.

Installation and

servicing is to be

conducted by quali ed personnel only.

Keep clear of suction

and discharge

openings. Do not insert ngers in

pump with power connected.

Always wear eye

protection when

working on pumps. Do not wear loose

clothing that may become entangled in

moving parts

Pumps build up heat

and pressure during

operation. Allow time

for pumps to cool

before handling or

servicing.

This pump is not

intended for use

in swimming pools or water

installations where human

contact with pumped uid.

Risk of electric shock.

To reduce risk of

electric shock, always disconnect

pump from power source before

handling. Lock out power & tag.

Do not us these

pumps in water over

104˚F. High temperature units PFSE51HT

200˚F. Do not exceed manufactures

recommended maximum performance, as

this could cause the motor to overheat.

Do not lift, carry or

hang pump by the

electrical cables. Damage to the

electrical cables can cause shock,

burnes or death. Never handle

connected power cords with wet hands. Use

appropriate lifting device.

Ground Fault Circuit

Interrupter (GFCI)

to be used with plug-in type power cord.

Sump and sewage

pumps often handle

materials which could cause illness or disease.

wear adequate protective clothing when

working on a used pump or piping. Never

enter a basin after it has been used.

Failure to permanently

ground the pump,

motor and controls before

connecting to power can cause

shock, burns or death.

These pumps are NOT

to be installed in

locations classi ed as hazardous in

accordance with the National

Electric Code, ANSI/NFPA 70.

The Uniform Plumbing

Code (UPC) states that

sewage systems shall have an audio and

visual alarm that signals a malfunction of

the systems that is required to reduce the

potential for property damage.

IMPORTANT!

Prior to installation, record Model

Number, MFG Date, Amps, Voltage, Phase

and HP, from pump name plate for future

reference. Also record the Voltage and

Current Readings at Startup:

1 Phase Models

Amps: Volts:

3 Phase Models

Amps L1-2: Volts L1-2:

Amps L2-3: Volts L2-3:

Amps L3-1: Volts L3-1:

Model Number: ____________________

MFG Date: ____________

PHASE: ______ HP: _________________

Other brand and product names are trademarks or registered trademarks of their respective holders.

Alteration Rights Reserved. 1/2011

Champion Pump Company, Inc • P.O. Box 528 • Ashland, OH 44805

2

Phone 419-281-4500 • toll free 800-659-4491 • fax 419-616-1100

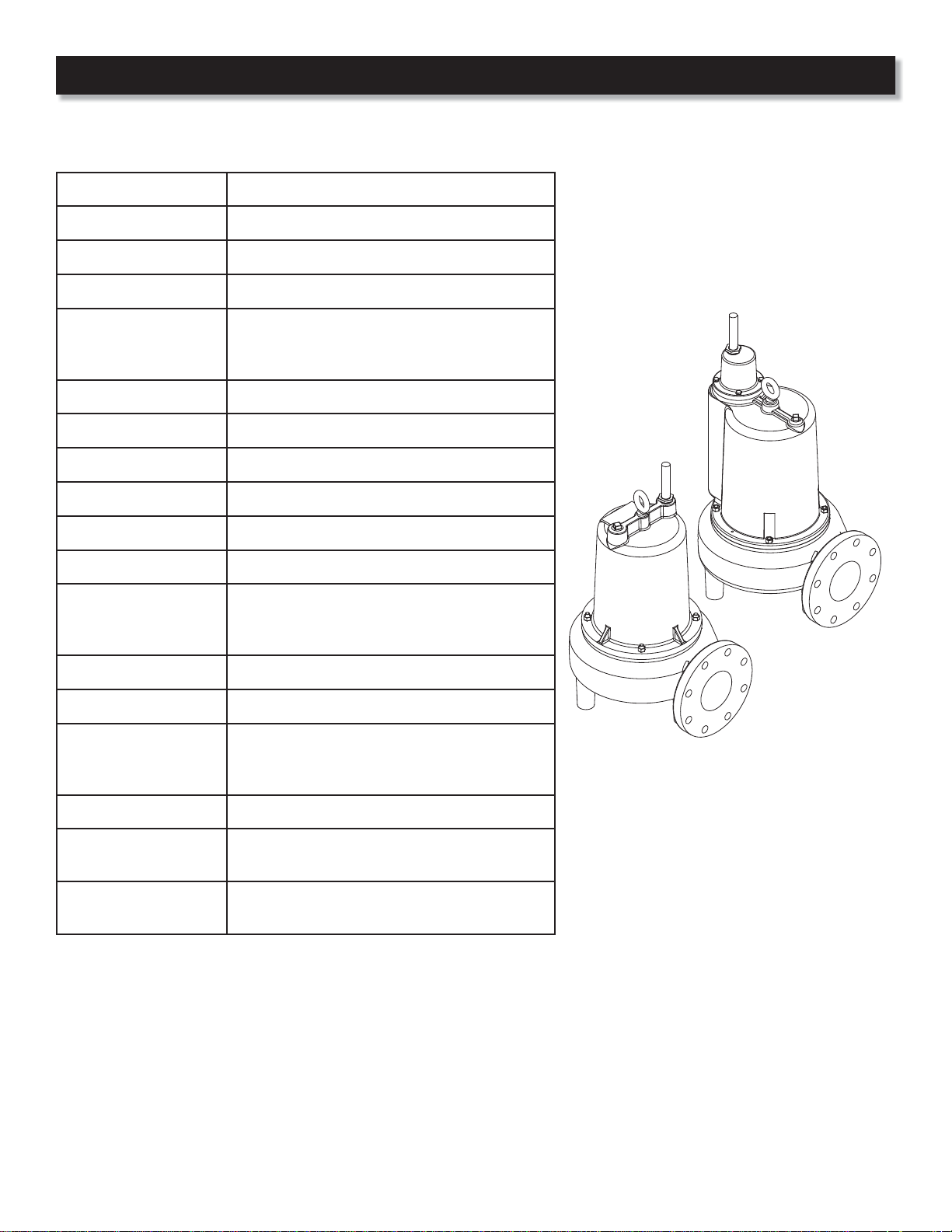

DISCHARGE 4” 125 lb., Flange Horizontal

LIQUID TEMPERATURE 104°F

MOTOR HOUSING Cast Iron, Class 30

VOLUTE Cast Iron, Class 30

2 vane open type with pump out vanes on back

IMPELLER

SOLIDS HANDLING 3” spherical

SHAFT Stainless steel

SEAL PLATE Cast Iron, Class 30

PAINT Air dry enamel

side, Dynamically balanced, ISO G6.3,

Cast Iron, Class 30

Speci cations

SQUARE RINGS Buna-N

HARDWARE Stainless steel

Single mechanical, Inboard, Oil Filled reservoir,

SEAL

UPPER BEARING Single row, ball, oil lubricated

LOWER BEARING Single row, ball, oil lubricated

POWER CORD

MOTOR Class B Insulation, Oil Filled

SINGLE PHASE

THREE PHASE

with Secondary Exclusion seal

Silicon Carbide/Buna-N

25 Ft. Cord. Epoxy sealed housing with

secondary Pressure grommet for sealing and

strain relief.

Permanent Split Capacitor (PSC)

Includes overload protection in motor

230/460 Volt. Dual Voltage. Requires overload

protection to be included in control panel.

Champion Pump Company, Inc • P.O. Box 528 • Ashland, OH 44805

Phone 419-281-4500 • toll free 800-659-4491 • fax 419-616-1100

3

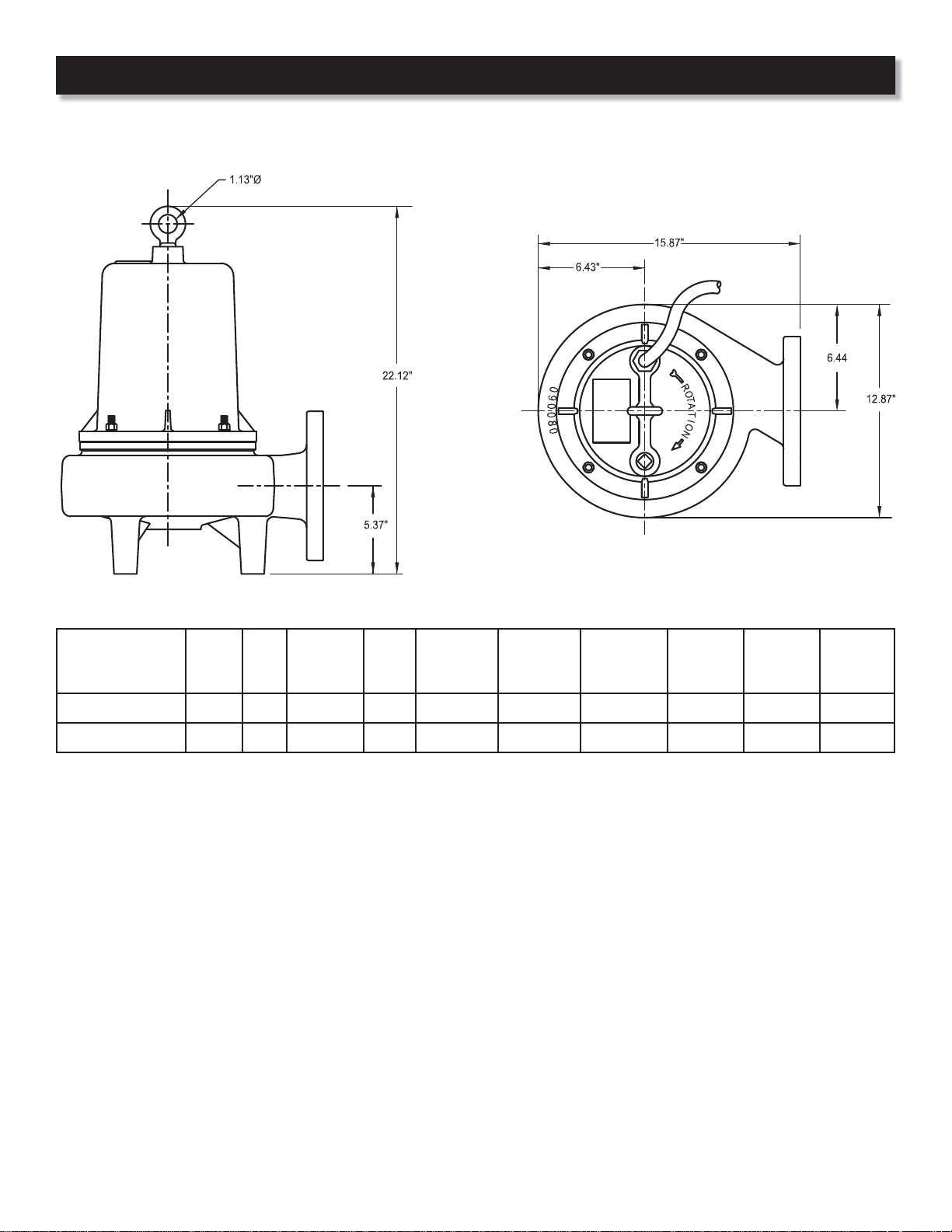

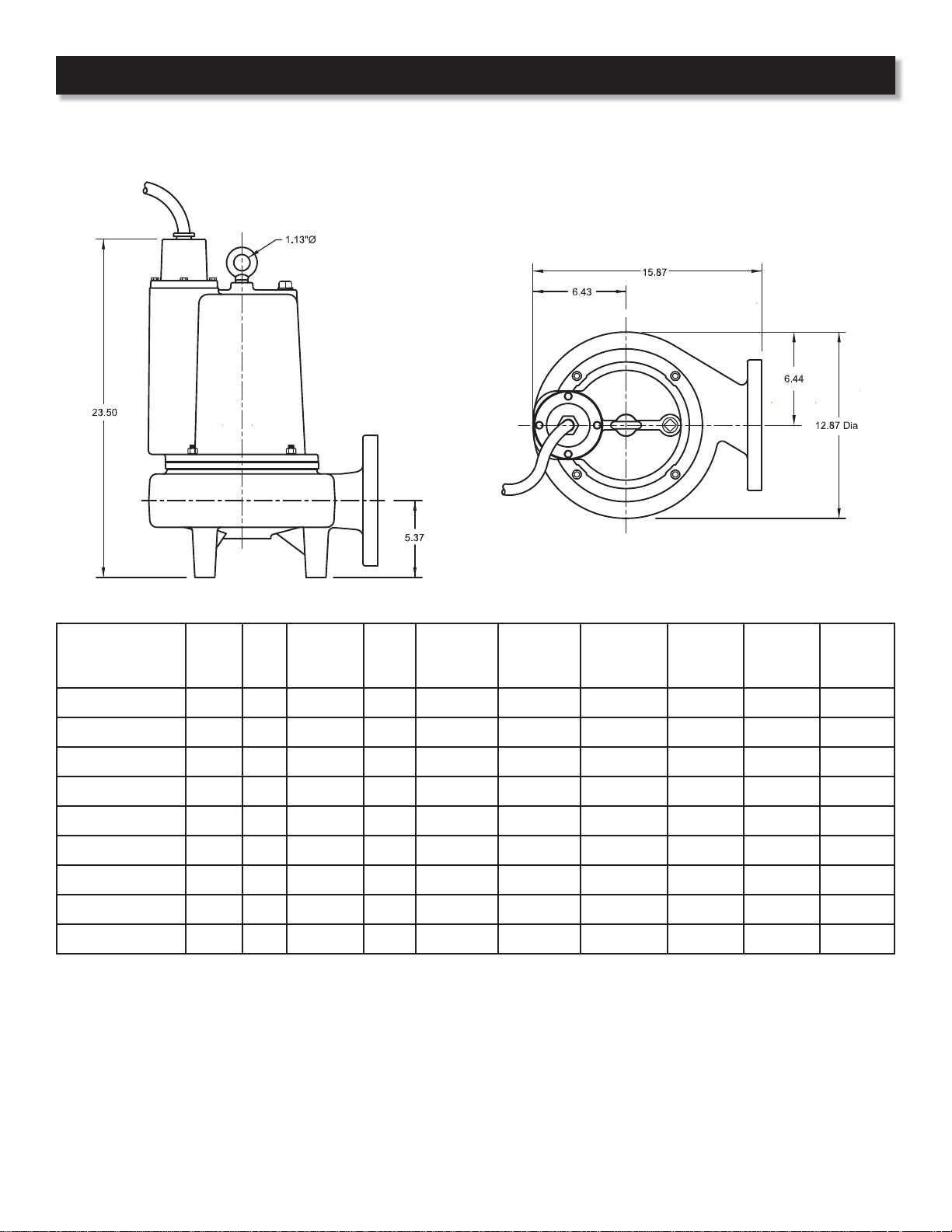

Dimensions

CP4NC2834SS, CP4NC2844SS

NEMA

MODEL HP Hz Volts/Ph RPM

CP4NC2834SS 2.8 60 230/3 1750 E 8.0 35.0 10/4 SOW 0.75

CP4NC2844SS 2.8 60 460/3 1750 E 4.0 17.5 10/4 SOW 0.75

Winding resistance ± 5% at terminal block.

Rated operation at ± 10% voltage at motor.

START

CODE

FULL

LOAD

AMPS

LOCKED

ROTOR

AMPS

CORD

SIZE

CORD

TYPE

CORD

O.D.

Champion Pump Company, Inc • P.O. Box 528 • Ashland, OH 44805

4

Phone 419-281-4500 • toll free 800-659-4491 • fax 419-616-1100

Dimensions

CP4NC2824SS, CP4NC3724SS, CP4NC3734SS, CP4NC3744SS,

CP4NC3764SS, CP4NC5024SS, CP4NC5034SS, CP4NC5044SS,

CP4NC5064SS

NEMA

MODEL HP Hz Volts/Ph RPM

CC4NC2824SS 2.8 60 230/1 1750 A 12.6 23.0 10/3 SOW 0.69

CP4NC3724SS 3.7 60 230/1 1750 A 18.5 29.0 10/3 SOW 0.69

CP4NC3734SS 3.7 60 230/3 1750 F 14.0 50.8 10/4 SOW 0.75

CP4NC3744SS 3.7 60 460/3 1750 F 7.0 25.4 10/4 SOW 0.75

CP4NC3764SS 3.7 60 208/3 1750 D 15.4 44.1 10/4 SOW 0.75

CP4NC5024SS 5.0 60 230/1 1750 A 28.0 59.0 10/3 SOW 0.69

CP4NC5034SS 5.0 60 230/3 1750 D 19.0 56.0 10/4 SOW 0.75

CP4NC5044SS 5.0 60 460/3 1750 D 9.0 28.0 10/4 SOW 0.75

CP4NC5064SS 5.0 60 208/3 1750 B 20.9 48.6 10/4 SOW 0.75

Winding resistance ± 5% at terminal block.

Rated operation at ± 10% voltage at motor.

START

CODE

FULL

LOAD

AMPS

LOCKED

ROTOR

AMPS

CORD

SIZE

CORD

TYPE

CORD

O.D.

Champion Pump Company, Inc • P.O. Box 528 • Ashland, OH 44805

Phone 419-281-4500 • toll free 800-659-4491 • fax 419-616-1100

5

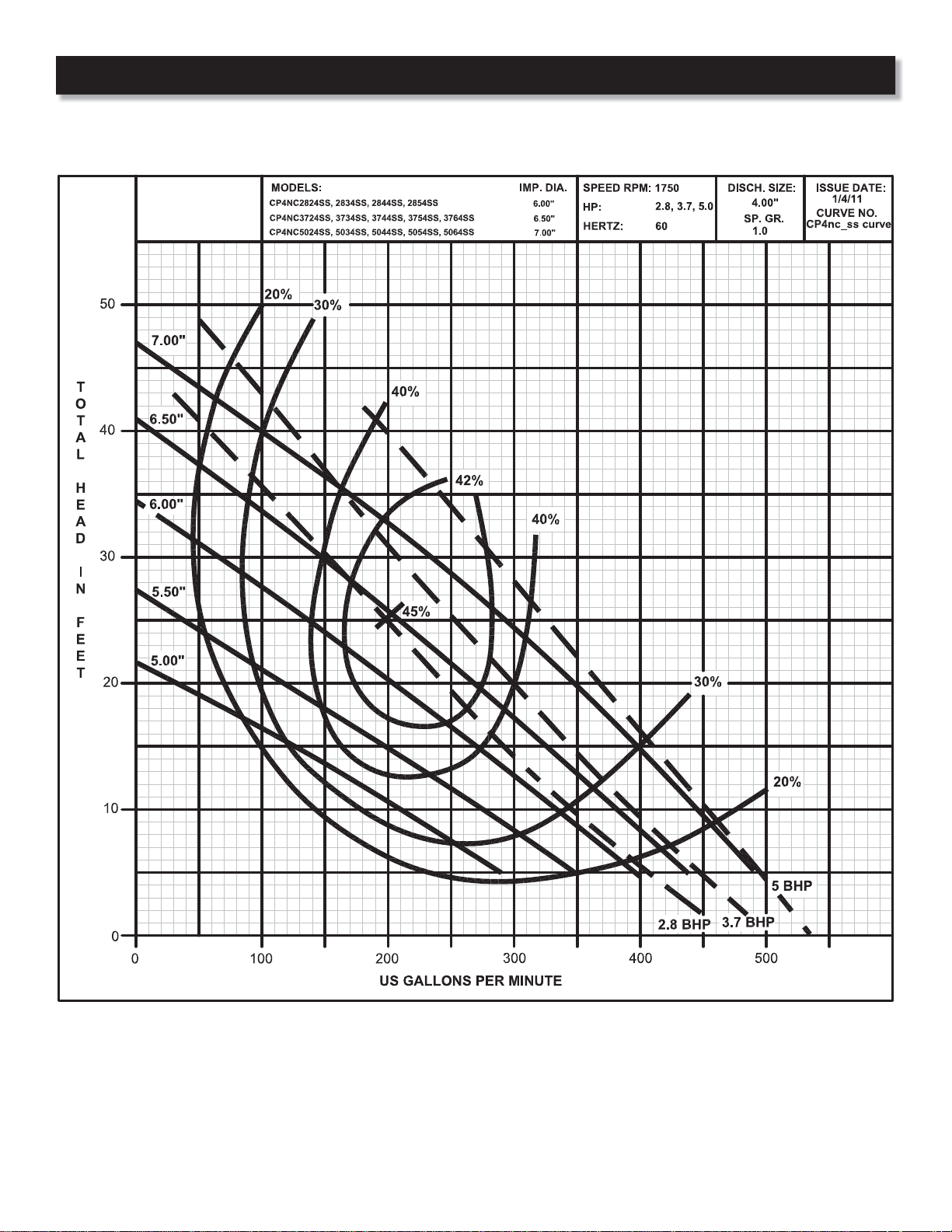

Performance

Champion Pump Company, Inc • P.O. Box 528 • Ashland, OH 44805

6

Phone 419-281-4500 • toll free 800-659-4491 • fax 419-616-1100

Receiving & Installation

Receiving Inspection

Upon receiving the pump, it should be

inspected for damage or shortages.

If damage has occurred, le a claim

immediately with the company that

delivered the pump. If the manual is

removed from the packaging, do not

lose or misplace.

Storage

Any product that is stored for a period

longer than six (6) months from the

date of purchase should be bench

tested prior to installation. A bench

test consists of, checking the impeller

to assure it is free turning and a run

test to assure the motor (and switch

if provided) operate properly. Do not

pump out of liquid.

Controls

Manual models require a separate

approved pump control device or panel

for automatic operation. Be sure the

electrical speci cation of the control

selected properly match the electrical

speci cations of the pump.

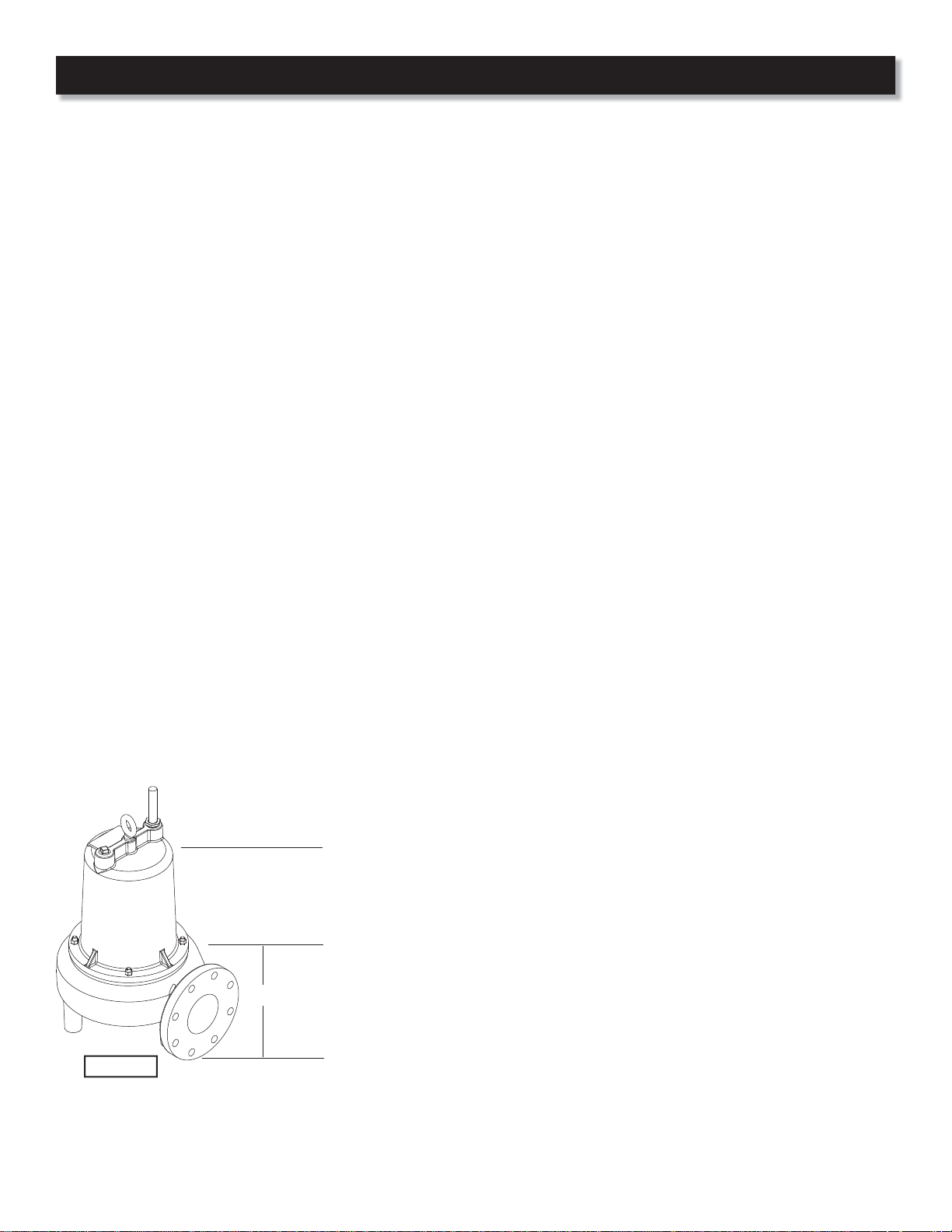

Submergence

The pump should always be operated in

the submerged condition. The minimum

sump liquid level should never be less than

above the pump’s volute (See Figure 1).

Installation

These pumps are recommended for

use in a sump, basin or lift station.

The sump, basin or lift station shall be

sealed and vented in accordance with

local plumbing codes. This pump is

designed to pump sewage, e uent

or wastewater, nonexplosive and

noncorrosive liquids and shall NOT

be installed in locations classi ed as

hazardous in accordance with the

National Electrical Code (NEC) ANSI/

NFPA 70 or Canadian Electric Code

(CEC). The pump should never be

installed in a trench, ditch, or hole with

a dirt bottom. The legs will sink into

the dirt and the suction will become

plugged.

The installation should be at a su cient

depth to ensure that all plumbing is

below the frost line. If this is not feasible,

remove the check valve and size the

basin to accommodate the additional

back ow volume.

Pumps are most commonly installed

in simplex or duplex stations or basins

with a slide rail system, which allows

the pump(s) to be installed or removed

without requiring personnel to enter

the station, or resting on the basin oor.

Liquid Level Controls

The level control(s) should be mounted

on the discharge piping, a cable rack

or oat pole. The level control should

have adequate clearance so it cannot

hang up in it’s swing and that the pump

is completely submerged when the

level control is in the “O ” mode. By

adjusting the cord tether the control

level can be changed. One cycle of

operation should be observed, so that any

potential problems can be corrected.

It is recommended that the level control

oat should be set to insure that the liquid

in the sump never drops below the top of

the motor housing or a minimum level of

10 inches above the basin oor.

Electrical Connections

Power cable:

The power cable mounted to the pump

must not be modied in any way except

for shortening to a specic application.

Any splice between the pump and the

control panel must be made in

accordance with the electric codes. It is

recommended that a junction box, if used,

be mounted outside the sump or be of

at a minimum Nema 4 construction if

located within the wet well. DO NOT USE

THE POWER CABLE TO LIFT PUMP.

Discharge Piping

Recommended

Submergence Level

Minimum

Submergence Level

10”

Figure 1

Champion Pump Company, Inc • P.O. Box 528 • Ashland, OH 44805

Phone 419-281-4500 • toll free 800-659-4491 • fax 419-616-1100

Bottom of Feet

Discharge piping should be as short

as possible and sized no smaller than

the pump discharge. Do not reduce

the discharge pipe size below that

which is provided on the pump. Both

a check valve and a shut-o valve are

recommended for each pump. The

check valve is used to prevent backow

into the sump. The shut-o valve is

used to manually stop system ow

during pump servicing.

Always rely upon a Certi ed Electrician

for installation.

Overload Protection:

Single Phase - The stator in-winding

overload protector used is referred to

as an inherent overheating protector

and operates on the combined e ect

of temperature and current. This means

that the overload protector will trip out

and shut the pump o if the windings

become too hot, or the load current

passing through them becomes too high.

7

Installation & Service

IMPORTANT ! - The overload will then

automatically reset and start the pump

up after the motor cools to a safe

temperature. In the event of an overload,

the source of this condition should be

determined and corrected immediately.

WARNING! - DO NOT LET

THE PUMP CYCLE OR RUN IF

AN OVERLOAD CONDITION

OCCURS !

If current through the temperature sensor

exceeds the values listed, an intermediate

control circuit relay must be used to

reduce the current or the sensor will not

work properly.

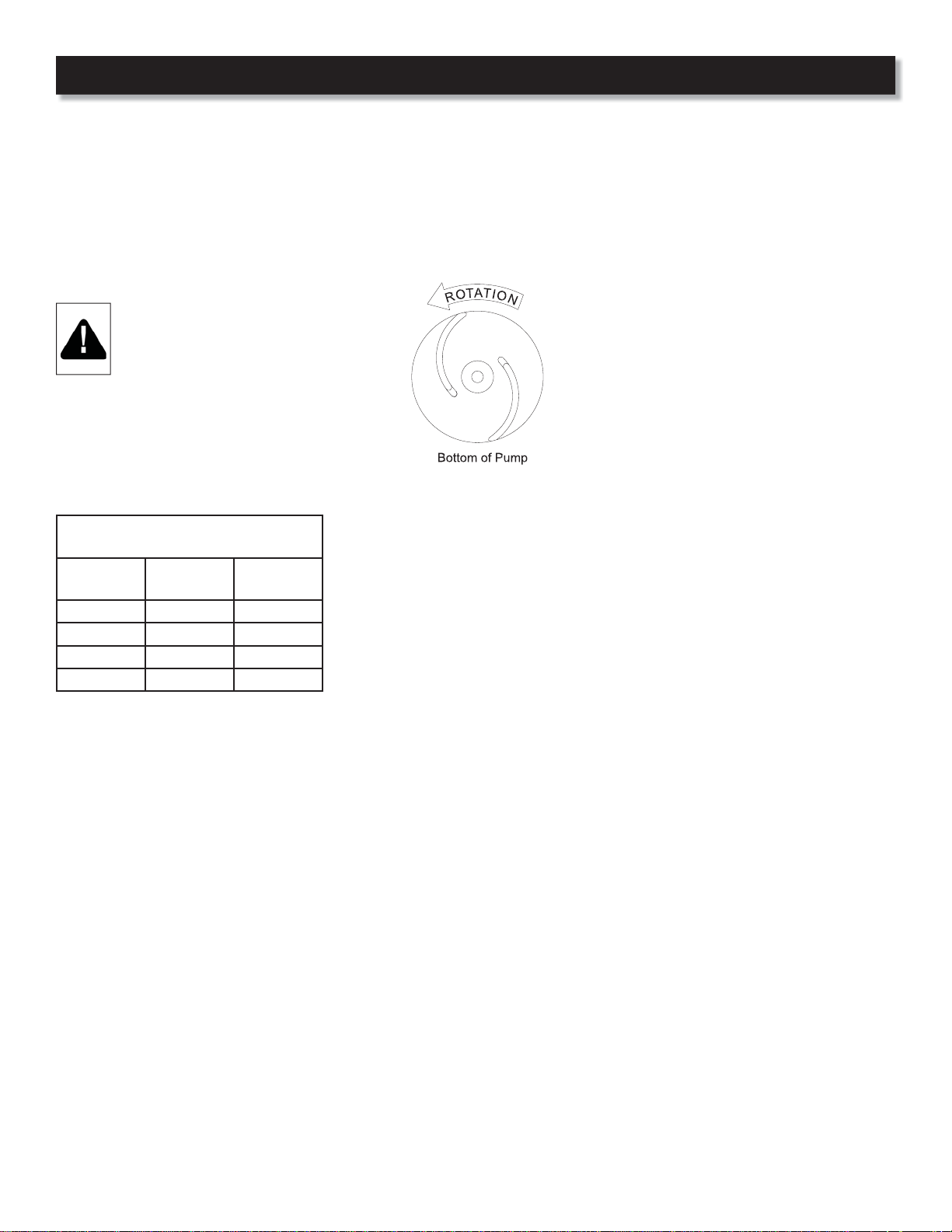

TEMPERATURE SENSOR ELECTRICAL

RATINGS

Volts Continuous

Amperes

110-120 3.00 30.0

220-240 1.50 15.0

440-480 0.75 7.5

600 0.60 6.0

Wire Size:

If longer power cable is required consult

a quali ed electrician for proper wire

size.

Inrush

Amperes

Pre-Operation

1. Check Voltage and Phase - Compare

the voltage and phase information

stamped on the pump name plate.

2. Check Pump Rotation - Improper

motor rotation can result in poor

pump performance and can damage

the motor and/or pump. Check

rotation on three phase units by

momentarily applying power and

observe the “kickback”.

Kickback should always be in a

counter-clockwise direction as

viewed from motor end or opposite

to impeller rotation. Impeller rotation

is counter-clockwise as viewed from

bottom of pump.

3. Name Plate - Record the information

from the pump name plate to

drawing in front of manual for future

reference.

4. Insulation Test - An insulation

(megger) test should be performed

on the motor. Before the pump is put

into service. The resistance values

(ohms) as well as the voltage (volts)

and current (amps) should be

recorded.

5. Pump-Down Test - Be sure pump

has been properly wired, lowered into

the basin, sump or lift station, check

the system by lling with liquid and

allowing the pump to operate through

its pumping cycle. The time needed to

empty the system, or pump-down

time along with the volume of water,

should be recorded.

Maintenance

No lubrication or maintenance is required.

Perform the following checks when pump

is removed from operation or when pump

performance deteriorates:

a). Inspect motor chamber for oil level

and contamination.

b). Inspect impeller and body for

excessive build-up or clogging.

c). Inspect motor, bearings and shaft seal

for wear or leakage.

Servicing

NOTE: Item numbers in ( ) refer to Figures

6 through 10.

Cooling Oil - Anytime the pump is

removed from operation, the cooling oil

in the motor housing should be checked

visually for oil level and contamination.

To check oil, set unit upright. Remove

pipe plug (20) from housing (4). With a

ashlight, visually inspect the oil in the

housing (4) to make sure it is clean and

clear, light amber in color and free from

suspended particles. Milky white oil

indicates the presence of water. Oil level

should be just above the motor when

pump is in vertical position.

Oil Testing

• Drain oil into a clean, dry container by

placing pump on it’s side, remove pipe

plug (20), from housing (4).

• Check oil for contamination using an

oil tester with a range to 30 Kilovolts

breakdown.

• If oil is found to be clean and

uncontaminated (measuring above

15 KV. breakdown), rell the housing.

• If oil is found to be dirty or

contaminated (or measures below

15 KV. breakdown), the pump must

be carefully inspected for leaks at the

shaft seal, cable assembly, square ring

and pipe plug, before relling with oil. To

locate the leak, perform a pressure test.

After leak is repaired, dispose of old oil

properly, and rell with new oil.

Champion Pump Company, Inc • P.O. Box 528 • Ashland, OH 44805

8

Phone 419-281-4500 • toll free 800-659-4491 • fax 419-616-1100

Loading...

Loading...